SINCE 1940, LOCKHEED HAD BEEN AFTER the Air Corps to build a pure-jet-powered airplane.

The potential of jet power had interested us for some time, particularly as we encountered the effects of compressibility on the P-38 fighter, first on the propeller, then on the wings. We decided there had to be a major change in the power-plant configurations for our fighter aircraft. During World War II, we had been able almost to double the power of the P-38, yet succeeded in increasing the speed only by about 17 miles per hour.

Independently, we developed a preliminary design for an airplane that would approach Mach 1—the speed of sound. It would be powered by a jet engine designed by a Lockheed consultant, Nate Price, a designer of great vision and knowledge of thermodynamics, materials, and mechanical design. We proposed to the Air Corps that Lockheed be permitted to build a prototype. The response was negative. We were told to devote our energies to solving the problems with the P-38 and other immediate wartime projects. In retrospect, of course, that was short-sighted.

But in 1941, when the British installed Frank Whittle’s jet engine in one of their small fighters, the Gloster Meteor, and demonstrated the speed potential, that attitude changed. The Air Corps commissioned use of the engine in the Bell P-59, originally designed as a propeller-driven airplane. When the jet-powered version flew in 1943, the performance was hardly better than that of the piston-powered P-38 and P-51.

Again we proposed to build an airframe and jet engine in a very short span of time. This time the Air Development Center was receptive.

The Germans by this time already had a number of jet-powered Me-262s in combat, and these planes were much faster than anything we had. They were well into the jet age while we were just starting. The Me-262 was a very good airplane, designed by Willy Messerschmitt, whose talent I respected.

One argument against our pursuing jet power had been that the airplanes were fuel-hungry and lacked range. The Germans didn’t have very far to go to reach England because they could take off from occupied territory in Holland and France, while the U.S. had to consider the large expanse of territory to be covered in Europe and in the Pacific. From Great Britain, we had to get to Berlin to be effective.

Within a week of hearing from Wright Field, I was back again in Dayton to present our design.

“We’ll give you a contract for the airplane, Kelly, and for Nate’s engine as well,” said Gen. Frank Carrol, commanding officer of Wright Field. “But you’ll have to use the British engine in the first airplane because we need it—and all the jet fighters you can build—as soon as possible to use against the Me-262. Your new engine couldn’t possibly be ready for service in time.”

Since I had promised to build a jet airplane within 180 days, I asked, “When will we get a contract? When will the time start?”

“You will have a Letter of Intent this afternoon by 1:30 p.m.” he replied. “There is a plane leaving Dayton for Burbank at two o’clock. Your time starts then.”

And it did. The date was June 8, 1943. Gen. H. H. “Hap” Arnold, himself, had approved the contract.

Back in Burbank, I knew I was in for a rough time. Lockheed already was producing 17 P-38s, four B-17s, and enough Hudsons, Lodestars, and PV-1s to total 28 airplanes each day. That was with three shifts a day, six days a week, and some work on Sundays. There were no spare engineers. There was no spare machinery and no available space.

When I showed Robert Gross a contract for our first jet fighter, he expressed some doubt that much would come of it. But he and Hibbard always were open to new ideas and backed me in many critical times.

“You brought this on yourself, Kelly,” Gross stated. “Go ahead and do it. But you’ve got to rake up your own engineering department and your own production people and figure out where to put this project.”

For some time I had been pestering Gross and Hibbard to let me set up an experimental department where the designers and shop artisans could work together closely in development of airplanes without the delays and complications of intermediate departments to handle administration, purchasing, and all the other support functions. I wanted a direct relationship between design engineer and mechanic and manufacturing. I decided to handle this new project just that way.

Absolutely the only place we could think to put the new work was adjacent to the wind tunnel. We already had a shop there to build the tunnel models, so this was the beginning of our machine shop. To get more tools, we had to buy out a small local machine shop. We found a lot of Wright engine boxes left over from deliveries for the Hudson bomber. They were just taking up space in the storage area and were made of good, heavy wood. We cleared the space and used the boxes to build the walls of our production area. For the roof, we rented a circus tent.

Somehow I got together 23 engineers, counting myself. I simply stole them from around the factory. I wanted people whose work I knew. Assistant project engineers were W. P. Ralston and Don Palmer, my good friend from college who by that time had joined Lockheed. The single-engine transport on which Vultee had staked its future—and on which Don was working—could not compete with Lockheed’s Electra, Boeing’s 247, and Douglas’s DC-2—all twin-engine models. Art Viereck was recruited to head the shop. We had our own purchasing department and every function we needed to operate independently of the main plant. This became the first “Skunk Works.”

How did it get that name? I’m not sure. But in the strict secrecy of wartime, and simply for efficiency and to avoid distractions, we allowed no one who wasn’t working on the project to wander in and out. The legend goes that one of our engineers—and I’d guess it was Irv Culver, a brilliant designer—was asked, “What the heck is Kelly doing in there?”

“Oh, he’s stirring up some kind of brew,” was the answer.

This brought to mind Al Capp’s popular comic strip of that day, “ ’Lil Abner,” and the hairy Indian who regularly stirred up a big brew, throwing in skunks, old shoes, and other likely material to make his “kickapoo joy juice.” Thus the Skunk Works was born and named.

When the Air Corps decided to move, it moved fast. Nine days after our go-ahead, we had a mockup conference at the Skunk Works with Col. M. S. Roth and Maj. Ralph Swofford, who became our project liaison officer. There were only six people from the military involved and two or three of us from Lockheed. We had approval to proceed that night. Six days later we had our government furnished equipment—guns, radio, wheels and tires, etc. At every stage of the work, we had excellent cooperation from Wright Field and the officers involved with the project. The job could not have been completed on such a tight schedule without it.

Pressures on everyone in our plant became intense as we counted off the contract days on a big scoreboard calendar. We had scheduled the work on the basis of a 10-hour day, six-day week. No one worked on Sunday. We had to enforce that rule because even with it the sickness rate during the last few weeks went as high as 50 percent daily. It was midwinter, and we had poor facilities in which to work and almost no heating. We could not afford to lose even one of our small supervisory staff to illness.

The airframe was never a problem, but the engine was. It didn’t arrive until seven days before we were ready to fly—we’d been working with a wooden mockup to design its installation. It didn’t help that the De Haviland engine expert sent over to help us had to spend time in a local jail. Guy Bristow had arrived secretly with the engine on an Air Corps plane without the usual travel papers. He made the mistake of jaywalking on Hollywood Boulevard and when the police cited him and discovered he had no draft card and wasn’t even a citizen, they detained him. When we discovered his plight, we had to call on the Air Corps to negotiate his release.

During a final engine run-up before the first flight scheduled for the next day, there was a tremendous bang. I was standing between the two engine ducts, watching the operation, and I almost lost my pants down the intake. The ducts had collapsed, pieces of metal had gone into the engine, and the compressor housing had cracked. The engine was beyond repair—the only engine we had. We had to wait for another.

Finally, on day 143, the plane was accepted by the Army Air Corps and ready for flight. We had beaten the schedule of 180 days. On the morning of January 8, 1944, the XP-80 flew for the first time. We had named the plane “Lulu-Belle”—we always nicknamed our “firsts.” Milo Burcham was at the controls at Muroc Dry Lake, now Edwards Air Force Base. It was the first American fighter to exceed 500 miles an hour—502 mph was top speed.

By this time the Air Corps had General Electric working on a bigger and more powerful version of the Whittle engine. Development was moving fast. Having proven our design with the first XP-80, we were asked to do the job over again with an airframe about 80 percent larger to accommodate the new GE engine. We were given a contract to build two such airplanes.

In 132 days, we built the first of these YP-80As. We gave it a coat of slick lacquer paint, off-white in color, so its nickname was the “Gray Ghost.” It had heavier armament, carried more fuel with extra wingtip fuel tanks, and added about 80 miles an hour to the speed of our first jet.

It was the forerunner of the P-80, later redesignated F-80, and its successor T-33 two-place trainer, and the derivative F-94 in A, B, and C versions. When the Air Corps ordered the plane into production, more than 6,000 were built in all. It became this country’s first tactical jet fighter. Robert Gross named it the “Shooting Star” in the Lockheed tradition of naming aircraft after stellar bodies.

Development was not without problems, of course. It was a complete new world of flying and testing.

The first problem we encountered had to do with compressibility again. But it was not the same as with the P-38. Here it came in shock waves jumping back and forth across the hingeline of the wing and aileron. Shock pressure changes would drive the ailerons and make them “buzz” at a very high frequency. We had known that we would encounter compressibility in some aspect with the airplane, and it was experienced at speeds of Mach .8 to .85. The pilot would get some warning. He would experience a little control stick shaking and feel the aileron “buzz” in the cockpit.

This effect we were able to overcome with hydraulic dampers acting as shock absorbers located on the aileron and attached firmly with no slop, or freedom, of movement.

Again, we used wind tunnels to find out what degree of safety we had. We fluttered a full-scale F-80 wing for more than 100 hours until it finally tore loose at the hinges and the ailerons flew down the tunnel. The NACA flew the airplane and exceeded that mark by flying to Mach .86. My hat is off to that pilot, because the test really made a shambles of the ailerons. But this top speed never became a limiting factor since the plane had more than enough speed for the competition.

A problem developed with the new engine. Test pilot Tony LeVier was flying F-80 No. 3 on a high-speed run at altitudes of 15,000 to 20,000 feet when suddenly there was a booming sound so loud that we could hear it on the ground. As we looked up, the airplane disintegrated and a parachute blossomed.

As Tony explained, “I was sitting there all fat and happy, when the airplane suddenly flipped over on its back, the wings broke off, and I was sitting out in space.” He had to release the cockpit canopy, of course, to get out. It took Tony about ten minutes of excited recollection to tell us this story once he had landed.

But a local farmer who had witnessed the same thing from the ground put it this way in less than ten seconds: “I looked up, there was a boom, and then a parachute.”

When we had collected all the aircraft and engine pieces. we found that the jet turbine disc had broken into three parts, slicing through the fuselage. The reason for the failure is a problem to this day. We do not have in this country a machine big enough to forge these large metal aircraft parts; they must be welded—and that always presents a possible failure point. The largest machines we have are the few we captured from the Germans after the war.

On the F-80, the engine had a weld in the main shaft that came off the big turbine disc, because the biggest press in the country at that time could not forge it—hub and disc—together. Six F-80s were lost for that reason.

We changed the design of the hub as much as we could, then spun each turbine with its shaft in a vacuum to speeds faster than operational. That always worried me—it seemed somewhat like seeing how far you could hang out a window of a ten-story building. The test procedure itself could have started a crack, which might then have been missed in X-ray, and the plane flown with this fault. However, this did not happen and the solution worked.

With the F-80, the Air Corps was able to develop tactics for flying against the German jets—both with bombers in defense and fighters in attack, not only with single aircraft but in formation. We spent several weeks flying with the military at Edwards. All the various U.S. fighters were there—P-38s, P-39s, P-47s, and P-51s—to be evaluated against the jet as escorts for our bombers. They were armed with gun cameras to record their “kills.” So were the B-17s and B-24s.

I spent more than five hours each day, at 25,000 feet—wearing tennis shoes, shorts, and a parachute—riding “piggyback” in a modified P-38 with Tony LeVier, watching them try to gun down the jet. We got into some very fancy maneuvers; all of us spun in trying to turn into the F-80. I must confess I enjoyed it; the P-38 was a good airplane for spins, easy to pull out.

“I got him! I got him!” the gunners would exclaim. But back on the ground, their film never showed a hit on the F-80.

The F-80 would make head-on passes at the bomber formation, roll over, and pass underneath inverted. Lateral and tail attacks were practiced. The fighters were flying defense. The air was crowded with airplanes.

These mock flights were very valuable. We discovered that while it was impossible to stop a frontal attack by the jet, it didn’t matter much. At a closing speed of more than 700 miles an hour the probability of an Me-262 pilot’s scoring a hit in the few seconds’ firing time he had while avoiding collision with the bombers and fighters was so remote that we decided not to worry about it. The main concern turned out to be attack from the rear quadrant, where the German jets could overtake our aircraft, fly at any matching speed, and have considerably more time to aim and fire. To counter this, the Air Corps developed the tactic of having the fighters watch the rear. These exercises with the F-80 saved the Eighth Air Force from having to discover in combat that characteristic of the German jet fighter.

One night test that provided valuable information also resulted in a tragic loss. An F-80 took off with a B-25 as observer to determine whether the jet left a telltale glowing exhaust trail. It didn’t, and the two planes collided in the darkness. Lockheed test pilot Ernie Claypool and the military pilot were killed.

Before World War II ended, four F-80s were sent to the European theater. They were there for indoctrination flights only, on patrol from England and Italy. We didn’t want them shot down where the Germans might capture them. The Air Corps needed familiarity with the airplane, with its high fuel consumption, high speed, and operating characteristics in varying weather conditions. We lost one of these planes and its pilot. Very skilled and experienced, Maj. Frank Barsodi completing a high-speed, low-altitude pass apparently decided he was going too fast for a landing and pulled back on the engine throttle in flight. The result was more pressure from ram air on the outside of the tailpipe than from within, and the tailpipe collapsed inward. At least, that is what I think happened. This was an unforeseen occurrence because its pipe had been designed to withstand inside pressure. The modification here was to vent the pipe so never again could the pressure become higher on the outside than inside.

Development of the F-80 was to cost yet another life—that of our long-time Lockheed test pilot Milo Burcham. In the first production model, as distinguished from the experimental models trucked to Edwards for flight test, Burcham took off from the east-west runway at what then was Lockheed Air Terminal, now Burbank-Glendale-Pasadena Airport. In those days there was a lot of open space where a pilot could pancake in if necessary. But there also was an open gravel pit near the runway. Barely off the ground at 200 feet, Milo lost all power. The drive to the fuel pump shaft had sheared the spline. He couldn’t avoid the gravel pit, and the plane exploded on impact. The design result was an improved spline and pump and installation of an emergency fuel system.

Ever since then, Lockheed aircraft always have had standby fuel systems, either double fuel pumps on the engine or a fuel pump on the engine and another with electric drive. Some other jets do not have this. Redundancy in systems since then became a mania with me. With everything we build, we make sure that we can relight, restart, and keep flying if the main engine pump fails. Milo’s death contributed to future safety for others.

The war in Europe ended before the F-80 could be proved in combat there. But development, testing, and production continued.

When the Air Corps team went to Germany after the war to inspect military capabilities, we at Lockheed were invited. I stayed home to work on the F-80 development, but my assistant, Ward Beman, made the trip and picked up a great deal of information.

We found that the Germans had been flying the only axial flow jet engine in the world, fundamentally more efficient than the centrifugal compressors of the British jets because it was of simpler design. The flow went straight into the inlet and progressed in a straight line through the engine and out the exhaust. In centrifugal flow, the air goes in two sides of a rotor, flows perpendicular to the flight path of the airplane, enters the burner cans, then goes through the rest of the machine; so that it changes flow 90 degrees at least twice. But we and the British had a great deal of experience and knowledge of centrifugal compressors from use with steam power plants so that had seemed a surer and safer development.

Postwar, the Air Corps dramatically demonstrated the capability of its new air-defense weapon. In January 1946, three F-80s departed the West Coast on the same day for cross-country flight—two with a refueling stop, one nonstop.

Col. William Councill took his F-80 from Long Beach to La Guardia Airport in New York in the record time of 4 hours, 13 minutes, covering the 2,470 miles at an average 584 miles an hour. The feat was widely heralded in the nation’s press. Councill’s plane had carried 300-gallon wingtip fuel tanks dropped over Kansas farmland when empty. We heard later that the tanks were cut in half by farmers and used as feed bins. Refueling stops—at Topeka, Kan.—for the other two planes were completed in just a few minutes, so there was very little difference between the one-stop and non-stop flight times.

There was an amusing aspect to the record-setting takeoff. The official FAA timer came over to our chief flight test engineer, Rudy Thoren, pulled out a dollar watch, and asked Thoren the time! Of course, the quality of his watch didn’t really matter. All he had to do was establish the starting time in any manner. Someone at the finish would record landing time. But the official image suffered somewhat.

More records fell. In 1947 when the Air Force became a separate service, Col. Albert Boyd averaged 623.8 miles per hour over a measured course for a world speed record. Incidentally, jet fuel in those days, more like kerosene than gasoline, cost about 13 cents per gallon, not the $1.50 it costs today in the ’80s.

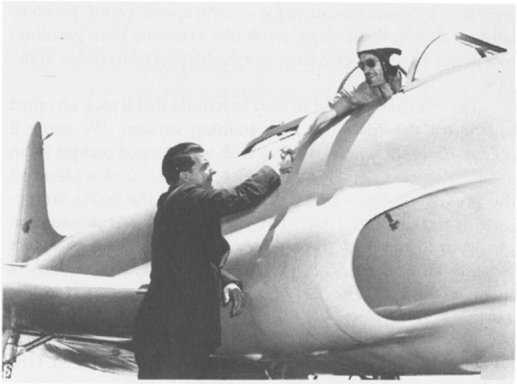

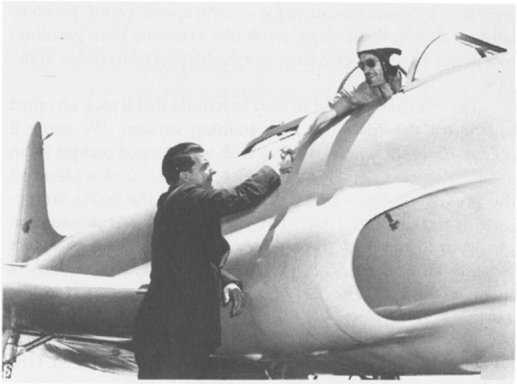

Congratulating Tony LeVier following a successful test flight during development of the F-80, the nation’s first tactical jet fighter. Below, even by today’s standards the Shooting Star looks sleek and swift in this earlier photo.

The F-80 had proved so easy to handle that it took an effort to interest the Air Force in a training version. We made a piggyback version first—that is, with an enlarged cockpit so an observer could ride behind the pilot. Then we took a plane off the production line—had it disappear from the books temporarily—and converted it to a two-man model for demonstration purposes to convince the military of the need for a two-place version. Once convinced, the Air Force bought thousands of them, as the T-33. The Navy bought a trainer version, too, the TV-1.

Sometimes it’s awfully difficult to convince the customer of what we think he needs, and sometimes we don’t succeed. One such proposal was our Universal Flight Trainer.

In 1954 we suggested equipping the T-33 with “black boxes” to simulate performance of any other kind of aircraft—long before we had such flight simulators in the laboratory. But I could not sell the idea. Airplanes have been used in this manner since—both the JetStar and the F-104 Starfighter have been instrumented to simulate various phases of Space Shuttle performance, for example.

The current “new generation trainer,” I believe, will have some of this capability. Such a “universal trainer” still would be practical and productive in research and development.

The F-80s in the Air Force were able to prove themselves in combat when North Korea invaded South Korea in 1950. In history’s first jet battle, an F-80 shot down a Russian-built MiG-15. And that dual fuel pump that resulted from Milo’s death brought a lot of pilots home from combat in the war zone. Jet combat in that theater provided other lessons we would use in aircraft development. We knew we had enough to keep us busy for some time.