FEBRUARY 29, 1964. PRESIDENT REVEALS SECRET AIRCRAFT:

“The United States has successfully developed an advanced experimental jet aircraft, the A-11, which has been tested in sustained flight at more than 2,000 mph and at altitudes in excess of 70,000 feet,” President Lyndon Johnson announced today.…

“The performance of the A-11 far exceeds that of any other aircraft in the world today.…

“The project was first started in 1958…. The Lockheed Aircraft Corporation at Burbank, California is the manufacturer of the aircraft. The aircraft engine, the J-58, was designed and built by the Pratt & Whitney Division, United Aircraft Corporation. The experimental fire control and air-to-air missile system for the A-11 was developed by the Hughes Aircraft Company.

“In view of the continuing importance of these developments to our national security, the detailed performance of the A-11 will remain strictly classified and all individuals associated with the program have been directed to refrain from making any further disclosure.…”

JULY 24, 1964. PRESIDENT ANNOUNCES NEW SPY PLANE

President Lyndon Johnson at a press conference: “I would like to announce the successful development of a major new strategic manned aircraft system which will be employed by the Strategic Air Command. This system employs the new SR-71 aircraft and provides a long-range advanced strategic reconnaissance plane for military use capable of world-wide reconnaissance for military operations.…

“The SR-71 aircraft reconnaissance system is the most advanced in the world. The aircraft will fly at more than three times the speed of sound. It will operate at altitudes in excess of 80,000 feet. It will use the most advanced observation equipment of all times in the world … an outstanding reconnaissance capability.… The SR-71 uses the same J-58 engine as the experimental interceptor previously announced but it is substantially heavier and it has a longer range. The considerably heavier gross weight permits it to accommodate the multiple reconnaissance sensors needed by the Strategic Air Command to accomplish the strategic reconnaissance mission in a military environment.

“This billion dollar program was initiated in February 1963. The first operational aircraft will begin flight testing in early 1965, and deployment of production units to the Strategic Air Command will begin shortly thereafter.…”

DECEMBER 23, 1964. DEPARTMENT OF DEFENSE NEWS ANNOUNCEMENT

“First flight of the U.S. Air Force SR-71, the new long-range strategic reconnaissance aircraft, took place yesterday at Palmdale, California.

“The Lockheed-built aircraft, flown by company test pilot Robert Gilliland, was in the air approximately one hour.

“… All test objectives were met.

“The aircraft will be assigned to the Strategic Air Command at Beale Air Force Base, Marysville, California, in 1965.”

Almost as soon as the U-2 was in operation, we began to plan its successor.

Efforts to improve the U-2 had yielded very little gain. A new design would be necessary. We set up our own requirements. There were none officially yet—just the need. We knew we needed more altitude and, especially, more speed.

Vulnerability studies led us to the decision that the next airplane should operate at altitudes well over 80,000 to 85,000 feet, fly at speeds well over Mach 3, and be able to out-maneuver any SA-2 missile the Russians might develop. It had to be stable enough in flight to take a good photograph from altitudes above 90,000 feet. It had to retain the characteristics of the U-2—be able to photograph very, very small targets on the ground—while flying four to five times as fast. We wanted it to have global range—with multiple midair refuelings from the KC-135 aerial tankers. The aircraft also should present an extremely low radar cross-section—be very difficult to detect.

The decision to assign this project to Lockheed was arrived at only after consideration of several design proposals from other companies. From April 21, 1958, through September 1, 1959, I made a series of proposals for Mach 3-plus reconnaissance aircraft to Richard Bissell of the CIA and to the USAF Bissell, as chairman of the review committee, was reluctant to award the contract for its successor to the same company that had built the U-2 without a design competition.

Some of the other entries were interesting.

A Navy in-house concept proposed an inflatable rubber vehicle which could be carried to altitude by a balloon, then boosted by rocket power to a speed where its own ramjets could take over. This rapidly was demonstrated to be unfeasible. The balloon would have had to be a mile in diameter to lift the unit, which itself had a proposed wing area of one-seventh of an acre.

Convair proposed a ramjet-powered Mach 4 aircraft, which also had to be carried aloft by another vehicle and launched at supersonic speeds where the ramjet power could take over. Unfortunately, the launch vehicle was the B-58, which could not attain supersonic speed with the bird in place. Even if it could, the survivability of the piloted vehicle was in question because of probable ramjet blowout in maneuvers.

The total flight time for the Marquardt ramjet at the time was not over seven hours, obtained mainly on the ramjet test vehicle for the Boeing Bomarc missile. This test vehicle, the X-7, had been built and operated by the Skunk Works.

On August 29, 1959, our A-12 design, the twelfth in the series, was declared the winner and Bissell gave us a limited go-ahead. We were to conduct tests on models, build a full-scale mockup, and investigate specific electronic features of the airplane over a four-month period.

On January 30, 1960, we were given a full go-ahead for design, manufacture, and test of 12 aircraft.

The code name was Oxcart, a name selected from a list of deliberately deceptive identifications. Obviously an oxcart is a slow-moving body. This CIA program led to other versions of the design for the U.S. Air Force. The next would be a long-range fighter for the Air Defense Command, first discussed with Gen. Hal Estes on March 16 and 17 of that same year. It became the YF-12A.

In January 1961, I made a proposal for a strategic reconnaissance airplane to Air Force Secretary Dr. Joseph Charyk, U-2 project officer Col. Leo Geary, and Lew Meyer, an Air Force finance officer. This encountered initial opposition in some quarters where it was seen as competition for funds for the North American B-70 program, then the object of considerable controversy. But it became the SR-71, the prime reconnaissance airplane for the Air Force today. There also would be a fourth verson—the D-21, an unmanned drone.

The aircraft that were to become the “Blackbirds” were the first to use the “Stealth” technology we developed for radar avoidance. We had tried to work it into the U-2 as a modification after the aircraft already were in operation and got nowhere. To be “stealthy,” aircraft must have certain features incorporated in design from the very beginning, not added later. “Stealth” must be designed into the airplane from the first three-view drawing to be effective. This is what we did with the Mach 3-plus aircraft.

We had achieved Mach 4 flight earlier for a few seconds with the X-17, our ramjet test vehicle—before that the X-7. The idea of attaining and staying at Mach 3.2 over long flights was the toughest job the Skunk Works ever had and the most difficult of my career. Early in the development stage, I promised $50 to anyone who could find anything easy to do. I might as well have offered $1,000 because I still have the money.

Aircraft operating at those speeds and altitudes would require development of special fuels, structural materials, manufacturing tools and techniques, hydraulic fluid, fuel-tank sealants, paints, plastics, wiring and connecting plugs, as well as basic aircraft and engine design. Everything about the aircraft had to be invented. Everything.

In the search for a suitable fuel we considered initially such exotic candidates as liquid hydrogen, coal slurries, and boron slurries.

Design of a liquid hydrogen powered airplane actually was carried to the point approaching a production contract for a substantial number of them. The concept had seemed promising. While the airplane was very large, it was very light in weight. Powered by special engines developed by Pratt & Whitney, it would have a cruising altitude well above 100,000 feet—higher than the Blackbirds later achieved, although with less speed and range. But the further we went into development, the worse the problems we perceived.

The CL-400 was essentially a big flying vacuum bottle, with the liquid hydrogen heavily insulated to keep it at very low temperatures and as close to absolute zero as possible. The problems of transporting this fuel from a plant in the United States to wherever the airplane could be based would have been prohibitive. It would have required a whole fleet of C-124s to keep just a few liquid hydrogen planes flying. No foreign nation was likely to approve our flying in with such quantities of it nor to allow us to put a ship in their harbors and liquefy it on the site.

We had engaged the Pomeroy Company to design a hydrogen liquefaction plant that was to have been erected near our aircraft plants and the Palmdale Airport in the Mojave Desert. It would have used ten percent of the natural gas input to the city of Los Angeles in 1972 and ’73!

One day we were visited at Lockheed by Assistant Air Force Secretary James Douglas and Gen. Clarence Irvine of the Air Force. Their question was, “How much stretch have you got in this thing, Kelly?”

“Let’s take a look at it,” I said. “Here’s the inboard view. You can see it’s totally liquid hydrogen from one end to the other except for a small cockpit up front.”

You do not put liquid hydrogen in nooks and crannies and odd-shaped tanks. The container has to be cylindrical—and very well insulated. With this airplane, we didn’t have the condition we’ve always had with other aircraft, both piston-powered and jets, where extra fuel could be added for a little more power and range. The Constellation gross weight, for example, doubled in its lifetime. We were able to do the same with most of the fighters, too. But with the liquid hydrogen airplane, once you set down the tank volume, that’s it. You could carry external tanks, but it would be difficult, and the airplane would carry added drag because of air resistance.

So the Secretary and the General turned to Perry Pratt, head of Pratt & Whitney engine design. “Maybe there’s something in the engine. Perry, how much stretch do you have in this engine?”

“Perhaps three to four percent in five years,” was the answer.

Overall, it wasn’t a very good forecast. We all agreed to cancel that effort without any more expenditure of funds. And had we proceeded, we would have run right into the energy crunch of the 1970s.

Coal slurries—finely-ground-up coal mixed with a light oil base and water—were a possible power source, injected into the engines as fuel. But the tiny coal cinders tended to ruin the turbine blades.

Boron compounds—in slurries—were tried, too. But these were difficult to use and plugged up the injector nozzles, not only in the engine but afterburners as well.

We decided to stick with liquid petroleum as fuel. It would have to be a very special fuel, though, for those operating altitudes and temperatures—from – 90°F for midair refueling at high altitude to + 650°F in supersonic flight.

We put the problem to our old friend, Jimmy Doolittle, now a top executive with Shell Oil. That company had come up with what we called LF-1A, “Lockheed Lighter Fluid 1 for the U-2; and it was a good fuel for that airplane. Shell came through again, with cooperation from the Ashland and Monsanto companies and Pratt & Whitney, with a new chemical lubricant and fuel for the Mach 3-plus aircraft. This we call LF-2A. The Air Force has its own designations, of course.

Development of that fuel took a lot of doing. It was very expensive, but it’s an excellent fuel.

The fuel in this design also acts as an insulating element. The fuel tanks not only contain the fuel but are constructed to protect the landing gear. The gear retract up into the middle of the tanks. With radiant cooling to the fuel, the rubber tires are insulated against the very high temperatures the plane encounters during hour after hour of flight. And the plane doesn’t land with the tires ready to blow out.

In selection of structural materials for a Mach 3-plus airplane, aluminum automatically was ruled out. It would not withstand the ram-air temperatures of 800°F over the body of the plane. High-strength stainless steel alloys or titanium would be required for the basic structure. And high-temperature plastics would have to be developed for radomes, cockpits, and certain other areas.

Stainless steel actually is a better high-temperature material than titanium. But visiting the Lockheed-Georgia plant, which was building parts for the supersonic B-70 bomber, I saw what it took to make basic honeycomb panels for the fuselage: a “clean-room” environment—what was essentially a big pressurized airbag—with pressure locks for entrance and exit, everyone in white clean-room suits, and all the controls necessary to observe sterile conditions.

I reverted to my old Skunk Works axiom, “Keep it simple, stupid.” The more complexity, the more potential for problems. This is too sophisticated for the Skunk Works, I decided. We’ll use the material we’ve worked on experimentally for ten years, the new advanced titanium in conventional structure.

The shape of the airplane itself was determined after a great many wind-tunnel and other tests. The result, head on, looks like a snake swallowing three mice. And for good reason. We added chines on the fuselage to get aerodynamic lift, among other things. We had some without them, but a terrific amount with them.

Before we got into high gear on production, we thought it advisable to build several test samples of the most complex sections: the nose and the basic wing structure.

The first wing section was a catastrophe. When we put it in a “hot box” to simulate high in-flight temperatures, it wrinkled up like an old dishrag. The solution was to divorce the skin panels from the wing spars in each direction and put corrugations and dimples in the skin—the wing surface. When the titanium got really hot, the corrugations merely deepened. I was accused of making a Mach 3 Ford Trimotor—that was made all of corrugated aluminum. But it was a very effective solution to a really difficult problem.

The nose section of the airplane presented other problems. We put it in the hot box to study cooling requirements for the pilot and the gear. We produced 6,000 parts; and of them fewer than ten percent were any good. The material was so brittle that if you dropped a piece on the floor it would shatter.

Obviously, we were doing something wrong. We queried Titanium Metals Corporation on why we had hydrogen embrittlement from our processes. They didn’t know. So we threw out our entire titanium processing system and replaced it with the same methods TMC used in making the original sheets and forgings at their factory.

After the initial shambles on the nose segment heat treat tests, we put into effect a quality-control program that I believe was and is unequaled anywhere. For every ten parts manufactured, we made three sample parts. These would be heat-treated and otherwise tested before any of the others of the batch would be put in storage for future use. One sample went into a tensile strength test machine to find out how strong the material itself was. In the second, we made a short cut—about one-quarter inch long—and bent the sample at that cut around a form with a very small radius—as small as 32 times the thickness of the sheet—to see if it would crack. The third sample was used in case a re-heat-treat test was necessary. We didn’t want to throw away the whole batch needlessly; it was too darned expensive.

We could trace back to the mill and know the direction of the sheet rolling, and whether the part was cut with or against the grain. Before we would do all the expensive machining to cut landing gears from the huge heavy extrusions we would cut twelve samples, and unless everyone met the test we devised for them, we would not use that extrusion to make a landing gear. We’ve had no landing gear failures on the birds despite the hard landings that go with in-service flying.

There were times when I thought we were doing nothing but making test samples. But the test effort was worth it. By the early 1980s, we had made more than 13,000,000 titanium production parts for all of our Skunk Works airplanes and also for the Lockheed L-1011 commercial transport and the company’s big military cargo aircraft.

Titanium is such a rigid material that it cannot be shoved into place—as can some other metals—and therefore cut to less-exact tolerances. It must be tooled to fit. While this exact tooling is very expensive, it saves in the long run on scrap parts—of which there were almost none in production.

We had to invent a very large press that would shape titanium under very high temperatures—up to 1500°F and very high pressures.

The tough titanium actually is a very sensitive material to handle. Everything wants to poison it. We learned at an early date that we had to take cadmium-plated tools out of the mechanics’ tool boxes if they were going to work around the engine, because the cadmium would flake off enough to poison the bolts. After only one or two runs where they attained temperatures above 600°F, the bolt heads would just fall off. We had to keep cadmium away from the titanium.

We found that the spotwelds on the wing panels failed very early in their test life when we built the panels in the summer, but if they were built in the winter they would last indefinitely. Analyzing all the processes, we discovered that in summer the water supply system for the city of Burbank was loaded with chlorine to reduce algae. When we washed the welds with pure water, there was no problem.

Special tools were required. When we first tried to drill the heat-treated B-120 titanium, a drill would be totally destroyed after about 17 rivet holes. Finally we found suitable drills developed in West Germany. Today we can drill more than 150 holes with a drill; and resharpened, it will drill another 150 holes.

We had to train thousands of people, not only our own, but Air Force mechanics and employees of our subcontractors and vendors—more than 300—in how to handle the machined parts. It’s difficult to get an old-time machinist to change his ways. He wants to discover on his own how to do something. So in the Skunk Works we put them in the experimental shop under the engineers’ direction and made them a party to developing the data. That always is a good tactic: involve the employee in the whole program as much as possible to arouse his interest and inspire his best performance.

One thing we learned in manufacturing the first Oxcart airplane was not to trust color coding. I had insisted on color codes for all wires and tubes and other connections, so that plumbing and other systems could not be installed incorrectly. Working with that many people, we discovered that ten percent were color blind. We’ve found a part bent over four inches to be connected incorrectly. We still color code, but we also use odd-shaped terminals that will fit only one way for those who can’t distinguish colors.

Materials and manufacturing were only part of the problem. There were the systems—hydraulic, electrical, and others.

Redundancy of systems has been a design requirement of mine ever since we added the auxiliary fuel pump to the F-80 after we lost Milo Burcham. The Constellation had it for the first completely power-boosted controls. The Lockheed L-1011 airliner has it in triple and quadruple systems. The Blackbirds have triple redundancy. It is a safety factor that pilots especially appreciate. The cost, if you start with it in original design, is only a few tenths of a percent of the total. When you consider the value of the human lives and the vehicle this redundancy is protecting, the cost seems even smaller.

Hydraulic fluid was another special problem. First, of course, we surveyed all the suppliers to see if any of them had a high-temperature fluid, able to operate at above 600°F. One responded with literature on a fluid that worked at 960°F. I requested a sample immediately. It came in a canvas bag! That’s a funny way to ship hydraulic fluid, I thought. When I opened the package I found a white crystal.

Yes, it would operate at 960°F, but it was a solid at ordinary temperatures. You’d have to thaw out the hydraulic system with a blowtorch—not too useful for an airplane. So, the hydraulic fluid became a development project, too. The final product was a basic fluid developed by Pennsylvania State University, but with seven ingredients that we added so that it would withstand the temperatures and still function as a lubricant for the pumps and other hydraulic gear.

There were a few other little items—all important. Leather washers or rubber O-rings could not be used at those temperatures. Steel was the answer, giving no trouble at high or low temperatures. Fuel tank sealants to contain the fuel were another necessary development. While the airplane is not totally tight and will leak some on the hangar floor, the fuel has such a high ignition point that it is much safer than ordinary fuel.

Electrical problems alone threatened success of the project. We were not able to complete a flight on the Oxcart without some kind of failure due to the electrical system—which controlled the autopilot, flight control system, navigation system, and with electrical transducers even the hydraulic system.

At one time, 17 percent of our flights had to be cut short because we couldn’t measure oil pressure. We could not take a chance on burning out those very expensive engines. We had to institute a cooling system for the oil temperature gauge.

Especially critical was the electrical transducer measuring air displacement related to proper positioning of the inlet spike. It was our toughest electrical problem.

We simply were not able to get the electrical system to work reliably under conditions of very high altitude, very high temperature, and very substantial vibration.

I personally spent six weeks at the test base working on this problem. The entire project was at stake.

Finally, we had to invent our own wire for the electrical system. We used high-temperature Kevlar wiring and just wrapped asbestos around it in the critically hot sections.

Special plastics were designed not only to withstand the high temperatures but to provide low radar return.

The Blackbirds take their name from the dark blue-black paint. The color was determined after tests for emissivity—heat emission from the hot airplane in flight. Emissivity can make a difference of 50 to 80 degrees in temperature on the aircraft, so it is a critically important item. Actually, the color of the Blackbirds becomes blue as temperatures increase at high speed and altitude.

We had to invent a special paint for the Air Force insignia. After just one hot flight, the red would turn brown and white become mottled. Getting the paint to adhere to the plane at all was another problem. We were getting little pockmarks on the painted high-temperature plastic that makes up 20 percent of the aircraft surface. We found that when fuel had been spilled, and temperatures of 550 to 600 degrees reached, little miniature explosions were occurring on the plastic skin. The paint had to be made fuel proof as well as rain proof.

The various payloads—cameras, very sophisticated electronic gear, navigation systems, inertial systems—all were the result of great effort in development.

The inertial navigation system is so good that you can take off, put in 16 different check points, and on autopilot fly at speed, altitude, and direction desired. When the pilot says, “Home, James,” the system takes him home. The powerplant for the Blackbirds is a marvelous development on the part of Pratt & Whitney. It is the only engine of its kind in the world.

It started out as a Navy engine for an airplane that never was built. When we saw the size of it, we wanted to adapt it to high Mach numbers. P&W put in what I will call a gear shift system. When speed of a couple of thousand miles an hour is reached, the engine shifts into another cycle, bypassing the high compressor for conventional jet operation and flying as a ramjet. With no machinery obstructing airflow, the faster the plane goes the faster it wants to go.

But the hardest task of all was to make the air flow properly through the engine inlet and outlet in supersonic flight. Consider that the air hitting the tip of the spike on the inlet to the engine nacelle encounters temperatures above 800°F, then has to expand, and in the duct undergo a 50-to-one compression. This must happen without separation of airflow from the walls of the inlet duct.

It took many years to develop that inlet so the engine would operate under all flight conditions. In the early days, we often had blowouts when the flow would separate. The engine would drop from 16,000 to 20,000 pounds of thrust to about 16,000 pounds of drag—in a fraction of a second. The pilot would be so battered around by the vibration that he could not even tell which engine was out.

We solved that by putting an automatic control on the rudder, so that in .15 second the pilot could sense an engine had blown, which one it was, and kick in 9 degrees of rudder with the hydraulic steering system. The airplane then would continue in level flight.

Now we have an automatic restart. This works so well that I was concerned when the SR-71 was in service in Southeast Asia that some of the pilots flying those rough missions never had experienced a blowout; so we reintroduced practice blowouts in flight training.

Efficient as the engine is, I have kidded my friends at Pratt & Whitney that it is supplying only 17 percent of the push for the airplane in flight. Our inlet duct and the ejector make up all the rest of the thrust. Of course, we wouldn’t have the rest of it without that vital 17 percent!

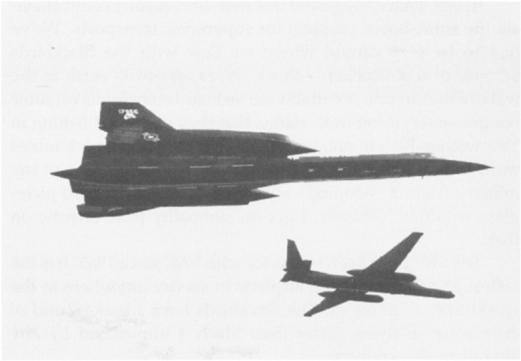

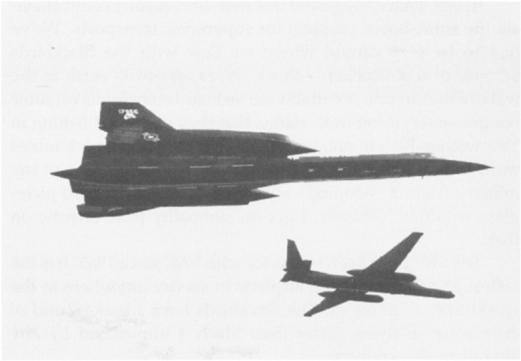

When President Johnson first announced the A-11, the photo released actually showed its successor, the YF-12A, in flight. In developing the triple-sonic planes, we worked through design numbers A-1 to A-12. A-11 was just a design number. We built 12 of the A-12s. The YF-12 photo probably was substituted for security reasons. It revealed less about aircraft capability than another model.

The YF-12 first flew on August 7, 1963. The Air Force had had difficulties with an earlier candidate for a high-altitude interceptor and accepted our proposal to make a long-range, high-speed, high-altitude interceptor. Gen. Hal Estes wanted us to incorporate the ASG-18 radar system that Hughes Aircraft had been working on and to be able to fire the Hughes GAR-9 missile. We used both, but a substantial amount of development testing still remained.

With its large fuselage, the YF-12 could easily contain three of the large missiles. But no one ever had fired a missile from such high altitude and at such high speed. It took us three years to do it.

It was a real development problem to be able to open the bomb bay doors, eject the missile, and ignite it, so that it would hold its path and not, instead, come up between the first and second cockpits. There had been big problems with launching missiles from aircraft even at much lower speeds.

To keep the missiles away from the airplane, we had to develop thrusters that would push down with a certain force on the forward end of the missile and another force on the rear—all in just a few seconds. The missile was ejected to a distance about 40 feet below the airplane and then fired.

Launched from the airplane at well above Mach 3, and accelerating on its own at another Mach 4, the missile was speeding hypersonically at Mach 7 at the peak of its course. We fired at target drones at altitudes ranging from sea level to more than 100,000 feet, and hit targets more than 140 miles away. We proved that we could hit targets flying over ocean or over land.

Our success rate was better than 90 percent hits. The GAR-9 missile and the ASG-18 radar system performed beautifully. Development of the missile in the YF-12 led to the Phoenix system used in the F-14 today.

Three YF-12As were built on the prototype contract, and from their performance the Air Force determined that a fleet should be produced for the Air Defense Command. Gen. Arthur Agan needed replacements for the outmoded F-102s and F106s. At one point, he said publicly that with his inadequate interceptors and without a radar network he could not protect Air Force One flying the President across this country from Washington to Los Angeles.

Three times in three years Congress appropriated funds, more than $90 million, to start production of 93 of the big fighters—F-12B—for the ADC. But Secretary of Defense Robert McNamara, guided by his “Whiz Kids,” decided no need existed for such a high-performance airplane, that our potential enemies did not have anything comparable, and that an airplane couldn’t hit a target going that fast anyway. Of course, the airplane had a better than 90 percent hit rate in firings at Mach 3.

And the threat that wasn’t there soon surfaced in the Russian supersonic Backfire bomber.

The Backfire can outrun any of the American fighters, including the F-15, and F-16, and others. For that matter, so can the commercial Concorde transport; both Concorde and Backfire are in the Mach 2 category. Our present fighters have a supersonic range of only 50 to 100 miles before they exhaust their fuel supply. The YF-12A, now principally assigned to NASA research, has the speed and range at Mach 3-plus. The F-12B, of course, could easily have flown up to inspect or shoot down a Backfire, which, while capable of Mach 2, can reach the speed only for brief runs, not sustained cruise.

Rather than re-equip the Air Defense Command, the decision then was made to downgrade its role.

Even without a contract for production of the plane, the existence of F-12B tooling was viewed by the McNamara team as a threat to funds for the B-70 supersonic bomber and the F-15 fighter. We retained the tooling for three years, but then were ordered to scrap it—which we did at 7 1/2 cents per pound. The cost to replace it today and put such a plane into production would be totally out of the ballpark—hundreds of millions of dollars for the tooling and $70 or $80 million for each airplane. At the time, the airplanes would have cost about $19 million, and there is no fighter-interceptor in this country’s air forces today with comparable capability.

But the Blackbird technology was to see other applications. The Air Force wanted an advanced reconnaissance airplane that could carry larger cameras and more sophisticated gear than the glider-like U-2. The customer was the Strategic Air Command, which in my book is the most sophisticated of them all for development of aircraft and materiel. The SR-71 was the result.

By the end of 1962, we had an initial contract to build six of them. I should say the RS-71 was the result, but when President Johnson announced first flight of the airplane two years later in 1964, he reversed the initials. It meant a lot of scrambling by SAC and the Skunk Works to revise the designations. The original meant “reconnaissance strike;” the revision was called “strategic reconnaissance.” We still use the nickname “Strike Recci.”

The SR-71 carries a pilot in the front cockpit and a reconnaissance officer in the rear to handle the cameras and certain navigation jobs. It is a much heavier airplane than the earlier Blackbirds in that it carries more fuel and more and improved instrumentation. It looks much like the earlier models, but the structure is considerably improved. And by the time we got to the third Blackbird we had that air inlet development well in hand, so the flight test program went ahead rapidly.

It was on the SR-71 that we worked with Wyman-Gordon to develop large titanium forgings that we could machine down to final form for installation on the aircraft. It took $1,000,000 for Wyman-Gordon to develop the forging methods, and it cost the Skunk Works another $1,000,000 to learn how to cut the forgings into parts. But, for example, one forged part replaced some 96 parts that we had had to build up into a single part for prior airplanes. The net result was a saving to the military, and the taxpayers, of $19.5 million from that single program.

Two other aeronautical masterpieces in which Kelly Johnson had the essential role as a legendary contributor to national security: the SR-71 and TR-1.

It has become something of a crusade with me to advocate development in this country of a huge metal forming press. We need a 250,000-ton machine, five times larger than the biggest one available to us here today. When we have to machine away 90 percent of rough forgings to make very large aircraft parts—specifically, titanium nacelle rings and landing gear for the SR-71 and aluminum fuselage side rings for the C-5 transport—that seems very wasteful. The Russians have not hesitated to make this investment. They have more and larger forging presses than the United States.

In-flight refueling, developed to give the SR-71 global range, has become routine. By the early 1980s we had made more than 18,000 of them and can refuel in the air anywhere.

In fact, I have suggested that mid-air refueling could alleviate the sonic-boom problem for supersonic transports. We’ve had to be very careful where we flew with the Blackbirds because of that problem—shock waves carried to earth in the wake of the aircraft. Inevitably we’ve heard complaints on sonic booms—everything from claims that they disturbed fishing in Yellowstone Park to one insistence that they made pack mules want to jump trail. I had a complaint, too, when one of my military friends “boomed” my ranch and broke a $450 plateglass window. Naturally, I got no sympathy from anyone on that.

The SR-71 has been in service with SAC since 1965. It is the fastest and highest flying airplane in service anywhere in the world that we know of. The Blackbirds have a background of experience in flying faster than Mach 3 unmatched by any aircraft in any country.

On April 27, 1971, a USAF SR-71 cruising above 80,000 feet set duration and distance records on a 10½ hour flight covering 15,000 miles for which the Air Force received the Mackay Trophy “for the most meritorious flight of the year,” and the Harmon International Trophy in 1972 for “the most outstanding international achievement in the art/science of aeronautics.”

On September 1, 1974, a USAF SR-71 set a transatlantic record of 1 hour, 54 minutes, 57 seconds, on the 3,470 statute mile course from New York to London, en route to the semiannual Farnborough Air Show and its first public appearance before an international audience. The return flight from London to Los Angeles established a world speed record for the distance—3 hours, 47 minutes, 35 seconds, over the 5,463 statute miles.

On July 27, 1976, Strategic Air Command pilots flying out of Beale AFB in California set six new world records for speed and altitude, including closed circuit speed of 2,086 mph; straight course of 2,189 mph; and absolute altitude and altitude in horizontal flight of 86,000 feet.

There is a fourth Blackbird, and until very recently I was not allowed to talk about it. As so often happens, clearance came because of a news photo and story. A number of the aircraft were shown in mothballs at Davis Monthan AFB in Arizona.

This is the highest performing of all the Blackbird series—it flew higher, faster, and farther. It is an unmanned remotely piloted vehicle—the D-21, a drone. As our equipment becomes smarter, more powerful, more sophisticated, I wonder about the need always for a man in it. The answer may be to leave the man on the ground, but in control of the vehicle.