THREE

THE ONLY SAFE REACTOR

A few days after Christmas 2010 the container ship Altona, bound for China and carrying a load of 770,000 tons of uranium concentrate— known as yellowcake, the transportable form of uranium that will eventually be processed into fuel for nuclear reactors—was steaming west across the South Pacific. Somewhere between Hawaii and the Midway Islands it ran into a storm. After three days of gales and heaving seas, the crew (like most modern superships, the Altona was manned by only a skeleton crew) discovered that the containers in the hold had shifted and two drums of yellowcake had been smashed open. There was loose uranium in the hold.

Owned by Canadian mining giant Cameco, the Altona was delivering yellowcake to a Chinese utility in Zhangjiang. (China has become one of the world’s largest consumers of uranium.) The ship turned around and headed back to British Columbia, and Cameco executives assured the world press that there was no serious danger of the uranium leaking into the sea or harming the crew. The Altona berthed at Vancouver before transferring up the coast to a Cameco plant for clean-up.

The mishap sparked little outcry, joining the dozens of incidents yearly in which uranium in its various forms is mishandled, spilled, mined, or stored in violation of environmental regulations—or simply lost.1 The Altona averted disaster, but it is an apt symbol for the unsettled waters into which the nuclear power industry is sailing.

Until the earthquake-bred tsunami struck the nuclear power plant at Fukushima, Japan on March 11, 2010, nuclear power was enjoying its most promising year in a few decades. The renaissance for conventional nuclear power—based almost entirely on light-water reactors and entirely on the uranium fuel cycle—promised the construction of dozens of new reactors, the addition of several gigawatts of carbon-free power, and a long-delayed windfall for nuclear power producers. China alone has announced plans to add 110 gigawatts of nuclear power-generation capacity before 2021, an amount equal to 25 percent of the total world nuclear power today. Since China’s seemingly inexhaustible appetite for coal, the world’s dirtiest energy source, threatens to torpedo international efforts to curb global climate change, the shift to nuclear power, which emits no carbon, would be a welcome development—if it could be pulled off.

India plans to add dozens of new reactors by 2050, many eventually powered by thorium (see chapter 7 for a full look at India’s thorium power plans). Other countries with ambitious plans for nuclear power plants include South Korea and Japan—although new nuke plants in Japan could well be derailed by the backlash from the accident at Fukushima. Cameco forecasts that more than 100 new reactors could be added worldwide by 2022, further stretching already thin supplies of uranium.

And then there’s the United States, where no new nuclear plants have been permitted since the 1970s and none have come online since 1996.2 U.S. energy producers, particularly the large nuclear utilities Exelon and Duke Energy, have embraced the nuclear renaissance with enthusiasm.

According to the Nuclear Energy Institute, the industry’s trade association, 17 companies are planning at least 30 new nuclear plants in the United States. Operators have applied for licenses from the U.S. Nuclear Regulatory Commission (NRC) for 20 plants.

So far, the renaissance has been more heat than power, as it were. Not a single new nuclear plant has won licensing from the NRC. Schemes are afoot to expedite the NRC’s famously glacial approval process, which can take a decade or more, but they have not yet borne fruit. Investors looking at the huge upfront capital costs for nuclear power, projected to reach several billion dollars, plus the 10- to 20-year timeline to completion, are hardly rushing to pour money into new nuclear projects. (I’d add, though, that a coal plant also will cost billions of dollars to build—especially as environmental groups and federal agencies succeed in preventing power utilities from passing on the social and environmental costs of dirty coal to ratepayers.)

Several U.S. nuclear power plant projects have been delayed or canceled. In October 2010 Constellation Energy said it was backing out of the Calvert Cliffs nuclear plant project in Maryland. At one time Constellation and its partner, Électricité de France, planned to add a third reactor based on a new design to the two existing reactors at the site, doubling the power output. Constellation quarreled with the U.S. Department of Energy (DOE) about the fees the DOE planned to charge for guaranteeing loans for the $7.5 billion project and finally pulled out.

Six months later NRG Energy killed its South Texas Project, which included plans for two 1,350-megawatt advanced boiling water reactors. NRG cited “multiple uncertainties” regarding funding from investors—the Tokyo Electric Power Company and the Japan Export Bank—stemming, obviously, from the Fukushima incident.

NRG was among the first entrants in the new nuclear derby: the company filed a license application with the NRC in September 2007. Besides investors’ second thoughts, the South Texas Project fell victim to another brute fact of new energy programs in the twenty-first century: “It is cheaper, and faster, to build new natural gas fired electrical generation plants than to build new nuclear reactors,” wrote the nuclear power journalist Dan Yurman on his blog, Idaho Samizdat. “Texas is swimming in a huge surplus of natural gas that sets the price for electricity.”

The average two-reactor nuclear plant, based on conventional technology, costs $5–$20 billion to build, once the cost of capital is included. A comparable natural gas plant costs about half as much. You can build a small, 150-megawatt natural gas plant for about $200 million. Meanwhile the world’s existing reactors, which include many facilities already years beyond their original planned production life, could be reduced in the coming years. An April 2011 study by the financial services giant UBS found that as many as 30 nuclear plants, including many in areas of seismic activity, could shut down by 2016.

TH90 • TH90 • TH90

THEN THERE IS THE QUESTION OF FUEL SUPPLY. Supplies of uranium, which have been in surplus since the fall of the Soviet Union, have tightened and prices are rising again after plummeting during the world financial crisis of 2008–2009. Anticipation of new nuclear construction has helped drive the price of uranium to levels not seen in years: uranium hit a three-year high of $73 a pound on the spot market at the beginning of February 2011, and there are predictions that it could go much, much higher. A pair of analysts at CRU Group, a commodities and minerals analysis and consulting firm, said in a report in early 2010 that prices in the next decade could challenge the all-time high of $136 per pound, set in the pre-crash days of 2007. As with many energy commodities, the wild card in this calculation is China.

“The current unknown is when and to what extent the Chinese will buy uranium,” said Philip Macoun of CRU.3 The amount of uranium China is buying has surprised most analysts and has helped push the price upward.

Rising prices are good news if you’re a producer of uranium, like Cameco or the French nuclear giant Areva, or a uranium-rich country, like Kazakhstan (which in 2010 took over as the world’s number one source of mined uranium). If you’re a nuclear power utility in a country where developing new uranium supplies has not been a high priority—like, say, the United States—the scenario is less rosy. Fuel costs for existing reactors have been historically low for a long time and comprise a fraction of the cost of nuclear power. One way or another, though, major changes are coming to the uranium market in the next 20 to 30 years. Demand, and prices, are certain to rise; uranium suppliers like Cameco, operating on the theory that “if you look hard enough, you’ll find it,” are confident that there’s enough uranium in the ground to meet any future supply needs. But uncertainty has begun to leak into the market.

Those uncertainties are fueled by two parallel developments: rising demand for freshly mined uranium and the falloff of the so-called secondary market—that is, uranium that has already been produced. After the Iron Curtain fell, the United States began the Megatons to Megawatts program (M2M) to secure and safely reprocess dismantled nuclear warheads in the former Soviet Union. Since the mid-1990s M2M, which was scheduled to end in 2012, has dumped hundreds of tons of uranium onto the world market. Along with existing above-ground supplies, the repurposed Soviet material accounts for nearly one-third of the annual requirements of the world’s nuclear plants. That means that the yearly supply of newly mined uranium falls short of demand by 20 to 30 percent. The world consumes on the order of 180 million pounds of uranium a year and produces only about 140 million. With the end of M2M and the depletion of uranium inventories built up in the 1990s and early 2000s, “new primary production will be required,” Cameco’s CEO, Gerald Grandey, said in the spring of 2011.4

Ken Peterson, vice president of nuclear fuels at the Chicago-based Exelon Corporation, the largest producer of nuclear energy in the United States, pointed out to me in an interview that major American utilities are covered by long-term uranium contracts lasting into the next decade. “We have 100 percent [supply] coverage through 2015.”

That may be enough for Exelon’s executives and investors, but it demonstrates a blinkered view in terms of the longer term and the broader market. The third factor affecting uranium supply is the long lead time for bringing new uranium finds into production: at least ten, and often 15, years. That means there’s a doughnut hole in long-term uranium forecasting: although there’s plenty of uranium in the ground, the problem is bringing it to market fast enough to meet the needs of power plants, according to Grandey. “Our challenge is investing and permitting and developing new mines fast enough to overcome the drop-off in Megatons to Megawatts,” he said at an industry symposium in Denver in the spring of 2011.

Indeed, supply disruptions have occurred recently at big mines, including the Ranger and Olympic Dam deposits in Australia, while several large projects in development, such as Trekkopje in Namibia and Cameco’s Cigar Lake mine in northern Saskatchewan, have been delayed.

That’s why the rapidly developing nations of India and China, as well as developed Asian countries like South Korea, are moving aggressively to build partnerships and form joint ventures with uranium producers, particularly those in the former Soviet Union. In January 2011 Moscow and Tokyo announced an agreement to jointly prospect for and develop uranium ore deposits, as well as construct and operate new reactors. China, meanwhile, may well be stockpiling uranium: the country reportedly imported about 5,500 tons of yellowcake last year, while it consumes only half that much.

Burned by aggressive supply contracts and failed uranium-mining ventures in the 1970s and 1980s, U.S. utilities—most of which pay more heed to signals from Wall Street than from the world’s uranium mines—take a shorter-term, not to say more complacent, view.

The Americans are “out of synch with the rest of the world,” says Mariangeles Major-Sosia, the vice president of international network coordination at Areva. “They don’t have the longer vision that other countries have, because the U.S. doesn’t really have an energy policy. They’re publicly traded companies, so they’re making decisions to next year or next quarter,” she told me when we met at the symposium in Denver.

As long as the current generation of utility executives remains in power, that’s unlikely to change. The renaissance waits upon a change not only in energy policy and economics but in leadership.

TH90 • TH90 • TH90

CHARLES HESS WAS NEVER one of those executives, in the corner suite and chauffeured town car sense of the word, but he has spent 35 years in the nuclear power business as a chief engineer, research director, and plant operator. He lived out the contraction era, and he is now living through the prospective new age of expansion. And he has come to believe that thorium is nuclear power’s inevitable future.

In March 1979 Hess was working at a nuclear plant in New Jersey. The Three Mile Island accident started before dawn on March 28. That morning he and his fellow engineers at Oyster Creek Generating Station in Ocean County heard about the accident on the radio, and later that day he was devising ways to deal with the radioactive gas that was accumulating in TMI’s main reactor building and the neighboring auxiliary building. He spent the next six months as one of the lead engineers trying to contain the radioactive spillovers from the accident. The experience profoundly redirected Hess’s career as well as the nuclear power industry in the United States.

Specifically, Hess worked on a method to transfer the highly radioactive standing water in the reactor building to tanks in the spent fuel pools nearby. This was not a simple operation; in fact, nothing like it had been done before. The job was complicated by internal politics: essentially Hess and his colleagues were treated as if they were responsible for the accident. Hess developed eductors (also called jet pumps or Venturi pumps) to remove steam from the storage tanks. Ultimately, none of the systems that Hess designed and built at Three Mile Island was ever used. This would become a common theme in his career and that of many other long-time nuclear technologists’: work for years on a project, or a reactor technology, only to see it delayed, mothballed, and finally canceled. The nuclear power industry has been full of dead ends since the early 1980s.

Hess spent much of the 1990s working on the next generation of advanced light-water reactors (new versions of the uranium-based reactors that already dominated the industry) for the Department of Energy. Designed to be the third generation of nuclear reactors, the advanced designs included a breeder reactor cooled with liquid metal from GE. Liquid metal breeder reactors were the ultimate dream of the nuclearati; these machines would run on spent fuel from conventional light-water reactors while creating more fuel and burning up the long-lived isotopes that in nuclear waste remain radioactive for thousands of years. These advanced breeder reactors made previous plants look as outmoded as nineteenth-century coal furnaces. On paper, on computer screens, they were elegant, possessing the beauty of highly engineered machines. They were the products of the finest nuclear technologists in the world, and R&D on them totaled billions of dollars in the 1980s and 1990s. While a few have been built and have supplied power to the grid, they are inconsequential as a percentage of total nuclear power. The liquid metal breeder program was finally canceled by the Clinton administration, which killed all nuclear and fossil power programs at the DOE. By the mid-90s, government-supported research and development on new nuclear technology in the United States had effectively halted.

TH90 • TH90 • TH90

SLOWLY, IN THE LATE 1990S, the nuclear power industry began to show signs of life. In 1998 Entergy Corporation, the second-largest producer of nuclear power in the country behind Exelon, bought the Pilgrim nuclear station on the coast of Massachusetts. It was the first time in more than a decade that an American company had willingly expanded its nuclear assets, and it set off a wave of other deals that culminated in a bidding war for the Millstone plant, the only nuclear power station in Connecticut. Sold in 2000 to Dominion Resources, Millstone was purchased for about $800 per kilowatt of capacity, about half of the cost of a new nuclear plant. That sale convinced a lot of insiders, like Charlie Hess, that nuclear was back. By the turn of the century, the industry had found a new business model that didn’t require expensive new builds: extend the life of existing plants, “uprate” them to run at close to 100 percent capacity, refinance debt, take advantage of rising prices for electricity, and sit back and watch the cash roll in. When George W. Bush took office in January 2001, no one in this country and hardly anyone in other countries was seriously considering building a new nuclear power plant. When Bush left office eight years later, the NRC had more than a dozen applications for construction and operating licenses for more than 30 plants.

Hess took a job with the International Nuclear Safety Program, the progenitor of M2M. He helped Russian nuclear plants, which are not exactly known for their sophisticated safety mechanisms, improve their shielding and containment systems. It was work he liked, collaborating with men who had, earlier in their careers, studied ways to obliterate U.S. cities. When he came back to the States, he joined the Shaw Group, a big engineering and construction firm that includes a high-end nuclear consulting arm. Hess became the project manager of Shaw’s Next-Generation Nuclear Plant program, helping plot the technological road map for the twenty-first century. The program’s main focus is the pebble bed reactor, another design that has been on the books for decades. Pebble bed reactors offer safety and efficiency improvements over conventional light-water designs. But by now Charlie Hess had seen the future of nuclear power, and it was based on thorium.

“It is clearly the next step,” he told me in one of our phone conversations. “I think first we’ll see sodium-cooled fast reactors, and after that thorium is the obvious choice.”

With the election of Barack Obama, the window of possibility for alternative nuclear energy opened a bit wider. Obama favored nuclear power but for political reasons was adamantly opposed to storing nuclear waste at the Yucca Mountain facility in Nevada. Soon after his inauguration he formed the so-called Blue Ribbon Panel to study the problem of long-term waste storage. The new energy secretary, Steven Chu, had been vocal in his support for nuclear power, particularly advanced reactor designs. Charlie Hess was asked to head up a DOE subcommittee charged with making recommendations on technology roadmaps going forward. The nuclear renaissance seemed to finally be reaching critical mass (a popular metaphor among the nuclearati).

In early 2011 Hess’s team recommended two possible pathways: the pebble bed reactor and a thorium-fueled fast reactor that would convert thorium to plutonium fuel. It was, to Hess’s knowledge, the first time since the 1960s that an official government-sanctioned body had recommended pursuing thorium power.

Then came Fukushima, and the future of nuclear power was once again cast into doubt. Although the industry was approaching record profits, anyone with a creative approach or an alternative design had long since chosen to leave, or been driven out of, nuclear power. Why take a risk on a new fuel, even one with proved advantages over uranium—in safety, environmental concerns, and unsuitability for conversion to weapons—when the industry was finally in the black?

Nevertheless, the thorium revolution “is certainly going to happen,” said Hess. “It’s happening right now in India, and it’s going to happen in a lot of other countries.”

The United States has already ceded its leadership position in nuclear R&D. The future of innovation belongs to international consortia of mega-corporations and perhaps to agile, risk-taking entrepreneurial start-ups. “It’s a new world,” said Hess.

TH90 • TH90 • TH90

THE NEW WORLD WILL REQUIRE NEW APPROACHES, not only to reactor design but to the nuclear fuel cycle and the entire art and science of nuclear power. The “if it ain’t broke, don’t fix it” complacency represented by long-time executives like John Rowe of Exelon was definitively killed off by the Fukushima-Daiichi accident. To be sure, the nuclearati believe they have the technology to support the nuclear renaissance. At least a dozen so-called Gen III and Gen IV reactor designs are currently being studied, and in some cases they actually have been funded, but they all share a common flaw. They’re all based on uranium.

Here I’ll review the basic structure and operation of a nuclear power reactor. In its simplest form a reactor is nothing more than a machine for generating heat, which in turn is used, most often by way of a steam-powered turbine, to make electricity. In the core a nuclear reaction—sustained in U-235, in plutonium, in thorium-born U-233—generates energy in the form of heat. The core heats water, which generates steam. The steam turns a turbine, converting the kinetic energy of the superheated fluid to mechanical energy. The turbine spins a set of windings inside an electrical generator that converts the mechanical energy into electricity. In its outline this description could fit any form of turbine, whether turned by falling water, burning coal, or natural gas. Heat source, steam, turbine, generator. Electricity from simplicity.

The dangerous and fickle nature of radioactivity, though, adds several complexities to this simple system; three are the most significant. The first is that, unlike, say, a coal-fired power plant, you can’t just turn off the system by depriving it of fuel. Apart from the residual heat from coal already in the burner, a coal plant without fuel shuts off and begins to cool immediately. Once you start a nuclear reaction, you can’t just shut off the heat. You can quickly reduce the fission reactions by inserting control rods that slow down the reaction, but the production of residual heat from the decay of fission products keeps going until all the material in the core has decayed to stable isotopes—that is, for a very long time at a very high temperature. That’s why the Pandora’s box and genie-in-a-bottle metaphors have appealed to antinuclear activists since the dawn of the Atomic Age. The nuclear power bottle is hard to recork.

The second complexity is in the plumbing. Light-water reactors come in two main versions: pressurized water reactors (PWRs) and less-common boiling water reactors (BWRs). Both operate under high pressure: 2,200 to 2,500 pounds per square inch (psi) in PWRs and 1,000 to 1,100 psi for BWRs. Circulating water and steam from reactor to turbine under such high pressures requires a complicated network of pipes, valves, and other plumbing that can fail, corrode, or fall prey to operator error. What’s more, in PWRs the radioactive primary coolant does not actually generate the steam that drives the turbine. A secondary cooling system, with a second heat exchanger called a steam generator, produces the steam that turns the turbine. Naturally this extra layer reduces the efficiency of the system. More important for this discussion, it adds to the complexity of the machine, nearly doubling the sheer volume of plumbing and increasing the opportunities for failure and explosions.

Secondary cooling systems are not unique to solid fuel reactors; most liquid fuel designs require some form of secondary liquid. But early in the research into nuclear reactors it became apparent to scientists that a liquid-core reactor would greatly simplify the overall system. Among the leaders of the Manhattan Project, this concept appealed most forcefully to Eugene Wigner. Wigner’s ideas gave birth to the Molten Salt Reactor Experiment, described in detail in chapter 6.

To return to conventional reactors, the third complexity is the moderator. Uranium-fueled reactors require some type of moderator to slow down the scattering neutrons enough to sustain the fission reaction. Many, many materials have been used to moderate commercial reactors: ordinary water, heavy water, solid graphite, and so on. The choice of moderator determines many other characteristics of the reactor: type of fuel, type of fuel cladding, operating temperature, the metal used in the core vessel, and the like. No moderator is ideal; all have their advantages and disadvantages. Uranium is like a finicky child at a buffet: only the right combination of moderator, fuel, core design, and materials will produce a sustained fission reaction, and even then the ratio of inherent energy in the fuel to electricity produced is low.

In general, it must be said, the light-water reactor has worked as advertised. Despite a few notorious accidents (Three Mile Island, Fukushima-Daiichi) and one genuine disaster (Chernobyl), the overall safety record of nuclear power is quite good—which nuclear power executives, as tone-deaf to public mistrust as any group of business leaders outside the tobacco industry, never tire of pointing out. Once built, nuclear power plants produce power as inexpensively as any energy source (a statistic underlined by the low price of uranium during the industry’s Dark Age, from 1980 to the early 2000s). Uranium mining, the effects of which ravaged many Native American communities of the American Southwest in the middle decades of the twentieth century, is still opposed in many places on environmental grounds. But by the limited standards of the nuclearati, nuclear power is a success.

From a wider perspective nuclear power has failed dismally to fulfill its promise. In his famous “Atoms for Peace” speech to the United Nations in 1954, President Eisenhower touched on the promise of the Atomic Age: “Who can doubt that, if the entire body of the world’s scientists and engineers had adequate amounts of fissionable material with which to test and develop their ideas, this capability would rapidly be transformed into universal, efficient, and economic usage?”

Universal it is not. Nuclear power today produces only about one-fifth of the electricity in the United States; in a few countries, like France, that figure has reached four-fifths, but they are exceptions, and several countries, including Germany, which has Europe’s largest economy, have said in the wake of Fukushima that they will abandon nuclear power altogether. In Japan nuclear power provides 30 percent of the nation’s electricity; how that will change in the post-Fukushima era remains to be seen.

Nor is nuclear power economical. Nuclear plants are now so expensive to license, not to mention build, that there is little prospect of investors’ receiving reasonable returns. Many, many words have been written about the “true costs of nuclear power.” Much of this analysis is based on faulty reasoning or is outright bogus, but there is no question that the rosy pronouncements of industry groups like the Nuclear Energy Institute are specious, given the true social costs of producing power from uranium.

Nuclear power has also failed to demonstrate that it has the third of Eisenhower’s predicted attributes. No power source that leaves behind 95 percent of its fuel’s available energy, in a form that remains intensely toxic for tens of thousands of years, can be considered efficient. The problem of nuclear waste in the United States is insoluble under current political and market conditions. (In other countries this is not so: France has been recycling its spent fuel for decades). The position of the Obama administration—supporting the development of advanced nuclear power while effectively killing off the Yucca Mountain disposal facility—is self-canceling. Without some long-term, politically acceptable method of storing nuclear waste (or, better yet, vastly reducing the volume and radiotoxicity of the waste in the first place), none of the optimistic forecasts of the nuclear renaissance will come true.

The longer I reported on nuclear issues, the more I found myself holding two sharply conflicting opinions: on the one hand the conclusion that only nuclear power can rescue us from the cycle of dependency on dwindling fossil fuels and destructive climate change in which we’re trapped, and on the other a deep frustration with the nuclear power industry as it is constituted. The biggest barrier to the revival of thorium power has nothing to do with thorium itself. The biggest barrier is the intransigence and complacency of the industry itself and the inability of our political leaders to reform it.

TH90 • TH90 • TH90

URANIUM’S SHORTCOMINGS AS A SOURCE of energy have been evident since the days of Madame Curie, plain to everyone who has worked with it, but its advantages, both as a reactor fuel and a bomb-making material, have hidden the shortcomings in much the same way that uranium itself has overshadowed thorium. The shortcomings fall into four main categories.

The first flaw is uranium’s natural state: as Bohr realized on the eve of World War II, only the smallest fragment of uranium ore, the 0.7 percent U-235, is actually fissile. The rest is radioactive but relatively stable U-238. You can produce energy from unenriched uranium—Canadian companies have been doing it for decades—but it requires more sophisticated reactors than the United States has, and the electricity is more expensive. Enrichment is an expensive process that requires industrial scale and an advanced level of technology.

The second flaw is that, once uranium has been refined enough to use it in a nuclear reactor, it can be used to make nuclear weapons. No one has ever successfully constructed a bomb using smuggled or stolen uranium, but that is not for lack of trying. Entire ministries and government agencies have as their sole raison d’être the control of the traffic in enriched uranium; though the danger of losing, misplacing, or being robbed of the stuff is admittedly small, it adds greatly to the expense, risk, and the public opprobrium of running nuclear reactors.

Uranium’s third flaw is that, even though it’s such an efficient source of energy compared with coal and other carbon-based fuels, current nuclear plants use only 3 to 5 percent of the available energy in a given amount of low-enriched uranium. The rest is thrown out as spent fuel, presenting a disposal problem that the industry has never fully solved.

The final flaw is more complicated, and it has to do with the basic nature of uranium atoms and the inherent processes of nuclear fission. In brief, in nuclear engineering language, you can’t build a breeder reactor in the thermal spectrum using uranium; a uranium breeder must be a fast reactor.

To uncoil that sentence, recall the batter analogy from chapter 2. The slower the pitcher’s average velocity, the greater chance the hitter will connect with any given pitch; as average velocity rises, the chances of a hit go down, rapidly. In a conventional light-water reactor, a moderator—usually plain water, sometimes graphite—is used to reduce the energy of neutrons careening off from nuclear fissions. It’s as if between the pitcher’s mound and home plate there were an invisible barrier that slows the baseball without stopping it altogether.

The equivalent of batting average in a nuclear reactor is known as the cross section: the probability that any neutron will interact with another atom and cause it to fission. (There’s also a cross section for neutron capture, which is not what you want in a reactor. Capture and fission are inversely related; as more neutrons are captured, fewer atoms split, reducing the chances of prolonging the fission reaction.)

In thermal reactors, which account for the vast majority of nuclear plants worldwide, neutrons travel at speeds of about 2,200 meters per second. In fast reactors, they move much, much faster, reaching speeds of 9 million meters per second. That’s about 336,000 miles per minute, or about 3 percent of the speed of light. In other words it’s about 17 million times as much energy, the increase gained simply by removing or changing the moderating material. Water, which contains two hydrogen atoms per molecule, is an excellent moderator because hydrogen atoms are good at slowing down neutrons. Fast reactors, on the other hand, typically use heavier elements, like sodium, which is much less of a speed bump for neutrons. (Paradoxically, lighter atoms are more effective at slowing down atoms. To understand why, picture a pool table with a bowling ball on it. If the cue ball strikes the eight-ball, the cue ball will transfer most of its energy to the other ball, often stopping dead. If the cue ball strikes the bowling ball, on the other hand, it will carom off at almost the same speed at which it was traveling before the collision.)

Uranium-238, the most common form of natural uranium, will actually fission at sufficiently high energies (typically more than two million electron-volts). In physicists’ parlance, it is fissionable but not fissile; it will split apart only when struck by a neutron traveling very, very fast.

In a fast reactor, the fission cross section goes down, but the breeding ratio goes up (in technical terms the “neutron flux”—the density of neutrons zipping around—is higher). The breeding ratio is simply the ratio of the fuel produced to the fuel consumed. A liquid metal fast breeder, for example, is fueled with uranium and plutonium. Its breeding ratio is between 1.1 and 1.4 to 1, meaning it produces 10 to 40 percent more fuel than it burns. That’s possible because the number of neutrons released per fission is high: well above two. Because of the high number of neutrons released in the fast fission of plutonium-239, it’s possible to not only sustain the fission reaction (the burning of U-238) but also to create more PU-239 than you are consuming. The reactor makes up in volume what it loses in efficiency.

Put another way, a fast breeder is like a party for 500 college students with plenty of blaring music, strobe lights, and alcohol. Put that many young people in the same place with that much sexual energy, and you’re bound to produce a certain number of hook-ups. At the same time, the potential for mishaps is high.

One of the earliest fast breeders, the Sodium Reactor Experiment at Santa Susana Laboratory, in California, suffered a partial meltdown in July 1959, when a so-called power excursion caused the core to overheat. A third of the fuel melted, and a significant amount of radioactive gas was vented into the atmosphere. Seven years later the Fermi–1 breeder in Monroe, Michigan, partially melted down after a fragment of zirconium cladding, which lined the meltdown cone, got stuck in a pipe in the cooling system. Fast breeders are “twitchy beasts,” as Kirk Sorensen likes to say, for a few reasons: primarily because events inside the reactor are simply sped up, and dramatic changes can occur instantaneously, reducing the margin for error.

Second, the most common coolant in fast breeders, liquid sodium, explodes when it comes into contact with air or water. When Fermi–1 was restarted in May 1970, a sodium explosion damaged the core, delaying things another few months. The twitchy plant shut down two years later after its operating license expired and was not renewed. The exotic materials needed to safely run fast breeders require a level of diligence and sophistication that the nuclear power industry has not always exhibited. That hasn’t stopped the industry, and the government-funded national labs, from pursuing fast breeders at a cost of thousands of human work hours and billions of dollars. Thorium reactors lost out to light-water reactors as the industry’s original choice for its workhorse reactor; then thorium reactors lost out to fast breeders as the choice for the future of advanced reactors, despite the questions and objections that dogged fast breeders throughout the 1970s and 1980s.

“The need for the holy grail that drove this whole business, namely the fast breeder reactor, became subject to searching questions that could not be satisfactorily answered, . . . and not only on grounds of safety and proliferation.”5 Not only were fast breeders dangerous and difficult to operate, but they would take a long time to justify their high costs: as much as a century to reach “doubling time,” the amount of time required to produce enough excess fuel to start another reactor of the same size, even if you could keep fast breeders running without everything going kerflooey. Today’s designs for Gen IV fast breeders claim a doubling time of 20 years or less, but that’s on paper.

Expense and inherent safety have never been primary requirements for the next revolution in reactor technology; the industry’s pursuit of fast breeders has gone on for more than 60 years and continues today. In 2010 the Monju reactor in Japan, a fast breeder that was shut down for almost 15 years after a 1995 fire caused by a leak in the secondary coolant, was shut down again after a refueling accident. Japanese officials, who mounted a strenuous cover-up in the years immediately following the accident, said the reactor would not be restarted until at least 2014. But they were not giving up.

A 2010 report from the International Panel on Fissile Materials noted that more than $50 billion had been spent worldwide on fast breeder R&D, including more than $10 billion each by Japan, Russia, and the United States. “None of these efforts has produced a reactor that is anywhere near economically competitive with light-water reactors,” the report concluded. “After six decades and the expenditure of the equivalent of tens of billions of dollars, the promise of breeder reactors remains largely unfulfilled and efforts to commercialize them have been steadily cut back in most countries.”

So much for the holy grail.

TH90 • TH90 • TH90

SO, IF YOU WERE GOING TO DESIGN and build a new nuclear reactor from scratch, what would it look like?

First of all, you’d make it small. The old antinuke saw says, “Nuclear reactors come in only one size: extra large.” But compact modular reactors that can be prefabricated, transported by shipping container, and assembled on site are now seen by many experts as the future of nuclear energy.

“If you go small, and manufacture reactors like Henry Ford did cars, there’s a host of advantages,” Tom Sanders told me shortly before he took over as president of the American Nuclear Society in 2009. (He is now its president emeritus.) “You could use automated manufacturing processes instead of doing every weld individually, you could get the plants licensed in a two-year time frame instead of seven, and it’d be much cheaper on a per-kilowatt basis.”

Virtually all the major nuclear vendors, including GE-Hitachi Nuclear Energy, Bechtel (a company not exactly renowned for miniaturization), Babcock & Wilcox, and Westinghouse (now owned by the Korean tech giant Toshiba) are developing small modular reactors (SMRs). These reactors can use uranium or thorium (or even plutonium), but thorium, with its higher efficiency, offers unique qualities that make it well-suited for miniaturization. They produce less than 300 megawatts, the limit for an officially small reactor. Future versions that could fit on the back of a flatbed truck are envisioned at 60 or even 30 megawatts. Like mobile homes, SMRs can be manufactured centrally and assembled on site, facilitating financing and shortening the time to production; in theory, multiple SMRs could be combined to create a large generating station. Keeping the plants small and dispersed, though, makes them less tempting targets for would-be terrorists—as does fueling them with thorium.

More important, they could produce energy at a lower price per kilowatt than conventional nuclear plants, bringing the cost of nuclear power more into line with low-cost coal production. Newly infatuated with what’s known as distributed power generation (lots of smaller reactors scattered in lots of places), the nuclear industry has finally realized that bigger is not always better.

More compact and more affordable are good things; even better is the prospect that thorium-powered SMRs could help solve the problem of nuclear waste storage and disposal. Some ambitious nuclear designers have even started to dream up small, modular fast breeder reactors, which is a bit like trying to control a tiger by putting it in a smaller cage.

Bringing these designs into commercial production could take a decade or more. The three main barriers to widespread deployment, as Philip Moor puts it, are the same that face any new nuclear plant: “Dirt, licensing, and money,” he told me. Moor heads up a special committee of the American Nuclear Society formed to examine the business and manufacturing issues around SMRs.

The Savannah River Site, a nuclear industrial complex operated by the DOE near Augusta, Georgia, will supply the dirt (the real estate and infrastructure), and industry heavyweights like GE, Westinghouse, and Bechtel are lining up to provide the money, at least for demonstration projects. That leaves licensing.

“Once we start the demonstration projects, we can start pursuing the license application,” said Sanders of the American Nuclear Society. But “we need something operating on the ground.”

That’s hardly a slam dunk. It’s worth noting that building minireactors is not a new concept. GE actually started the Power Reactor Innovation Small Modular (PRISM) program back in 1981, and in 1994 the NRC issued a report that said the commissioners foresaw no impediments to licensing. The project was abandoned in 2001 and then got a second life in 2006. With huge new supplies of natural gas starting to reach the market, and coal plants still the least expensive form of power generation, new nuclear plants will continue to look expensive. And investors looking back at 30 years of nuclear dead ends are sure to be wary of new technological marvels, however promising. The history of nuclear power demonstrates that nothing is truly viable until the core starts chain-reacting.

Still, thorium-powered SMRs offer the best way forward for new nuclear power—and a potential solution for global warming. Smaller is beautiful, and in this case it could be more profitable as well.

TH90 • TH90 • TH90

SECOND, YOU’D MAKE YOUR NEW REACTOR a breeder, preferably a thermal breeder. The failure of fast breeders to fulfill their promise has not erased their appeal; it has just caused the quest for a fast breeder to go in (slightly) new directions. Breeders would be advantageous not only because, theoretically, you’d never run out of fuel, but also because you can use them to process nuclear waste from conventional reactors. At least in the United States, the question of how to store nuclear waste has no clear answer, and there may not be one for the next decade. Building self-sustaining breeder reactors would, as the nuclearati like to say, “close the fuel cycle”; little radioactive material would be left over to dispose of.

Then you’d want to make your reactor inherently safe. Inherent safety— not to be confused with passive safety, a very different thing—is a term much beloved by nuclear engineers.6 It has been applied to just about every reactor design, including the uranium-fueled light-water reactor and the sodium-cooled fast breeder, machines whose inherent safety is, to say the least, questionable. Traditionally, the solution to this problem has been external safeguards, also called overengineering: add more controls, more redundancy, more miles of piping, more plumbing and alarms and sensors and gauges, and the inherent twitchiness of the world’s most volatile energy source could be contained and controlled. Unfortunately, all that engineering brings more complexity, and complexity in itself adds risk. Virtually all the reactor accidents that have ever occurred have had one of two causes: either a fiendishly complex mechanism failed because of a simple mishap (like a loose chunk of zirconium) or a human being failed at the task of monitoring and managing a fiendishly complex mechanism.

The only truly inherently safe reactor is a liquid-core reactor, like the molten salt reactor that was created at Oak Ridge in the 1960s. For the purposes of a reactor designer, liquid—whether it’s water, liquid metal, or some type of liquid fluoride—has a marvelous characteristic: it expands rapidly when it gets hot. All materials expand when heated, of course. In a liquid-core reactor, as the energy of the liquid rises, it expands and naturally, passively, slows down the reaction, making a runaway accident nearly impossible. In technical terms, this is known as a “negative temperature coefficient of reactivity.” That means that as the temperature rises (which typically is what happens when something goes wrong in a nuclear reactor), the reactivity goes down. When the reactivity goes down, the reactor is essentially turning itself off.

Liquid fuels have several other characteristics that make them safer than conventional solid fuel reactors. This is where the benefits of thorium, which for a variety of reasons is uniquely well suited to liquid fuel reactors, extend beyond the nature of the element itself. No matter how you use it—in a light-water reactor, in a pebble bed reactor—thorium offers advantages over uranium. But in a liquid fuel reactor, that advantage is magnified. If you put high-octane gas in a 1975 Ford Pinto, you’ll see some marginal performance enhancement. To get the full benefit, though, you should put it in a Ferrari Testarossa. Using thorium in a liquid fuel reactor is similar: its unique qualities as an energy source are fully exploited.

For example, in liquids—particularly in molten salts—fission products tend to be stable, making it easier to isolate and remove them. One of these fission products, xenon-135, is a nuclear poison that tends to build up in conventional reactors, slowing down the reactions. It renders the fuel unusable after only a small percentage of the potential energy has been used, and it’s hideously difficult to handle as part of the nuclear waste stream. In fluid fuels, because xenon forms a noble gas (one that is impervious to chemical reactions), xenon is easy to remove. In a LFTR it can be boiled off as a gas and processed while the reactor continues operating, reducing downtime and increasing the amount of the potential energy that can be extracted from the thorium fuel. A ton of thorium can produce energy equivalent to that produced by 200 tons of uranium in a conventional light-water reactor.

Liquid fuels are also impervious to radiation damage, solving one of the thorniest problems in solid fuel reactors. Continuous bombardment by neutrons over periods of weeks or months wears down not only the solid uranium pellets in a light-water reactor but also the cladding (usually made of zirconium) that contains them. Because of radiation damage and the buildup of fission poisons like xenon, fuel rods age quickly; they have to be replaced every few years, even though only 3 to 5 percent of their energy has been consumed.

Liquid fuels have one other characteristic that makes them ideal for reactor cores: they flow. Gravity, not elaborate control systems or so-called passive safety systems, gives LFTRs their ultimate protection against a serious nuclear accident. In a criticality accident (i.e., if the fission reaction in the core starts to get out of control), a specially designed freeze plug in the reactor vessel melts and the liquid core simply drains out of the reactor into an underground shielded container, like a bathtub when the drain plug is pulled. The fission reactions quickly cease, and (thanks to the expansive quality noted earlier) the fluid cools rapidly. Decay heat is contained harmlessly. Meltdown is impossible, and there are no solid fuel rods too radioactive to remove. Inherently safe, LFTRs pose less threat than light-water reactors, coal-fired power plants, oil refineries, or just about any other form of large energy or chemical plant. Built small and modular, they will be less expensive to build and operate than just about any other energy source.

TH90 • TH90 • TH90

FINALLY YOU’D FUEL YOUR SMALL, breeding, inherently safe, liquid-core reactor with thorium. I mentioned in chapters 1 and 2 many of thorium’s sterling qualities as a nuclear fuel; they bear reviewing.

It is abundant. In fact, used properly, it’s effectively inexhaustible.

It requires no special refining or processing beyond purifying it from the monazite ore in which it is most commonly found. It can be mined safely, with none of the tailings and other results of uranium mining that, in the early years of the Atomic Age, poisoned whole communities in Russia and the United States.

It’s no good for making weapons. In fact, it’s not fissile at all. It requires a kind of nuclear alchemy to be transmuted into uranium-233, which is a more efficient and safe source of energy than U-235.

Finally reactors based on thorium—or, rather, U-233, into which thorium transforms in a nuclear reactor—consume far more of the latent energy trapped inside the fuel, vastly reducing or even eliminating the problem of nuclear waste.

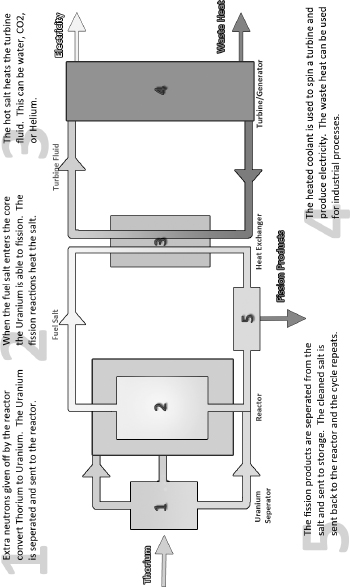

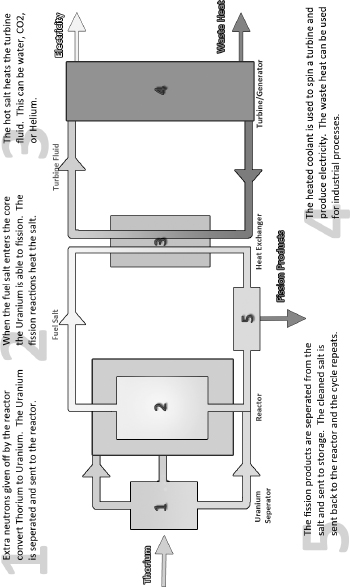

In short, you’d build a liquid fluoride thorium reactor, or LFTR. LFTRs are the first truly revolutionary reactor design to come along since the development in the 1960s of the molten salt reactor, progenitor of the LFTR. LFTRs are designed with an outer blanket of liquid fluoride that contains dissolved thorium-232—thorium tetrafluoride, to be precise (a fluoride is simply a combination of fluorine and another element; tetrafluoride means four atoms of fluorine). The thorium is borne in a solution of lithium and beryllium fluorides that has maximum heat-transfer properties, making it a supremely efficient coolant. This radioactive cocktail surrounds a core of uranium-233 that is produced from the natural decay of Th-232 bombarded by neutrons.

The neutron source, to start the reaction, is typically a small amount of fissile uranium, although the neutrons can also come from a particle accelerator, of the sort used in physics experiments to smash particles together. The blanket and inner core are in two concentric containers. It’s essentially a double boiler: the inner core, sheathed in an exotic alloy of a metal such as zirconium, contains the fissile U-233, and the outer shell, or blanket, contains the fertile thorium.

In this simplified diagram of a liquid fluoride thorium reactor, thorium is converted to uranium-233, which sustains the fission reaction, heating a secondary liquid that powers a turbine to create electricity. (Brad Nielsen)

Once the reactor core goes critical, the fission reactions in the core continuously throw off neutrons that keep the thorium, in the blanket, in a constant state of transformation, creating a virtuous cycle. Such a plant has two separate loops of piping: one carries the fertile thorium tetrafluoride salt, once it has been sufficiently bombarded to start the decay chain, into a decay tank from which U-233 can be transferred to the inner core; the other sends the hot U-233 salt from the core to a heat exchanger to drive a steam turbine.7 There are several variations on this basic design, which use various fluids to transfer heat from the reactor core to the turbine; suffice it to say that whichever is chosen, it will be significantly more efficient than a conventional nuclear plant.

After passing through the heat exchanger, the second loop, carrying hot U-233 fuel salt, cycles back into the core, with a small secondary side stream passing through a reprocessor, where the fission products are removed, preventing them from poisoning the reaction, before being cycled back into the core for further fission reactions.

Because the core is liquid, it operates at atmospheric pressure, meaning that the extremely thick-walled, pressurized vessels used in conventional reactors, which have an unfortunate tendency to blow their top, are unnecessary. Because LFTRs consume virtually all their nuclear fuel, the majority of the waste products are not long-lived fissile material but rather fission products, about 83 percent of which are safe within a decade. While LFTRs, like every other nuclear reactor, generate fission products that are highly radioactive, their half-lives tend to be measured in dozens of years, not thousands. The long-lived radioactivity of LFTR waste is one ten-thousandth that of a conventional reactor. The leftovers, a small fraction of the waste produced by conventional reactors, must be stored in radiation-proof geological sites for about three centuries, compared with ten thousand years for nuclear waste from conventional uranium reactors. In fact, LFTRs themselves make great garbage dumps for spent nuclear fuel: they can refine standard nuclear waste into LFTR by-products, essentially solving the currently intractable toxic waste storage problems that plague today’s nuclear power industry.

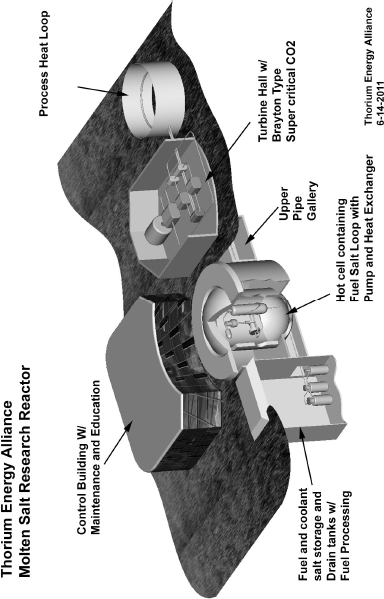

This schematic shows a full thorium power plant including a reactor vessel, drain tanks, and a Brayton-cycle turbine using supercritical carbon dioxide. (Thorium Energy Alliance)

With their high negative temperature coefficient, LFTRs are impervious to sudden overheating. They’re also exquisitely tunable; the concentration of fuel in the outer blanket can be adjusted continually, making it easy to control the reactivity in the core.

Finally, they can run practically forever. The reactions in a LFTR produce enough excess neutrons to breed their own fuel. LFTRs are the only type of reactor that can breed more fuel than they consume in the thermal, or lower-energy, spectrum. They have the virtues of fast breeders without the volatility.

Here it is useful to think back to the nature of fission and neutron absorption. In today’s conventional reactors, the great majority of the fuel is U-238, which transmutes to the transuranic element plutonium-239 when the U-238 absorbs a single neutron. Thorium-232, by contrast, requires five neutrons to become a transuranic (neptunium-237, which can be safely burned down, or processed, in the reactor). That too makes LFTRs inherently safer than solid-fuel uranium reactors.

While liquid-core reactors can be built to operate without moderators, in some LFTR designs the core does use moderators—typically graphite rods, just as in a conventional uranium reactor. Just as the LFTR has unique qualities that make it superior to light-water reactors, though, U-233 has some distinct advantages over uranium-235, the fissile material that runs the vast majority of the world’s nuclear power stations today. U-233 displays a quality that nuclear engineers love: high neutron economy, usually expressed as η in physics equations. That means that an atom of U-233, after absorbing a stray neutron and fissioning, produces on average 2.16 neutrons. Since one neutron is required to continue the chain reaction, 1.16 neutrons are freed up to produce new fuel.

Overall, LFTRs are 200 to 300 times more fuel efficient than standard reactors. They are safer, simpler, smaller, less expensive to build, and less expensive to run to produce electricity on a cost-per-kilowatt basis. No rational from-scratch approach to nuclear power would build anything else, yet we are burdened (some would argue stuck) with a supply of costly, overengineered, unsafe uranium reactors that produce tons of long-lived nuclear waste. All of which raises these questions: How did this happen? Why were thorium-based molten salt reactors abandoned when they showed such promise at the dawn of the Atomic Age?

The answers, as they say, are complicated. And the history of the nuclear power industry is entwined with the destinies of two brilliant and very different men: Alvin Weinberg and Hyman Rickover.