If you have a full-size table saw, you’re all set for making plywood cuts. And if you have a portable table saw, you can use it for smaller ripping jobs like making shelving and drawer parts. But you can also do a fine job with only a circular saw fitted with a cabinet-grade, smooth-cutting blade and a couple of simple screw-together jigs made from cheap melamine closet shelving stock.

Use an 8-ft. length of 16-in.-wide shelving to build the ripping jig. Draw a line 3 in. from the edge and cut along it with the circular saw. Screw this piece to the larger piece about 3 in. away from one edge, with the factory edge facing the widest section of shelving as shown. Then use that edge as a guide to cut off the melamine. Now it’s just a matter of lining up that edge with marks on plywood stock and clamping it to make perfect cuts up to 8 ft. long on any piece of plywood.

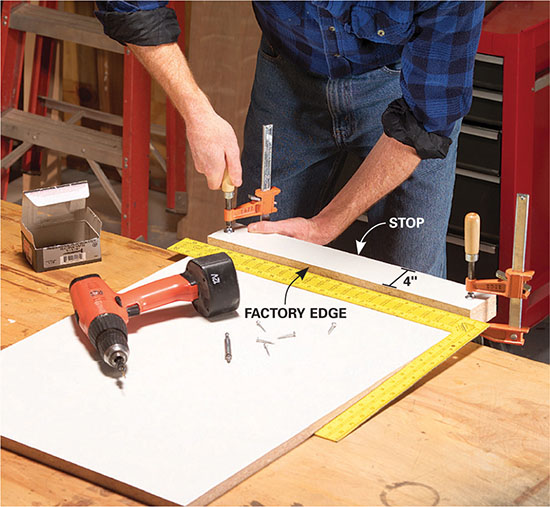

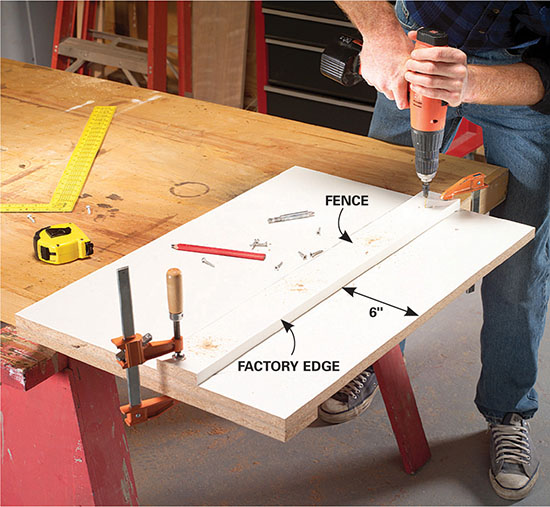

You can use the ripping jig for crosscutting, too, but this crosscutting jig has the advantage of a stop on the bottom. Push the stop against the plywood, align it with the cutting mark and clamp for quick, accurate crosscuts. Make it from a 4-ft. length of 24-in.-wide melamine shelving (or plywood if wide shelving isn’t available). Cut a 4-in.-wide strip for the stop from one end and another 4-in.-wide strip from one edge for the fence. Align the factory edge of the short piece with the factory edge at the other end of the shelving to make the stop. Then clamp and screw the two pieces together while checking alignment with a carpenter’s square. Flip the jig over and measure from the long factory edge 6 in. to position and screw the long saw guide as shown. The key with both jigs is to use the straight factory edges for guiding the saw.