German tunnellers by the top of a mine shaft at the junction of Fernsprecher Weg (‘telephone way’). One of the team, left, mans the cranking handle of the manual ventilator system, the large flexible pipe of which disappears into the mine. In the entrance of the working another soldier holds a miner’s lamp: much safer than a naked flame where flammable gases might be encountered. The wood is to shore up the excavation. (Author’s collection)

A static front with no obvious flanks presented a situation very much like that of the classic siege of old – and so it was that many of the techniques of the siege engineer were quickly brought back into use. Of these perhaps the most spectacular was the mine: a tunnel dug under the enemy lines, packed with explosives at its end chamber, and then detonated remotely, so blowing up a section of the enemy trenches. Such attacks had a history that went back to the medieval era, and were taught in the engineering branches of most modern armies. The Prussian manual of military mining dated back to 1866, and the German Army had practised mining in the field in the 1890s. In Britain an extensive tunnelling exercise had been conducted as recently as 1913 at Lulworth in Dorset. Before the end of 1914, mining had commenced on the Western Front – the first British mine being a relatively modest shallow 13 yards long tunnel dug near Festubert with the idea of supporting an attack by Indian troops. In the event enemy mortar fire intervened and this charge was never detonated, but the Germans launched their own underground war with a series of detonations in the same area on the evening of 20 December. Assault troops then succeeded in capturing sections of the line where they found some of the defenders still sitting, apparently unmarked and killed by concussion.

As a German VII Corps report explained:

Sap heads had been dug out from our line to within 3 metres of the enemy position. The enemy, who was very active in throwing hand grenades, had forced us to cover our sap heads. He himself made no saps in the region of the attack. From the ten sap heads in the zone of the attack, mines were laid under the enemy’s trenches, each charged with 50kg of explosives. To ensure the ignition of the mines, the attack was arranged for 9am so that the leads could be tested by the company commander and his second in command, and that any improvement which appeared necessary could be made by daylight. A mine was also laid under a house, held by the enemy on the right front of the attack (Quinque Rue), and was charged with 300kg of explosive. All telephone communications were manned to ensure the neighbouring sectors commencing the attack simultaneously in the event of there being any delay in the explosion. Actually the explosion did not take place till 10.25 in the morning owing to special difficulties in the connection with one of the leads. When it was reported to the senior pioneer officer on the front of the attack that all the mines were ready, he had three signal flares fired simultaneously. This signal was only meant for pioneers, who then fired all the mines, including the one under the house in Quinque Rue.

At the same time a number of Minenwerfer directed their fire on the cover trench. The explosion was the signal for the attack, which was carried out as follows by the 2nd and 3rd Battalions, 57 Infantry, 2nd and 3rd Companies of the 7th Pioneer Battalion (less two sections) and the 1st Battalion, 19th Pioneer Regiment (less one Company). A storming party of half a section of infantry with 12 pioneers was in readiness in each of the ten saps. They rushed into the enemy’s trench, searched it for mines, and cleared it with hand grenades and incendiary torches. A second storming party (in strength, a section of infantry between every two saps) rushed simultaneously across the open from their own position on both sides of the sap (sortie steps had been prepared for this), and reached the cover trench behind the enemy’s position. A third party – a company from each Battalion – occupied our own trench in case of counter-attack. A working party in reserve – the remaining sections of the six attacking companies with pioneer detachments and material for providing cover (shields, sandbags etc.) – followed the attacking party into the enemy’s cover trench for the purpose of reconstructing this into a new position facing West.

The Morte Homme memorial at the summit of Cote 295, near Verdun. It depicts a dead man holding a French flag, and the words ‘They shall not pass’. Taken and retaken during the battle of Verdun the hill was so heavily shelled that it was described as ‘erupting like a volcano’. Underground intensive tunnelling added another dimension to the struggle. (Author’s collection)

The ten mines were exploded simultaneously, and the attacking parties immediately rushed forwards with few losses. Amongst the booty seized by the attackers were six machine guns and 11 small trench mortars: there were 834 prisoners, and many more were claimed killed.

British efforts began with what were known as ‘Brigade Mining Sections’, usually small and rather ad hoc groupings brought under a Royal Engineers officer. Full-blown ‘Tunnelling Companies’ were formed in early 1915, the first units being designated as Tunnelling Companies numbers 170 to 178. Very rapidly mining was started at various sectors of the front including Hill 60, St Eloi, Ploegsteert, Houplines, Fauquissart, Givenchy and Cuinchy. Many of the early recruits were ‘clay kickers’, civilians who had worked on subterranean civil projects in the UK, brought together by Norton Griffiths, the Conservative Member of Parliament for Wednesbury – an early enthusiast of what he called military ‘moles’, who had the ear of Lord Kitchener. In the clay-kicking technique the man working at the head of the excavation rested on a wooden board or ‘cross’, and used a specially shaped spade, or ‘grafting tool’, with his feet. The spoil was removed by another man, and transported out of the tunnel in sacks, often in miniature trucks – known by German Pioneers as Minenhund, or ‘mine dogs’. Often these trucks ran on narrow gauge rail tracks. The tunnel sides could be shored with props and boards. The smallest of the mines were the camouflets (or Quetschmine), which were designed to intercept and blow in enemy tunnels before they could reach their targets. As mine warfare developed, more sophisticated methods were applied including mechanically driven boring machines, clay cutters and coal mining equipment. Nevertheless skilled manpower was generally found to be most reliable. Electric and handheld power tools were also tested experimentally, but the noise they were likely to cause, plus the problems of maintaining power at the end of a long tunnel, ensured that they never entered general service.

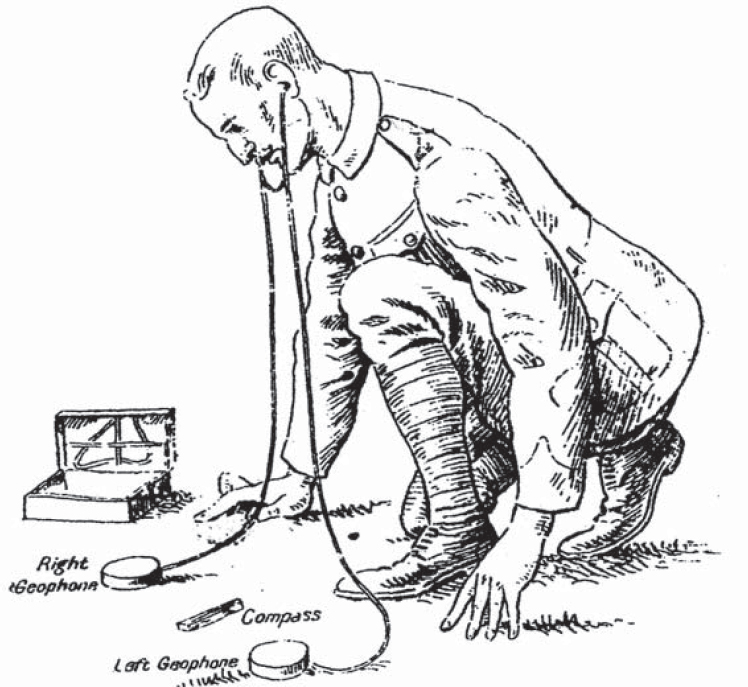

Listening for enemy activity, from surface listening posts or underground galleries, became a vital skill in the tunnelling war. This began with periods of silence and the naked ear, simple measures such as tubes, and tins of water whose surface vibrated when diggers were near. ‘Listening sticks’, as used to trace leaks in water mains, were also procured from the Metropolitan Water Board. Other devices soon came into play. The ‘geophone’, of which several models were used by both sides, worked on the principle of amplifying vibration, or magnifying sounds through sensors and earphones. In the most popular British version the pair of wooden sensors contained mercury trapped between mica discs and the listener used a stethoscope. Moving the sensors to bring sounds into balance helped to indicate direction. Canadian tunnelling officer Lieutenant B. C. Hall recalled that on occasions it was not only possible to count the footsteps of enemy miners up and down tunnels, but, by correlating sounds from different points, to work out exactly where individuals were. Mining Notes gave useful tables of the likely distances different types of sound travelled underground. Perhaps surprisingly a pick on chalk was detectable with a geophone through solid rock at 300 feet – whilst at the other end of the scale talking was usually only evident from a yard or two away through the muffling effect of sand or loam.

Apart from keeping quiet there were various attempts to stifle underground noise, including soft footwear, blankets hung to deaden noise, and even rugs or carpeting on tunnel floors. There was also a specially designed single wheel barrow shod with a solid rubber tyre. One special trick mentioned in British literature was the use of dummy picks and shovels, which could be operated at a distance using a cord. Some struck at a surface, others scraped like a shovel, thereby misleading the enemy or covering the noise of real activity. Nevertheless lengthy listening vigils sometimes yielded extraordinary results as, for example, when 181st Tunnelling Company actually holed an enemy gallery at the end of May 1916, and were able to hear the enemy at such close quarters that conversation was fully intelligible. For almost three days an intelligence officer, aided by an interpreter, was able to take notes on the German works, shift changes and other details 50 feet below ground level. The exercise concluded when the British tunnellers blew four 300lb charges and a raid was launched.

German soldiers of 3rd Battalion, 15th Infantry Regiment demonstrate the magnitude of a typical mine crater, 1915. Many were much larger than this. Lochnagar Crater on the Somme is 300 feet across; Caterpillar Crater at Hill 60 still contains a small lake. (Author’s collection)

The plans of some of the earliest mines appear haphazard, dendritic, almost like the branches of trees heading out from the trench system, but later more organized layouts became the norm. In the fully mature British tunnel system access to underground works was usually from a shaft in the trench system, preferably from the forward lip of a trench which was therefore less susceptible to enemy shelling. Wooden rungs allowed miners to pass down the shaft, but usually winch and pulley systems were rigged for the lifting of spoil and the descent of materials. Where it was made necessary by poor ground conditions all or part of the shaft might be ‘tubbed’ – or fitted with tubular steel segments that were sunk using screw jacks and bolted together. From the bottom of the shaft a tunnel led to a ‘lateral gallery’ running roughly parallel to, and in front of, the trench system. This lateral gallery serviced the active tunnels, which led at right angles under No Man’s Land out towards the enemy. Some of these ended in explosive chambers underneath the enemy trenches, and these were packed and ‘tamped’, or stopped up, prior to firing in order to focus the full effect of the explosion upward. Other tunnels parallel to the main mines might be used for listening, camouflets or as fighting tunnels to impede enemy work, and be further developed as need required.

In every tunnel lighting and ventilation were problems to be confronted. Lighting could be problematic since naked flame, put together with various forms of gas and explosive, presented a potentially lethal cocktail. Possible solutions included civilian type miners’ lamps and sealed electric lighting. Canaries or mice in cages gave early warning of dangerous concentrations of toxic gases and lack of oxygen. In many tunnels mechanical ventilation systems were used, the earliest of which appear to have been based on bellows acquired from civilian smithies in the war zone. More complex devices included the British Holman air pump, with a lever that delivered airflow on both its forward and back strokes and rotary fans. In some cases where ventilation failed or gas gathered, full breathing equipment with cylinders might be worn, such as the British ‘Proto’ or German ‘Draeger’ equipments.

In January 1917 German mine warfare was examined as part of the document Summary of Recent Information Regarding the German Army and its Methods:

A German mine usually commences with an incline, which terminates in a chamber from which a vertical, or almost vertical shaft is sunk. The depth of the system will vary with the nature of the ground and the scheme in hand. The enemy, like ourselves, locates the entrances to his mine system in the support trenches, or even further back.

A re-excavated trench at Hooge, which gives some idea how wet Flanders trenches could become if not properly drained or pumped. (Author’s collection)

Prior to blowing a mine the Germans would often attempt to induce enemy troops to gather in the danger area, perhaps by decoy patrols, or by bombardments on either flank of the mine area. Sometimes German mines were blown less for offensive than defensive purposes, as for example when a crater could be used as an observation point overlooking an area, or to form screened machine gun emplacements. Whilst early in the war craters had been rare and tended to attract a good deal of shelling, by 1917 they were common, and could often quietly be ‘improved’ without great danger from artillery. Often the technique was to ‘sap’ towards the crater and dig a trench behind the near lip, then gradually to take in the crater around the sides, using the far lip as the parapet of the forward position. These works could then be further linked to the main trench system. The British estimate was that the Germans had blown no fewer than 696 mines on their front in 1916 alone. The busiest month was June 1916, when an average of four mines per day were exploded.

There were certain places where mines and counter-mine craters finally overlapped to the extent that vast channelled features and areas of virtual moonscape were the result. At Vauquois on a relatively short sector of the Franco-German front near Verdun there were about a hundred mine detonations in less than a year. The 950-feet high Butte de Vauquois, once the site of a village, was transformed into a desert of craters and barbed wire. On a short section of the Cuinchy front trench maps recorded more than 50 mine craters, many of them interlinked. On the Hohenzollern south sector in the vicinity of ‘Big Willie’ trench there were a similar number of craters, the majority of which overlapped so much that they formed larger features, and eight were known collectively as ‘Clifford Craters’. At Hill 60 the work incorporated an old French shaft now designated ‘M3’ – in bad condition with many changes of direction and level, and full of corpses – as well as new British tunnels. In places the section of the galleries to be negotiated was as little as 2 feet by 3 feet, which caused extreme difficulty when explosives had to be manhandled through such tiny spaces. Nevertheless, as the Royal Engineers history remarked with no little satisfaction, the mine literally ‘blew out’ the inside of the hill. Two overlapping craters, here ‘M1’ and ‘M1(a)’, formed a new feature 180 feet in length, whilst M3 created a hole 30 feet wide. At Hooge Chateau vast craters eventually encroached upon the German concrete bunkers, and today remain as a lake in the grounds of what is now a hotel. Biggest of all was the enormous Lochnagar Crater at La Boiselle, blown using 60,000lb of gun cotton on 1 July 1916 – the huge hole was 300 feet across and 90 feet deep.

Also on the Somme, the blowing of the mine at Hawthorn Redoubt was witnessed by cinematographer Lieutenant Geoffrey Malins:

I looked at my exposure dial. I had used over a thousand feet. The horrible thought flashed through my mind, that the film might run out before the mine blew. Would it go up before I had time to reload? The thought brought beads of perspiration to my forehead. The agony was awful; indescribable. My hand began to shake. Another 250 feet. I had to keep on. Then it happened. The ground where I stood gave a mighty convulsion. It rocked and swayed. I gripped hold of my tripod to steady myself. Then, for all the world like a gigantic sponge, the earth rose in the air to the height of hundreds of feet. Higher and higher it rose, and with a horrible, grinding roar the earth fell back upon itself, leaving in its place a mountain of smoke. From the moment the mine went up my feelings changed. The crisis was over, and from that second I was cold, cool, and calculating. I looked upon all that followed from a purely pictorial point of view, and even felt annoyed if a shell burst outside the range of my camera…1

By the time of the Somme tunnelling units were fully developed. There were now no fewer than 25 British, three Australian, three Canadian and one New Zealand company, so that well over 2,000 men were deployed on underground works. Along one particular sector, from the La Bassée canal to Hulloch, there was such activity that it was now possible to walk underground for almost 4 miles along the front. On the other side of the line in 1916 German tunnellers were reorganized into Mineur Kompagnien – or ‘mining companies’ – not so different from the British model. Eventually there would be more than 50 of these.

From Royal Engineers History, showing the method of use of Geophone. (Author’s collection)

The Messines operations of June 1917 were arguably the most impressive mines of the war. The Hill 60 area had been mined several times already by the time 70,000lb of explosive was positioned under the Caterpillar in October 1916. The charge was placed a hundred feet underground, at the end of a gallery 1,380 feet in length. The 204th German Division holding the Hill 60 area lost ten officers and 677 men in the detonation of the Caterpillar and the adjoining Hill 60 gallery. The Caterpillar left a ‘diameter of complete obliteration’ 380 feet across, within which the actual crater was 260 feet wide. Large as the Caterpillar explosion was it was actually not the largest of the Messines mines, being somewhat dwarfed by the 91,000lb of ammonal at Spanbroekmolen, the 94,000lb of explosive at Maedelstede Farm, and two others of similar scale. The detonations of the Messines operations, which exceeded a million pounds of explosives altogether, were felt in London. As the florid description in the German Official History put it:

Nineteen gigantic roses with carmine petals, like enormous mushrooms, rose up slowly and majestically out of the ground and then split into pieces with a mighty roar, sending up multi-coloured columns of flame mixed with a mass of earth and splinters high into the sky.

On some sectors the effect on the enemy was dramatic. In front of 19th Division the Germans ran forward to surrender, or back to escape. Three lines of trenches were captured, initially with surprisingly light losses, and altogether 140 officers and 7,000 men were captured. Most of the British casualties occurred on the objectives, after they had been taken.

What trench garrisons were supposed to do whilst mining was in progress, and how to react to the explosion of a mine, was sometimes covered in ‘Trench Standing Orders’. The 1917 orders for the 63rd Royal Naval Division made it clear that mining operations were to be regarded as integral. No troops were to mention friendly mines, and brigades were to provide working parties to remove the bags of spoil, the contents of which were to be scattered on specified ‘dumping grounds’ – not left to block trenches and dugouts. When a British mine was exploded the garrison was to leave ‘a clear space of 5 yards’ on either side of the rear of the shaft, thus avoiding any back blast. Enemy mine craters were to be immediately occupied ‘by the nearest troops’, this order being made known to all ranks. According to the 1916 official manual Consolidation of Trenches and Localities the full drill was as follows:

When mines are exploded by us in connection with an attack on the enemy’s trenches, our object should be to seize and hold the whole of the mine crater or craters, or a line in front of them. The latter plan is usually best, and the craters to the rear can then be turned into strong points… When craters are formed as a result of an attack by the enemy on our trenches, or in the course of underground fighting, our object will usually be to seize and hold the near lip of the crater. Parties must be rushed out at once to seize the lip. It may be impossible to open up communication to these parties till after dark. They should, therefore, take sufficient grenades, water etc., and must be prepared to hold on though isolated.

Wherever possible attempts to forecast the likely upshot of detonations were to be made and stores laid in accordingly for the consolidation of the void. Dugouts were ideally placed in crater slopes – not at the bottom where they might be prone to flood or burial – and trenches strutted for support, and dug into the craters at two or more points. Copious supplies of wire were also demanded, not merely for conventional linear defences but to be thrown into disputed craters to deny them as jumping off points to the enemy.

Apart from the ever-present danger of being buried alive one of the tunnellers’ worst fears was underground confrontation with the enemy – and battles in dark confined spaces with pistols, grenades and daggers certainly obtained nightmarish qualities. During the major works entailed during the digging of the mines under Messines Ridge in late 1916 and 1917 one encounter was described by a Royal Engineer:

One day we broke into the top of an enemy gallery, and as the enemy were heard close by, an emergency charge of 15 pounds of gun cotton was tamped and fired near the hole. Actually, while the charge was being lit, the enemy were heard trying to enlarge the hole they had discovered in their gallery. After the charge had gone up and the mine was reported free from gas, an exploration party was organised and an advance was made into the enemy gallery. This gallery was lit by electric light and when the Germans heard our party advancing they turned on the light. But our officer had foreseen this danger. He had run forward and cut the leads of the lamps well forward of the party, with the result that the only part of the gallery occupied by the enemy was illuminated. Two Germans were seen advancing, one of whom was shot. Both sides then retired, and after two attempts to destroy the gallery with small charges we eventually placed a charge of 200 pounds in position and exploded it, with the result that the German gallery was entirely closed up.2

Interestingly, trench raids and infantry attacks could also have a mining dimension, as raiders might be tasked to attack works from the enemy end of the tunnel, perhaps with the intention of blowing them in. The Royal Engineers history contains reference to just such a scheme:

Following the explosion of mines under the German trenches on March 2nd, 1916, a raiding party of tunnellers accompanied the infantry attack. This party comprised an officer with two NCOs and eight men. The NCOs each carried a revolver, electric torch and hatchet, and the men with a 15lb box of guncotton, with 60 yards of instantaneous fuze.

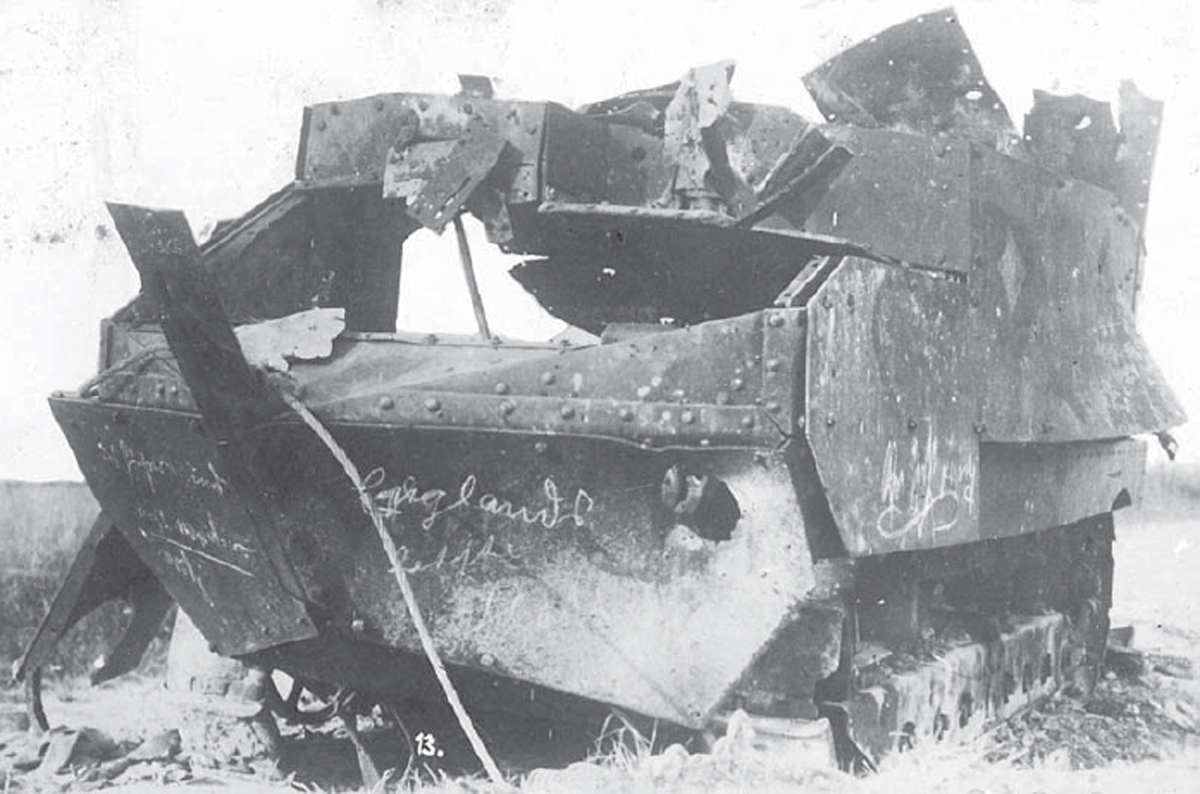

A French Schneider tank blown open like a tin can after shelling. French industry did well to field armoured vehicles in numbers from 1917 but the Schneider was vulnerable to both artillery and armour piercing bullets.

The raiders located the entrance to the German mine inside an old crater, together with some of the tools used, and proceeded inside posting sentries behind them as they entered what turned out to be a complex of works already related to three craters. As indicated by draft, one of the galleries was still attached to the enemy-occupied trench system, so this was attacked with a charge which partially blocked the tunnel. Meanwhile the Germans counter-attacked, and reoccupied one of the craters. The British miners therefore responded by starting to dig a new connecting tunnel, and then prepared three further mines, up to 300lb in size, to cave in enemy access routes.3