4

THE DEVILLS BIRDS

THE FRENCH KING Charles VIII was a fop. The grandson of the man whose guns had blasted the English off the Continent kept a royal perfumer to supply him with concoctions of orange blossom, civet, and oil of roses. His father, Louis XI, had died in 1483 when Charles was only 13. The young prince had left the administration of his realm in the hands of his older sister Anne, and had spent his time reading novels of chivalry. He developed a quixotic fascination with the glories of war. On grasping the reins of power in 1492, Charles realized that he had the means to turn his flamboyant dreams into reality.

During the previous half century, artillery had been undergoing a rapid transformation. Building on the foundation laid down by the brothers Bureau, French powdermakers and gun casters had reshaped the awkward bombard into an efficient prototype of the modern cannon. Lighter, more maneuverable guns firing an energetic new form of powder created a terrifying destructive potential.

Charles, stupid and vainglorious, dazzled by the possibilities of the big guns, devised a plan that was as foolish in its conception as it was tragic in its repercussions. Claiming rights to the kingdom of Naples through a convoluted inheritance, he set off to conquer Italy. His ambition did not stop there. He planned to embark from Naples, retake Constantinople, turn back the Turks, and establish himself as emperor of the eastern world.

Though the Italy that Charles invaded in 1494 was that of Leonardo da Vinci and the Medici, it was the French dunce who held the trump card. His thirty-six heavy cannon, fashioned from gleaming bronze and firing compact iron balls, battered the fortifications of the Florentine stronghold Fivizzano with such violence that the citizens of many other Italian cities surrendered at the mere approach of the French batteries. The cannon were “planted against the walls with such speed,” one observer reported, “the space between the shots was so brief, and the balls flew so speedily, and were driven with such force, that as much execution was inflicted in a few hours as used to be done in Italy over the same number of days.” This was no exaggeration. In February of 1495 the French attacked the Neapolitan citadel of San Giovanni, a fort that had earlier withstood a siege of seven years. The cannon opened a breach in four hours.

The 24-year-old Frenchman won Naples, but with his lines of communication drawn thin and a league of Italian states and their allies forming against him, he headed back to France. Ironically, his heavy guns so slowed his retreat that he narrowly avoided being defeated by the Italians in the battle of Fornovo. Charles died three years later from an accident. He left a heinous legacy—Italy suffered more than sixty years of war as the French vied with the Hapsburg emperors and their Spanish allies for control of the peninsula. The Italian city-states, forced to make alliances of convenience with the invaders, saw their autonomy fade.

CHARLES VIII, for all his temerity, had taken advantage of a new potential of gunpowder. Throughout the previous 150 years, military strategists had been seeking a role for the dangerous black powder, and by the end of the fifteenth century they had achieved fundamental breakthroughs in powder formulation and gun design. Their achievement would constitute one of the key engineering feats of the Renaissance, bringing gunpowder technology to a level of development that, with minor changes, would remain the state of the art for a remarkable 300 years.

This feat was accomplished with scant contribution from science, which had yet to find a solid footing or rigorous method of experiment. Rather, the work was carried on by craftsmen who were described as masters of artillery, gun founders, powdermen, or gunners. They were in fact the earliest engineers. Engineering had originated as a military craft—engineers handled the “engines” of war such as catapults and trebuchets—and designed fortifications to defend against them. When cannon arrived, engineers became versed in the manufacture and use of gunpowder and in the forging of artillery.

Early cannon presented these engineers with both unprecedented opportunities and stubborn, complex problems. The most pressing difficulty was the inordinate danger that went hand-in-hand with gunpowder manufacture. Though gunpowder does not, like some modern explosives, detonate easily from impact, it is wildly sensitive to spark or flame. A teaspoon of gunpowder can dissipate its gases when it goes off, resulting in a harmless cloud of smoke. But a few pounds of loose powder generates so much hot gas so quickly that it can blow a building apart. Accidents were frequent.

In large part, the danger came from the demands of making effective powder. If gunners had loosely mixed the explosive’s three ingredients they would have created a grayish powder that burned fitfully without exploding. The oxygen given off by heated saltpeter had to combine immediately with the sulfur–charcoal fuel in order for an explosive chain reaction to get going. For this to happen, the powder-maker had to force the ingredients into contact at the most minute, the most intimate level.

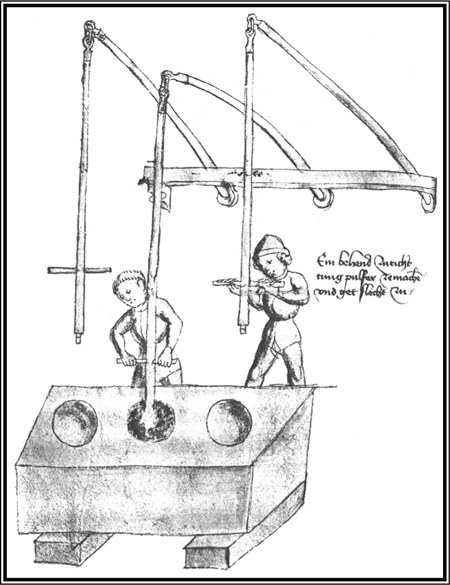

Grinding powder by hand in the fifteenth century using pestles attached to spring poles.

His means of doing this was to grind the ingredients in a mortar with a pestle, a laborious process known as “incorporation.” Twenty-four hours of pounding was needed in order to bring out the explosive potential. The result was a material as fine as flour. Gunners called it “meal,” or “serpentine” after a primitive artillery piece that used it.

During the incorporation, the powdermaker faced the greatest danger. Friction, a bit of iron that gave rise to a spark, or carelessness with a lamp meant instant cataclysm. When the fine powder was agitated it gave off a cloud of dust. This made the mill extraordinarily hazardous–the dust could drift to an open flame, ignite, and carry the fire back to the mass of powder. Dust could easily seep from cracks in barrels or waft from open containers, extending the danger to anyone who transported, stored or used the powder.

Another goblin that plagued early powdermakers was damp. Water molecules in the air cling to the surface of certain solids, build up, and gradually wet them. These substances are said to be hygroscopic. Ordinary table salt shows its hygroscopic nature when it clogs the shaker in humid weather. Charcoal is somewhat hygroscopic. It becomes more so when it’s finely ground because of the greater surface exposed to moisture. When the moisture content of powder rises above one percent, the mixture begins to lose its explosive power. Stored in cellars, transported in rainstorms, shipped across the sea, gunpowder routinely deteriorated into damp, useless clumps. Saltpeter contaminated with calcium nitrate significantly exacerbated the problem. Gunners could never be sure whether their powder would provide a robust explosion or a disappointing fizzle. They spent a good part of their time drying and “repairing” powder.

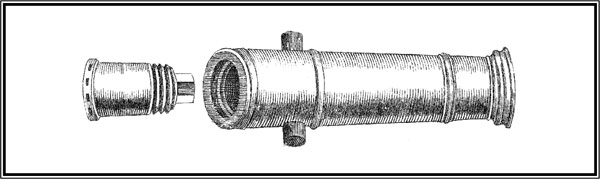

Serpentine powder made the process of shooting early cannon slow and chancy. When gunpowder particles were packed tightly together, the mixture took fire only from the surface. The Chinese had made use of this quality when they developed their fire lances and rockets. But a gun required rapid deflagration of the whole mass of powder. Gunners could not completely fill the powder chambers of their bombards but needed to include carefully controlled empty space to assure that the powder was loosely packed and burned in an effective manner.

They loaded the powder chamber—the thick-walled container at the rear of the cannon—only about half full. They hammered in a wooden bung that sealed the chamber, then positioned the projectile just forward of it.

When fire was introduced to the chamber through the touchhole, the powder on the surface of the charge inside flared up. This combustion created turbulence that lofted additional powder, which instantly took fire as well. If the gunner packed the powder either too tightly or too loosely, or if he did not distribute it properly inside the chamber, the result was an erratic burn and a feeble shot.

A bombard with its powder chamber unscrewed

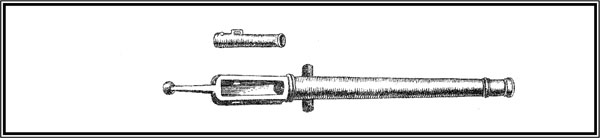

An early breech loading gun with separate powder chamber

Until late in the fifteenth century, loading a bombard took hours, and firing one could be an all-day event. At a siege of the Flemish city of Metz in 1437, a master gunner managed to fire three rounds from a large bombard in one day. The feat so astounded his employers that they made him undertake a penitential pilgrimage to Rome. Such rapid shooting, they assumed, could not have been achieved without help from Beelzebub.

One solution to the problems of damp and dustiness was to bring the gunpowder ingredients to the siege site separately and incorporate the powder on the spot. This eliminated the danger during transport, as the ingredients weren’t explosive until combined. The gunners could also dry any damp saltpeter or charcoal before mixing. Such industrial operations on the plains of war were not unusual—blacksmiths and carpenters found similar employment.

At some point, probably during the late fourteenth century, powdermakers began to try a new approach to the incorporation process, one that would, over the century that followed, ameliorate both danger and spoilage and, as an unexpected bonus, enormously increase the explosive power and practicality of gunpowder. To reduce the danger during incorporation, engineers added a small quantity of liquid to the three ingredients before pounding them in the mortar. Sometimes they used distilled wine spirits, a substance thought to drive out impurities. Human urine was also favored, preferably of wine drinkers, ideally of imbibing bishops. The dampening reduced the dust and with it the risk of explosion. Instead of a loose powder, they ended up with a moist paste. Drying this paste was well worth the extra effort.

By adding liquid while incorporating, artisans also hit on a way to fend off the dampness the powder absorbed later. This counterintuitive discovery was related to the amount of surface area. A fine powder presents an enormous surface to the air, speeding the uptake of moisture. Instead of merely spreading the damp powder to dry, makers shaped the paste, known as mill cake, into balls. These might be of any size, from pebbles to chunks as big as loaves of bread. Once thoroughly dry, these hard masses minimized exposure to air because of their smaller surface. The result was a product that kept much better.

This single step, dampening the powder during milling, helped alleviate two key problems, safety and spoilage. But it raised another worrisome difficulty. Gunners carried to the war the gunpowder balls, known in German as Knollen or dumplings. They also brought along mortars and pestles, which they used, when the time came to fire the guns, to crush the balls to a powder. Inevitably, some of the explosive remained caked together as crumbs. This powder went off in the gun with much greater force. The increased brisance, as it was called, made firing a large gun even more of a death-defying act. Gunners tried to adjust by lowering the proportion of saltpeter in this powder, thereby diminishing its force. Still, the explosion could easily split wrought iron barrels, if not blow them to pieces. The powder chamber might disintegrate or fly off—this was this type of accident that killed the Scottish King James II.

Yet gunners were intrigued by the qualities of what they were calling “corned” powder, corn referring to a small grain. Some estimated that the new powder was 30 percent more powerful, others thought it two or three times as potent as serpentine. A cannon needed 34 pounds of serpentine powder to shoot a 47-pound ball, but only 18 pounds of the corned variety.

Today we have a pretty clear idea of why the crushed Knollen produced stronger powder. Fire spread through the mixture by means of a spray of hot, molten saltpeter and gas that leaped from a burning particle to its neighbors. This mechanism required space. To achieve a true chain reaction, particles of powder had to be surrounded by small gaps. Just as pieces of kindling are better than sawdust for starting a fire, gunpowder burned better in granular rather than floury form. The point was not to provide air—gunpowder supplied its own oxygen. But in the absence of gaps, the flame did not saturate the mixture. With corned powder, rapid combustion was assured.

The new powder also proved much easier to load into guns. Even when compressed tightly, the granules never fit together as closely as the tiny particles of serpentine powder. In effect, the new powder carried its own space, so gunners didn’t have to leave part of the powder chamber empty. This simplified loading by letting the gunner pack the powder chamber, holding the charge in place with a wad of cloth rather than a wooden bung.

Gunpowder makers of the fifteenth century began to create these grains deliberately. They might have started by sifting the broken Knollen and selecting larger grains for their cannon. Eventually, they stopped forming the balls in the first place and forced moist powder through sieves, the size of the holes determining the dimensions of the grains. They varied the size depending on the type of gun in which they would use the powder. Large-grained powder seemed to work better in large cannon, finer grains in small arms.

Even as the corning process became standard, powder makers were learning to “purify” their saltpeter, a step that included converting calcium nitrate to potassium nitrate. The petermen took the liquor they leached from dung and mixed it with wood ashes, which contained abundant potassium carbonate. The calcium atoms joined the carbonate to form an insoluble material that dropped to the bottom; the nitrate radical was left to mate with the potassium. Artisans clarified this stew with the help of ox blood, alum, and slices of turnip. Relying on folk wisdom and crude experiment, they created the potassium nitrate needed for a durable and reliable powder.

All of these steps, discovered haphazardly over many decades, combined to yield a more powerful, more easily handled, and safer gunpowder. With only minor changes, corned powder would remain the standard ever after.

VANNOCCIO BIRINGUCCIO was 14 when Charles VIII’s state-ofthe-art guns brought war to the Italian peninsula in 1494. Born in Siena to a stone worker who served as superintendent of streets, the young man allied himself with the politically powerful Petrucci family and set out to become a contributor to the on-going improvement in gunpowder technology. The craft of fire was one of the most exciting professions open to a young man at the time, and one of the most modern. Encouraged by profligate military spending, such craftsmen had made enormous technical advances during the previous half century. Biringuccio would help push forward the allied fields of gunpowder, metallurgy, and artillery design.

Like the Renaissance artist who ground his own pigments and made his own brushes, Biringuccio was the embodiment of the integrated professional. He oversaw the entire process of gunpowder technology: assembled and refined the ingredients, ground the powder, supervised the mining and smelting of ores, designed and cast the guns. He arranged for the transportation of the bulky pieces to battle. During a siege he directed the positioning, loading, aiming, and firing of the big guns. If on the winning side in a conflict, he stage-managed the fireworks celebration that followed. Such a craftsman was in a perfect position to develop an intuition about gunpowder.

Yet engineers were operating largely in the dark when it came to theory. They had only a vague notion as to why the combination of ingredients in gunpowder produced an explosion. “Gunpowder is a corporeal and earthy thing composed of four elemental powers,” Biringuccio speculated. “When the fire is introduced into the part of its greatest dryness by means of sulfur, it makes a great multiplication of air and fire.”

Gunners had to be the masters of many trades. Mercklin Gast, a gunsmith from Frankfurt at the end of the fourteenth century, boasted that he was able to “restore spoilt gunpowder to its original state . . . separate and refine saltpeter . . . make powder that will last 60 years . . . shoot with large and small guns . . . cast from iron small-arms and other guns.” Biringuccio developed similar talents including wire drawing, distillation, and the minting of coins. Their skills made them supremely practical men. Biringuccio had no patience with superstition. He scoffed at divining rods and the hocus-pocus of alchemists. “I have no knowledge,” he wrote, “other than that gained through my own eyes.” It was a startlingly modern perspective in the early years of the sixteenth century.

Like other craftsmen, most fire workers closely guarded the secrets of gunpowder formulation and cannon casting. They formed guilds, such as the Fraternità di Santa Barbara, which administered tests to hopeful apprentices, collected dues, allotted pensions. They passed knowledge of the trade only to trusted apprentices. In this, Biringuccio was an exception. He set down what he knew about gunpowder and metalwork in a book called Pyrotechnia. Written in the vernacular and published posthumously in 1540, less than a century after the invention of printing itself, the volume was the first printed book dealing with the gunner’s various arts. It was a ground-breaking work, vastly expanding the practical knowledge available in this critical field. Nine editions were published over 138 years. By breaking the shroud of secrecy regarding the fire arts, it paved the way for treatises in many other practical fields. Pyrotechnia forms one of the deepest roots of the information age in which we now live.

ANOTHER ACHIEVEMENT of late fifteenth-and early sixteenth-century engineers that neatly complemented the new way of making powder was the improved design of guns. In all the millennia before the industrial revolution, metal presented artisans with staggering problems. Ores were elusive, mining techniques primitive. Extreme temperatures and complex chemical interactions were needed to obtain results. Something as subtle as the rate of cooling of a casting or the addition of a particular mineral salt to the smelting furnace could have significant impact on the final product.

Those who had grappled with the problem in the Middle Ages were the casters of the giant church bells that graced Gothic cathedrals. Bronze bells were the largest metal objects cast at the time—some weighed several tons. The resemblance between the gun and bell, both metal cylinders with hollow cores, did not escape the notice of gun makers. Forged wrought iron had offered a cheaper alternative to bronze casting. But the explosive force of corned powder called for a more durable container than the pieced-together bombard.

Since both contained large quantities of very valuable metal, bells and guns exchanged form with each other frequently over the centuries. During war, a city’s conqueror invariably claimed its bells, melted them, and reshaped them into guns—a custom that continued into World War II when the Nazis looted thousands of bells from European churches. A peace treaty might see obsolete cannon re-formed into bells. In 1508 Michelangelo melted a great bell captured in Bologna to cast a statue of Pope Julius II. The Duke of Ferrara, known as Il Bombardiere, got hold of the sculpture three years later and destroyed it to cast a massive cannon that he named “Giulia.”

Casting was always a demanding process. It required founders to achieve and maintain extremely high temperatures, to handle enormously heavy materials, and to bring about a precise mix of ingredients. Biringuccio, who discussed the casting of both bells and guns, commented on the difficulty of the art, which “appears to be more dependent on fortune than on ability.” But as foundry expertise improved, and whenever cost allowed, rulers increasingly demanded stronger cast guns.

Gunners could not load these new guns from the breech. The powder chamber was formed as an integral part of the piece and had to be reached from the front. Corned power, though, made the process of muzzle loading straightforward. The gunner simply thrust a ladle attached to a pole down the barrel and upended it to insert a measured amount of explosive. He rammed a wad and ball in after it. Breech-loading guns faded and would not return until late in the nineteenth century.

In Burgundian-controlled Holland around 1450, gun makers began to cast lugs jutting from either side of the cannon barrel—together they formed a short axle. These “trunnions” significantly improved both mobility and aiming. Their secret was balance. Set just in front of the gun’s center of gravity, the trunnions provided a pivot around which the gunner could raise or lower the barrel for aiming. They also added a support that allowed gunners to attach the barrel to a two-wheeled carriage—a modified cart of heavy timbers—without hindering vertical movement. The tail attached to the carriage allowed the gun to be swiveled easily from side to side. When the crew lifted the tail and attached it to a two-wheeled limber they created an articulated four-wheel wagon for transporting the piece. They no longer needed to dismount a cannon with hoists and set it on a specially prepared wooden shooting platform.

The successful manufacture of strong cast guns in turn led to denser ammunition. The carved stone balls that had been fired from bombards required the expensive labor of masons. When hurled against a wall, the ball shattered, dissipating some of its destructive energy. In searching for a better way to make use of stronger guns and powder, engineers found that cast iron shot, because it was three times as dense as stone, allowed a smaller gun to project as much force as a behemoth. Iron balls concentrated the force of corned gunpowder for greater effect. Because they could be produced using molds, iron balls obviated the masons’ work. They could also be reused. And being more perfectly spherical, they fit into the cannon barrel with a smaller gap, making more efficient use of the force of the powder.

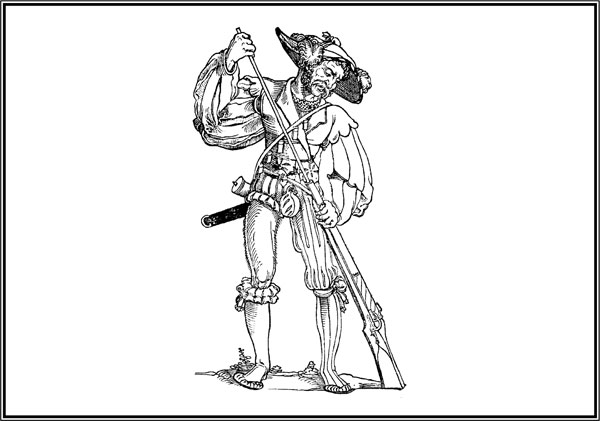

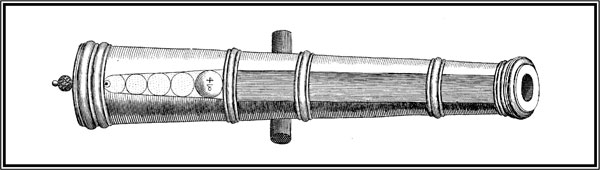

Renaissance soldier loading an arquebus

Engineers had assembled all the elements of a radical new technology: more explosive corned powder, smaller but stronger cast guns, dense iron ammunition. To make the guns safer while cutting down on their weight, they were cast with a thick breech end and a tapered barrel. Eight inches of solid metal at the breech would contain the sharp explosion of powder, while farther along the barrel, where the pressure was less, two or three inches might be enough. The barrels grew longer relative to the size of the bore in order to give the powder time to burn while the ball was still in the gun. The result was the classic tapered cannon that would set the standard for the rest of the gunpowder era.

The new guns, sleeker, longer, and lighter than the old bombards, threw their dense balls at a much higher speed. Gunners achieved velocity by gradually fueling their pieces with more powder. In early guns they limited the charge to 15 percent of the weight of the projectile. By the sixteenth century they were daring to load powder amounting to 50 percent, even 100 percent of projectile weight. The simple, easy-loading new cannon also made for a much more rapid rate of fire. At Brescia in 1564 an Italian gunner unloosed 108 balls from his heavy gun in five hours, a pace that would have astounded artillerymen of a generation earlier.

A classic cannon showing a powder chamber four times as long as the diameter of the bore

By the early 1500s engineers had devised a form of artillery that would be seen as the epitome of gunpowder weaponry for centuries to come. The cast smoothbore, muzzle-loading cannon was one of the most durable technologies ever invented. When armies fought each other in the American Civil War three hundred years later, they would field guns remarkably similar to those manufactured by Biringuccio and his fellows.

DURING THIS experimental period, the types of artillery pieces proliferated. Guns were named for birds of prey: Falcon and Saker and Sparrow-hawk.

The Basilisk took its name from the legendary serpent with lethal breath and gaze. Nightingale, one was called, Pelican.

Serpentine. Culverin, a snake, was applied to a whole class of guns.

Gog and Magog, they were called. The Doctor. The Pious One. Dragon, Lion, Fierce Buck, No-More-Words.

Brutal Butcher. “He will dance across moats, through ring walls, inner walls and bastions,” its inscription said. “What he does not destroy directly will fall indirectly through his ‘kiss.’”

In 1463 Louis XI christened two bombards Jason and Medea. Civic pride prompted names like Paris, La Dauphine, Londres, La Plus du Monde. Strasbourg commissioned The Ostrich because its gunstones resembled enormous eggs. One big gun was called Lazy Servant Girl.

A cannon fashioned in 1404 for Sigismond of Austria warned: “I am named Katrin, beware of what I hold, I punish injustice.”

Pope Pius II named two of his guns after himself, another for his mother. Emperor Charles V and the English king Henry VIII both ordered batteries to be known as The Twelve Apostles. In 1513 the cannon Saint John fell from grace when it became hopelessly stuck in the mud and was captured.

A poet complained:

The devills birds I thinke were fitter names

- To call them by, that spit such cruell flames.

WHILE CORNED powder was radically changing the nature of cannon, it was also elevating the handheld gun from a marginal to a central role as a way of throwing missiles. The earliest handgun had resembled a small cannon, with a stick inserted into a socket at the rear end to provide the shooter a better grip. This tiller also helped a soldier to aim the short tube—its appearance was not so different from that of a Chinese fire lance. The shooter ignited it the same way the cannoneer fired his piece, by applying a hot iron or slowly burning cord to the touchhole. An illustration from around 1400 shows a soldier with his hand cannon propped on a tripod.

Awkward to handle, these guns shared the problems of bombards when loaded with serpentine powder: If packed too tightly, the powder didn’t have room to burn. The small chamber at the end of the tube made it difficult to insert just the right charge. Small arms also took time to reload, exposing the shooter to retaliation during a battle. As a result, though they appeared during the 1300s, they saw little development before corned gunpowder became common.

As the use of granulated powder spread, gun makers made the barrel longer and narrower. Like cannon designers, they used the new powder to fire a smaller projectile at a higher speed. But while the big guns stood on their own, handheld firearms had to be designed to fit a man’s anatomy. Gunsmiths shaped the wooden stick so that the shooter could brace the piece against the shock of the recoil. At first the infantryman held the butt end against his chest. Later, gunmakers adapted the carved wood, known as a stock, to shoulder fire.

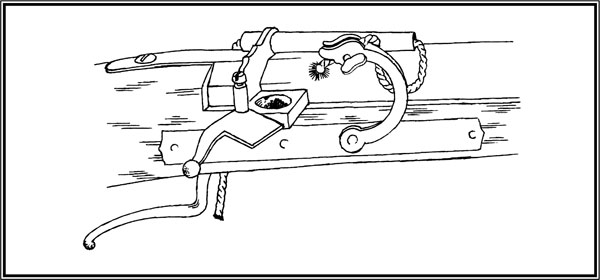

Applying fire to the touchhole while holding the gun steady was a challenge. The most dramatic improvement to the handgun came in the form of a lever attached to a metal hook. The hook held a smoldering piece of cord known as a match. When the shooter pressed the lever with his fingers, he lowered the match into a pan of priming powder beside the touchhole at the side of the gun, setting off the charge inside.

In the 1440s, a spring and sear (a catch for the lever) were invented. When the shooter pushed a button, the spring snapped the match into the pan. Soon after, a trigger replaced the button and has remained standard ever since. Because this mechanism resembled a household lock, it borrowed the name. The gun known as the matchlock took its place as the premier military firearm, beginning a reign that would not end until the flintlock arrived two centuries later. The handheld gun was now complete: lock, stock, and barrel.

This early matchlock, which became increasingly common during the late 1400s, went by the name “arquebus,” a word that derived from the German Hackenbusche or hook gun. That name had been used for early defensive guns that included a hook to fit over the edge of a wall for steadying the gun and dampening the recoil. Powdermen made a special form of gunpowder for the weapon—finely grained, quick burning, fashioned to more exacting specifications, and more expensive than common cannon powder.

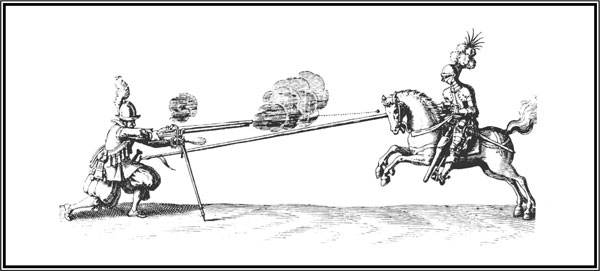

During the 1530s the arquebus was joined by a larger weapon, the musket. “Musket” was the term that later described all military infantry firearms, but this early version was a larger variation on the arquebus. It was intended to fire a ball that could penetrate the heaviest armor. Musketeers had to be particularly muscular to handle the powerful 25-pound gun, which they supported on a forked rest when firing. The heavy bullet, almost an inch across, blasted from the 54-inch barrel, could bring down a horse at 200 paces.

A sixteenth-century matchlock firearm. Pressing the lever upward brings the glowing match down onto the pan of priming powder.

In spite of their simplicity, handguns required an elaborate loading routine. The shooter measured powder from a flask, poured it down the barrel, rammed wad and ball after it. He had to fill the primer pan with a finer powder from another flask. Then he blew on his length of slow match to make it glow and inserted it into the cocked lever. According to military historian Sir Charles Oman, “It was said that muskets would be more practical if Nature had endowed mankind with three hands instead of two.” The chance of the gun going off when finally loaded was about fifty-fifty.

Matchlock weapons were far from perfect. Handling powder in close proximity to a burning match was a hazardous undertaking—a spark could spell disaster. Rain was another concern. A shower made firing impossible—the shooter could then only use the gun as a crude club. Yet after a century of experimentation, the handheld gun was evolving into a reliable means of killing from a distance. Like the cannon, it arrived at a form that would not alter in any basic sense until the middle of the nineteenth century.

A musketeer firing at a knight

Through the work of the military engineers of the early modern period, gunpowder had finally come of age. These inveterate artisans had devised all the tools needed to turn the explosive powder into a truly lethal means of inflicting violence. Charles VIII took advantage of their labor to touch off a period of gunpowder violence that would disturb the peace of Europe for the next century and a half. During that time, gunpowder would increasingly dominate the plans of military strategists even as it assumed a troubled role in society as a whole.