13

THE OLD ARTICLE

“I WAS LOOKING up at the window over the door when, before I heard the noise, I recollect distinctly seeing the whole glass fly out of the window, each pane apparently whole, then break and fall.” Lammot du Pont was 3 years old as this scene unfolded before him. Growing up in the midst of the world’s biggest gunpowder factory, he would witness other strange and violent events during his lifetime.

Lammot pursued an interest in chemistry at the University of Pennsylvania. Unaffected by the melancholy that afflicted his grandfather, the tall, lanky youth enjoyed slim cigars and clowning. When he graduated in 1849, he was tempted to try his luck in the California gold fields. Instead, he joined the firm and soon took over supervision of the refinery, preparing saltpeter for the mill. The “family chemist” established a laboratory and spent his spare time investigating the qualities and possibilities of gunpowder.

Potassium nitrate had long been recognized as the ideal ingredient to provide the oxygen that turned the combustion of carbon and sulfur into an explosive deflagration. Its drawback was cost. Whether it was obtained from the soils of India or leached from rotting manure, its gathering and processing were expensive.

Sodium nitrate worked just as well as the basis of gunpowder, and unlike its potassium cousin, it was dirt cheap. Enormous quantities were available in the coastal regions of Chile. Its serious disadvantage was that it readily absorbed moisture, rendering the powder damp.

Lammot investigated ways to use this form of nitrate for making serviceable powder. Trial and error, informed by his insight into chemistry, led him in 1857 to patent an “improvement in gunpowder.” It was the only fundamental alteration to the traditional formula that proved practical over gunpowder’s long history.

Having ground sodium nitrate, sulfur, and charcoal together in the usual way, he tumbled the resulting grains with graphite for a full twelve hours. The graphite formed a coating that dramatically reduced the tendency to pick up moisture.

One characteristic of the new gunpowder, known as “B” blasting powder, was remarkable: It was of no use in guns. For the first time in the history of this ancient explosive, a variety had been formulated that was intended only for commercial purposes. These uses—blasting tunnels, working mines, leveling grades—had outpaced military applications.

His uncle Henry wisely promoted Lammot to partner in the firm and sent him to Europe in 1858 to make a thorough investigation of the state of gunpowder manufacturing across the Atlantic.

“From what I have seen of the mills here they are far behind us,” Lammot reported. In spite of this confidence, Lammot paid careful attention to everything he saw as he made his grand gunpowder tour. At the venerable Waltham Abbey works in England, he investigated the modern steam engine that powered the rolling mills. The impeccable mill in Spandau, west of Berlin, boasted carpeting on all the floors—the works had not experienced an accident in more than twenty years. Visiting the French factories where his grandfather had studied with Lavoisier, Lammot saw stamp mills still in operation. The French, he was told, were working on a way to form nitric acid and combine it with potash in order to make saltpeter synthetically.

Lammot Du Pont (1831–1884)

Back home, Lammot’s blasting powder was proving a great success. One of the fastest-growing markets for powder was the anthracite coal mines of eastern Pennsylvania. The Du Ponts sold their product there through agents in mining towns like Mauch Chunk, Scranton, and Pittston. They shipped the powder first by wagon and canal, later by rail. But shipping costs, delays, and damage to the powder en route put the company at a disadvantage in relation to local mills.

In 1859, Henry du Pont, with Lammot’s support, purchased a small, bankrupt gunpowder mill on the Wapwallopen Creek, twenty miles south of Wilkes-Barre. The move was commonplace on its surface. For the Du Ponts it was unprecedented. During more than half a century, they had produced powder only on the Brandywine. Close personal supervision by family members gave their products the highest reputation for quality. This small expansion marked a turning point in the industry as a whole. The Du Pont appetite for acquiring competing companies would prove insatiable. Over the next half century, the firm would aim at nothing less than a total monopoly over the making of gunpowder in America.

The Civil War left in its wake a glut of gunpowder and a surplus of gunpowder manufacturers. Entrepreneurs had set up and expanded mills to feed the appetite of the guns and the demands of civilian users. With peace, the government craving for gunpowder disappeared overnight. The market became crowded and hotly competitive. The small mills, many still barely past the craft stage of production, fought for local markets in mining areas. In the western United States, a group of miners had invested $100,000 to start the California Powder Works when their powder supplies were cut off during the war. This and other firms battled the eastern companies trying to reestablish a foothold in the West.

With the chaos in the industry, it was difficult for anyone to make money grinding powder in the postwar era. The solution larger firms hit on was market regulation: fixing prices and controlling competition. Monopoly was in the air in the late 1800s—Rockefeller sought to corner the market in oil, Carnegie in steel, Swift in beef. Even in this climate, the consolidation of the gunpowder industry was remarkable for its ruthlessness.

Already in his fifties as the war ended, Henry du Pont was the conservative, even cantankerous autocrat of the growing Du Pont empire. Notoriously parsimonious, he gathered willow branches as he walked the grounds and instructed that they be added to the supply of charcoal. He resisted electricity and the typewriter, writing his letters with a quill pen by candlelight. Always a shrewd businessman, he had guided the partnership to solid profitability.

A worker at the Du Pont plant beside kegs of gunpowder

Charles Belin, a Du Pont in-law who ran their outpost on the Wap-wallopen, noted in an 1870 letter that “financial matters are like military operations, the bigger force runs the day, the small fry will have to clear the track or go to the devil.” Lammot took the same attitude. He headed a memo on the subject “Propose war.” The first target of this war was the Schuylkill coal district around Pottstown, Pennsylvania. Miners blasted seven million tons of anthracite there every year. It was a buyer’s market for gunpowder as both large and small powdermen vied for business.

As a bridgehead, Lammot secretly purchased the mill of Henry Weldy, leaving Weldy as front man. He then met with Albert Rand, president of Laflin & Rand, the New York–based gunpowder maker that was second only to the Du Pont firm. The two companies forged an agreement to divide the business in the Schuylkill fields. Their treatment of the “small fry” was to be strictly cutthroat.

First, the small mill owners were given a chance to sell out or join the Big Two in a cartel. Few agreed. Next, Du Pont dropped prices, hoping to force the “enemy mills” out of business. The campaign was intended, as Weldy put it, to “sicken the small men.” It took longer than Lammot had hoped. Coal companies, the ultimate victims of the war, saw the direction events were taking and continued to buy from local producers, even at higher prices, to stave off the monopoly.

Solomon Turck, who became president of Laflin & Rand in 1873, questioned some of the rapacious tactics being proposed by his partner in the venture. “I feel that this world is big enough for all,” he said, “and I know that we can take nothing out when we leave.” The Du Ponts were adamant. Rights to water power were purchased in order to deprive competing mills. Workers were hired away from the enemy. Weldy intercepted the mail of his skilled employees to look for job offers. Machinery makers were threatened, mine bosses bribed. In the end the bigger force did run the day. By 1878 almost all the small mill owners had either sold out or gone bankrupt.

Henry had meanwhile expanded the war to the national level. In April 1872, joined by representatives from Laflin & Rand and a handful of other major gunpowder producers, he oversaw the formation of the Gunpowder Trade Association, which became known simply as the Powder Trust. The owners of the Warren Powder Company in Maine soon learned what it meant to defy the Trust. When they refused to keep their prices in line, Lammot sent a two-man delegation to demand compliance. They refused to be cowed. The cartel emissaries offered to buy them out. No go. The Association began to undersell Warren in its market area. The powdermen at Warren fought back, struggling on for seven years before finally descending into bankruptcy.

It didn’t take too many incidents like this to put a healthy fear of Trust power into the minds of those whose money was invested in gunpowder mills. They generally preferred acquiescence to financial ruin. When the Trust was formed, the members already controlled 78 percent of the gunpowder market in the nation, with Du Pont responsible for 37 percent itself. These figures climbed as the consolidation proceeded. The day of the small gunpowder mill was over.

Even as the Trust was concentrating the industry, Du Pont was itself expanding. In 1876 the Delaware firm purchased the Hazard Powder Company, the third largest powdermaker in America—the change of ownership was kept secret. By the end of the 1870s, with Laflin & Rand the only serious competitor left standing, Lammot admitted that the Powder Trust was “only another name for Du Pont and Co.”

By 1889, the Trust controlled 95 percent of the U.S. market for rifle powder and sold 90 percent of the blasting powder. Henry explained his perspective on the consolidation this way: “We do not allow anybody to dictate to us as to what price, terms, and conditions we shall dictate. We do our own dictating.”

IN THE 1870S LAMMOT DU PONT RETURNED to the issue of improving gunpowder. As he knew from his collaboration with Thomas Rodman, who died in 1871, large guns needed a powder that burned slowly, generating pressure as the projectile moved up the bore. Lammot conducted hundreds of experiments to achieve a consistent powder providing the most favorable ballistics. At one point he meticulously counted the grains in several 100-pound barrels of powder to investigate the effect of grain size variation.

The result of these investigations, perfected in 1875, was a form of powder called Hexagonal. Shaped plates were used in the pressing to produce nuggets an inch and a half in diameter with a small hole in the middle—they were roughly the shape of wagon wheel nuts. Because the hole widened as the powder burned, the generation of hot gas increased while the space behind the projectile grew. More consistent than Mammoth powder, Hexagonal would be used in all large U.S. cannon for the next two decades.

Besides bringing gunpowder close to its most effective form, the collaboration between Rodman and Du Pont had represented one of the earliest science-based research projects for military purposes. In the 1850s rules of thumb and intuition still prevailed in the formulation of gunpowder. By the 1870s systematic research rooted in theory, mathematics, and accurate instruments was standard.

For their part, British powdermakers developed a highly compressed “rifle large-grain” powder for use in their larger artillery. In 1882, German technicians retarded burning still further by reducing the proportion of sulfur to only 2 percent and using charcoal made from rye straw that had not been thoroughly charred. They pressed this powder into inch-and-a-half-wide prisms with a central hole, a shape similar to Du Pont’s Hexagonal powder. Brown prismatic powder, or “cocoa powder,” topped all other powders in large guns: It threw projectiles the farthest with the most consistent trajectory and least strain on the gun. Artillerymen used it in massive 100-ton guns, which required a charge of more than 800 pounds of powder to blast a projectile out the barrel.

These were to be the last significant improvements in gunpowder. Over its long history, the mixture’s possibilities had been thoroughly explored, its limitations starkly outlined. The next big developments, in both shooting and blasting, would be the discovery of substitutes for the ancient explosive. Gunpowder was about to become obsolete.

CHRISTIAN FRIEDRICH Schönbein, a professor of chemistry at the University of Basel, was an unsophisticated, roly-poly man who loved “eating sauerkraut, black sausages and dumplings.” In 1840 he discovered ozone. In 1845 he dipped cotton fibers into a fuming combination of nitric and sulfuric acids. When he dried them, he found that they had become highly flammable, even explosive.

Gunpowder makers had long coaxed carbon fuel to interact with oxygen-rich nitrate by forcing charcoal and saltpeter into an intimate mixture. Yet the ingredients had always remained distinct chemicals. Schönbein had, in effect, incorporated the nitrate and carbon into a single molecule. The foundation was the cellulose of the cotton, a string of simple sugars that was the most common of all organic chemicals. The new material, nitrocellulose, or “guncotton,” was unstable. A great deal of chemical energy was required to hold it together. When heat or a shock upset the balance, it broke apart, its material converting instantly to gas and releasing the binding energy as heat.

Schönbein knew immediately that he was onto something—he had stumbled across a potential rival to gunpowder. “Explosive cotton,” he wrote, “should rapidly find a place in the pyrotechnic arts.” He gave a demonstration of his discovery at Britain’s Woolwich Arsenal in 1846. He presented Queen Victoria and the Prince Consort with the first brace of partridges killed with shot propelled by guncotton. Schönbein’s hopes for turning the substance into a new form of gunpowder literally went up in smoke when the compound proved too volatile to be manufactured commercially.

The same year that Schönbein was presenting his game birds to the royal couple, an Italian chemist, Ascanio Sobrero, was trying the nitrification trick on glycerin, a by-product of soapmaking. Previous attempts had resulted in a noxious red vapor. But Sobrero carefully dripped the sweet-tasting syrup into a chilled bath of nitric and sulfuric acids, stirring the while. He created an insoluble oil that sank to the bottom of the container. He drew it off and washed it in water to remove the acids. This material, when struck sharply with a hammer, set off a window-rattling explosion. He called it “piroglicerina.” Under the name nitroglycerin, it was destined to become gunpowder’s first serious rival.

Sobrero was a man of scruples. “Science,” he said, “should not be made a pretext or means of dishonorable undertakings or of business speculations.” Not everyone agreed.

ONE MAN FAILED to be deterred by either the danger or the technical challenges involved in turning nitroglycerin into a money-making product. Alfred Nobel had been drawn into the explosives industry by his father Immanuel, a hustling Swedish entrepreneur who, after an early bankruptcy, had surfaced in St. Petersburg, Russia, in the 1840s. There he constructed some of the first floating gunpowder torpedoes ever to damage ships. He amassed a small fortune during the Crimean War, gave his son a first-class education, then lost everything and returned to Sweden. Searching for a better explosive with which to charge his mines, he turned to Sobrero’s discovery.

Alfred was a sickly, morose youth who spoke five languages and loved the romantic poets, especially Shelley. But it was explosives that set fire to his imagination. During his late twenties, a determination of almost superhuman intensity overtook him. Even after his laboratory on the outskirts of Stockholm blew up, killing his 20-year-old brother Emil, he pushed forward. When nitroglycerin manufacture was banned inside the city limits, he moved his operation to a barge in a lake.

The problem that Nobel faced was how to get nitroglycerin to explode reliably. Unlike gunpowder, the oil did not go off when lit with a flame or fuse. Nobel’s idea, remarkable in its simplicity, was to put a vial of gunpowder inside a container of nitro. Fire from a fuse set off the powder. The shock of the small explosion acted as a hammer to shake apart the nitroglycerin molecules, resulting in an energy-releasing chain reaction.

This simple idea of using the force of one explosive to detonate another opened the door to the use of synthetic chemical explosives. Nobel packed his initiator into a small copper container with an attached fuse, substituting mercury fulminate for the original gunpowder. He patented this blasting cap in 1864. The era of high explosives had arrived.

A gunpowder explosion differed from natural fire in the speed at which energy was released. The combustion of gunpowder generated the same amount of energy as ordinary burning, only much faster, bursting into hot gas and smoky residue in a few thousandths of a second. This lightning speed, though, was snail-paced compared to the explosion of nitroglycerin, which went off in millionths of a second. Imagine that the explosion of a gunpowder bomb were slowed down, so that half an hour elapsed between the touch of flame to the powder and the bursting of the container. On that same scale, a nitroglycerin explosion would be over in two seconds.

The reaction, known as a detonation, happened so suddenly that air molecules had no time to move out of the way of the expanding gases, but piled up on each other, forming a shock wave. The shock wave traveled outward faster than the speed of sound. Nitroglycerin needed no container to bring about an explosion, as gunpowder did.

The volatile new explosive got off to a shaky start. On November 15, 1865, a group of Sunday morning tipplers in the bar of the Wyoming Hotel, on New York City’s Greenwich Street, complained of an odd smell drifting through the tavern. A porter carried a fuming box outside and set it down in the gutter. A few seconds later, a massive explosion shook the street, blowing out windows for a hundred yards. The parcel had belonged to a peddler hawking “glonoin oil,” a new blasting agent. In San Francisco, in Panama, in Sydney, Australia, and Hamburg, Germany, accidental nitroglycerine explosions were doing even more damage. Alarmed governments took action. France and Belgium outlawed the possession of nitroglycerin. Great Britain excluded it. The U.S. Congress considered sentencing irresponsible shippers to hang. The age of high explosives seemed on the verge of ending before it had begun.

Nobel had almost single-handedly established the nitroglycerin industry, promoting its use around the world, setting up factories to make it. In light of these devastating explosions, he never blinked. Returning to his laboratory, he pursued the problem with his usual resolve. He suspected that many of the accidents that had given blasting oil a bad name had resulted from the liquid being spilled. He searched for a way to make spills impossible. After trying many absorbents—charcoal, sawdust, cement—he hit on diatomaceous earth, the tiny silica skeletons of algae, as the ideal dope. Kieselguhr, as it was called, absorbed three times its weight in nitroglycerine, and it turned the volatile chemical into a much more stable commodity. Like many important advances in technology, the idea was brilliant in its simplicity and seemed obvious after the fact. Even the name that Nobel selected for his creation was pure genius. He borrowed a word from the Greek that meant power, calling the nitroglycerin sticks “dynamite.”

He patented this discovery in 1867. Now gunpowder faced a serious, versatile challenger as a blasting agent. To say that the dynamite industry’s growth was explosive is neither pun nor exaggeration. Nobel packed the kieselguhr–nitroglycerin mixture into paper tubes and set out to sell it to the world. Buyers stood in line to purchase it.

Gunpowder manufacturers viewed the advent of dynamite with concern. Modern chemistry was, in essence, pulling the market out from under the powder business. As is so often the case in such circumstances, a pair of blinders proved more comfortable than a bold examination of the facts. Powdermen were encouraged by the early nitroglycerin accidents. Even after the introduction of dynamite, Henry du Pont declared that high explosives were “all vastly more dangerous than gunpowder, and no man’s life is safe who uses them.”

During the 1870s gunpowder makers watched their customers switch to high explosives in droves. The California Powder Company, of which the Du Pont family owned a controlling interest, began to feel the pressure first. Hard-rock miners of the West more and more preferred the dynamite being sold by the Giant Powder Company, which had licensed the rights from Nobel. Henry allowed the western firm to produce a competing product, but would not countenance it at the Brandywine works.

Many gunpowder makers remained loyal to the centuries-old product, which by now was being designated “black powder.” Linus Austin of the Austin Powder Company in Cleveland still swore by “the old article,” and figured customers would always prefer the “more conservative and more reliable black powder.” Paul Oliver, one of the few anthracite powdermen whose firm, the Luzerne Powder Company, had not been gobbled up by the Du Pont cartel, considered high explosives “wretched stuff.” “Decent and respectable black powder,” he insisted, “will do more work for a given amount of dollars and cents.”

But as the 1880s wore on, the challenge of high explosives mounted. Their promoters slapped ever cockier names on the variations that streamed out of the laboratories: Ajax, Rend Rock, Vigorite, Rippite, Earthquake Powder—there seemed no end to the parade of improvements.

As a chemist, Lammot du Pont understood that science was creating ever more effective substitutes for the product on which his family’s empire rested. For a time, Uncle Henry swore by the “old article” as fiercely as any other powderman. But in 1880 he gave Lammot permission to set up a dynamite factory. “We are going into the high explosives business,” the old man announced.

Lammot built a modern dynamite works from scratch in Repauno, New Jersey, carefully separating the buildings with earthen berms. One Saturday in 1884 he was called to see about “trouble in the nitro house.” He found a vat containing a ton of fuming, unstable nitroglycerin. He ordered the men out, began tapping the oil into a pool of water, and left the building himself. At that instant, the nitro exploded, killing him. The manufacture of explosives had not ceased to be a dangerous business.

The dynamite industry grew faster than any other business in history, hammering the lid on the coffin of gunpowder. Nobel became fabulously wealthy. In 1888 he opened a newspaper and read his own obituary. His brother Ludvig had died recently and the reporter mistook the name. Alfred was stunned to find that he was described as a “Merchant of Death.”

To assure that his actual obituary would read more favorably than the mistaken one, Nobel wrote a will leaving the bulk of his fortune to establish prizes for those who made notable contributions to the sciences, literature, and world peace. In a final ironic twist, Nobel developed angina pectoris in his last years. His doctor prescribed nitroglycerin, which had become the standard remedy for the heart ailment.

IN THE 1860S, the Albany, New York, company Phelan & Collender, the nation’s leading manufacturer of billiard equipment, offered a tempting $10,000 prize to anyone who could come up with a substitute for ivory, long used to make billiard balls but increasingly difficult to come by. A man named John Wesley Hyatt took up the challenge. Though a printer by trade, he was an avid inventor and knew of the experiments that had been done with nitrated organic chemicals.

One of those chemicals was a sticky, syrupy form of nitrated cellulose called collodion, originally developed by Schönbein, which had been used to dress wounds during the Civil War. Hyatt dissolved this chemical in camphor under high heat and pressure. The result was a material that could be molded when hot—it was “plastic.” When cooled, it became as hard as the ivory he was trying to replace. Hyatt called it celluloid. It was the first of the long parade of synthetic materials that we now know as plastics.

Munitions researchers took a keen interest in celluloid. Guncotton and nitroglycerin were far too explosive to use in guns. The chemicals detonated rather than burned, blowing up the chamber instead of propelling the bullet. The process for making celluloid, based on a raw material similar to the explosive nitrogen compounds, suggested to them a way to unseat gunpowder from its role as a propellant.

The demands on a propellant were many and subtle compared to those on an explosive. The propellant had to ignite reliably and burn evenly. It had to be able to withstand shock, and couldn’t absorb moisture or generate noxious fumes when fired. Ideally it would not produce smoke or residues. That the craftsmen who developed gunpowder over its long history were able to make natural ingredients fulfill many of these requirements is testimony both to their skill and to the almost magical versatility of the mixture itself. Chemists struggled to produce an equivalent.

What was wanted was a hard material, energetic but resistant to detonation, that could be fashioned into grains. The material would be very similar, in fact, to the plastic that Hyatt had developed for billiard balls. During the 1880s, French inventor Paul Vieille became the first to find a way to plasticize guncotton by mixing energetic nitrocellulose with a solvent of ether and alcohol. The dried result was a hard, nonporous material that he could form into any size particles. When it burned, it created little smoke or residue. Vieille unveiled this “smokeless” powder, known as Poudre B, in 1886.

Alfred Nobel developed a rival propellant two years later by including nitroglycerin in the mix. Alarmed at the progress on the Continent, the British formulated a brew similar to Nobel’s, adding petroleum jelly. The mixture formed a dough that could be forced through dies to produce long strings—the new propellant was christened “Cordite.”

One prominent advantage of smokeless powder, as its name implies, was that on burning virtually all of its material turned to hot gas. The combustion products of gunpowder were half gaseous, half solid. Besides engendering smoke and fouling the inside of the barrel, the solid material reduced the force of the explosion. Smokeless powder was considerably more powerful than the same weight of gunpowder.

The new synthetics, in a remarkably short time, displaced gunpowder from its 900-year-old niche as the world’s only effective propellant. By the 1890s nations across Europe were rushing to switch to the improved powder. At first, smokeless powders needed to be distinguished from standard gunpowder. But the balance quickly shifted. “Gunpowder” began to refer to the modern synthetic, whereas “black powder” was used to designate the ancient mixture.

JUST AS EUROPEANS had taken advantage of their early lead in gunpowder weapons to support a wave of world conquest, they ushered out the age of powder with a second and more comprehensive program of colonial domination. Their superiority in mass production and metalworking, which allowed them to use gunpowder with increasing effectiveness, made the difference. From 1617 until 1852, British authorities issued 300 patents connected with firearms. During the six years ending in 1858, inventors took out 600 more such patents. This frantic pace of arms development accelerated through the latter part of the century.

Native blacksmiths in Africa and Asia had been able to copy or repair muskets quite handily. But they lacked machine tools and sophisticated metalworking capability to reproduce or even fix modern rifles. Repeating rifles in particular gave small groups of Europeans such a superiority of firepower that they could face down vastly larger numbers. The Chinese still used heavy, old-fashioned cannon that Jesuits had cast for Ming emperors 300 years earlier. The Burmese required each soldier to grind his own gunpowder. British conquest of these areas was child’s play.

The last and easiest target was Africa. So sure were European rulers of their military superiority that they divided the continent into spheres of influence even before venturing out to subdue the natives. They had good reason for confidence. They had long been shipping muskets to Africa as part of the slave trade, but the weapons were of consistently poor quality. Locally ground gunpowder was also inferior. The British used Gatling guns against Zulus during wars in 1871 and 1879. That same decade, General Garnet Wolseley defeated the mighty West African Ashanti kingdom with a force of only 6,500 soldiers. The French put the machine gun to use in Egypt in 1884. They fired repeating rifles to bring down Senegalese fighters armed with spears and poisoned arrows. Many Africans in the interior had no experience with firearms at all. “The whites did not seize their enemy as we do by the body, but thundered from afar,” reported one survivor of an encounter with European forces. “Death raged everywhere—like the death vomited forth from the tempest.”

Americans also dabbled in imperialism, and in doing so had the distinction of taking part in the last major conflict that used gunpowder fashioned from saltpeter, charcoal, and sulfur. In March of 1898, prompted by a rabble-rousing press and by the mysterious explosion of the battleship Maine in Havana harbor, U.S. president William McKinley declared war on Spain. Neither the U.S. military—the army had only 28,000 regular troops—nor the Du Pont partnership, which by now effectively controlled the American gunpowder market, were ready for the hostilities.

Efforts to develop effective smokeless military powder in the United States had languished. Many American soldiers carried the Model 1889 firearm, known as the “trapdoor rifle” because of its rather primitive breech-loading mechanism. It used cartridges loaded with black powder. The trapdoor rifle suffered from a number of disadvantages compared to the smokeless, repeater rifles used by Spanish troops. The worst was the cloud of smoke that announced the shooter’s position to enemy riflemen, inevitably leading to additional American casualties.

In spite of the disadvantages of their reliance on black powder, U.S. troops won the Spanish-American War handily by August. Afterward, American armed forces quickly converted to rifles and artillery firing smokeless powder. The military use of the original gunpowder, whose tortuous history stretched back to the raids of Edward III and to the battles of medieval China, had come to an end.

IN 1875, ALFRED Nobel, who was helping bring about the demise of gunpowder, wrote something of an epitaph for the ancient substance: “That old mixture possesses a truly admirable elasticity which permits its adaptation to purposes of the most varied nature. Thus, in the mine it is wanted to blast without propelling; in a gun to propel without blasting. . . . But like a servant of all work, it lacks perfection in each department, and modern science, armed with better tools, is gradually encroaching on its old domain.”

At the dawn of the twentieth century, that encroachment was almost complete. For military purposes, black powder was obsolete, replaced by smokeless powder and high explosives. Suppliers would continue to sell black powder cartridges for older sporting guns. Even in the 1920s some sportsmen swore by black powder as equal, if not superior, to synthetic propellants, especially in shotguns.

High explosives manufacturers claimed that their product “surpasses the power of gunpowder as much as the ball of a gun surpasses in swiftness and destructive power the dart of an Indian.” In spite of this acknowledged power, using high explosives underground was tricky business, and it was in the mines that gunpowder hung on the longest. Coal miners in particular were reluctant to switch to newer explosives. They maintained an affection for gunpowder blasting long after modern chemistry began offering safer and more effective explosives. Gunpowder had been tested over centuries; it was familiar, predictable, and inexpensive. Miners used it regularly up until the 1920s, giving it up only reluctantly. More than a few stuck with the old article into the 1950s, when gunpowder finally disappeared from the mines.

In response to this continued viability, the Du Ponts, in 1888, twenty years after the introduction of dynamite, began building what would become the largest black powder plant in the world. The site was near Keokuk, Iowa. The works, known as the Mooar Mills, was the first Du Pont operation west of the Mississippi. In addition to being a shrewd effort to profit from the growing Midwestern coal fields, the mills were Henry du Pont’s final expression of faith in the product that had made his fortune—he died a year after they opened. The firm expanded the mills in 1892, again in 1900, and one last time in 1918. At the operation’s peak, sixteen pairs of grinding wheels were turning out an astonishing 80 tons of powder every day.

In 1902 the Du Pont firm celebrated its centennial by swallowing its last significant competitor in the gunpowder business, Laflin & Rand. Five years later, President Teddy Roosevelt turned his trust-busting sights on the powder monopoly. A federal court dismantled the firm, splitting off the Atlas Powder Company and the Hercules Powder Company in an attempt to restore competition in the explosives market.

In 1921, a year after a last accidental explosion, the company shut down its gunpowder mills on the Brandywine. The grinding wheels had been turning there continually for 117 years. In 1971, Du Pont announced that it was leaving the black powder business altogether.

Black powder still found uses throughout the twentieth century. Quarrymen working with slate and similar rock needed the “soft” explosion that was characteristic of gunpowder, not the shattering effect of high explosives. Fuse makers still used gunpowder because of its predictable burn rate. It served as a primer for large navy guns, setting off the smokeless powder that did the heavy lifting. The ranks of diehard sports shooters who preferred the old powder were joined by black powder enthusiasts who enjoyed the challenge of hunting with old-fashioned weapons. Hobbyists and history buffs took pleasure in reenacting bygone battles, forming another small market for traditional powder. Their games reproduced the smoke and smell of bygone battlefields.

And so, step by step, gunpowder eased off the world stage much as it had eased on, without fanfare. No headlines trumpeted the demise of a 900-year-old technology. No eulogy was read over its grave. Gunpowder was gradually replaced, fading into the haze of nostalgia. In only one field did its contribution continue intact. Appropriately, it was the same use to which the ancient Chinese had first put the magical and incendiary substance—delight.

THE HEART OF a modern fireworks display is a cardboard sphere six inches across. Inside is a small charge of gunpowder. The device is in fact a bomb and is often referred to as such by professionals. Its purpose is not destruction but enchantment. It contains nuggets of chemicals that, when set afire by the exploding gunpowder, fly through the air, burning with brilliant sapphire, crimson, or golden light. No matter how much modern apparatus accumulates on the periphery of his trade, the modern pyrotechnician continues to ply his art with gunpowder tools that are almost identical to those that have decorated the sky and ignited the imagination for centuries.

Attached to the sphere, also known as an aerial shell, is a small sack of gunpowder, the lift charge. The “shooter” inserts the whole device into a three-foot-long tube and ignites a fuse that quickly burns down to set off the lift charge. The explosion blows the sphere 800 feet into the air. An attached timing fuse, lit by the initial firing, ignites the powder inside the shell just as it reaches its apogee. The burst flings the flaming nuggets out against the black velvet night.

The pyrotechnician takes gunpowder back to its origins. He reenacts mankind’s primordial impulse to use the substance to captivate and gladden his fellows. Like any showman, he devotes hours to the prosaic preparations that lead to thirty minutes of spectacle. He endures the inevitable danger always associated with gunpowder. The electric fuses that fire some shows have reduced the risk, but accidents, sometimes fatal ones, continue to happen.

Fireworks remain, in most aspects, a product of craft. The shells, the fountains, the fiery chrysanthemums and peonies, all are made by hand. A show may be programmed by a computer, but the ingredients, the planning, the salutes and whistles and skyrockets, would be familiar to the pyrotechnicians who illuminated Louis XIV’s Versailles. During the nineteenth century, more sophisticated chemistry allowed pyrotechnicians to create dramatic new effects. More varied and richer colors became available as the salts of various metals were made to glow in the flames. Finely powdered magnesium added a brilliant white light. At the opening of New York’s Brooklyn Bridge in 1883, more than a million spectators gazed in awe at the riverwide “Niagara of Fire,” a cascade of magnesium flame that spilled from the new span.

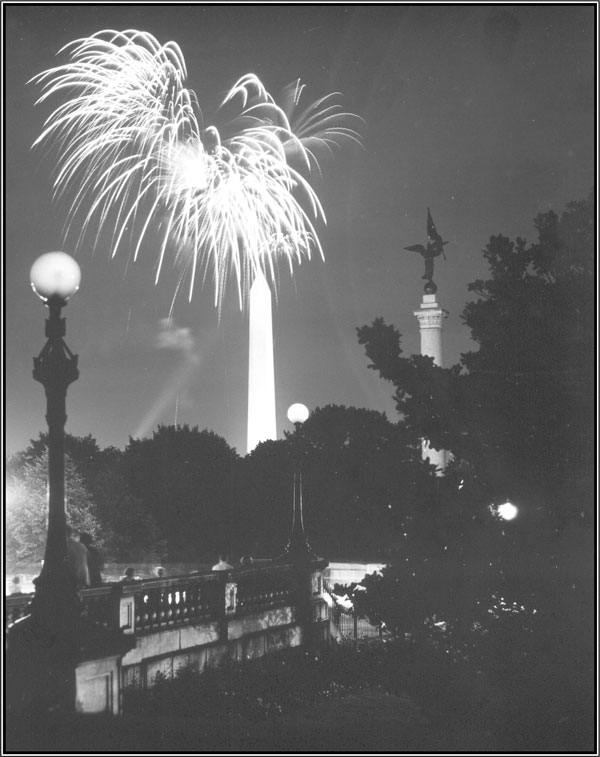

A fireworks show near the Washington Monument

Today, fireworks professionals and a few devoted amateurs continue a tradition that reaches back to the Renaissance and beyond. The pyrotechnician is more than a showman. He is heir to the alchemist, transforming the basest of materials—a handful of charcoal, some sulfur, salt leached from ordure—into gold. With that gold he etches the darkness.

A fireworks display gives the audience a symbolic reprise of gunpowder’s history—the concussions of bombards and cannon stretching back to Crécy, the explosions that carved the earth, the blossoms of fiery stars that enchanted monarchs and peasants centuries ago, the long pageant of joy and terror. The haze of smoke that lingers after the show brings to modern nostrils the smell that perfumed the night air in medieval China.

Many have tried to describe the evanescent beauty of fireworks. The explosions are splendid waste. They are wild-haired comets, silver rain, tinsel-starred bouquets. In 1540, Vannoccio Biringuccio wrote that fireworks “endure no longer than the kiss of a lover for his lady, if as long.” This ephemeral quality is the deepest secret of their appeal. However spectacular the incandescence, it fades in a moment. The quick and heartbreaking diminuendo instills fireworks with a bittersweet poignancy that has drawn involuntary sighs of wonder from onlookers down the ages.