Chapter 2: Equipment, Methods, and General Instructions

This chapter is not designed to provide an exhaustive description and list of every imaginable brand and type of equipment used in the preservation of different kinds of meat and fish. There should be sufficient information presented on different kinds of equipment that you will be able to understand what equipment you need to preserve any type of meat or fish you are interested in.

Freezing Appliances, Equipment, and Supplies

Because most people have access to a refrigerator, kitchen stove, and a freezer, the simplest method for preserving meat and fish is to cook it and put it in the freezer. Simple freezing projects, like bringing a package of meat home from the grocery store and dividing it up into portions that the family can use at a single meal, do not require a long list of complicated instructions or equipment. All that is needed is a clean place to cut the meat, a sharp knife, and some freezer bags or plastic containers to put the meat in. This size of a project is just about right for those of us who like to enjoy good food with minimum work.

There is some controversy about the ability to preserve or enhance the freshness of meat or fish products by “fast freezing” them. Fast freezing food means to bring the food down to extremely cold temperatures immediately after it is cooked and packaged. Fifty percent or more of the seafood that is caught is fast frozen in freezing equipment that uses liquid nitrogen at about -320 degrees. Immediately fast freezing fresh food products in this manner not only stops bacterial growth, but it also preserves the food in its fresh condition for a longer period of time than conventional freezing methods. Other commercial processes exist that accomplish the same ends, but these results are obviously not possible with the freezer in your home since most in-home freezers only bring food down to about -18° F. Additionally, home freezers take a little time to get the food down to the lowest temperature they possibly can. The only way for the home preserver to accomplish anything close to this process would be to make arrangements with a local locker plant.

Many people who read this book may not be familiar with what a meat locker plant is. With the diminishing number of people raising animals at home to supply meat for their family, locker plants are slowly disappearing. The locker plant is the place people bring the steer they have been raising for slaughter or the game they have harvested for butchering and processing. Some may call this a butcher shop; however, a locker plant not only butchers animal carcasses, but it also provides storage lockers for people who have large quantities of meat that needs to be kept frozen. The freezers at a locker plant are much more efficient than those found in the average home, so the closest the home preserver can get to fast freezing is to bring their meat products to a locker plant.

The quick freezing and fast freezing processes that commercial meat processing companies are able to use are not realistic options for home meat preservers. You can use a freezer thermometer to determine just exactly how cold of a temperature your freezer will reach. If you are going to purchase a new freezer, pay close attention to the specifications provided by the manufacturer. If the freezer specifications show the freezer is only going to reach -8 degrees, for example, this would not be the best freezer for long-term storage of meat products. Remember that fast freezing to very cold temperatures freezes food without creating large ice crystals. Most people have probably tasted ice cream that had not been frozen properly, and the milk has turned to crystals, ruining the texture and taste of the product. People who want to preserve meat in a freezer for six months or more need to use a freezer that is capable of holding the product consistently at the lowest possible temperature. Meat stored in freezers that do not keep the product at a constant temperature should not be stored for more than six months. Remember that even if your freezer reaches -18 degrees, every time you open the door, the temperature in the storage compartment rises and must be brought back down to the lowest temperature again over a period of time. For the person who is going to store large quantities of meat for over six months, using the cold storage facilities at a locker plant may be the best option.

A reality check would be good at this point. Commercial food processors are preparing their product to be shipped all across the country and cannot absolutely control all of the conditions the product may encounter, so the product must be frozen to standards that exceed home freezing expectations. Commercial meat handling standards begin at the processing plant. Meat processing facilities are rigorously inspected for safe and sanitary handling of animal carcasses and finished meat products. Meat-handling standards also are concerned with any substance that is artificially added to the product and ensuring meat product labels accurately reflect the contents of the finished product. Meat-handling regulations also specify that fresh and frozen products should be maintained at the proper temperature throughout storage, transportation, and presentation in the retail outlet. Although food frozen for commercial sale is packaged with expiration dates, manufacturers cannot be sure the food will be consumed by the expected expiration date. Consumers have the responsibility to protect themselves by not using meat products that have been in storage beyond the date that is printed on the package. Commercial packaging, freezing, and distribution standards must meet the highest possible food safety expectations.

Your home freezer will do just fine as long as it is in good working order and as long as you have prepared your meat and fish according to proper food-handling standards. Another factor to consider is how long you plan to store your meat or fish in the freezer. Larger cuts of meat, like roasts, steaks, or whole poultry products such as a turkey, can be safely stored in the freezer for up to 12 months. Items like ground beef and some fatty fish products are only safe in the freezer for around three months. Fatty fish such as salmon, tuna, sardines, mackerel, and trout should not be stored in the freezer beyond three months. Meat and fish left in the freezer beyond recommended safe storage limits will have a deteriorated taste and will lose the natural tenderness you expect. Pork sausage should not be stored for more than two months. In any case, we are not talking about years and years of storage in your freezer. The following list provides a quick list of safe meat storage limits. Meat and fish products that have reached the end of the safe storage life in the freezer must be immediately cooked and consumed or properly disposed of.

General Safe Meat and Fish Storage Limits

- Large items such as beef and lamb roasts: 12 months

- Lean fish, duck, and goose: 6 months

- Fatty fish and ground meats: 3 months

- Pork chops: 4 months

- Light items such as bacon: 1 month

The University of Georgia Cooperative Extension Service has a Web page titled “Preserving Food: Freezing Animal Products” that provides a detailed chart of proper time limits for leaving meat and fish in the freezer. The Internet address for this Web page is listed in the Appendix.

After the freezer, the rest of the equipment you will need is much smaller by comparison. Good kitchen knives are essential tools for people who are preparing meat for storage or for cooking. Kitchen knives should be kept sharp to avoid wasting valuable meat products and to keep you from injuries that are caused by using dull knives. The dangers that go with using dull knives cannot be understated. Dull knives only tear meat products, which leads to waste and makes the meat difficult to cook because the torn edges will not heat uniformly with the rest of the cut of meat. Dull knives can also be dangerous to the user because of the force that is needed to saw through meat products. The best kitchen investment any family can make is to purchase the best quality knives the budget will allow. Modern knives that are made of high-carbon stainless steel are considered the best choice. Carbon steel is soft enough to respond well to sharpening, but has the strength of stainless steel. Two quality knife companies are Zwilling J.A. Henckels® and Wusthof®, both of Germany. Regardless of which company you choose to purchase knives from, make sure you select knives that you would expect to use for a lifetime. Many people are now turning to the new ceramic knives as the best choice. The best approach to take when the time comes to make a significant investment in knives is to do some research on your own. If you purchase knives from an established company that provides a good warranty, you probably will not regret the decision. There are sources for good quality knives referenced in the Appendix to help you get started in your search.

Using good quality cooking pots and skillets ensures that meat is thoroughly cooked without burning or scorching. Buying brand-new equipment does not mean you will have the best quality possible. If you look in your grandmother’s kitchen cupboards, you will probably find some well-used equipment that will do a better job than a lot of the new stuff that is on the market today. For example, your grandmother may have some old-fashioned, high carbon steel knives in the drawer that will sharpen to a very fine cutting edge and yet remain very flexible. The only drawback to these knives is that they require extra care to keep them from tarnishing. Cooking pots and skillets that have been in use for many years and are still in good shape will continue to serve very well if you continue to take good care of them.

If you are going to grind meat to make hamburger of deer sausage, you will need as good of a grinder as your budget will allow. There are several items to consider when selecting a grinder for home use. The following short chart lists some important features to look for. Sources for grinders have been included in the Appendix.

- Can you get by with a hand-crank meat grinder, or do you need an electric grinder? This is important as you consider the volume of meat product that will be processed each year. There is not a specific recommendation for the amount of meat that would justify an upgrade to an electric grinder. If you will only use your grinder occasionally for small amounts of meat, then you may do very well with a manual machine. If you will use the machine on a regular basis, then the time and effort an electric machine will save may be sufficient to justify the extra expense of an electric machine. If you decide you need an electric model, then you must consider whether the power rating of the grinder is sufficient. You may be able to get along with a 150-watt machine that will handle most non-commercial kitchen meat grinding chores, or you may need a 1000-watt machine that is capable of grinding up to 175 pounds of meat in an hour. Purchasing a machine rated a little higher than you expect to need should ensure that you can meet any projected meat grinding chores that you may encounter throughout the life of your machine.

- Grinders that use stainless steel grinding and cutting blades will provide easier cleaning with an expectation of a longer useful service life than blades that are not made of high-quality stainless steel. Stainless steel blades may last up to three times longer than carbon steel blades because the carbon steel blades are more susceptible to corrosion and will not keep a sharp edge as long.

- Does the grinder include a food-pushing tool? A food-pushing tool provides the user with an extra measure of safety since the machine keeps fingers away from grinding blades.

- Is the rated capacity sufficient for the size of grinding projects you expect to accomplish?

- What is the durability rating of the grinder; does it have a good warranty?

To prepare your product for freezing, you will need freezer or butcher paper to wrap the meat or fish in. Some items, such as pork chops and ground beef patties, store better and separate easier when they are separated by freezer paper. There are a wide variety of plastic freezer containers you can use. Freezer bags are different than sandwich bags. Freezer bags are made of thicker material than sandwich bags, and they are manufactured with sealing features that are specifically designed to keep out air and moisture during long-term storage of food products. Sandwich bags will not provide the protection that frozen meats will need for long-term storage. Freezer storage bags come in many sizes. The key is to ensure that you use storage containers that have been made expressly for containing frozen food. Frozen food that will be consumed in small quantities should only be put in smaller bags, as it will be easier to close up the bag with the least amount of air left in the bag. Air and moisture that are allowed to remain in the bag will lead to freezer burn. Vacuum-sealing systems pull the air and moisture out of the freezer bag, and heat seals the bag securely.

An additional concern that needs to be addressed is how to keep track of what each freezer bag or container contains, and how long it has been in the freezer. Losing track of how long meat has been stored in the freezer will lead to waste. To solve this problem, you will need freezer labels to indicate what is in each container and the date it should be consumed by. A well-organized freezer will ensure that everything that has been prepared and stored will be available to feed your family and nothing will be lost. A number of good resources for storing food have been listed in the Appendix.

Farmers Bill and Kay Tomaszewski, along with their children, are very involved in preserving meat and fish in their home. With their extensive experience preserving meat, they provided another idea that would be helpful for people trying to preserve meat and fish in the home environment. “The ideal place to process meat is in a walk-in cooler to keep the meat cool to prevent deterioration and spoilage,” Bill said. “We don’t have that, but in the past we have processed in an outside room in the cold of winter. We process inside now — arthritis and age played a part in that — so we make sure everything is kept cool. The meat is maintained between 34 to 38 degrees. The room is kept less than 70 degrees Fahrenheit.”

Temperature requirements to fully cook meats

The finished cooking temperature of meat in restaurants has been much in the news the last few years. Many people like a good steak just a little on the “rare” side. The problem is that if the internal temperature is not high enough to kill dangerous bacteria, people can get very sick. The best way to ensure that the meat and fish you are preparing has been cooked enough is to use a meat thermometer. Satisfactory meat thermometers are not very expensive and can be easily obtained in the nearest hardware or department store.

General safe meat internal cooking temperatures

- Ground beef as in patties and meatloaf: 160° F

- Ground poultry: 165° F

- Well-done beef roast: 170° F

- Well-done pork: 170° F

The important point to remember is that meat must be cooked sufficiently to destroy bacterium that would cause a foodborne disease. A complete meat temperature chart from the University of Illinois is provided in the Appendix.

Canning Equipment and Supplies

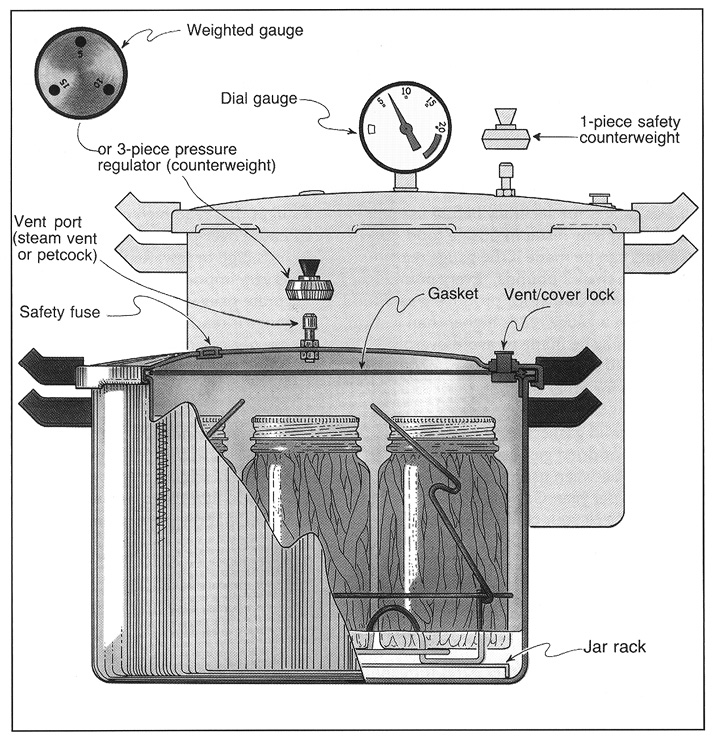

An essential piece of equipment for the home canner is the pressure canner, also called a canning pressure cooker. A canning pressure cooker heats both the meat and the jars to sufficient temperature to ensure safe and sanitary preparation of the product. Meat being canned must be heated to 240 degrees to ensure the canning jars seal and the product remains safe for consumption for as long as possible. Simply boiling the product and the jars on the stove top will only bring the heat to 212 degrees, which is 28 degrees below the safe temperature level.

A pressure cooker works on the same principle as the radiator in a car does. In order to raise the temperature of water above the boiling point without the water turning to steam, water must be heated in a sealed container under pressure. The pressure cap on a radiator, depending on the application, holds between 13 to 15 pounds of pressure before it vents off some of that pressure. Pressure must be vented off to keep the radiator or some other cooling system component from exploding. The pressure on the radiator allows the cooling system to handle temperatures much higher than the boiling point, keeping your car engine from boiling over on hot days.

A pressure cooker designed for canning will have a lid that seals tightly with a pressure gauge and a vent. It is very important to follow the manufacturer’s instructions for your elevation. Water boils at different temperatures according to elevation, so there will be different pressure requirements between coastal Florida and mile-high Colorado. Always inspect the seal and sealing mechanism for the lid whether the cooker is new or used. A lid that loses its seal after the pressure has built up is a formula for disaster. If a canning lid looses its seal, air can get into the meat, allowing deadly organisms such as botulism to grow that can cause food poisoning. People who become infected with a severe case of botulism can die from respiratory failure. People who receive timely medical treatment may have a long hospital stay requiring the use of a breathing machine with a long-term stay in an intensive care facility. Make sure the vent cap is working properly, and watch the gauge as the heat and pressure build. If there is a doubt that any part of the pressure canner is working correctly, remove the heat and fix the problem immediately.

Pressure canner safety checklist

1. Check the rubber seal that goes around the lid to be sure it is not cracked or torn. If the seal is defective, do not use the pressure canner until a new seal is installed. Also inspect the seal for cleanliness. A lid with a dirty seal will not hold pressure properly.

2. The pressure gauge and pressure vent should be inspected for condition. If they are defective or not working properly, they must be replaced before using the pressure canner. A defective pressure gauge may have broken glass over the gauge, or the needle may be stuck. The pressure vent may be bent or deformed from other kitchen equipment that was dropped on it in the cupboard, or it may have been damaged so it no longer sits on the lid properly any more.

3. If the pressure is not building as it should or begins to drop, increase the cooking heat immediately.

4. If the pressure drops below the prescribed amount on the chart for your pressure canner, increase the cooking heat to bring the pressure back up to specification. If this happens, you will need to begin the timing process all over again.

5. If you live above 1,000 feet, you must adjust the pressure for elevation. A time and pressure adjustment chart is provided at the end of this chapter.

6. When the pressure canning process begins, all the trapped air must be vented out of the cooker. Air that remains in the canner will reduce the temperature that can be reached for a particular pressure. Most pressure canners require 10 minutes of venting to insure all of the excess air is vented from the interior of the canner. During venting, you will be able to see the air venting out in the form of steam. After 10 minutes of continuous steam vapor, close the vent and begin building up the pressure.

This diagram shows the parts of a pressure canner. Image courtesy of the USDA.

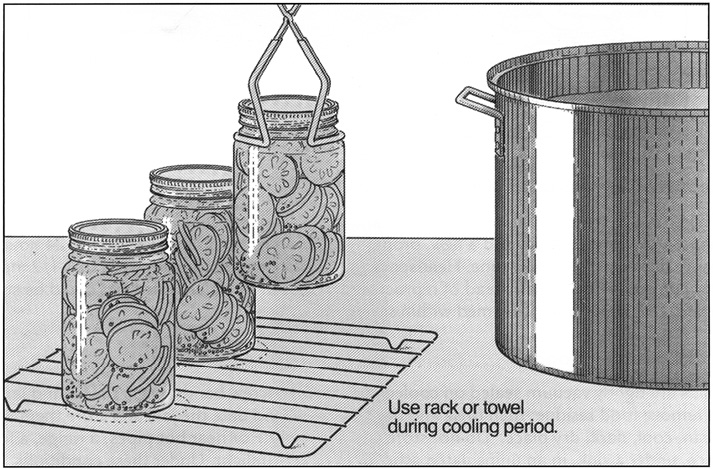

The key to ensuring that all jars are thoroughly heated is to be sure that no jars touch the sides of the pressure cooker and that no jars are touching each other. The hot water must be able to circulate completely around the canning jars to ensure that the meat and jars are completely brought up to the correct heat all the way through the contents of the jar. A jar that is touching the side of the pressure cooker or another jar may develop a “cold” spot. Canning jars should be left in the pressure canner after the removal of heat until the pressure returns to zero without any artificial cooling. The period of time the jars are left in the pressure canner after the heat has been removed is part of the processing time, and it is essential to finish the destruction of any deadly microorganisms. Do not rush the pressuring-down period by applying cool water or by using a cooling fan. The jars should be removed from the pressure canner just as soon as the pressure reaches zero. Set the jars on the counter to cool at room temperature. Jars with cold spots that have not been heated sufficiently will be easy to see after you set them on the counter to wait for the distinctive “pop” that indicates the jar has sealed properly. Meat that has not been cooked to a proper temperature will look differently than the meat in jars that has been heated properly. Canning jars should seal within 12 to 24 hours. Jars of meat that do not seal up properly must be refrigerated and consumed soon after or put back in the cooker to restart the process.

Cooling is an important part of the canning process. A rack and towel are all you need for cooling. Image courtesy of the USDA.

Always purchase the best canning pressure cooker you can afford. If you consider purchasing a used cooker, do a thorough inspection before the purchase is finalized. Check used pressure canners for cracks or deformities in the main body and the lid. Inspect the seal around the lid for cracks and stretching. Also inspect the pressure gauge for broken glass or a stuck needle. If the canner has a pressure vent, make sure it has not been damaged or bent. The safety of every person who eats the meat processed in the pressure cooker is at stake. There should never be any temptation to take shortcuts when canning meat or fish at any time for any reason.

The next question that many people ask is whether or not they can use a standard pressure cooker as a pressure canner. The answer is no. The standard pressure cooker uses less metal in its construction, and it is much smaller than a pressure canner. Since there is less metal in the standard pressure cooker, heating and cooling times will not be the same as a pressure canner. The total processing times in meat and fish canning recipes are based on the use of a pressure canner. If the meat or fish is under-processed, deadly organisms can form quickly, putting your family in danger of food poisoning.

A true pressure canner will include a wire rack for holding canning jars and will be able to hold at least four 1-quart jars. The wire rack allows hot water to circulate under the jars during cooking, and the pressure canner must be large enough so that hot water can completely circulate around the sides and top of the canning jars to ensure every part of the meat product is raised to a heat level sufficient to cook the meat and destroy any dangerous organisms. Finally, do not be tempted to create your own canning recipes. Established canning processing times have been developed by the United States Department of Agriculture (USDA) and are built into canning recipes. Canning meat and fish is not the place to be using your imagination. Please follow established canning recipes and procedures to ensure the safety of your loved ones. Resources for pressure canners can be found in the Appendix.

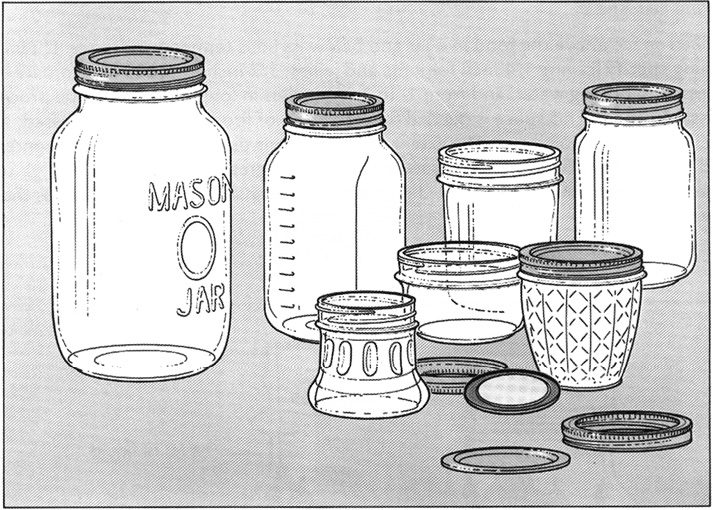

Canning jars are the most important ingredient in the recipe for a great day of canning. People have tried unsuccessfully to use pickle and jelly jars from the grocery store after they had been emptied. These types of jars are not made to withstand the temperatures and pressures of the canning pressure cooker. These types of jars expose you and your family to the danger of a jar bursting and causing a serious injury. Even genuine canning jars that have been in the family for a number of years may pose a risk of breakage or leakage. It is incumbent upon the person doing the canning to thoroughly inspect old jars for cracks in the body, chips around the top edge, or some weakness in the spiral grooves that will secure the lid.

There are four brand names of canning jars available in North America: Ball®, Kerr®, Bernardin®, and Golden Harvest®. Ball and Kerr jars use interchangeable lids and are considered to be of equal quality. Ball and Kerr canning jars can be found in most hardware and department stores around the country, although selection will be much better during the traditional fall canning season. Golden Harvest jars are sold in major discount department stores or hardware chain stores. Golden Harvest canning jars can be found at a lower price and have received mixed reviews, but they can serve very well if used with proper care. Bernardin canning jars are sold in Canada. Since 1993, all four brands have been made by the same company, Jarden Home Brands, which is a subsidiary of Jarden Corporation.

Jars come in many shapes and sizes, but for meat, you will use mostly quart jars. Image courtesy of the USDA.

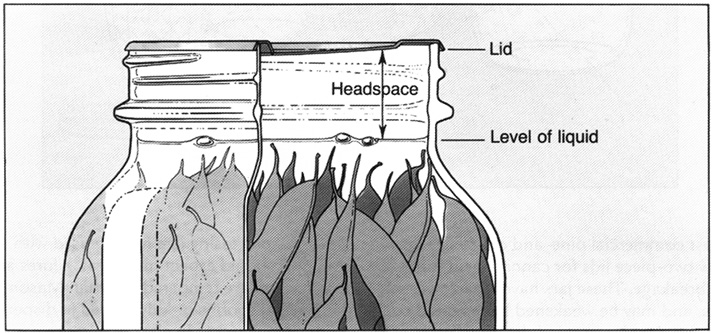

When selecting jars to can meat and fish, make sure you select jars that are large enough for the product that will be preserved. When the meat product is put in the jar, enough room must be left between the lid and the product for the canning sealing action to be successful. The amount of headspace you leave depends on the recipe and the product being canned, but it will generally be from ¼-inch to 1 inch. If you are using a recognized recipe, it will provide you with the specific headspace that will be required to safely can your food product. If a canning jar is filled too much, the product may boil out over the lip of the jar and make it impossible to get a good seal. Most meat and fish canning will be done with quart jars. Internet Web page addresses for canning jar resources are listed in the Appendix.

Proper headspace is essential to a good seal. Image courtesy of the USDA.

Proper care and sanitation of canning jars

By the very nature of being glass, canning jars can be easily broken. Children may be allowed to play with the pots and pans in the kitchen or may be allowed to rearrange the canned goods in the cupboard, but canning jars make dangerous toys.

With careful handling, canning jars can be used for many years. However, even the slightest crack or chip around the lid is sufficient reason to throw a jar out and get a new one. Some people may consider using the lids over, but that is not a recommended practice. The lids are generally bent or the sealing surface damaged when the jar was last opened. The metal rings that hold the lid down before being vacuum-sealed can be cleaned and used over again until they become distorted in some way.

Jars do not need to be sanitized separately when working with meat or fish because the sanitation process will take place in the pressure cooker. This is why the admonition in the last section was so strong to ensure the cooker gets to the correct heat and pressure for the elevation at which the canning is taking place. The success of a meat-canning project depends completely on getting enough heat around the jars to fully cook the meat, sanitize the jar and the contents, and get the vacuum seal to “pop.”

After the jars of beautiful food are on the shelf, please do not get complacent. The jars can be jostled around and get cracked. Even the slightest crack will break the vacuum seal and allow air to get into the jar and start the spoilage process. Occasionally inspect stored jars of food for lids with seals that have broken loose. Lids can come unsealed for any number of reasons. For example, if the headspace was not correct, the vacuum that holds the seal may fail, or if the lip of the jar was contaminated with food juices when the jar was sealed, the seal may fail. If the seal is broken, the safe rule is to dispose of the jar’s contents immediately as spoilage can take place rather quickly. During your inspection, if the food in a jar is a significantly different color than other jars with like product, it is a good indication that spoilage has taken place.

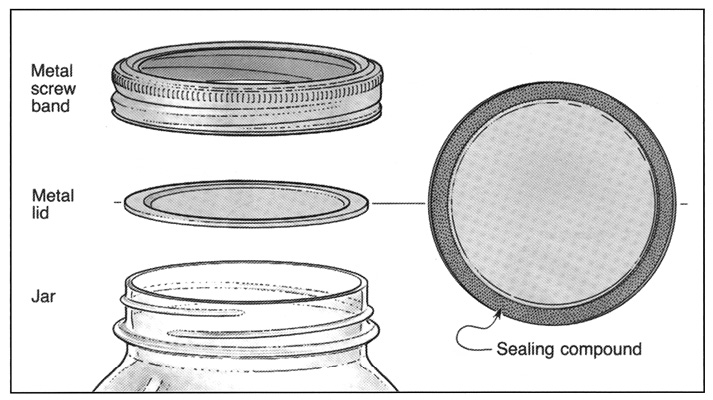

Quality canning jar lids are essential to the canning process. Canning jar lids include the round lid that fits on the top lip of the jar, and the outer band that secures the lid until the vacuum in the jar securely seals the lid. The outer bands hold the lid in place until the vacuum in the jar seals the lid. The vacuum seal takes place while the food is cooling over a 12- to 24-hour period. Once the lid is sealed, the bands are no longer necessary. Many people remove the bands at this point because the bands can rust in place and be difficult to remove later when you are ready to consume the meat.

Using flawless lids ensures a good seal. Image courtesy of the USDA.

Curing and Drying Equipment, Supplies, and Procedures

To understand the equipment that will be needed to cure and dry meat and fish, there is a need to understand the relationship between curing and drying. Curing is a process that uses an agent such as salt to preserve meat or fish for future use. The curing process is also used to impart a desired flavoring to meat or fish. It is important to remember that curing does not cook the meat, but rather preserves it for future use. Curing stops the biological processes that produce spoilage and cause harmful diseases. Salt is the primary agent for meat curing in the home, but in some cases, nitrates can be used. Meat and fish are not usually cooked prior to the curing process.

Learning how to cure meat is a skill that anyone can master with some education and practice. Ideally, the best time to begin a meat-curing project is during the fall and winter months when the outside is cool or even cold. If you are curing meat during warm weather and you do not have a cooler or refrigerator large enough to hold all of your meat in one piece, then you will need to cut your meat into pieces that can be stored safely in your refrigerator. If you are really going to get involved in curing meat, a good investment would be an extra refrigerator that you could dedicate to these kinds of projects.

There are several procedures that fall under the title of meat curing. Meat can be cured in a brine solution made up of salt, water, saltpeter, and nitrite. Meat can be dry cured by rubbing a dry cure compound on the meat and packing the product into a cure box for a period of time. Sugar curing involves adding sugar to the cure formula. The sugar offsets the salt and imparts its own flavoring to the meat. Many people will use the word “curing” in conjunction with the use of smoke to impart flavor to meat and to cook it if the temperature in the smokehouse is allowed to get high enough. In all of these curing processes, the control of the temperature that the meat is being exposed to is the important factor. Before the meat has been cooked or cured, it must be kept cold. During the time that you are cutting or grinding the meat, it is important to keep the temperature as cold as possible to inhibit the growth of deadly microorganisms. Even after the meat has been cured, the shelf life of the product will be extended if it is kept under refrigeration.

In many procedures, it will be essential to keep the meat cool after it has been cured for several hours or even days to give the salt a chance to penetrate all the way through the cut of meat. If any step in the curing process is skipped or bypassed, your meat may be spoiled. Brine or dry cure processes are designed to allow salt to penetrate into the meat and dissolve or remove as much moisture as possible. The removal of moisture helps to inhibit the growth of bacteria. In this way, salt brings about the curing in the meat product.

Saltpeter is used to maintain the red or pink color in processed meats. Several manufacturers produce pre-mixed curing formulas that can be purchased in a number of sizes. Using a commercially prepared curing mixture takes much of the guesswork out of curing meat. The use of a commercially manufactured curing mixture will help you to eliminate errors. Sources for pre-mixed curing compounds are the local grocery store and the local butcher shop, or you can look on the Internet for reliable sources.

To ensure success when applying a sugar cure, simply remember to keep the meat cold throughout the entire curing process. Limit as much as possible the amount of time your uncured meat product is not at 38 to 40 degrees Fahrenheit. During the time the meat is exposed to the sugar cure, if the temperature gets too cold, it will interfere with penetration of the curing agents. If the temperature is allowed to rise above 40 degrees Fahrenheit, the spoilage processes will begin.

Always weigh and measure your ingredients exactly as the instructions require. There are several types of salt that may be used. Just remember that each type of salt will measure out differently, and each type of salt will have its own curing characteristics. A general recommendation is to use salt that has not been iodized. Always use the exact measurements as much as possible.

When you are waiting for a meat project to cure, remember that curing is not a job you can spend a few minutes on and it is done. Sufficient time must be allowed for the curing agent to be absorbed into the meat. If you try to cut short the time the meat is exposed to the curing agent, the meat will probably spoil long before you expect it to. If you leave the meat in the curing agent for too long, the meat will become extremely salty and not taste good.

Dry curing involves rubbing a cure mixture on the surface of meat and packing it in a cure box for a period of time to allow the cure to naturally soak in and penetrate the meat completely. People have different approaches for rubbing the cure on the surface of the meat. Some people lightly rub the cure on the surface, making sure that all parts of the meat are covered. Other recipes direct you to rub the meat a number of times over a period of time. The best policy is to follow the instructions that are part of the recipe or procedure you are using. After you have become experienced in the art of preserving meat, you can experiment a little and find out what works best for you.

After you have rubbed your meat sufficiently, it is to be packed in a dry curing box. A dry curing box will have a bottom shelf with holes in it so that the brine that is produced can drain away from the meat. The meat will be loosely packed in layers with the dry cure compound packed all around each piece of meat. The curing box should be something that will not be reactive to the salt in the cure mixture, such as a wooden barrel, stoneware container, or even a burlap bag. The curing container is then put in a refrigerator set at the correct temperature, or if the weather is cool enough, out on the porch. Different recipes require that the rub be repeated periodically and the meat be turned over in the dry cure box. The frequency will be determined by the size of the meat cuts being cured, the amount of brine that is collecting in the bottom of the box, and the individual preference of the person curing the meat. It is not inconceivable that you will need to rotate the meat in the box every two or three days until the cure is complete. The entire process may take up to a week to complete.

When the curing cycle is complete, remove the meat from the curing pack and brush off the excess cure on the meat. You will then rinse all of the salt from the outside of the meat with cool clean water. This should not be done in a place where the runoff salt brine can damage a floor or counter top. This is the time to begin smoking the meat. The meat will need to be completely dry before it is exposed to the smoke and cooking process. Excess moisture on the meat works to counteract the effects of smoking.

The meat should be hung or placed on shelves in the smokehouse so that the pieces do not touch another piece of meat. Fire up the smokehouse using the type of hardwood that will impart the specific smoke flavor you are looking for. Some experienced smokers say that sawdust provides the best smoke, while others say to use small chunks of wood. If you have purchased a smoker in the store, follow the instructions that came with your smoker. Usually, cold or hot smoking takes more than one day to complete, so be patient.

Remember that cold smoking does not cook the meat. Cold-smoked meat will need to be cooked properly before it is consumed. Although hot smoking cooks the meat, it has been exposed to a curing agent, so it must still be refrigerated to extend the safe storage life of the meat. Never take any chances when it comes to food safety.

Drying meat and fish is the process of removing moisture, which aids in inhibiting the growth of bacteria. The main product that comes to mind when we think about drying is jerky. Making jerky is not a complicated process, but it provides a good example for learning the basics of drying meat. Only lean meats such as beef, deer, elk, or turkey are suitable for making jerky. Pork is sometimes too fatty to dry. During the drying process, the fatty portions are subject to oxidation and will turn rancid and stink, making the jerky inedible.

The relationship between curing and drying is important because meat and fish can be cured before they are exposed to the drying process, ensuring the product does not spoil before it is fully dried. Additionally, your desired flavoring can be added to the meat through the curing process. Meat that is going to be dried should be simmered or baked so it will be safe for consumption when it comes out of the dryer. Drying inhibits bacterial growth, but it does not destroy the organisms that cause disease. There are sources for food dehydrators listed in the Appendix. The following list describes the features you should look for in a food dehydrator:

- Stainless steel construction to increase durability and facilitate cleaning. A key to providing quality dried foods for your family is the ability to keep your machine clean. Plastic food driers may be subject to damage under hard use and may not be as easy to clean.

- The dehydrator you select should have the maximum possible space for everything you want to process in each session.

- The dehydrator you select should allow you to control the removal of moisture from the meat through the airflow. You do not want the meat to become hard and brittle when the drying process is complete, but sufficient moisture must be removed to prevent it from turning rancid. The controls should be easy to understand and operate.

- Select a machine that allows you to remove the shelves to facilitate not only cleaning, but also the placement of your meat or fish product.

- Although a built-in timer is not essential since you can use an external timer, it may be a very convenient option for you.

- It is important to select the correct size dehydrator so that you do not have a machine that is significantly larger than your need, or a machine that is so small it does not handle the amount of meat or fish you wish to dry efficiently.

- Modern technology makes it possible to purchase a machine with built-in programming features to make the process much more efficient.

The types and amount of equipment and supplies needed to cure meat depends completely on how large an operation you desire to have. People just beginning to learn how to cure meat can unnecessarily spend hundreds of dollars initially instead of slowly building up the equipment and supplies they will need. Many households already have plenty of utensils and supplies that can be adapted to use as curing equipment. For example, to cure with salt brine, a large plastic tub will suffice for mixing for the brine to cure the meat product. Meat and fish can be cut to size with kitchen knives that you already possess. Any cooking that will be required can be done in pots and pans that are already in the cupboard. If there is ready availability, the next step up is a large crock or hardwood barrel of sufficient size for the curing project you have in mind.

There are actually two primary methods used to dry cure meats and fish. In the first method, a dry cure compound is rubbed on the meat to start the preservation process. The dry cure compound will include salt, sodium nitrates, and the seasoning you desire to impart a particular flavor to the meat. After the curing compound is rubbed on the surface of the meat, the product is hung in a place that is dry, cool, and free from outside influences. A damp basement will not be a suitable place to hang meat to dry cure. The ideal dry curing temperature is between 38 degrees Fahrenheit to 40 degrees Fahrenheit. The meat hangs for periods of a few weeks to a year or more. The usual curing and drying time using this method is about six months. As the meat hangs, the cure will penetrate the meat at the same time the moisture content of the meat is reduced. When the time comes to bring the meat in, the weight will be reduced due to the loss of moisture. The long curing time will impart an intense flavor to the meat along with a darker coloring. This method is used to produce dry cured hams.

The second dry cure method involves using a container and actually packing the meat in the curing compound. There are a many variations in the methods people use to dry pack or dry cure meat and fish, but the basic principles are all the same. Before the meat is packed in the curing compound, the surface of the meat or fish should be rubbed with it. Regardless of the exact dry pack container you have, make sure it is large enough to hold the meat cuts and the dry pack compound. Place a layer of salt cure compound on the bottom of the curing surface. The curing surface should be supported above the bottom of the curing box since a brine mixture will form below the meat as moisture is drawn out of the meat and mixes with the salt. If a wooden box is used, then holes can be cut in the bottom for the liquid to drain out.

Place the meat on the bottom salt layer and cover the meat completely with the curing mixture. If more than one piece of meat will be cured, be sure they do not touch each other. Meat such as pork cuts, for example, can be stacked as long as there is a layer of salt between each piece of meat. One curing process requires that the procedure for placing the meat in the curing box should be repeated every two days for the first six days the meat is in the cure. In this process, each time the meat is repacked, the salt mixture should be completely changed and the old salt mixture disposed of. Another recipe suggests that the salt pack be changed every 12 hours for the first 24 hours. After a week in the dry cure pack, the meat is removed and can be stored under refrigeration or put through a smoking process. A key point to remember is that the danger zone for meat is between 40 and 140 degrees. Even meat that is thoroughly cured and smoked will not remain edible indefinitely.

A good question at this point would be what type of wood should the box be made of? There is not any particular type of wood that seems to be better for building a dry curing box. The exact design of the box is up to the builder as long as the box has a lid, holes in the bottom, is large enough for the meat and salt pack, and is supported off the ground. People have used old refrigerators, Styrofoam or plastic boxes, or even a burlap bag and hung the dry pack of meat from the rafters in a shed, as long as the temperature was cool enough. If the outside temperature is not cold enough, the meat will need to be hung in a refrigerator. A point to remember is that the salt in the cure will also have a long-term effect on your dry curing box. Salt can have a corrosive effect on metal and can deteriorate wood when in contact for long periods of time. Plastic will not be as adversely affected. It will be important to clean your dry cure box completely of salt when it is not in use.

The following case study provides two plans and should provide ample instruction on how to make both a dry cure cabinet to hang meat in, and how to make a box for packing meat in a dry cure mixture.

Brine Curing

The next process to explain is wet curing in liquid brine solutions. Brine curing of meat or fish is a process in which the product is soaked in a solution of salt for 24 to 48 hours. Brine solutions follow a number of different formulas depending on the type of meat or the length of time the meat is to be kept unrefrigerated. Suitable containers for soaking meat depend on the size of the cut of meat being salted. For small pieces of meat, a kitchen crock will do just fine. If you are going to use a brine solution to salt large quantities of meat, a large plastic tub or barrel that will hold water may be necessary.

Two other important tools for the curing process are a brine pump and a kitchen scale. The brine pump is used to inject the salt brine mixture into larger pieces of meat that may be too large for the salt brine to penetrate into. The kitchen scale is useful to know the weight of the meat product when mixing the salt brine or dry salt pack. Too much or too little salt will have significant impact on the success of the curing project. Several good resources on curing can be found listed in the Appendix.

Simple steps to make jerky:

- Slice meat into strips, cutting with the grain. The strips of meat should be ¼-inch thick. If the meat is slightly frozen, it may be easier to slice.

- To ensure the safety of the product for human consumption, the meat will need to be heated until the internal temperature reaches 160 degrees, either during the time it is soaking in the marinade or after it has been dried.

- If the meat is to be brought to an internal temperature of 160 degrees after it has finished drying, simply set the oven to 275 degrees, place the jerky on a flat baking pan, and heat the meat for about 10 minutes. If the strips are thicker than ¼-inch, it may take a little longer for the meat to reach the necessary internal temperature.

- The meat may be cooked by simmering it in marinade to flavor the meat to personal preference. Recipes are provided throughout the book for the various types of meats that work well as jerky.

- Remove the strips from the cooking liquid and drain. The strips may be placed in a preheated oven or dehydrator at around 170 degrees. Leave the oven door slightly ajar. This allows the moisture being removed from the meat to escape the oven. This process will take several hours. Any type of flavoring preferred can be spread on the jerky as the drying process is begun.

- The meat will shrivel up and turn a darker color as the moisture in the meat is removed.

- Remove the meat from the heat before it becomes too dry and hard to eat. The meat should be checked for tenderness after the first three hours of drying. The amount of time it will take to dry depends on the thickness of the strips and the type of meat that is being dried.

- Wipe off any remaining fat that has come to the surface.

- Jerky can be stored up to two months if dried properly, but will stay usable much longer if placed in a freezer bag and frozen. If jerky is kept in a refrigerator, or even frozen, it can be stored for up to a year.

Use your imagination when smoking meat and jerky. Any flavor combination can be added to the meat or fish. A fun way to experiment would be to try a variety of meat and fish. Simply look at all the different types of lean meat and fish that are covered in this book, and try something new and different. Using the kitchen oven the way it was described above may be a bit too expensive of a way to make jerky, as it will add significantly to your utility bill if you are going to prepare large amounts of meat. If you plan to get serious about making jerky, purchasing a good dehydrator would be a good investment. Dehydrators remove the moisture from food to preserve the product for storage and use at a later time. Removing moisture aids in inhibiting the growth of bacteria that can cause the food to spoil. Dehydrators have a heating element, a fan to circulate the air around the meat, and trays to lay the food on. To be successful, the drying process must bring the moisture content of the food product down to 15 percent or less. Food dehydrators are a very economical method for drying foods. There is a good commercial resource for dehydrators listed in the Appendix.

Smokers and Smoking Supplies

Smoking meat and fish may be the most popular way to preserve meat products. Smoked meat products come in a wide variety of styles and flavors. Many of the meat preparation procedures discussed already may also be considered preliminary steps to getting meat ready for the smoker. Smokers come in as many forms as there are people who use them. The common elements of a good smoker are a way to burn wood to make smoke, a chamber to hang the meat and expose the product to the smoke, a way to control the air flow, and a way to control the heat the meat is exposed to. The simplest homemade smoker can be made from a large metal garbage can, or you can create much more elaborate smokehouses made of brick. There are many commercially manufactured smokers available that use propane or electricity to produce heat to get the wood chips hot enough to make smoke.

With a little creativity, most people can find most of the necessary parts for a great smoker in the garage or lying around in the backyard. Some items that could be used in a smoker are racks to either hang or lay the meat on, pipe to transfer the smoke from the firebox to the smokehouse, or vents that could be used in the air flow system in the smokehouse. Here are a few ideas to start your creative juices flowing. Maybe you will have most of the necessary ingredients right in your backyard to build a wonderful smoker. The following list gives some ideas.

Smoker ideas

- The box could be made from an old shed.

- The box could be made from an old refrigerator.

- The box could be made from a clean 55-gallon drum.

- An important thing to think about will be temperature control. When cold smoking, the temperature must not get above 100 degrees, and when hot smoking, the temperature must bring the meat to a high enough temperature to cook it, usually 160 degrees.

- If an old refrigerator is used, the door needs to be secured so children and curious people are not able to get in and disrupt the controlled temperature. Also, dirt and moisture need to stay out.

- Other ideas include cutting a 55-gallon drum in half and using it to build a horizontal smoker, or you could go out and purchase a new commercially made smoker system. There are some commercial smoker resources listed in the Appendix.

If you are not a person who can build a smoker, there are many commercially manufactured smokers on the market that will do a wonderful job. Smokers can be purchased in any size and within any budget constraints you have.

The other major concern is the type and availability of wood. Depending on locality, quality wood can become expensive. Places to look for scrap wood are carpenter shops, sawmills, lumberyards, and a firewood business that cuts hardwoods. Some practice will be required to find the correct balance between a hot-burning fire and being able to hold down the flame to make smoke. Good hot coals from hardwood may be made to smolder and smoke for a long time with a little practice. A good example is the modern wood-burning stove people use to heat their homes. By controlling the air that enters the firebox, a well-built-up bank of wood and coals can be made to produce heat all night long. The quality of the smoke produced has a direct relationship to the quality of smoked meat that comes out of the smoker at the end of the day.

Other pieces of equipment that will be needed are cooking utensils such as knives, spatulas, pots, and pans. Also, the meat will need to be refrigerated once the meat is through being smoked. A meat thermometer is also a very important tool to have. The length of time meat or fish should be left in the smoker will depend on the recipe, size of meat cuts, and how strong the desired smoke flavoring is expected to be. The following charts will provide some time and temperature specifications for hot smoking and cold smoking meat, fish, and game.

Sample hot smoking chart

|

Type of Meat |

Temp during Smoking |

Time to Expose to Smoke |

Completed Temp |

|

Brisket, sliced |

225° F |

1.5 hr/lb |

180° F |

|

Brisket, pulled |

225° F |

1.5 hr/lb |

195° F |

|

Beef Ribs |

225° F |

3 hr |

175° F |

|

Pork Butt, sliced |

225° F |

1.5 hr/lb |

175° F |

|

Pork Butt, pulled |

225° F |

1.5 hr/lb |

190 to 205° F |

|

Breakfast Sausage |

230° F |

3 hr |

160° F |

|

Spare Ribs |

225 to 240° F |

6 hr |

172° F |

|

Whole Chicken |

250° F |

4 hr |

167° F |

|

Chicken Thighs |

250° F |

1.5 hr |

167° F |

|

Chicken Quarters |

250° F |

3 hr |

167° F |

|

Whole Turkey 12 lb |

240° F |

5 to 6 hr |

170° F |

|

Turkey leg |

250° F |

4 hr |

165° F |

|

Turkey Wings |

225° F |

2.5 hr |

165° F |

|

Whole Duck |

225 to 250°F |

3 to 4 hr |

170° F |

|

Pheasant |

200° F |

2.5 to 3 hr |

170° F |

|

Rabbit, 3.5 lb |

200° F |

3.5 to 4 hr |

160° F |

|

Venison Roast |

200 to 225° F |

1 to 1.5 hr |

160° F |

|

Catfish |

225 to 250° F |

2 to 3 hr |

Until Done |

Cold smoking tips

1. The ideal cold smoking temperature is 70 degrees Fahrenheit to 80 degrees Fahrenheit.

2. The temperature in a cold smoking chamber should never be allowed to exceed 90 degrees Fahrenheit to 100 degrees Fahrenheit.

3. The best time to cold smoke meat and fish is during the cooler months so that the temperature around the cold smoker is not above 70 degrees Fahrenheit.

4. If the humidity is low, the smoking process will become more of a drying process than a smoking process. Ideally, you should smoke meat and fish when the humidity is around 70 percent.

5. Safe smoking depends on how strong of a curing formula the meat and fish were exposed to. If the meat only received a light cure, then the smoking time must be limited to a few hours to prevent spoilage. If the meat or fish received a heavy brining, then the smoking process can continue for a few days to a few weeks. The concern is the growth of bacteria, since cold smoking does not bring the meat to a safe cooking temperature. If you desire a deep smoked flavor that comes from extended time in the smoker, then the meat or fish must be exposed to a heavy brine mixture prior to smoking.

6. At the conclusion of the smoking process, if the product will not be cooked immediately, it must be refrigerated.

Measurements to Help Make Quantity Adjustment in Recipes

Since many of the recipes in this book may be for quantities that are too large for you to conveniently use, this chart will help you to figure out how to reduce — or even increase — a recipe. Always remember the basics of required cooking temperatures; pressure canning times and pressure settings cannot be reduced. Some herbs and seasonings can change the flavor of a recipe very dramatically, so be careful when adding large quantities of herbs and seasonings.

Tables for Converting Ingredient Weights and Equivalent Measures

The information for this chart provided courtesy of North Dakota State University Extension and Julie Garden-Robinson.

Equivalent Measurements

|

4 cups = 1 quart |

2 pints = 1 quart |

16 ounces = 1 pint |

|

2 cups = 1 pint |

2 cups = 16 fluid ounces |

16 tablespoons = 1 cup |

|

8 liquid ounces = 1 cup |

4 tablespoons = 1/4 cup |

1/4 cup = 2 liquid ounces |

|

1 liquid ounce = 2 tablespoons |

3 teaspoons = 1 tablespoon |

1 pound salt = 1-1/2 cups |

|

1 pound sugar = 2-1/4 cups |

1 ounce cure = 1-1/2 tablespoons |

1 ounce MSG = 2-1/5 tablespoons |

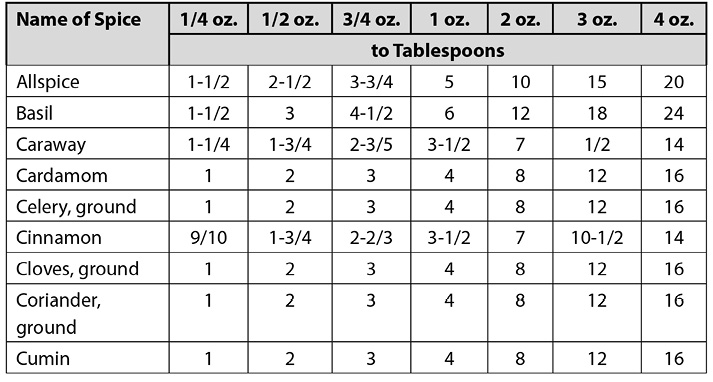

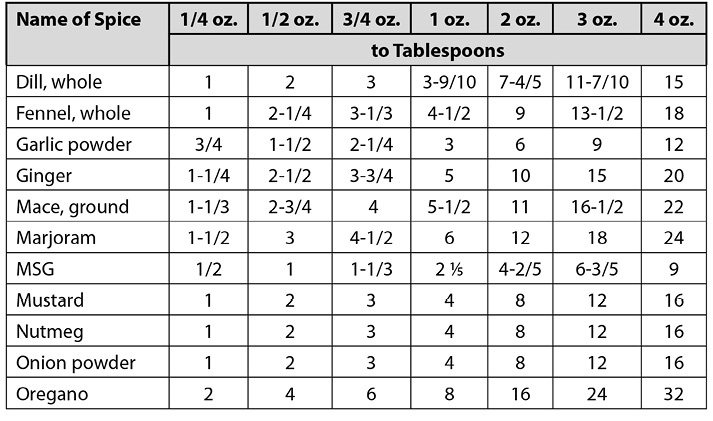

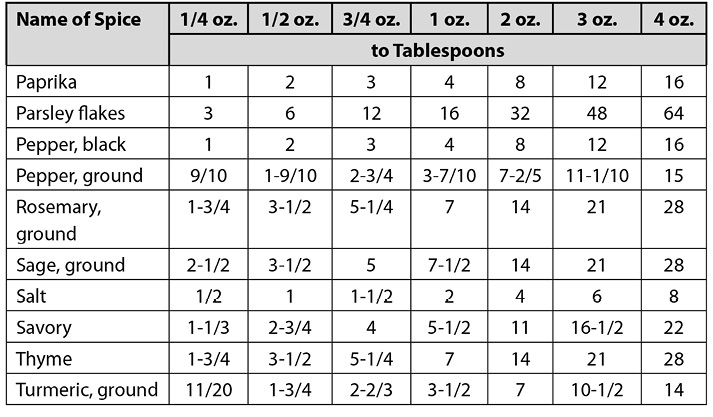

Approximate weights and measures of various spices

Conversion from ounces to tablespoons

Elevation, Time, and Pressure Canning Pressure Adjustments

David Blackburn has a very useful Web site on canning food, which includes a chart for adjusting canning cooking time and pressure adjustment for elevation. Blackburn allowed this chart from the Web site to be included in this book.

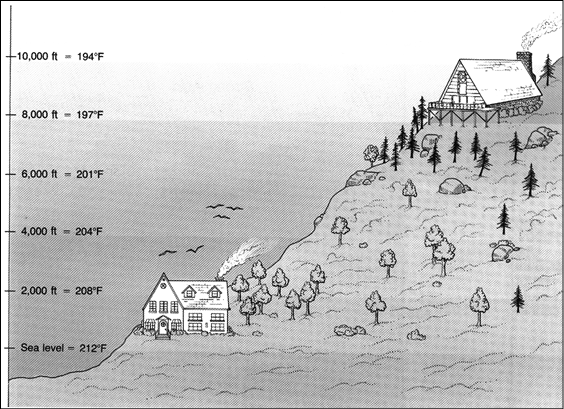

Water boils when its vapor pressure exceeds the atmospheric pressure, which reduces as the altitude increases. Water will boil and maintain a lower temperature at higher altitudes than at sea level. These lower boiling point temperatures increase the cooking times for any food, they increase the processing time for canning in a water bath, and they increase the pressure required to process in a pressure canner.

The temperatures and processing times that are listed in this chart are for elevations of sea level up to 1,000 feet. These adjustments should be made to ensure that your meat products are processed at a safe temperature and pressure for the elevation you live at.

BOILING WATER TEMPERATURE CHART IN FAHRENHEIT

|

Sea Level |

1,000 ft. |

3,000 ft. |

6,000 ft. |

8,000 ft. |

|

212° |

210.1° |

206.3° |

200.6° |

196.8° |

(Reflects a 1.9° reduction for each 1,000 foot elevation increase)

WATER BATH CANNER PROCESSING TIMES IN MINUTES

|

Sea Level |

1,000 ft. |

3,000 ft. |

6,000 ft. |

8,000 ft. |

|

5 |

10 |

15 |

20 |

25 |

|

10 |

15 |

20 |

25 |

30 |

|

15 |

20 |

25 |

30 |

35 |

|

30 |

35 |

40 |

45 |

50 |

|

45 |

50 |

55 |

60 |

65 |

|

60 |

65 |

70 |

75 |

80 |

|

75 |

80 |

85 |

90 |

95 |

|

90 |

95 |

100 |

110 |

120 |

ADJUSTMENT FOR PRESSURE CANNER, DIAL GAUGE

|

Sea Level |

1,000 ft. |

3,000 ft. |

6,000 ft. |

8,000 ft. |

|

5 lbs. |

6 lbs. |

7 lbs. |

8 lbs. |

9 lbs. |

|

10 lbs. |

11.5 lbs. |

13 lbs. |

14 lbs. |

15 lbs. |

ADJUSTMENT FOR PRESSURE CANNER, WEIGHTED GAUGE

|

Sea Level |

1,000 ft. |

3,000 ft. |

6,000 ft. |

8,000 ft. |

|

5 lbs. |

10 lbs. |

10 lbs. |

10 lbs. |

10 lbs. |

|

11 lbs. |

15 lbs. |

15 lbs. |

15 lbs. |

15 lbs. |

Processing times remain unchanged

Be sure to research your altitude above sea level. Your local extension office should be able to tell your specifics about your area. Image courtesy of the USDA.