![]()

Chapter 11: Purchasing

there are number of purposes for the food laws in the United States including: to monitor nutritional food used, to maintain and design proper procedures, to protect quality and quantity of basic foods, to keep producers, processors, and distributors honest and to offer informative and accurate labeling for consumers.

Steps in the procurement process

What are the steps in the food service procurement process? We will discuss each element in more detail, but this list will provide an overview.

Assessing Your Needs

• Determine menu items to be served.

• Use standardized recipes to guarantee consistent items.

• Use input from evaluation team.

• Gather input and feedback from your staff.

Project Sales Figures

• What are the purchasing methods to be used?

• What is the size of the facility?

• What is your purchasing volume?

• How often do you need deliveries?

• Where are your potential vendors located?

• How much storage space is available?

• How many staff members do you have and what are their skills?

Vendor List

• Who is your primary vendor?

• Who will supply other items your primary vendor does not offer?

• Determine and maintain your inventory system.

• Which items can be “just in time” items?

• Establish your perpetual inventory.

• Monitor your physical inventory.

• What is the dollar value of your inventory?

• How often will items be delivered?

Order Quantities

• Project menu items and quantities.

• Determine standardized portions.

• Which supplies will be needed?

• What food items do you have in stock?

Bids and Prices

• Establish food item specifications.

• Find best prices, quality, and service for each item.

Placing Orders

• Price.

• Quantity.

• Method to pay.

• Submit orders to appropriate people and places.

Receive Food and Supplies

• Receive the minimum number of orders.

• Verify delivery is accurate.

• Handle any returns or problems.

Store Orders

• Store food using appropriate methods for each type of food.

Issue Items

Let us start with purchasing and receiving. Purchasing is how food service managers obtain wholesome, safe ingredients for their menu items and the additional supplies needed for the operation of the restaurant. To satisfy your customers and offer a quality product, the items need to be available when needed. Quality depends on the standards in place. To maintain costs, these items need to be purchased at the lowest possible prices while still maintaining acceptable quality. Here are some considerations:

• Vendors are responsible for the safety of their food. You must choose vendors carefully.

• Federal and state governments monitor your suppliers to see that they use the HAACP system and train all employees in safe sanitation practices. HAACP will be discussed in full detail in Chapter 16.

• Delivery Trucks. Trucks used by vendors should have sufficient refrigeration and freezer capabilities. Food items should be packaged in leak proof, durable packaging. These quality standards should be stated in your purchase agreement with the vendor. You can also ask to see their most recent health and sanitation reports. Let the vendor know that you will inspect the cleanliness of their trucks periodically. It is much easier to make your position clear in the beginning instead of waiting until there are problems.

• Delivery Schedule. Quality vendors will work with you concerning deliveries and are usually willing to adjust their schedule around your busy times.

• Inventory System. You must have a good inventory system in place. I will discuss inventory procedures in Chapter 12 along with storage practices. The amount of food you need is based on sales history, sales projections, and your proposed menus. It is impossible to place an accurate and effective order before you inventory your items on hand. Have your menus in place before you make your order. A delivery “cushion” is important so that you do not run out of food and supplies before your next delivery. Over time and after reviewing the sales histories, you can determine a reasonable “cushion” without food expiring before it can be used. Any surplus will also tie up cash flow unnecessarily. After your purchasing is established, you can simply print a copy of your order list and fill in the blanks. Your order forms can include supplier names, prices, and unit sizes for each item, for example.

PURCHASING OR ORDERING?

Is there a difference between purchasing and ordering? Purchasing includes establishing policies to cover any possible measure or description of items being bought. After these parameters are determined, your individual orders will be simplified. The facility management negotiates terms and prices with the proposed distributors. Here are the basics of your purchasing program that need to be established:

• Purchasing Program. Your purchasing program includes what you will buy and which vendor you will use to provide the best quality for the best prices. To create an efficient purchasing program, you need standard purchase specifications based on your standardized recipes, standardized recipe yields, and portion controls. Each of these considerations will enable you to have accurate costs based on the portions served in the facility. The amounts you purchase need to be accurate. When you order too much, portioning suffers and you have excess spoilage, waste, and theft. Purchasing too little will raise your food costs as you may need to make costly substitutions.

• Procedures. Your procedures should include written specifications for each product that you buy from reliable and honest vendors.

Each of these elements is necessary to ensure a certain level of quality and standardization for your customers. A good purchasing program does these three things:

1. Allows you to acquire the items you need at the agreed upon prices.

2. Exercises control over your inventory and costs.

3. Determines procedures to guarantee the quality at the best prices.

You need to decide whether you will do the purchasing yourself or if it will be assigned to another team member. The prices must be kept up-to-date. Prices change frequently and you need the current prices to project and maintain food costs accurately.

It is a good idea to check prices with various vendors periodically. Some vendors will offer lower prices for a short time, but over time they are more expensive. If you find another vendor with lower prices, you can offer your current vendor a chance to give you an updated price quote.

ORDERING TIPS

It is impossible to place orders effectively until you understand the items in your inventory list. You need to be familiar with each item and inventory counts need to be established. Par levels and projected sales amounts need to be determined. It makes it much easier to compile an accurate order. You need to:

• Create a list of specific items needed.

• Create a vendor contact list.

• Add prices of items on your inventory list.

• Determine a simpler way to place your orders.

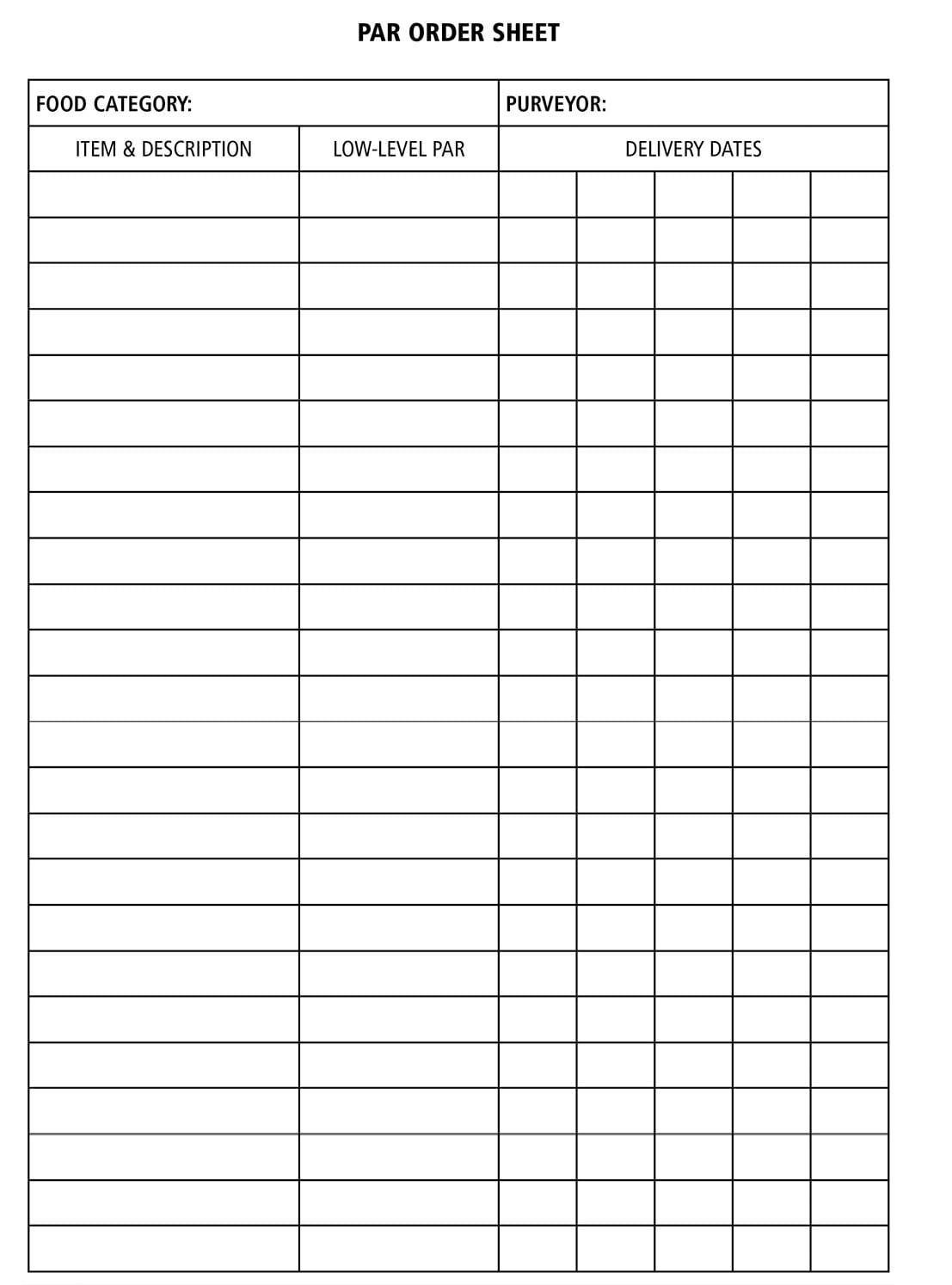

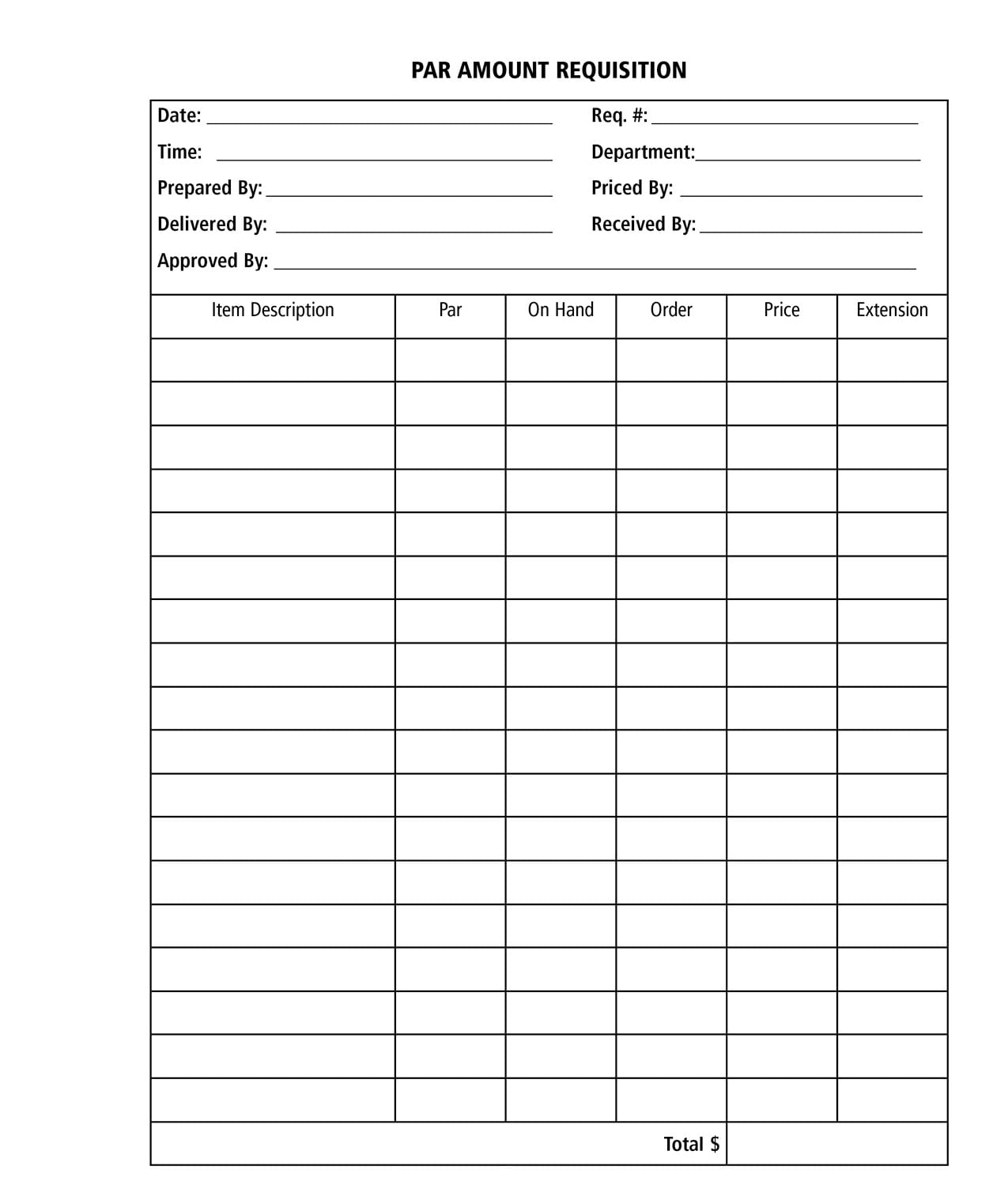

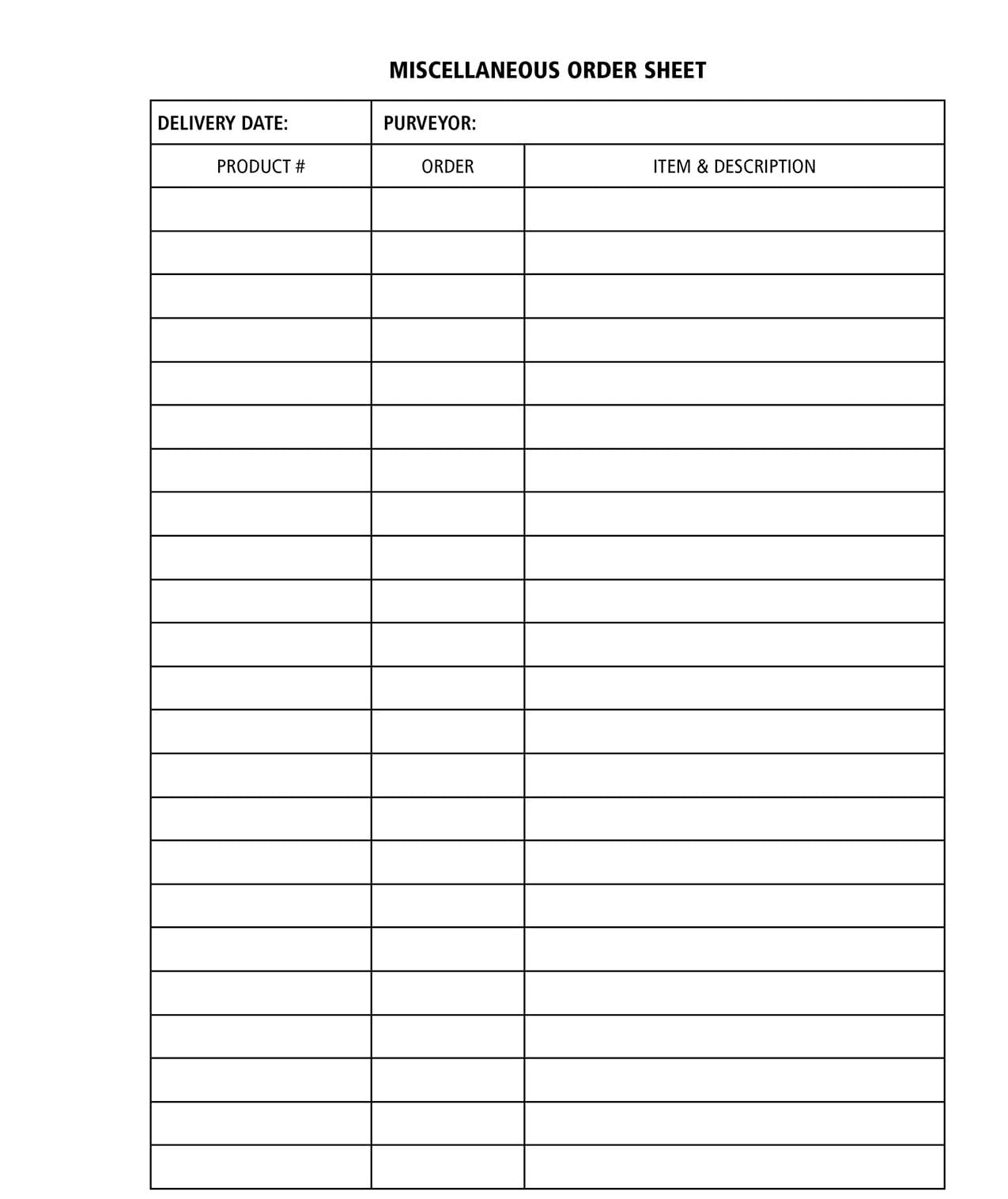

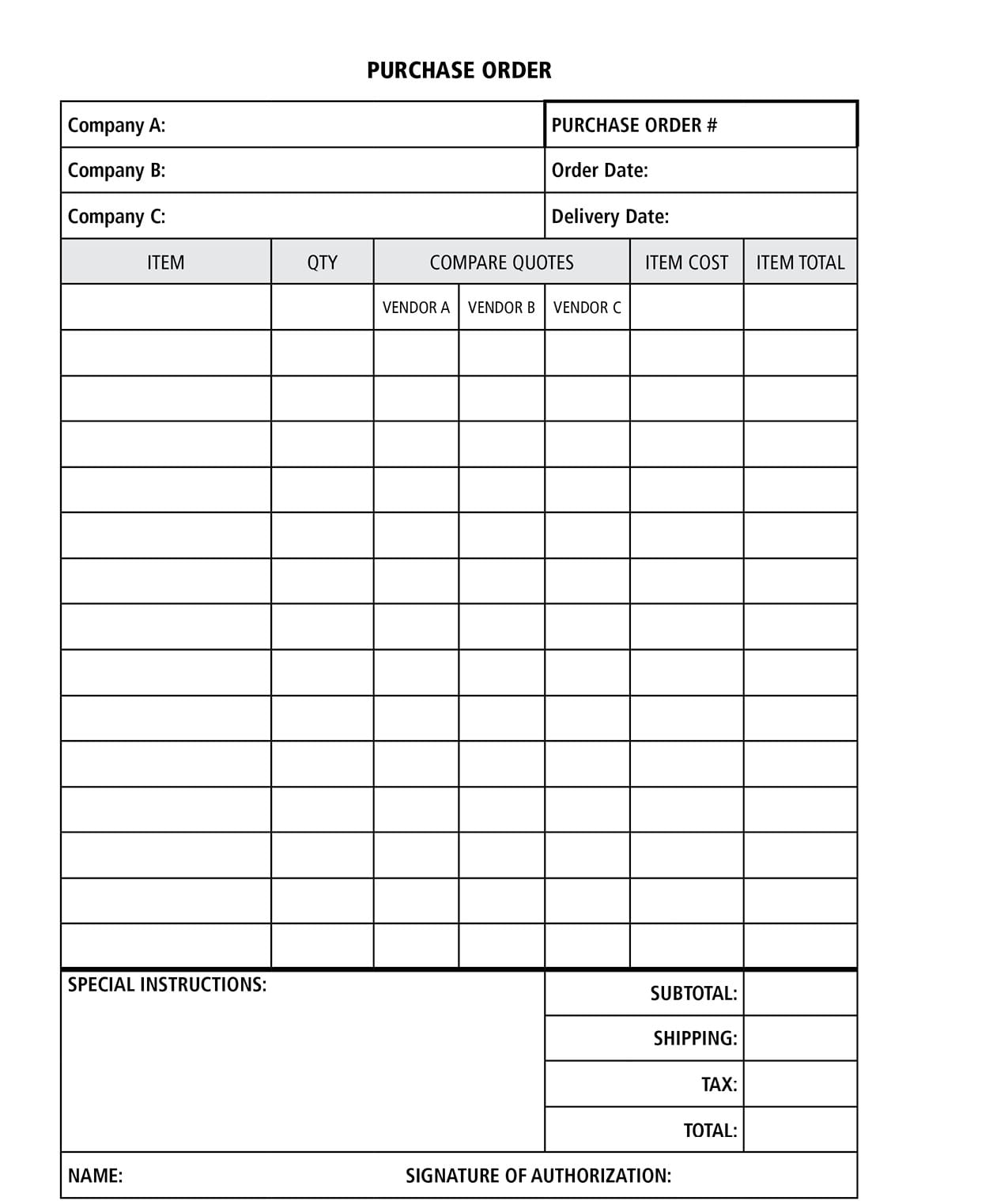

After you determine par levels, the Par Order Sheet or Par Amount Requisition may be helpful. It will enable you to identify quickly where your inventory is short and help you create an accurate food order. Or if you prefer to keep track of items more closely, the Daily Inventory Order Sheet and Miscellaneous Order Sheet may be more helpful. You can find examples of these forms at the end of this chapter.

Several things need to be kept in mind when you place orders. Consider each of these factors before you complete your order and inventory.

• Inventory Amount. Over-stocking means you have additional items to count and less control of the items in your inventory.

• Perishables. Meat, produce, and seafood have a shelf life of two or three days. Keep your orders tight when the shelf life is that short.

• Tie Up Cash. When you order too much, money is tied up.

• Food Usage Controls. It is human nature to serve greater portions when there is too much food available. It seems easier to control usage when you have less food available.

• Turnover. Your inventory should be turned over every five to eight days. There may be some unusual items that will not be used that quickly, but that time frame should work.

• Vendors. All managers need to meet with their vendor sales reps from time to time. Schedule these meetings for a time that suits you.

• Standing Orders. Many times you can place a “standing order,” especially when your sales are consistent. There were times when I had a standing order and made slight adjustments to accommodate special events.

• Primary Vendor. You will save additional work if you can use one primary vendor for most of the items you purchase. You will have fewer interruptions, deliveries, orders to place, possibilities of mistakes, invoices to handle, and no sales representatives to bother you. Being a larger customer will help you receive better service.

• Trade Magazines and Websites. You may find rebates from specific manufacturers. You can also check www.foodbuy.com for more information.

• Food Buying Groups. One of these groups can be found at www.foodservice.com. They offer you pre-negotiated prices on over 10,000 food and food related items from over 125 suppliers. Some of the familiar companies involved include: Ecolab, General Mills, Sara Lee, and Sweetheart.

• Buying Clubs. There are many warehouse buying clubs. Some of the most common include Sam’s Club www.samsclub.com, Costco www.costco.com, and Restaurant Depot www.restaurantdepot.com.

• Cash. Many vendors offer a small discount for early payments usually made within ten days or by the tenth of the month. Two percent may not seem like much, but if you purchase $500,000 a year, you will save $10,000.

• Fresh versus Canned. Take a close look at your recipes and see whether you can use canned fruits and vegetables instead of fresh. If you can make the substitution, you will save money. Remember to remove the word “fresh” from your menu if you used canned items.

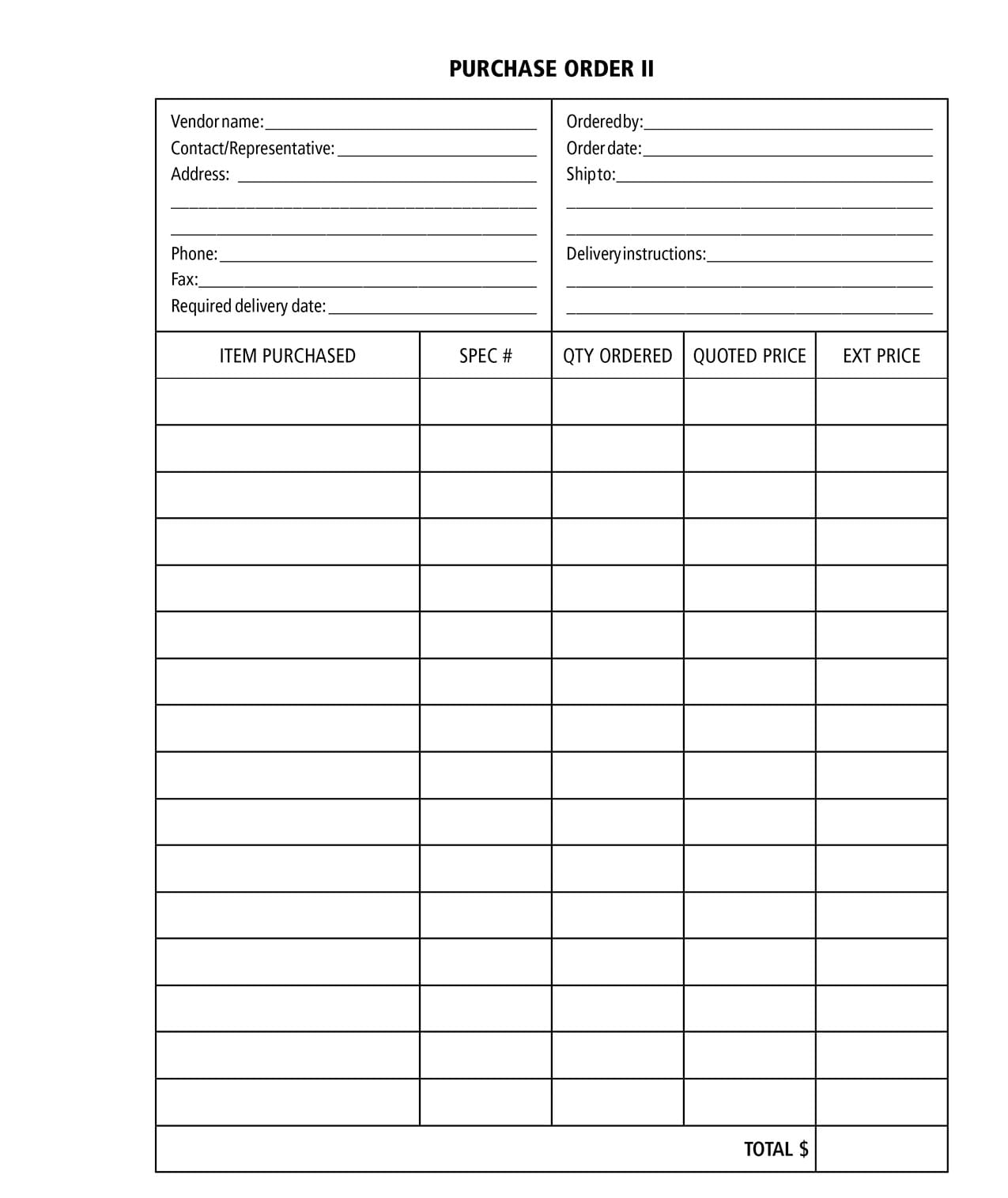

These forms are beneficial if you prepare your order manually. There are several choices to allow you to find the one that works best for your facility. Sample purchase orders can be found at the end of this chapter.

ESTABLISH SPECIFICATIONS

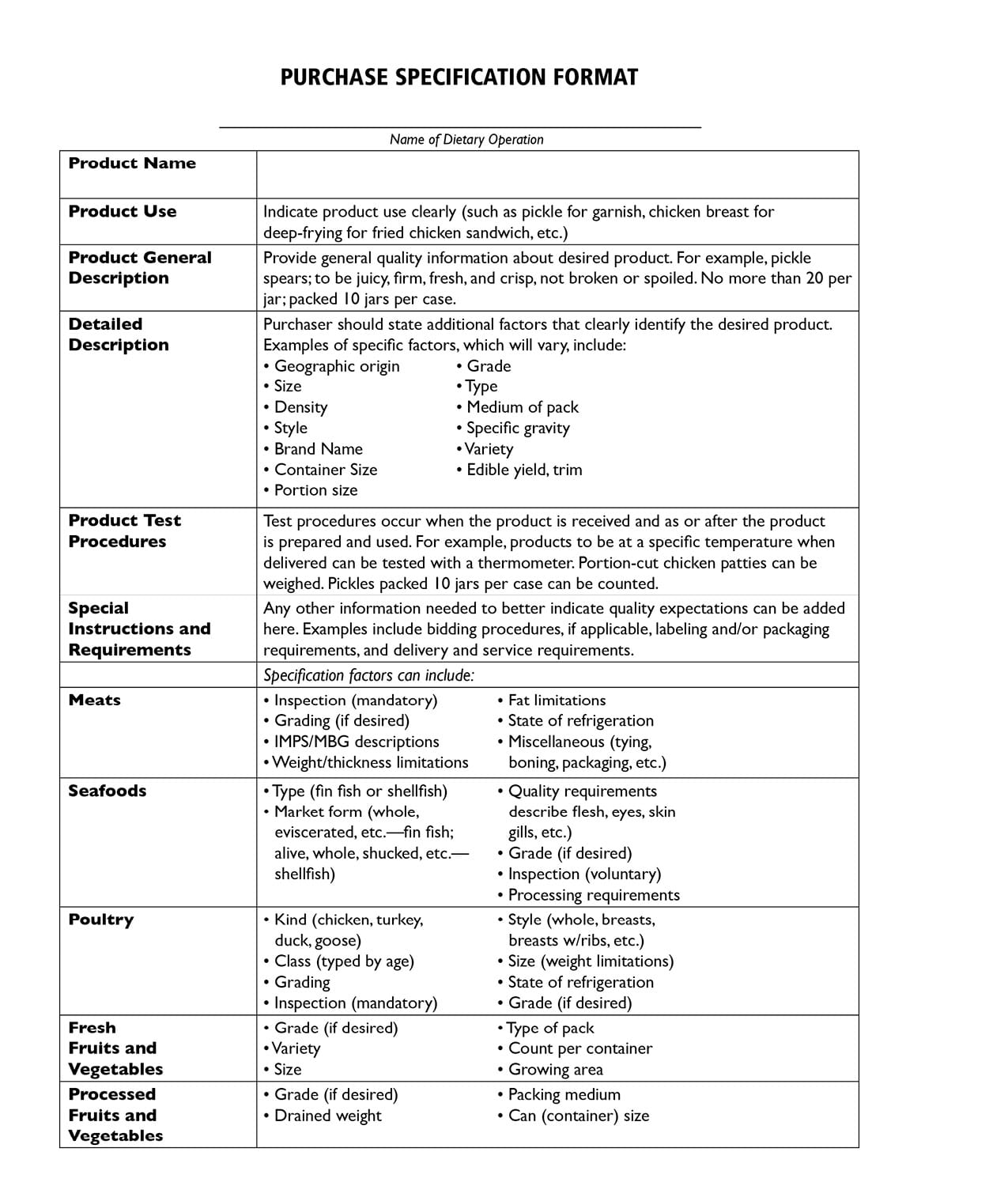

Creating purchasing specifications enables you to control the number and quality of items you purchase and to maintain consistency in the products you order. Consistency makes it easier when more than one person places orders.

Purchasing Specifications

These indicate the amount and quality of the items you purchase. They include:

• Product name.

• Quantity to be ordered – establish unit size.

• “Brand” or “grade” of the item if applicable.

• Find what unit was used to establish prices.

Here is some of the additional information you need:

• Meats must be inspected by the USDA or another agency. The federal or state inspection stamp should be on the packaging.

• Eggs are assigned a grade by the USDA. If you use frozen or dried eggs, they should be pasteurized.

• The FDA has a list of Certified Shellfish Shippers for all your shellfish orders. The supplier must have control tags available for live shellfish.

• Record everything. Your record sheet needs to be available for your employees to ensure they are ordering the correct items. You can also maintain the correct costs by using a record sheet.

Some people refer to specifications as the “heart of purchasing.” When they are written, keep them short and simple. Anyone who reads them needs to be able to understand them. There are three main types of specifications: internal, external, and general.

Internal menu specifications name the item, provide portion sizes, cooking instructions, a serving image or photo, handling information, and possibly cost information. These specs give employees all the information they need to prepare, cook, and serve a satisfactory menu item. Most importantly, they aid in maintaining control over the product.

External pertains to the menu items but includes vendor specifics, details that enable the vendor to give accurate quotes on the right products for your facility. It is a good idea to make a permanent record of these item specifications for your vendors. You need not repeat these details every time you place an order because they should be in the vendor’s file for your facility. Should any of your specifications change give the vendor verbal or written notification.

General includes delivery and food specifications included in purchasing for your facility such as delivery times, delivery practices and procedures, billing and payment, price quotes, and food specifications – brand, quality, grade, and similar details. Here are some of the ways that specifications are beneficial:

• Costs are lower.

• Quality is better.

• You have a written record of your orders.

• You save time.

• Verification of orders is simplified.

• You have more control.

• You have more consistent customer satisfaction.

• There should be fewer stock-outs (running out of items between deliveries).

• Trained employees can make decisions about delivery problems.

• You can negotiate for competitive prices and services.

• Misunderstandings between you and your vendors are fewer.

• Purchasing is organized.

Usually managers write these specifications, but it does not hurt to get input from others in the facility. The specifications will have an impact on everyone in the department, so ask for their feedback. You never know where a valuable idea will originate.

Other non-commercial food service managers could offer some great insights into which specifications to use. It would be helpful to see their lists, but these should only be used as a guide. Do not just copy them. No two facilities have the same needs and you need to customize your list to provide the best specifications for your facility.

As you work on the specifications, write down any ideas that come to mind and go back later to fine tune them. Some businesses choose to have an outsider write their specifications, but if you do, be sure the person has sufficient knowledge of your operation to make the specifications as beneficial as possible. When an outside person or company writes your specifications, they should be reviewed by you or someone else in the facility before they are finalized.

I have included some sample specifications at the end of this chapter to give you an idea of the information that should be included.

EVALUATE AND CHOOSE YOUR VENDORS

Your suppliers can make or break you. When you have trustworthy, timely suppliers, you can run a smooth operation and satisfy your customers. To select a vendor, consider cost, delivery, problem handling, promptness, quality, selection of products, and other services particular to your facility. There are four basic types of suppliers:

1. Full line suppliers

2. Local specialty wholesaler

3. National jobber

4. Supermarkets

Let us look at the advantages of these types of suppliers to help you determine what kind of suppliers you need.

Full Line Suppliers are also called one-stop or diversified suppliers. They handle large inventories and usually supply everything you need. If you can find one supplier for most of your needs, ordering and receiving will be simplified. They may offer fresh vegetables and fruits, frozen food, meat, fish, poultry, paper supplies, equipment, and chemicals, for example. Such a wide selection can save you time, paperwork, and money because one large delivery instead of several smaller orders costs less for delivery.

Local Specialty Wholesalers are suppliers who carry a limited selection, but their prices are often lower. They may carry only limited selections, but if they carry what you need at a better price, you should consider them a potential supplier.

National Jobbers will be especially useful for large operations, such as the military, school districts, and other similar operations. Some of these only sell full lot amounts while others sell only broken lots.

Supermarkets are better suited for small operations or the occasions when you run out of food. A small operation might not be able to attract the attention of larger suppliers. In this case the non-commercial food service facility may have to work with local grocery stores. If you have this problem, offer to pick up your orders from a supplier if you have suitable transportation.

When you evaluate suppliers, look for these characteristics: quality service and products and the best price. Each of these elements is important and you should consider each one individually and then make a decision based on all three plus the fact that suppliers offer many services for their customers beyond their products.

When you talk to potential suppliers, one of their most important qualities is dependability, including the time they deliver your supplies and the kind of supplies they offer. When your supplier does not have a set delivery time or schedule you will have untold problems and potential dissatisfaction from your customers. Some delivery methods are easier for you to process.

One consideration is the delay between the time you place your order and the time it is delivered to your door. What is their policy on billing and returns? Do they have the ability to provide the supplies you need? Do they have friendly, knowledgeable sales representatives who can answer your questions and make helpful suggestions? Consider which supplier will form a positive long-term relationship with you.

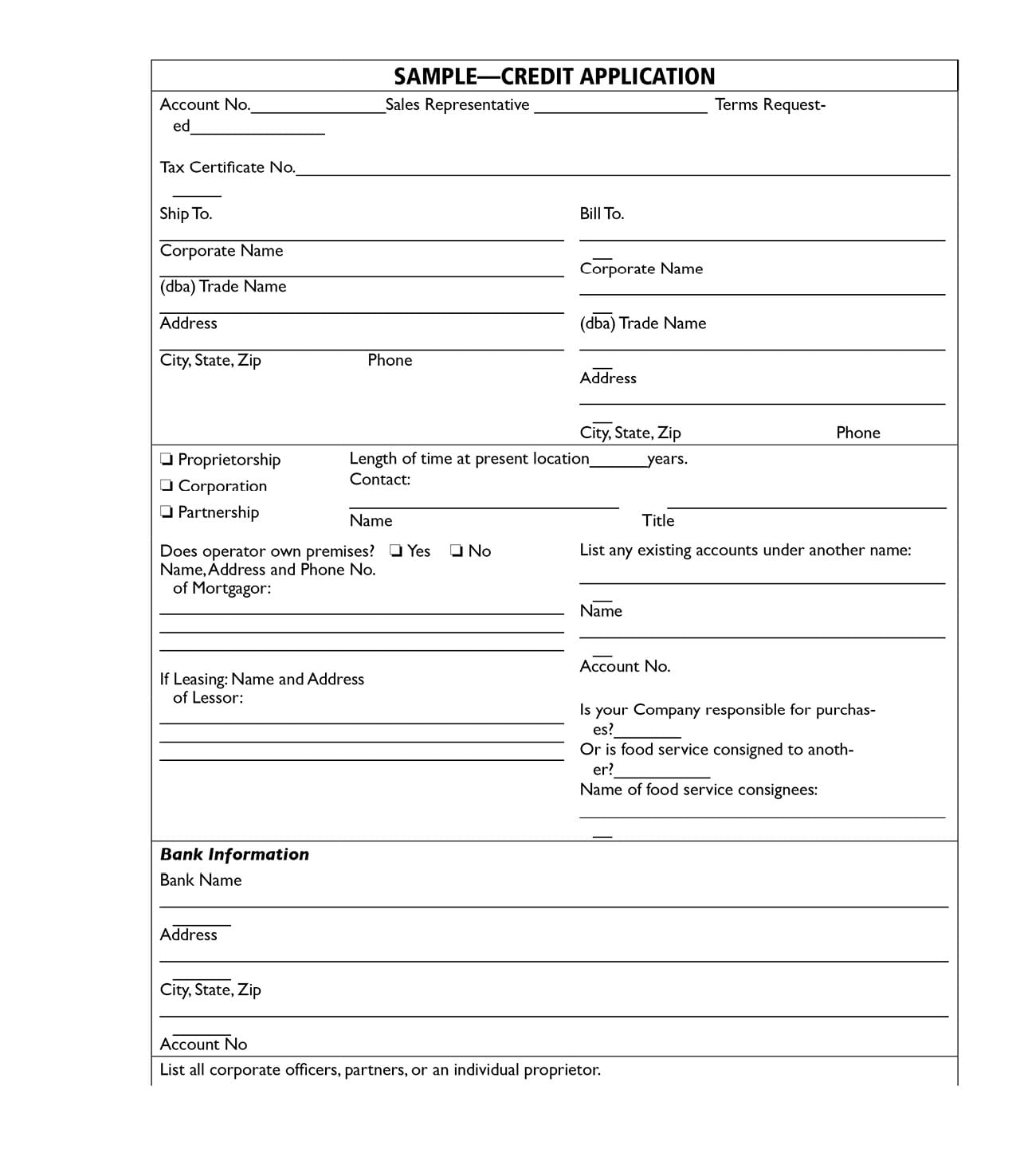

CREDIT

Not all vendors are willing to extend credit to their accounts, especially new ones. Paying for merchandise later can be risky business for them; therefore, they will require the facility to complete a credit application before they decide whether to extend credit.

Facilities need to create and maintain a good credit rating. A better rating will help you obtain favorable credit terms for a better overall relationship with your suppliers. When you have a good credit record with the supplier, they are more likely to work with you when money is short and you need to make payment arrangements. Be friendly with the credit managers and keep them informed of any problems or situations that develop. A copy of the sample credit application can be found at the end of this chapter.

PRODUCT QUALITY

It is important to offer a quality product to increase customer satisfaction. When determining the quality and items needed, start by listing the choices of menu items to be prepared such as fresh tomato sauce versus fresh sliced tomatoes. Quality could vary between these two items. In short, you need the right ingredients to make the right menu product.

The rule of thumb is that you do not always go with the lowest price. Instead, consider the quality of the product and the menu item to be prepared, as well as the price. These three factors determine what to purchase.

PRICE

First-time decision makers may emphasize price and end up spending more money but not getting the best results. When considering price, also consider how many hands these items pass through. When you buy from a retailer, they purchase from a wholesaler and they purchase from another supplier. By the time it gets to you, several separate businesses have been paid. Can you work with companies that cut out the middle man?

Some facilities have few vendors to choose from because of their location or they must get supplies from a central commissary. In these situations, look at the overall picture and not just the price.

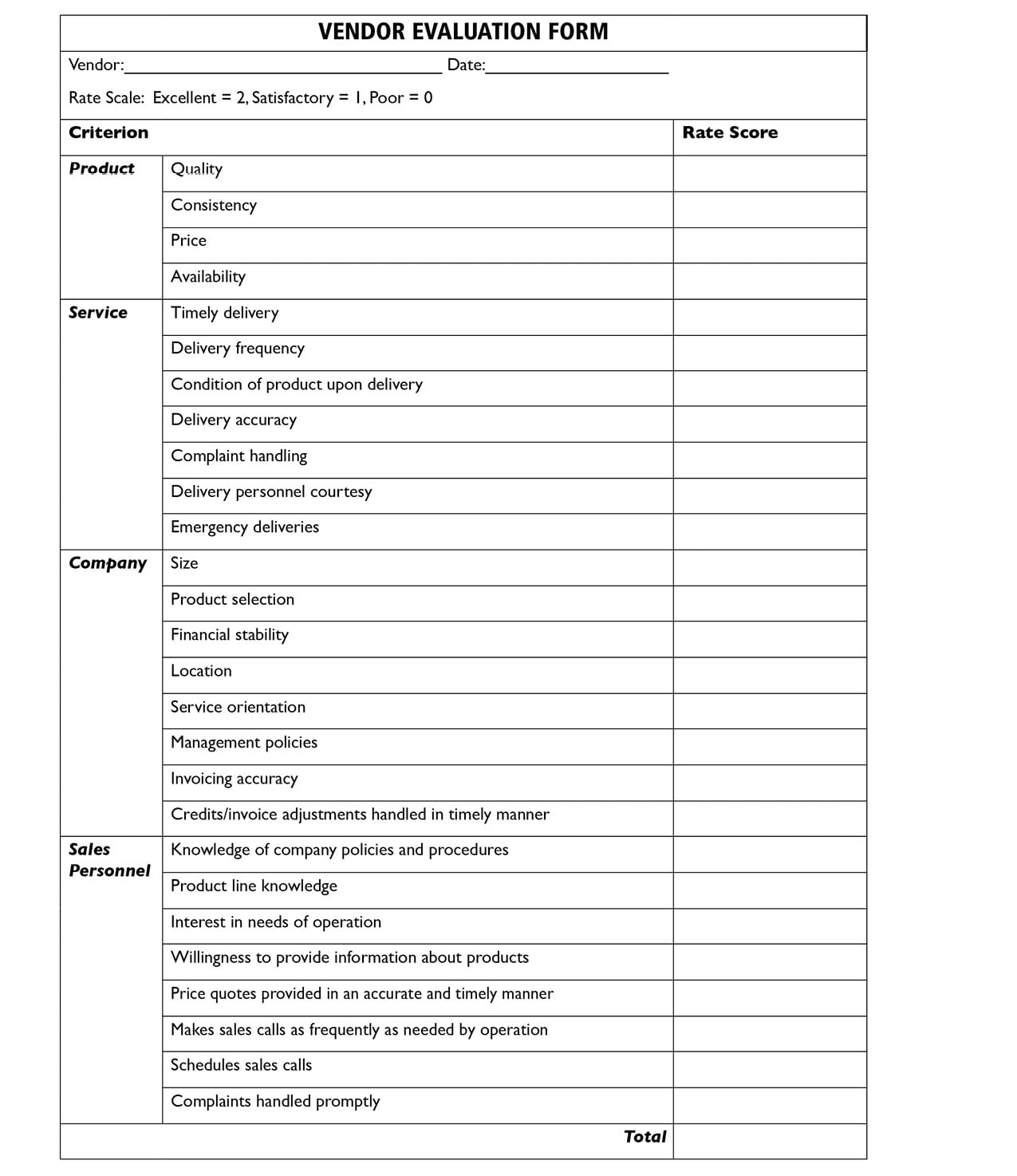

There are some managers who like to visit the supplier’s facility to see how they are set up and to inspect cleanliness and sanitation practices. It is a good idea to check whether their trucks are refrigerated and in good working condition. Some may offer service, quality, and good prices, but an unsanitary facility might eliminate them from consideration. After you have made a list of vendors, you can use a Vendor Evaluation Form to determine which will be the best for your facility. This form is shown at the end of this chapter.

DEALING WITH SUPPLIERS

The way you deal with suppliers can make a big difference in your job. You want to establish and maintain a good relationship with vendors and sales representatives. Here are some tips:

• Take the time to get to know the delivery driver and the person who takes your order. Do not take this person for granted as he plays an important role in your success. It is also good to ask for the same person each time to help you establish a good working relationship.

• Sometimes the vendor may have an overstocked item. You can help them liquidate the inventory and negotiate a good price for your facility.

• If you use the same items each week, the vendor might give you a small discount.

• Does your vendor have a website? It can save you time and some sites even provide industry information that might be helpful. An example would be: www.sysco.com.

• Keep an eye on prices. Do you take time each month to check on prices with other vendors? When you find someone offering your items at a lower price, you can try to negotiate lower prices with your vendor.

THE CHANGING FACE OF DISTRIBUTORS

Distributors are expanding the products and services they offer to food service facilities. At one time they offered only food products, but now offer supplies and equipment, including recycled packaging for the good of the environment. Their additional services may include:

• Computerized services for clients.

• Information about new products, such as nutrition and food costs.

• Instruction, development, merchandising, and marketing services.

• Consultation services regarding design, layout, and equipment.

• Coordinating recycling efforts.

• Discounts for early invoice payment.

• Quantity purchasing discounts.

• Coupons and rebates for their customers.

These are some of the ways today’s food service distributors strive to earn your business. Does your sales representative offer these services to you? Today the sales representative must be a consultant, problem solver — not just an order taker. They must offer additional information about products, packaging, economics, marketing suggestions, inventory control, product, and supply availability along with promotional and recipe ideas for your facility. Efficient sales representatives should have thorough and accurate knowledge of your needs and the product lines they represent. These company representatives can be valuable to a food service manager.

BUYER RESPONSIBILITIES

A buyer’s responsibilities in non-commercial food service depend on the size of the facility. While large facilities may have a person dedicated to handling all buying, smaller facilities generally delegate this responsibility to the manager. The food buyer’s responsibilities include:

• Evaluating and determining product equipment and service needs.

• Developing or selecting purchasing methods to be used.

• Evaluating and choosing vendors.

• Participating in awarding bids for contracts to vendors.

• Placing orders and following up with vendors or sales representatives.

• Fully training and supervising any staff members involved in receiving, storing, and issuing food and supplies.

• Establishing and maintaining proper, effective inventory control.

• Researching and evaluating new products.

• Establishing and maintaining effective relations with food vendors.

• Weighing cost-benefits of additional services offered by distributors.

• Researching and providing product information including cost and nutritional data in the department.

• Offering ways to track changes in the food market and economic conditions, attending trade and food shows, and staying abreast of trends by reading trade and professional magazines and publications.

• Learning to use technical advances to facilitate food procurement.

• Encouraging and demonstrating ways to keep communication lines open in the department and with others in the institution or facility.

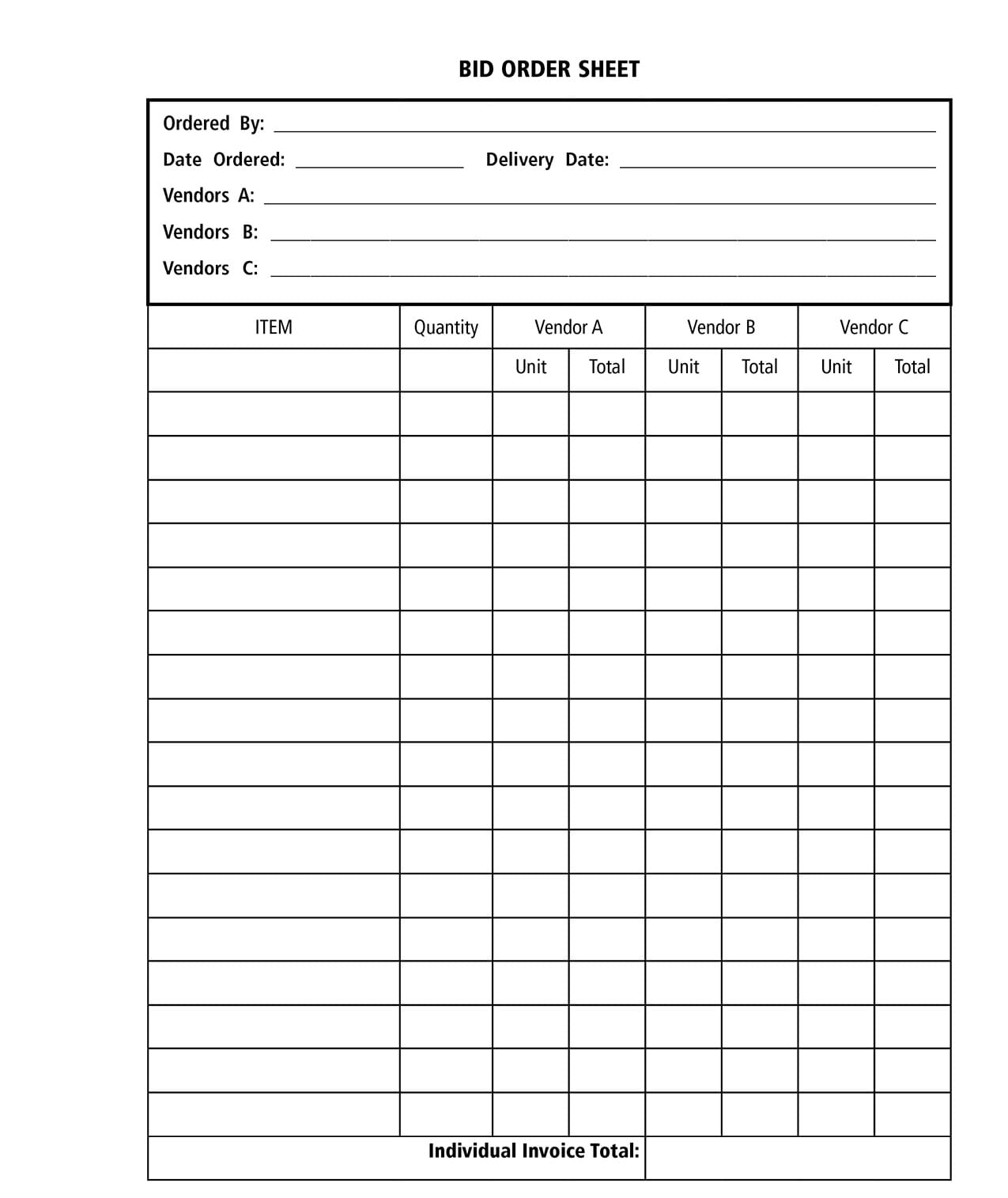

Buyers who submit items for bids will find these forms helpful. They include the Bid Order Sheet and Bid Sheet to help you keep the specifics for each vendor organized to make an accurate decision.

Steps in the bidding process

1. New Products. Identify any new products needed. All new product sales visits should be handled by the person or department who handles purchasing.

2. Specifications. Be specific about the amount, size, quantity, and quality that you need. Include all of the necessary information in your specifications.

3. Usage Levels. How much of each item will you need? It is critical when negotiating prices. Do not inflate your numbers, but give all details.

4. Vendor List. The food service manager and purchasing person need to compile a list of vendors who will be asked to place a bid.

5. Bid Documentation and Distribution. This documentation needs to be distributed in packets to all vendors who will bid. Include instructions, the deadline, and criteria to be used to award the bid and how questions will be handled. Include instructions about whom to contact and how questions should be submitted (in writing, by fax, or e-mail).

6. Receiving Completed Bids. Only the purchasing person or department should receive bids. Make that clear on the bid instructions.

7. Analysis of Bids. First, determine which bidders followed instructions. Eliminate any that did not. All suggested substitutions must be evaluated to determine if they are appropriate or if they should be approved. If items are not acceptable, the bidder must be eliminated.

8. Awarding the Bids. Purchasing recommends the winning bidder, but food service must review the recommendations. Objections and concerns need to be reviewed and handled. The actual decision to award the bid is handled by the administrators who sign contracts.

9. Notify Vendors. Purchasing is responsible for notifying winners and losers. Food service staff members are not to answer questions about the decisions that were made. Purchasing handles all inquiries.

10. Verify Pricing. Food service verifies that the items being delivered are in compliance with the bid details and needs to notify purchasing when there are discrepancies. Purchasing will take action on this information.

11. Contract Dissolution. If the vendor is unable or unwilling to provide items in compliance with the winning bid, the contract may be dissolved. The final decision is made by administration based on recommendations from the purchasing, food service, and legal departments.

BUYER QUALIFICATIONS

Buyer qualifications include food quality, background, product specifications, computer skills, marketing and distribution experience, accounting, business management, purchasing experience, soliciting and awarding bids, and contracts. A good buyer will also have personal attributes that serve him well in the non-commercial food service industry. An organized mind that pays attention to detail and accuracy is a must. New buyers and leaders who have a team mind set along with initiatives and good communication skills can be valuable in food service.

Good buyers keep an eye open at all times for ways to improve the department. This requires initiative and creativity along with the ability to develop and execute responsibilities. An effective manager must control costs while maintaining other food service responsibilities.

Each of these abilities enables the manager and buyer to control costs and eliminate waste. Keep in mind that you should always be on the watch for better products, equipment, and ways to provide better services for your customers while working within the financial constraints of the facility.

ALTERNATIVE PURCHASING SYSTEMS

If no one in the food service facility has the experience to handle purchasing, you may want to use an “indirect purchasing program.” There are three main types of indirect purchasing programs:

1. Programs that guarantee pricing, specific products, brands, and grades. Delivery, payment arrangements, and problems are handled by the institution. Some purchasing departments handle negotiations and most purchasing for every department in the institution.

2. Programs with guaranteed pricing and some management service to include educational services, additional product knowledge, workshops and training for managers, marketing ideas, and assistance.

3. Some other programs offer services for the manager, but no guaranteed prices.

Would one of these services work for your facility? Determining which program would be most beneficial depends on the qualifications your staff members have and what additional services are needed. Each of these programs will cost the institution so you must decide whether the savings outweigh the costs incurred. If not, you can obtain additional training for personnel or hire someone with the proper skills.

PURCHASING KICKBACKS AND GIFTS

Some areas of the food service industry are well known for kickbacks. One of the downsides is that people who are not involved end up paying for these kickbacks with higher prices. Below are a few tips to keep kickbacks out of your facility.

• Purchasing and receiving should be handled by two different people to keep both people honest. One person places the order and another verifies that correct supplies were received.

• Have a standard policy in your employee handbook stating that no employee can receive a kickback from a vendor or a potential vendor. Also state the action to be taken if someone does receive a kickback.

• You may need to have employees change jobs from time to time. If you notice problems, job-changing can be a simple way to keep people honest.

• Verify prices for expensive items yourself. Anything out of the ordinary can be checked for your peace of mind. It does not hurt to let your team members know that you double check invoices and their work. They are accountable to do their jobs, and you are responsible for the facility.

BRANDS AND QUALITY

Well-known brands have first, second, and third quality products identified on their labels.

• First quality. Grade A for canned and frozen vegetables and frozen fruits; Grade B for canned fruits except when Grade B fruits are packaged with a conditional quality label.

• Frosty Acres French Fries. Package color indicates length of potato. Red = extra long, Brown = long, Blue = various lengths.

• North American Buying Group. Their “house” brand uses different colors and codes although they use the same quality standards.

• Sysco. The labeling system has been changed. Supreme Gold = rare items; Imperial Blue = fancy vegetables and choice fruits from prime growing areas; Classic Green = fancy vegetables and choice fruits from non-prime growing areas.

• NIFDA. Prime Pak = fancy vegetables and choice fruits from prime growing regions; Royal Pak = fancy vegetables and choice fruits from any region; Dandy Pak = fancy vegetables and choice fruits that meet the USDA standards.

Purchasing is a critical element in any food service organization. Once the food and supplies are ordered, you need an effective, thorough receiving procedure.