![]()

Chapter 16: Essentials of Food Safety, HACCP, and Sanitation

Preparing and serving quality food in a safe environment is each employee’s responsibility. In order to guarantee the quality and safety of your food, you must understand the basics of controlling food contamination. The definition of food contamination is the spread of infectious diseases.

Food safety is another issue that needs to be addressed in your employee training. Give them the know-how and necessary tools to allow them to establish and practice effective food-handling and sanitation procedures.

These are some things you must provide for your employees:

• Give your employees hands-on training, reminders, and training manuals.

• Provide hair nets, uniforms, gloves, hand and nail brushes, germicidal hand soaps, and first-aid kits.

• Provide hand sinks at each workstation, sanitary employee bathrooms and lockers, scrub brushes, gloves, and disposable towels.

• Equipment and storage supplies should have dated labels and standard rotation procedures. Give your employees color-coded utensils, test kits, and quality-control standards. These standards must be enforced.

Many types of bugs, animal pests, and bacteria can reside within your restaurant. These intruders search for food, water, and warmth. Since these unwanted creatures can be plentiful in your shop, make conditions unfavorable for them.

HACCP DEFINED

Hazard Analysis of Critical Control Points (HACCP) is a system to monitor food preparation to reduce the risk of food-borne illness. HACCP focuses on how food is processed – beginning with purchasing to how it is served. You and your staff need to understand the potential problems during each stage of preparation.

HACCP provides the necessary procedures to control food preparation in order to avoid the potential hazards. It helps you identify these critical control points (CCP). Each of these points can allow bacteria or harmful organisms to grow and contaminate food.

Atlantic Publishing offers a variety of HACCP products which can give you more in-depth information about HACCP regulations; a training kit, labels, and posters for employees, at www.atlantic-pub.com/HACCP_Main.htm. You can order the items you need or they offer a HACCP kit which contains many items that you can use with your staff. The special sanitation package includes:

• HACCP & Sanitation in Restaurants and Food Service Operations: A Practical Guide Based on the FDA Food Code: With Companion CD-ROM

• A complete set of 20 Safety & Sanitation Labels (five each of four different labels)

• Sixteen sanitation and safety posters (pictured at right)

• Ten workplace safety posters

WHY SHOULD YOU USE HACCP?

You are the owner of a restaurant and that means you are responsible for serving safe food to your customers. You must educate and motivate your employees to implement food safety procedures. These procedures must:

• Identify potential hazards.

• Implement safety procedures.

• Monitor how successful your safety system is on a consistent basis.

If the raw ingredients are safe and the process is safe, then the finished product is safe. Using HACCP allows you to identify potentially hazardous foods and stages in the food preparation process where bacterial contamination, survival, and growth can occur.

IMPLEMENTING HACCP

These are the key steps to implementing HACCP:

STEP 1: ASSESS THE HAZARDS

• Have a system to track food from purchasing, receiving, preparation, serving, and reheating, if needed.

• Review your menu items. Identify the potentially hazardous foods and foods that could become contaminated.

• Risk can be reduced by removing very hazardous items from your menu.

• Review how you store, prep, cook, and serve items to identify any areas where contamination might occur.

• Rank the hazards based on whether they are severe or probable.

STEP 2: “ CRITICAL CONTROL POINTS”

Identify areas in your process that can be controlled or prevented. Develop a step-by-step list that details the preparation of potentially hazardous foods. Then, identify ways to prevent, reduce, and eliminate recontamination at each step you listed.

These are ways food service workers can reduce the risk of food-borne illness:

• Practice good personal hygiene.

• Avoid cross-contamination.

• Use proper storage, cooking, and cooling procedures.

• Reduce the steps involved in preparing and serving.

Remember to review how your vendors handle your food, including being sure the food is transported and handled properly during delivery.

STEP 3: “ CRITICAL LIMITS”

Part of this process requires that you establish the critical limits. These are standards that can be seen and measured. Include time and temperature rules.

• What is required to meet each standard? Avoid vague descriptions like “cook until done,” and use “cook to internal temperature of 170 degrees within two hours.”

• Your thermometers need to be calibrated on a regular basis.

• Your recipes need to include the end cooking, reheating, and hot-holding temperatures, along with thawing, cooking, and cooling times.

• Have sufficient staff at peak hours to ensure food is prepared and served safely.

STEP 4: MONITOR “CRITICAL CONTROL POINTS”

Step-by-step charts will show you potentially hazardous steps. Review your process and compare with the requirements to avoid potential problems in your process. Identify any problems and make the needed changes.

STEP 5: MAKE NEEDED CHANGES

Make changes as needed. Some reasons for change are:

• Food contaminated by hands or equipment must be rewashed or discarded.

• Food temperatures are not sufficient after cooking. Continue cooking to the required temperature.

• If food temperatures exceed 55 degrees Fahrenheit during prep or serving, discard it.

STEP 6: DEVELOP A RECORDKEEPING SYSTEM

Develop a system to document the HACCP process to monitor your results. Your employees can log their compliance. These records can provide proof that food-borne illnesses did not originate at your restaurant.

STEP 7: VERIFY YOUR SYSTEM IS EFFECTIVE

Verify that the HACCP process for your facility works. These are some ways you can do that:

• Note how often you need corrective actions. If frequent corrections are needed, evaluate the need to change, or fine-tune, your system. You may need to find time to retrain your employees.

• How can you test the strength of your sanitizing solution? Examine your records. Are employees entering actual valid data?

• Ensure your dishwashing and sanitizing equipment work properly. They need regular calibration and maintenance.

• The board of health can give you a non-biased assessment of whether or not your process is working.

HACCP PROCEDURES

PURCHASING

When you purchase the food for your restaurant, you have several goals:

• To obtain safe and wholesome ingredients.

• Prepare food to meet your production and menu standards.

Carefully choose your vendors. They must meet the federal and state health standards. They should use the HACCP system in their operations and train their employees in sanitation. Delivery trucks need adequate refrigeration and freezer units. Foods should be packaged in protective, leak-proof, durable packaging.

Be clear with vendors, from the beginning, about what you expect from them. Include food safety standards in your purchase agreements. Ask to see the most recent board of health sanitation reports and tell them you will inspect their trucks quarterly or more often if warranted.

RECEIVING

The goals of receiving are:

• To ensure food is fresh and safe when it enters your facility.

• To transfer food to proper storage as quickly as possible.

These are the two important parts of receiving:

1. Preparing to receive food.

2. Inspecting the food when it arrives.

Keep these guidelines in mind, and complete these tasks when you receive food:

• Stock sanitary carts in your receiving area to transport goods.

• Prepare sufficient refrigerator and freezer space before deliveries arrive, especially during special events or high volume time periods.

• Label all deliveries with the date they arrived and a “use by” date.

• The designated receiving area needs to be well-lit and clean.

• All trash left after deliveries needs to be thrown into trash containers.

• Keep the floors free of food and debris.

• How does the delivery truck look when it arrives at your store? Is it clean and are the refrigerator units working properly?

Next inspect the food:

• Check expiration dates for all perishable items.

• Check that the shelf life dates have not expired.

• Check that frozen foods are airtight and moisture-proof.

• Check for any sign that food has been thawed and refrozen.

If there are any signs of refreezing, reject the items. Some signs include large crystals, solid areas of ice, or excessive ice in containers.

• Check cans for swollen areas, flawed seals or seams, dents, or rust. Also, reject cans that contain foamy or bad-smelling items.

• Check temperature of refrigerated and frozen foods, especially items that spoil quickly.

• Check for signs of insect infestations.

• Check for dirt on flats or crates that are dirty. If you find any, reject them.

STORAGE OPTIONS AND REQUIREMENTS

There are four ways to store food:

1. Dry storage is ideal for holding items longer and for less perishable items.

2. Refrigeration is for short-term and perishable items.

3. Deep chilling units are good for short-term storage.

4. Freezing is recommended for long-term storage of perishable foods.

You and your staff need to be familiar with safety and sanitation requirements for each type of storage.

DRY STORAGE

When you plan your storage areas, keep in mind that many items can be stored in a sanitary storeroom. You can store canned goods, baking supplies, grain, items like flour, and any other dry items. Some vegetables like onions, potatoes, and tomatoes should be stored in dry areas. It is best to have proper ventilation in this space and a temperature that will discourage bacteria and mold. Remember this:

• Dry goods should be stored at 50 degrees, but 60 to 70 is adequate.

• Calibrate the wall thermometer to gauge the temperature in this area.

• Packages in this area should be in unopened cans or in tightly covered containers. These items need to be rotated using the “first in, first out” (FIFO) system. To ensure accuracy, date the packages when they arrive and place new items behind older ones.

• Clean all spills immediately and thoroughly to avoid pest infestation and cross-contamination. Do not store trash or garbage cans in food areas.

• No items should be placed on the floor. The bottom shelf of your storage shelves must be six inches off of the ground. You can use pallets on the floor and store paper products on them.

• Never use or store cleaning agents or other chemicals where they could contaminate foods. Label all chemicals in a separate area and label all containers. Always store chemicals in their original containers.

REFRIGERATED STORAGE

Fresh meat, poultry, seafood, dairy products, most fresh fruits and vegetables, and hot leftovers should be stored in the refrigerator at temperatures below 40 degrees Fahrenheit. Keep in mind that food will not keep forever, even in a refrigerator. However, refrigeration does extend the shelf life and the cold keeps it safe from bacteria.

A refrigerator unit should have slotted shelves that allow air to circulate around the food. You should not line the shelves with foil or paper. Be careful not to overload the refrigerator or shelves. Empty space improves air circulation. Refrigerated food should also be dated and sealed.

Additional refrigerator tips:

• Use clean, nonabsorbent, covered containers for food storage.

• Dairy products are to be stored away from onions, cabbage, and seafood.

• Raw and uncooked food must be stored below prepared and ready-to-eat food to prevent cross contamination.

• Keep poultry, fish, and meat fluids away from other foods.

• The proper temperature for perishable items is critical to prevent food-borne illnesses. Check regularly to be sure the temperature stays below 40 degrees Fahrenheit. Each time the door opens and closes affects the inside temperature.

Have a backup thermometer for your refrigerator in addition to the built-in thermometers. Use several thermometers in different sections of the refrigerator, especially in a walk-in unit. Be sure you have a consistent temperature throughout and ensure no area is too warm.

DEEP CHILLING

Deep or super-chilling foods, at a temperature between 26 and 32 degrees Fahrenheit, decreases the growth of bacteria, extends the life of poultry, meat, and seafood without compromising their quality through freezing, and can be done in specially designed units or by lowering the refrigerator temperature.

FROZEN STORAGE

Frozen meats, poultry, seafood, fruits and vegetables, and some dairy products should be stored in a freezer at 0 degrees Fahrenheit to keep them fresh and safe for an extended period.

It is best to only freeze items that were shipped to you already frozen. When you freeze perishable foods, you can damage their quality. Storing food in the freezer for extended periods increases the chance of contamination and spoilage. Arrange your freezer to allow air to circulate through the shelves and around the food just like you do in your refrigerator.

Tips to maximize the efficiency of your freezer:

• Store frozen foods in moisture-proof containers to minimize loss of flavor, discoloration, dehydration, and odor absorption.

• Monitor the temperature using various thermometers to ensure consistent temperatures. Keep a written record of the temperatures of each freezer.

• Open freezer doors only when necessary and take multiple items each time. A “cold curtain” can guard against heat gain.

• Maintain the temperature by lowering the temperature of warm foods before storing.

• Use the first-in, first-out (FIFO) method to keep your inventory fresh.

• Date (with a freezer marker) “occasional-use” items. When anything has been in the freezer over the recommended time, it should be thrown out. The manufacturer or food vendor can give you their recommendations.

PREPARING FOOD

PREPPING

Most fruits and vegetables should be washed to remove dirt, sand, and insects. Soap and water should remove these and residual pesticides. You might use a food-safe disinfectant solution as a precaution for “high-risk” customers.

To prepare raw ingredients and to avoid contamination:

• Sanitize employees’ hands and work surfaces before handling.

• Knives, choppers, and peelers should be sanitized between uses.

• Scrub produce before it is peeled or sliced to avoid transferring germs and chemicals.

When you prepare raw foods, it is necessary to do everything possible to avoid contamination. One way to do this is through the use of colored cutting boards. DayMark Safety Systems offers colored Cut-N-Carry cutting boards. The durable construction provides superior heat, chemical and warp resistance in commercial dishwashers. The tough surface won’t dull knives and prevent unsafe cut-grooving where dirt and bacteria can hide. For more information, call 800-847-0101 or visit www.daymarksafety.com.

To prep many foods, you need the appropriate brushes. Some are used to clean the food items and others are used to clean your work area. Several types of brushes are shown at www.tucel.com/cgi-bin/store/agora.cgi within the prep food area. You can contact Tucel by phone at 800-558-8235 or via fax at 802-247-6826.

THAWING AND MARINATING

Freezing keeps bacteria from multiplying, but it does not kill them. Any bacteria, when food is removed from the freezer, will multiply rapidly when thawed at the wrong temperature. So it is critical to thaw foods below the temperature danger zone. Never thaw foods on a counter or in a non-refrigerated area.

Two of the best methods to thaw food:

1. Place a pan on the lowest shelf in a refrigerator below 40 degrees.

2. Place under drinkable running water at 70 degrees or less for no more than two hours or until the item is thawed.

Marinating Do’s and Don’ts

• Always marinate meat, fish, and poultry in the refrigerator.

• Never marinate at room temperature.

• Never save and reuse marinade.

• With all methods, be careful not to cross-contaminate.

COLD FOOD PRECAUTIONS

Preparing cold ingredients is a hazardous point in the process. These are the reasons:

• Cold food preparation is done at room temperature.

• Cold food is a common point of contamination and cross-contamination.

Be especially cautious of cold foods that will not be cooked. There is greater reason to properly clean and prepare these items. Chill the various ingredients and combine them while chilled.

Important precautions to remember:

• Do not prepare food too far in advance.

• Prepare small batches and place them in the refrigerator immediately.

• Store prepared cold foods below 40 degrees Fahrenheit.

• Wash all fresh fruits and vegetables with plain water to remove surface pesticide residues and other impurities.

• When you cut into thick-skinned produce, it can be contaminated.

• Scrub thick-skinned produce with a brush.

To avoid cross-contamination, you must:

• Sanitize hands before and after handling each item.

• Keep raw products away from prepared foods.

• Sanitize cutting boards, knives, and surfaces after each food item.

• Color-coded prep equipment can identify those used for produce, chicken, and other risky items.

• Discard leftover batter, breading, or marinade after it is used.

COOKING

Potentially hazardous foods can contain contaminates even when properly handled. Cooking to a proper internal temperature will kill bacteria. Keep in mind that conventional cooking procedures will not destroy bacteria.

Some “safe cooking” tips:

• Stir foods in deep pots frequently to mix and ensure thorough cooking.

• Consistent sizes make cooking time predictable and uniform.

• Do not interrupt the cooking process. Partially cooking poultry or meat can create conditions that encourage bacterial growth.

• Verify the accuracy of heating equipment by using thermometers.

• Use a thermometer to ensure food reaches the proper temperature. Use a sanitized metal-stemmed, a numerically scaled, or a digital thermometer.

• Check food temperature in several areas, including the thickest parts, to ensure it is thoroughly cooked.

• Always cook food to an internal temperature of 165 degrees Fahrenheit.

Ovens need to be cleaned. How you clean them depends on the type of oven you use. Deck ovens need to be scrubbed with an oven brush like the one that is sold by www.tucel.com/cgi-bin/store/agora.cgi. The products are listed in the Equipment Cleaning Supplies. You will need many types of brushes to keep your restaurant clean and many can be found in this section. You can contact Tucel at 800-558-8235 or by fax at 802-247-6826.

SERVING AND HOLDING

Food is not guaranteed to be safe because it has been cooked. If your holding temperature is too low, the food can be contaminated. To avoid this type of problem:

• Keep hot foods in hot-holding equipment above 140 degrees Fahrenheit.

• Keep cold foods in a refrigeration unit or below 40 degrees Fahrenheit.

Safe Serving and Holding:

• Use steam tables and hot food carts during service but not to reheat.

• Stir foods consistently to ensure even heating.

• Use a food thermometer to check temperatures every 30 minutes.

• Sanitize thermometers before each use or use a digital infrared thermometer that never touches the food.

• Cover hot-holding equipment to contain heat and prevent contamination.

• Monitor the temperature of hot-holding equipment.

• Discard food held in the “temperature danger zone” over four hours.

• Never add fresh food to a serving pan with food that has been served.

Important points:

• Wash hands with soap and warm water for at least 20 seconds before serving food.

• Use cleaned and sanitized long-handled ladles and spoons, so your bare hands do not touch food.

• Never touch parts of glasses, cups, plates, or tableware that come into contact with food.

• Never touch parts of dishes that come into contact with the customer’s mouth.

• Wear gloves if serving food by hand.

• Cover cuts or infections with bandages or gloves.

• Discard gloves when they touch an unsanitary surface.

• Use tongs or wear gloves to distribute rolls and bread.

• Clean and sanitize equipment and utensils thoroughly after each use.

• Use lids and sneeze guards to protect food from contamination.

• Keep cash handling duties separate from food handling, when possible.

• Wash hands, utensils, and contact surfaces after contact with raw meat or poultry and before contact with cooked meat or poultry.

SANITARY SELF-SERVICE

Workers and customers can contaminate the food. Your customers are not trained in sanitation. Here are some things to watch for:

• Touching food and plastic ware with their hands.

• Touching the edges of utensils and equipment.

• Sneezing or coughing into food or self-serve displays.

• Touching salt and pepper shaker tops, sugar bowls, and condiment containers.

• Returning food items to avoid waste.

It is critical that you remove any food that could be contaminated as soon as you see something questionable. If you are unsure, throw it out. Some ways to protect your customers include:

• Serve sealed packages of crackers, breadsticks, and condiments.

• Pre-wrap, date, and label sandwiches, if possible.

Rosseto dispensers are a safe and sanitary way for customers to serve themselves and to help you control contamination. Toppings, cereal and other items are beautifully displayed and customers get measured portions. These items are ideal for salads, snacks, cereal, and ice cream. The design keeps your toppings fresh longer. The equipment is easy to use and easy to clean. Visit www.rosseto.com or call 847-491-9166 for more details.

COOLING

There will be times when you will prepare foods in advance and use leftovers. Leftovers can lead to problems. It can be the number one cause of food-borne illnesses. Two key precautions to prevent these problems at this point are rapid cooling and protection from contamination.

Chilling It Quickly

Leftovers should be chilled to an internal temperature of below 40 degrees Fahrenheit. Quick chill any leftovers larger than a half a gallon or two pounds.

Simple Steps to Quick chill:

• Reduce food mass. Smaller amounts of food chill quicker than large amounts. Cut items into smaller pieces or divide into several containers.

• Shallow, pre-chilled pans (no more than four inches deep). Use stainless-steel containers because stainless-steel transfers heat better and cools faster than plastic.

• Chill. It is best to place food in an ice-water bath or quick-chill unit (26 to 32 degrees Fahrenheit) instead of a refrigerator. Water conducts better than air. Food cools quicker in an ice bath than in a refrigerator. Refrigeration units keep cold foods cold, rather than chilling hot foods. It can take too long to cool foods to safe temperatures.

• Pre-chill foods in a freezer for about 30 minutes and then refrigerate.

• Separate items so air can flow around them. Do not stack shallow pans. Never cool at room temperature.

• Stir frequently. Stirring accelerates cooling and gets cold air to all parts of the food.

• Check temperature periodically. Food should reach 70 degrees Fahrenheit within two hours and 40 degrees Fahrenheit within four hours. This time must be reduced if food spent time in the “temperature danger zone” during preparation and serving.

• Tightly cover and label cooled foods. List preparation date and time.

• Store food on the upper shelves of the cooler and cover the container when they reach 45 degrees Fahrenheit. Uncovered foods cool faster and have an increased risk for cross-contamination. Never store prepared foods beneath raw foods.

REHEATING

Remember that leftovers are not safe. During reheating and serving leftovers, be careful not to allow contamination. Tips to safely reheat and serve leftovers:

• Boil sauces, soups, and gravies and heat other foods to a minimum of 165 degrees Fahrenheit within two hours of taking food out of the refrigerator.

• Never reheat food in hot-holding equipment.

• Never mix a leftover food with fresh food.

• Never reheat food more than once.

Keeping the product warm and free from contamination makes a difference in how much you sell and how much you throw out. Heated holding cabinets from Henny Penny can make this difference for you. They provide floor or counter top units. They are energy efficient and built to last. For more information, visit www.hennypenny.com/pd/pd1.phtml or call 800-417-8417.

CLEAN VERSUS SANITARY

Heat or chemicals can reduce bacteria to acceptable levels. They can also combat other harmful microorganisms. Heat sanitizing requires exposing equipment to high heat for an adequate period of time. It can be done by placing equipment in 170 to 195 degrees Fahrenheit water for at least 30 seconds or in a dishwasher that washes at 150 degrees Fahrenheit and rinses at 180 degrees Fahrenheit. It is critical that you check water temperatures on a regular basis.

Equipment can be chemically sanitized by dipping or wiping it with bleach or sanitizing solution. Use a half ounce, or one tablespoon, of 5 percent bleach per gallon of water. Commercial cleaning agents contain manufacturers’ instructions. These chemicals are regulated by the EPA.

Follow the instructions carefully. You can also use chemical test strips to test the strength of the sanitizing solution. Since exposure to air can dilute the strength of these agents test often.

Henny Penny has a full line of quality cleaning products that are formulated to sanitize Henny Penny equipment. These products are also useful for cleaning your food prep and serving areas. For more information, visit www.hennypenny.com/pd/pd2.phtml?formTarget=cleaning. Contact Henny Penny at 800-417-8417 or by fax at 800-417-8402.

Sanitize Portable Equipment

Properly cleaning and sanitizing portable equipment requires a sink with three separate compartments for cleaning, rinsing, and sanitizing. Have a separate area to scrape and rinse food and debris into the garbage or disposal before washing and another drain board for clean and soiled items.

The correct procedure to sanitize a piece of equipment:

1. Clean and sanitize sinks and work surfaces.

2. Scrape and rinse food into garbage or disposal. Pre-soak items like silverware.

3. First Sink – Immerse the equipment in a clean detergent solution at about 120 degrees. Use a brush or cloth to loosen and remove any remaining visible soil.

4. Second Sink – Use clear, clean water between 120 and 140 degrees Fahrenheit to remove all traces of food, debris, and detergent.

5. Third Sink – Sanitize items in hot water at 170 degrees Fahrenheit for 30 seconds or in a chemical sanitizing solution for one minute. Cover all surfaces of the equipment with hot water or sanitizing solution and keep them in it for the appropriate amount of time.

6. If soapsuds disappear in the first compartment or remain in the second, if the water temperature cools, or if water in any compartment becomes dirty and cloudy, empty the compartment and refill it.

7. Air dry. Drying with a towel can re-contaminate equipment and remove the sanitizing solution before it finishes working.

8. Let equipment dry before putting it into storage; moisture can foster bacterial growth.

Sanitizing In-Place Equipment

Larger and immobile equipment must be washed, rinsed, and sanitized. Use this procedure:

1. Unplug electrically powered equipment.

2. Remove food particles and scraps.

3. Wash, rinse, and sanitize removable parts using the immersion method described in steps three through five of the previous section.

4. Wash the food-contact surfaces and rinse with clean water. Wipe with a chemical sanitizing solution, using the manufacturer’s directions.

5. Wipe down non-food surfaces with a sanitized cloth and allow them to air-dry before reassembling. Sanitize cloth before and during sanitizing by rinsing it in sanitizing solution.

6. Re-sanitize external food-contact surfaces that were handled when reassembled.

7. Scrub wooden surfaces, like cutting boards, with a detergent solution and a stiff-bristled nylon brush. Then rinse in clear, clean water and wipe down with a sanitizing solution after every use.

A FIRST-RATE FACILITY

Safe and sanitary food service begins with a clean facility that is in good repair. The entire facility should be laid out for easy cleaning.

Eliminate and reorganize any areas that are hard to clean. You should also replace overloaded refrigerators or other equipment. The easier it is to clean an area, the more likely it will be cleaned.

FLOORS, WALLS, AND CEILINGS

Here are some tips to keep your floors, walls and ceilings in top condition:

• Keep dirt and moisture away from floors, walls, and ceilings.

• Clean walls by wiping down with a cleaning solution. Sweep floors and then clean with a spray method or by mopping.

• Swab ceilings to keep from soaking lights and ceiling fans.

• Do not ignore corners and other hard-to-reach areas.

With Sanifloor, the food goes in the floor, not on it. The potential for slip and fall accidents are dramatically reduced. It controls liquids, crumbs, and other items that are dropped on the floor, limiting the need to clean the floor during the work shift, allowing you to offer better customer service. The ability to flush the floor eliminates unpleasant smells and situations that attract pests. Visit the website for more information at http://sanifloor.com. For information on pricing or installing Sani-Floor units, call 760-345-7987 or e-mail info@sanifloor.com.

Various cleaning supplies are used to maintain a clean floor. Once source for these items is www.tucel.com/cgi-bin/store/agora.cgi in the Floor and Wall Clean section. These items include brooms, mops, and dust pans. They also offer mops to clean your walls. You can contact them at 800-558-8235, by fax at 802-247-6826, or by e-mailing info@tucel.com.

WORK AREAS

Choose nonporous materials in your work areas. These need to be able to withstand chemical and/or steam cleaning. You should also purchase tables and counters without seams or joints that are hard to clean. Worktables on wheels can be moved to useful areas during busy times.

VENTILATION

Ventilation is critical to a clean environment. Effective ventilation will remove smoke, steam, grease, and heat from your food-preparation area, improving air quality and reducing the possibility of fire from accumulated grease. Ventilation eliminates condensation and other airborne contaminants. In addition, it:

• Reduces the accumulation of dirt.

• Reduces odors, gases, and fumes.

• Reduces mold growth by reducing humidity.

Ensure good ventilation by:

• Using exhaust fans to remove odors and smoke.

• Using hoods over cooking areas and dishwashing equipment.

• Checking exhaust fans and hoods to make sure they operate properly.

• Cleaning hood filters according to the manufacturer’s instructions.

RESTROOMS

Provide restrooms that are convenient, sanitary, and adequately stocked with the following:

• Toilet paper.

• Antiseptic liquid soap.

• Disposable paper towels and/or air blowers.

• Covered trash receptacles with a foot pedal for the lid.

Someone needs to check public restrooms and clean them throughout the day. Provide nail brushes and sanitizing solution in employee restrooms.

CROSS-CONTAMINATION CONCERNS

Cross-contamination is a common cause of food-borne illness. It is the transfer of bacteria and viruses from food to food, hand to food, or equipment to food.

• Food to food. Raw, contaminated ingredients can be added to foods or fluids from raw foods may drip into foods that are not cooked. A common mistake is leaving meat on an upper refrigerator shelf where it can drip onto prepared foods stored below.

• Hand to food. Bacteria is located all over the body: in the hair, on the skin, in clothing, in the mouth, in the nose and throat, in the intestinal tract, and on scabs or scars from skin wounds. The bacteria can end up on hands where it can spread to food. People can transfer bacteria by touching raw food and transferring it to cooked or ready-to-eat food.

• Equipment to food. Bacteria can pass from equipment to food when the equipment touches contaminated food and is used to prepare other food without proper cleaning and sanitizing.

Plastic wrap can hold bacteria and transfer it to other containers and food. A can opener, boxes of wrap, or a food slicer can all create cross-contamination when they are not sanitized properly.

Contributing to Foodborne Illness

The Centers for Disease Control (CDC) reveals the most common reason food-borne illness occurs is because of food mishandling. According the Center for Disease Control’s Surveillance for Food-borne Disease Outbreaks (1988-1992) these are the major factors:

|

Causes of Foodborne Illnesses |

|

|

Action |

Percent Caused |

|

Use of leftovers |

4% |

|

Improper Cleaning |

7% |

|

Cross-Contamination |

7% |

|

Contaminated raw food |

7% |

|

Inadequate reheating |

12% |

|

Improper hot storage |

16% |

|

Inadequate cooking |

16% |

|

Infected people touching food |

20% |

|

Time between preparing and serving |

21% |

|

Improper cooling of foods |

40% |

CONTROLLING BACTERIA

Some good ways to control bacteria are:

• Good personal hygiene.

• Eliminating cross-contamination.

• Monitoring time and temperature.

• Employing a sanitation program.

Your first step is to limit bacteria’s access to the restaurant. All products need to be clean when they enter your restaurant. Following all the suggestions that have been discussed in this chapter is a great start.

TIME AND TEMPERATURE CONTROL

Controlling time and temperature can be a great way to avoid contamination. Most disease causing bacteria grows between 41 and 140 degrees. When food is cooked, reheated, and stored in the correct temperatures, the potential problems are reduced. Believe it or not, bacteria can double every 15 minutes, which will generate over 1,000,000 cells in just five hours. There can be enough bacteria within four hours in the temperature danger zone to cause food-borne illnesses. You can prevent food-borne illnesses by using correct storage practices.

There will be times when food has to be in risky temperatures. You must minimize those times. If you take a break, put the food back in the refrigerator briefly.

BACTERIA

Bacteria can be found everywhere: in the air, in your restaurant, and all over your body. Not all bacteria are bad and some are even beneficial. There are some types of bacteria that are added to foods. But a small amount will cause food to spoil and can generate food poisoning when eaten.

Bacteria are in a vegetative state and reproduce like any other living organism. There are types of bacteria that form spores which enable the bacteria to live in less than ideal situations, including cooking, high-salt environments, and freezing. These activities will not kill those bacteria. These spores must have the “ideal” conditions to multiply and cause illness.

These are the things bacteria need to reproduce:

• Food

• Acid

• Temperature

• Time

• Oxygen

• Moisture

Food

High protein or carbohydrate foods like meats, poultry, seafood, cooked potatoes, and diary products.

Acid

Most bacteria flourish in a neutral environment, but they are capable of growing in foods that have pH levels between 4.5 and 9.0. The “pH” is indicative of how acidic or alkaline a food is. pH ranges from 0.0 to 14.0, with 7.0 being neutral. High acid foods discourage the growth of bacteria. You can limit the hazard of lower pH foods by adding acidic ingredients to increase the pH level.

Temperature

Most disease-causing bacteria grow at between 41 to 140 degrees Fahrenheit. Listeria monocytogenes, the bacteria that causes food-borne illness related to processed luncheon meats, can grow below 41 degrees.

Time

Bacteria needs about four hours — the total time the food is in the temperature danger zone — to reproduce enough cells to cause a food-borne illness.

Oxygen

Aerobic and anaerobic bacteria have different oxygen requirements. Aerobic bacteria need oxygen to grow. Anaerobic bacteria do not. Anaerobic bacteria grow well in vacuum packed or canned items.

Moisture

The amount of water in a food to support bacterial growth is called water activity. It is measured on a scale of 0.0 and 1.0. The water activity must be greater than 0.85 to support bacterial growth.

The growth of bacteria is dependent on how favorable these conditions are. Bacteria prefer moisture-saturated foods. In turn, they will grow in dry conditions.

DANGEROUS BACTERIA

There is an estimated 76 million cases of food-borne diseases in the United States each year. Most of these are mild and do not last long. The CDC estimates 325,000 hospitalizations and 5,000 deaths are caused by food-borne diseases each year. The elderly and the young are the most at risk.

The most commonly recognized food-borne infections are those caused by the bacteria Campylobacter, Salmonella, E. coli O157:H7, and by a group of viruses known as the Norwalk and Norwalk-like viruses.

• Campylobacter causes fever, diarrhea, and abdominal cramps. Eating undercooked chicken or food contaminated with juices dripping from raw chicken is the most frequent source of this infection.

• Salmonella causes fever, diarrhea, and abdominal cramps. When this bacterium attacks a person with poor health, it can cause serious infections.

• E. coli O157:H7 is usually caused by consuming water that is contaminated with microscopic amounts of cow feces, causing severe and bloody diarrhea and painful abdominal cramps without much fever. If the condition becomes more severe, it includes temporary anemia, profuse bleeding, and kidney failure.

• Calicivirus, or a Norwalk-like virus, causes an acute gastrointestinal illness, which is characterized with more vomiting than diarrhea and lasts about two days. It is usually spread from one infected person to another. Infected kitchen staff can contaminate cold foods during preparation.

More information can be found on the FDA’s website at www.cfsan.fda.gov/~mow/intro.html.

PERSONAL HYGIENE

One of the best and easiest ways to stop bacteria is personal hygiene. Hands are a big source of contamination and need to be washed throughout the day. Any time you sneeze or scratch your head you expose your hands to bacteria and then pass those bacteria on to other things you touch. Some great things that help prevent the spread of bacteria are: nail brushes, disposable gloves, and anti-bacterial soaps. It is critical that you train your employees properly and follow up to ensure they are following these standards.

These are some basic ways to practice good basic hygiene:

• Short hair and/or use a hairnet.

• Clean shaven face.

• Clean clothes/uniforms.

• Clean hands and short nails.

• No unnecessary and large jewelry.

• A daily shower or bath.

• No smoking in or near the kitchen.

• Hand washing prior to work, periodically, and after handling foreign objects.

Many hand cleaning supplies are available to maintain the hygiene of your employees. These can be found at www.tucel.com/cgi-bin/store/agora.cgi in the Infection Control Clean section.

When employees are getting a cold or have a cut, they should not be at work. It is a way to spread bacteria. Some businesses require employees to take a complete medical exam with blood and urine tests, but the cost is prohibitive for others.

HAND WASHING

Hand washing is the most critical aspect of personal hygiene. Unless they are washing fruits and vegetables, employees should not touch ready-to-eat foods with their bare hands. Instead, they can use single use gloves, spatulas, tongs, or deli paper.

“Hand washing is the single most effective means of preventing the spread of disease,” according to the Centers for Disease Control and Prevention. The Quik-Wash Hand Wash Faucet Control is an economical choice which can be better than the costly electronic faucets. The faucet offers automatic closing and hands-free positions. For additional information, visit www.fmponline.com/featuredproduct.html. You can contact FMP for more information by phone at 800-257-7737, by fax at 800-255-9866, or through e-mail at sales@fmponline.com.

Always wash your hands after these activities:

• Smoking

• Eating

• Using the restroom

• Handling money

• Touching raw food

• Touching or combing your hair

• Taking a break

• Handling anything dirty

• Coughing, sneezing, or blowing your nose

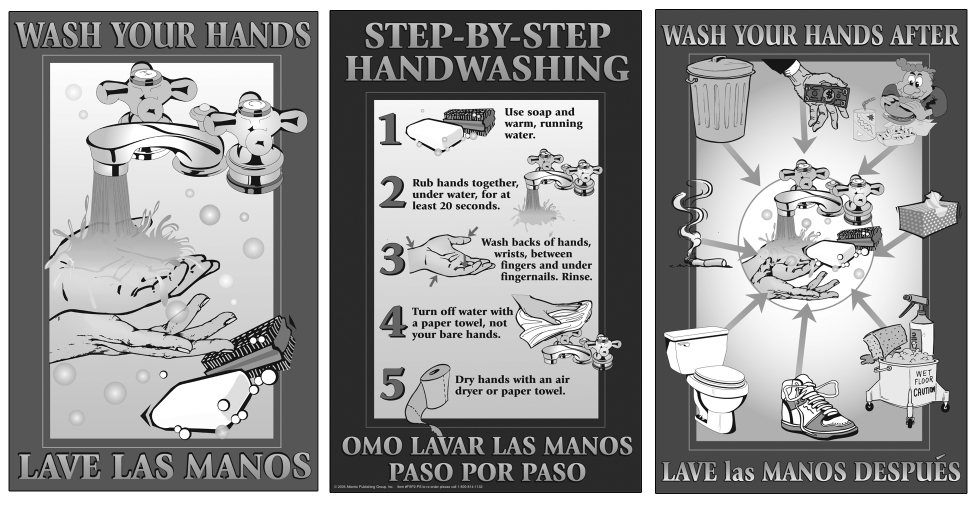

You should make sure all employees know and practice proper hand washing procedures. Posters are an excellent on-going reminder. Atlantic Publishing offers three different handwashing posters: “Wash Your Hands” (Item #FSP1-PS), “Step-By-Step Handwashing” (Item #FSP2-PS) and “Wash Your Hands After” (Item #FSP3-PS), Each brightly colored poster is in both Spanish and English and laminated with sealed edges. They are $8.95 each and available at www.atlantic-pub.com or by calling 800-814-1132.

CLOTHING

Dirty clothes can hold bacteria, whether these are your work clothes or personal clothing. It is common to touch your clothing while working, transferring bacteria to the food. Another problem is that customers get a bad message when they see employees in dirty clothes.

Aprons, Etc provides a wide variety of apron options. There are washable and disposable choices. You have the opportunity to have your business name and logo printed on your aprons. Keep in mind that you will need a lot of aprons and will need to wash them. Some of the aprons available are displayed at www.apronsetc.com/aprons.htm#1.

Dickies Chef Aprons and Hats are high quality products. These items are functional and have the durability that Dickies is famous for. The aprons provide oversized pockets and are constructed to be comfortable for your staff. They are available with a soil resistant finish. Dickies has a wide selection of aprons, chef hats, shirts, pants, and vests. They can be seen at www.dickieschef.com. Call 866-262-6288 or fax 877-353-9044 for more information.

Royal Industries offers aprons, chef’s coats, and chef’s hats. These are all options for your cook staff. Royal Industries, Inc. is an innovative leader in the food service industry, serving a nationwide market of commercial products for the food service industry. Their website is www.royalindustriesinc.com and you can contact them by phone at 800-782-1200 or by fax at 800-321-3295.

EATING, DRINKING, OR USING TOBACCO

Some employees feel it is acceptable to eat in the food preparation area because they work in a restaurant, but smoking, eating, and drinking need to be prohibited in the food preparation area. These activities increase the chance of spreading bacteria and other contaminants to the food.

EYES, NOSE, AND MOUTH

When you or your employees have a cold or even allergy problems, there will be sneezing and coughing, easily contaminating food, utensils, equipment, and linen. While employees are sick or sneezing, assign them to a duty where they do not come into contact with the food.

HAIR RESTRAINTS

Customers are concerned about hair contamination in their food. Be aware of this common concern and be sure your employees use caps or hairnets. It is a simple way to keep hair out of the food that is being prepared. The food can also be contaminated when employees touch their hair and then continue working.

DayMark Safety Systems offers a complete line of personal safety equipment including hair nets and beard guards. You can view the complete line at www.daymarksafety.com or call 800-847-0101.

DISHWARE

Even though your employees have been trained to wash their hands correctly, they still need to use care when handling dishware. These tips will help your employees handle dishware without contaminating the portions that will touch the customers’ food or mouth.

• Use tongs, scoops, or food grade rubber gloves to pick up food items.

• Pick up glasses from the outside and hold cups from the handle or the bottom to avoid touching the rims or inside.

• Pick up forks and spoons by the handles.

• Carry plates by the bottoms or edges. Do not stack dishes, cups, and saucers to carry more.

• Wash your hands after handling soiled dishes.

• Always wash your hands before putting on gloves. Those gloves can be contaminated if you do something else while wearing them. When your gloves are contaminated throw them away, wash your hands, and put on fresh gloves before returning to the food preparation.

• Do not use a utensil to taste more than one food item.

GLOVES

Multiuse gloves can be a breeding ground for pathogens. These gloves must be washed, sanitized, and rinsed between uses. Hands must also be washed before putting gloves on. When gloves are soiled or the inside is contaminated, they should be discarded. Do not use slash-resistant gloves with ready-to-eat foods because they cannot be cleaned and sanitized easily.

Disposable gloves are a great tool for keeping food safe from contamination. Vinyl gloves provide a safe and sanitary second skin to perform tasks requiring sensitivity and dexterity.

Food-handlers should change their gloves:

• As soon as they become soiled

• Before beginning a different task

• At least every 4 hours during continual use, more often when necessary

• After handling raw meats

The chart below outlines the features and benefits of the four common materials that disposable gloves are made from:

|

Disposable Glove Characteristics |

||||

|

Nitrile |

Vinyl |

Poly |

Latex (Rubber) |

|

|

Barrier Protection |

Excellent |

Fair / Poor |

Poor |

Excellent |

|

Strength & Durability |

Excellent |

Excellent |

Poor |

Fair |

|

Elasticity |

Good |

Poor |

Poor |

Excellent |

|

Puncture/Cut/Snag Resistance |

Excellent |

Poor |

Poor |

Good |

|

Chemical Resistance |

Excellent |

Poor |

None |

Good |

|

Fit and Comfort |

Excellent (Loose) |

Good |

Poor |

Excellent (Tight) |

|

Protein Allergy |

None |

None |

None |

Possible |

It is also important that gloves fit employees correctly. DayMark offers a wide variety of vinyl, poly, and nitrile disposable gloves. You can view the complete product line at www.daymarksafety.com or request a catalog by calling 800-847-010.

Summary

Each of these techniques is a way to protect your restaurant and your customers from bacteria and contamination. There are many sources for additional information. Although these tips involve more work and training, they will help you protect your business and your customers.