Production of Bioactive Compounds From Waste

Christianah O. Jayeola; Babasola A. Adebowale; Lateef E. Yahaya; Semiu O. Ogunwolu; Olayiwola Olubamiwa Cocoa Research Institute of Nigeria (CRIN), Ibadan, Nigeria

Abstract

In the past, organic waste had been long considered useless, and potentially hazardous to the environment. Today it is seen and referred to as raw material for the production of various products, and is well regarded for its economic value. Technology has substantially improved the physical and nutritional value of many waste products because many countries are shifting their focus and efforts toward industrialization. Rather than exporting their wastes for meager foreign exchange earnings, many countries are developing technological capabilities to convert more of their wastes into useful products. Many of the technologies which for bioconversion of waste are environmentally friendly, some require little effort to achieve the desired positive outcomes. For this reason, bioconversion technologies are rapidly gaining attention, a timely change now that organic agriculture is proffering better fresh food alternatives. Agro-wastes, like cocoa pod husk, kola pod husk, and maize stover, are increasingly being used as fertilizer and amendments on crops. Agro-wastes improve the physical properties of soil, reducing run-off, and erosion and increasing the amount of organic carbon and other major elements, while at the same time reducing mineral fertilizer use and increasing biomass and microbial activity. This chapter highlights the impacts of technological innovation on the bioconversion of several available agro-wastes, and their applications in the arena of modern agriculture.

Keywords

Bioconversion; Bioactive; Waste; Technological innovation; Hazard

1 Introduction

Waste refers to anything considered useless, but produced by the same action that produces something useful. It could be a by-product of household, industrial, agricultural, municipal, mining, and commercial activities. When something is unwanted and no longer serves a purpose, it is generally thought of as waste and then discarded. Waste can also be defined as unwanted materials which are discarded from a variety of sources. Wastes pose significant potential for new products and economic developments, with particular focus on resources recoverable from agricultural wastes to produce byproducts which can be commercialized to enrich individuals and ameliorate whole communities and regions.

Wastes are generated at the household level, in agricultural activities and by industrial processes, including industrial agro-food processing activities. Agricultural activities produce many types of wastes in their daily operations, such as biological waste, solid waste, hazardous waste, and waste water. It is important that these wastes are identified and managed properly to protect nearby communities, as well as the environment.

Agricultural wastes all consist of plant-derived or animal-derived materials that are considered useless, either because they have no known positive economic importance, or because they are not grown or raised for any specific use. The problem of efficient disposal and management of organic solid wastes has become more significant, due to recent rapid population increases, and intensification in agricultural and industrial activities. The various types of environmental and disposal problems caused by the production of large quantities of organic waste worldwide requires a sustainable approach in a cost effective manner (Edwards and Bater, 1992). This has become a very important issue for maintaining healthy environment (Senapati and Julka, 1993).

1.1 Types of Agricultural Waste

Wastes produced due to agricultural activities are classified as:

- Crop residues,

- Pruning residues from trees,

- Weeds and water weeds harvested from rivers, canals, and drains,

- Animal droppings,

- Food processing wastes.

Residue from agricultural production makes up 30%–60% of the product that is used for human consumption and animal feed. Agricultural wastes are produced and generated through agricultural processes such as food manufacturing, animal rearing, and household wastes from kitchens. On the other hand, industrial wastes come from various industrial activities. Wastes from agricultural processes can generally be categorized as solid or liquid wastes. Large quantities of vegetable wastes may also be generated by production of field crops or livestock. Over the years, due to increase in population, consumerism, urbanization, and industrialization, increased agricultural production and other related factors have substantially increased the amount of waste generated. While wastes generated from field crops and agro-food processes are rich in lignocellulose, those produced from livestock agro-food processes contain unique animal residues.

It has been reported that one of the major problems facing most developing nations is the challenge to increase agricultural production without degrading the environment. Food is a basic human need and producing enough to feed the growing populations of developing nations is one of the biggest challenges facing a large proportion of nations. Hence, there should be a greater intervention in the form of environment friendly science and technology in food production. One such intervention is effective management of wastes, particularly agricultural and food processing wastes. The quality of the environment and health status of a population are related to the quality and quantity of wastes generated in those areas, and is partly determined by the nature of activities carried out by the populace. It is extremely important that serious considerations be given to the methods used in handling, treating, and disposing of wastes. This is due to the fact that wastes dumped into streams, drainage channels, creeks, lagoons, and other water impoundment points create serious environmental problems likely to produce adverse effects to air, water, and soil conditions, and may constitute a serious threat to those dwelling nearby, downstream, and downwind. Improper waste management may result from lack of proper education, adequate information concerning the amount and type of waste generated, lack of knowledge about the best options for handling, treatment, and disposal of wastes on the farms and allocations, and the cost of handling waste. Most of the facilities and equipment for collecting, spreading, and treating waste are capital intensive. Waste handling is also laborious, therefore, knowledge of types and quantity of waste generated is critical. It is of utmost importance to develop methods of waste processing for all wastes generated, which results in economic gains to the processor.

1.2 Health Implications of Unused Waste

Waste can exist either as solid, liquid or gas, and the effect of each phase varies. The health implications of these wastes include: breeding of flies which carry germs on their bodies and legs and deposit them on our food; mosquitoes (a vector of malaria parasites and other disease agents) breed in stagnant water, blocked drainage sites, in cans, tires, and other castoffs, which collect rain water; breeding of rats and other rodents which spread infectious diseases (typhus, salmonella, leptospirosis, Lassa fever) and cause injury by biting and spoiling millions of tons of food.

The refuse workers themselves also face hazards including parasite infestation and infected cuts resulting from skin contact with refuse. Other threats to workers include hazards on disposal sites, for example injuries from glass, razor blades, syringes, tissue damage or infection through respiration, ingestion or skin contact.

Traditional methods of disposing crop residues and animal droppings are not highly efficient, and therefore present a regular source of hazard to human and animal health, as well as being a major source of environmental pollution. Therefore, creating wealth from these wastes will not only sanitize the environment, but will spur economic growth, provide employment and improve the national economy.

1.3 Way Forward for Converting Waste to Wealth

The concept of waste as a material “which has no use” is changing. A new perspective has developed, seeing waste as a resource by converting it into secondary materials and products through modification. Wastes can thus be converted into useful resources used at home or even sold for wealth. Waste to wealth involves collection of discarded materials, such as husks, peels, poultry droppings, cow dung, and biomass, and processing these materials, turning them into new products which can be sold. It is a process of turning what has been considered as waste into useful products. An additional goal is to minimize the quantities of waste exposed to our environment and the consequent health hazards.

1.4 Benefit of Utilizing Waste

- 1. It reduces the amount of waste requiring disposal

- 2. It saves natural resources including nonrenewable resources such as petroleum.

- 3. It reduces the amount of energy needed to manufacture new products

- 4. It reduces pollution and destruction caused while obtaining new raw materials.

- 5. It provides employment opportunities.

- 6. It helps the national economy because fewer raw materials have to be imported.

Measures must be taken to manage generation of waste if the unpleasant consequences of accumulation is be averted. Hence, various waste management options have been adopted overtime, most of which consider waste as a zero value entity which must be wholly disposed of. However, modern concepts of waste management tend to see waste from a different perspective, regarding waste as not completely lacking in value and recognizing it as a salvageable resource. This is particularly the case with agro-food wastes which are comprised of a considerable percentage of biomass. Fortunately, the entrapped resources are bioconvertible into useful products: animal foods and feeds, biofertilizers, industrial chemicals/raw materials, biofuels, biogas, and other energy renewable alternatives. With respect to these, one can hardly overstate the role of value adding to wastes as a method to exploit this once ignored resource.

1.5 The Case of Agro-Industrial Wastes in Nigeria

Many by-products from preparation of human foods are referred to as wastes. The sources and quantity of wastes in Nigeria varies from individual households, small, medium, and major industries. The quantity of waste depends on the level of involvement of machines and technology. Thus, crop residues and agro-industrial by-products include a great number of materials, such as straw from cereal crops, stover from maize and sorghum, maize cobs and bagasse, are among those of greatest importance quantitatively Kossila (1984). The scope of this paper will primarily focus on fibrous by-products of cocoa: cocoa pod husk (CPH) and cocoa bean shell. The extent to which these residues are utilized as animal feed varies greatly, depending partly on the degree of processing, as well as the kind of animal recipient. As new technology develops for processing human foods, additional by-products are constantly being introduced.

1.6 Bioconversion

Awareness of the importance of waste utilization has become a reality, especially in the effort to clean up the environment, add value to crops and generate more income to sustain communities and families. Considering the high cost of living and the rate of employment within the country, this writing will be of great assistance to entrepreneurs and young graduates, bolstering their efforts to be self supporting, self sustaining, and employers of labor, starting their businesses from what has formerly been considered waste.

It has now been shown that there is wealth in waste. With creativity and ingenuity, there is untapped potential to create something from all the wastes in the environment.

2 Cocoa Wastes

2.1 Wealth Out of Cocoa Waste

In the early eighties, cocoa pod husk had nor perceived market value. At the time, the main concern of farmers was the bean extracted from the pod. Initially, when farmers harvests were still moderate, pod husks were left to rot. As larger areas of land were being acquired for cocoa cultivation, pod and bean harvest and processing increased, eventually leading to pod heaps at various points on the farm. Heaps like these were estimated to be several tons on farms in Nigeria. This scenario was common practice for several years, until decomposing pod remnant heaps resulted in the outbreak of a chronic disease afflicting the cocoa tree, black pod disease nick-named “witch broom.” The causative agent was identified as phytoptora spp. A series of surveys conducted in the eighties indicated that over 800,000 tons of this by-product sat in various states of decomposition in Nigeria. Consequently, the case of cocoa pod husk in Nigeria in the eighties and early nineties reinforced the notion that the leftover harvest material had no value and was waste. Additionally, it had also become environmental hazard, harboring different kinds of pathogens, not to mention the threat posed to the cocoa plants themselves. Owing to cocoa being a cash crop, government policies regularly feature ways to encourage cultivation. The Nigerian livestock sector, on the other hand, was facing critically acute shortages in the supply of essential ingredients in formulation of supplemental feeds. This situation consequently resulted in reduction of livestock populations. The drive to create wealth from waste, or convert waste to wealth, has now led to encouraging reclamation of cocoa pod husks and cocoa bean shells as substitutes for basal feed ingredients such as maize, wheat bran, and palm kernel cake. Table compiled by Adegbola et al. (1988) highlighted some crop residues or by-products available in Nigeria, estimated the quantities available and constraints militating against each of them. In the case of cocoa pod husk, lack of information coupled with reduced exposure to experimental animals presented obstacles to progress. About 600,000 tons of cocoa pod husk was available in Nigeria, and only ruminants were considered for feed trials. However, the present situation in feed confirmed the fact that research and development has changed the status of pod husks from waste to wealth. A series of research studies employing multidisciplinary approach have led to notable success in the effort to convert waste to wealth, with respect to cocoa pod husk.

Usable wastes that can be generated from cocoa are:

- Cocoa sweating/pulp/mucilage

- Cocoa pod husk

- Potassium salts for soap

- Cacao pigment

- Pod gums

- Cocoa husk endocarp

- Cocoa bean shell

2.2 Cocoa Sweating/Pulp/Mucilage

This is the whitish substance that covers the bean inside the pod; it is also referred to as pulp, juice or cocoa sweating. Cocoa seeds are surrounded by an aromatic pulp which arises from the seed teguments (technically an aril). The mucilaginous pulp is composed of spongy parenchymatous cells containing cell sap rich in sugars (10%–13%), pentosans (2%–3%), citric acid (1%–2%), and salts (8%–10%).

During on-farm processing of cocoa seed (the exportable products), the pulp is removed by fermentation and is hydrolyzed by microorganisms. Hydrolyzed pulp is known in the industry as “sweatings.” During fermentation, the pulp provides the substrate for various microorganisms which are essential to the development of chocolate flavor precursors, which are fully expressed later, during the roasting process. Fermentation was once thought to be simply an easy way to remove the pulp to facilitate drying, but its importance to cocoa quality has been well established. The schedules for fermentation vary according to location and season, chamber size, depth of seed layer, and physical turning of the seed. Although pulp is necessary for fermentation, often more pulp occurs than is needed for optimal bean processing. Extraction of pulp does not interfere with subsequent seed fermentation, and reduction of pulp before fermentation may be beneficial to cocoa quality. In Brazil, seed quality is improved by the removal of pulp in order to reduce acidity. Commercial depulping machines of various sizes have been developed, based on a revolving cylinder, which removes about 60% of the pulp and does not injure the seeds. Bahia alone produces about 300,000 tons of dry cocoa seeds. Each ton of dry seeds represents 300,000 tons of pulp, of which 60% will be needed for fermentation, leaving an excess of 120,000 t. If only 10% of this was utilized, there would be sufficient raw product available to produce 12,000 tons of pulp. Although cocoa pulp is now essentially a waste product, exploitation will require a considerable investment in freezer processing equipment.

In the Cocoa Research Institute of Nigeria, excess pulp, which has a delightful tropical flavor, has been used to produce the following products: cocoa juice, cocoa wine, cocoa jelly, pectin, alcohol, and vinegar.

2.2.1 Cocoa Juice

Cocoa juice is the natural water or juice (sweating) obtained from the cocoa beans during primary processing of the beans, this juice is hygienically collected, pasteurized, and bottled. It is a highly refreshing drink when drunk cold.

2.2.2 Cocoa Wine

Cocoa wine is produced from the juice or cocoa sweating that is obtained during primary processing of the bean. Then processing continues with sterilization, inoculation with wine yeast, fermentation, racking, aging, pasteurization, and bottling of the wine. Presently CRIN has a small scale laboratory production of cocoa wine within the Institute.

2.2.3 Cocoa Jelly

Approximately 40 L of cocoa sweating/pulp can be obtained from 800 kg of wet seeds. Cocoa jelly is produced by cooking fresh pulp mixed with sugar at the rate of 300–600 g to 1 L of pulp. The pulp contains about 1% pectin. The jelly has a fruity acidic flavor and is a popular delicacy.

2.2.4 Alcoholic Spirit

Cocoa pulp juice is inoculated naturally with yeast and is then allowed to ferment for 3 days. The alcohol is distilled using a distillation plant. It may be blended and bottled to make gin or brandy. It may also be used as a technical grade alcohol. By controlled fermentation and distillation, sweating can be made into an alcoholic spirit with 43% ethanol. The alcohol produced can be further fermented by Acetobacter sp. to produce acetic acid, but the vinegar has not yet been promoted as a commercial product.

2.2.5 Pectin

Pectin is extracted from fresh pulp juice by precipitation with 60% alcohol. The pectin is used to prepare marmalade and jam.

2.3 Cocoa Pod Husk

The pod of the cocoa tree is a bulbous outgrowth which grows attached along the main and lateral branches. Cocoa pods vary in shape and colors. In cocoa fruit, the cocoa pod (husk) is about 56% of the whole weight of matured fruit. Proximate and chemical analyses of cocoa pod husk revealed it to contain the following: crude protein—5.0%–6.2%, crude fiber—32.1%–35.0%, crude fat–0.87%, ash—8.76%. Acid detergent fiber, neutral detergent fiber, and total digestible nutrient are 43.8%, 56.6%, and 60.0% respectively.

This pod husk itself is made up of three layers:

- Epicarp—the outermost layer

- Mesocarp—the inner layer

- Endocarp—the innermost

After the fresh cocoa pod is opened and the seeds are removed, the empty pod is known as the husk. Nigeria is presently producing over 1 million tons of husks, most of which go to waste. Each ton of dry seeds represents about 10 tons of husks (fresh weight). At the present time, pod husks are a waste product of the cocoa industry, and present a serious disposal problem. Harvested cocoa pods are collected at a central location in the cocoa farm. Here, the pods are broken, cocoa beans are removed and the husks are then discarded as waste. This waste becomes a potential source of pathogens, such as black pod disease, because the pods harbors Phytophthora palmivora, the causal fungus of the disease. Moreover, they become a significant source of disease inoculum when used as mulch inside the plantation. It was advised that husks be burnt into ash as a method of farm sanitation and for the control of the disease. When measured dry, about 60% of the cocoa pod is made up of husk; this means that the quantity of cocoa husk generated on cocoa farms is about 20% more than that of dry cocoa beans. Research efforts of turning waste into wealth have led to various attempts to find diverse uses for cocoa pod husks.

2.3.1 Cocoa Husk Endocarp

This is another newly discovered feedstuff from cocoa pod husks. Husk endocarp is the inner lining of the husk. It is less fibrous and thus succulent.

Cocoa husk endocarp has a considerably lower crude protein and higher crude protein compared to CPH. Because it is an emergent feedstuff, it has undergone few experiments to determine its various qualities and properties. In CRIN, consider the waste mitigation potential if cocoa pod husk were to replace about 15% of maize in poultry diets, 20% of maize in quail feeds, 35% of basal ingredients in cow, sheep, and goat feeds, and 10% of maize in fish feed. What enormous proportion of the over 1 million tons of discarded husk could be salvaged? Similarly, a substantial reduction in both the cost of feed production, as well as the overall cost of the animal in question. This is by no means a total shift from waste-to-wealth, but is closer to the mission of the End Uses Research Department (EUR) of CRIN.

2.3.2 Cocoa Pod Husk

The following economic products could be made from cocoa pod husk:

- Animal feed: In the production of animal feed, fresh pod husks are sliced into small flakes, dried, and milled with other ingredients for feed formulation for chicken, pigs, and sheep. Also, CPH could be used as wet feed for pigs, sheep, and horses.

- Potash: Cocoa pod husk ash is produced by drying fresh CPH, incineration in an ashing kiln into ash. The ash is used for soft soap and detergent manufacture. It could also be used as fertilizer for cocoa, vegetable, and food crops.

- Fertilizer: use in the production of organic fertilizer.

CPH as Animal Feeds

CPH contains nutritive value, enabling its use in animal feed materials, but this is limited by the theobromine content which is toxic to livestock.

Dried CPH can be fed to cattle up to 7 kg per day without toxic effects, and up to 2 kg per day to pigs without adverse symptoms. Animals fed on CPH diet tend to consume more water, due to the high sodium content of CPH. Water absorption in the small intestine is proportional to the rate of sodium chloride adsorption. More importantly, animals fed CPH diets tend to have a leaner body. It has been discovered that in chickens, when consuming more than 10% CPH, laying hens produce darker yolks and broiler birds produce larger gizzards, which both are preferred. Fresh or dried husks may be used as livestock feed, but theobromine content (ca. 0.4%) restricts the proportion which can be consumed, and its use has been limited. Although acceptability by animals is satisfactory, digestibility is considered poor and dependent on the husk processing. Reports indicate that pod meal can constitute 20% of ration for poultry, 30%–50% for pigs, and 50% for sheep, goats, and dairy cattle, but these values may be too high. The toxic dose of theobromine for rats (LD50) is 1254 mg/kg. Low digestibility of polysaccharides restricts the use of pod husks for methane production in biodigestors. There are two known antinutritional factors present in cocoa husk, theobromine and caffeine. The one most widely reported on in literature is theobromine. Theobromine is a key antinutritional content of cocoa pod husk. Therefore to make CPH useful, various treatments have been tested to solve the antinutritional problem in order to make it possible for inclusion in livestock diets. These treatments include sun drying and alkaline treatment.

The following studies were conducted in CRIN with the use of CPH inclusion in animal feed:

- (a) In layers mash—20% optimum level of CPH inclusion in layer diet has been established as economical for laying hens.

- (b) In broiler mash (starter and finisher)—10% replacement level of CPH is reported to be optimum in raising broiler chicks.

- (c) In cockerel diet—20% inclusion of CPH in cockerel diets can be used to produce table size cockerel.

- (d) In quail feed—14% dietary inclusion of CPH has also been established for raising growing quail.

- (e) In fish diet—15% substitution of maize for cocoa pod husk, cocoa husk endocarp has been reported suitable for feeding both catfish and tilapia species of fish.

- (f) In growing land snail—up to 40% maize replacement level can be tolerated by growing snails.

- (g) Dried CPH as energy source in fish smoking—dried CPH has been established as a suitable heat energy source for fish smoking.

CPH-Source of Potash for Soap

Cocoa pod husks contain 3%–4% potassium on a dry basis. Pod husk ash has been used to make soap in Ghana and Nigeria. The application of potash from CPH for soap production as a means of converting waste to wealth has brought smiles to cocoa farmers across the producing states. The word potash is derived from extraction of wood ashes with water to produce potassium hydroxide or potassium carbonate solution. The use of waste CPH on cocoa farms as a source of potash will meet few or no obstacles in terms of raw material availability. Its use as laboratory reagent and will also serve domestic and industrial purposes.

Potash Extraction From Cocoa Pod Husk

Potassium salt which is used for soap production can be extracted from cocoa pod husk. The following steps are involved in the process:

- Collection of cocoa pod husk: Cocoa pods are harvested, the beans removed, leaving the pod husk. This procedure involves using a club to reduce injury to the beans and the husks are collected together. One advantage of this process is reduction of pathogenic host in cocoa farms (Fig. 1).

- Drying of cocoa pod husk: Conventionally, this is achieved through sun drying. This is done to lower moisture level to reduce mold growth.

- Ashing: This involve burning dried CPH. Two main burning methods are employed: the kiln and the drum methods. These two methods are preferable to normal open burning because they ensure controlled burning conditions by managing exposure to oxygen.

- Extraction: The ashes are transferred to a truncated and perforated metallic drum lined with a sack or plastic mesh. The barrel containing the ash is placed on a stand with a receptacle (catch basin) placed underneath. Sufficient clean water is poured on the ash in the barrel to dissolve the salt. The salt solution is drained into the receptacle.

- Crystallization: The solution is then transferred into another metal barrel. The barrel is heated to boiling point and the water evaporates, leaving the salt. After evaporation, the metal barrel is removed from the heat source and the content stirred to prevent formation of lumps. The salt is continuously stirred in the pot until it is cooled to ambient temperature.

- Packaging of potash: This is carried using any suitable packaging material.

- Safety precautions: The purity percentage for the salt is high (≈ 70%) thus, workers’ skin must NEVER be exposed to the salt, especially with bare hands. Intense heat and smoke generated during husk burning, as well as during the evaporation process. Coveralls, heat resistant coats, goggles, safety boots and heat/chemical resistant gloves must be worn throughout the processing.

Procedure

The red color of palm oil (PO) is removed through bleaching at high temperatures—the oil becomes oxidized. The bleached palm oil (PO), palm kernel oil (PKO) and the butter are blended in the right proportion, heated and stirred to ensure a homogeneous mixture.

The oil mixture is allowed to cool almost room temperature. The mixture is filtered into a plastic bowl or a stainless steel container. It is then ready for saponification. A calculated amount of caustic soda, equivalent to the SV of the blend, is made into a solution and allowed to cool to room temperature. It is slowly incorporated into the oil employing one-direction stirring until it forms a viscous, uniformly thick mass. It is then poured into molds and allowed to solidify overnight. There is a need to reduce the moisture content of the crude soap to 10%–15% for it to qualify for cake or bar soap production. The crude soap is shredded into smaller pieces to facilitate drying at a temperature of about 40°C. The resulting dry soap chips become the base material for body soap. The soap chips are mixed with additives, including fragrance and dye, in a mixing machine. The mixture is poured into a three-roll mill where it is squeezed through the first two rolls and picked up by a faster roll to ensure that the mixture becomes homogenized. The ribbons scrapped from the final roll are thoroughly uniform. The ribbons are fed into an extruder where an internal screw forces the soap into a compression area terminated by a tapered outlet fitted with a die through which a bar of soap is continuously extruded. The soap bars are cut into predetermined smaller bars to fit a dice (mold). The cut soaps are then stamped in a mold which has the appropriate inscription or brand of soap.

Dried CPH can be burnt and the ash is used as a source of potassium carbonate for the manufacture of soft soap. The CRIN has set up a pilot scale liquid soap production within the institute, and training program is underway for interested farmers or individuals to develop skills and knowledge in value addition. Some of the marketable by products currently being produced are as follows.

Liquid Detergent

This is a by-product obtained from cocoa pod husk ash. It is been produced in CRIN and many interested individuals can manage its production alongside their cocoa farms for value addition.

Black Soap

This is a body soap obtained from the ash of cocoa pod husk. It is used as bathing soap with good quality foaming and cleaning ability.

Body and Hair Cream

This is the incorporation of cocoa butter into ingredients that are later used to produce body and hair cream.

2.3.3 CPH as Fertilizer

Cocoa pod husk contains high amount of potassium and has been used as fertilizer or compost. It is been used as compost or mulch when left to rot in the cocoa farm where it recycles nutrients back to soil, and also serve as breeding ground for midges. Midges are the chief pollinators of cocoa; increasing the amount of midges enhances pollination efficiency, and ultimately, pod yields.

Cocoa pod husks can also be burnt and the ash used to manufacture a potassium containing fertilizer. This can be packaged and sold to farmers.

2.4 Cocoa Bean Shell for Animal Diet

Cocoa bean shell (CBS) is the brownish outer covering of a cocoa bean. It is the sheet which envelops the bean cotyledon. Cocoa bean shell is an industrial ligno-cellulosic waste material produced at cocoa and chocolate factories, especially in industrialized countries and it forms 12%–14% of the roasted cocoa bean. CBS disposal did not appear as a problem in Nigeria when cocoa processing industries were still at infant stage. However, as many industries started to grow, disposal of this byproduct gradually became an issue. The possibility of using this CBS as a potential tropical feed resource and its utilization in animal feed, greatly reduces the disposal problem facing cocoa processing factories. The dried CBS contains 13.12% crude protein, 13.00% crude fiber, 8.71% ether extract, and 9.15% ash.

Treatments for antinutritional factors are the same as with cocoa pod husks. The CRIN has significantly contributed toward the evaluation of cocoa bean shells as ingredient in animal diets. To address this problem, a series of studies were conducted on the best processing techniques to pretreat cocoa bean shell so as to make it better utilized by animals. Further studies were then conducted to incorporate both the raw and treated CBS into various classes of animals (particularly mono-gastrics). Results from these studies established that perboiling of CBS for 15 min and re-drying it, is the most efficient method to de-theobromize CBS. Several other feeding trials were done, to ascertain the biological efficiency of the husk. These studies include: 5% and 7.5% inclusion rate of CBS in broiler diets (starter and finisher), 10%, and 15% inclusion in cockerel starter and finisher. Additionally, CBS has been commercially evaluated for inclusion in layer feed. It was found to be biologically efficient at 15% inclusion rate.

Up to 0.8 kg of cocoa bean shell (a good source of vitamin D) are acceptable to cows, but pose health risks to the animal. This is also the case with pigs. This can be rendered harmless if the theobromine is removed by cooking in water for 1½ h, filtering, and drying. After this treatment, up to 25% of treated product can be included in rations for pigs without reduction in weight gain or feed efficiency.

Cocoa bean shell can be used as mulching as it contains 2.5% nitrogen, 1% phosphate, and 3% potash, as well as natural gum which is activated when moistened. It slows moisture loss and inhibits weed growth. The texture of coca been shell also deters slugs and snail which helps prevent plant loss.

2.4.1 Cacao Pigment

A cocoa husk extract, called cacao pigment, is a mixture of condensed or polymerized flavonoids (such as anthocyanidins, catechins, leukoanthycyanidin), and sometimes linked with glucose. It has been used in Japanese food industries (Kimura, 1979). Recently this extract has been shown to inhibit cytopathic effects of HIV in cell culture (Unten et al., 1991). The anti-HIV activity was attributable to interference with the virus adsorption, rather than inhibition of the virus replication after adsorption.

3 Cashew Waste

3.1 Value Addition for Cashew Waste

The cashew plant (Anacaduimoccidentale L.) is a native of Central Brazil in South America. Today the plant is widely grown in the continents of Asia, Europe as well as Africa. Historically, Mozambique and Tanzania were the main cashew producing countries in Africa, with smaller amounts produced in a number of other countries. It was introduced into Nigeria in the 15th and 16th century by Portuguese traders. Cashew is hardy and drought-resistant; it grows well in most tropical soils and climates. The nut is obviously an important product of the cashew tree, but this tree also yields the pear-shaped apple to which the nut is attached. About 16 years ago, Nigeria was reported to be the highest producer of cashew, with about 176,000 tons produced. The cashew apple was relatively neglected until recently, when the idea of waste-to-wealth conversion began to gain greater attention. Cashew fruit is made up of the apple that bears the nut in which the kernel is embedded. Of the cashew fruit, the two main edible products are the cashew nut and the cashew apple. In the past, cashew nut was the sole target of cashew farmers. Because of this, very little attention is given to other produce from the cashew tree. Almost all the cashew apples produced annually are left to waste. Consumption of the apple (eaten raw) is isolated to people who live in the rural areas where cashews are grown. A greater percentage of production is lost as waste on farms when overripe apples drop freely from trees and are left to rot on the ground. Presently, advancement in the field of technology has considerably enhanced the relevance of this waste to the benefit of both people and animals. Today, cashew apple is now used for wealth creation in various ways. These include: cashew juice, cashew wine, ethanol production, as well as a dried form of cashew apple (baggase) which can be substituted or be used to supplement an animal diet. Additionally, Vitamin C extraction from the juice could be used to augment other sources in animal diet.

Very little economic value is realized by farmers who cultivate cashews.

The three main cashew products traded in the international market are raw cashew nuts, cashew kernels and cashew nut shell liquid.

The cashew is widely cultivated across the coastal regions of the tropics and is known to have high utility value. The fruits, leaves, bark, wood, and roots have all been reported to be of valuable commercial use for food, medicine, industry, and the environment. The cashew kernel is widely consumed roasted, fried, as savory or sweet snacks, and as an ingredient for confectionery and bakery products, and as a food ingredient, because it contains vital minerals which are seldom found in other staple foods. The relative abundance of monounsaturated fatty acid in cashew nut is conducive to the promotion of good health, and the relative abundance of fat in cashew nuts pose no health risks. The advantage of the cashew nut is that it has a delightful taste, is meaty and quite palatable as is. This has resulted in an upsurge of growing interest in the cashew.

The seed has a double shell containing an allergic phenolic resin; arcadic acid, a potent skin irritant chemically related to the better known allergenic oil (urushiol) found in poison ivy. Properly roasting cashew nuts destroys the toxin. The cashew nut is a high value nut which yields two oils. One of them is obtained between the seed coat and the nut; it is known as the cashew nut shell liquid (CNSL). It is not a triglyceride, therefore cannot be converted to biodiesel, but it does contain a high proportion of phenolic compound that can be polymerized in a variety of ways. This makes it a versatile raw material for industrial application, with diverse uses in friction linings, paints, varnishes, laminating and epoxy resins, foundry chemicals and as an intermediary of chemicals. It is, however, toxic and corrosive to the skin. The second oil obtained from the nuts contains triglyceride, therefore it is a potential and abundant source of feedstock for the production of biodiesel. It is used for manufacturing wood preservatives, coating and friction materials. Cashew nut rejects is a waste material/product from the cashew nut processing industry. It is regarded unsuitable for human consumption because of its lower quality grade.

In most of the African countries, especially Nigeria, the tree is grown mainly for its pseudo apple and nuts, which are mainly consumed raw, that is unprocessed. It is an economically important tropical and subtropical evergreen tree with a low spreading habit, reaching an average height of 10–15 m. The economic produce of the crop is the apple and the nut. The apple is the swollen flower stalk, appearing bright orange or yellow color when ripe. Its flavor is sweat with a slight astringency. An array of edible preparations such as juice, syrup, jam, and candy can be made out of the apples because of its highly fermentable nature and sugar content.

Various opportunities exist in cashew production and its by-products, which could generate and increase farmers’ revenue. However, these opportunities are not currently adequately utilized because the present consumption of the cashew pseudo apple is about 10% of total cashew production. Most of the cashew nuts produced in Nigeria are exported, therefore the economy of the producing areas depends considerably on price fluctuations in the international market.

The waste generated from the production and processing of Cashew are:

- Cashew apple; Pomace

- Cashew nut shell; Cashew nut shell liquid

- Cashew testa

The utilization of these wastes has great potential to generate additional wealth for the farmers and other stakeholders. The utilizations are as follows.

3.2 Cashew Apple

The cashew ‘fruiť is very peculiar and is really not a fruit, but rather a swollen pedicle that grows behind the real fruit, which yields the nut, the cashew. This large pulpy and juicy part is a pseudo fruit, with a true sweet flavor and aroma. The cashew apple is almost pear shaped, and looks like an overripe apple. Its color seems to be a blend of varying amounts of purple, red, and yellow. The weight of the fruit is 3–6 times that of the kernel. Juice and concentrate of cashew apple tends to become dark, due to the presence of leucoanthocyanins or other polyphenols. The major polyphenolic constituent in cashew apple is reported to be Leucodelphinidin. Browning generally starts when the juice has been concentrated at 20–22°Bx. The pulp is dull yellow, tough, and very juicy, some varieties have an astringent flavor, and the juice is generally treated with gelatin solution. Often the fruit is very low in acid content.

The cashew apple can be eaten raw or used in the production of jam, chutney, pickles or various beverages such as juice and wine. The cashew apple is used mostly for the production of juice. Its residue is composed of the skin and the husk. It is frequently used for animal feed or altogether discarded as waste. The residue has a dark yellow color, fibrous aspect, and typically has an astringent aroma due to the presence of tannins. This could be a limiting factor for acceptability of the cashew apple and the juice, especially in foreign countries. More recently, many studies have been conducted to develop new cashew products and to make a better use of this source of dietary fiber.

3.2.1 Cashew Apple Waste as Cashew Juice

Cashew apple, a product of the fruit of the cashew tree and a by-product of cashew nut harvest, is presently underutilized in Nigeria. There is so much wastage of the fresh apple on farms because only a negligible portion is consumed by the harvester. Extensive efforts have been made by CRIN to capture the value of this wastage and turn it into commercially viable human foods or food ingredients. Much progress has already been made on the production of juice from the apple.

- The cashew apple is about five times the weight of the nut. It contains 85% juice with 10% sugar, most of which are invert sugars.

- Most juice provides vitamin C, a necessary constituent of the human diet. Vitamin C deficiency causes scurvy and delays the healing of wounds. The vitamin C content of the juice ranges between 90 and 170 mg/100 (levels far higher than oranges) and its use will increase the nutritional health of the rural communities where it is produced.

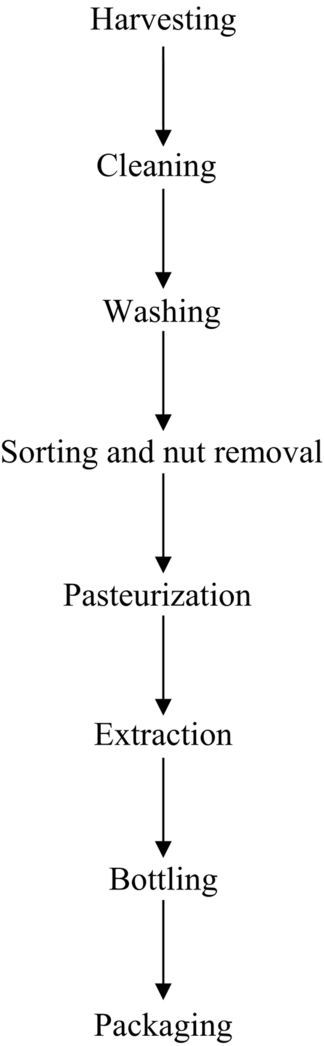

Cashew juice production involves the these steps: picking mature and ripe apples during peak season, sorting to remove damaged and infested apples, washing, using manual cashew juice extractors to express the juice, and packaging the cashew juice.

Production of cashew juice involves pasteurization, extraction, and bottling. The process involves the use of cashew juice extractor and pasteurizer. Recently, a cashew juice extractor was locally fabricated for cottage cashew juice production. The machine proved feasible and commercially viable. An economic evaluation of the extractor machine revealed that the locally fabricated small-scale equipment will process 31.82 kg apples per hour with a yield of 67.88% at 87.20% efficiency. This is equivalent to 172.8 L of juice or 493 bottles (35 cL) per day following an 8-h working operation. Therefore, it is important to encourage extraction of the juice from the cashew apple utilizing the locally fabricated equipment. Support should be given to CRIN farmers and other local entrepreneurs running small-scale operations. Additionally, in order to increase the growth of this cottage industry in most cashew producing areas, small-scale farmer groups or co-operatives, comprising no less than 20 members are eligible for assistance from credit programs designed to promote small-scale enterprise (Fig. 2).

3.2.2 Cashew Apple for Cashew Wine

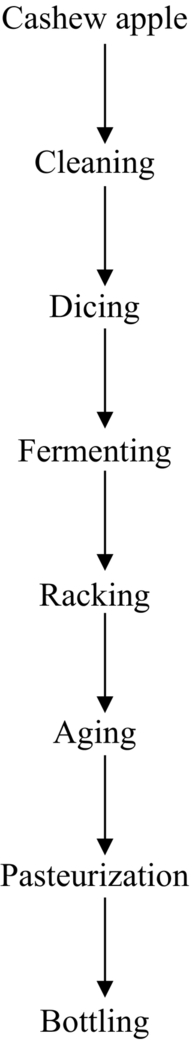

Juice from ripened cashew apples are fermented into wine using the wine yeast Saccharomycescerevisae. The fruits contain sufficient amounts of fermentable sugars necessary for fermentation. If fermentation continues, all the sugars are used up and the resulting wine will be dry. If it is halted while some sugars remain, the resulting wine will be sweeter. The alcohol content of cashew wine produced in CRIN is 10%.

Wine production involved fermentation, racking, aging, pasteurization, and bottling. Cashew wine is widely accepted and compared favorably to commercial wines. It is characterized with a unique cashew apple flavor (Fig. 3).

3.2.3 Cashew Apple Waste

Cashew apple waste (CAW) is the residue or by product obtained from processed cashew apples after juice extraction. Until quite recently, the waste, usually referred to as shaft, was neglected and thrown away. Now, with the advent of research findings, it has been enlisted among the emerging agro feedstuffs. After extraction, CAW is then sun dried to reduce the moisture content. This can then be ground into pieces or added directly to feed, depending on the type of livestock.

The proximate composition of the CAW in percent of dry matter is C·P—18.7%, C·F—8.4%, E.E—2.4%, ash—5.4% with notable quantities of mineral elements and total sugars.

To date, no antinutritional or toxic factors have been reported present in CAW.

3.2.4 Cashew Apple Hamburger

The production of hamburgers with partial substitution of beef with cashew apple residue improved the product and which presented high nutritional quality which was rich in dietary fiber and low in fat when compared to conventional ones. It was higher in proteins when compared to vegetable hamburgers. They produced a good yield and a lower rate of shortening when compared to the control sample. The addition of up to 10.7% of cashew apple residue did not significantly change the sensorial qualities in terms of taste when compared to the control sample. Therefore, product prepared with partial substitution of meat with this residue can be considered a very feasible product for use in commercialized food production.

3.2.5 Cashew Apple Livestock Feeds

Cashew apple waste is a good feed resource for rabbits and can be included in their diets, up to 30%, without significant adverse effects on performance, protein digestibility and meat quality.

3.3 Cashew Nut

The cashew nut grows externally in its own kidney shaped hard shell at the end of the pseudo fruit or pedicle, which is commonly referred to as the cashew fruit or cashew apple. The shell is 2–3 m thick, with a leathery outer case and a thinner, harder inner case, between which is a honey comb structure containing the phenolic cashew nut shell liquid.

The primary product of the cashew nut is its kernel which is used extensively in the confectionery and baking trade. The cashew nut kernels are popular desserts, generally eaten roasted and salted. The kernel is protected from the latter by the tough skin and the inner case, and is a rich source of protein, carbohydrate, and triglyceride found in the cashew kernel oil. The kernel and the shell liquid each comprise 20%–25% of the nut. The remaining parts are comprised of the testa and shell structure. Cashew kernel oil, as a good source of vegetable oil, has been recognized and is used in domestic cooking and pharmaceutics. Cashew kernels have high nutritive value. They contain protein (21%), fat (47%), moisture (5.9%), carbohydrates (22%), phosphorus (0.45%), calcium (0.05%), and iron (5%), as well as other mineral elements. Cashew kernels contains 47% fat, however 82% of this is unsaturated fatty acid, which lowers cholesterol levels in blood. The most prominent vitamins in cashews are vitamin A, D, and E, which help to assimilate fats and increase the immunity level. The cashew has a long record as a useful plant, but only in the 20th century did it become an important tree crop. It has the potential to provide a source of livelihood for the cashew growers, empower rural women in the processing sector, create employment opportunities, and generate foreign exchange through exports.

3.3.1 Chemical Composition

The chemical composition of cashew nut is.

3.3.2 Cashew Nut Crumbs

Cashew nut crumbs (not to be confused with cashew apple waste) is obtained from the cashew nut after the shell has been removed during processing. Cashew nut crumbs are the pieces of broken nuts occasioned by the nut extractor during processing. These crumbs usually come in a mixture of pieces of nut testa. Formerly, they were thrown away as waste. Recently, results of proximate analysis established cashew nut crumbs as a possible replacement for protein sources in conventional feedstuffs.

No antinutritional or toxic factors have been reported present in cashew nut crumbs.

Cashew Shell Cake

Crushed cashew shells are compacted to make fuel cake. This burns at very high temperatures and is used in the cashew industry, as well as industries with high energy requirements such as tile and brick making.

3.3.3 Uses of Cashew Kernel

Snacks, cashew kernel oil, vegetable oil, cashew kernel milk, yoghurt production, fortified cookies, crackers, and bread

3.4 Cashew Testa

The cashew kernel posses a seed coat, the testa, which, like a peanut skin, tightly covers the cashew kernel and has to be removed in shelling. Though it has been treated as a waste and is discarded, cashew testa has commercial uses too. It is used in poultry and ruminant feed, and also in tanning leather a reddish color. It is use for making dyes, pigments, and paints.

3.5 Cashew Tree Bark Gum

The gum, which is produced in appreciable amounts by the cashew tree, represents nonconventional alternatives for the farmers (Smith and Montgomery, 1959). Gums taken from the exudates and extracts of plants have been given a lot of attention due to the many potential uses in industries and potential international market value. To date, most of these industries use gum Arabic which is mostly imported and limited in supply. Cashew gum has been found to be similar to gum Arabic in terms of organoleptic and rheological properties (Gyedu-Akoto et al., 2007). It has also been found to possess good physico-chemical properties and high mineral levels, and therefore, can be used in meal replacers, nutritional beverages and weight-loss products (Gyedu-Akoto et al., 2008).

3.6 Cashew Nut Shell Liquid

Cashew nut shell liquid (CNSL) is embedded in the honey comb pericarp of the nut. It is a viscous brown liquid which is phenolic in nature. It is a byproduct of the cashew nut industry. The components of this liquid include: Anacardic acid (71.7%), cardol (18.7%), cardanol (4.7%), novel phenol (2.7%) and an minor unknown ingredient (2.2%) (Tyman and Morris, 1967). The liquid has been identified as an important industrial raw material (Ghatge and Maldar, 1981). For example, CNSL has been recognized as a good source of unsaturated phenol, an excellent monomer for polymer production. It is a good natural alternative to petrochemically derived phenol.

The interesting molecular structure of cardanol gives some interesting properties, such as quick drying after baking, high electrical insulation and good thermal stability. Additionally, cardanol based resin possesses outstanding resistance to the softening action of mineral oils, as well as high resistance to acids and alkalis, antimicrobial properties, and termite and insect resistance. On the basis of these properties, cardanol excels over petroleum based phenol products and can be used as a substitute, often at significantly reduced cost.

CNSL holds a high place of significance as a source of unsaturated phenol, an excellent monomer for polymer production. Its derivative, cardanol, is extensively used in the laminating industries for reducing brittleness and improving the flexibility of laminates. CNSL has also been put to use in brake linings, as antifade, and adhesives. Apart from the polymeric products, CNSL forms the basis raw material for a vast number of industrially important chemicals and chemical intermediates, for example chlorinated products of hydrogenated cardanol were found to possess pesticidal capabilities.

Toxic cashew nut shell liquid is found in the hard, honey-comb shell that surrounds the cashew kernel. Workers shelling cashews try to avoid contact with CNSL because it can ruin the cashews and irritate workers’ skin. CNSL is extracted from cashew shells by cooking the broken shells at high temperatures. Due to its high resistance to heat, CNSL is used in the manufacture of brake linings and epoxy coatings. It is also used in paints, varnishes, and specialty inks.

CNSL is an excellent source of phenol for polymer production.

3.6.1 Uses of Cashew Nut Shell

Cashew nut shell liquid (CNSL) contains dermatogenicphenolic resin, urushiol, which is a potent skin irritant toxin. It can be used to cure fungal infections on human skin. It is used for surface coatings, resins, brake linings, and brake fluid.

Cashew nut shell is used as activated carbon which serve as an adsorbent. It is also used as a source of fuel.

3.6.2 CNSL in Surface Coating

The use of paints and related finishing material for protective and decorative values is as old as humankind itself. The organic coating industry has continued to grow in outlook, and has provided products of improved quality. Supplied with an increasing diversity of new raw material by the chemical industry, coating research technology has been able to come up with new coating materials and systems, and has also modified the older product lines to meet the demand for higher quality finishes at reasonable cost.

In a remarkable state of preservation, neolithic paints have been found used on the walls of caves of our primitive ancestors in western Europe.

The desire to protect their weapons and armor from rust prompted the Romans to develop varnish made of tar. However, the first paint made was discovered and recorded by an American in the early part of the 19th century. This consisted of white lead impregnated in linseed oil with ochre as pigment. Research on the chemistry of coatings, coupled with improved marketing technique, has led to the development of more excellent and economical coatings.

3.6.3 Formulation of Surface Coating Using CNSL

In the early stages of the surface coating industry, substances of natural origin, such as linseed oil, bitumen, and Congo resin, were used as binders. But because of the advancement in technology, the modern coating systems uses synthetic resins that possess qualities far superior to those of natural origin.

Beside alkyd resin, which formed the largest class of synthetic resins in surface coatings, the presence of phenolic components in CNSL has made it an important low cost and widely versatile raw material in several multifarious chemical applications, including surface treatments. Protective coating based on CNSL was synthesized by workers and the performance of these coating materials was evaluated by accelerated and chemical resistance tests. The results proved the material could be used for protection in corrosive environments.

Other areas of application of CNSL is in flame retardation. Workers have evaluated the flame retardant characteristics of natural rubber modified with the derivative of CNSL, and have found them excellent in this regard. Resin coating has been synthesized using CNSL and the results indicated excellent performance.

3.6.4 CNSL in Rubber Processing

The rapid growth of the rubber industry has led to an increasing demand for auxiliary chemicals commonly called rubber ingredients. These are substances, principally organic, used in compounding for vulcanization, facilitating the fabrication of the product, and improving its quality and stability. Cashew nut shell liquid and its derivatives have found wide application in the rubber industry. For example, when sulfur is heated with CNSL, a gummy material which can be used for impregnation and as a rubber substitute is obtained (Harvey, 1930). He also reported that a rubber-like substance can be obtained by heating CNSL with glycerin at about 240°C, which can be used in a variety of applications. Other workers (Newman et al., 1995) also reported that when CNSL is intermixed with natural rubber, it enhance the insolubility of the vulcanized material in petroleum solvent. In vulcanized state, CNSL makes the rubber insoluble, but in the unvulcanized state or partly vulcanized state, the effect is the opposite, and the speed of dissolution in benzene, petroleum carbon disulfide is enhanced. The presence of CNSL also helps the process of incorporation of sulfur and other ingredients, and increases the resistance to moisture. Latex of styrene butadiene rubber or nitrite rubber can also be mixed with CNSL modified phenolic resins and hexamine, and then mixed with fillers to get composites suitable for molding and extrusion.

CNSL derivable chemicals have been used for vulcanization of synthetic rubbers. The synthesis of a new active nonsulfur vulcanizing agent, 2-pentadecyl benzoquinone dioxime from CNSL, was also reported.

More recently, the vulcanization characteristic of unfilled natural rubber compound was studied (Menon et al., 1998) in the presence and absence of cashew nut shell liquid, using an oscillating disc rheometer at various temperatures. Results showed that modification of a gum, NR compound with 10 phr of CNSL, results in a decrease in the state of cure and increases in the cure rate index and rate constant of vulcanization.

4 Coffee Waste and Its By-Products

4.1 Coffee Waste

In coffee processing, two different main methods are used to obtain intermediate products that are usually treated in the same way to provide coffee bean of high commercial value. These methods are dry processing, which produces dry cherry coffee and is generally used for robusta coffee; and wet processing, which produces (dry) parchment coffee and is mainly used for Arabica, a mild coffee, when fermentation is included in the preparation process. The green coffee of international commerce constitutes only 55% of dry matter of the ripe cherry (18% on a fresh weight basis). The remaining materials are recorded as waste, which can be diverted into a variety of value added by-products.

At different stages, from harvesting, to processing and consumption, several residues, namely coffee pulp or husk, leaves and spent-grounds, are generated in a quantity over 2 million tons yearly. Among these byproducts, coffee pulp is the most important. It is formed from the epicarp and part of the mesocarp of the fruit, and it represents about 28.7% on a dry weight basis when obtained by the wet coffee processing method. Millions of tons of coffee pulp are produced worldwide every year and, due to its difficult and improper handling, it causes many water pollution problems in rivers and insalubrious conditions in the areas where it is discarded.

Coffee is an agricultural crop of significant economic importance. After processing to obtain the bean, the major wastes generated are:

- Coffee hull/husk

- Coffee pulp

- Coffee mucilage

- Coffee waste water

Better utilization of these by-products could make the cultivation and processing of coffee more economical and diminish its environmental impact.

4.2 Coffee Husk/Hull

4.2.1 Coffee Husk as a Fuel

Coffee husk is practically pure lingo-cellulose and has no fertilizer value at all. Dried coffee husks are a useful source of cheap fuel with a calorific value of around 14 MJ/kg. It is normally burnt in crude furnaces to dry the coffee parchment. If most of the parchment is partially sun dried for quality reasons, then, even using crude single pass hot air driers, it is still possible to have a surplus of fuel after the drying operation is finished. They are used extensively for this purpose in coffee drying, and because any excess may be burnt, they pose no serious disposal problems. Another potential process is to burn the husk in a gas producer, and then run an engine on the gas to produce electricity. Once again, as with biogas, the waste heat from the gas producer and engine can be used to heat a clean air stream to dry more coffee beans. Conversion of surplus husks to charcoal, in which the energy is more concentrated (calorific value 29.4 MJ/kg), would reduce fuel transport costs and may offer some positive financial returns.

4.2.2 Husk as Animal Feed

Husks have the virtue of being readily available at low cost during the harvest season. Results from various studies present opposing conclusions regarding the use of coffee bean husks as animal feed. In a study carried out by Rogerson, the nutritive value of coffee husks was assessed and it was concluded that it could neither be a useful basic feed, nor as concentrate supplement, because the digestive protein content was very low and the starch equivalent value did not exceed that of fairly poor quality hay. However, a subsequent trial in East Africa showed that the husks can replace up to 20% of the total ration without affecting food intake, weight gain or feed conversion. In another study, it was shown that a 20% inclusion rate in dairy cow rations had no significant effect on the quantity and quality of milk yield.

Utilization of the Coffee Pulp

Coffee pulp is the major primary byproduct from wet processing of coffee cherries. For years, the only use for coffee pulp was as a fertilizer for the coffee plant, a practice dictated more by the lack of alternative usage of the pulp, than by its effectiveness as a fertilizer. The uses of the coffee pulp are: growing mushrooms, composting, livestock feed, production of ethanol and wine, production of vinegar

4.2.3 Coffee Pulp for Growing Mushrooms

Coffee pulp can be handled on the small-scale family level operation with ease. The fermented and partially dried pulp can be used as a substrate for growing exotic mushrooms. Of particular interest is the remixing of husk and semidried pulp for rapid growth (in weeks) of shiitake, linchi, and other mushrooms, which usually take many months to grow using billets of cut oak wood. The production of pleurotus or oyster mushrooms, which normally grow on rotting trees in the wild, is even more rapid. In areas where mushrooms are a prized food delicacy, smallholder coffee growers can bring in significant cash flow from their local markets.

4.2.4 Coffee Pulp Solids as Compost

Composting is a system of solid waste management in which environmental conditions are optimized to accelerate the process of decomposition. Correctly operated, it is produced quickly and without nuisance, creating a harmless and mild end product which can easily be handled, stored, and applied to land with no adverse effects. Coffee pulp solids contain only one fifth of the nutrients taken out of the soil by export of the green bean. However, it is a good source of humus and organic soil carbon. If coffee pulp is heaped, turned over every few days, in 3 weeks time it will compost down to one fifth the original volume, into a stable earthy smelling material which does not attract flies. In conventional compost making, the material is preserved for a few years. Additionally, coffee pulp solid compost left to mature for 3 months undercover will reduce further to become very nice dry earthy compost, which is a good soil conserver and conditioning agent, and also will improve the long term quality of the soil.

4.2.5 Coffee Pulp as Livestock Feeds

Coffee pulp can replace up to 20% of commercial concentrates in dairy cattle feed, with no adverse effects to the animal and a 30% cost savings. Coffee pulp contains about 10% crude protein on a dry weight basis, with a protein quality similar to that of soya. Overall results from feeding studies with pigs indicate that corn can be substituted by dehydrated coffee pulp for up to 16% of the total ration, with no detrimental effect on weight gain or feed conversion. This means that at the end of the finishing period, each reared pig has left nearly 50 kg of corn available for human consumption or other uses. Besides pigs, coffee pulp feeding trials were carried out with fish, chicks, lambs, and rabbits. The feeding trials included the determination of daily body weight gain, daily dry matter intake, and feed conversion efficiency. Pigs fed with rations containing up to 15% of coffee pulp ensiled with 5% molasses, had equal or better total weight gain than those fed commercial concentrates. Coffee pulp silage is a viable alternative to handling and storing the huge amounts of coffee pulp produced in the factories around the world. The inclusion of coffee pulp silage (CPS) in the diets of some farm animals could contribute to lowering the meat and milk production costs, especially in developing countries. Its use as an animal feed ingredient has been limited by its seasonal availability (2–3 months in a year), its high water content and consequent perishability, and by the presence of antinutritional factors in the pulp which restricts the quantities which can be used in a ration. Coffee pulp is a by-product of wet coffee processing. It is usually dried before mixing with other feed ingredients. Because of its tough nature, little attention is given to its utilization as feedstuff. Some scientists do co-ensile it with other agro wastes like poultry droppings or cow dung to pretreat for nutrient enrichment, before incorporating it into animal diets. Coffee pulp is one of the main byproducts of the coffee agro-industry, and represents a valuable potential for several purposes including feedstuff for animals in coffee producing countries. Several trials have been done on cattle and poultry. Incorporation of coffee pulp to diets was also tested on several fish species.

4.2.6 Coffee Pulp for Ethanol and Wine

Ethanol is a chemical that has a wide variety of uses as it functions as the physiologically active ingredient in alcoholic beverages, as a solvent or reactant in chemical processes and products, and as a liquid fuel. Dry white wine has been produced from coffee pulp on an experimental basis. The wine is characterized with high alcohol content which can be reduced to that of table wine if additional sugar is added during fermentation. The practical yield of ethanol from carbohydrates such as sucrose, glucose, and fructose, the principal fermentable sugars in coffee pulp, is usually of the order 516–582 L per ton of dry matter.

4.2.7 Coffee Pulp for Vinegar

The production of vinegar from coffee pulp involved a two-stage fermentation process. The first stage involved yeast fermentation that converted sugar into ethanol, and the second stage involved acetification of the ethanol which was oxidized by bacteria to acetic acid.

4.3 Utilization of Coffee Mucilage

From coffee industrial wastes we can obtain the following types of materials in varying states of purity from coffee mucilage. These are the following.

4.3.1 Pectins

The possibility of using coffee pulp and mucilage as a source of pectin has been widely investigated. Pectin is a polysaccharide consisting primarily of 1-4-linked d-galacturonic acid residues partially esterified with methanol. It is an important structural component of the tissues of higher plants and is exploited commercially for its gelling properties. Pectins with a high degree of esterification (60%–75%) form an acid-sugar pectin gel and are used in the production of jam and confectionery jellies. Products with a low degree of esterification (20%–45%) form calcium pectinate gels which are used in sugar-free or low-sugar jellies. Pectin extracted from fresh coffee pulp was generally of the “slow set” type with a degree of esterification in the range 59%–62%. This pectin can be either thermo reversible soluble gels, or nonreversible cross linked gels which have a different mouth feel.

4.3.2 Natural Coffee Fruit Sugars, Mainly From the Recycled Pulping Water

Coffee fruit sugars are principally monosaccharides, glucose, galactose, rhamnose, and arabinose, with a unique flavor reminiscent of plums. These sugars have potential alternative sweeteners to cane and beetroot sugars for connoisseurs of coffee products.

4.3.3 Antioxidants and Flavonoid Compounds

These are mainly the anthocyanin fruit color compounds, but they also contain other polyphenolics, such as chlorogenic acids and caffeine. These materials can be combined into several combinations to make various food additives, of possible interest to the health food industry. Extraction of antinutritional factors would detoxify pulp and improve its value, possibly creating marketable byproducts such as caffeine.

4.3.4 Colorless Pro Anthocyanins

This is normally used as a resource base for other food manufacture, or the possible synthesis of complex chemicals.

4.4 Parchment Charcoal

Coffee parchment (waste) is the testa removed from coffee beans during processing.

The parchment and silver skin is removed in the last stage processing of wet coffee. Traditionally, this waste has been collected and spread in cattle pens, where it is trampled into cow dung to produce a manure-parchment mixture used as fertilizer by coffee plantations. In Kenya, charcoal briquettes for domestic use have been developed and produced from parchment. The product has longer burning characteristics than conventionally produced wood charcoal, presumably due to a greater density, and is being heavily promoted in both urban and rural areas as a means of decreasing the alarming rate of deforestation. Coffee, being a stimulant, contains some principal alkaloids which impede growth of the fed organism. These alkaloids include theobromine, caffeine, tannin, thiamin, and xanthine.

4.5 Coffee Waste Water

The water drained from coffee cherry extract is another potential source of biogas production.

4.5.1 Biogass

Coffee cherry juice, if kept in a bag or in bulk for several house after picking, will heat up from the activity of a seething mass of micro-organisms of all kinds, working on the released sticky fruit juices. Controlled fermentation and other procedures can lower the pH and further neutralize the process, creating CO2, foam (mainly acetate salts, and raise the pH from 3.8 to 6.1) floating solids, principally dark colored tannins and polyphenolics.

5 Utilization of Waste Kolanut

The genius cola, a member of family Sterculiacea, is indigenous to tropical Africa. It is represented by over 40 species in West Africa alone. Two species, Cola nitida (vent) schott and Endl, and C. acuminate (P. Beav) Schott and Endl., are of major economic importance in West and Central Africa, the Caribbean Islands, Mauritius, Sri Lanka, and Malaysia.

About 70% of kola nuts worldwide are produced in Nigeria. A loss of up to 50% per ton due to storage mold has been recorded, owing to poorly stored nuts. The vast majority of kola nuts produced in the southwest geopolitical zone is consumed raw in the northern part of Nigeria.

5.1 Kolanut Waste

A lot of the kola nut is wasted during postharvest handling, owing to damage by weevils. Discarded kola nuts are an economic loss to the farmer, for lack of effective processing, good curing and control of postharvest losses during curing and storage. Recuperating these losses could increase farmers’ income substantially. Industrial kola nut processors can also benefit from the otherwise lost raw material; the high levels of caffeine which can be obtained through sun-drying of nuts could be put to industrial use.

The seed of kola nuts contains 13.5% water, 9.5% crude protein, 1.4% fat, 45% sugar and starch, 7.0% cellulose, 3.8% tannin, and 3% ash. It is also rich in caffeine and theobromine, 0.05%. Kola nut is comparatively richer in caffeine than cocoa and coffee.

In some developed countries, kola nut extract is used industrially for the manufacturing of many cola type soft drink flavors, as a source of caffeine used for manufacture of pharmaceutical products, for essential oils, and as a main ingredient in production of heat-tolerant chocolate bars. Additionally, caffeine is known to be a fat burner, and could therefore be beneficial in assisting weight loss.

The leaves, twigs, flowers, fruit follicles, and bark of C. nitida, C.anomala and C. acuminata, are used to prepare a concoction as a remedy for dysentery, coughs, diarrhea, vomiting, and chest complaints. Kola nut is also of high socio-cultural importance to many African peoples. It is offered in birth, naming, and funerary ceremonies, and as acknowledgment of respect to visitors. It is also shared to demonstrate peace and consensus after settling disputes between conflicting parties.

Waste generated from kola production can be use for the following.

5.2 Kola Pod Husk

Like cocoa pod husk (CPH), the kola pod husk (KPH) is a fibrous byproduct from the kola nut. It is a rough dark green case which holds the seeds together. Its use and processing for animal feedstuff is similar to that of CPH. It is more acceptable to animals when sun dried and milled. The most common method of treatment is sun drying. KPH has a higher crude protein content and lower crude fiber content than CPH.

5.3 Kola Pod Husk in Animal Diets

The nutritional value of kola pod husk has been evaluated by CRIN scientists in collaboration with various institutions, toward the utilization and value addition of the kola pod husk, which was formerly considered waste.

Kola pod husk was determined to contain (g/kg); 139 crude protein, 173 crude fiber, 12.5 crude fat, 58.5 ash, and 5562 kcal/kg gross energy. The cellulose content is 8.1%–9.0%, carbohydrate 52.4%, caffeine 3.2%, and nicotine 0.2%.

The three reported antinutritional factors in KPH are caffeine, theobromine, and nicotine. Kola nut shell can be substituted for 60% of the maize in layer mash, for 20% of the maize in broiler diet, and for 50% of the maize in rabbit diet.

5.4 Kola Pod Husk in Fertilizer

Kola pod husk has been used successfully for organic fertilizer in CRIN. The process is similar to that of cocoa pod husks (see CPH for fertilizer).

5.5 Kola Testa

Kola testa is structurally similar to CBS. It is the thin leathery covering of the nut, and is white when fresh. Like the cocoa husk endocarp, it is succulent, with higher crude protein than KPH. Its processing requires the use of a knife to peel off the seed testa while fresh, and is then sun dried before storage. As with cocoa husk endocarp, limited research has been done kola testa as a feed additive.

On analysis, kola testa feedstuff was reported to contain C·P—14.9, C·F—26.9, ash—4.67, moisture—12.7, and caffeine—0.26. Due to the fact that the testa is obtained from the kola nut tree, caffeine, and other alkaloids, are the only reported toxic compounds in the feedstuff.

5.6 Waste Nuts From Defective Nuts/Weevil Nut

5.6.1 Production of Caffeine

Global consumption of caffeine has been estimated at 120,000 tones per year, making it the world’s most popular psychoactive substance. This amounts to one serving of a caffeinated beverage for every person every day. Caffeine is known to stimulate the central nervous system and can stimulate metabolic processes as well. It is used both recreationally and medically, to reduce physical fatigue and restore mental alertness when unusual weakness or drowsiness occurs. Caffeine and other methylxanthine derivatives are also used on newborns to treat and correct irregular heartbeats. Caffeine stimulates the central nervous system, first at the higher levels, resulting in increased alertness and wakefulness, faster and clearer flow of thought, increased focus, and better general body coordination, and later at the spinal cord level at higher doses. Once inside the body, it has a complex chemistry, and acts through several mechanisms as described below.

The exact composition of Cola nitida have been shown to include xathine alkaloids (caffeine, theophylline, theobronine), tamin, betaine, and kolanine. The bitter taste is due to the presence of tamin and betaine, while the reddish stain extracted is due to the kolatine and kolanine content. It occurs in the fruit and bark of a number of plants, like tea leaves, coffee, cocoa, kola nuts, beans, and mate leaves. Its molecular formula is C8H10O2N4 with 28.85% nitrogen content.

5.6.2 Purification of Caffeine

The crude caffeine was dissolved in hot water, activated charcoal was added to absorb the gas and coloring matter, and then it was filtered. The filtrate was cooled to room temperature, followed by drip extraction. The solvent was evaporated on a hot plate. The purified dry caffeine was recovered and stored in the desiccator.

5.7 Kola Nut in Beverages and Pharmaceutical Industry

Kola nuts that are of no commercial value, especially when the weeviled part had been removed with knives, can be used as a flavoring agent in beverages. It is more popular in the western world as a component flavoring agent and source of caffeine in cola beverages and other similar drinks. The first cola soft drink, Coca Cola, was invented in 1800 by mixing the extracts of kola and coca with sugar, carbonated water and other ingredients. However, Coca-Cola no longer uses kola nut extracts in their drinks. Kola nut has a bitter taste but is immensely rich in compounds that have medicinal properties. The main constituents of the kola nut include caffeine, theophylline, theobromine, sugar, water and phenolic compounds such as phlobaphens, tannic acid, d-catechin and epicatechin.

6 Tea (Camellia sinensis) Wastes

6.1 Wastes From Tea

(Camellia sinensis) popularly known as tea leaf (TL) is usually processed into a beverage which has been brewed in hot water. After brewing, the leaves are not consumed with the drink, and become a part of the household waste which must be disposed of. Like other biomass residues, tea wastes represent an unused resource and pose increasing disposal problems. Tea beverages are typically available as green, black or oolong tea, depending on the manufacturing methods used. Black tea, made from the mild oxidation of tea leaves, amounts to around 78% of whole production, followed by green tea (20%) and oolong tea (2%). Apart from this, overgrown tea plants produce seed which is usually left as waste. For these reasons, strategies are being investigated to evaluate the possible use of spent tea leaves and tea seeds in value-added applications. Therefore, wealth can be generated from the following:

- Spent tea leaf (STL)

- Tea seed oil (TSO)

6.2 Spent Tea Leaf as Animal Feed