A modern small bladder-type accumulator tank. The tank is pumped up with air, which pressurises the water.

Pressurised water

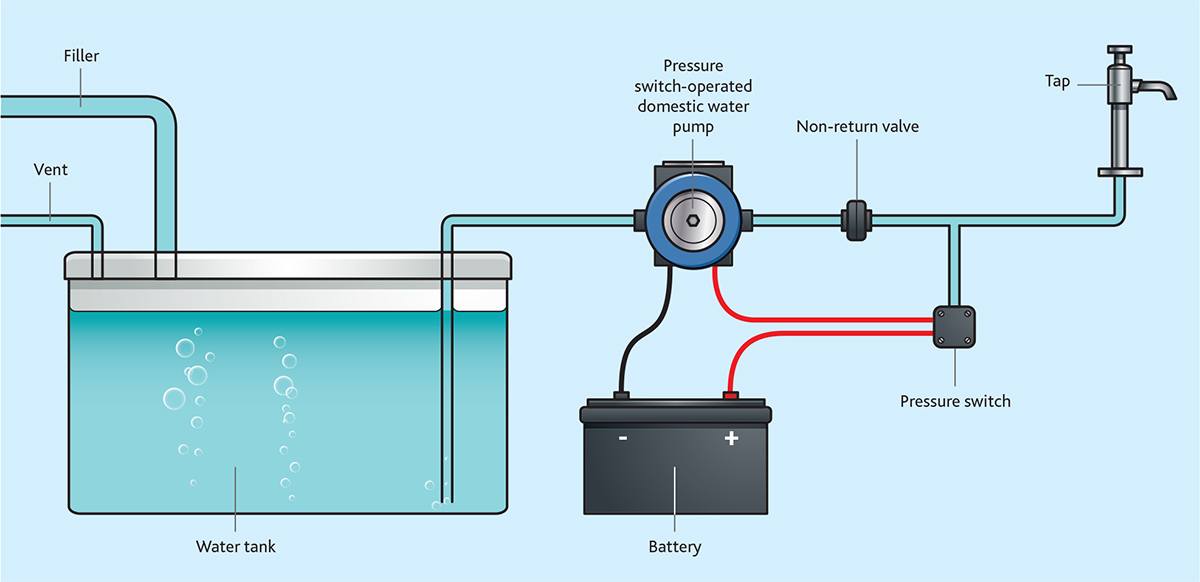

Pressurised water systems have been around for many years, but one of the most popular misconceptions is that the pressure switch built into the system actually affects the water pressure at the tap. In fact, the pressure switch turns on the pump when the tap is opened and off when the tap is closed.

The only way to increase the water pressure within a pressurised system is to fit a larger capacity pump to provide a greater flow of water. Although the water pressure at the pump is no higher, the restriction at the tap or showerhead provides higher pressure as the flow of water is restrained.

When there is pressure on the switch the electrical contacts are open and current cannot pass to operate the pump. Pressure within the system is created when the taps are all closed but the pump is still running. The pump will continue to run until pressure has reached the cut-out point of the switch (20 pound-force per square inch/psi in the UK). Once this pressure setting is reached, the switch is operated by water pressure pushing against the rubber cover, which forces the switch to the open position and stops the pump. A non-return valve is fitted within the system to maintain the pressure, which keeps the pump switched off.

The most basic of cold water-only pressurised water systems includes the pressure switch in the pump, examples of which are the very robust and reliable Jabsco 3600 series pumps. An accumulator tank can be added to this system to give the smooth flow of water expected when a tap is turned on.

A modern small bladder-type accumulator tank. The tank is pumped up with air, which pressurises the water.

A basic cold water system includes the pressure switch in the pump. Equipment such as fuses and strainers have been omitted for clarity.

Types of tank

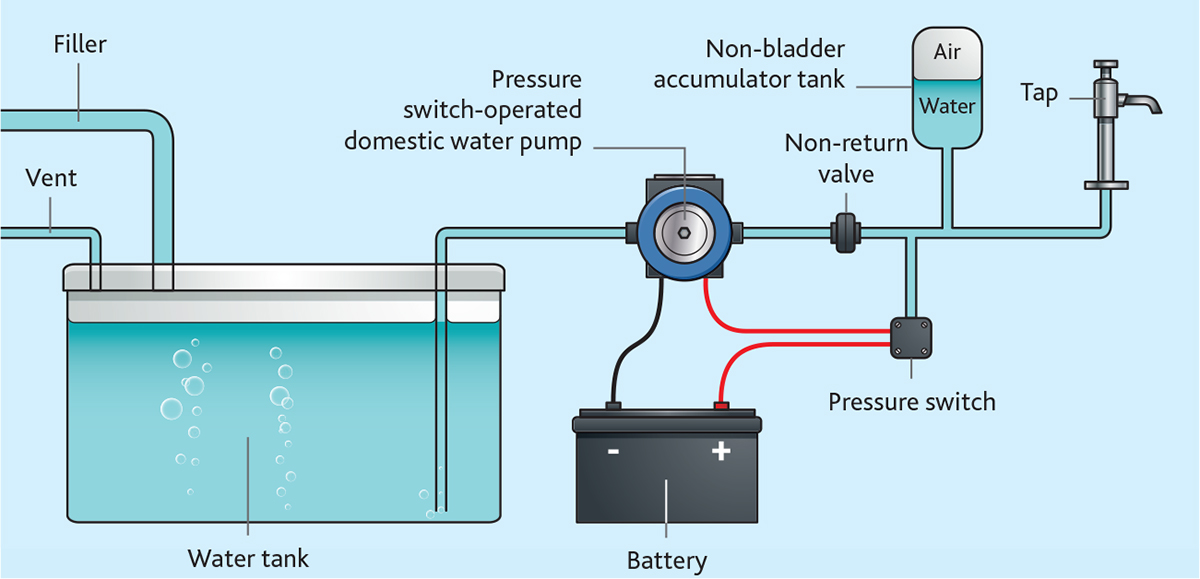

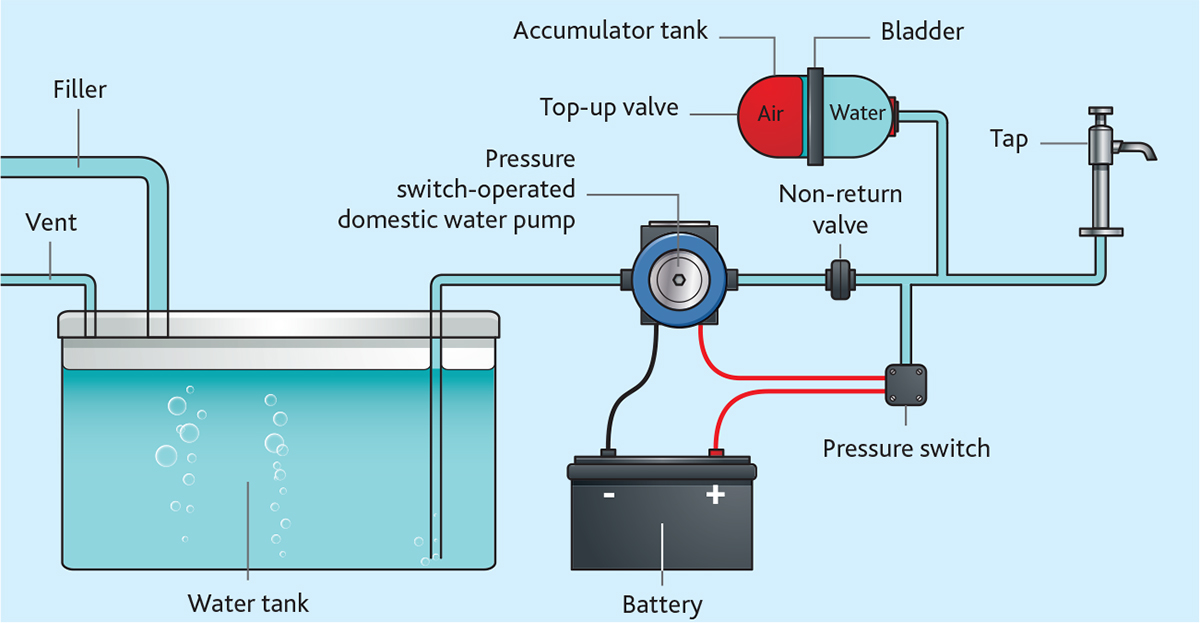

There are two types of accumulator tank. The most simple type comprises a small cylinder mounted vertically, which traps an air pocket in the top half of the cylinder as water fills from the bottom. A more sophisticated model incorporates an internal pressurised air bladder (rubber diaphragm) against which water pressure builds up. This type can be mounted in any orientation.

Connecting to the system

Both types of tank connect into the system between the non-return valve and the tap, and their purpose is to accumulate a pressurised air pocket within the cylinder.

The air pocket prevents the pump from rapidly switching on and off (cycling), which happens in systems using powerful pumps without an accumulator tank. As the pump runs, pressure builds up faster than the escaping water, which causes the pressure switch to operate and turn the pump off. This creates an immediate drop in pressure, which allows the pump to switch on again. This on/off cycle continues with the water pulsating out of the tap instead of running in a smooth flow.

With the accumulator tank in the system, the pressure fluctuation is smoothed out by the air in the cylinder compressing and decompressing faster than the pressure can build up to operate the switch, thus providing a smooth flow of water.

A small, vertically mounted cylinder traps an air pocket in the top half of the cylinder as water fills from the bottom.

The more sophisticated model has an internal pressurised air bladder against which water pressure builds up.

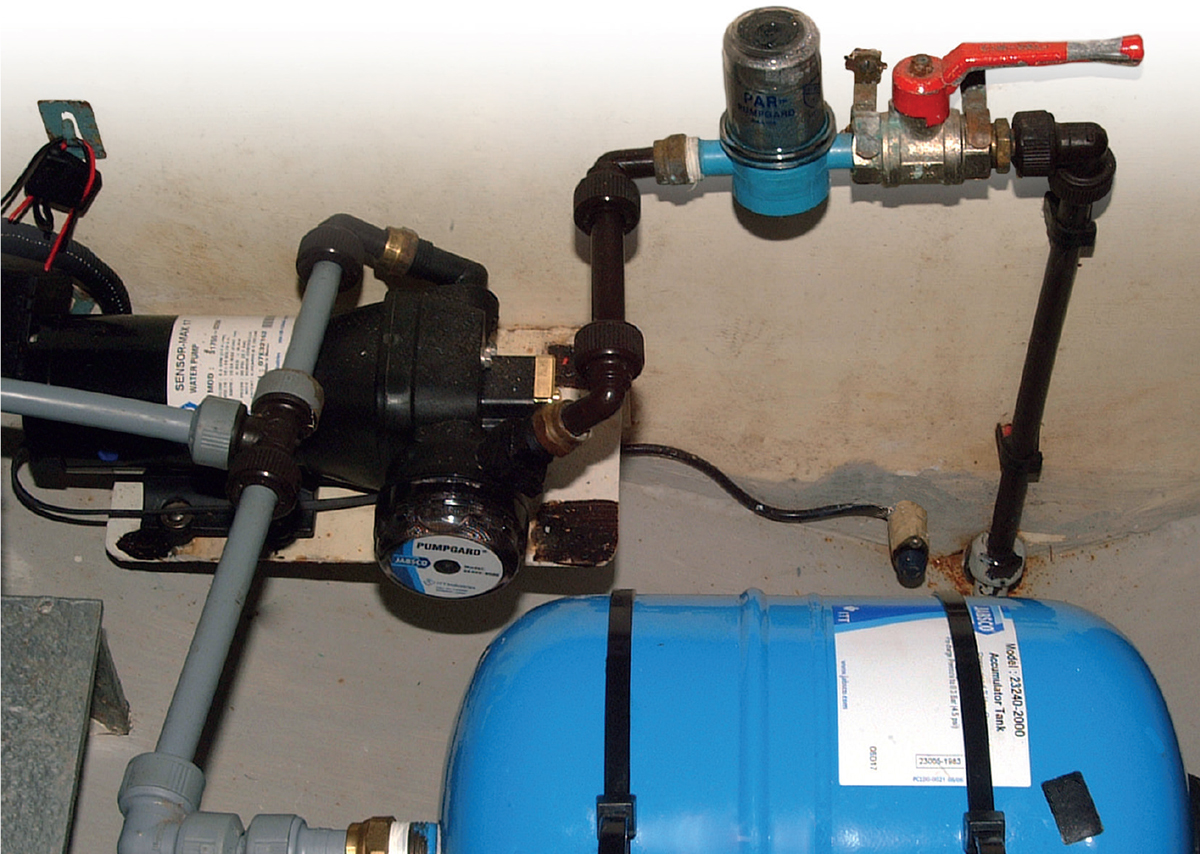

A modern pump in a system with bladder-type accumulator tank, isolating valve and coarse water strainer to the left of the valve.