4. Decoration: a path to hi-tech

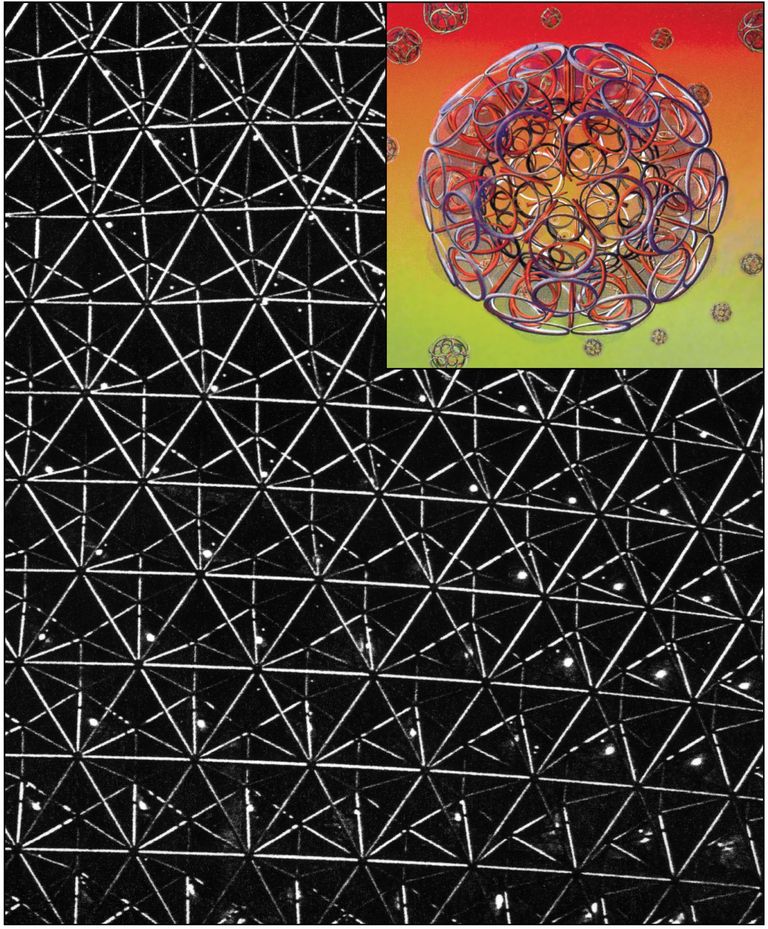

Fuller dome structure; C-60 Soccer Ball, Kenneth Snelson (inset)

Scientists and artists discover similar forms. Buckminsterfullerene is a spherical molecule made up of sixty carbon atoms, with particularly interesting conductive properties. It was named after the architect R. Buckminster Fuller, because it resembles his geodesic domes, which can enclose vast spaces.

Decorative patterns and mathematics

Unlike architecture and the performing arts, which take many of their cues from science and technology, in decorative arts and design artists have traditionally led the way. For thousands of years, designs were woven into fabrics, painted on walls and incorporated into the mosaic floors of palaces and temples. One wonders what interior force drove people to cover vast spaces with flowers, spirals and geometrical shapes.

A natural tendency towards simple schemes, such as symmetrical ones, seem to almost respond to a “biological sense of order.” Moreover, similarities can be found in patterns created independently by artists in Arabic, Christian and Far Eastern cultures. Perhaps the human brain has some special affinity for repeating patterns.

Ornamentation, reflecting the collective psyche, has reached amazing heights in nearly every culture, from African textiles to Maori tattoos. What would St. Peter’s Cathedral in Rome or the Palace of Versailles look like if they were stripped of their decor? It was only at the turn of the twentieth century that decorative or applied arts moved down in the hierarchy of Western arts. Decoration, previously part of the craftsman’s domain, became the designer’s prerogative.

Throughout history, mathematics formed the basis for decorative patterns. While geometric representation is of a visual order, arithmetic appears to be more closely related to music. The writing of numerals seems to have preceded that of words. The decimal system, based on ten independent signs, was initially developed to enhance the beauty of Indian legends, but its practical aspect would be transmitted to the rest of the world.

The Mesopotamians were largely responsible for laying down the foundations of calculation by developing the technique of expressing numbers by position and sign. Ancient peoples in the Middle East worked out practical tables for multiplication and square roots. By contrast, Greek philosophers reached for an aesthetic apogee with conic sections, ellipses and perspective geometry. Aristotle held that: “Philosophers who believe that there is no place for Beauty in mathematical sciences are wrong. Mathematics is indeed the greatest form of Beauty.”

Elaborate ornaments whose designs are based on geometry constitute the basis of Islamic art, liberating artists from religious constraints. Westerners during the Renaissance further developed Arabic art and science by introducing various symbols—letters for constants and variables, plus and minus signs, the x of multiplication—which made mathematics an almost universal language.

Ancient decorative schemes did not easily reveal their secrets even though astronomers such as Kepler attempted to unravel them. Only in the nineteenth century did we begin to understand their foundations. Mathematicians, often passionate musicians, such as Leonhard Euler (1707–1783) or Joseph-Louis de Lagrange (1736–1813), sought to reformulate natural phenomena into a more refined language than that of their predecessors.

Seventeen symmetry schemes, Peter Stevens, 1981

Ancient cultures used all these patterns in decoration. Mathematicians were able to reconstruct them when advanced calculus used for crystallography was summoned to the task. Analysis then indicated that regular repetition of elements in a plane is restricted to these seventeen basic archetypes.

Scientists are seduced by the aesthetic nature of theories when these are expressed with style. Ludwig Boltzmann (1844–1906) wrote: “As a musician can recognize his Mozart, Beethoven or Schubert after hearing the first few bars, so a mathematician can recognize his Cauchy, Gauss, Jacobi, after the first few pages.”

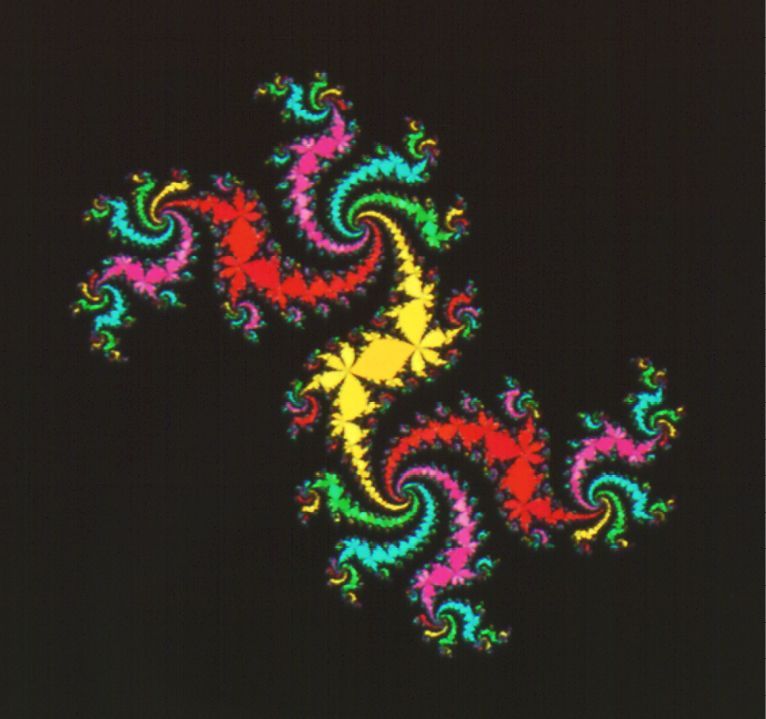

Contemporary researchers believe that even the most intricate figures can be described in mathematical language by means of “fractals” which are known to the public for their visual beauty. (A fractal image is made up of smaller identical structures, each of which represents the whole picture.) In commenting on this computer-made art, its inventor, the mathematician Mandelbrot, noted in the 1980s that “it is premature to ask if it will ever be able to compete with painting or photography, but it is legitimate and useful to raise the question.”

Self-squared Fractal Dragon, Benoit Mandelbrot, 1982

When developed by computer, the formula Z’ = Z(Z - 1) gives rise to a fractal image that looks like a dragon.

Artists and scientists seek to represent nature’s structures. Considered beautiful for their forms and the logic they embody, these structures provide a coherent language for the arts and sciences alike.

The German philosopher Johann von Herder (1744–1803), Goethe’s friend and mentor, wrote: “From stones to crystals, from crystals to metals, from these to plants, from plants to brutes, and from brutes to man, we have seen the form of organization ascend, and with this the powers and propensities of the creatures have become more various, till at length they have all united in the human frame.”

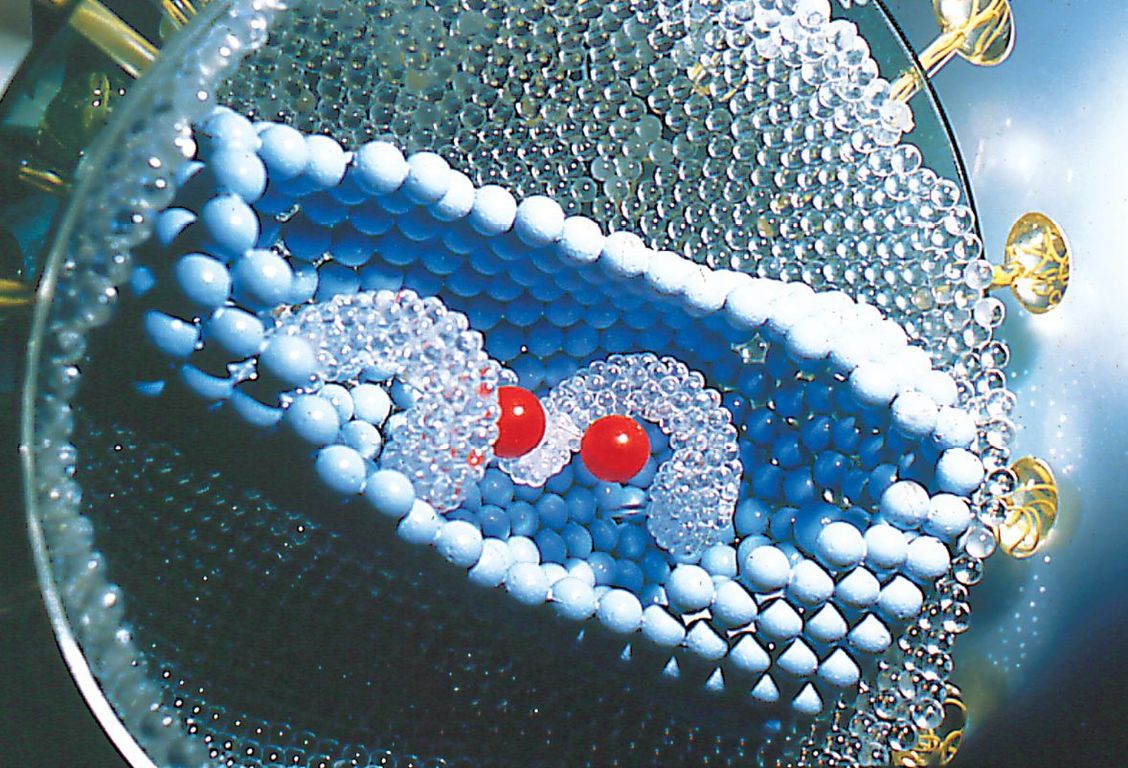

Detail of the AIDS virus model

Decorative patterns resemble natural shapes; most forms in nature, however, possess a sophistication that defies copying by scientists or artists.

Self-portrait Fosters Pond, Arno Rafael Minkkinen, 1989

Nature’s patterns, such as proteins, brains or bodies, are fundamentally asymmetrical. The physicist Wolfgang Pauli called God “a weak left-hander,” believing that asymmetry may be necessary for the universe to hold together.

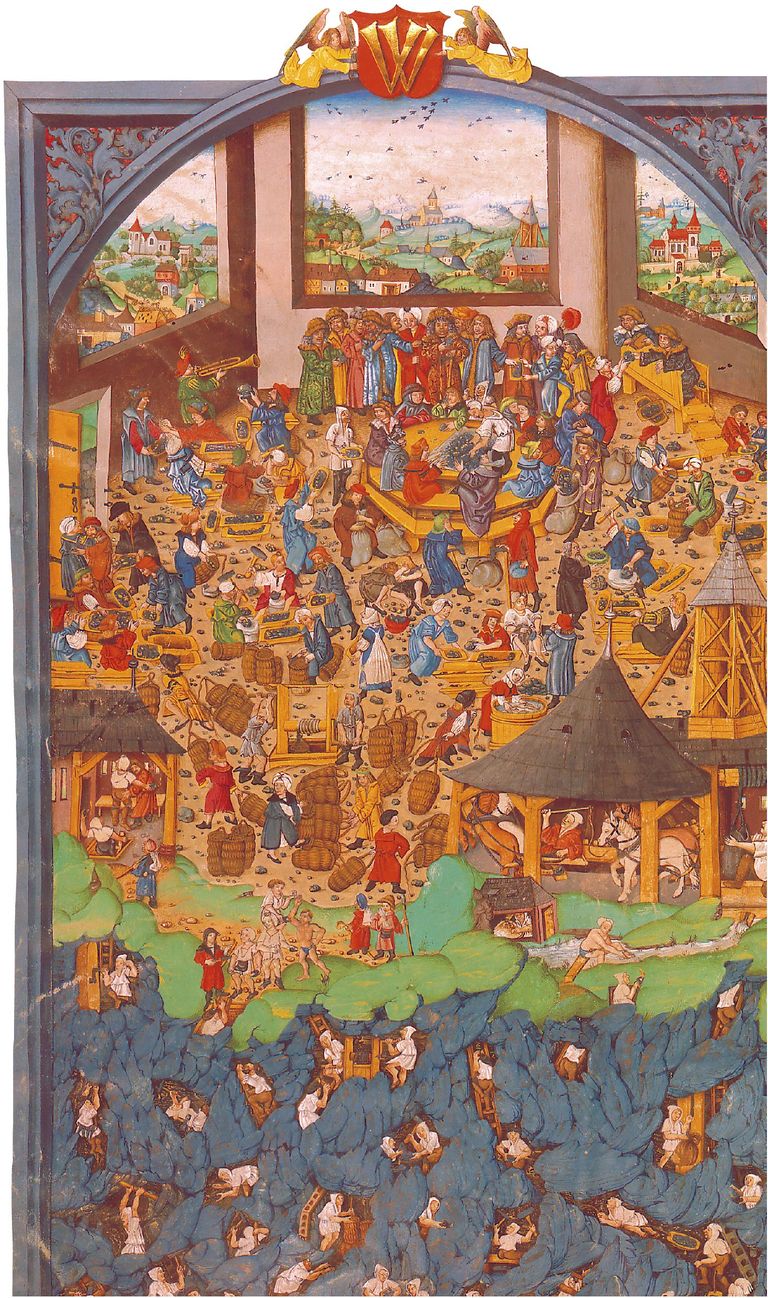

Thousands of years ago, plants such as cotton were already being cultivated for fabric production; elaborate patterns were woven according to ancestral techniques. There has been little change since; in fact, the design of ancient Peruvian textiles, for example, was finer than that of modern ones. Textile motifs are considered as one of the most ancient forms of visual art, and are even alluded to in such contemporary styles as Op Art.

Much earlier, man’s use of bone needles already marked an important step in the elaboration of clothing. Fabric remained a luxury in the West until the end of the Middle Ages, when the horizontal loom, which speeded-up weaving enormously, and the spinning wheel were invented. Sartorial fashion gained further ground in the fourteenth century with the introduction of knitting and the button.

The cloth business became the basis of Renaissance prosperity and allowed the Fugger and the Medici dynasties to establish multinational enterprises. These prompted the development of the double-accounting system, still used today. By setting in place an annual balance of profits and losses, the income of the business could be visualized and controlled. Luca Pacioli (1445–1540), who developed this system, was a protégé of the painter Piero della Francesca (1416–1492); Leonardo himself illustrated one of Luca’s books.

The Mathematician, Jacopo de Barbari, c. 1470

Barbari, also a mathematician, wrote a book on the Golden Section. This painting, in which a polyhedron seems to “float,” represents Pacioli practicing geometry with the right hand and arithmetic with the left.

Museo Nazionale di Capodimonte, Naples

During the fifteenth century, businessmen who carried out large transactions found themselves drowning in complicated fractions (such as 5432434/2980764!). Simon Stevin (1548–1620), a mathematician from Bruges, thus developed a system to calculate decimal fractions. He published it in a 36-page booklet which immediately became famous. A polymath engineer, specializing in weight and length measurements, Stevin also developed musical theory.

Meanwhile, luxury silk, an even more lucrative trade than cloth, penetrated the West. According to legend, the fourteen-year-old wife of the emperor who built the Great Wall of China discovered silk by dropping a cocoon into warm water and unwinding a glistening thread.

Bombyx (silkworm) larvae were transported from the East via Constantinople to Sicily and from there to northern Italy. The precious silkworms created a major problem for the French economy, as gold to pay for silk poured out to Italy. King Louis XI (1423–1483) sought to stem the flow by converting Lyon from a local weaving center into the European silk capital.

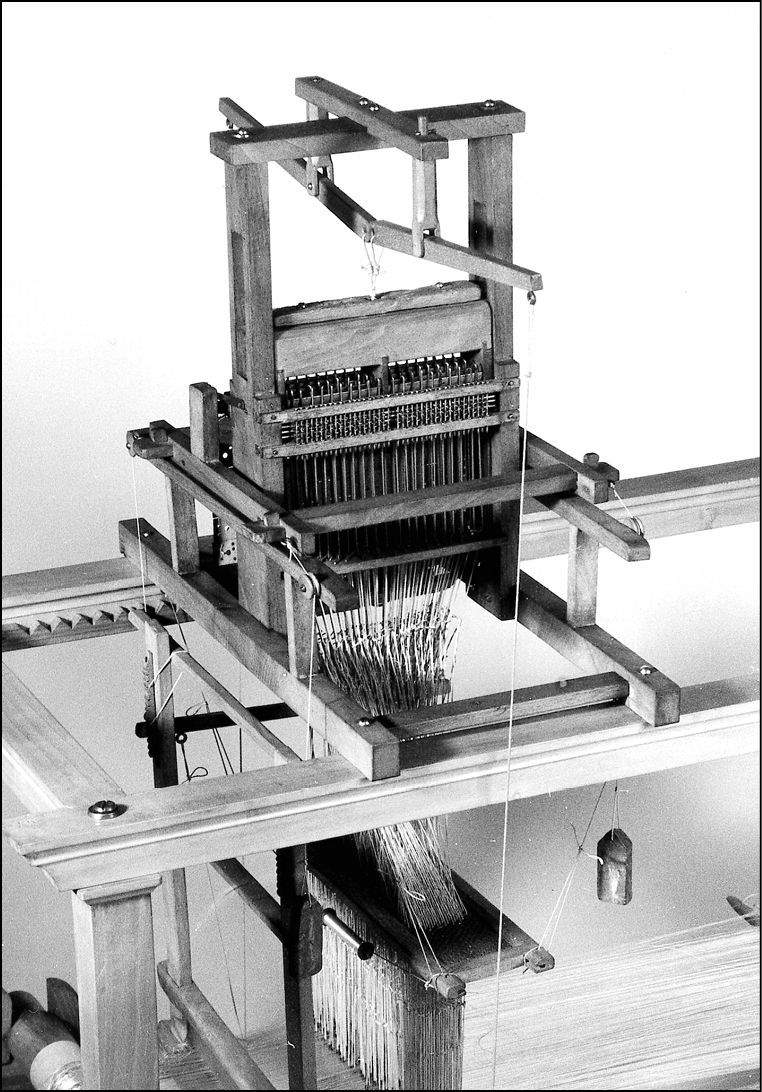

In 1741, around the time of the Industrial Revolution, a mechanical silk loom was invented by Jacques de Vaucanson, who made all kinds of automata. The loom was later improved by Joseph-Marie Jacquard (1752–1834), who introduced a system of punched cards that directed machines to weave elaborate designs—each card carrying a separate section of pattern. A similar technique is in use in today’s power looms.

Detail of the automated silk loom, Joseph-Marie Jacquard, 1804

The automation of silk manufacturing caused social upheaval, much like computerization does today. Moreover, the punched-card system that governed the machinery is essentially the same as the one employed in computers, two centuries later.

Musée des Arts et Métiers–CNAM, Paris

Ada, Countess of Lovelace, a brilliant mathematician who is sometimes called the first computer programmer, collaborated in the 1830s with Charles Babbage on his Analytical Engine, a precursor of the computer, which found no immediate practical applications.

Statistical studies and logarithms all required machines, yet nothing much happened on the computer front for more than a century. Then the need grew for powerful calculating tools; during the Second World War the “electronic brain” prototype proved its worth. Much work still remained to be done to turn this slow-working machine into a commercially appealing product … and few believed it would ever happen.

Early electronic calculating devices required thousands of vacuum tubes to transmit electronic signals. (The first computer—designed to crack German secret codes—was named Colossus because of its size.) Tiny devices, called transistors, were able to amplify electric signals and thus replaced the vacuum tubes. Since then, transistors have been packed on crystals made of fingernail-sized “chips” of silicon.

Like many scientific inventions that develop in fits and starts over great distances, the development of computers showed that science, like art, does not always evolve in a linear fashion. Technologies and concepts ignored for years are reharnessed and perfected when a real need is identified.

In the eighteenth century, the discovery of punched cards for silk weaving eventually led to the invention of the computer … some two hundred years later. The transition from Andean weaving to information systems entailed much trial and error by generations of artists, craftsmen and scientists.

Ada Augusta King, Countess of Lovelace, c. 1840

The countess, daughter of the poet Byron, invented computer programming. One of the modern information languages bears her first name, ADA. Of the analytical machine she said: “It weaves algebra patterns like Jacquard’s silk loom weaves flowers and leaves.” Today, using computers, 3-D clothes can be custom-woven during a fashion show.

Science Museum, London

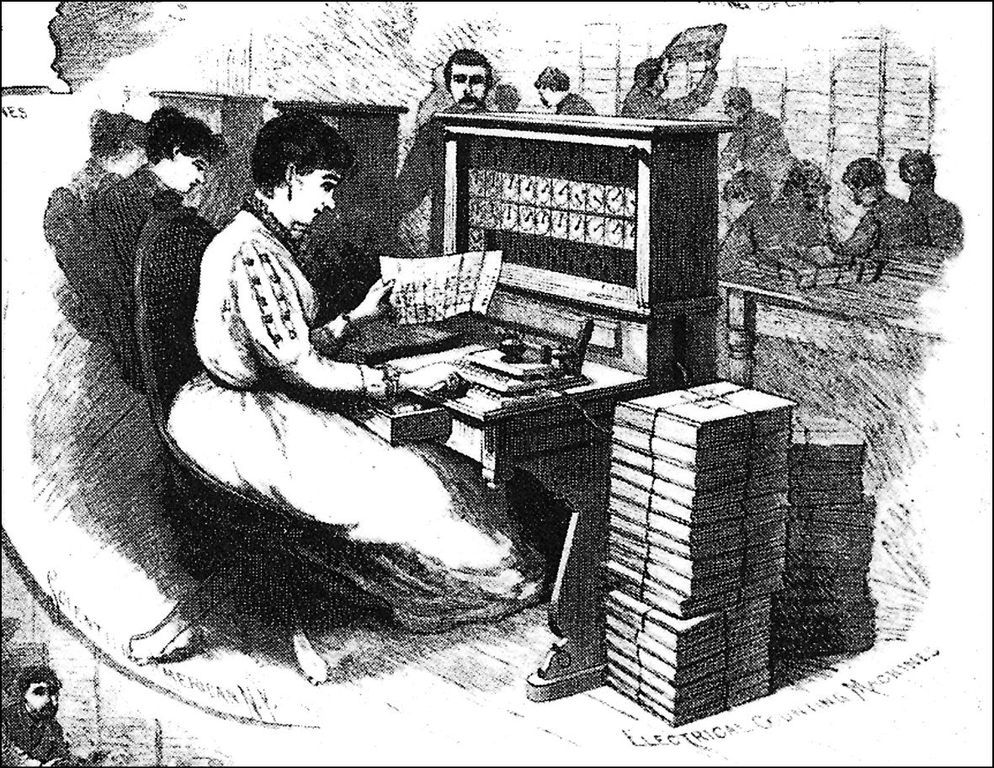

The United States Census, 1890

Electrically driven punched-card machines were used by Hermann Hollerith for the first large-scale census. He extended their use for data processing in other areas and founded the company later known as International Business Machines (IBM).

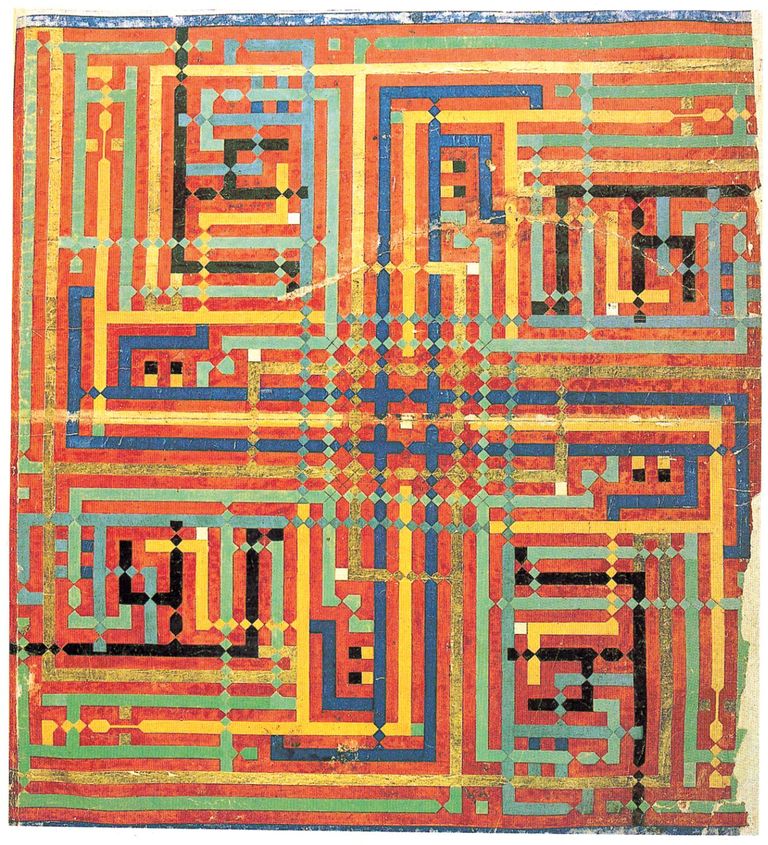

Persian calligraphy representing the name of Allah, fifteenth century

For Arabic calligraphers, “the letter is the body and the number is the soul.” Ancient decorative shapes can look strikingly similar to microchip patterns—the latter were originally selected through design competitions.

Topkapı Palace Museum, Istanbul; H.2152

Man’s fascination with patterns was paralleled by an early desire to experiment with color. Dyes were made from substances of animal, mineral and vegetable origin. Introduced as early as 1000 B.C. by the Phoenicians in the Mediterranean Basin, fabric dye extracted from purple snails would be reserved for high-ranking citizens in Rome.

Deep blue pigment from lapis lazuli, a stone found in Afghanistan, traveled all the way to the monasteries of Ireland. Indigo came from India to Britain; pastel blue from Provence. Dyes were the basis of a luxury trade which prompted chemists, botanists and mineralogists to seek samples from all over the world, to discover new colors and the technical means of obtaining them. Gradually, scarlet, blue of Saxony, Prussian blue and many other shades enriched the costly repertoire.

The first artificial dyes were the result of the Industrial Revolution. Coal tar, used to illuminate the gas streetlights of London (1792), yielded by-products such as benzene. These by-products were available in large quantities, waiting for scientists to find potential uses for them. The accidental discovery in 1856 of mauveine by William Perkin, aged eighteen (while he was trying to synthesize the colorless quinine—a structurally related compound), marked the beginning of a true industry of pigments.

When synthetic dye was presented at the World Exhibition in London, manufacturers were reluctant to invest. In France, the Empress Eugénie launched the “mauve craze;” a large-scale industry expanded rapidly with several derived colors and shades of blue, violet and green.

The springboard of today’s chemical empires was in place and its implications for the industrial arts would be immense. As the Italian poet Dante (1265–1321) said: “Art imitates nature as well as it can” … and so does science.

The revolution in pigments spread to textiles. Around the time that the Lyon silk industry was almost devastated by parasites, fabric research moved in yet another direction: artificial fibers. Although Louis Pasteur found the cure for silkworm disease, the impetus to discover a means of producing cheaper textiles remained strong.

Artificial silk was promptly developed in 1905 and, soon afterwards in 1910, synthetic stockings appeared on the market. A breakthrough occurred when Wallace Hume Carothers, working on benzene derivatives, patented nylon (1937)—thereby paving the way for a generation of fibers that could cover people, cars, aircraft, roads and buildings. These fabrics revolutionized the material and aesthetic worlds, and the lives of everyone they touched.

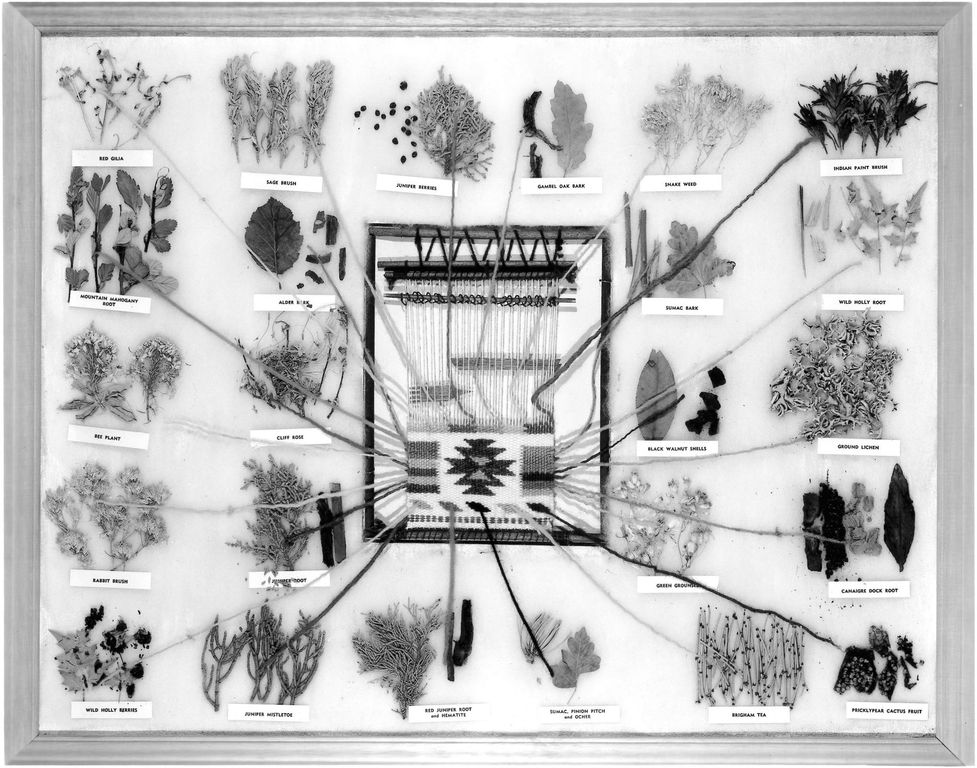

Chart of plant-based dyes, Navajo tribe, c. 1973–74

Ancient Peruvians produced almost two hundred hues. Carmine was extracted from a cochineal living in a Mexican cactus; ember red was imported from Brazil.

213⁄4 × 273⁄4 in. (55.2 × 70.5 cm)

Cleveland Museum of Art; Harold T. Clark Educational Extension Fund, 1974.1060

Glass-blowers and telecommunications

Experimenting with earthen materials resulted in glass-making in the Orient 5,000 years ago. The Roman historian, Pliny the Elder (23–79), relates that glass was discovered by accident. According to legend, the momentous event occurred when a Phoenician crew landed on a beach and made a fire for cooking: all the basic ingredients happened to be there to produce the noble material.

However, the complex chemical process of glass-making requires a mixture of sand, ash and lime, combined with other substances (such as an alkali which lowers the vitrification temperature) and heated into a molten state. After quick cooling, the surface becomes covered with a transparent vitreous layer that can be worked in various ways.

This extraordinary material, compounded from ordinary ingredients, has inspired artists and scientists through the ages, who have penetrated its secrets and coaxed it to simulate the appearance of precious stones and metals. Some of the oldest known glass objects are translucent shards used for inlay work and colored beads.

Composite glass necklace, Egypt, c. 1400 B.C.

Corning Museum of Glass, Corning, New York

As knowledge and technical skills increased, molten glass was wrapped around a heat-resistant core made of lime-like material to which glass does not adhere.

The nucleus could be encased in several layers of glass with various decorative shapes and then destroyed, leaving the object intact.

Throne of Tutankhamen, c. 1350 B.C.

This throne was inlaid with precious and semi-precious materials: glazed ceramic, gold, silver and colored glass paste.

Museum of Egyptian Antiquities, Cairo

The Greeks did not develop much interest in glass-making. The technique of blowing was invented somewhere along the Syro-Palestinian coast around the first century B.C., by then Roman territory. By blowing into a long hollow rod craftsmen would force molten glass into a mold. Free-form blowing followed, allowing for diversity of form and greater translucency.

The Romans made great strides in glass-making. They invented ways to eliminate defective color due to impurities, and developed techniques for applying decorative motifs, incising, engraving and gilding. Magnificent objects (oil lamps and perfume bottles), as well as sturdy glassware for everyday use, resulted. Production of the latter became a major industry.

Glass “cage cup,” Roman, c. 300 A.D.

This cut-glass bowl seems to be resting in a cage. The iridescence frequently seen in ancient Roman ware is a sign of glass decay.

Corning Museum of Glass, Corning, New York; Gift, funds from Arthur Rubloff Residuary Trust

In the Middle Ages, glass was placed alongside precious gems in jewelery and reliquaries, while alchemists searched for the “deep red” formula. It was believed that drinking from a ruby-colored glass protected against many ills. Glass features prominently in legends, and toasts are still proclaimed when glasses are raised.

Chemicals, in the form of metallic oxides added during the melting process, greatly extended the color range. The fruits of these experiments were, of course, the stained-glass windows of Gothic cathedrals in the North, and the sumptuous mosaics in the South. Apart from color, however, most of the hard-won knowledge of glass-making was eventually lost to Europe.

In the Arab world, techniques continued to improve and reached an artistic height. The versatility of Islamic glass-makers resulted in some objects that looked as solid as rock crystal, and others that were translucent and paper-thin. One lamp bears the inscription: “God’s light is as a niche in which there is a lamp of glass, as if it were a glittering star.”

Venice then took over as the world’s glass-making capital. Venetians developed mirrors and cristallo (crystal was invented by the Englishman George Ravenscroft)—a luminous material resembling rock crystal that made a clear resonant bell-like sound when struck. Venetians refined techniques used to produce millefiori, filigree, diamond engraving and enamelling.

Glass-making was restricted to the island of Murano, ostensibly to avoid the danger of fire in Venice itself, but also to prevent the glass-makers (who were forbidden to leave the island) from divulging precious professional secrets. Despite the law, many established themselves in Bohemia and in other royal courts. The Venetian style dominated Europe for nearly two centuries, until regional styles took root and began to undermine its preeminence.

Microscope of the Duke of Chaulnes, eighteenth century

European courts were fascinated by scientific toys based on glass; microscopes were often richly decorated. A Dutch ambassador to King Louis XIV described one of them as: “almost one-and-a-half feet long, made of gilt brass two inches in diameter, mounted on three dolphins of brass, on a base of a disk of ebony.”

Musée des Arts et Métiers–CNAM, Paris

Influenced by the Arts and Crafts movement, nineteenth-century glass artists such as the Frenchman Émile Gallé (1846–1904) and the American Louis Comfort Tiffany (1848–1933), developed an immense range of methods and materials and created objects of great beauty. Many of their stylistic innovations were based on rediscoveries of earlier Roman and Venetian glass-making methods, and of Egyptian and Japanese styles.

Innovative achievements today are due to the autonomy gained by the artist following the invention of the small furnace. This piece of equipment made it possible for glass-makers to establish private studios and thus function as independent artists. It was technology that finally put them on a par with painters and sculptors.

Crystal vase, Émile Gallé, 1892.

ABOVE: Detail

Gallé admired scientists and made this vase for Pasteur’s jubilee. A microscope and a dog with symptoms of rabies are featured on the vase, inscribed with these lines by Victor Hugo: “I move about in meditation, and at all moments a certain instinct obliges me to seek and find what lies behind the suffering of men.”

Institut Pasteur, Paris

The inherent properties of glass made it an obvious choice as an art medium, but scientists were equally intrigued by the material. Convex lenses were known as early as 300 B.C. Much later, Arab scientists developed parabolic mirrors resembling those used in telescopes, and also explained how lenses work.

Scholar wearing eyeglasses, Tommaso da Modena or da Barasino, c. 1352

Scientists knew about lenses long before this first image of spectacles, invented in 1290, was painted.

Fresco

Seminario Vescovile di Treviso, Italy

The English philosopher Roger Bacon (c. 1214–1294) explored an extraordinary breadth of disciplines. Of optics, his favorite subject, he wrote: “It is possible that some other science may be more useful, but no other has so much sweetness and beauty of utility.” For him, optics was almost a form of visual art. He studied the laws of reflection and refraction, and presented a theory of the rainbow as an example of elegant inductive reasoning.

Bacon made a description of lenses and eyeglasses, and expounded on their merits for the far-sighted. Lenses were then ignored by scholars for a very long time: three hundred years elapsed between the first recorded use of eyeglasses and the next major discovery dependent on glass, the telescope. Moreover, at the time no one guessed that it would be instrumental in revolutionizing man’s understanding of the universe; the telescope’s initial purpose was to help develop more accurate artillery.

As the developing prosperity of the Western world brought about a growing need for private housing, plate glass was much in demand. In England, where window production was particularly intense, glass-making precipitated a timber shortage. Forests receded farther and farther from the factories, and it became obvious that an alternative form of fuel would have to be found.

View of the glass centerpiece at the Crystal Palace, London, 1851

Sponsored by the Royal Family, the first World Exhibition was held in this gigantic glass greenhouse made entirely of prefabricated elements, which covered an area of twenty acres. The show was dedicated to the applications of art and science from nearly ninety countries. Dinosaur bones, the latest agricultural tools, hi-tech musical instruments, etc., drew enormous crowds. The centerpiece of this giant fair, “the gem of the transept,” was a huge glass fountain.

Research Library of the Corning Museum of Glass, Corning, New York; Collection of Juliette K. and Leonard S. Bakow

Glass production thus played a significant role in the Industrial Revolution. It was also the first industry established on American soil. Benjamin Franklin used glass equipment in his experiments with electricity. Modern chemistry and physics all advanced substantially with the help of glass instruments.

One of the most important of all inventions was, of course, the electric light bulb. Yet glass was important in utilizing natural light. In buildings, windows eventually became wall-size, resulting in the virtual elimination of visual barriers between indoors and out. Glass has changed our perception of light and our concepts of art and architecture.

It continues to change our lives. Analysis of the properties of this astonishing material has led to the creation of semi-conductors used in electronic components. New forms, such as glass fibers invented by Narinder Kapary (1955), can transmit numerous high-resolution signals.

The first picture taken in utero by a camera placed at the end of an endoscope (a tube lined with glass fibers, inserted into the body), exemplified how glass contributes to the practice of medicine. Its role is spectacular in today’s aerospace industry, and the telecommunications revolution of the twentieth century rested on a glass foundation.

Throughout history, materials resembling glass—lacquer, enamel and amber—were considered to be imbued with special powers and integrated into crafted objects with important functions.

According to Joseph Needham (1900–1995)—a prolific British biochemist and historian who spent decades writing a monumental history of science and technology in China—lacquer was a symbol of immortality, since “it was present at birth as a crib, accompanied life as a spoon, then a chair, and could serve as … a coffin.”

Needham described lacquer as the first “plastic.” This resinous substance, obtained from lac tree-sap, remains liquid if mixed with crab extract, which prevents hardening. Completing a single object could take up to several months, since twenty or more layers are required. The illusion of depth caused by the reflection of light depends on the build-up of layers and their optical quality.

Lacquer production thus demands intuitive knowledge of physics and high-level skills. The technique, which was also used to improve durability of ordinary tools, is said to have been known 3,000 years ago in China; it saw a marked growth when production became organized under imperial control, and it was further refined in Japan.

Imperial lacquer throne, China, eighteenth century

First, a wooden core was fashioned in the shape of the final object. After meticulous smoothing it was covered with several layers of cloth impregnated with a mixture of liquid lacquer and clay. Each layer was carefully dried and polished before the next one was added until a final colored layer, which could vary from bright to deep red, or black, was applied. The surface decoration was then worked out with the addition of gold, silver, shells and precious stones.

Victoria and Albert Museum, London

Enamel, originally used in finishing ceramic surfaces, became an artistic medium in its own right, with the use of the technique known as cloisonné. This class of decorative objects was made by pouring liquid enamel into connected cells formed by metal wire and arranged in a variety of shapes and patterns.

Cloisonné brooch, Ostrogoth, c. 500 A.D.

Western cloisonné may have been intended to simulate the look of Byzantine mosaics. It could frame enamel, gems or glass paste, and was frequently used by the Franks and the Goths, whose small transportable objects probably contributed to the development of stained-glass windows.

Germanisches Nationalmuseum, Nuremberg

The complex process, which required the skills of the metallurgist, the coppersmith, the painter and the engraver, probably originated in central Asia.

Amber, another glass-like mythical material, is a fossil resin whose color varies from pale yellow to deep red. Used in jewelery and ornaments, it was transported by the ancient trade routes from the Baltic all the way to the Black Sea. In an Assyrian inscription, a king said that his caravans “went fishing for yellow saffron in the sea under the polar star.”

The Ancient Greeks knew that amber, elektrike, had static electrical properties. Scientists have recently cloned the DNA of primitive insects trapped in this natural resin, hoping to bring extinct species back to life.

Long before fashioning threads into garments and smelting glass, men molded earth. In ancient finds, figurines tend to predate pots: magical intentions may have preceded practical ones.

Vestiges of ancient ceramics have been found in nearly every region of the world. Clay hardens naturally in high heat and perhaps, thousands of years ago, someone dropped a clay object in the fire and discovered that it hardened and retained its hardness ever after.

Experiments with progressively higher temperatures ensued and minerals were added, resulting in pots that were not only increasingly sturdy and useful, but also colorful and pleasing to the eye. Ceramics evolved into a most elegant art.

Restored Ishtar gate, Babylon, sixth century B.C.

The gates of Ishtar, goddess of fertility, were paved with brightly-colored ceramic protective tiles. The Mesopotamians added copper powder to their clay to produce pottery the color of lapis lazuli.

Vorderasiatisches Museum, Staatliche Museen zu Berlin

The Mesopotamians and Egyptians, using simple kilns, attempted to simulate in their pottery the look of precious marble and alabaster. Coating glazes that contained chemicals such as lead were admired for their luster, moreover, they reduced deformation of the object during cooling. These research efforts were probably related, technically, to the manufacturing of glass. The practice of all these crafts carried symbolic meanings. Meanwhile, the introduction of the potter’s wheel, in Mesopotamia around 3500 B.C., made regular forms and smooth surfaces relatively easy to achieve.

In Greece, the potter’s wheel became widespread around 1000 B.C. The ingredients used were very basic, even though skills were amazingly sophisticated. Artistic heights were reached around 500 B.C., when red figures replaced black ones, allowing for livelier depiction. (The entire vase turns black when the inlet of the kiln is closed; when the air vents are opened again, the iron in the clay body returns to its red color.)

Detail of a Greek vase, fifth century B.C.

The early figures on Greek vases featured black on a red background. Details were achieved by scratching out the figures; these subjects could never be very expressive and were thus often presented in profile. Greek potters then switched from black to red images, which allowed for more detail, which was painted with a fine brush on the figure.

Staatliche Museen zu Berlin

Through experimental cycles called reduction and oxidation and the use of clay-slip layers of differing composition, Greek artists suggested methods to the natural philosophers that would serve as premises of geology and chemistry. But, above all, Greek potters transformed a simple craft into one of the most admired art forms, which more than any other has brought antiquity to life.

In China, pottery production developed much earlier than in the West, under the Shang dynasty (1766–1122 B.C.)—the same period that saw the appearance of famous cast-bronze vessels. The two techniques were closely related: pottery vitrifies in a temperature range similar to that necessary for bronze smelting.

Figurines of camels in glazed pottery, Tang dynasty, China, 618–907 A.D.

The Chinese experimented with a wide array of pigments to expand the color range of their ceramics.

University of Pennsylvania Museum of Archaeology and Anthropology, Philadelphia; Objects 466, 465

A long tradition of firing at ever-higher temperatures gave Chinese stoneware a harder and more fused body than that of Western ceramics. True porcelain was made by firing above 1,000°C China clay (kaolin) mixed with petuntse, a combination which vitrifies at low temperatures and increases translucency. This technique, already known in the sixth century, was not fully exploited until later.

The Chinese identified porcelain by the clear sound it emits when struck, although the term was reserved for white, translucent ware: white was the symbol of purity. Chinese potters also liked to give their creations the appearance of jade, which they considered the noblest material. The typical green “celadon” was obtained by firing iron contained in the glaze. (The opalescent quality is due to the reflection of scattered light by water vapor bubbles trapped during the firing process.)

Increasingly subtle shades of yellow, amber and brown were attained as chemical experimentation progressed, and pigments continued to be traded across Asia. For example, adding Persian cobalt under particularly exacting conditions resulted in the typical Ming blue. Aubergine, green, pink and yellow enamels were used to create varieties of china that were exported worldwide and that state-owned factories developed all over the country.

By the end of the sixteenth century, many clay deposits were depleted and the famous tradition declined. The first sample of China clay was probably brought to Europe by Portuguese navigators around 1520. Westerners hoped to make porcelain instantly, but it took them several centuries to succeed.

Islamic pottery made its way north from Spain and Italy. The Arabs’ knowledge of earthenware production was fragmentary because the basic Chinese ingredients were lacking. Pottery was fired at low temperature, shape was lost in the process and the objects remained relatively soft. Nevertheless, Arab techniques flourished in Europe, where brightly colored majolica and faenza—after the names of the manufacturing centers—became popular export products.

The Renaissance saw advances in the natural sciences with the emergence of such artist-scientists like Frenchman Bernard Palissy (1510–1589). He was a maker of stained-glass windows who developed pottery glazes and rediscovered enamelling techniques. He passionately researched a wide range of geological and chemical issues (and went as far as burning his furniture to keep his furnace going). An expert on natural history, especially fossils, Palissy was particularly good at representing naturalistic subjects. His technique was widely imitated in the following centuries.

Meanwhile, the race was still on to duplicate the quality of Chinese pottery. Around 1708, Johann Böttger, experimenting with very high temperatures, finally uncovered the secrets of hard porcelain. His effort was funded in large part by the Elector of Saxony, who actually expected that it would yield … gold!

Oval dish, after Bernard Palissy, sixteenth century

During the Renaissance, artists showed interest in the earth sciences. Palissy also designed an artificial grotto for Catherine de Medici’s garden.

Lead-glazed earthenware

Museum of Fine Arts, Boston; Arthur Mason Knapp Fund and anonymous gift, 60.8

The secrets of porcelain-making were soon leaked and factories sprang up throughout Europe. The pottery at Sèvres in France (founded in 1756) was famous for its blue ware, and each court wanted to compete with its own distinctive colors and shapes. Royal feasts were ideal occasions for creating new styles.

Pharmacy jars, sixteenth century

Brightly painted pharmaceutical jars, which were commonly produced in Italy, contained a mixture of more than seventy ingredients called Theriaca, considered a cure for all ills until the nineteenth century.

Science Museum, London

While artists created porcelain masterpieces, scientists such as the Frenchman, René de Réaumur (1683–1757), researched the chemical and physical rationale for the vitrification process of earth, for which pottery appeared to be a good model. Samples of various materials were sent to him by explorers from the far corners of the world.

Research was also being conducted in the United Kingdom. Several techniques for making porcelain had been tried before the chemist Josiah Wedgwood (1730–1795) made his breakthrough. Having a strong interest in antiques, he produced an exceptional stoneware called “jasper,” which could be stained lavender or green and suggested the look of an antique translucent cameo.

In order to carry out his experiments with clay, he invented a special instrument for measuring high temperatures. Wedgwood founded a modern ceramics production facility which boasted the first factory to use steam power. He developed the basis of a fully integrated industry—starting from research and development to production and marketing.

Among Wedgwood’s acquaintances were Erasmus Darwin (1731–1802), naturalist, poet, and grandfather of Charles; Joseph Priestley (1733–1804), the chemist who discovered oxygen; and James Watt (1736–1819), who developed the steam engine. Most of them were distinguished members of the Lunar Society, which promoted the arts and sciences. They were called “lunatics” because monthly meetings took place on the Monday nearing the full moon (so that participants would have an easy time seeing their way home).

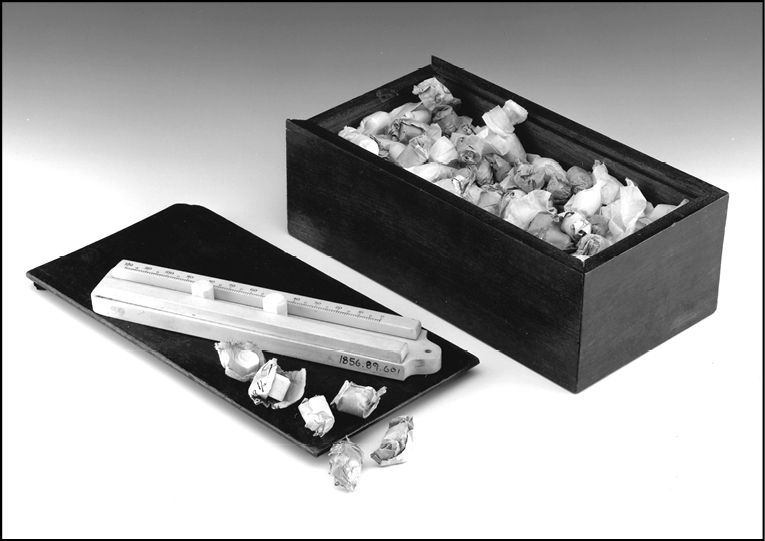

Wedgwood pyrometer, unsigned, c. 1780

Wedgwood invented a device which became a reference for measuring temperatures, and was particularly useful in pottery making.

National Museums of Scotland

England’s scientific community was flourishing. The increase in the prospecting of coal and ores stimulated interest in fossils and rocks: geology became an important science because the building of canals and railways depended on it. Geology became so popular that Harriett Martineau (1802–1876), a political and historical writer, commented: “the general middle-class public purchased five copies of an expensive work on geology to one of the most popular novels of the time.”

Jasperware copy of the Portland Vase, Josiah Wedgwood, c. 1790

Wedgwood reflects the exceptional relationship between science, industry and art that existed during his time. He had a particular taste for neo-classical art and founded a ceramics industry in Etruria (Staffordshire, UK), a name inspired by the antiques craze triggered by the discoveries at Pompeii. This vase is a high-quality copy of a then recently discovered Roman amphora.

Victoria and Albert Museum, London

A new theory of the earth’s formation was then advanced, naming heat as the principal agent responsible for the earth’s crust. It contradicted the view that sedimentation and crystallization of water were the main causes. Eventually, The Principles of Geology by Sir Charles Lyell (1797–1875) explained that the changes were a result of an ongoing process rather than an isolated cataclysmic event, such as a flood or a volcanic eruption. Lyell’s theory would greatly inspire Charles Darwin as he traveled the globe.

In the meantime, the small-scale pottery had become a large industry. Wedgwood’s signature, cream-colored earthenware which he was permitted to call “Queen’s ware,” became a household staple, and his lavender ware can still be purchased all over the world.

Two hundred years ago, science and technology helped turn an antique art form into a pleasing commodity. According to scientist-philosopher Cyril Smith: “It was, however, ceramics made by Neolithic creators who unwittingly caused the atoms in the clay to lock tightly together through the action of heat, that marked the true beginning of material sciences.”

Figure of Voltaire, Josiah Wedgwood, c. 1775

Wedgwood immortalized Voltaire, whose companion, Émilie du Châtelet, was a knowledgeable mathematician. She translated Newton’s notes into French.

Potteries Museum, Stoke-on-Trent, England

Of all the earth’s materials, metal is the most fascinating. In an oriental myth, the birth of metal is described as the result of the death of a superior being. Lead was extracted from his head, tin from his blood, silver from his marrow, copper from his bones, steel from his flesh and gold from his soul.

Since stone knives were as sharp as blades, metal itself at first had no practical advantage and was probably used for magical purposes. Some metals occur naturally and are easily detected as shiny, malleable lumps on the earth’s surface. The earliest metal objects, mostly small ornaments of gold and silver, were directly cut and carved.

According to the Greek historian Herodotus (c. 484–420 B.C.), Pactolus was the river with the richest source of gold in the world. This precious metal could be simply scratched from rocks and used as payment. King Croesus (sixth century B.C.), from the nearby region, introduced gold coinage. Meanwhile, several civilizations developed goldsmithing skills to a high degree.

Center-bead and two Triratna-shaped necklace pendants, India, Sunga Period, 185–72 B.C.

Etruscans and Indians mastered filigree and granulation techniques exceptionally well. Minuscule spherical beads of pure gold were heated and rolled until they became solid, then thrown in water or dust before being chemically fixed to the ornamental piece.

Gold repoussé with granulation, height: 21⁄4 in. (5.7 cm)

Cleveland Museum of Art; John L. Severance Fund, 1973.66–68

Unlike gold, most metals are not found in their pure form but have to be extracted and smelted. About five thousand years ago it was discovered that when green stone malachite and some other minerals were subjected to fire they produced red copper that could be hammered, cast, molded, reheated and reshaped. The possibilities for making ornaments, vessels and tools increased dramatically as a result. But there was one major drawback: copper is soft.

The problem was overcome when it was discovered (perhaps accidentally) that when copper was combined with tin—which is even softer—an alloy was created that was surprisingly harder and more durable than either of its components. That tougher material was bronze (c. 3000 B.C.).

It took scientists until the twentieth century to understand the mechanism of this phenomenon, which is caused by changes in atomic structure. (Pure copper is like a wafer of parallel planes which slip easily when the metal is bent. Tin atoms act as anchorage points within the copper structure, preventing the planes from sliding.)

The amount of tin in bronze can range from 5 to 20 percent; ancient Shang bronzes are usually found to contain the ideal proportions for creating the highest quality material. Many ancient civilizations worked with bronze, but the Chinese attained the greatest mastery of the medium.

Bronze elephant vase with elephant cover, Shang, c. twelfth century B.C.

To make such an object, separate piece-molds were impressed on clay models; the “negatives” were carved and incised. When the pieces were assembled, molten metal was poured into the cavity between the core and the mold. In early vessels, bronze leaked between adjacent segments, producing “fins.” In later times, these fins were integrated into the design of the finished objects. (Note the elephants’ tails.)

Freer Gallery of Art, Smithsonian Institution, Washington, D.C.; 36.6

On the other hand, the Sumerians called iron the “metal of heaven” because it was delivered by meteorites; Homer even put iron on a par with gold. In its pure form, it is also rather soft; man-made iron from terrestrial ores was developed late because processing required high temperatures. When people realized that it could be used for making hard tools and weapons, life was transformed.

Hence the existence of an early Stone Age, then a Bronze Age, followed by an Iron Age. (This categorization was drawn up by a Dane, Christian Jurgensen Thomsen (1788–1865) who, while searching for megaliths, found artefacts that he classified according to their constituent materials.) Thus materials and their production technologies form the basis for the chronology of civilization.

In the Far East, it was known by the fourth century B.C. that iron containing a small amount of carbon was easier to melt and cast than its purer counterpart. These experiments marked the first steps in the development of metallurgy. In order to attain high temperatures in the kiln, the Chinese covered its inside walls with heat-reflecting materials. In addition, large-scale use of furnace bellows driven by waterwheels contributed to the astonishing development of iron and steel in China, around 1000 A.D.

The Japanese, on the other hand, raised steel-working to an art that culminated in the production of ceremonial swords. Making one that was both flexible (having a forged iron core) and had hard cutting edges (made of steel) could require up to twenty phases of repeated heating, hammering and folding. However, fabrication process was closer to a religious ritual than to a practical manufacturing procedure.

While Far Eastern craftsmen created metal masterworks, Westerners were still struggling to fabricate rough cast iron. The Ancient Greeks performed a significant mental feat in hypothesizing that physical elements underlie the world’s creations. By doing so, they stated that the universe could be ordered and framed. They had intuitive knowledge of the structure of materials: atom means indivisible in Greek and atoms in combination were named moleculon.

Dagger, Nyudo Kotetsu, Edo period, Japan

The Japanese fashioned steel swords into functional works of art. The ornate scabbards were highly individual.

Various metals and lacquer, overall length: 161⁄8 in. (41.1 cm), blade: 111⁄4 in. (28.5 cm)

Cleveland Museum of Art; Gift of Bascom Little Estate, 1974.56

The belief that the four elements could blend into an infinite number of combinations to create phenomena, remained popular until well into the Renaissance. Alchemical concepts such as these flourished independently in Eastern cultures, too. In Europe they centered around the Philosopher’s Stone, a substance believed to have the power of turning base metal into gold.

Mary the Jewess was credited with having invented the double-boiler and distillation. While studying the cycles of life and death, recording the secrets of metal, she said: “Unite the male with the female and you will find what you seek.” Maturation of metal was indeed believed to accelerate the rhythm of nature. The alchemist Cleopatra (fourth century A.D.) wrote a book on the transmutation of gold.

In the eighth century, Jabir, known as the Mystical Arab, took important theoretical and experimental steps. Much later, a unique textbook on mining by Georgius Agricola (1494–1555) gave Western research a hefty boost, but it was not until 1722 that a scientific treatise was written on the conversion of iron into steel. The combined knowledge of geology and metallurgy slowly paved the way for chemistry.

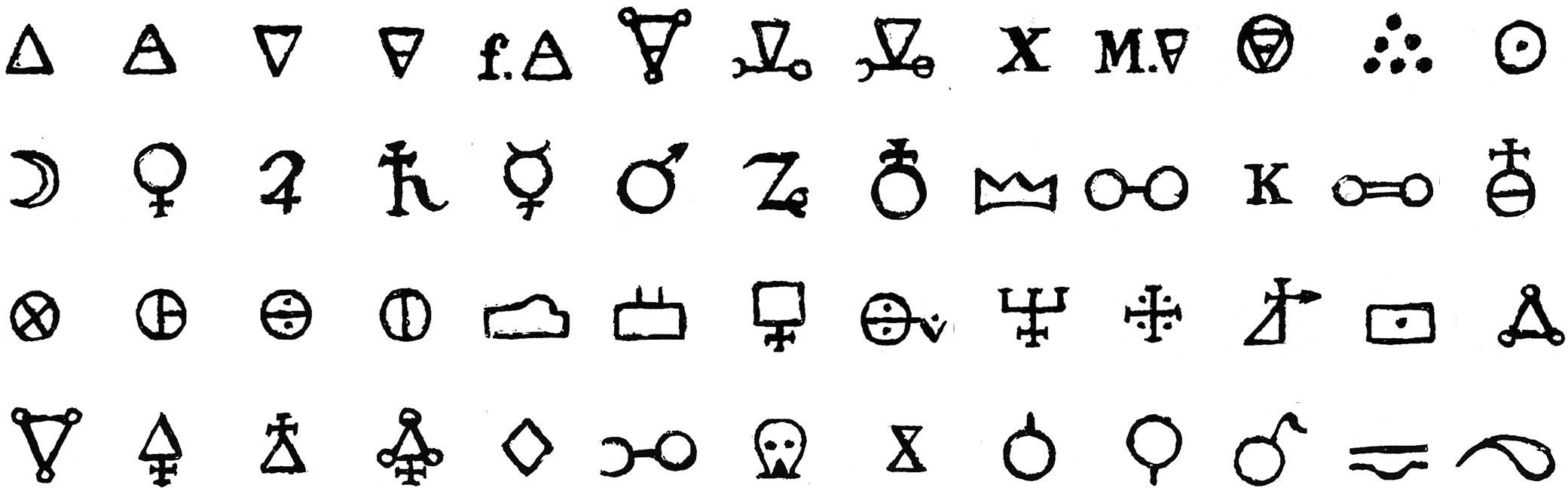

Symbols used in alchemy until the eighteenth century

Chemistry was long a subject of fantasy; flowers of zinc, diaphoretic antimony, butter of antimony, vitriolated tartar, etc., were part of the poetic language.

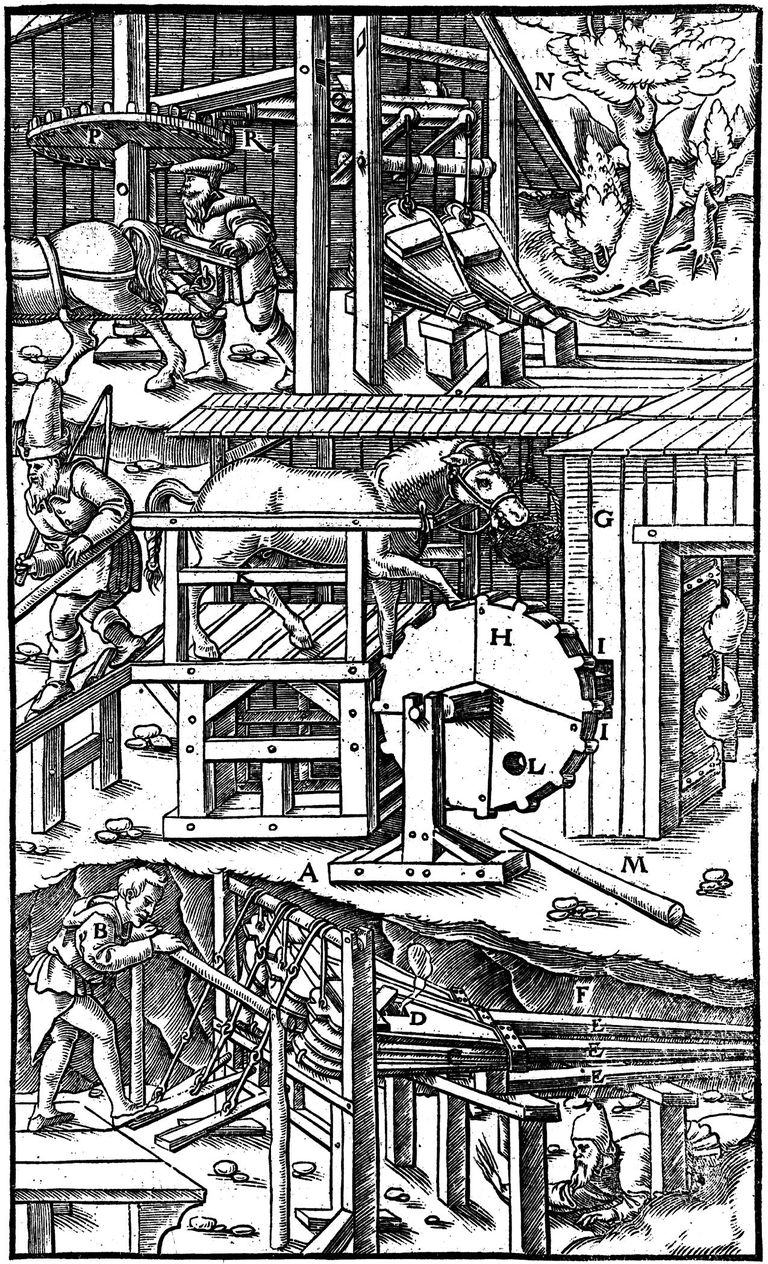

Mine Ventilation in De Re Metallica, Georgius Agricola, c. 1556

Agricola wrote a textbook on mining that was the definitive work on the subject for two hundred years. He delayed its publication by decades in order to produce the 291 accompanying illustrations (the book as a result was published posthumously). Agricola offered a detailed description of where mineral veins are found. He introduced the word “fossil” (believing that it was an odd rock that looked like bones). The silver mines near Joachimsthal, where Agricola worked, gave their name to the taler, which in turn became the dollar.

Science Museum, London

The chemist’s futuristic materials

During the eighteenth century, the study of combustion and respiration stimulated a particular interest in gas (pronounced “chaos” by the Dutch scientists who coined it). The English consolidated the experimental knowledge of gases, while the French developed its theoretical properties. Antoine Laurent de Lavoisier (1743–1794), concluded that air is made of oxygen and nitrogen; water was not an indivisible element either, as previously thought, but a compound made of oxygen and hydrogen.

A system was developed for classifying elements that could not be reduced to smaller units. Each atom was considered to have a specific mass that remained unchanged during chemical processes. Laws that account for conservation of matter during chemical reactions could then be established. From there on, progress in understanding the structure and synthesis of matter was incredibly rapid and intense.

A Russian visionary, Dmitri Mendeleyev (1834–1907), began to list the elements in order of their atomic masses. He described a basic table of 63 and correctly predicted the discovery of many others; today, their number exceeds 110. Although we know that the atoms, too, can be split, since they are made up of smaller particles, Mendeleyev’s model is still applicable.

Progress in chemistry resulted in immediate applications in the artistic realm. A close friend of Count Alessandro Volta (1745–1827), the inventor of the battery, developed it in order to plate sculptures and crafted objects with gold. Depositing a coat of metal on to a core by means of electrolysis became instantly popular.

But the public demanded more new products and the time was ripe for materials that combined atoms by way of elaborate chemical processes into long chains called polymers. An early commercial application of such products served as a replacement for the expensive ivory used to make piano keys and billiard balls.

Alexander Parkes (1813–1890) developed the first synthetic polymer, precursor of the gigantic plastics business. By-products of the coal and oil industry soon yielded a plethora of compounds (polystyrene, polyvinyl, neoprene, polyurethane, silicone, etc.) which reshaped decoration, painting, sculpture and architecture.

Thanks to computerized modeling techniques, and powerful microscopes which enable us to visualize atomic structures, matter can literally be created to measure. Atoms can be arranged in order to produce specific features such as conductivity, strength, and resistance to fire or bacteria. Nanoparticles, or particles between one and one hundred nanometers in diameter—a size at which many materials display surprising properties—are a promising new field. While scientists are finding applications for nanoparticles in medicine, optics, and electronics, their artistic potential is not being neglected.

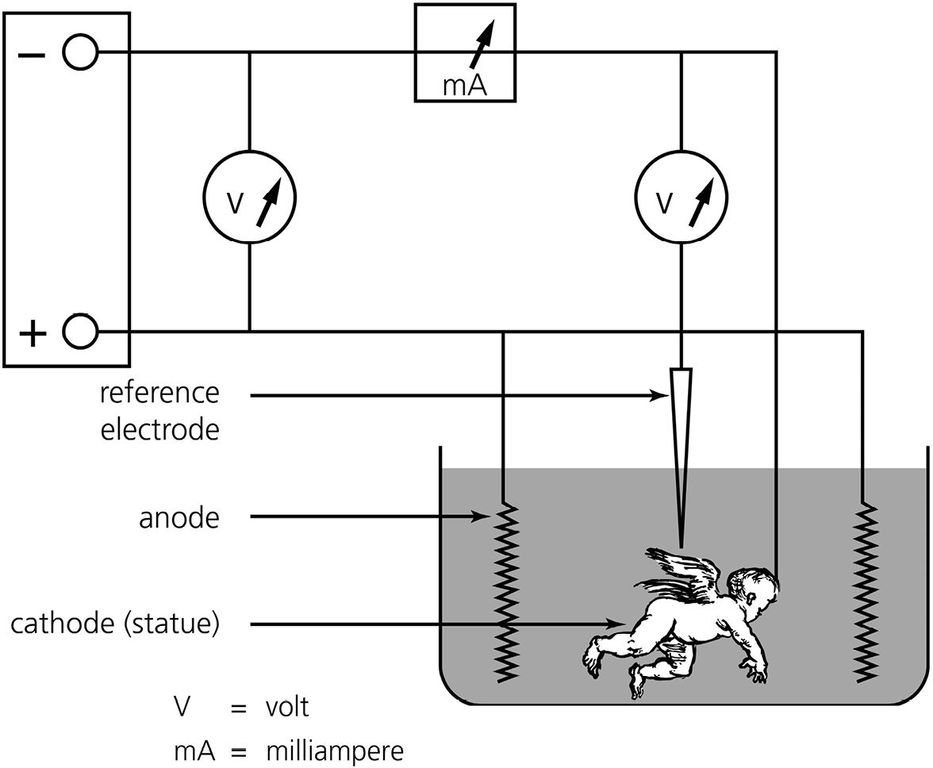

Gold-plating by electrolysis

Electrolysis was adopted on a large scale for reproducing works of art. Pre-Columbian Indians may have used a similar technique to gold-plate ritual objects.

Cyril Smith said: “With the development of material sciences in the twentieth century, the scientist is now finding out something the artist has always known: imperfections in symmetry are the key to a higher level of interest.… And, of course artists did not think in terms of physicists’ theories, but they did select the materials that would behave in the way they wanted.”

Since ancient times, decorators have inspired scientists by manipulating and alloying substances. Until the nineteenth century, nearly all available materials had been known for 5,000 years. Fine objects made of glass, porcelain and bronze are being progressively replaced by synthetic ones.

Although technology is overtaking a field traditionally dominated by artisans, artists and scientists together keep fueling innovation in the decorative arts.

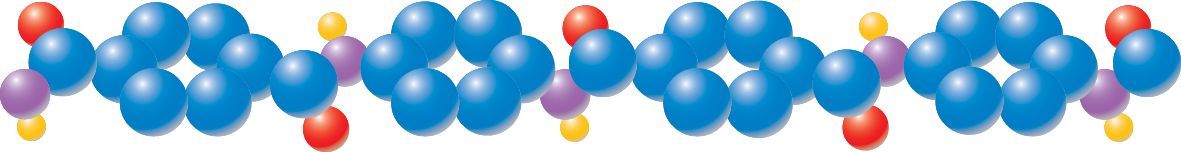

Molecule of Kevlar®

Long chains of atoms result in fibers that are several times stronger than steel, and yet lighter than nylon. They can be used for bulletproof jackets as well as a huge scenic decor. Seen through a microscope, this strand looks like a delicate necklace.

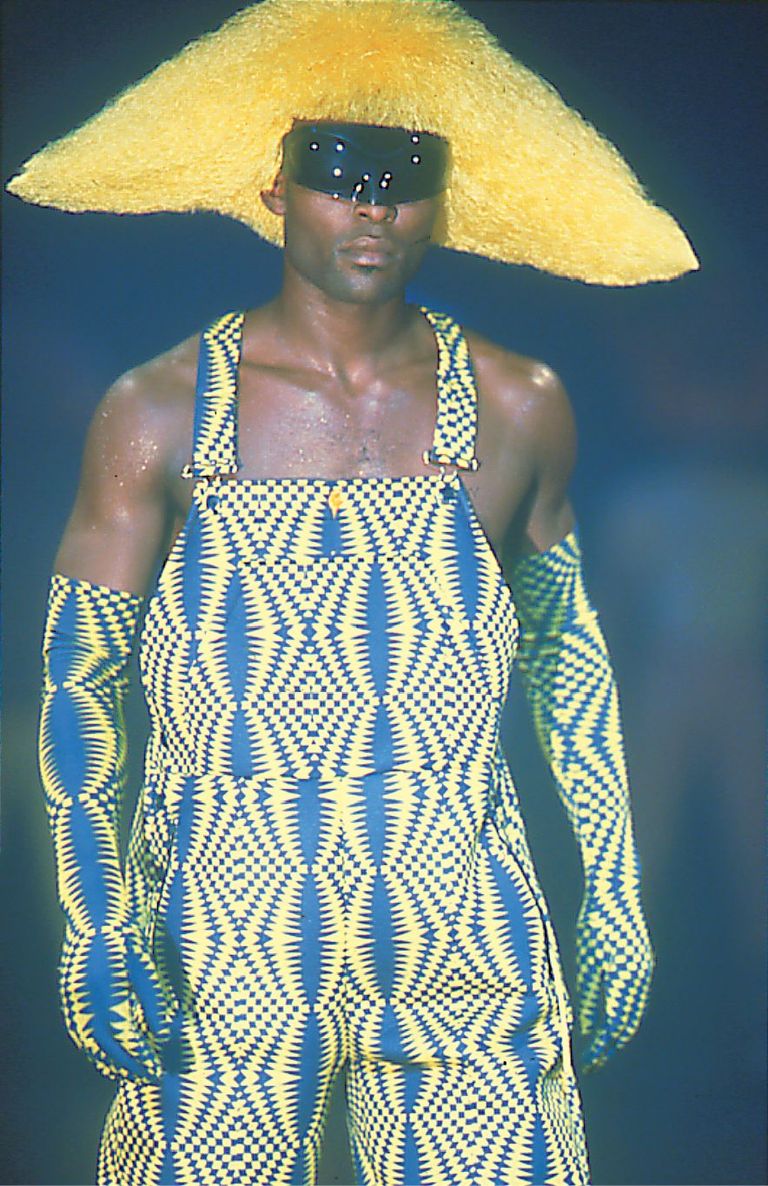

Optical wave print fabric

Synthetic materials have revolutionized fashion by making bold and expressive styles available to all. Now we can also augment our outfits with devices such as Google Glass, eyeglasses with a heads-up display connected to the Internet, and the Apple Watch, a wristwatch that functions as a fitness monitor and a digital wallet, among many other things. Of course, as with any wearable item, aesthetic criteria will play a large part in the adoption of these electronic accessories.

W & L.T., spring/summer 1996