5

Materials, Appliances, and Fixtures

GETTING STARTED

Creating kitchens and baths that are functional and beautiful in addition to being sustainable is the responsibility of today’s designer. Sustainably aware designers recognize their position as responsible stewards of our planet and its resources. Our planet is full. Past habits of continued economic growth, creating waste and overpopulation, have resulted in a planet that is overused. According to the Living Planet Report 2010, we currently need 1.5 earths to sustain our current economy and wasteful habits.1 That means to sustain our current way of life, we need 50 percent more earth—which is not going to happen.

We need to make a change today!

This chapter focuses on material choices and other decisions you can help your client make that are not only feasible, functional for their lifestyle, and beautiful to look at, but most important are sustainable for our planet. Yes, you can have all of this, but it takes work.

- Learning Objective 1: Apply green criteria to selecting materials.

- Learning Objective 2: Research and specify appliances using sustainability criteria.

- Learning Objective 3: Demonstrate best practices related to selection of material product.

A word of caution: We wish to preface this entire chapter with the caveat that “there is no perfect product.” No matter how much we would love to be able to supply you with a list of perfectly sustainable products for your tool box, we cannot do so, for there are none.

We can, however, give you the tools to decipher information to help you and your clients make the best selections possible for them, for you, and for the environment.

Material Properties

Material selection begins on a project earlier than you might expect. There are a few reasons for this, but number one is clients’ delight in choosing the surfaces they will interact with on a daily basis. In our experience, backsplash tile, cabinets, flooring, countertops, and more are often selected before the basic space planning is completed.

Specifying materials can be overwhelming enough without the added criteria of sourcing green options. Without taking sustainability into account, here is snapshot of where material selection begins:

- Appearance

- Appropriate use (durability and maintenance)

- Cost (budget)

- Availability

Designers work with their clients to develop palettes of materials: groupings that represent the whole project (see Figure 5.1). As the palette is pulled together, research is conducted: price, durability, availability, material content, and installation methods.

Figure 5.1 Green materials palette created for a kitchen remodel: Wood for cabinets is Forest Stewardship Council–certified; countertops are Eco by Cosentino (recycled content); Marmoleum by Forbo (natural material) is chosen for flooring; Yolo Paint (zero VOC) and Pratt and Larson Tile (locally sourced) are used.

NKBA

This chapter focuses on understanding which questions to ask in regard to the sustainability of materials. The importance of third-party evaluators was discussed in Chapter 2. It is crucial to have access to ratings of materials so that you can make the best choices for your clients. Around the country, some companies specialize in offering only materials that are environmentally sound. Their showrooms are a valuable resource. Research into the sustainable nature of a material takes time, and a vetted company can offer time-saving advice. Learn how to decipher a product’s material safety and data sheet (MSDS). This will tell you about which materials go into the fabrication of a finished product.

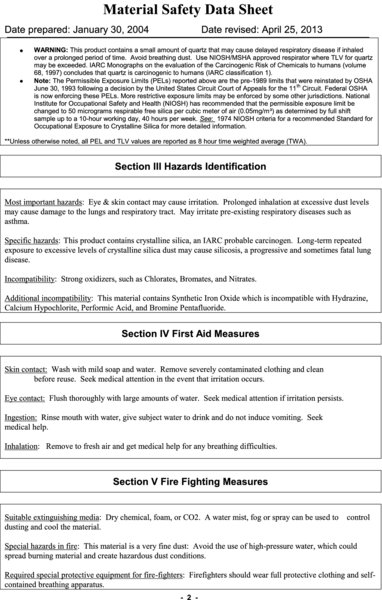

Material Safety and Data Sheets

The MSDS or product safety data sheet is a valuable component of product stewardship and occupational safety and health. Its intended use is to supply information for safe handling procedures of a product. It also aids emergency personal in case of any physical contamination created by accident or misuse. In both Canada and the United States, this information is required to be available for all products (adhesives, paints, grouts, etc.) installed on a project site (see Figure 5.2). Today MSDSs from most companies are downloadable from their Web sites.

Figure 5.2 Material Safety and Data Sheet by American Clay for their pigments. Each product by American Clay has its own MSDS. Today, most companies have their MSDS available for download from their websites.

MSDS Courtesy of American Clay

Green Product Declarations

While the MSDS does offer some information about a product, there are still holes in the available information. Globally, there is a movement towards more transparency of what goes in to each product. Creating a standard report or a “nutrition label” that includes environmental, social and health impacts would make choosing the appropriate materials for your project easier. The goal is for full disclosure, but the vision is seen from two separate viewpoints. One camp is moving towards creating the Environmental Product Declaration (EPD). This report assesses the products environmental impact over its life cycle (LCA). The second camp, Health Product Declaration (HPD) assesses the product as it relates to the health impact on the human population.

Environmental Product Declaration

The goal of the EPD is to “provide a summary of the environmental characteristics of a product in a way that is accessible, consistent and ultimately comparable.”2 EPDs are used globally. It is a third-party verification report that helps to compare “apples to apples” of like products. “The goal of the global EPD system is to create a tool that helps purchasers understand product life-cycle impacts and therefore make smarter purchasing decisions,” says Heather Gadonniex, EPD program manager at UL Environment. “To do that, you have to use the same LCA methodology, the same data quality, and report of the same additional criteria in the EPD.”

The problem with an EPD is that the 20-page report includes the key points from the LCA only and it does not include social or human health impacts. The length of the report makes it too technical and long for most designers to assimilate the information. There is a movement to create an EPD label that is more user-friendly.

Health Product Declaration

Where EPD’s evaluate a product based on its environmental impact, the HPD evaluates a product based on its human health impact. The creation of the HPD is backed by the HPD Open Standard Working Group, which includes members from the Healthy Building Network (HBN—the creators of the Pharos Index) and Building Green, Inc. (publisher of the Environmental Building News). The HPE Open Standard requires manufacturers to “provide the hazard profile for 100 percent of ingredients (that go into a product), even ingredients that are not identified.”3 Currently, the HPD is only used in North America, but the goal is to have it incorporated with the EPD.

Social Impacts

Neither the EPD nor the HPD include the company’s social impact, downstream impacts of production or “includes the manufacturer’s overall environmental footprint”4 in their report.

The MSDS gives product information, such as:

- Physical data: melting point, boiling point, and flash point

- Toxicity

- Health effects

- First aid

- Storage

- Disposal

- Protective equipment required in its installation

- Spill handling procedures

- Instructions for safe handling

- Potential hazards

- Environmental risks

EMBODIED ENERGY

The biggest challenge the designer faces in materials selection is that each product is part of a bigger picture. Let’s take flooring: You are not just purchasing flooring—for this example, cork flooring (a very sustainable option)—you are purchasing:

- Growing of the cork tree (including labor, fertilizer, watering)

- Labor and machinery to harvest the cork

- Transportation of the raw material to the processing plant

- Packaging (and all the energy and natural resources that go into the creation of the cardboard, plastic, labels, and more)

- Shipping

- Storing

- Shipping again

- Installation (including the glue, labor, setting materials)

- Final finishing

And this is not even a complete picture.

This entire process is referred to as embodied energy.

In Chapter 2 we began the discussion of embodied energy; here we complete the picture.

First we need to give you some parameters and definitions based on DuPont’s “Glossary of Common Sustainability Terms”:5

- Cradle-to-gate. An assessment of a partial product life cycle from the manufacture to the factory gate (before it is shipped to the warehouse, installer, or final end user). The term is used in the calculation of embodied energy.

- Cradle-to-site. An assessment of a product life cycle that continues on cradle-to-gate and includes all of the energy consumed until the product reaches its point of use (the client’s home).

- Cradle-to-grave. An assessment that continues from cradle-to-site to include the life of the product in the client’s home (including maintenance) to the end of its useful life and the disposing of the final product.

- Cradle-to-cradle. A design protocol that advocates the elimination of waste by recycling a material or product into a new or similar product at the end of its intended life rather than sending the product to a landfill. Embodied energy calculations start with the extraction of the raw materials (including the fuels needed in the extraction process), transportation of the raw materials to the manufacturing plant, the energy it takes to run the plant, and creating the packaging the finish product requires for shipping.

The decision to set the boundary for determining embodied energy from cradle-to-site to stopping at the gate was based on the assumption that “[i]n many cases, transport from factory gate to construction site would be negligible. Whilst this may be true for many materials, and normally true for high embodied energy and carbon materials, this is not exclusively the case. In the case of very low embodied energy and carbon materials, such as sand and aggregates, transportation is likely to be significant. For these reasons the ideal boundaries have been modified to cradle to gate.6 Many of our materials travel long distances to get to the project site; as a designer, you should determine if this travel distance should be a factor in the final product decision.

Many clients consider transportation of a product to the project site in their buying decisions. It is commonly referred to as buying locally.

Embodied energy assessments do not consider the life of the product once it leaves the factory and arrives at the client’s home. To accurately assess a product, one must include maintenance (materials and labor required to maintain the product and how the product is to be disposed of when it ends its usable life. We consider embodied energy assessments to be only half of the story.

LIFE CYCLE ASSESSMENT

A more complete way to look at material selections is through life cycle assessment (LCA) (see Figure 5.3). LCA is a comprehensive evaluation of the environmental impact a product has from the initial sourcing of raw materials to the product’s eventual disposal.

Figure 5.3 Applying the Life Cycle Assessment to the products you specify will help you and your client understand the product’s green story.

NKBA

According to the Athena Sustainable Materials Institute (ASMI), LCA includes:

- Resource extraction and product/materials transportation

- Material processing and product manufacturing

- On-site building construction requirements

- Occupancy and maintenance considerations

- Building decommissioning and demolition

- Materials disposal, reuse, and recycling7

Incorporating LCA in the decision-making process enables both governments and industry to determine the cradle-to-grave impact of a product. Government agencies are moving toward the incorporation of LCA in regulations. Businesses are voluntarily incorporating initiatives that contain LCA and product stewardship components. Finally, consumers are interested in knowing about a product’s environmental qualities. LCA is a holistic approach to the selection of materials, fixtures, and appliances.

There are three aspects to consider when reviewing a product through LCA:

- Goal definition and scoping. Identifying the purpose and what to include or exclude from your process. This is where you define your client’s goals for sustainability. During your interview process, you can determine your client’s focus. Consider these factors; are they important to your clients?

- Indoor air quality (IAC)

- Sourcing products locally

- High recycled content

- Water conservation

- High energy efficiency

- Low maintenance

- Life cycle inventory. This phase determines the energy and raw material inputs and environmental outputs during each stage of production (the embodied energy used during manufacturing). What resources are used in the creation of the final product? What about transportation?

- Impact assessment. This determines what waste produced during the production stage have an impact on the environment and human health. Does the processing release waste that contributes to global warming, acid rain, or fossil fuel depletion? This is where we assess the volatile organic compound (VOC) emissions and the product’s impact on IAC, including the products needed for installation and continued maintenance. At this stage, we assess the end of life of the product. Can it be recycled or reused? Does it go into the landfill?

Strengths to Using LCA Evaluation

The criteria for evaluating what is green change over time. What was once thought to be a green material can later be labeled something different. The reason for this is the increased breadth of the evaluation process. Ten years ago, everyone was concerned with renewable resources. Today products are subject to much more scrutiny, such as the LCA. Tomorrow there will be added criteria. This scrutiny can be overwhelming, but with third-party evaluators and some basic education on the part of the specifier, products with increased green value will be selected.

Systems Thinking

Recognizing that each product is only part of the big picture brings us to systems thinking.

Systems thinking (which is also discussed in Chapter 1) is the concept that to fully understand why a problem occurs and continues, we need to understand the parts in relation to the whole. We can apply this way of thinking to material selection.

Consider the process of choosing the appropriate flooring material for your client. Choosing a flooring option is not that easy. First you have to take into account the client’s initial desires, (i.e., hand-scraped oak flooring), but mindful designers use that as a jumping-off point. Although you may want to begin the selection process, sustainability is only one factor; you must also consider:

- Aesthetics. What is the overall look and feel to the room? What is the idea behind the idea or the design concept? Dark, warm, traditional or light, airy, and beachy?

- Lifestyle. How many children and adults are there? What about pets? Do people wear shoes at home? If you take time to observe the details of your client’s home, much will be revealed.

- Maintenance. Do clients employ a housekeeper? Are they willing, for example, to have wood floors resurfaced every five to ten years or have stone sealed once a year? Or are they willing to live with a patina that develops as the material wears?

- Body limitations. Do clients have back issues? Do they need a softer floor over a hard one? Should the floor absorb sound (noise reduction coefficiency)?

- Environmental concerns. What are the clients’ environmental goals for the project? IAC? Recycled content? Locally sourced? Minimal maintenance? How dedicated are they to sustainable choices?

- Life expectancy in the home. Do clients intend to live in the home for more than five years? More than 20?

Specific LCA and Environmental Matters Items to Consider

- Does a third-party environmental evaluator certify the product?

- Does the product contain low or zero amounts of environmentally harmful substances?

- Does the supplier/manufacturer recycle preconsumer waste?

- Does the supplier/manufacturer have a mission statement that incorporates environmental stewardship?

- Is the distribution of the product efficient?

- Is the product packaged as simply as possible?

- Is the product designed for easier recycling at the end of its life (once un-installed)?

Consider cork flooring. Cork is an easily renewed material that is made from bark harvested from a type of oak tree. The tree is not cut down, and the cork tree’s bark regrows, as seen in Figure 5.4. It takes 10 to 12 years for the bark to regenerate to the thickness needed before harvesting. Cork-producing oak tree plantations are credited with capturing 5 percent of the carbon dioxide (CO2) in the local environment on their own.

Figure 5.4 Cork harvesting process

“The cork industry does not destroy the ecosystem where the tree lives, but instead creates wealth while keeping nature as it is,” says Paulo Nogueira, managing director of the cork producer and distributor Amorim Flooring in Hanover, Maryland. He adds that the cork industry represents $3 billion of Portugal’s gross domestic product and employs over 150,000 people. “We can create jobs and economic activity in balance with the world in which we live.”8

This might make cork an easy choice if it is appropriate for the application. Consider, however, the carbon footprint of cork. Cork bark comes from Portugal. It is then fabricated in the United States. Your project is in California and will require additional transportation. With these factors in mind, how does cork stack up against locally produced oak flooring?

Green Product Directories

Understanding what goes into the raw materials that create the finished product is the biggest step to choosing sustainable materials. But how do you gather all of this information to make the most informed decision? (See Table 5.1.)

Table 5.1 Initial Product Assessment Guide

| Basic Information | Best Practice (what to look for) | Where to Find Information |

| Raw material | Renewable sources | Manufacturer’s specifications |

| Manufacturing | Embodied energy | Third-party evaluators: ENERGY STAR, Regreen, etc. |

| Transport | Embodied energy | Location of manufacturer |

There are many avenues to help designers find the most sustainable products. These include building material stores that sell only green products, manufacturers’ Web sites, third-party evaluators, and the Internet. Firms that are focused on sustainable practices use databases which evaluate the greenness of a product. Such databases can be found at these Web sites, among others: www.energystar.gov, www.buildinggreen.org, www.regreenprogram.org. Some databases, such as the Pharos Index (www.pharosproject.net), require a paid membership. Spend some time reviewing these sites and others to determine which will be most useful in your practice.

The Pharos Index was developed to help designers, architects, and builders make sustainable choices in material selection. The materials covered are specific manufactured products. You will not see simply “quartz countertop” in the Pharos Index but rather brand names. Note that the Pharos rating is a system. Since there is no such thing as a perfectly “green” product, users of the index can analyze each product to determine which is best for their client. The five rating components of the Pharos system are:

- Presence of VOCs

- Toxic content

- Manufacturing toxins

- Renewable materials

- Renewable energy

When researching a product for your projects, ask these questions, among others:

Manufacturers

- What is their environmental policy?

- Do they comply with industry standards and voluntary testing programs?

- What is the company’s social impact on their employees (do they offer health coverage, education benefits, retirement etc.) and the community (do they support community events, employee volunteering activities, etc.)?

Products

- Where are the raw materials extracted?

- Where is the product manufactured?

- What is the environmental impact of the manufacturing process?

- What is the composition of the final product? (Research the MSDS.)

- What products are needed for the installation and maintenance of the final product?

- How will the product impact the indoor air quality (IAQ) of the home?

- What is the life span of the product?

- What is the recycled content of the product?

- How much packaging is used in shipping the product?

- How can the product be disposed of at the end of its use?

- Does this product fit in the client’s budget?

As you apply these questions to each product you specify, you will create your own list of sustainable products. Remember, though, as we have previously stated, the parameters for determining the greenness of a product change over time. Therefore, continuing education is a requirement for all highly successful designers. As you continue with your education, consider obtaining professional certifications, such as those offered through the National Kitchen & Bath Association (NKBA). Obtaining your AKBD, CKD, CBD, and eventually your CMKBD and others, will support your continuing education process and enhance your professional success.

Longevity and Universal Design

Sustainability involves much more than environmental issues. If we believe that sustainable design incorporates the following principles:

- Optimize site potential and protection of existing landscape

- Minimize the consumption of nonrenewable energy

- Conserve and protect water

- Maximize the indoor environmental quality

- Balance long-term economic, social, and environmental needs

- Provide cost-effective development solutions

- Enhance clients’ quality of life

then the real definition of sustainable design is “Design created to meet the needs of the present without compromising the needs of the future.” This is where the concept of universal design comes into play.

Universal design focuses on meeting the changing needs of inhabitants of a home. It really doesn’t matter if the home you design today incorporates green materials if in 50 years the house has to undergo a major remodel that sends most of the green materials used to the landfill. Universal design is discussed in greater detail in the Bath Planning and Kitchen Planning volumes of the NKBA Professional Resource Library.

It is important to note that universal design is not only for older people. Children grow, and social patterns and the basic use of the home change over time. Today’s designers must be able to incorporate these changes into their designs. The more flexible and ergonomic the design is, the more it can meet the needs of both homeowners and the planet. Incorporating high-tech energy-efficiency controls for heating may be wonderful, but if their use is not intuitive and easy, the efficiency factor will be compromised.

Incorporate and note blocking for grab bars on every bathroom design, whether clients specifically request them or note. Consider this story, for example, from certified designer Rhonda Knoche, CMKBD/CAPS. “We recently successfully completed a full bathroom remodel for a new client. Six months later we received a frantic call from the wife saying that we were going to need to tear out the newly tiled shower to add grab bar blocking. Her husband had had a stroke and needed support in the shower. Because we had incorporated the appropriate blocking in the shower and at the toilet, and properly noted the locations on the plans, by the time the husband came home from the hospital, we had grab bars installed.”9 Not only did the designer save the homeowner a costly remodel, the designer’s thoughtful design created a client for life.

Incorporating the NKBA’s accessible standards into your kitchen and bath designs gives you and your clients the opportunity to create homes that are durable, flexible, and environmentally supportive.

MATERIALS

As we have discussed, there are many aspects in determining the green factor of a product. In this section we break down product categories, their advantages, disadvantages, and applications. Remember, there is no perfect product.

Cement

Ordinary Portland cement (OPC) is a material seen everywhere. It is the main ingredient in all concrete, mortar, and grout. Cement is considered a hydraulic material because it absorbs and is activated by the addition of water. A relatively inert surface once installed, cement is a good example of how important it is to understand the carbon footprint of a material.

Manufacturing Process

Portland cement is mined from the earth and is the basic ingredient in concrete. It is made from calcium, silicon, aluminum, and iron. Other ingredients can include limestone, shells, chalk, shale, slag silica sand, and iron ore. At the final stages, gypsum is added to help in the setting-up time.

Once the raw materials are mined, they are transported to the processing plant, where the rocks are crushed, mixed with water, and fed into a kiln. The kiln is heated to 2700 degrees Fahrenheit (1482 Celsius). During this process, off-gassing occurs.

Contemporary manufacturing processes capture the heat from the cooling-off period and return that energy to the kiln, saving fuel and increasing burning efficiency. Some plants integrate the use of waste materials, such as sewer sludge and old tires, as fuel for the kilns. On one hand, this is good, as the plants are using waste materials to create new products, but, on the other hand, the off-gassing of some of these combustibles adds to poor air quality.

Environmental Impact

Although cement is durable and its ability to be formed into any shape makes it an attractive and affordable building material, cement has a very high embodied energy and releases large amounts of CO2, nitrous oxides (NOx), sulfur oxides (SOx), and other pollutants. The largest environmental burden of cement occurs during the kiln phase, where the greatest amount of fossil fuel is used. Studies have determined that the creation 1 ton of cement produces over 1 ton of CO2. The net result of the production of cement produces approximately 8 percent of the world’s CO2 emissions, which is a large percentage coming from one industry.10

Options Available

There are ways to reduce the environmental impact of cement-based materials. Consider specifying a custom concrete mix that incorporates the use of fly ash. Fly ash is a by-product of coal burning. While this may seem counterintuitive, fly ash can take the place of cement (up to 25 percent in many mixes), and it strengthens the concrete. Unfortunately, fly ash can contain a considerable amount of toxic metals, as this product survives the combustion process. While it is unlikely that these toxic metals will leach from the cured material, it brings into question the disposal of the concrete later.

Applications of Cement

As a designer, you will come across cement used in many ways. The two most common are:

- Mortar. All mortars are an adhesive. They are used to bond one type of material to another. Mortars are made with cement for strength, sand as an aggregate, and lime for added bonding strength and for flexibility.

- In tile installations, thinset (a type of mortar) will commonly be used. Thinset uses a cellulose-based product instead of lime to help it retain water and give the material flexibility. The aggregate in thinset is a very fine sand so that it is more flexible. A latex additive is sometimes added for more flexibility.

- Most mortars and thinsets emit high levels of VOCs, however, with research, one can find products that are certified for IAQ standards for low VOCs.

- Cement grout. Necessary for most tile installations, conventional grout is used to fill the joints between tiles to create a continuous, relatively impermeable surface. Its main ingredient is Portland cement and pigments. It is easy to install, has little to no VOC emissions, and cleans up with water. Its high alkaline content can be an irritant to skin so gloves are recommend for installation. Contact with the eyes can cause serious irritation, and eyewash should be used if the product comes in contact with an installer’s eyes.

Cement grout does require the continued use of sealers to minimize the growth of mold and mildew and to create a waterproof surface. (See the section called “Sealers” for additional environmental considerations.)

Concrete

Concrete is the most widely used construction material in the world today. With its Portland cement content, the production of concrete is extremely energy and fossil fuel-intensive and is one of our largest emitters of carbon dioxide. The current method of production makes concrete one of the most environmentally destructive materials. Concrete is produced by mixing cement with fine aggregate (sand), coarse aggregate (gravel or crushed stone), water, and small amounts of various chemicals called admixtures that control such properties as setting time and plasticity. The mining of aggregates (gravel, stone and sand) further add to the environmental impact of concrete.

There are options available to minimize the environmental impact of concrete. Replacing Portland cement with recyclable materials and minerals helps to reduce the amount of CO2 released into the atmosphere and diverts materials from landfills.

High-volume fly ash concrete is a promising alternative. Fly-ash is a by-product of coal-burning power plants. The mixture of fly-ash, lime and water forms a compound similar to Portland cement and is strong and durable. In the past, almost 75 percent of fly-ash went directly to the landfill; this product helps to divert approximately up to 50 percent from landfills.

Other concrete options include AshCrete, blast furnace slag, and carbon concrete. AshCrete is created from 97 percent recycled materials and is known for its strength, approximately twice as strong as Portland cement. Blast furnace slag uses byproducts from blast furnaces that are used to produce iron. Slag is easier to obtain than fly ash and when mixed with lime and water creates a very strong cement.

Carbon concrete, a byproduct of oil refineries, is new to the industry. As a thermoplastic it replaces the use of cement in the making of concrete. Due to its nature to settle, it is not used for tall buildings; it is primarily used as a flooring material and for road paving.

Applications of Concrete

Concrete flooring sits on the fence when it comes to its “sustainable” factor. The type of cement that goes into your concrete will greatly raise or lower its “sustainability” rating. If you do choose to incorporate concrete flooring into your project, it is helpful to know that it can be finished in a myriad of options: acid-stained, painted, textured, patterned, and more. Because of its ability to retain heat, incorporating concrete floors with radiant heat or installing in passive solar homes is environmentally beneficial.

Maintenance for concrete floors is relatively easy, making them a good option for homeowners with allergies.

Epoxy Grout

The development of an epoxy-based grout in recent years has given designers and homeowners reason to be excited. Epoxy grout is almost stain-proof, a welcome attribute for tile installations on the floor and in bathrooms where mildew can be a threat. The green reality, however, is that epoxy manufacturing and use is not good for the environment. Third-party evaluators are excellent sources for specific information on building products such as epoxy.

During the installation process, epoxy grout emits VOCs due to the presence of a chemical hardener. Once the product hardens, there is no additional release of harmful VOCs.

The cost of epoxy grout is higher than cement-based grout due to the product cost and additional labor required for installation. Cement-based grout goes on with a trowel or float and is wiped off with a sponge. Epoxy is much trickier. Uninitiated installers can ruin the tile if the epoxy is not applied properly. However, epoxy grout wears like iron, and its performance is far superior to cement-based grout.

Epoxy grout is easier to clean than cement grout and requires no sealing. If you do decide to research epoxy grout, check the product’s MSDS for a good look at the contents of the product. Epoxy grout is an excellent example of the LCA conundrum. As we have stated throughout, the perfect green product does not exist.

WALL FINISHES

With the plethora of wall finish options available, it is good to have an idea of which finish you intend to use as it can affect the overall budget.

Wallboard (Sheetrock)

Most of our interior walls are created with a stud and sheathing system. Gypsum wallboard (Sheetrock) is the most popular interior sheathing material. Gypsum is affordable, and its installation is entrenched in our residential building culture.

The creation of gypsum is similar to that of concrete: The raw material is mined and delivered to a plant where the material is heated in kilns to very high temperatures to render the gypsum into a powder, also called plaster. The kilns do not need to go as hot as those for concrete, so less fuel is used to create the gypsum plaster, but this process gives gypsum a high embodied energy characteristic that is worth considering when designing an interior. Over 80 percent of the gypsum extracted is used in the manufacturing of drywall.11

In the United States, approximately 50 percent of all gypsum is flue-gas desulfurization (FGD) gypsum. FGD is the process of removing polluting gases from the stacks of fossil-fueled power plants and purifying them into a hard substance that is then manufactured into gypsum board.12 This process minimizes the harmful emissions into the atmosphere.

For more than 50 years, the gypsum industry has used recycled newspaper and other postconsumer paper in the manufacturing of the wallboard face and back paper. Currently the industry diverts more than 40 million cubic yards of paper material from landfills.13

Gypsum wallboard can be readily recycled across North America, although according to the Construction and Demolition Recycling Organization, most ends up in the landfill. Determine if your local municipality offers this service, and have a conversation with your contractor to add this to the scope of the project.

Recycled drywall can be used in a number of ways; some examples are provided next.

- Content for new drywall

- Content for cement

- Added to soil and crops to improve drainage and plant growth

- Content for fertilizer

- Additive to composting

Moisture-Resistant Wallboards and Tile Backerboards

Moisture management is paramount to preventing mold growth in a home. (See Chapter 4 for a discussion on ventilation for the prevention of mold growth.) The selection of the most efficient backerboard for wet areas such as tubs and shower surrounds will aid in the prevention of mold and mildew. Options for tile backerboards are cementitious, coated glass mat, and fiber cement.

Whereas gypsum board can be recycled, these types of wallboards cannot. Both cementitious and fiber cement boards have a higher environmental impact due to the high embodied energy content of the cement. For a more sustainable product, specify backerboards with higher fly ash content.

In the case of tile backerboards, you and the client are making a choice between IAQ (health benefits) and high embodied energy.

Paint

Paint is the most economical and efficient way to make change in a room. Color can be incredibly uplifting, and a new, uniform finish can pull an entire room together. There are still many contractors and designers who consider an oil-based paint to be more durable than latex or water-based formulas. This may be the case, but bear in mind that oil-based paint will off-gas solvents for a much longer time period than water-based paint.

The Truth about Zero-VOC Paint

Conventional paints are manufactured from petrochemical-based solvents that off-gas (i.e., they are high-VOC). When specifying paint, instead of conventional paints, look for low-VOC and zero-VOC formulas. These paints both cover well and have the lowest amount of harmful emissions. The label “zero-VOC” is a misnomer. VOCs are present in all paints, although those labeled as zero VOC have not exceeded the applicable government limits. It is important to note that some paints of this type have lower emissions than others. This greenwashing is very prevalent in paints. Use a third-party evaluator rather than manufacturers’ information to make your final choice of which brand to specify.

Natural Paints

“Natural paints” are made from renewable or naturally occurring materials and are available as water, oil, or milk based. Ingredients include citrus oil, lime, clay, linseed oil, casein, and chalk. They contain no petroleum products and emit few if any VOCs regulated by the US Environmental Protection Agency (EPA); however, they may emit VOCs from additives, such as citrus-based solvents.

The manufacturing process for natural paints is cleaner than that for traditional paints, but be sure to refer to a third-party rating system for more information on each specific brand’s processes.

Typically, these products are healthier and environmentally safer than traditional paints, chemically sensitive clients may find some of the ingredients in natural products, such as citrus oil, hard to endure. Not all of the natural ingredients are safe; some, such as cadmium (a yellow pigment), are toxic. Refer to each product’s MSDS ingredient list for compatibility for your client.

Milk-based paints (made from powdered casein) are the least toxic and environmentally impacting paint. They are not, however, recommended in high-moisture areas, such as kitchens or bathrooms, as moisture may damage the finish and encourage mold growth. If it is to be used in these locations, a sealer must be applied. The use of a low-VOC, water-based sealer will further support the health and environmental benefits.

Milk-based paints require the addition of a preservative to extend their shelf lives. Due to the paint’s short shelf life after opening, touch-ups require a new batch and may not match the original finish.

Natural paints cost 20 to 80 percent more than traditional paints and take two or more days to dry. They may not always be compatible with existing latex or oil painted surfaces; therefore, they require extensive prep work as these paints are best used on clean-primed surfaces.

Clay Plasters

There are many alternatives to using paint as a covering of gypsum or plaster in an older home. Hand-applied clay-based mixes provide endless opportunities for custom, one- of-a-kind surfaces. The biggest hurdle you will experience with these surfaces is cost of installation. The application is in layers, which is time consuming (see Figures 5.5 and 5.6). The cost of the material is comparable to higher-end paint (in general), and the fact that it comes in powder form and is mixed with water on site means little waste of unused product.

Figure 5.5 American Clay installed in a bathroom

Figure 5.6 American Clay installed in a kitchen

Homeowners generally can make small repairs to walls with clay-based plaster, but large damage may require a professional.

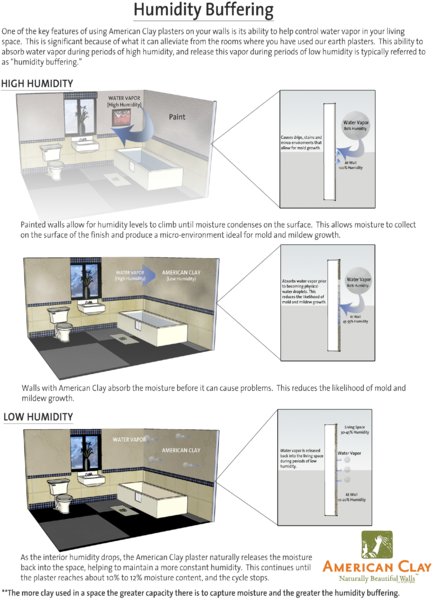

The advantage to using clay-based products in wet areas such as bathrooms is their ability to help control moisture. These products have can absorb moisture during high-humidity periods (e.g., after a shower) and release it during low-humidity times. This is referred to as humidity buffering (see Figure 5.7).

Figure 5.7 Humidity buffering in a bathroom

Painted surfaces do not absorb moisture. During a shower, the moisture level rises in a bathroom and condenses on the surface of the painted walls. This creates the perfect environment for the growth of mold and mildew.

Plastered surfaces absorb excess moisture, reducing the opportunities for mold and mildew to grow. As the room’s humidity level drops, the plastered surfaces release the excess moisture, helping to maintain a constant humidity level. The release of moisture “continues until the plaster reaches about 10 to 12 percent moisture content.”14

A waxed surface or Venetian plaster is similar to a clay-based wall surface. Natural pigments are mixed with plaster and troweled onto a wall. The next layer is mixed with paraffin and or beeswax. The result is a beautiful, custom surface that shines. There are no VOCs and little wasted product. The surface is amazingly durable but, of course, it is susceptible to damage as is any wall. Therefore, it is not recommended in high-traffic areas, such as entryways on walls that line paths of high circulation in a kitchen.

Ceramics

Tile made from clay is responsible for the surface durability of many kitchen and bath interiors. Ceramic tile can be an affordable and durable alternative to stone. However, it can also be one of the most unique and expensive materials in a project.

The installation of tile can cost more per square foot than the material cost itself. Clay tile needs to be installed on a dry and level surface. Most tile installation problems have to do with an uneven substrate. For most wall applications, a thinset installation is recommended. For floors, either a thinset method is specified or, if a slope is necessary, a thickset installation is recommended.

Clay tile is installed over a thinset mortar bed, which is a cement product. The embodied energy of cement is considerable, as previously discussed.

Any tile installation requires a sealant to the grout. Depending on the type of tile (low-fire ceramic or a softer stone such as marble), the sealant will also help to prevent staining. Again, look to the third-party evaluators to determine a sealant that has a relatively low VOC content.

There are locally made tile materials that can add an artistic touch to a project and will align your project with a local artisan community.

Sinks made of vitreous clay are popular for their high gloss and durability. Porcelain sinks can be both the drop-in and under-mount versions.

Countertops

Concrete

Artisans use concrete to create unique countertops that are very durable. Reinforcement in the form of glass fiber, rebar, or wire mesh is added to the fabrication. Labor is considerable in relationship to the raw materials, which results in a higher-end finished material.

Concrete countertops are unique, hand-crafted, and personalized. A designer has the ability to customize the color, finish, size, shape, and edge detail.

Concrete countertops are not for everyone. Staining is common, especially if used in a kitchen. Over time, minor hairline cracks may occur. These cracks usually are nonstructural, and are due to the shrinkage of the final product. Inform your client that scratches can and will occur with normal use. Acids (from vinegars, wine, mustard, citrus, and others) may etch the finished surface if they are not cleaned up immediately.

Due to the porous nature of concrete, it is recommended that a food-grade sealer or finishing wax is regularly applied to prevent staining and water absorption. See “Sealers” for more information. Concrete can withstand heat, but excessive heat can harm the integrity of the sealer, requiring a reapplication.

Some fabricators use glass-fiber-reinforced concrete (GFRC) instead of the conventional precast process. This option is considered more sustainable as it makes the final product lighter, uses less Portland cement, and incorporates more recycled materials. GFRC is stronger than conventional concrete and allows for a thinner application.

Concrete countertops can be repurposed at the end of their lives. They can be reused or cut for smaller applications. Old concrete can be crushed and used as aggregate for new concrete, saving energy through recycling.

To maintain a concrete countertop, clients should use a pH-neutral cleaner and avoid the use of abrasive cleaners and scrubbing pads. If a countertop gets stained, there may be options for removal. Contact your fabricator for removal methods they recommend.

Terrazzo-Type Products

Terrazzo by definition is a composite consisting of marble, quartz, granite, glass, and other materials in a cementitious, polymer, or epoxy base. It is typically poured in place or precast. Terrazzo flooring has been a building material for over 1,500 years and is one of the first recycled products. Terrazzo is manufactured from recycled product, has a long life, is durable (some original terrazzo floors have been in use for over 1000 years), and can be recycled at its end of life.

Terrazzo has been incorporated into slab material meant for countertop use. Examples of this application include Icestone, Vetrazzo, GEOS, and Fuez (see Figure 5.8). Icestone and Vetrazzo currently hold silver certifications with C2C. Their process for achieving this rating included discontinuing some products that did not comply with McDonough Braungart Design Chemistry’s (MBDC) strict standards for material health; they also built a state-of-the-art water recycling system for their manufacturing process.15

Figure 5.8 Recycled glass surface used for a kitchen island countertop

Courtesy of EOS Surfaces, LLC

Terrazzo is porous and should be sealed twice a year, unless your client is comfortable with some staining.

Paper Composite and Fiber Cement Countertops

Paper-fiber composite products typically use postconsumer recycled paper that has been soaked in phenolic resins. Phenolic resins are synthetic resins created through the reaction of phenol or a substituted phenol with formaldehyde. Paperstone® (see Figure 5.9) has created a proprietary PetroFreetm phenolic resin. The formaldehyde and phenol become inert when combined and cured. Other products, such as Slatescape, incorporate Portland cement and ultra-fine silica as the binder for the recycled newsprint.

Figure 5.9 Kitchen counter made of Paperstone®

Courtesy of Paperstone®

Originally created for use in industrial applications, composite countertops are water resistant and clean up easily. Most products are heat resistant to 350 degrees Fahrenheit (176 Celsius). Composite countertops will darken over time due to oxidation and sunlight exposure.

Colors for these products are earth based, ranging from browns to blues. The color goes all the way through. Maintenance includes daily cleaning with a soft cloth and warm water; nonabrasive cleaners are acceptable. Periodic sealing with mineral oil or wax is recommended. Cutting directly on these types of countertops is not recommended.

Stone

Stone has had a tough time staying popular with the focus on green materials. Treasured for its unique beauty (by nature, no piece of stone is exactly the same as another), stone presents a green dilemma. It is a natural material, quarried from the earth, and comes out of the ground ready to be shaped and installed. However, it is heavy. The transport of stone gives the material a considerable carbon footprint as does the energy required to fabricate the stone to usable “dimension-stone” sizes. Ethically, some stone quarries in some parts of the world exploit workers, making the installation of stone a conflicted decision. Do your homework and consider specifying stone that is not from across the globe but closer to your job site.

Choosing the correct stone for clients depends on uses and lifestyles. Granite is much harder than marble and is more forgiving. Some clients will appreciate the patina created over years of use on a marble countertop while others cannot live with stains. Limestone is a beautiful stone, but its use in a shower requires a much more diligent maintenance schedule.

Soapstone is expensive and available in limited colors (black and green) but needs no sealing and is virtually heatproof due to its excellent thermal qualities. It is stain resistant. Soapstone darkens as it ages. To speed up the darkening process, clients can apply food-grade mineral oil every few months.

Sealants are available to protect stone from staining, but the use of a volatile chemical sealant in a client’s home is questionable. Slabs of stone that are impregnated with sealants at a factory prior to delivery to a stone yard are available but the question should be, for what purpose? Only cosmetic? If stains and wear are of considerable concern for your clients, you may want to steer them toward a quartz composite material.

Quartz Surfaces

Engineered quartz surfacing has become a very popular choice for homeowners as a countertop material due to its durability, stain resistance, and ease of maintenance. Many quartz countertops manufacturers are GREENGUARD and NSF certified (see Chapter 2) Some, such as Eco by Cosentino (see Figure 5.10) and Caesarstone, have been awarded C2C certifications. Quartz products are manufactured from preindustrial waste and many include recycled materials. Eco by Cosentino is 75 percent recycled content and holds both C2C Silver and GREENGUARD certifications.

Figure 5.10 This ECO countertop is made with recycled materials.

Courtesy of Cosentino

Many of these companies, such as Cosentino (Eco and Silestone) and Caesarstone, have manufacturing processes that recycle as much as 94 percent of the water used.16 Cambria quartz (also GreenGuard certified) offers a quartz product whose material is primarily mined and fabricated in North America, which gives designers in the United States and Canada a domestically produced option.

Engineered stone comes is many thicknesses and can be used for countertops, wall cladding, and even flooring in some cases.

Quartz does not need to be sealed, which makes it a popular choice for designers and consumers concerned about the environment and the impact sealants can have on the IAQ of their home.

Like other heavy materials, quartz has a considerable carbon footprint due to transport. For a more sustainable option, consider specifying domestically produced products.

Solid Surfacing

Polymer-based products (such as Corian) offer a continuous surface that is great for adding a seamless installation to kitchens and baths. Solid surfacing offers an antimicrobial, impervious surface with relatively low maintenance. Drawbacks include price and the susceptibility to damage with heat.

Solid surfaces offer designers the opportunity to create virtually seamless installations as sinks can be installed seamlessly. Major repairs can be done by professionals, and the product can be reused and refabricated years later.

Polymers are a synthetic material. If you and your client are concerned about the use of man-made materials, you may want to consider stone or wood countertops. Look to third-party evaluators for a complete rating of VOC emissions, toxicity, and a rating on regenerative content.

Wood Countertops

The most environmentally sustainable counter surface, wood countertops provoke the most passionate opinions. On one hand, this surface allows you to cut food directly on the surface; on the other hand, many clients cringe at the thought of cutting on a countertop.

I have specified wood counters for my designs for over 20 years to divisive responses. For the clients who have chosen wood counters, they have found them to be easy to use and maintain. I tell my clients that they can cut anything on their counters from meat to vegetables as long as they use soap after cutting meat. Wood is naturally microbial, so bacteria does not live in the wood as long as you clean it regularly. Antibacterial soap is not a requirement in cleaning. Once every three months it is recommended to apply food-grade linseed oil on your wood counters—although I have personally had wood counters for 15 years and apply oil on them perhaps once a year. They hold up just beautifully!

—Robin Rigby Fisher, CMKBD

Choosing wood countertops that are certified as sustainably harvested by the Forest Stewardship Council (FSC) helps to protect wood as a natural resource. Specify hard, dense woods such as hard rock maple, madrone, cherry, bamboo (as end-grain butcher block), oak, or white ash (end-grain butcher block), which will best stand up to sharp knives.

Stains or burns on wood countertops can be easily repaired by lightly sanding and finishing with warm (food-grade) mineral oil. Rub it in, let it soak for 20 to 30 minutes, then wipe the excess with a clean cloth. Do not use cooking oils, which will turn rancid. For extra protection, apply 1 part beeswax or paraffin wax melted in 4 parts mineral oil, and rub it into the bare wood while the mix is still warm.

Laminates

Made from plastic-coated synthetics, originally all laminate countertops were manufactured with high-VOC papers and adhesives. Healthier versions are available today. Choose laminates that is certified by GREENGUARD, which are made from formaldehyde-free paper and low VOC or nontoxic glues.

Laminates are easy to clean and are inexpensive but are not repairable, have a short life span (15 to 20 years), and are not recyclable

If laminate is the best product for your client, specify a substrate made with non-urea-added formaldehyde (NUAF) and low-VOC, solvent-free or water-based adhesives.

Metals

Like wood, metals are used throughout a project. There are hidden sources of metal: nails, screws, reinforcement in concrete, drawer slides, and, in some projects, wall studs (just to name a few of the many locations). Metals are ubiquitous in a project. There are the exposed metals that every designer appreciates: hardware, light fixtures, tile finishes, appliances, and hoods for cooking surfaces—the list goes on. The coordination of metals is one of the first things a designer does to create a palette that is cohesive and makes sense.

The extraction of metal ore from the earth is done by mining, which causes extreme damage to the environment (see Figure 5.11). The creation of the mine requires energy and the use of fossil fuels. Leaching from mining into nearby water sources such as rivers causes pollution from the mineral ore.

Figure 5.11 Copper mining

By Peripitus (own work) [GFDL (www.gnu.org/copyleft/fdl.html) or CC-BY-SA-3.0-2.5-2.0-1.0 (http://creativecommons.org/licenses/by-sa/3.0)

To minimize the use of new raw materials, look to companies that use some amount of recycled metal content in their hardware and sinks. Many metals, such as copper and cast iron, already contain recycled content. The Kohler Company creates cast iron tubs that are made with 80 percent recycled iron (see Figure 5.12). Cast iron lasts longer than fiberglass or composite.

Figure 5.12 Tub made with recycled iron

Courtesy of Kohler Company

Stainless Steel

Stainless steel is a combination of steel, chromium, and nickel. Although the mining of these materials does impact the environment, stainless steel contains a “minimum of 67 percent recycled scrap,” according to North American Stainless, a metal manufacturer based in Kentucky.17 Stainless steel is heat and stain resistant, durable, and easy to clean, and it can be recycled at the end of its life. Brushed or textured surfaces can minimize a myriad of scratches. It can, however, dent easily and is expensive.

Copper

Copper for kitchen countertops is a beautiful option. It is a naturally antimicrobial surface. Copper is easy to maintain, but clients need to understand that if it is not waxed on a regular basis, it will darken and achieve a rich patina. Copper dents and scratches easily and requires a substrate. (Substrates are discussed at the end of the “Countertops” section.)

Sinks often are made from recycled copper. Native Trails, of San Luis Obispo, California, manufactures sinks (see Figure 5.13) from recycled copper.

Figure 5.13 A kitchen sink made of recycled copper

Courtesy of Native Trails

Recycled Aluminum

Not recommended for kitchen countertops, recycled aluminum is a sustainable choice for sinks, hardware, light fixtures, and decorative tiles. Companies such as Eleek, located in Portland, Oregon, manufacture products made from cast aluminum (see Figure 5.14) from 100 percent recycled material, with postconsumer content between 85 to 100 percent, depending on the product line.18

Figure 5.14 A recycled aluminum custom hood

Design by Robin Rigby Fisher, CMKBD, CAPS, Robin Rigby Fisher Design, Portland, OR

Donate All Metal from the Project

Salvage and donate all fixtures that are removed from the job site and put that metal back into use rather than in a landfill. Hardware and fixtures are some of the most easily retrofitted building materials. In your specifications, incorporate a line item listing all materials that will be saved for donation or recycle.

Substrates

To minimize your environmental impact, specify a counter substrate made with NUAF and low-VOC, solvent-free, or water-based adhesives.

SEALERS

The use of sealers on finished surfaces depends on a few variables: the type of material used (concrete, granite, marble, soapstone, limestone, wood, etc.), where it is installed (showers, countertops, walls, floors), the client’s commitment to reapplication, and the impact the sealer may have on the IAQ.

Why should a product be sealed? The purpose of a sealer is to protect a surface from staining and etching. Not all sealers are alike or are appropriate for all surfaces.

Types of Sealers

There are two types of sealers commonly used for stone, concrete, and tile. They are penetrating and topical:

Penetrating (or impregnators) sealers soak into the material (if the material is porous), minimizing absorption and staining. Penetrating sealers do not change the appearance of the finished surface.

In the case of concrete, a penetrating sealer is applied to bare concrete and allowed to soak in. These sealers are recommended for concrete surfaces with a polished or honed surface.

Tile with a crackle glaze should be sealed with a penetrating sealer if used in a shower in order to minimize the growth of mold and mildew.

Some types of stones, such as soapstone, only need mineral oil. Mineral oil is not a sealer; rather, it is a means to speed up the natural darkening process that the stone goes through over time.

Topical sealers include wax, acrylics, and epoxies.

Wax (carnauba and/or beeswax) is the most basic sealer and is recommended on concrete over a penetrating sealer. It leaves the surface with a low- to high-sheen finish that darkens or enhances the finish of the concrete. It is easy to apply and is very forgiving. Wax will not scratch, but anything left on the surface for a period of time will leave a mark. Hot temperatures can soften this finish, and acids like vinegar or lemon juice can remove the wax and etch the surface below.

Acrylic or solvent-based sealers are the most commonly used on concrete. They harden upon curing and provide fairly good stain protection but are easily scratched. The unprotected surface of the concrete is then susceptible to staining. These types of sealers contain high VOCs.

Although not very environmentally sustainable, epoxy sealers offer good stain resistance. Epoxy is an expensive sealer for concrete and must be applied by a professional.

Determining if Your Product Needs Sealer

Not all surfaces need to be sealed. Some, such as concrete, should be sealed regularly, but some stones, such as certain types of granite, do not need to be sealed. According to Rocky Mountain Bathrooms of Littleton, Colorado, “Less than 20 percent of polished granite actually requires being sealed. That means that upwards of 80 percent of polished granite installed in homes requires no sealer at all.”19 Sealing honed surfaces is strongly recommended.

How do you determine if the product you want to specify on a project should be sealed? There are a few tests you can do on a sample.

Using a sample, apply water on the surface for 10 to 15 minutes and then remove it. If the sample has not darkened, it will not absorb water-based products. To determine if your sample will absorb solvent-based products, apply mineral oil on your sample and wait 5 to10 minutes. If it hasn’t darkened, your sample does not need to be sealed. If the mineral oil did darken the sample, wait a while, and the oil will evaporate, leaving your sample ready to be tested again.

In short, if neither water or oil darkens your sample, your choice does not need sealer, thus saving your client time and money and maintaining the health of the home.

Some finish materials, such as marble, may pass both of these tests but will etch from the chemical reaction between what is left on the surface and the minerals in the stone. These etches are not stains, and no sealer will protect the surface from these reactions. The etching can be removed only through resurfacing.

Industry Voices on Sealers

Amy Bright is a professional resource associate with many years of experience in stone and tile sales. She advocates for questioning the use of sealants and highly recommends getting to know your client and researching your material options: “What are your clients’ wants and needs? How can a material best serve them? What is your client’s approach to maintenance?” There are ways to guide your clients to create a green home with no added chemicals to add to poor IAQ.

Sandy Hayes is a Certified Master Kitchen and Bath Designer (CMKBD). She says: “We never sealed granite in Canada, and I often tell the story of my own countertops and how I do not seal them.”

Helping clients choose the best material for their home that serves their lifestyle well and supports a healthy environment is not difficult; it does, however, require research and the support of your suppliers.

Flooring

Cork

Cork has been used as a flooring material for over 100 years. Naturally soft, cork is insulating (warm to the touch) and absorbs sound. Cork oak trees live for over 200 years; the cork is harvested every 10 to 12 years. Cork is self-healing; most dents will come out over time. Damaged areas can be removed, and the floor can be resealed. Cork is naturally water-resistant, and many types of cork flooring can be used in all rooms of the home including the bathroom.

Cork flooring comes in many options and at different price levels. Click, engineered, veneered, and glue-down options are available; different applications require different selections. Before finalizing your specifications, be sure to confirm with your supplier that the cork you chose is appropriate for your specific application. Some questions to ask:

- Is this product recommended for a bathroom installation?

- How often can this cork be refinished? (Some engineered corks are only a veneer and cannot be refinished.)

- If using a glue-down cork: What are the manufacturer’s recommendations for substrate installation? What types of adhesives are required? The substrate of a glue-down cork must be installed properly, according to the manufacturer. If the substrate is not smooth, screws are not counter-sunk filled, the seams and screw holes will be seen on the finished floor.

- Does this product need to be finished after installation?

- How does this product need to be maintained after installation?

Linoleum

Made from renewable resources such as linseed oil, pine rosin, wood flour, limestone, and cork dust and natural pigments with a jute backing, linoleum was invented in the late 1800s by Frederick Walton.

Naturally nonallergenic and antistatic, linoleum is durable, lasting 30 to 40 years in high-traffic area. “From a resource standpoint, it’s great,” says Environmental Building News editor Alex Wilson. “It’s made from natural, largely renewable, materials, and there are no environmental toxins involved in its manufacturing or disposal.”20

Because linoleum is made from linseed oil, when it’s first installed there will be a yellow cast to the flooring (called ambering). Linseed oil is a yellow liquid. As the floor gets exposed to the light, the linseed oil will evaporate, taking the yellow hue with it. This process cannot be rushed by washing the floor; only time and natural lighting will remove it. Be sure to inform clients that if they lay a rug on the floor, the yellowing will come back. Again, it will evaporate with time.

Linoleum requires specific underlayment and adhesives. Be sure to note in your specifications that “all installation must be done according to manufacturer’s specifications.”

Maintenance is easy with just sweeping and regular mopping required; waxing is not necessary. Repairs, including burns, scratches, and cuts, can easily be repaired by professionals.

Cabinetry

Making sure your clients are well informed about the environmental impact of their choice of cabinetry is an important part of your kitchen and design practice. Off-gassing from materials used to make cabinets can cause some of the worst IAQ. This is because of the presence of urea-based formaldehyde and other toxic adhesives used in much of the composite wood products that are used in cabinetry construction.

We spoke with Darrill Andries, CKD, a California-based NKBA designer and cabinetry installer who is dedicated to education regarding green cabinets. Darrill explained that the California Environmental Protection Agency (CalEPA) leads the way in emissions control. This includes toxic emissions and VOC emissions from composite wood products and cabinetry finishing. The state’s environmental protection agency is behind the Air Resources Board (ARB), which determined an Airborne Toxic Control Measure (ATCM) in 2007 to reduce formaldehyde emissions from the use of composite wood products. This ATCM has changed the face of cabinetry manufacturing and installation in the state of California.

The ATCM established by CalEPA is also the inspiration in part for the green cabinetry certification from the Kitchen Cabinetry Manufacturers Association (KCMA). The KCMA represents the interests of over 300 cabinetry makers in North America. Darrill pointed out as an example the KCMA’s Environmental Stewardship Program (ESP.) Here are just a few of the stringent standards that must be met to qualify in the voluntary ESP program:

- 100 percent of the particleboard, medium-density fiberboard (MDF), and plywood used in the cabinets must meet the formaldehyde emission level of the California Air Resources Compwood ATCM and must be third-party certified to meet low formaldehyde emission standards.

- 75 percent of cabinets must be finished in the United States or Canada. Finishes emit no greater hazardous air pollutants than allowed by local plant operating permits.

- 80 percent of the particleboard and medium-density fiberboard used in cabinets must contain 100 percent recycled or recovered fiber content

- Manufacturers utilize an annual, written training plan to educate their hardwood suppliers of their preference for purchasing certified lumber.

- Manufacturer has a comprehensive recycling program for process waste.

- Manufacturer is required to have a written policy stating a firm commitment to environmental quality.21

Best Practices for Specifying Sustainably Constructed Cabinets

Two of the largest expenses of a kitchen remodel are the cabinets and appliances. Many times clients who start the design process with sustainability as their end goal wind up deviating from their original path due to budgetary restrictions. More often than not, cabinet quality ends up on the budget chopping-block. As a designer, it is your responsibility to assist your clients in understanding the value of investing in higher-quality and more sustainable cabinet options, and to explain how these choices will benefit them for many years into the future.

- Drawer boxes. Quality cabinetry is constructed of solid wood drawer boxes rather than particle board. Ask about FSC-certified wood. Also, easily renewable and strong options such as poplar and alder are good choices for drawer boxes.

- Hardware. Look for domestically manufactured hardware. Hardware is a great example of an LCA application. Poorly made hardware is more likely to bend and break, thus creating the need for replacement. Drawer runners and closures aren’t seen but their quality is felt each time the drawer is used.

- Doors and drawer fronts. Look for wood and veneers that are FSC certified. If you are working with painted surfaces, speak to the fabricator about the use of low- and no-VOC paint.

- Finishing. If you are working with a cabinet maker, make sure to specify paints, stains, and all finishes with low to no VOC emissions. There are advantages and disadvantages to the use of low-VOC finishes. Conventional finishes in general cure to a harder surface and protect the cabinetry better. Do your homework and learn about what types of finishes your cabinet supplier or fabricator is using.

- Source locally. The use of wood that is locally produced will mean less fossil fuel is used in the transport of the wood. This adds to local economy and gives your project a strong sense of local character (see Figure 5.15).

Figure 5.15 Locally sourced cabinets built by L & Z Specialties, Portland, Oregon. NUAF plywood case construction.

Courtesy of L & Z Specialties. Photo by Dale Lang

If you are going to install cabinets on a smaller budget, most likely the drawer boxes and the bodies of the cabinets will be made of MDF. Ask your manufacturer or local fabricator about its use of products that are aligned with California’s ATCM standards.

Appliances

There is a certain point in the design process when everything comes to a halt and there is only so far you can proceed until appliances are chosen. Assisting clients in assessing which appliances best fit their needs is partly the designer’s responsibility and mostly the appliance specialist’s responsibility. We recommend creating a strong relationship with an appliance specialist; this person will be instrumental in aiding in the success of the project and the ultimate happiness of the client.

On using the services of a professional resource associate, author Robin Rigby-Fisher writes:

I have been working with Michael for over 12 years. During my initial meetings with my clients, I determine their cooking needs, aesthetic style and budget. I then send this information along with preliminary designs to Michael and schedule a meeting for my clients with him to discuss their appliance needs. Because of my relationship with Michael, he knows my design style, what products I recommend and trusts my suggestions. The client does not need me to be a part of this process. I trust Michael to serve my client well and they love him!

The technology in appliances changes so rapidly it would take full-time work just to keep up. Designers need to know enough about appliances to help direct clients in the right direction. While a designer needs a general knowledge of appliances, a strong relationship with an appliance specialist only adds to your professionalism. A designer should do the homework, researching appliances endorsed by ENERGY STAR, the EPA’s WaterSense program, Consumer Reports, and Good Guide (www.goodguide.com) to evaluate the green characteristics of various appliance choices.

Source domestically made appliances. Sourcing appliances that are made domestically means your client will have access to a warranty that is much easier to work with. The carbon footprint of the transport of the appliance is much less than if it was created overseas or in another country. You are also helping the domestic economy.

Cooking Appliances

The cooktop is the workhorse of kitchen. For years, gas has been the cooking fuel of choice in high-end kitchens. But recently, induction cooktops have gained the interest of the industry and of consumers. Induction cooking has been around for many years. It holds a large market share in Europe but accounts for only 5 percent of the market in the United States.

Induction cooking works through the use of magnets. A magnetic field is created between the cooking element and the pan. The cooking appliance does not get hot, which results in less energy being used and wasted. Pots and pans that contain ferrous material are required for induction cooking. This type of electric cooking performs at the level of gas (instant on and off.)

Induction has three advantages over gas (see Figure 5.16):

- Safety: The unit itself does not get hot, which eliminates residual heat. Once the pan has been removed from the cooking surface, there is less heat to affect the ambient air. This type of cooking appliance is well suited for a home with small children or a family member with developmental disabilities or dementia. Even after bringing a pot of water to a full boil, within 1 to 2 minutes it is safe to touch the cooking surface. Many of these units incorporate a lock-out option to further enhance the safety feature.

- Energy efficiency: Induction cooktops require a 220-volt electrical source. The unit transfers energy directly to the food more efficiently than any other cooking surface, and the residual heat is minimal resulting in energy savings of approximately 20 percent over coil electric and almost twice the savings over gas.

- Indoor air quality: Induction cooktops do not release any impurities into the air the way natural-gas-fueled cooktops do. Their use will not require additional venting, as commercial-grade gas-fueled cooktops require. Therefore, induction cooktops are highly recommended for any client who has an environmental sensitivity or diminished immune system.

Figure 5.16 An induction cooktop

Courtesy of Wolf

Gas will be the most popular choice for your clients. Although natural gas is an affordable fuel, its use deteriorates the quality of the air in the home. See Chapter 4 for specifics on IAQ and the use of gas cooking surfaces.

Electric cooktops are affordable. New products work very efficiently. Similar to induction cooking surfaces, they do not release impurities into the air as gas-fueled cooking surfaces do.

Dishwashers

In regard to efficiency, many ENERGY STAR–rated dishwashers use 41 percent less energy than those that meet the government’s minimum efficiency standards.22

In regard to water conservation, ENERGY STAR–rated versions use about a third less water (approximately 4 gallons per load rather than the standard 6 gallons used in a conventional dishwasher).

Additional Appliances

Determining the additional appliances in the kitchen is based on your client’s needs, wants, desires, and budget. For energy efficiency, consider the ENERGY STAR label if available or look to the Good Guide for information on energy efficiency. The smaller the ENERGY STAR label number is, the less energy the appliance will use.

Warming Drawers

At first glance, a warming drawer seems more of a frivolity than a sustainable choice. This could not be further from the truth. Consider the costs of eating out or worst of all, the garbage involved with take-out. Warming drawers allow a busy family to cook a healthy meal early in the day, and keep it at a safe temperature (160 degrees Fahrenheit, 71 Celsius) and in a moisture-controlled environment until they are ready to eat.

The ENERGY STAR program rates and recommends warming drawers, those wonderful add-ons to a custom kitchen that make serving dinner so much easier. Look to the Good Guide for a sense of how energy efficient some choices are. Opt for domestically manufactured drawers.

Wine Storage

Currently, wine coolers are not listed under the ENERGY STAR program. According to Consumer Reports, some of the models that were tested used as much energy as an 18-cubic-foot refrigerator and some models required twice the energy as similar models in the same category. Do your homework and check about the energy use. Wine coolers are on constantly, which makes energy conservation important. The Good Guide rates wine coolers for energy use on their website.

FIXTURES AND FITTINGS

After the refrigerator, the sink and faucet are the most used items in the kitchen. Since many of these items have a high embodied energy content, the designer may have to consider other options and sustainability factors such as recycled content, water flow, and where the product is manufactured. Luckily, we have many manufacturers who produce their products in North America and even incorporate recycled or pre-industrial waste in the fabrication process.

Sinks

Kitchen sinks are specified by how they look first and then how they perform. How noisy are they? Do dishes break more easily in some models rather than in others? How do they react to heat and very hot pans just off the cooktop? Which version is the most sustainable choice?

Do your research and look for models to choose from that are created domestically. Many sinks, particularly stainless steel versions, are created overseas, adding to the sinks’ carbon footprint. Planning for longevity is very important as well. If a sink is susceptible to scorching and burning, its likelihood of needing to be replaced is higher than another choice may be. Consider the embodied energy conversation in the beginning of the chapter on metal versus ceramic. This may help tip the scale as you help your client make choices.

Consider a repurposed sink from the local Habitat for Humanity ReStore or a local building salvage shop (see Figure 5.17). You may find something totally unique and interesting. Check carefully. Repurposed sinks often have no warranty, and it is the responsibility of the client and/or designer to coordinate the installation.

Figure 5.17 With careful and diligent searching, a sink may be sourced from building salvage stores, such as the Habitat for Humanity ReStore.

Photo courtesy of ReStore. Photo by Harvey Thomas