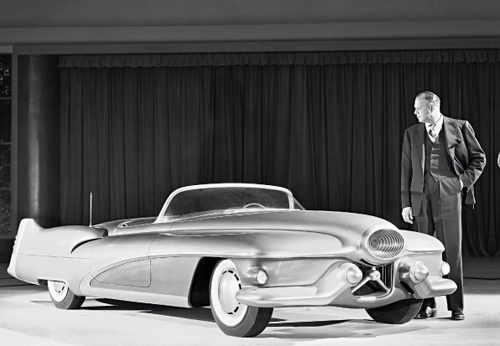

This General Motors styling exercise is emblematic of the extraordinary efflorescence of ornament and jet-plane imagery in the auto industry of the post-World War II United States. It also might be said to be a typical creation of GM’s design chief, Harley Earl (1893–1969), famous for his crushingly intimidating personality and lots of pale suits, often changed twice a day. Then, of course, there is the relationship between Earl’s design imagination and the development of the business model of planned obsolescence – a symbiosis that led the US car industry, by the 1960s, to what the US activist Ralph Nader has called ‘a glittering pinnacle of triviality’.

However, the real importance of the LeSabre lies elsewhere. Like Earl’s Buick ‘Y’ job of 1937, it was one of the first ‘concept cars’ – a new idea in the car world. Concept cars were built both to intrigue and to lead public taste by signalling what was coming soon. More importantly, these cars made real experiments with sculptural forms and motifs and enabled designers and manufacturers to see how these might gel.

At GM, Earl established technical procedures that have become fundamental to the practice of car design around the world. Most important is the use of modelling clay, a technique that frankly admits that car design is a sculptural art. GM also introduced the use of the styling bridge, a rigid measuring tool in the form of an arch that was passed over the full-sized model from front to back, allowing precise measurements of the form to be taken as ‘slices’ at numerous ‘stations’. This data in effect constitutes a mathematical 3D model of the car and is vital for the production of the purpose-made press tools that will translate the model into series-produced steel bodies. This mathematical procedure, moreover, was an essential step in the development of the computer-modelling techniques used today.

Harley Earl and the LeSabre. The sculptural complexity of the car (whatever you think of it) shows GM’s incredible control of the processes of clay modelling and then transforming shapes into sheet steel – technical procedures established at GM that spread throughout the industry.