If you are interested in eco-friendly brewing, you’ve probably noticed that most beer recipes call for ingredients that aren’t organic or locally available. This can be very frustrating, but it does not have to be. These days there is a wide enough range of organic ingredients available that you should be able to craft almost any style of beer imaginable. If you are willing to work with the palette of ingredients available without lamenting the lack of this or that, the array of beers you can make is simply dazzling. Where there is a will, there is a way!

Instead of thinking about substituting malts or hops as compromising, think of it as adapting. It can lead to outstanding beers that are packed with local character and flavor — even if they are slightly different from the standard profile. Over the years my organic beers have won many awards, even though I was competing against entries brewed with the full range of conventionally grown malts and hops.

The charts in this chapter will help you tweak conventional recipes into organic recipes, and to use your homegrown ingredients in place of what a recipe calls for. Substituting organic ingredients for conventional ingredients is just a matter of understanding the characteristics of those ingredients. You can develop that understanding by reading about them, tasting and smelling them, and by studying these charts. In most cases you can simply substitute organic ingredients for nonorganic ones, pound for pound or ounce for ounce.

To develop your own recipes, you have to train your senses to aid in the quest of crafting great, individual beers that are exclusively organic. This takes a little more finesse and skill than simply substituting ingredients while following the basic blueprint of a recipe. And it takes time and hands-on experience to fine-tune your brewing taste buds. Each time you brew with a new ingredient, you should smell and taste it and observe how those flavors and smells work when combined with the rest of the ingredients and fermented into beer.

Brewing is as much art as it is science. Most homebrewers enjoy both aspects and tend to hang out in the safer middle ground where art and science converge. This is not only safe, it is practical, sensible, and usually cost-effective, because either extreme poses risks that can lead to an expensive waste of ingredients. Some brewers tend to veer toward one or the other. I love the science of brewing, but I often drift to the arty side of the equation. Instead of precise measuring, I am prone to adding a dash of this or a dash of that. Usually it works out, but I have brewed many not-so-great beers, too. Even after 20 years, every batch I make is a learning journey that helps me refine my brewing senses.

Most great beers are born by successfully adhering to the highest standards in three areas: use good ingredients, practice excellence in brewing techniques, and follow a great recipe. If you’re reading this chapter, you should already have a good grasp of the first two criteria. If you are committed to using organic ingredients to create your beers while following your favorite great recipes, read on.

When converting a conventional recipe to organic, the easiest thing to convert is malt extract, because you don’t have a lot of choices. As a general rule of thumb, you can substitute pound for pound the total amount of liquid or dry malt extract that the recipe calls for with organic liquid or dry malt extract. Typically, dry malt extract is lighter in color than liquid, so for recipes that call for the lightest-color extract, choose dry.

Dry malt extract is more highly concentrated, and liquid malt extract is about 20 percent water weight. When using dry malt extract in place of liquid malt extract, use 20 percent less, and when using liquid malt extract in place of dry, use 20 percent more. So if a recipe calls for 5 pounds of dry malt extract, you need 20 percent more liquid malt extract, or 6 pounds.

The only organic malt extract currently available in the United States as of this writing is pale malt extract, which can replace light, golden, or pilsner extract (see Resources). To replace light or pilsner, use light or pale dry malt extract if you can, and if possible choose a recipe that calls for a mini mash or partial mash with at least 3 pounds of whole barley malt. This will help you achieve the lighter color of these beers. The grains add little color themselves and dilute the color contributed by the extract.

Most modern homebrew recipes do not call for dark extract, and few call for amber extract, because darker extract can be a bit of a mystery. What dark grains were used in the manufacture of the dark extract, and how much? The exact contents do not need to be included on the label when extract is packaged for the homebrewing market, so it is entirely possible that a caramel color was added instead of actual malt. You will brew better-tasting beer by using fresh specialty grains to add color and flavor to your amber to dark beers.

Amber extract substitutions. Use pale malt extract plus 1⁄2 pound of caramel 60°L malt. Use 1⁄4 pound less extract than the recipe calls for.

Dark extract substitutions. Use pale malt extract plus 1⁄2 pound of chocolate malt and 1⁄4 pound caramel 120°L malt. Use 1⁄3 pound less extract than the recipe calls for.

A decent variety of organically grown malts is available to homebrewers. There are a few gaps in the selection, and the more exact your recipe and standards are, the more difficult it will be to find the right substitution. In general, it is easier to substitute malts in darker beers and beers with strong hop or spice flavors than it is in very light beers that derive a lot of their flavor from the malts used.

It may be more of a challenge to create a pilsner that tastes exactly like Pilsner Urquell, for instance, although crafting a great-tasting, excellent-quality pilsner-style beer with organic pilsner malt is very doable. To a particularly sensitive palate, the difference might be noticeable, but most beer drinkers are not that picky, and most well-trained beer judges will not lower scores unless the beer falls outside the style range.

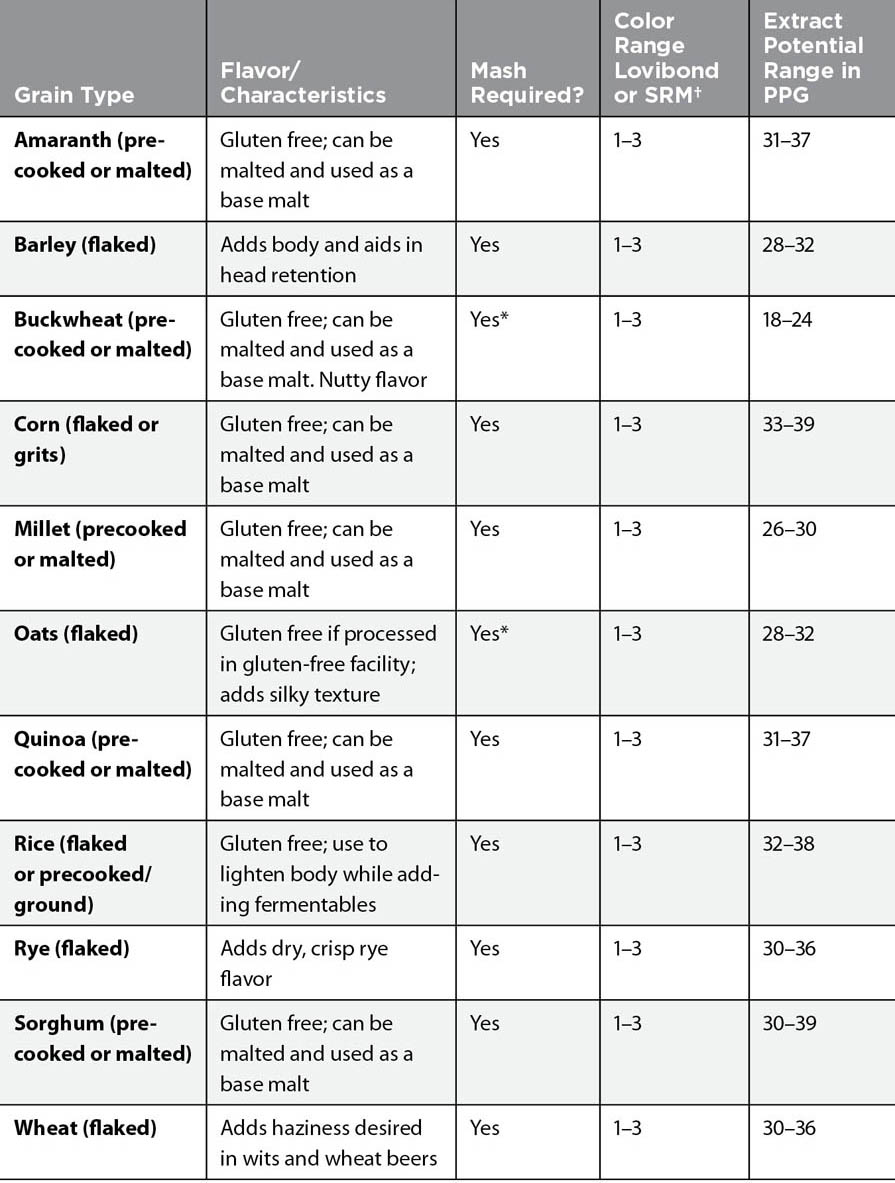

The following charts will help you choose malts, adjunct grains, and fermentable sugars for an established recipe, make substitutions as needed, or build a recipe from scratch. The extract potential data is used to estimate the specific gravity of a new recipe (see Developing Recipes from Scratch). If you are simply substituting a malt in a recipe, you do not really need this information; it is included here for reference when building a new recipe from scratch.

†SRM stands for Standard Reference Method, which is one of the systems brewers use to measure the color of beer. Although there are slight differences between this and the Lovibond (°L) scale, the scales are close enough to use the numbers interchangeably for homebrewing purposes.

*Although mashing is required to extract fermentable sugars from these grains, small amounts may be steeped to add flavor.

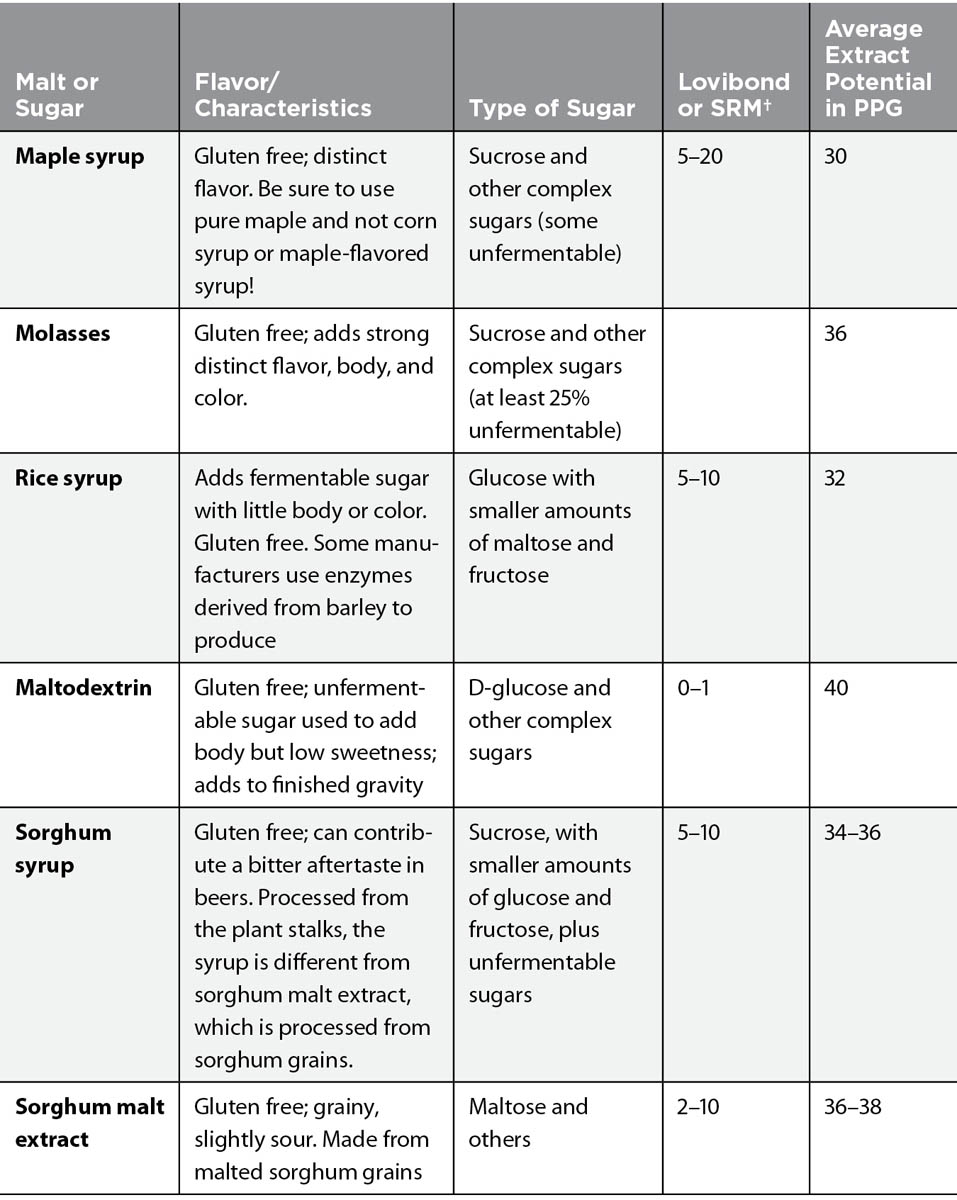

†SRM stands for Standard Reference Method, which is one of the systems brewers use to measure the color of beer. Although there are slight differences between this and the Lovibond (°L) scale, the scales are close enough to use the numbers interchangeably for homebrewing purposes.

*Although mashing is required to extract fermentable sugars from these grains, small amounts may be steeped to add flavor.

Using extracts and sugars in brewing is very straightforward, and substitutions of different extracts can be made as long as the total points per pound per gallon (PPG) for the batch remains constant and the item substituted is reasonably close in character and type of sugar. It does not benefit the finished flavor of most beers to replace all or part of the malt extract with table sugar, but it would result in the same starting gravity and alcohol content as long as the total PPG remained constant. (See Using Candi Sugar for information on making your own candi, or invert, sugar.)

†SRM stands for Standard Reference Method, which is one of the systems brewers use to measure the color of beer. Although there are slight differences between this and the Lovibond (°L) scale, the scales are close enough to use the numbers interchangeably for homebrewing purposes.

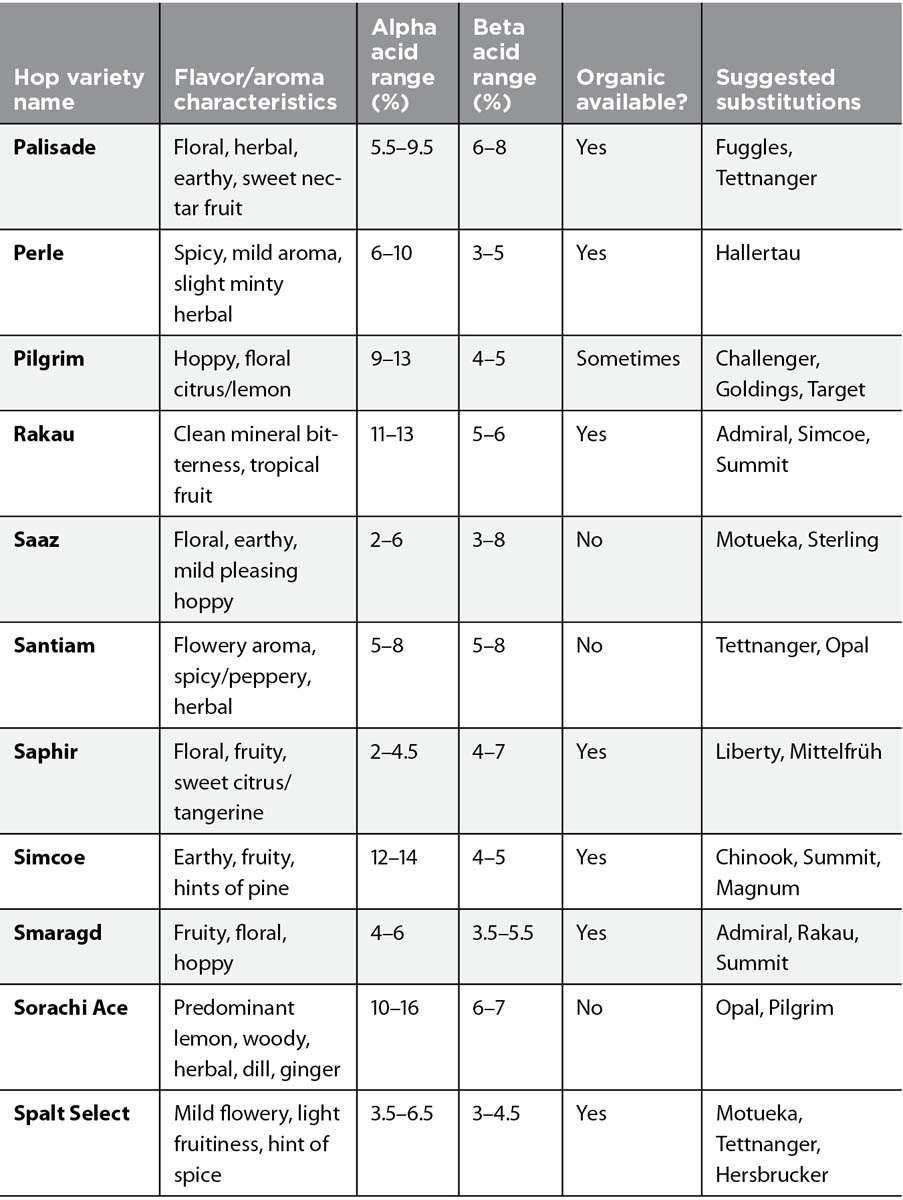

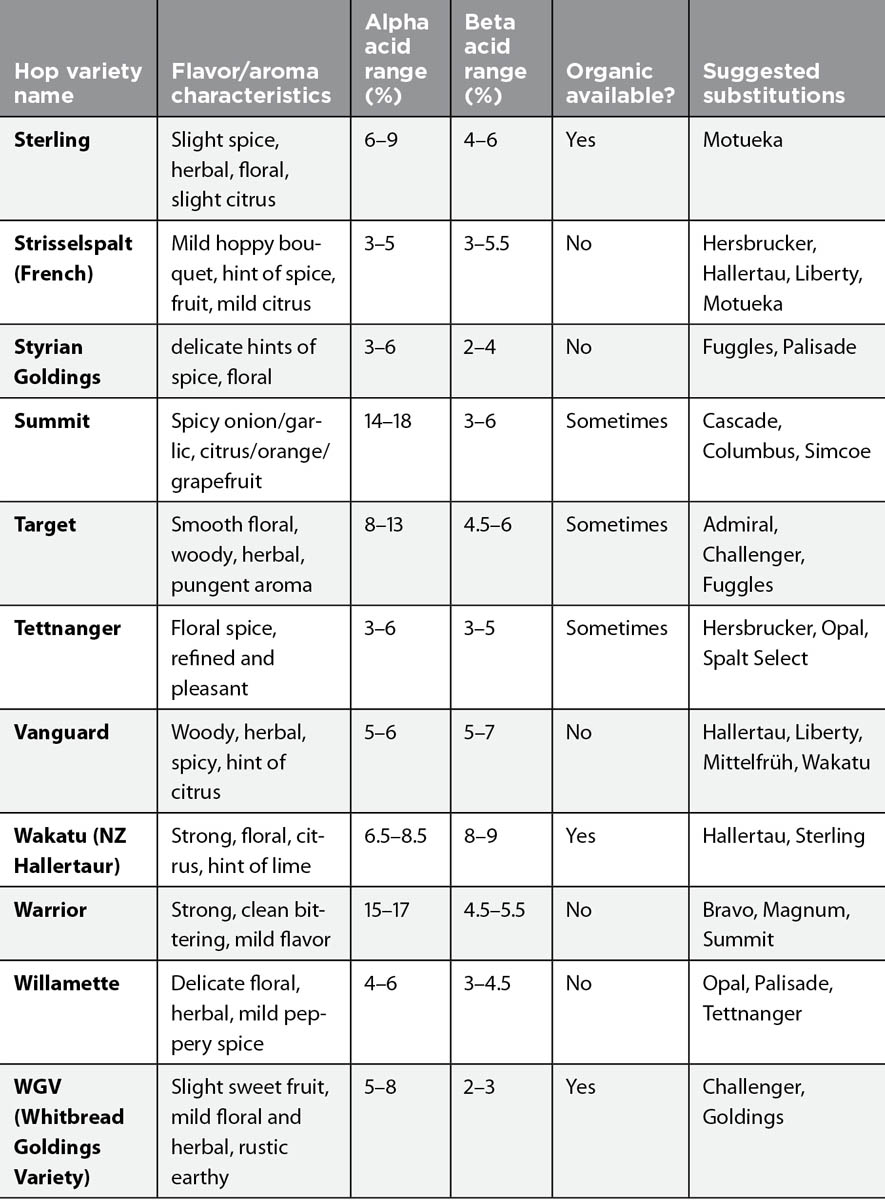

Until recently, obtaining organic hops was the biggest challenge for brewers because certain varieties were simply not available. This is rapidly changing as American hop growers have gotten into the business of growing organic hops. Not all of this bounty trickles down to the homebrewer’s marketplace, however, and some of these are not available in other countries, so homebrewers still have a limited selection.

One way around this is to grow some of your own hops, and another is to mail-order hops even if it means shipping them a great distance. The average weight of hops in a typical batch of homebrew is about two ounces, or about 0.5 percent of the weight of the finished beer. That represents a relatively small carbon cost, especially if you buy a year’s supply in one shipment that can be stored in your freezer.

With hops, whether you are substituting varieties or not, you must be careful to adjust for the alpha acid level, which varies from crop to crop. Often organic hops have higher alpha acid levels, so it is important to check this. The reason organic hops have higher alpha acid levels than conventionally grown ones is not entirely clear, but some speculate that the natural fertilizers and absence of inhibiting chemicals have something to do with it.

This chart (below) lists most of the conventionally grown hop varieties available as of this writing and offers suggestions for substituting organic hops. It also includes the typical alpha and beta acid ranges to help you choose appropriate hops when formulating your own recipes. The alpha acid should always be made available to you when buying hops from a dealer — usually it is printed right on the package. If it isn’t, inquire before purchasing. Beta acid is not always as easy to determine, but each hop variety has a typical range that stays consistent from season to season. Beta levels are not as critical to a beer style as the alpha levels.

To develop a new beer recipe, you need to figure out the starting gravity (original gravity), hop bitterness (measured in IBU), and color (measured in degrees Lovibond) to make sure the beer comes out the way you want. In addition to the measurable statistics of a new recipe, the aromas and flavors from the hops, malts, and other ingredients need to be taken into account. Aroma and flavor cannot truly be measured, but as you gain experience working with various ingredients, you will learn to apply your senses to the development of your homebrew recipes.

The first thing to figure out in a new recipe is how strong the beer will be by calculating the starting specific gravity. To do this you need to know how much sugar or specific gravity points will be contributed by each ingredient. For ingredients such as malt extract, sugar, or honey, this is a reasonably straightforward calculation, because you are simply dissolving the sugar in water and looking up that ingredient’s yield in points per pound per gallon (PPG). Each gravity point equals 0.001 specific gravity. The charts in the preceding section list common brewing ingredients and the typical PPG for each ingredient.

To arrive at a starting gravity for a recipe, first multiply the weight of each ingredient by the PPG, and add the totals together. This gives you the total gravity if you dissolved all that extract in 1 gallon of water, which would be an insanely concentrated brew! To deduce the starting gravity of your recipe, divide the total PPG by the number of gallons of finished beer, multiply by 0.001, then add 1. Since most hydrometers are only accurate to 0.001, it doesn’t hurt to round off the finished result.

For example, here are the ingredients in a simple recipe for a 5-gallon batch of pale ale brewed with extract:

7 pounds liquid malt extract × 36PPG = 252

1 pound corn sugar × 46PPG = 46

298 total PPG ÷ 5 gallons = 59.6 × .001 + 1 = 1.060 SG

The PPG listed in the Extract and Fermentable Sugars and the Malt and Fermentable Adjuncts charts on pages 311 to 316 is the simplified typical PPG, rather than the more detailed maximum PPG listed in some brewing references. For small-scale brewing volumes of under 20 gallons the typical PPG is accurate enough, and saves you from having to work out the projected gravity point yields from the %Extract figures provided on a typical malt analysis sheet. You can do the longer math by hand for each recipe, if you wish, but many of us would rather use a simple reference guide and get on with the brewing!

That being said, it is good to know how to do the math and understand how the PPG numbers are arrived at. If you have a malt that is not on this chart and you cannot find the PPG, or if you malt your own grain and want to know how much you will need to brew a beer with a predetermined starting gravity, you need to determine the %Extract.

The %Extract is the maximum percentage of the total weight of the malt that can yield sugars (both fermentable and nonfermentable) that will be converted in the mash, then dissolved into the liquid and extracted by the lauter. The portion that can be dissolved in solution is referred to as soluble extract. Most malts have husk material and proteins that never dissolve and are left behind when the soluble extract is flushed from the grains.

For most base malts such as pale malt, the %Extract is determined in a laboratory, where a carefully measured amount of malt is ground into a powder, mashed precisely, and strained completely. The remaining ground-up material is thoroughly dried to zero percent moisture, then weighed. The weight difference is listed as the %Extract (see The Congress Mash.)

If the %Extract of a malt is known but the PPG is not, calculating the PPG is a snap. Simply multiply the %Extract by the PPG of table sugar, 46, which is the standard of measure. For a grain with a %Extract of 80, the PPG is calculated just so:

PPG: 80% × 46 = 36.8

With barley malt you have to consider the starch conversion rate. Most homebrewing environments do not have laboratory precision — nor do they need it to brew great beer. Although determining the %Extract is possible in a lab with a finely ground sample, brewing with finely ground malt is completely impractical on a homebrewing scale. The extract efficiency takes into account the difference between the maximum possible yield and the everyday yield you get with your all-grain brewing system at home. For most homebrewers this efficiency rating is between 70 and 80 percent of the maximum yield.

The extract efficiency must be factored into the equation to secure a good estimate of the actual yield. When using PPG to calculate the estimated gravity for whole grains and malts that are steeped or mashed, you have to multiply the PPG by the extract efficiency to arrive at a realistic estimate of starting gravity.

For example, here is how to calculate the estimated starting gravity for an all-grain version of the pale ale recipe I used as an example above. I’ll assume an average extract efficiency of 75 percent:

9.25 pounds pale ale malt × 36 PPG = 333 × 75% extract efficiency = 249.75

1 pound corn sugar × 46PPG = 46

295.75 total PPG ÷ 5 gallons = 59.15 × .001 + 1 = 1.059 SG

Note that the extract efficiency is not applied to the corn sugar because the corn sugar does not need to be mashed or extracted — it dissolves 100 percent in solutions, as do all the sugars listed in the Extract and Fermentable Sugars chart.

In chapter 3 I covered using hops by making sure the AAUs are the same each time you make a certain recipe, even if the alpha acid levels are different from the hops used in the original recipe. This is an easy and perfectly suitable method for achieving consistency from batch to batch when brewing from an existing recipe. To build your own recipe from scratch, you need a slightly more sophisticated method to ensure the beer will have the balance of hop bitterness to malt body and sweetness that you are striving for. International bitterness units (IBUs) are the standard for measuring hop bitterness.

When hops are boiled in wort, the bittering acids are extracted slowly. The extraction of bitterness is affected by the density, or specific gravity, of the wort; the length of time the hops are boiled; and the form of hop used: whole or pellet. The hop resins that contribute bitterness are not water soluble, and it takes the heat and motion of a boil to change the alpha acid compounds enough to dissolve in water. Even with optimal conditions, it is rare to achieve an extraction of more than 30 percent. This rate of extraction is known as the hop utilization rate, and this value is required to calculate the IBUs for a given recipe.

Hop pellets, because they are made from hops ground into small pieces, have a larger surface area that contacts the wort; thus bitterness is extracted at a higher rate than with whole hops. The density of wort influences utilization rates, because a higher-gravity wort contains more sugar molecules, which reduces the solubility of the alpha acids, while a lower-gravity wort allows a higher percentage of alpha acids to dissolve.

Other variables, such as the total volume of the boil and the gradual increase in specific gravity as water evaporates during the boil, also have an effect on hop utilization, but these factors are more difficult to measure and thus are not usually calculated for small-scale brewing. The variables that affect hop utilization are many, and not all of them are easily measured or even understood. Greater minds than mine have studied this very carefully, and results from these studies provide brewers with data we can use to determine the hop utilization value for our recipes.

Before you calculate IBUs, it is a good idea to evaluate the malt-to-hop balance of your recipe to make sure it fits the style of beer you are brewing. The great beers of the world are usually balanced, although there are some extreme styles out there! In the beginning it is a good idea to keep within generally accepted guidelines until you develop a more refined instinct for what levels suit your own tastes the best. Beers with a lower specific gravity are lighter in flavor and malt sweetness, and the hop bitterness comes through strong even at lower IBU levels.

Most low-gravity beers have a correspondingly low IBU — otherwise, they would taste unpleasantly bitter. Higher-gravity beers have more malt body and residual sweetness; thus, a higher IBU level is needed to balance out the sweetness. I use the following guidelines for balancing hop bitterness in my recipes, unless I am aiming to target a specific style, in which case I use the IBU range specified for that style.

The Beer Judge Certification Program (BJCP) beer-style guidelines offer a good resource for targeting the IBU level of certain beer styles. If you are brewing one of these styles, or a beer that is similar, matching the starting gravity and IBU levels of the style is highly recommended. The complete beer-style guidelines can be found at the BJCP website. Apps are available for most devices as well.

Using the Hop Utilization Table, along with the alpha acid numbers for the hops, the starting gravity of your beer, and the desired bitterness level, you can now calculate the IBUs for your recipe. To be accurate, one IBU is 1 milligram of iso-alpha acid per liter of beer. English units are used universally, so the basic equation includes a conversion factor of 1.34 to allow us to do the math with ounces and gallons and still arrive at the correct IBU figure. For this formula to work properly, the percentages for alpha acid and hop utilization are expressed as whole numbers rather than decimals. Thus an alpha acid of 10 percent is recorded as the number 10, and a utilization value of 25 percent is recorded as the number 25.

IBU = weight of hops (ounces) × alpha acid% × %Utilization (from chart) ÷ total gallons of finished beer × 1.34

This example is for a 5-gallon brew with 1 ounce of pellet hops with an alpha acid of 10 percent boiled for 60 minutes in a wort with a specific gravity of 1.060. From the Hop Utilization Table the utilization rate for a 60-minute boil in a 1.060 SG wort is 0.211. The math looks like this:

(1 oz × 10 × .211) ÷ (5 × 1.34) = 31.5 IBUs

Often it is more desirable to work the formula backwards, because we already know our target IBU but need to determine the weight of hops needed to reach the target IBU. The pale ale recipe we have been using as an example is a beer with a midrange starting gravity of 1.060, so we are looking for an IBU of about 30 for a balanced beer. This recipe calls for Summit hops (14% AA) for bittering and Cascade hops (7% AA) for flavor. Most of the IBUs will be coming from the Summit hops because they have a higher alpha acid content and they will be boiled for 60 minutes. We also have to allow for some bitterness to come from the Cascade hops, since they will be boiled for 20 minutes.

For starters I’ll aim for 24 IBU from the bittering hops. The utilization for a 1.60 wort and a 60-minute boil is 21.1, as before. The remaining 6 IBUs will come from the flavor hops. The utilization for a 1.60 wort and a 20-minute boil is 10.7. First, the formula:

ounces of hops = IBUs × total gallons of finished beer ÷ alpha acid% × %Utilization

Then, plug in the numbers:

Summit hops: 24 × 5 ÷ 14 × 21.1 = 0.41 ounce

Cascade hops: 6 × 5 ÷ 7 × 10.7 = 0.4 ounce

Depending on the accuracy of your scale, you may need to round the numbers down further or convert to grams. Convert to grams by multiplying ounces by 28.3. Doing this, I have figured the hop schedule for this beer as follows:

0.4 oz (11 grams) Summit hops (14% AA) – 24 IBU

0.4 oz (11 grams) Cascade hops (7% AA) – 6 IBU

The pale ale recipe also uses a late hop addition for the last 1 minute of boiling time to give it the hoppy nose so characteristic of the style. As you can see from the Hop Utilization Table, the utilization rate is so low for boil times of under 5 minutes that it does not contribute a noticeable amount of bitterness; thus, it is perfectly acceptable to leave this hop out of the calculations. The recipe also calls for a dry hop addition added to the secondary fermenter. Because dry hops are not boiled at all, they are not factored into the IBU equations.

When I look at the above recipe with an experienced eye, I immediately notice a flaw. The math is correct, and the bitterness level will be accurate, but what is missing is additional flavor, which can only come from flavor hop additions. Flavor is not a quality that is easily measured. There are many essential oils and volatile compounds that are not fully understood, yet they add a desirable finish to a beer that lets it stand apart from scientifically correct beers. This is where art and instinct come in.

My instincts tell me that my American-style pale ale will not have the hoppy flavor I am looking for if I use just 0.4 ounce of Cascade hops for the flavor addition. For the sake of great beer, it is worth reworking my calculations to account for that citrus hop character I am looking for. Based on past experience, I want to use at least 1 ounce of hops. Therefore, I will calculate the IBUs that are contributed by boiling 1 ounce of Cascade in my 1.060 wort for 20 minutes:

1 oz × 7 × 10.7 ÷ 5 × 1.34 = 11.2 IBUs

After this adjustment I will need an additional 18.8 IBUs to achieve the target of 30 IBUs:

Summit hops: 18.8 × 5 ÷ 14 × 21.1 = 0.32 ounce or 9 grams

Thus with some simple math plus an instinct for beer flavor and style, art and science can work in concert to design a wonderful beer!

If the boiling gravity of the wort is significantly different from the final gravity of the finished beer, it is important to take this into account when calculating the IBUs. For example, if you can only boil 3 gallons of a beer with a final gravity of 1.060, the actual specific gravity during the boil will be much higher than the finishing gravity, and this will affect the hop utilization. If accuracy is important, you must adjust the hopping rates to account for the difference in wort gravity. A partial boil is only truly possible with an extract or partial mash brew. To determine your boiling gravity, just quickly redo the starting gravity calculations for Pale Rider Ale that we started with at the beginning of the chapter:

7 pounds liquid malt extract × 36PPG = 252

1 pound corn sugar × 46PPG = 46

298 total PPG ÷ 3 gallons = 99.3 × 0.001 + 1 = 1.099 SG

With a higher gravity we have a different utilization rate of 14.7. With this, the formula for bittering hops can be redone:

Summit hops: 18.8 × 5 ÷ 14 × 14.7 = 0.46 ounce or 13 grams

Because the change in utilization rate is much lower with the shorter boil time for the flavor hops, recalculating the IBUs for the later hop additions is rarely necessary.

The jury is still out on this, but many trusted sources suggest that whole hops have a lower utilization rate than pellet hops. In whole hops the lupulin glands that contain the bittering acids are intact, and the time it takes for them to burst when added to the boil results in a slightly lower utilization rate. The lupulin glands are broken during the pelletizing process; thus, the acids are more immediately available for isomerization in the boil.

All of the formulas for IBU calculation in this book assume the use of pellet hops. To adjust for the difference between whole hops, calculate the IBUs and hop weights as described above, then add 10 percent to the weight to adjust for the lower utilization levels of whole hops.

So for our pale ale recipe, our new hop schedule will be this:

0.4 oz (11 grams) Summit hops × 1.1 = 0.44 oz (12 grams)

0.4 oz (11 grams) Cascade hops × 1.1 = 0.44 oz (12 grams)

Chart courtesy of Glenn Tinseth (www.realbeer.com/hops)

To be honest, most homebrewers today use some sort of recipe development software, instead of doing the math by hand. Recipe development software can really speed up the process of calculating the vital statistics of a new recipe. However, even if you use software on a regular basis, it helps to understand how the calculations work.

If you know how to determine malt yields and calculate hop bitterness, and you have a good grasp of the typical profiles of common ingredients, you will be able to spot an error if it occurs when using software. Inputting an incorrect number or being off by a decimal point can really mess up a brew, until you have brewed enough to realize that a 30-pound malt bill for a 5-gallon batch is not going to give you a starting gravity of 1.040.

There is a myriad of homebrew recipe development applications available to homebrewers. Most programs will calculate the estimated specific gravity, bitterness (usually in IBUs), color range, and alcohol percentage. A good application can also save recipes and allow you to print out a copy to use on brew day. Most can help you compare your recipe to the style guidelines and can help you track the progress through fermentation, bottling, and evaluation.

Some of the more sophisticated programs can even manage your inventory of brewing ingredients and provide you with a shopping list of ingredients you need to purchase to complete your recipe. See Resources for some applications I feel comfortable recommending.

Many recipes, especially Belgian-style recipes, call for candi sugar or invert sugar, which increases alcohol without adding too much body. Some of the darker candi sugars also contribute subtle caramel flavors plus a hint of color. Most true Belgian breweries use invert sugar, which is sometimes called candi sugar syrup.

The crystallized rock candy that is sold in homebrew stores as candi sugar is not the same as invert syrup and will basically contribute the same flavors to beer as plain old table sugar. You could simply use the same weight of organic cane sugar in recipes that call for the rock candy type. Boiling it for a full hour with the rest of the ingredients results in the best flavor, as the heat and acidity of the wort will cause the sugar to invert, at least to some degree. If you want to brew a more authentic Belgian-style beer, you need to make some candi syrup, which is fairly simple and quite a bit like canning.

Sugar in its granulated form is sucrose, a complex sugar that is hard for yeast to digest. This accounts for the development of less-desirable flavors, usually described as thin or cidery. Invert sugar has undergone a simple chemical reaction that converts the sucrose into glucose and fructose, both of which are more highly fermentable by yeast than sucrose. Invert sugar tastes sweeter and is less prone to crystallization; it is prized by bakers for this reason.

Sucrose inverts to glucose and fructose when it is dissolved in water and heated. The process can be accelerated by the addition of a small amount of acid, such as lemon juice or cream of tartar. An acid-accelerated conversion does not allow enough time for caramel colors and flavors to develop, and the common acids do not yield the rich flavors that the best candi syrups are renowned for. It takes a nitrogen source to develop complex caramel and fruit flavors and the deepest caramel colors. Diammonium phosphate (DAP), a chemical sold in homebrew shops, is commonly used, but ammonium carbonate (baker’s leavening or baker’s ammonia, sold in specialty shops) may also be used. I have used both, but prefer the flavor of candi syrup made with ammonium carbonate.

Adding the nitrogen to the sugar solution speeds up the Maillard reaction, causing a browning effect similar to the caramelization used in the baking and confectionary world. The more DAP or baker’s leavening added, the darker the final color. The final cooking temperature is also important — a higher temperature results in a darker syrup with a stronger flavor. The cooking process should take at least 30 minutes, and up to 90 minutes for large amounts of dark syrup. The long cooking process is important when using DAP or baker’s ammonia, because it enables the ammonia portion to evaporate. Residual ammonia can contribute an unpleasant flavor to the final product.

The process for candi syrup is basically the same for each of the following recipes. A longer cook time is required for darker syrup, and more water must be added during and at the end of the cooking process to replace the liquid that evaporates away. Each recipe produces 1 pint (16 fl oz) of syrup, which weighs 24 ounces or 1.5 pounds. As long as you observe the ratio of 1 pound of sugar to 1 pint of syrup, the final PPG per pound will be between 30 and 32.

The following recipes may be increased by a factor of up to 6 without changing procedure much, except for a longer cook time and possibly a larger pot. If your vessel is too small, you are likely to have a miserable boilover and a nasty cleaning job on your hands. Use a cooking pot that is at least three times the volume of the amount of sugar being made.

Choose the highest-quality pot you have. A heavy-bottom stainless steel pot with straight sides is best. Steep sides allow crystals to wash back into solution more readily, and boilover is less likely.

A very mellow syrup with light vanilla flavors and hints of apricot; it will be light amber in color if unbleached sugar is used. Makes 1 pint.

Heat above mixture to 260°F (127°C), then add:

Bring temperature back up to 240°F (116°C), then remove from heat immediately.

This sweet syrup has flavors of vanilla, caramel, and warm bread. Makes 1 pint.

Bring temperature back up to 240°F (116°C), then remove from heat immediately.

This rich, deep red-amber syrup adds chocolate and toffee notes, plus nuances of dried cherries or plums. Makes 1 pint.

Bring temperature back up to 240°F (116°C), then remove from heat immediately.

This syrup has a rich mahogany color; it lends intense bittersweet coffee and dark chocolate flavors, and hints of fig and anise. Makes 1 pint.

Bring temperature back up to 240°F (116°C), then remove from heat immediately.

No, this is not several different malt parties with enzymes that cannot agree to work together on anything! The Congress Mash is a brewing industry standard method of determining the %Extract. It is a procedure that always uses the same time, temperature, and water proportions so that results can be compared against a standard of measure. Pure crystallized sugar is used as the standard of measure because it completely dissolves in solution, thus resulting in a %Extract of 100. One pound of pure sugar dissolved in 1 gallon of water results in a specific gravity of 1.046, or 46 PPG. Comparing this standard to soluble extracts from different types of malt can provide meaningful information to the brewer.

Although a laboratory is not available to most of us homebrewers, it is not too difficult to do this type of test on your own malt samples at home. An accurate scale and thermometer, a food processor or coffee mill to grind the malt finely, a fine mesh strainer, and filter paper or paper towels are all that are required. The results may not be as accurate as those a laboratory can produce, but they will give you a good ballpark figure to work with when formulating recipes with your own homegrown grain or unusual malt that does not have a PPG listed for it.

This gives you what is known as %Extract As-Is Basis. In the laboratory the malt sample can be dried to 0 percent moisture, which is almost impossible to do in a home setting without starting a fire. When the malt sample being tested is dried to 0 percent moisture, it gives a %Extract Dry Basis, which is usually listed on a malt analysis sheet.