Most eco-brewers are motivated to use freshly malted grains because doing so has the lowest cost to the environment. Manufacturing extract from fresh grains is an intermediary step that takes resources, including significant amounts of power and water. Commercial extract production is a centralized operation that requires expensive equipment and trained specialists, thus it usually requires more shipping of raw materials than does producing whole malt. Skipping this intermediary step reduces the total amount of fossil fuel and water needed to produce a pint of beer.

Although you can make almost any beer using the partial-mash brewing method described in the previous chapter, brewing with all grain makes it possible to brew a much wider range of beer styles than with extract and specialty grains alone. Here are some other reasons that all-grain brewing is a good thing to do.

As with any process there are pros and cons to weigh. Here are some of the drawbacks to all-grain brewing.

Although it involves a lot of fascinating scientific details and complicated-sounding methods, making beer from scratch is quite easy. And for most of us it is fun! Seriously, all you do is mix the grains with hot water and hold at a temperature of about 150°F (66°C) for 30 to 60 minutes, then rinse out the mixture with some fresh hot water and collect all the liquid that results. In essence you are making your own extract before proceeding with your usual brewing routine.

Making good beer from all grain really can be this straightforward, though, of course, once you figure out the basics, there is a lot more to learn before you master all the possibilities. These are the basic steps for obtaining beer from whole grains:

To brew from scratch you do need a few pieces of specialty equipment, but they are not complicated and for the most part not particularly expensive.

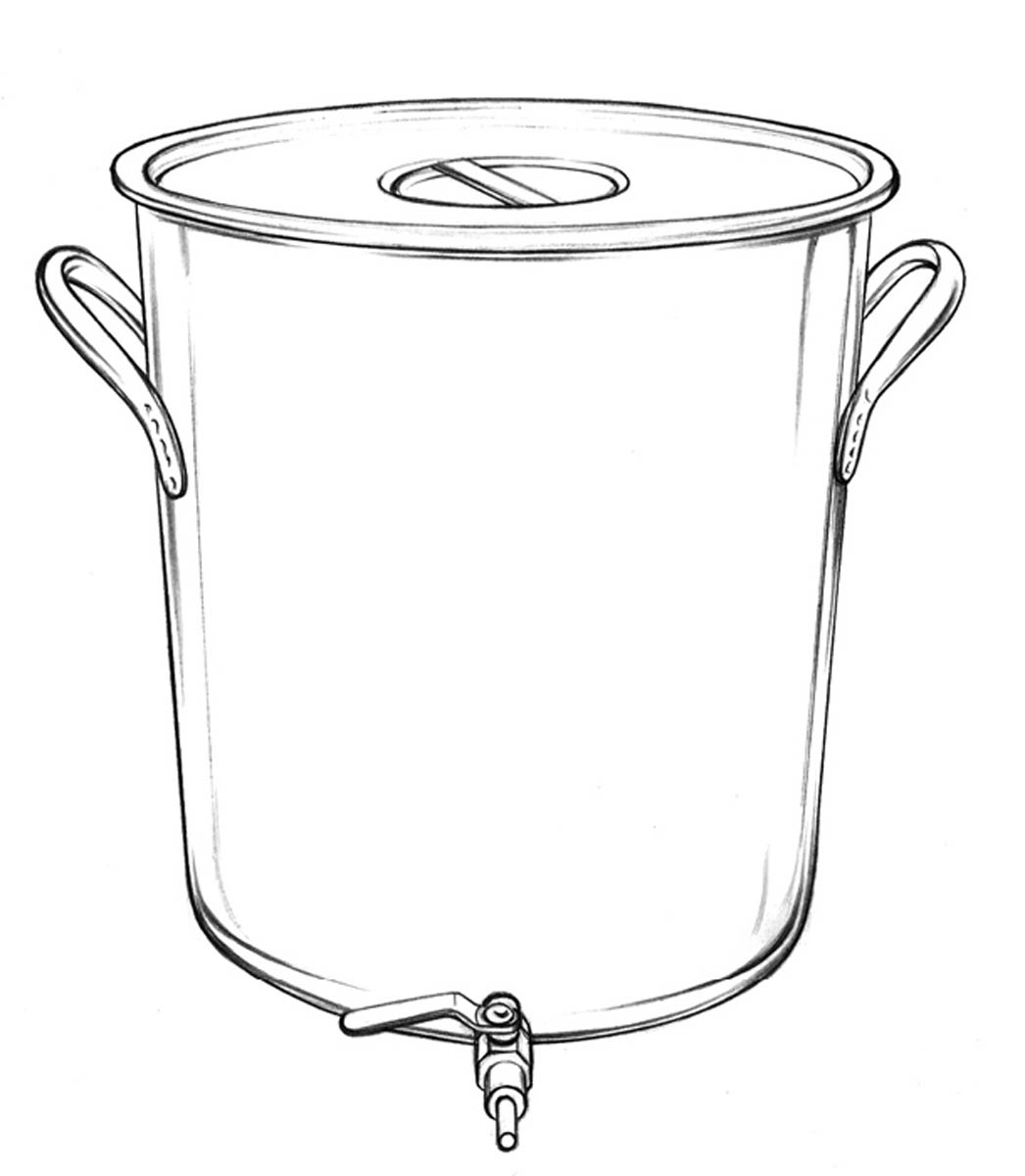

The mash tun (from an Old German word) is just a container that you do the mash in; it can double as your brew pot. A very basic mash tun is a pot, bucket, or tub large enough to hold at least the amount of mash mixture required by your recipe. For a 5-gallon batch, the capacity should be at least 5 gallons to accommodate the volume of mash required for a strong beer. Ideally, you want the tun to hold at least as many gallons as your all-grain system will brew. If it is a few gallons larger, that is better. You never know when you will want to brew an imperial IPA or a barley wine, which could require a capacity of up to double the batch size. If you plan on setting up a 10-gallon brewing system, you can do just fine with a 10-gallon mash tun if you scale down to a 5-gallon batch size for really big beers.

Because most recipes require holding the mash at a constant temperature in the 150 to 155°F (66–68°C) range for up to an hour, a mash tun should be either insulated to hold heat or flameproof so it can be heated if needed. With an insulated but not flameproof vessel, temperature adjustments can be made by adding hot or cold water. Many homebrewers use large plastic water or picnic coolers for a mash tun, but a stainless steel, ceramic, or wooden vessel is preferred in most eco-friendly home breweries.

Many mash tuns are actually dual purpose because they have a built-in filtering system that allows them to function as a lauter tun as well.

All or most of the fermentable sugars in all-grain beer come from the grains, so it is important to strain out the grains properly. The lauter tun must be at least as large as the mash tun and have a strainer or filter built into it. The most efficient setups have a straining apparatus directly above a spigot at the bottom of the lauter tun. It is preferable to have the straining apparatus at the bottom of the container because more sugars will be extracted as the liquid flows through the grain. If the rinsing water can flow out the sides, such as with a colander or straining bag, some of it will miss the dissolved sugars rather than flushing them all out the bottom.

A lauter tun can be as simple as a 5-gallon bucket made of food-grade plastic with a number of 1⁄8-inch holes drilled in it, nested inside another bucket that has a spigot installed in it. This is a reasonable option for all-grain brewing on a budget, and you can get plastic buckets for free from a grocery store or deli. Just avoid any plastic that held pickles or any other strong-smelling ingredients, because these flavors are easily transferred to your beer.

When using a separate lauter tun, most homebrewers simply use their brew pot as a mash tun. Once the mash is ready for sparging, the grains are transferred to the lauter tun, and the brew pot then can be rinsed out and used to collect the wort for boiling. If you have concerns about toxins leeching from plastic buckets used for lautering, this method is preferable to doing the whole mash in plastic because it limits the amount of time the hot liquid is in contact with plastic.

Often the lautering filter is built into the mash tun; thus the mash tun also serves as the lauter tun. During the mash it is called a mash tun. While the wort is being strained out of the grains, it is called a lauter tun. Most of us just call it a mash/lauter tun, and we’re good. What you call it is not all that important, although having fancy names for every piece of brewing gear you own is sure to impress your friends and family. The filter can be a false bottom, a coil of slotted copper tubing, a braided stainless steel tube with the plastic liner removed, or any other ingenious filtering device you can invent that will strain the sweet wort out from the grains.

The ideal choice for a combo mash/lauter tun is a stainless steel pot with a false bottom. Very nice examples of these are manufactured specifically for homebrewers by several different companies, including Polar Ware and Blichmann Engineering. Although more expensive up front, stainless steel is the easiest material to keep sanitary and will last for a lifetime of brewing quality beers. (See DIY Mash/Lauter Tun.)

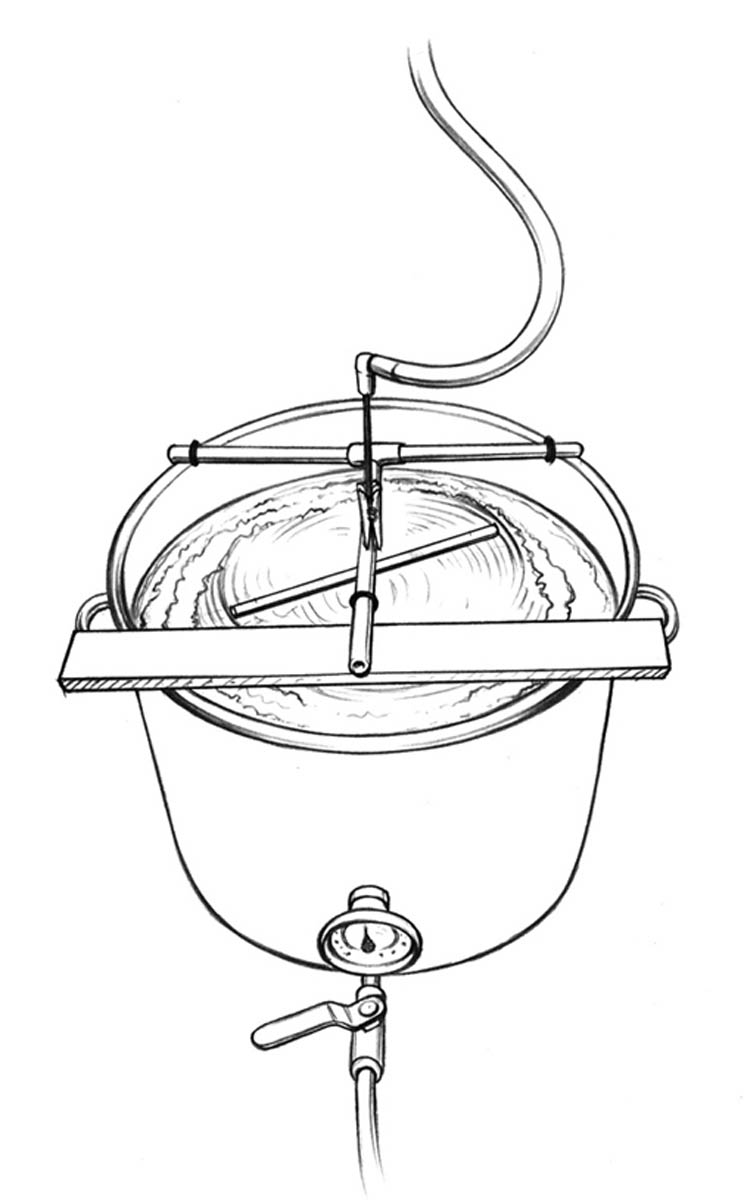

A hot liquor or sparge water tank holds the water that is used for lautering or sparging the grains. (In this sense “liquor” has the old meaning of “liquid,” not necessarily alcohol.) The tank often has a spigot and is placed above the lauter tun so the hot water can be fed by gravity into the top of the mash tun. A sparge arm or other sparging accessory is commonly used to set up a really efficient lautering cycle. The method of sparging or lautering that you use will dictate what type of sparge water tank you need. If you are hand ladling the sparge water or batch sparging, you do not need a special hot liquor tank at all; any pot large enough to heat up the required amount of sparge water will do.

The objective of sparging is to have the water flow gently over the top of the grain bed so the grains are disturbed as little as possible. You can ladle the hot water over the grain bed by hand, which can be a Zen-like experience if you are the patient type. If you brew often or do large batches, however, it can become rather tedious. Buying or making a simple sparging device can be a worthwhile time-saving investment.

A sparge arm, a sprinkler type of device (think of a showerhead), or ring of copper tubing with holes punched in the bottom that the hot sparge water is run through can help automate the task of lautering and improve the final yield from a mash. Rotating sparge arms are miniature versions of sparging arms often employed in large breweries and are rather fun to use but are usually the more expensive option.

Continuous sparge setup

Because water pH is influenced by many different factors and can change dramatically when combined with malt in the mash, the best time to measure the pH when brewing a new style of beer is at the very start of the mash. You should have supplies on hand to make adjustments if needed. To test pH you can use pH test strips or a pH meter, both of which are available at most homebrew supply stores or via Internet suppliers.

Precision pH strips such as the ColorpHast brand will give more accurate results. A pH meter is even more accurate and can come in handy for other projects, such as testing soil pH for gardening. For beer brewing purposes you need to take an accurate reading of the mash, so if using pH test paper, look for strips that measure a range of at least 4.6 to 6.2. A less accurate strip that can measure from at least 3 to 10 is also very useful for testing water and wine.

When you brew beer from whole grains, you add a few steps, but after the mash is done, the basic process is unchanged: boiling the wort, adding hops, cooling, pitching yeast, fermentation, and packaging in bottles or kegs. If you have decided to start your hobby right out of the gate with whole grains and skip the extract brewing stage completely, you still need to learn all the other stages of the brewing process that are covered in chapter 3.

This chapter focuses on the process of extracting sugar from malted grains, from the mechanics to the chemistry. When brewing with extract, things such as mash pH and water chemistry are not critical to success, but they can be when brewing with all grains. Having a basic understanding of what goes on with enzymes, pH, and water mineral profiles is important if you want to brew quality beers consistently.

By now you probably have a good idea of the basic concept of mashing. There are three commonly used methods of mashing malt to make beer — single infusion, step infusion, and decoction mash.

Single infusion. The water is heated to a temperature slightly higher than the desired mash temperature before the grains are added. Because the grains are at room temperature, the water temperature drops to the target range when the grains are mixed in, and then it is held for 30 to 60 minutes until starch conversion is complete. This method is the most widely used today because most professionally malted grains contain a large quantity of enzymes and will complete the starch conversion with no more effort than this.

Step infusion. When brewing with a large percentage of unmalted grains such as flaked oats or precooked millet, or if you are working with undermodified malt (grains that have not developed to optimal enzyme and protein levels in the malting process — rare these days) or home-malted grains, the mash will need to be held at two or more temperature levels to break down additional proteins and beta-glucans that may be present. The mash routine is often specified in the recipe, but in general it is first held at a lower temperature for a while, and then more heat is added to bring the mash to the next stage. Heat can be added by turning on a burner or adding boiling water, or by straining out some of the wort, gently heating it up, then adding it back to the mash. Most step infusion mashes require a single temperature adjustment, but it is possible for a very complex recipe to have three or four stages.

Decoction mash. This type of mashing requires boiling a portion of the mash, grains and all, and returning it back to the mash tun. This process develops more caramel flavors by cooking the mash over several stages, and was developed to obtain better extraction rates from malt made from old-world barley that was difficult to malt properly. The extended cooking during the mash process breaks down the less soluble starches present in undermodified malts. If you grow and malt your own barley, this type of mashing might help you increase your extract yields. It is sometimes used when brewing German bock and Oktoberfest styles to develop the desired deep caramel flavors. If you want to try this method of mashing, see the recipe for Bawk-Bawk Bock.

You can build your own stainless mash/lauter tun by converting a retired 15-gallon sanke keg or a stainless steel kettle. You can do this using a power drill and one of the widely available weld-free ball valves on the market, in combination with a premade false bottom or a mash filter you build yourself out of copper tubing. If you have the tools and the skill to weld stainless steel yourself, you can install a spigot fitting permanently, typically a half-inch coupler with a female pipe thread fitting, which can fit a stainless steel ball valve.

If you are not equipped to weld stainless steel yourself, it may be worth it to hire a local welding professional to do the job for you, which should cost less than fifty dollars. Sometimes a bottle or two of your finest homebrew will help you work out a better deal for the service! One of the weld-free kits generally works reasonably well but can become leaky if any of the metal parts or the area where it is installed on the pot become warped or dented. An expert weld job should serve you well for many years. I had a pot custom-modified when I first started brewing, and I still use it every time I brew, 18 years later!

When brewing with large amounts of grains, the proper crush level is critical. When grains are properly crushed, each grain is split open so the starchy contents are exposed and can be dissolved in the mash. If the grains are ground too finely, the mash becomes too mushy and thick, and straining the wort from the grains is very difficult. A fine balance is needed — too coarse and the extract yield suffers; too fine and the lauter tun can get clogged. The milled grain mix is called grist.

A good roller mill is the preferred option; it cracks the grains without pulverizing the husks too badly. Plate mills, which have one or two disks that catch the grain and shred it, are widely available but are not ideal. If you have a choice between using a plate mill and having your grain milled on a roller mill when you purchase it, choose the milling service unless you will not be able to brew with the grains for over a week. A plate-style mill can be purchased for fifty or sixty dollars. Decent-quality roller mills are available starting at a hundred dollars.

If you are milling a combination of grains yourself, it is generally a good idea to weigh them and mix them together before milling. Different malts have different sizes and hardness, and you can get a more consistent crush by milling them together. Set the mill for the optimum crush for the largest quantity of grain used, usually the base malt for the recipe. That way, you will not have to change the setting on your grain mill in midprocess. If this isn’t possible, just do the best job you can milling the grains, and 99 times out of 100 all will be well. In some ways brewing can be very forgiving.

Use 1.5 to 2 quarts of brewing-quality water for each pound of grain. If you need to adjust minerals for a specific beer style, do so before adding the grains. For a single infusion mash, heat the water 10 to 15°F (6–8°C) higher than the desired mashing temperature. This starting temperature is usually referred to as the strike temperature.

If the ratio of water to malt is 1.5 to 1 and you want a starting mash temperature of 150°F (66°C), the strike temperature should be about 165°F (74°C). With a ratio of 2:1, the strike temperature should be a bit lower, or about 160°F (71°C). If your mash/lauter tun has a false bottom, you’ll need to add extra water to account for the space underneath and drop the strike temperature a degree or two. After a few batches you will start to learn your system and will develop a good sense for how much temperature change will occur in your own particular setup.

When adding grain to the strike water, it is important to mix thoroughly to make sure all the grain particles are completely soaked. If you are heating the strike water in a separate pot from the mash tun, you can add a portion of the water, then a portion of the grains, and so on. Working in thirds usually works well. If you are heating up the water directly in your mash tun, it is fine to add your grain in batches, stirring after each addition, to the entire volume of mash water, and there is no need to dump some of the water out and then mix it back in. The point is to evenly mix the grains and water, so it doesn’t matter whether you add the grains to the water or the water to the grains, so long as you mix them thoroughly.

(If math is fun for you, you can calculate precisely the exact strike temperature needed for x gallons of water mixed with y pounds of grain. You will need to know the starting temperature of the grain, the exact volume of water, and the exact weight of the grain. The basic formula is described in chapter 16 of How to Brew by John Palmer, or see Resources for an online calculator.)

Once you have done a few all-grain batches, you will start to develop an instinct for getting the balance of strike water temperature to grain right, and you will rarely need to correct it. It is always a good idea to start with a lower ratio of strike water to grist. That way if your temperature is too high or too low you can easily correct it by adding boiling water or cold water, a little at a time as needed, without skewing the water-to-grain ratio too badly. Keep adding water until the desired temperature is reached. Stir well after each water addition to make sure equilibrium is reached before adding more water.

If you really miscalculate and your mash temperature exceeds 167°F (75°C), the enzymes that are needed to do the starch conversion will be denatured and your mash will not succeed. It’s a harsh lesson but probably a mistake you’ll only make once. (And if you keep chickens they may be pretty happy with the extrarich “spent” grain.)

When you first add the grains to hot water, the water is cloudy from all the pulverized bits of starchy grains. The wort becomes less and less cloudy as starches are transformed into sugars by the mash enzymes. The flavor also is transformed from being bready or grainy to syrupy and sweet. It can be tricky to figure out exactly when the process is complete; one way is to do a starch test. Some substances — one being iodine — produce a visible reaction when mixed with a solution containing starch. For this test you can use the same iodine solution you use for sanitizing.

A tincture of iodine will turn from red to a dark purplish black when mixed with a starchy liquid. To witness this reaction at its strongest level, pull a sample from the mash at the very beginning. Carefully tilt a spoon into the liquid to draw away some liquid without bits of grain in it. If you prefer, you can pull a sample, then strain it through a fine screen. Put several drops of iodine into the sample, swirl to mix, and observe the reaction. It should happen very quickly, and the change should be obvious.

When the mash water has cleared and becomes sweet, do another iodine test. If no color change occurs, the mash is done. Sometimes a slight reaction will occur even after the starches have converted as much as they possibly can. This is due to minute particles of grain husk and other proteins reacting with the iodine. This is why I suggest doing a reading at the beginning of the mash; it will give you a benchmark by which to gauge the extent of the change.

As you gain experience with mashing, you can learn to rely on your sense of taste to ascertain when a mash has finished. To this end, every time you brew you should frequently taste a small sample of the mash as it progresses so you can train your taste buds to detect subtle changes in the flavor. When just learning to mash or if tasting the mash does not work well for you, a starch test is very reliable and easy to perform.

Once the starch conversion is complete, it is time to lauter the grains. Lautering is the process of flushing or rinsing the grains with hot water to wash all the fermentable sugars into the wort for the boil. Technically, to sparge is to spray or sprinkle hot water over the grain bed. The terms “lauter” and “sparge” are often used interchangeably by homebrewers. Both mean to wash the sugars out of the mashed grains.

Heat the quantity of sparge water called for in your recipe to between 165 and 170°F (74 and 77°C). Take into account the amount of heat loss that occurs as the liquid travels between the sparge water tank and the top of the grain bed in the mash. Unless you’re brewing in a very cold environment or the water has to travel an unusually long distance, the temperature drop is usually less than 10°F (6°C).

Lauter tun with built-in thermometer

Water temperature, volume of water, and flow rate are all very important in this process. Keep these tips in mind:

The above method is known as continuous sparging. A less widely used technique is batch sparging. To batch-sparge, all the sweet wort is drained from the grains, and the mash tun (still filled with grains) is refilled with hot sparge water. The grains are steeped in this second batch of water for a short time — usually about 10 minutes — then drained again. If needed, a third batch of sparge water is used. Batch sparging is less efficient, resulting in yields up to 15 percent lower than continuous sparging, but it may be easier given available equipment.

Once the wort has been collected from the grains, the all-grain part of the process is basically done, and the rest of the brew works the same way as an extract or partial-mash brew does. The wort is boiled, hops are added, the wort is cooled, yeast is pitched, and so on. The only difference would occur if, as an extract brewer, you were used to doing partial-boil batches. When brewing all grain, you do not have the option to do a partial boil — in fact, it is usually the other way around. Often extra wort is collected and needs to be condensed slightly, which usually occurs in a 60-minute boil. In some circumstances it becomes necessary to extend the boil up to 90 or even 120 minutes to concentrate the wort down to the finished volume called for in the recipe.

To determine whether you need to adjust the mineral content or pH of your brewing water, you need to find out what your brewing water chemistry is like. Once you know your water chemistry, you can make adjustments for certain styles of beer. If the content of minerals other than bicarbonates is too high, the only way to reduce the parts per million (ppm) is by diluting with distilled or reverse osmosis (RO)–filtered water. If they are too low, you can add a measured amount of the right mineral to make adjustments.

If you are on a municipal water supply, in most areas you can request a basic analysis free of charge from the water department. If you have a well or rely on another source for your brewing water, you might want to have the water tested. A number of laboratories offer affordable water testing services; check agricultural testing companies that also do soil tests for farmers (see Resources). A basic household water mineral test should, at a minimum, give you the results listed below.

Bicarbonate (HCO3). The best range for brewing is 0 to 250 ppm. Lower levels (0–50 ppm) are good for brewing lagers and light beers, and high levels (150–250 ppm) are good for strong and dark beers, with most other beer styles falling somewhere in between. Excess bicarbonate is easily removed by boiling; after 30 minutes most of the bicarbonate will precipitate out as a sediment or film at the bottom of the kettle. Then just carefully decant the water off the sediment. The drawback is that boiling also removes calcium, so if it would lower your calcium levels too much, diluting your brewing water with distilled or RO-filtered water may be a better option. Alternatively, after boiling to precipitate out the excess bicarbonate, you can add minerals to increase calcium levels.

Calcium (Ca). Best range for brewing is 5 to 150 ppm. Calcium is very important for enzyme function in the mash, protein reactions in the boil, and yeast metabolism. Calcium can be increased by the addition of calcium chloride, calcium sulfate (gypsum), or calcium carbonate.

Chlorine (Cl). Best range for brewing is 0 to 150 ppm. Within this range sodium helps to balance flavors and accentuate malt sweetness. Too high, and beer will taste salty. Adding calcium chloride or sodium chloride will increase chlorine levels, which might be appropriate for specialty beer styles — Gose, for instance.

Magnesium (Mg). Best range for brewing is 10 to 30 ppm. Levels over 50 ppm can cause a sour taste. Magnesium is important for yeast function, and some enzyme reactions rely on it. Add magnesium sulfate to increase levels.

Potassium (K). Best range for brewing is 0 to 10 ppm. Higher levels of potassium inhibit enzyme activity and are detrimental to yeast function. Additions of potassium are generally not needed. If your house uses a water softener, you should avoid using your tap water for brewing, as potassium levels are likely to be too high.

Sodium (Na). Best range for brewing is 0 to 150 ppm. As with chlorine too much sodium can lead to salty-tasting beer. Sodium at levels of 70 to 150 ppm can have a balancing effect on flavors in beer just as it does in food, but too much is never a good thing.

Other values given in a water report are:

pH value. This is often between 7 and 8. Remember that the pH value drops when malt is added to the water, so the important pH measurement is the one you take of the mash.

Total alkalinity. With this value and some fairly complex math you can estimate what the mash pH will be. I rarely find this to be necessary, but it can be a useful tool if you are experiencing problems with mash pH or having problems with full starch conversion. (See Resources for an online spreadsheet with these calculations, or consult chapter 15 of How to Brew by John Palmer.)

Although water hardness and pH can vary throughout the year, a single test should give you a ballpark snapshot of your water qualities and give you enough information to meet your homebrewing needs, unless you feel it is necessary to work with information of pinpoint accuracy. In that case a test during the driest season and one during the wettest season may serve you better.

For many centuries brewers made perfectly fine beer without adjusting water chemistry. This is one of the reasons different styles of beer evolved that are unique to their brewing region. From an ecological perspective it makes sense to brew with local water and make beer styles that take advantage of the local flavor without adding imported minerals. Why not celebrate the natural advantages of your water to develop your own local flavor? If you have naturally hard water, you will do well with stouts, IPAs, and English-style IPAs. If your water is soft, pilsners and European ales are good candidates for becoming your signature local beer.

If you want to tailor your beer to a specific style, there are charts online to help you figure out the correct water profile (see Resources). To keep it simple for everyday brewing, though, you just want to keep the ppm of each mineral within the optimal brewing range described above. I find that as long as my water mineral levels are within the brewing “sweet spot,” it is rarely necessary to change mineral levels or adjust the pH. My water is of average hardness, and when I am brewing styles that call for hard water, I find that adding a small amount of gypsum (calcium sulfate) gives the most pleasant-tasting result.

For most of us tweaking the water chemistry is important only if we are brewing for a competition or are correcting a problem that contributes an off-flavor to our beer. In competitions adherence to the style profile is important. If the water chemistry is markedly different from the standard for that style, it could cost you a few points, which could make the difference between a blue ribbon and no ribbon!

The level of acidity or alkalinity of a solution, the pH, is measured on a scale of 1 to 14. One is considered extremely acidic, 7 is considered neutral, and 14 is extremely alkaline (or basic). Pure water usually has a pH of 7.0, but as the mineral content, or hardness, increases, the alkalinity goes up. This can sometimes be a problem for all-grain brewers. When working with mashing and wort, the ideal range for most mashes is 5.4 to 5.8 (measured at room temperature). In most cases simply mixing barley malt with water that is pH neutral or slightly alkaline will result in a pH within this range, because the acidity of the mash naturally lowers the pH. This is the range in which most of the desirable enzymatic activity happens at a lively pace.

In the mash, water temperature is the most important aspect to be precise about — as long as temperatures are within a few degrees of the optimum, everything will work out fine unless the pH is way out of balance. Many brewers mash without worrying too much about pH and make great beer without ever taking a pH reading. When brewing all grain it is sometimes necessary to make adjustments to the mash to achieve a balanced pH and produce a beer that meets your expectations.

If the pH is too high and the mash is too alkaline, too many tannins could be extracted from the grains and enzyme activity may be somewhat inhibited, slowing conversion rates and possibly reducing the yields. Too much tannin in the wort can cause a hint of bitterness or astringency in the finished beer. A pH that is too low will slow enzyme activity and may cause hints of acetone and excessive hop bitterness in finished beers. Darker malts tend to acidify the mash more than lighter malts, so a pH adjustment may be necessary when brewing one type of beer but not another.

During mashing the goal is usually to hit the sweet spot of 5.4 to 5.8 pH, but as long as you are within a few points of this range, your beer should turn out well. Most of the time you will be looking to lower the pH. It is very important to note that pH reading changes with temperature. By most accepted standards of measuring, the sample should be cooled to room temperature, or between 60 and 70°F (16 and 21°C), before the measurement is taken. The pH reading will be lower at mash temperatures of around 150°F (66°C).

If your reading is outside the range, it is good science to take a second reading before making any adjustments, just in case something went wrong the first time. A chunk of grain or a mash that was not adequately mixed could throw the reading off.

Malted grains are basically seeds that have been modified by soaking and sprouting. If the sprouted grain is allowed to grow into a seedling, enzymes in the seed will convert starches into sugars to feed the seedling. Drying the grains at a peak point in the cycle, when both the starch and enzyme levels are high, stops that conversion process and preserves the enzymes and starches in a compact form with a good shelf life. The enzymes remain dormant in dry malt, even if heated; to become active they need to be dissolved in water. The activity level of malt enzymes is primarily affected by temperature of the liquid mash, although pH can influence their effectiveness as well.

It is useful to understand how the malting process works even though it is not necessary to malt your own grains to brew beer from whole-grain malt. Enzymes act as a catalyst that is like biological rocket fuel that speeds up reactions essential for life; without them the starch-to-sugar conversion would happen too slowly and the plant would starve and die. In malted grain several different types of enzymes work in concert to break down the complex starch and protein molecules into simpler, more digestible sugars and amino acids that yeast can eat. Some enzymes break the starches into sugars while others act on the proteins and cellulose in the grain.

Each of these specialized enzymes is most effective within a specific temperature range and pH level. Because we know which enzymes perform which functions at which temperature range, we can guide the outcome of our mash with precision, as long as the pH is not too far out of balance. Although all these different enzymes are working together in the mash to make it into wort, for most all-grain brewing we mainly need to concern ourselves with a few types of enzymes: alpha-amylases and beta-amylases, proteases, and beta-glucanases. Each has a slightly different job to do in the mash:

Alpha-amylase. A fast-acting enzyme tha t works in the mash between 140 and 167°F (60 and 75°C) and most rapidly between 140 and 158°F (60 and 70°C). Alpha- or a-amylases break apart larger, more complex chains of starch molecules, producing maltose and other sugars. Amylase is present in human saliva, where it has been used by primitive cultures to start the mashing process by chewing whole grains (a last resort for homebrewing!).

Beta-amylase. This enzyme produces only maltose; it is most active between 140 and 150°F (60 and 66°C), and performs optimally at 140 to 145°F (60–63°C). A somewhat fragile, plant-based enzyme, it becomes completely denatured within 10 to 20 minutes at temperatures over 155°F (68°C). To create a beer with a lighter body, hold the temperature around 145°F (63°C) for a short while to allow more of the enzymes to break down more of the complex carbohydrates that make a fuller beer.

Protease. Barley malt contains a fair amount of protein that is too complex for yeast to eat. Protease enzymes break down proteins into amino acids, which aid in yeast metabolism and reproduction, essentially providing two valuable services to brewers for the price of one. Proteases are most active between 68° and 149°F (20 and 65°C) and perform best at 113 to 131°F (45–55°C). In modern malting processes many of the proteins are broken down; thus nothing special needs to be done by the brewer because the remaining proteins will be broken down sufficiently during a single temperature mash. If you are using a large proportion of unmalted grain (or grain that has been inexpertly malted at home), allowing a protein rest during the mash cycle or using a decoction mash may help reduce excess proteins that could cause chill haze in a finished beer. Be careful, though — a mash held at the protein-rest temperature range of 120 to 130°F (49–54°C) for longer than 30 minutes could result in a beer that is too thin.

Beta-glucanase. Beta-glucans are nonstarch polysaccharides, basically plant cellulose and bran. Too many can be a problem in brewing, because if they are not broken down by beta-glucanases, the grains will have a thicker, gummy quality that can make it hard to rinse the fermentable sugars from the grains, thus lowering the yield. Allowing some beta-glucans to remain in the finished beer contributes a silky mouthfeel and body to beers such as oatmeal stout. B-glucanase is active between 68 and 122°F (20 and 50°C). A rest period during the mash in the optimal temperature range of 95 to 110°F (35–43°C) for 10 to 20 minutes will reduce the levels of beta-glucans and is suggested for grain bills that include a portion of unmalted grains that exceeds 20 percent.

If an adjustment is merited, there are several methods you can employ to adjust the mash pH. There are other substances available than those suggested here, but in my estimation some methods rely too much on chemical means and shouldn’t be employed by eco-minded brewers.

Raising mash pH. If the mash is too acidic (pH is too low), add an alkaline substance such as calcium carbonate, or chalk (CaCO3), or lime (Ca(OH)2).

Lowering mash pH. It is more common to lower mash pH (make it more acidic) than to raise it, using common mineral salts such as gypsum (CaSO4) or Epsom salts (MgSO4•7H2O). Lactic acid or distilled white vinegar can also be used, although they (as well as other liquid acids I don’t recommend, such as hydrochloric acid or muriatic acids, often used by commercial brewers) can give a sour taste to the beer, which may be desirable in certain beer styles and definitely not wanted in others. Using one of the mineral salts will avoid this effect. Alternatively, a sour mash or acid malt can be used. See the recipe for Cultured Farm Girl, a Berliner Weisse, for a basic sour mash guide.

As an eco-minded brewer, I shy away from tweaking the chemistry of my mash and wort too much. Adding chemicals such as phosphoric acid or potassium hydroxide to balance pH runs counter to my sense of nature’s balance. I only resort to adjustments if a problem is pronounced and will result in an unsatisfactory beer; then I use simpler ingredients such as gypsum or chalk whenever possible.

Making the adjustment. Whatever you use, add it slowly. The best method is to make a solution with the additive and add a small amount, stir well, wait a minute, then take a reading. For powdered minerals I suggest a solution of 1 teaspoon in 3 tablespoons of water, then add the mixture 1 tablespoon at a time until the desired pH is reached. For liquids such as lactic acid or vinegar, add 1 tablespoon at a time for a 5-gallon batch. Many compounds in the mash act as buffers, so a threshold will need to be reached before a change takes effect, and that change can be dramatic if too much is added all at once.

Here is an area where common sense should also prevail. You are adding stuff to beer that you will drink. Would you want to drink a glass of water mixed with some of that powder you are planning on adding to your brewing water? Adding minerals and acids can adversely affect the taste. You don’t want your beer to taste like chalk or vinegar or something even nastier. By making small adjustments you will give yourself more fine-tuned control over the end result, and you will minimize your use of additives altogether. Take notes on what you are doing, so that if you like the results you can duplicate them or adjust them again if you aren’t quite happy.

A higher-temperature mash will produce a wort with more unfermentable sugars and a beer that is fuller bodied and sweeter. A lower-temperature mash will produce a thinner wort and a beer that is drier and more crisp. A short rest at a temperature range of 110 to 130°F (43–54°C) will reduce proteins and beta-glucans and is usually only necessary for beers with a percentage of unmalted grains higher than 20 percent.

The ideal environment for efficient mashing of most malt into wort for homebrewing purposes will consist of:

In the past dozen years or so, wort aeration has been given a lot more attention, as it rightly should be. Oxygen is a very important nutrient for the cellular reproduction of yeast. If there is not enough oxygen in the wort when the yeast is introduced, the yeast will still function, but in a diminished capacity, and the fermentation will not be as healthy as it should be.

The boiling process drives all the oxygen out of the wort, so it has to be added back in before fermentation begins. The higher the initial gravity of the wort, the higher the level of oxygen needs to be, because high-gravity beers require a larger population of yeast to do a proper job of fermenting. If you use the yeast pitching guide, How Much Yeast to Pitch?, and aerate the heck out of the really strong beers, you will be well on your way to master (home)brewer status!

Aeration isn’t rocket science, although I am sure some rocket scientists have applied their considerable talents to the challenge of aerating their homebrew over the years. The object is to mix as much oxygen into the wort as possible without contaminating it, hopefully without making a huge mess. It is possible to achieve up to 8 ppm of dissolved oxygen by mixing air into the wort by one of the methods described below. Five ppm is the minimum required for healthy yeast growth.

Pouring/splashing. Pouring the beer into the carboy through a strainer or splashing it through a sanitized screen will partially aerate the wort. Using a siphon wort aeration device such as the Siphon Spray Wort Aerator made by Fermentap can enhance the process. For many beers a splash-as-you-transfer approach is all that is needed for adequate aeration. Note I said “adequate.” If you aspire to greatness in your beers, you should always aerate well. This requires agitating, stirring, or using an oxygenation system after this step to enhance the aeration and propel your beer into the realm of greatness.

Agitating. If the beer is in a carboy, you can gently rock the vessel back and forth so the beer sloshes around inside. I find it helpful to put the stopper in so the airlock hole allows air in but no liquid escapes as long as you are careful. I put the carboy on a soft surface such as a thick rug or rubber mat while agitating it. A broken carboy full of homebrew is a real tragedy and in the worst-case scenario could cause a serious injury.

Stirring. If you are using a widemouthed fermenter, you can use a clean, sanitized stainless steel whisk to whip air into the wort. Choose one with a long handle to keep your hands away from the liquid. You could attach the whisk to a cordless drill to save your wrist, and homebrew shops sell aeration devices that attach to power drills. A strong word of caution about this: Never use a corded drill unless it is plugged into a ground-fault circuit interrupter (GFCI) outlet. If you drop an ungrounded drill into liquid, you could be electrocuted.

When it comes to aerating your wort, perserverance is more effective than brute force. Depending on the style of beer being made, agitate or stir for 1 to 5 minutes to ensure you have sufficiently aerated the wort. If you agitate really fast, the wort will foam up quickly, but it’s likely that only the top third of the wort will be sufficiently aerated. A slow and steady agitation causes the oxygen to dissolve evenly throughout the fermenter from top to bottom.

Once several inches of foam have formed, the wort is usually sufficiently aerated — although strong beers can foam up quickly because of the higher density of the liquid. Since they need a higher level of aeration than an average- or low-gravity beer, a longer amount of time spent agitating the wort can really pay off with a more robust fermentation.

Another way to aerate wort is by injecting air or even pure oxygen with an aeration stone. You can buy a kit that includes the stone, a filter, and either a small pump or a small regulator that attaches to the type of recyclable oxygen tanks sold for welding. If you often brew lagers or high-gravity beers, one of these devices may be worth the investment.

Aeration systems push air (or pure oxygen from a tank) via an aquarium pump through a stone that has hundreds of tiny holes. The holes create very small bubbles that dissolve into the wort much more quickly than normal air bubbles do. A higher concentration of dissolved oxygen can be achieved using an aeration stone and pure oxygen than any manual method of mixing air into the wort.

Most commercial breweries use pure-oxygen aeration systems for this reason. It is one thing they can do that will help ensure they produce good beer every time.

The subject of whether using pure oxygen makes better-tasting beer is one that experts disagree on. I don’t think it’s necessary; I have always found that my yeastie beasties thrive on plain old life-giving air.

It’s extremely important to keep track of the temperatures at which you are mashing and fermenting. A mash can be very forgiving, and the magic of starch conversion can happen over a fairly wide temperature range, but for consistent and predictable results, an accurate thermometer is essential (and make sure to keep it calibrated). I often use two thermometers when precision is required, just to make sure I am getting accurate results.

Doing every mash in the temperature range of 150 to 155°F (66–68°C) will always succeed in starch conversion and will usually make decent beer. To address potential flaws, reproduce the mash schedule of a classic beer style, or deal with excess proteins and beta-glucans in large amounts of unmalted grains, you may need more accurate target temperatures, and the process may require several temperature stages.

In general, brewing beers with fuller body and sweetness calls for a higher mash temperature (153–158°F [67–70°C]), while beers that are lighter bodied and dry require a lower range (149–152°F [65–67°C]). To break down a larger amount of insoluble proteins, you can implement a protein rest by holding the mash at 120 to 130°F (49–54°C) for 10 to 20 minutes. To increase the activity of enzymes that break up the gummy beta-glucans, you can hold the mash in the optimal temperature range for beta-glucanases of 95 to 110°F (35–43°C) for 10 to 20 minutes. See The Nitty-Gritty Details: How Mashing Works for more details about enzyme reactions and what happens in the mash at different temperature ranges.

This is an area where many homebrewers fail, despite being extra careful at every other stage of the brewing process. Maintaining the ideal fermentation temperature range can be a real challenge, especially when the weather is particularly hot or cold or the temperature in your fermentation area fluctuates quite a bit throughout the day. Professional breweries rely on refrigeration, glycol-cooled fermenter jackets, or heated fermentation rooms to maintain precise temperatures. Most homebrewers do not have budgets that allow for that kind of equipment, but there are many low-tech solutions, and some of them are very eco-friendly.

The first thing you should do when starting to brew is to find the best area of your house to store your fermenters while the yeast does its work. This may not always be the most convenient spot, but we brewers do what we must. An ideal location maintains a consistent temperature between 60 and 70°F (16 and 21°C). If you have such a spot in your house, count yourself lucky, because you will rarely need to do more than occasional monitoring to ensure successful ferments, except when brewing a lager (see Maintaining Lager Fermentation Temperatures, below). If not, you may have to modify an existing area or build a fermentation chamber. The eco-friendly option is always the one that does not require additional electricity.

If the only fermentation area available to you is drafty and cold, your only option may be to install some type of heat source. For a single fermenter, heating pads and heating belts transfer heat directly to the fermenter, using less energy than heating a whole room. A seedling heating mat can serve double duty as a fermentation heater, though it usually warms to a set temperature that cannot be adjusted.

If you have more than one fermenter, heating the area around them might be a better option. If the area is very small and well insulated, it will not take much energy to control the ambient temperature. A small closet or cabinet often works, or you can build an insulated fermentation chamber. In a small enough space, the heat source can be a heating pad, an incandescent lightbulb, or a very small heater. If the chamber is well insulated, a no-power option might even be hot-water bottles or heated ceramic tiles. This is an excellent option if you have a woodstove or radiator where water bottles or stones can be heated without having to turn on an oven or heat water.

Whenever you are working with heating sources in small spaces, especially electric-powered ones, I strongly urge the highest level of caution to prevent the disaster of a fire. Always make sure that any flammable materials are kept away from heat sources. After setting up any kind of heating for your fermenting brew, check on it often, especially in the first 24 hours. Not only will this close monitoring give you peace of mind, it will also help you prevent overheating your fermenter, which could be as devastating to your beer as temperatures that are too cool.

Maintaining the cooler temperatures required for crafting high-quality lagers can be more challenging than keeping fermenters warm. I grew up in Vermont, and during the winter our cellar was usually a chill 40 to 50°F (4–10°C). Alas, by the time I started brewing, I had moved to warmer climates. If you live in an area with a real winter and you have a basement, you can plan your lager fermentations to occur during the winter months so you never have to worry about artificial cooling methods.

Refrigerators and freezers. Many brewers have to resort to a temperature-controlled refrigerator, a fermentation chamber, or a lagering tub to maintain the necessary 40 to 50°F (4–10°C). (See Using Temperature Controllers.) A converted refrigerator is the most common solution, but running an extra refrigerator just to make beer might seem a little excessive. On the other hand, beer is food for mind, body, and soul, and, well, this is a choice each of us has to make. Whenever possible, it is best to utilize the resources already at hand. If there is a way to use existing refrigeration, it is usually preferable to maintaining a whole separate fridge.

If you do buy a dedicated homebrewing refrigerator, consider these factors:

A small, well-insulated chamber makes it easier to maintain constant temperatures, using a small heating or cooling source as needed. A large cooler or discarded refrigerator can easily be converted, or use a small closet or cabinet and add additional insulation.

If well insulated, the chamber can be kept at temperatures in the 45 to 55°F range (7–13°C) simply by placing blocks or plastic bottles of ice inside regularly. If you are lucky enough to find an old-fashioned icebox still in good shape and at an affordable price, it could make a fabulous and fashionable fermentation chamber. All you need is enough room in your household freezer to freeze blocks of ice, which will not increase your energy consumption appreciably. In a pinch you can also buy block ice.

If you are not able to reach cold enough temperatures with ice alone, piping in air via a fan and ductwork over a pan of water can provide additional cooling by harnessing evaporative cooling principles. The fermentation chamber can be built to fit exactly into the opening of a small, low-energy-demand refrigerator, essentially extending the capacity of the unit.

Another method is to use a small air conditioner and port the cold air into the chamber via ducting. Crafty homebrewers have published many different plans online, but because these methods use a large amount of energy, they are not really appropriate for an eco-friendly homebrewing guide.

External-thermostat temperature controllers are available in most homebrew supply stores in both analog and digital models. Johnson Controls and Ranco are two brands. Prices for most models range from fifty to one hundred dollars. The digital ones are more expensive but offer a wider temperature range. Some analog controllers work with either heating or cooling but not both. A dual-purpose controller may be worth the additional expense if you expect to need both capabilities.

If you use a seedling heating mat as a heat source, you can buy a thermostat to maintain the temperature of the mat between 65 and 110°F (18 and 43°C). I use a mat made by Hydrofarm (it cost about thirty dollars) for everything from heating seedlings to warming my yogurt cultures to brewing a Belgian-style beer that needs more heat than my fermenting area maintains.

These controllers have a temperature-sensing probe that is run inside the fermentation chamber or that can be taped to the outside of the fermenter. The heating or cooling device is plugged into the controller, and the desired temperature is set. Once plugged in, the controller will turn the heating or cooling unit on when the temperature falls outside the specified temperature.

Because they override the power switch of the device, temperature controllers only work with appliances that turn on automatically when plugged in with the switch set to “on.” Some units have a digital switch and will not turn on when being plugged in unless a user switches them on. Most quality controller units include a built-in differential or variance that prevents excessive switching on and off, which can cause unnecessary wear and tear on the appliance and shorten its service life.

Other thermostats perform a function similar to that of the remote- probe thermostats but lack the probe, which limits their usefulness if you need to regulate cooling temperatures in a refrigerator or chest freezer. They work great in small fermentation areas with a power source located inside the chamber, because the thermostat is on the unit itself. These are designed to be plugged into a wall outlet; prices range from thirty to sixty dollars. Most can be set within a temperature range of 45 to 90°F (7–32°C), which covers beer fermenting temperatures.

My brewing area takes up my side of the master bedroom closet. Instead of clothes (which I keep in a different room), it has wire racks with all my brewing gear and ingredients, and underneath is space enough to hold at least eight fermenters. It is all very neat and organized so I can find the brewing tools I need in a heartbeat. My husband’s side of the closet is overflowing with clothes (organization is not his strong point), and we love the humor in it, but this is the best place in the house for my fermenters. It is not near an outside wall, and the temperature averages about 65°F (18°C). The floor is linoleum, and the back patio where I brew is right outside the bedroom door. It’s perfect!

A lot of energy is used to maintain fermenters at lagering temperatures. If your fermenting area is too hot for brewing lagers, you have several low-tech options for lowering the fermentation temperature. Rigging an evaporative cooling system is the simplest and is effective if you need to lower the temperature by up to 25°F (14°C). This system works well in hot, arid climates where temperatures need to be lowered from over 85°F (29°C) to under 70°F (21°C).

A basic evaporative cooling system involves setting the fermenter in a tub of water and wrapping a towel around it so the towel wicks moisture from the tub. Setting a fan (a solar-powered one, preferably!) so it blows a steady breeze across the towel completes the effect. Instead of a fan you can place the fermenter near a window or door that has some natural airflow (but out of direct sunlight).

To achieve much lower lagering temperatures without refrigeration, further measures are usually required. It is not too difficult to maintain temperatures of 45 to 55°F (7–13°C) by keeping the fermenter in a cold-water bath and regularly adding ice. Freeze water in plastic bottles and simply rotate them as needed to maintain the temperature (twice a day is usually enough). You can take this concept one step further and build a fermentation chamber, which is basically an insulated cooler large enough to fit your whole fermenter in.

Finally, a root cellar is a great option if you have the land. At depths of 5 to 50 feet, underground temperatures generally stay at about the annual temperature average for the region, which in many areas is between 50 and 55°F (10 and 13°C). This happens to be a decent temperature for lagering as well as for serving ales, which are more flavorful at this temperature than they are at the 45°F (7°C) that most refrigerators maintain.

If you have the space to dig a small root cellar, it will be useful for lagering throughout the year as well as for storing not only homebrew but vegetables and preserves. A root cellar can greatly reduce your overall reliance on refrigeration.