Chapter 6

Buckling Analysis

In this chapter, you will learn the following:

• Introduction to Buckling Analysis

• Buckling Analysis of a Pipe Support

• Buckling Analysis of a Beam

• Buckling Analysis of a Column

In earlier chapters, you have learned about performing the static analysis of various components and assemblies. In this chapter, you will learn about performing the buckling analysis.

Introduction to Buckling Analysis

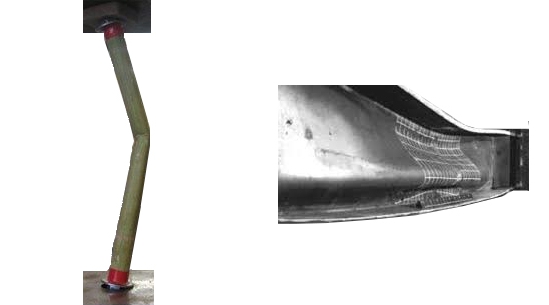

The buckling analysis is used to calculate the buckling load which is also known as the critical load. It is the load under which the model can start buckling even if the maximum stress developed in the model is within the yield strength of the material. Buckling refers to a larger deformation occurred due to the compressive axial loads acting on the structures such as long slender columns and thin sheet components, see Figure 6.1.

Figure 6.1

The minimum bucking load or critical load, when a structure can start bucking is calculated by the following formula:

F= π²EI / (KL)²

Where,

F= Minimum bucking load or Critical load

E = Modulus of elasticity

I = Area Moment of inertia of the cross-section of the structure

K = Structure (column) effective length, which depends on the end conditions

L = Length of the structure

It clear from the above formula that the buckling load does not depend upon the compressive strength of the material. As a result, the structure can buckle or fail, even if the maximum stress developed in the structure is within the compressive yield strength of the material. Also, on increasing the length of the structure, the force required to buckle the structure gets reduced.

In SOLIDWORKS Simulation, you can perform the buckling analysis of a structure to calculate the minimum bucking load factor and its associated buckling mode shape, when the structure can buckle under the compressive axial loads.

Case Study 1: Buckling Analysis of a Pipe Support

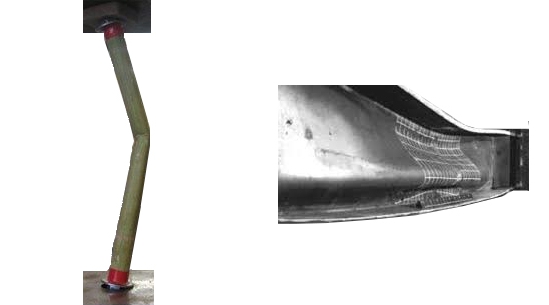

In this case study, you will perform the buckling analysis of a Pipe Support, see Figure 6.2 and determine its minimum bucking load.

Figure 6.2

Project Description

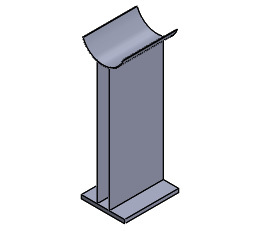

The Pipe Support is fixed at its bottom and the 9500 Newton compressive axial load is subjected on its top face, see Figure 6.3. The Pipe Support is made up of

Alloy Steel

material.

Figure 6.3

Project Summary

In this case study, you will run the buckling analysis of a Pipe Support and determine its buckling factor of safety under the applied compressive load. Also, you need to calculate the buckling load or critical load based on the buckling factor of safety.

Learning Objectives

In this case study, you will learn the following:

1. Downloading Files of Chapter 6

2. Opening the Pipe Support

3. Starting the Buckling Study

4. Applying the Material, Fixture, and Load

5. Generating the Mesh

6. Defining the Buckling modes

7. Running the Buckling Analysis

8. Displaying the Buckling Factor of Safety

9. Calculating the Buckling Load or Critical Load

10. Saving Results

Section 1: Downloading Files of Chapter 6

1. Login to the CADArtifex

website

(www.cadartifex.com)

with your user name and password. If you are a new user, first you need to register on CADArtifex website as a student.

2. After login to the CADArtifex website, click on

SOLIDWORKS Simulation > SOLIDWORKS Simulation 2018

. All resource files of this textbook appear in the respective drop-down lists.

3. Click on

Case Studies > C06 Case Studies

. The downloading of

Co6 Case Studies

file gets started. Once the downloading is complete, you need to unzip the downloaded file.

4. Save the unzipped

C06 Case Studies

file in the

Case Studies

folder inside the

SOLIDWORKS Simulation

folder.

Section 2: Opening the Pipe Support

1. Start SOLIDWORKS, if not already started.

2. Click on the

Open

button in the

Welcome

dialog box or the

Open

tool in the

Standard

toolbar. The

Open

dialog box appears.

3. Browse to the location

> SOLIDWORKS Simulation > Case Studies > C06 Case Studies > Case Study 1

. Next, select the

Pipe Support

and then click on the

Open

button in the dialog box. The Pipe Support is opened in SOLIDWORKS.

Section 3: Starting the Buckling Study

1. Click on the

Simulation

tab in the

Simulation

CommandManager

. The tools of the

Simulation

CommandManager

appear.

2. Click on the

New

Study

tool in the

Simulation

CommandManager

. The

Study

PropertyManager

appears at the left of the graphics area.

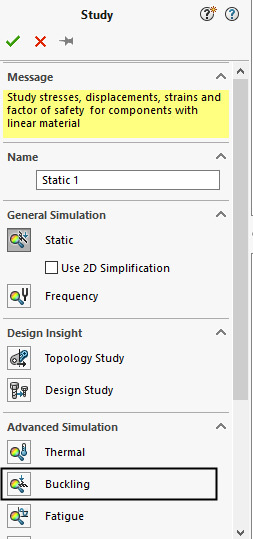

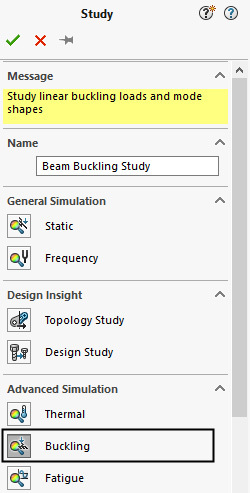

3. Click on the

Buckling

button in the

Advanced

Simulation

rollout of the

Study

PropertyManager

to perform the buckling analysis, see Figure 6.4.

Figure 6.4

4. Enter

Pipe Support

Buckling Study

in the

Study

name

field of the

Name

rollout in the PropertyManager.

5. Click on the green tick-mark button in the PropertyManager. The

Pipe Support

Buckling Study

is

added in the

Simulation Study Tree.

Section 4: Applying the Material, Fixture, and Load

Now, you need to apply the material, fixture and load to the model. The procedures to apply the material, fixture, and load in the Buckling analysis are the same as in the static analysis.

1. Invoke the

Material

dialog box by clicking on the

Apply

Material

tool in the

Simulation

CommandManager

and then apply the

Alloy Steel

material. Next, close the dialog box.

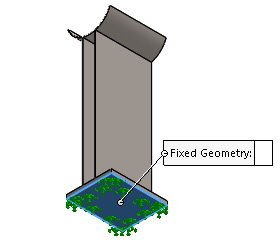

Now, you need to apply the Fixed Geometry fixture.

2. Right-click on the

Fixtures

option in the Simulation Study Tree and then click on the

Fixed

Geometry

tool in the shortcut menu appeared. The

Fixture

PropertyManager

appears.

3. Rotate the model such that you can view the bottom face of the Pipe Support model and then select it to apply the Fixed Geometry fixture, see Figure 6.5. Next, click on the green tick-mark button in the PropertyManager.

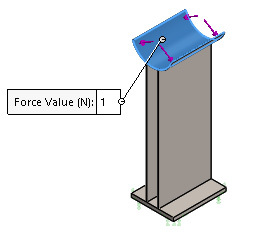

Now, you need to apply the compressive axial load on the top face of the model.

4. Right-click on the

External

Loads

option in the Simulation Study Tree and then click on the

Force

tool in the shortcut menu appeared. The

Force/Torque PropertyManager

appears.

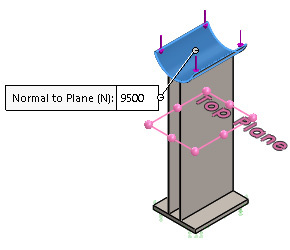

5. Change the orientation of the model to isometric and then select the top semi-cylindrical face of the Pipe Support model to apply the load, see Figure 6.6.

Figure 6.6

6. Select the

Selected direction

radio button in the PropertyManager. The

Face, Edge, Plane for Direction

field appears.

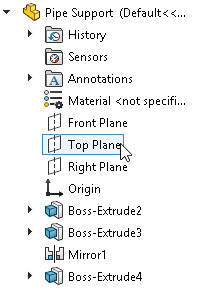

7. Expand the FeatureManager Design Tree, see Figure 6.7. Next, click on the

Top Plane

as the reference plane to define the direction of force.

8. Click on the

Normal to Plane

button in the

Force

rollout of the PropertyManager and then enter

9500

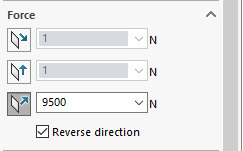

as the axial load acting on the model, see Figure 6.8.

Figure 6.8

9. Select the

Reverse

direction

check box in the

Force

rollout to reverse the direction of force downward, see Figure 6.9.

Figure 6.9

10. Click on the green tick-mark button in the PropertyManager. The specified compressive axial load is applied on the Pipe Support.

Section 5: Generating the Mesh

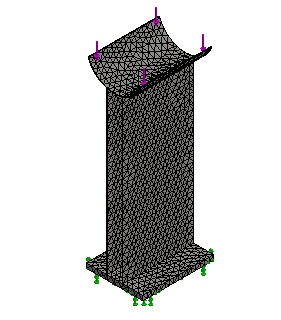

1. Generate the curvature-based mesh with the default mesh parameters by using the

Create Mesh

tool. Figure 6.10 shows the meshed model.

Figure 6.10

Section 6: Defining the Buckling modes

Now, you need to define the required number of buckling modes to be calculated by the program. By default, SOLIDWORKS Simulation calculates the first buckling mode of the model.

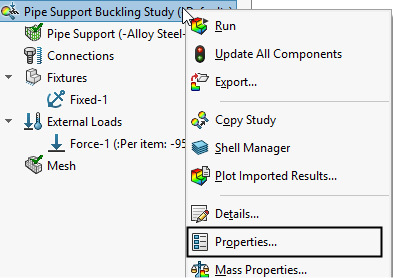

1. Right-click on the

Pipe Support Buckling Study

(

name of the study

)

in the Simulation Study Tree and then click on the

Properties

tool in the shortcut menu appears, see Figure 6.11. The

Buckling

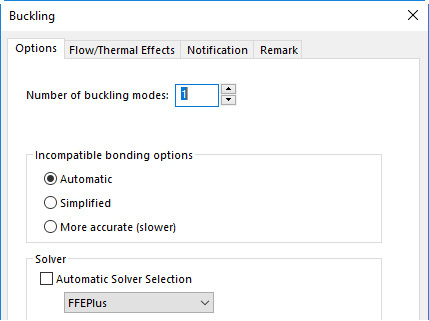

dialog box appears, see Figure 6.12.

Figure 6.11

Figure 6.12

2. Enter

5

in the

Number of buckling modes

field of the

Options

tab in the dialog box to calculate five different buckling safety factors and the associated buckling modes for the Pipe Support.

3. Click on the

OK

button in the dialog box.

Section 7: Running the Buckling Analysis

1. Click on the

Run This Study

tool in the

Simulation

CommandManager

. The

Pipe Support

Buckling Study

(

name of the study

)

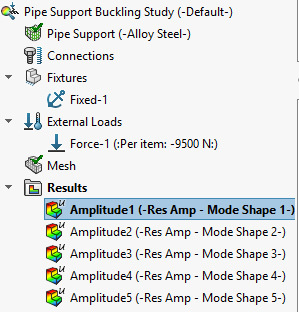

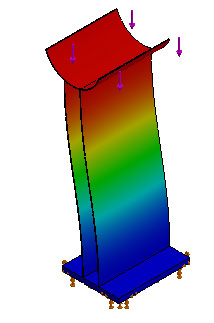

window appears which displays the progress of analysis. After the analysis completes, the

Results

folder is added in the Simulation Study Tree with the five different mode shapes, see Figure 6.13. By default, the

Amplitude1 (-Res Amp - Mode Shape 1-)

is

activated in the

Results

folder. As a result, the first buckling mode shape of the model, which occurs first when the model starts buckling, appears in the graphics area, see Figure 6.14.

Figure 6.13

Figure 6.14

You can also display the remaining buckling mode shapes of the model by double-clicking on the respective option in the

Results

folder of the Simulation Study Tree.

Section 8: Displaying the Buckling Factor of Safety

Now, you need to display the buckling factor of safety of the Pipe Support.

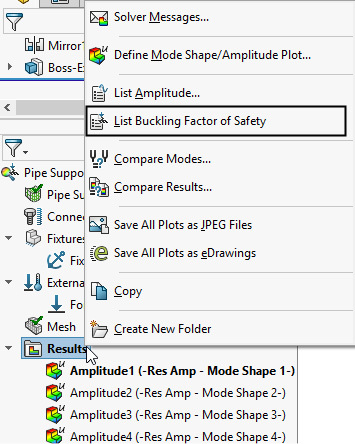

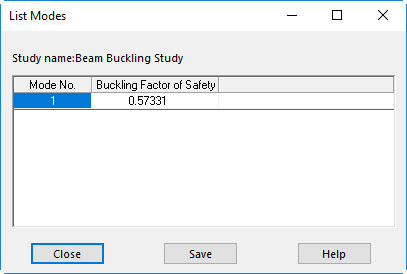

1. Right-click on the

Results

folder in the Simulation Study Tree and then click on the

List Buckling Factor of Safety

tool in the shortcut menu appeared, see Figure 6.15. The

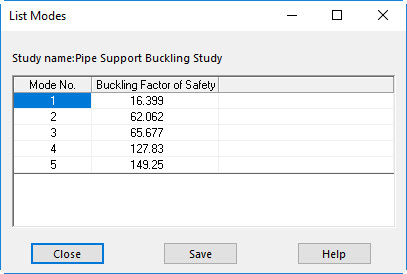

List Modes

dialog box appears, see Figure 6.16.

Figure 6.15

Figure 6.16

The

List Modes

dialog box displays the specified number of buckling modes and the associated buckling factor of safety of each mode. The first buckling load factor is always smaller than the other buckling load factors and for any given load, it occurs first. Therefore, you can calculate the buckling load or critical load when the model can start buckling by using the first buckling factor of safety.

In this study, the first calculated buckling factor of safety is

16.399

. It means that the design is safe.

NOTE:

The buckling load factor is the ratio of buckling/critical load to the applied load.

Buckling Load Factor = Buckling Load / Applied Load

If the buckling load factor is greater than 1, the design is considered to be safe. If the buckling load factor is equal to 1 then the buckling starts occurring in the design. If the buckling load factor is less than 1, the design is considered to be failure and the buckling occurs in the design.

2. Close the

List Modes

dialog box.

Section 9: Calculating the Buckling Load or Critical Load

Now, you need to calculate the buckling load when the Pipe Support start buckling.

1. Calculate the buckling load by using the following formula.

Buckling Load = Buckling Load Factor X Applied Load

=

16.399 X 9500 N

= 155790.5 N

The 155790.5 N load is the calculated buckling load or critical load when the Pipe Support can start buckling.

Section 10: Saving Results

Now, you need to save the model and its results.

1. Click on the

Save

tool in the

Standard

toolbar. The model and its results are saved in the location

> SOLIDWORKS Simulation > Case Studies > C06 Case Studies > Case Study 1

.

2. Close the SOLIDWORKS session.

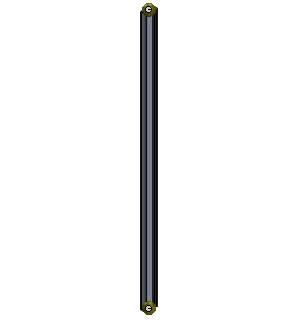

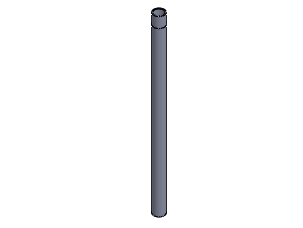

Case Study 2: Buckling Analysis of a Beam

In this case study, you will perform the buckling analysis of a long Beam, see Figure 6.17. Determine the bucking load or critical load when the Beam can start buckling.

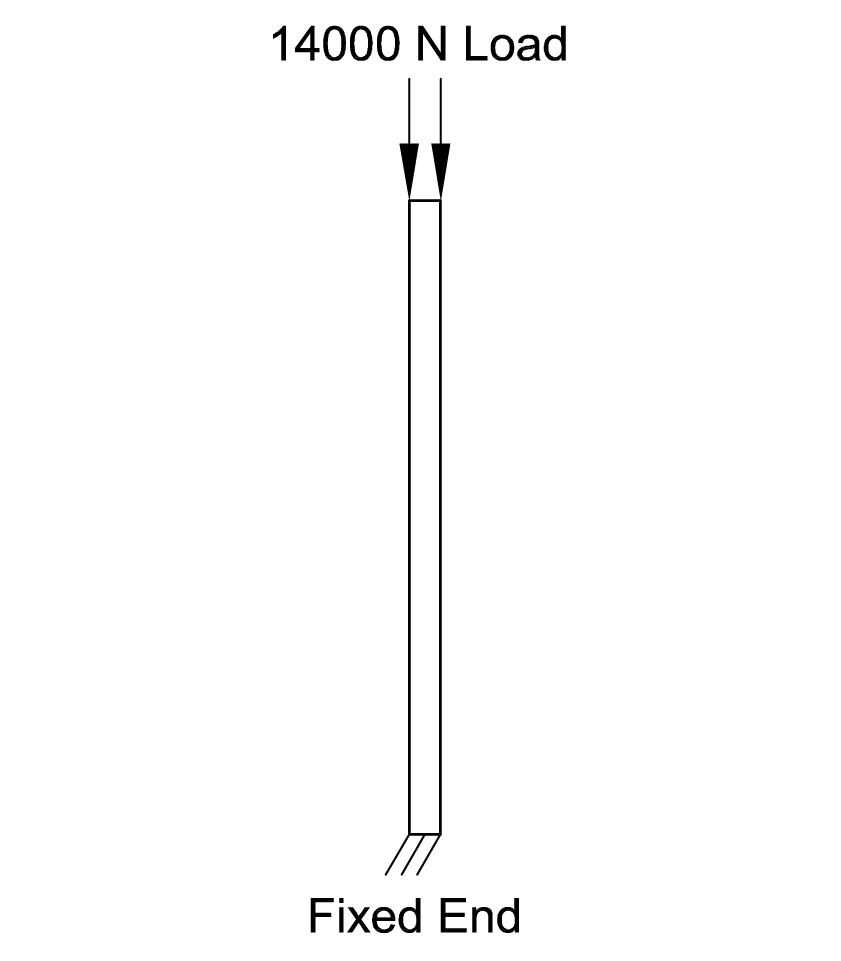

Project Description

The Beam is fixed at its bottom and the 14000 Newton compressive axial load is subjected on its top face, see Figure 6.18. The Beam is made up of

AISI 304

steel

material.

Figure 6.17

Figure 6.18

Project Summary

In this case study, you will run the buckling analysis of a beam and determine the buckling factor of safety of the beam under the applied compressive load. Also, you need to calculate the buckling load or critical load based on the buckling factor of safety of the beam.

Learning Objectives

In this case study, you will learn the following:

1. Starting the Buckling Analysis

2. Applying the Material, Fixture, and Load

3. Generating the Mesh

4. Running the Buckling Analysis

5. Displaying the Buckling Factor of Safety

6. Calculating the Buckling Load or Critical Load

7. Saving Results

Section 1: Starting the Buckling Analysis

1. Start SOLIDWORKS and then open the Beam model from the location

> SOLIDWORKS Simulation > Case Studies > C06 Case Studies > Case Study 2

.

NOTE:

You need to download the C06 Case Studies file by logging to the CADArtifex website (www.cadartifex.com), if not downloaded earlier.

2. When the Beam model is opened in SOLIDWORKS, click on the

Simulation

tab in the

Simulation

CommandManager

. The tools of the

Simulation CommandManager

appear.

3. Click on the

New

Study

tool in the

Simulation

CommandManager

. The

Study

PropertyManager

appears at the left of the graphics area.

4. Click on the

Buckling

button in the

Advanced

Simulation

rollout of the

Study

PropertyManager

to perform the buckling analysis, see Figure 619.

5. Enter

Beam

Buckling Study

in the

Study

name

field of the

Name

rollout in the PropertyManager, see Figure 619.

Figure 6.19

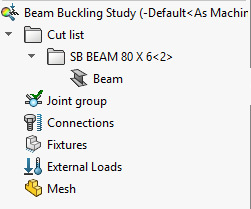

6. Click on the green tick-mark button in the PropertyManager. The

Beam Buckling Study

is

added in the

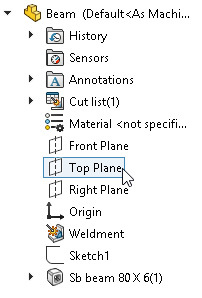

Simulation Study Tree, see Figure 6.20. Also, the joints appear on the beam member in the graphics area, see Figure 6.21. It is because, SOLIDWORKS Simulation, automatically identifies the geometry as a beam and calculates its joints.

Figure 6.20

Figure 6.21

Section 2: Applying the Material, Fixture, and Load

Now, you need to apply the material, fixture and load on the beam.

1. Invoke the

Material

dialog box by clicking on the

Apply Material

tool in the

Simulation

CommandManager

and then apply the

AISI 304

steel

material. Next, close the dialog box.

Now, you need to apply the Fixed Geometry fixture.

2. Right-click on the

Fixtures

option in the Simulation Study Tree and then click on the

Fixed

Geometry

tool in the shortcut menu appeared. The

Fixture PropertyManager

appears.

3. Select the yellow joints appeared at the bottom of the beam in the graphics area, see Figure 6.22. Next, click on the green tick-mark button in the PropertyManager. The Fixed Geometry fixture is applied at the bottom joint of the beam.

Figure 6.22

Now, you need to apply the compressive axial load on the top joint of the beam.

4. Right-click on the

External

Loads

option in the Simulation Study Tree and then click on the

Force

tool in the shortcut menu appeared. The

Force/Torque PropertyManager

appears, see Figure 6.23.

By default, the

Vertices,

Points

button is activated in the

Selection

rollout of the PropertyManager. As a result, you can select the vertices and points of the beam members to apply the load. On selecting the

Joints

button, you can select a beam joint to apply the load.

5. Click on the

Joints

button in the

Selection

rollout of the PropertyManager to select the beam joint for applying the load.

6. Select the top beam joint. The name of the selected beam joint appears in the field of the

Selection

rollout in the PropertyManager.

7. Click on the

Face, Edge, Plane for Direction

field of the

Selection

rollout in the PropertyManager. Next, expand the FeatureManager Design Tree and then click on the

Top Plane

as the reference plane to define the direction of force, see Figure 6.24.

Figure 6.24

8. Make sure that the

SI

is selected as the unit in the

Unit

drop-down list of the

Units

rollout in the PropertyManager.

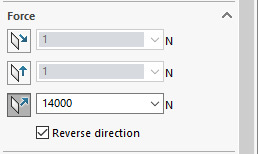

9. Click on the

Normal to Plane

button in the

Force

rollout of the PropertyManager and then enter

14000

as the axial load on the beam, see Figure 6.25.

Figure 6.25

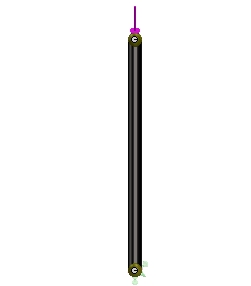

10. Select the

Reverse

direction

check box in the

Force

rollout to reverse the direction of force downward, see Figure 6.26.

Figure 6.26

11. Click on the green tick-mark button in the PropertyManager. The specified compressive axial load is applied on the beam.

Section 3: Generating the Mesh

1. Right-click on the

Mesh

option in the Simulation Study Tree and then click on the

Create

Mesh

tool in the shortcut menu appeared. The

Mesh Progress

window appears and the process of meshing the beam starts. After it is complete, the meshed beam with beam elements, which are represented by hollow cylinders, appear in the graphics area, see Figure 6.27.

Figure 6.27

Section 4: Running the Buckling Analysis

1. Click on the

Run This Study

tool in the

Simulation

CommandManager

. The

Beam

Buckling Study

(

name of the study

)

window appears which displays the progress of analysis. When it is complete, the

Results

folder is added in the Simulation Study Tree with the resultant amplitude of the first mode shape. Also, the first mode shape of the beam appears in the graphics area, see Figure 6.28.

Figure 6.28

Section 5: Displaying the Buckling Factor of Safety

Now, you need to display the buckling factor of safety of the beam.

1. Right-click on the

Results

folder in the Simulation Study Tree and then click on the

List Buckling Factor of Safety

tool in the shortcut menu appeared. The

List Modes

dialog box appears, see Figure 6.29.

NOTE:

The

List Modes

dialog box displays the number of specified buckling modes and the associated buckling factor of safety of each mode. By default, SOLIDWORKS Simulation, calculates the first buckling factor of safety. It is because, the first buckling load factor is always smaller and for any given load, it occurs first. However, as discussed in the Case Study 1, you can specify multiple buckling modes and the associated buckling factors of safety to be calculated by the program.

Figure 6.29

The calculated buckling factor of safety is

0.57331

. It means that the design is considered to be failure and the buckling starts when the applied load is equal to

8026.34 N

[14000 (applied load) X 0.57331 (buckling load factor)]. Note that you may find difference in the results due to the service packs installed on your system.

Section 6: Calculating the Buckling Load or Critical Load

Now, you need to calculate the buckling load when the beam can start buckling.

1. Calculate the buckling load by using the following formula.

Buckling Load = Buckling Load Factor X Applied Load

= 0.57331 X 14000

= 8026.34 N

Section 7: Saving the Results

Now, you need to save the results.

1. Click on the

Save

tool in the

Standard

toolbar. The model and its results are saved in the location

> SOLIDWORKS Simulation > Case Studies > C06 Case Studies > Case Study 2

.

2. Close the SOLIDWORKS Simulation session.

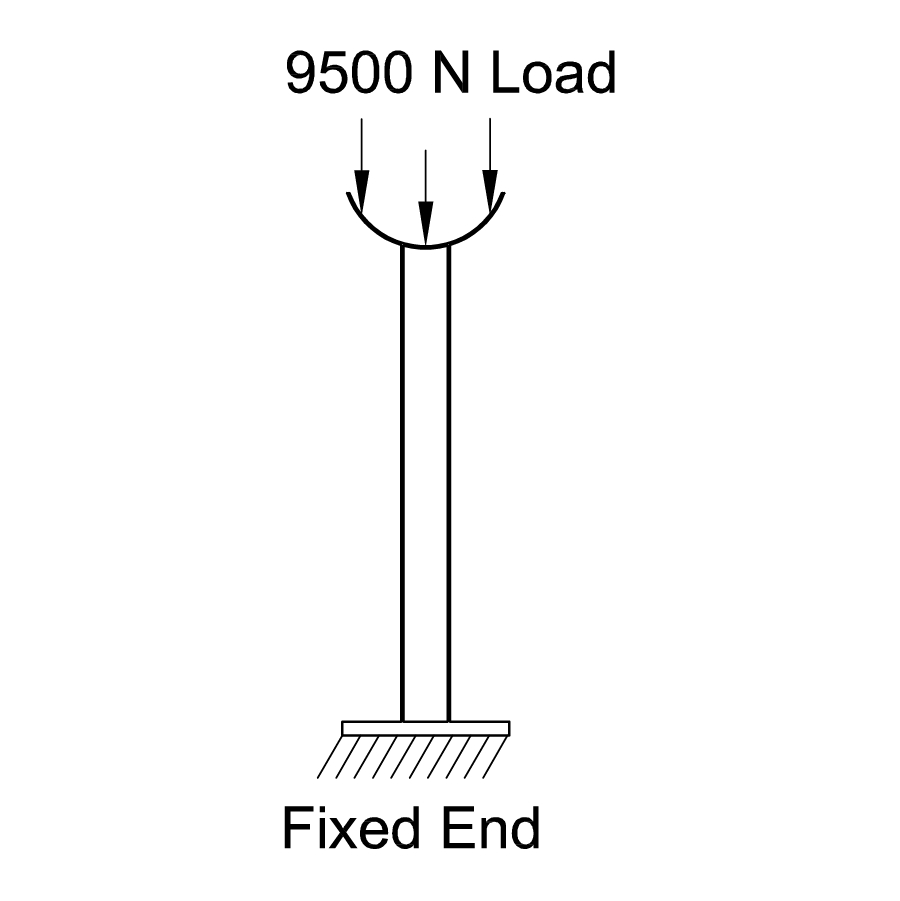

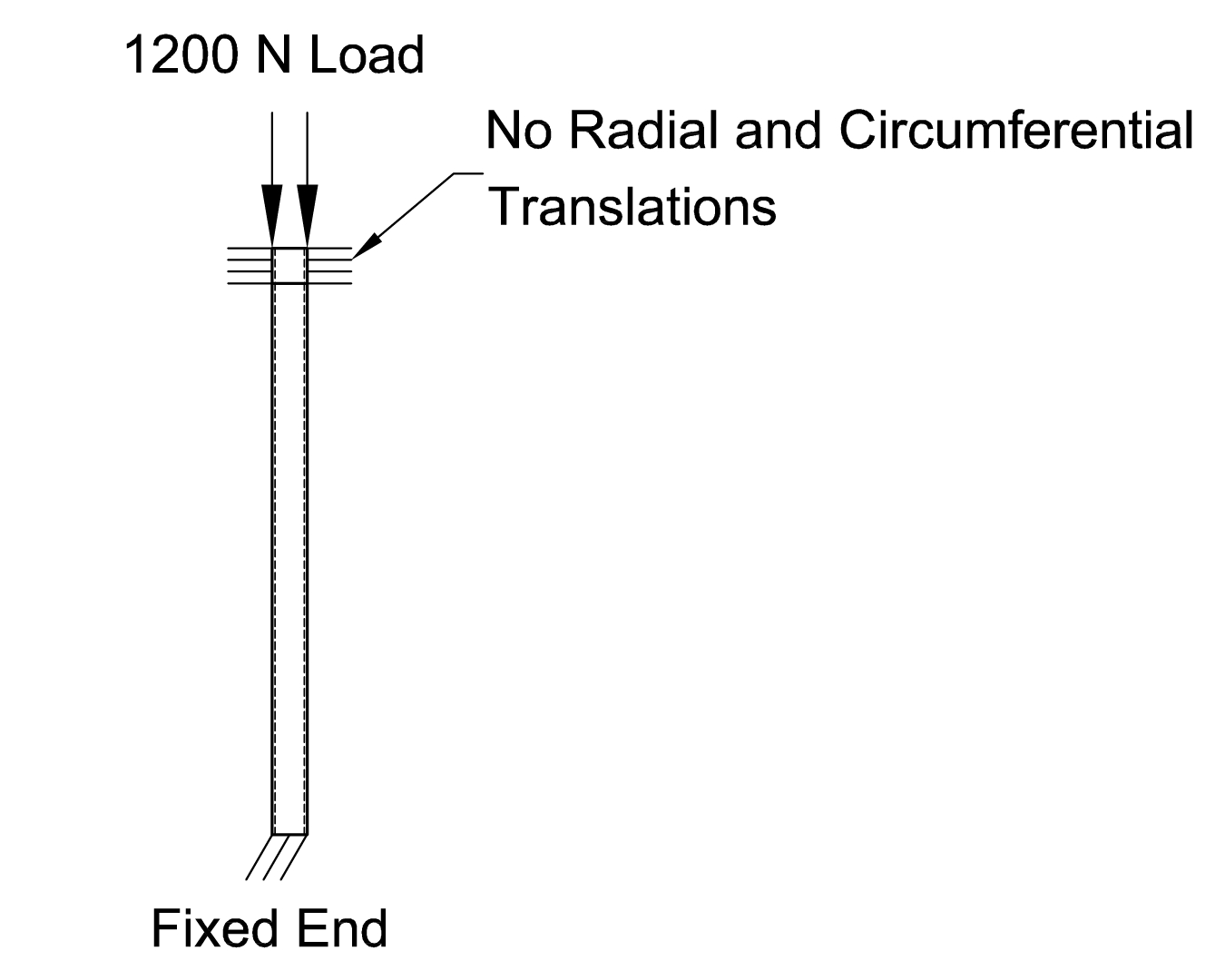

Hands-on Test Drive 1: Buckling Analysis of a Column

Perform the buckling analysis of a long hollow column shown in Figure 6.30 and determine the buckling load or critical load when the column can start buckling.

Figure 6.30

Project Description

The column is clamped at its both ends (top and bottom). You need to apply the Fixed Geometry fixture at the bottom face of the column to represent its clamped connection with the ground, see Figure 6.31. To represent the clamped connection at the top of the column, you need to restrict the radial and circumferential translations of the column at the top so that the column can only translate along its axial direction due to the applied load, see Figure 6.31. The column is subjected to the 1200 Newton compressive axial load on its top, see Figure 6.31. The column is made up of Alloy Steel

material.

Figure 6.31

Hint:

To restrict the radial and circumferential translations of the column at the top, you can apply the On Cylindrical Faces fixture and specify the 0 values for the radial and circumferential translations.

Project Summary

In this case study, you will run the buckling analysis of a column which is clamped at its both ends and determine the buckling factor of safety of the beam under the applied compressive load. You also need to calculate the buckling load or critical load based on the minimum buckling factor of safety of the column when it can start buckling.

Summary

In this chapter, you have learned about the concept of the buckling analysis. You have also learned about performing the buckling analysis of various case studies. Also, you have learned how to calculate the buckling load or critical load when the structure can start buckling.

Questions

• The ________ refers to the larger deformation occurred on a structure due to the compressive axial loads

.

• The buckling load is also known as the ________ , when the model can start buckling

.

• A structure can buckle even if the maximum stress developed in the structure is within the ________ strength of the material.

• The ________ field of the

Buckling

dialog box is used to specify the number of buckling modes to be calculated by the program.

• The ________ tool is used to display the specified number of buckling modes and the associated buckling factor of safety.

• For any given load, the ________ calculated buckling factor of safety is always smaller than the other buckling load factors.

• The ________ dialog box displays the specified number of buckling modes and the associated buckling factor of safety of each mode.

• The buckling load factor is the ratio of ________ load to the ________ load.

• If the buckling load factor is greater than 1, the design is consider to be ________.

• If the buckling load factor is less than 1, the design is consider to be ________ and the buckling occurs in the design due to the applied load.

• On increasing the length of a structure, the force required to buckle it gets ________.

• The buckling load or critical load does not depend upon the ________ strength of the material.

• You can calculate the buckling load or critical load of a structure, when it can starts buckling, by using the ________ buckling factor of safety.