Chapter 8

Frequency Analysis

In this chapter, you will learn the following:

• Introduction to Frequency Analysis

• Frequency Analysis of a Wine Glass

• Frequency Analysis of a Pulley Assembly

• Frequency Analysis of a Cantilever Beam

In this chapter, you will learn about frequency analysis, which is used to calculate the natural frequencies of an object. The natural frequencies also known as resonant frequencies. The natural or resonant frequency of an object is defined as the energy required to produce vibration in the object. Every object has different natural frequencies depending on its geometry, material properties, and boundary conditions. A real-world object has an infinite number of natural frequencies in which it vibrates. However, in the finite element analysis, the natural frequencies of an object are considered equal to the number of its degrees of freedom. Each natural frequency of an object is associated with a shape called mode shape, which occurs when the object vibrates at that frequency. When an object vibrates due to an external force with a frequency which matches with one of its natural frequencies, the object undergoes large displacements and stresses, which causes failure of the object. This phenomena of failure is known as resonance. For example, a structure like bridge vibrates due to a frequency that is generated due to many reasons like traffic, high wind speed, or a high footfall. When this frequency matches with one of its natural frequencies of the vibrations then the bridge can fall down.

Introduction to Frequency Analysis

The frequency analysis is used to calculate the natural frequencies of an object and their associated mode shapes. By knowing the natural frequencies of an object, you can ensure that the actual operating frequency of an object will not coincide with any of its natural frequencies to avoid the failure of the object due the resonance.

Case Study 1: Frequency Analysis of a Wine Glass

In this case study, you will perform the frequency analysis of a Wine Glass, see Figure 8.1 and determine its first three natural/resonant frequencies and their associated mode shapes. Also, determine the mass participation in the X, Y, and Z directions.

Figure 8.1

Project Description

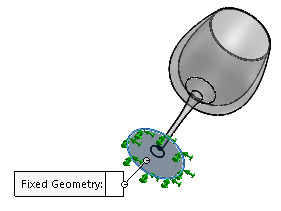

Fix the Wine Glass at its bottom to represent its operation conditions, see Figure 8.2. The Wine Glass is made up of

Glass

material.

Figure 8.2

Project Summary

In this case study, you will run the frequency analysis on a Wine Glass without applying any external force.

NOTE:

You can run the frequency analysis with or without applying the fixtures and loads. However, it is recommended to apply the required fixtures to the model to represent its real operating conditions. Although, applying external loads to the model is optional but, if you do so, their effects are considered in the frequency analysis.

Learning Objectives

In this case study, you will learn the following:

1. Downloading Files of Chapter 8

2. Opening the Wine Glass

3. Starting the Frequency Analysis

4. Defining Properties for the Frequency Analysis

5. Applying the Material and Fixture

6. Generating the Mesh

7. Running the Frequency Analysis

8. Displaying Natural/Resonant Frequencies

9. Viewing Different Mode Shapes

10. Displaying the Mass Participation

11. Saving Results

Section 1: Downloading Files of Chapter 8

1. Login to the

CADArtifex

website

(www.cadartifex.com)

with your user name and password.

2. After login to the CADArtifex website, click on

SOLIDWORKS Simulation > SOLIDWORKS Simulation 2018

. All resource files of this textbook appear in the respective drop-down lists.

3. Click on

Case Studies > C08 Case Studies

. The downloading of

Co8 Case Studies

file gets started. Once the downloading completed, you need to unzip the downloaded file.

4. Save the unzipped

C08 Case Studies

file in the

Case Studies

folder inside the

SOLIDWORKS Simulation

folder.

Section 2: Opening the Wine Glass

1. Start SOLIDWORKS, if not already started.

2. Click on the

Open

button in the

Welcome

dialog box or the

Open

tool in the

Standard

toolbar. The

Open

dialog box appears.

3. Browse to the location

> SOLIDWORKS Simulation > Case Studies > C08 Case Studies > Case Study 1

of the local drive of your system. Next, select the

Wine Glass

and then click on the

Open

button in the dialog box. The Wine Glass is opened in SOLIDWORKS.

Section 3: Starting the Frequency Analysis

1. Click on the

Simulation

tab in the

Simulation

CommandManager

. The tools of the

Simulation

CommandManager

appear.

2. Click on the

New

Study

tool in the

Simulation

CommandManager

. The

Study

PropertyManager

appears at the left of the graphics area.

3. Click on the

Frequency

button in the

General

Simulation

rollout of the PropertyManager to perform the frequency analysis, see Figure 8.3.

4. Enter

Wine Glass Frequency Study

in the

Study

name

field of the

Name

rollout in the PropertyManager, see Figure 8.3.

5. Click on the green tick-mark button in the PropertyManager. The

Wine Glass Frequency Study

is

added in the

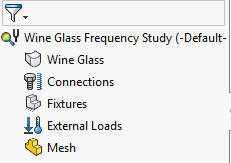

Simulation Study Tree, see Figure 8.4.

Figure 8.4

Section 4: Defining Properties for the Frequency Analysis

Before you start performing the frequency analysis, you need to define its properties.

1. Right-click on the

Wine Glass Frequency Study

(

name of the study

)

in the Simulation Study Tree and then click on the

Properties

tool in the shortcut menu appeared, see Figure 8.5. The

Frequency

dialog box appears, see Figure 8.6.

Figure 8.5

Figure 8.6

2. Enter

3

in the

Number of frequencies

field of the

Options

area in the dialog box to calculate first three natural frequencies of the Wine Glass.

Tip:

You can also calculate the frequencies closest to the frequency of your interest. For doing so, you need to select the

Calculate frequencies closest to: (Frequency Shift)

check box in the

Options

area of the dialog box and then enter the frequency value of your interest. The

Upper bound frequency

radio button is used to specify an upper limit for the frequencies to be calculated. On doing so, the program calculates the frequencies which are below the specified limit.

3. Click on the

OK

button in the dialog box. The first three number of frequencies to be calculated are defined.

Section 5: Applying the Material and Fixture

Now, you need to apply the material and fixture to the model.

1. Invoke the

Material

dialog box by clicking on the

Apply

Material

tool in the

Simulation

CommandManager

.

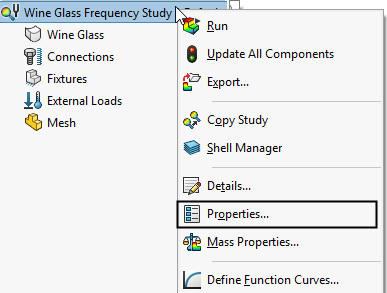

2. Expand the

Other Non-metals

category of the

SOLIDWORKS Materials

library in the

Material

dialog box and then click on the

Glass

material, see Figure 8.7. All the properties of the Glass material appears on the right panel of the dialog box, see Figure 8.7.

Figure 8.7

3. Click on the

Apply

button and then click on the

Close

button in the

Material

dialog box. The Glass material is applied to the model and its appearance changes, accordingly in the graphics area.

Now, you need to apply the Fixed Geometry fixture.

4. Right-click on the

Fixtures

option in the Simulation Study Tree and then click on the

Fixed

Geometry

tool in the shortcut menu appeared. The

Fixture

PropertyManager

appears.

5. Rotate the model such that you can view its bottom face and then select it to apply the Fixed Geometry fixture, see Figure 8.8.

Figure 8.8

6. Click on the green tick-mark button in the PropertyManager. The Fixed Geometry fixture is applied to the bottom face of the Wine Glass. Now, change the orientation of the model back to isometric.

Figure 8.9

Section 6: Generating the Mesh

Now, you need to generate the mesh on the model.

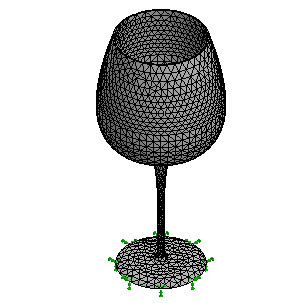

1. Generate the curvature-based mesh with the default mesh parameters by using the

Create Mesh

tool. Figure 8.9 shows the meshed model.

Section 7: Running the Frequency Analysis

Now, you need to run the static study.

1. Click on the

Run This Study

tool in the

Simulation

CommandManager

. The

Wine Glass Frequency Study

(

name of the study

)

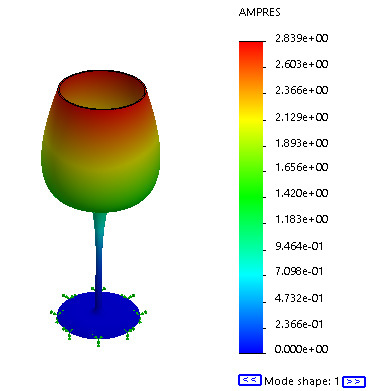

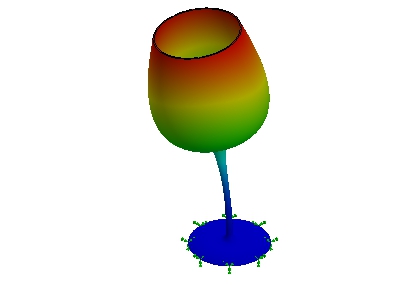

window appears which displays the progress of analysis. After the process of running the analysis completes, the

Results

folder is added in the Simulation Study Tree with the amplitude results of specified number of mode shapes. By default, the first mode shape is activated. As a result, the mode shape and the resultant amplitude plot of the first natural frequency appear in the graphics area, see Figure 8.10.

Figure 8.10

Section 8: Displaying Natural/Resonant Frequencies

Now, you need to display the natural/resonant frequencies of the Wine Glass.

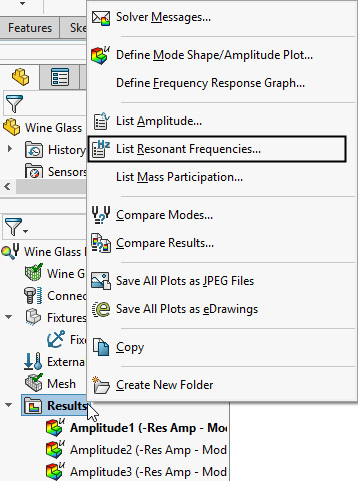

1. Right-click on the

Results

folder in the Simulation Study Tree and then click on the

List Resonant

Frequencies

tool in shortcut menu appeared, see Figure 8.11. The

List Modes

window appears, see Figure 8.12.

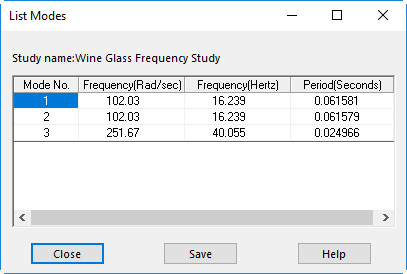

Figure 8.11

Figure 8.12

The

List Modes

window displays the list of calculated natural/resonant frequencies of the model associated with the respective mode numbers in Rad/sec and Hertz. Also, it displays the corresponding period in seconds for each natural frequency, refer to Figure 8.12.

2. Review the calculated natural frequency of the Wine Glass for different mode numbers. The mode number 1 has the frequency of 6.239 hertz, the mode number 2 has the frequency of 16.239 hertz, and mode number 3 has the frequency of 40.055. You need to ensure that the Wine Glass does not operate in the frequency which matches with any one of its calculated natural frequencies to avoid the failure due to the resonance.

3. Click on the

Save

button in the

List Modes

window. The

Save As

dialog box appears. In this dialog box, browse to the location where you want to save the calculated results of the natural frequencies. Next, click on the

Save

button in the dialog box. The results file is saved with the

.csv

file extension in the specified location. You can open the

.csv

files in the Microsoft Excel.

4. Click on

Close

button in the

List

Modes

window to close it.

Section 9: Viewing Different Mode Shapes

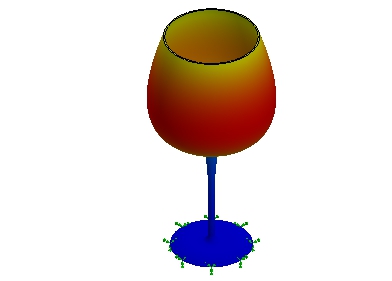

1. By default, the

Amplitude1 (-Res Amp - Mode Shape 1-)

result

is activated in the

Results

folder of the Simulation Study Tree. As a result, the mode shape 1 of the Wine Glass appears in the graphics area. To display the mode shapes 2 and 3, double-click on their respective results in the Simulation Study Tree. Figures 8.13 and 8.14 show the mode shapes 2 and 3, respectively.

Figure 8.13

Figure 8.14

Tip:

You can rotate the model to view the mode shapes of the model at different orientations.

Section 10: Displaying the Mass Participation

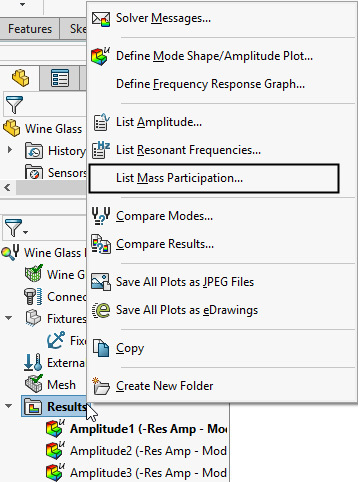

1. Right-click on the

Results

folder in the Simulation Study Tree and then click on the

List

Mass

Participation

tool in the shortcut menu appeared, see Figure 8.15. The

Mass

Participation

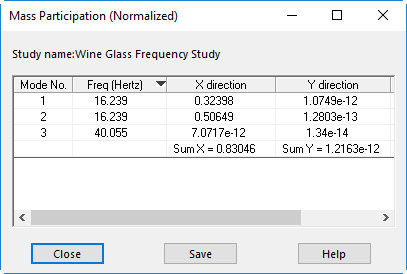

window appears, see Figure 8.16.

Figure 8.15

Figure 8.16

The

Mass Participation

window displays the list of natural/resonant frequencies and the mass participation in the X, Y, and Z directions for each mode number.

2. Review the mass participation for each mode number in the

Mass Participation

window. For example, the mass participation for the mode number 1 is approximately 0.32398 in the X-direction, 1.0749e-12 in the Y-direction, and 0.50649 in the Z-direction.

Section 11: Saving Results

Now, you need to save the model and its results.

1. Click on the

Save

tool in the

Standard

toolbar. The model and its results are saved in the location

> SOLIDWORKS Simulation > Case Studies > C08 Case Studies > Case Study 1

.

2. Close the SOLIDWORKS session.

Case Study 2: Frequency Analysis of a Pulley Assembly

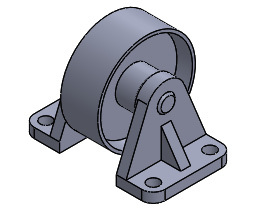

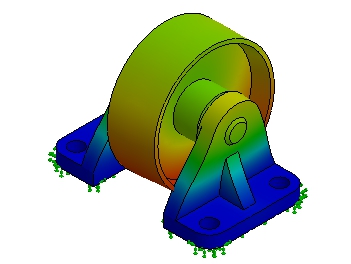

In this case study, you will perform the frequency analysis of a Pulley Assembly, see Figure 8.17 and determine its first five natural/resonant frequencies and their associated mode shapes.

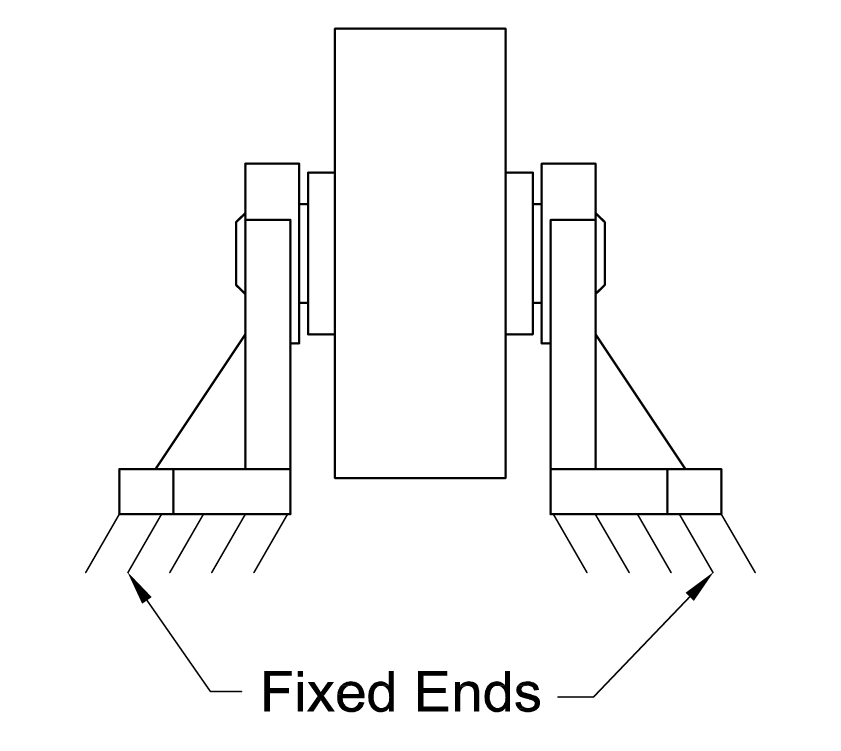

Project Description

Both the Support components of the Pulley Assembly are fixed at the bottom, see Figure 8.18. All the components of the Pulley Assembly are made up of

Alloy Steel (SS)

material.

Figure 8.18

Project Summary

In this case study, you will run the frequency analysis on a Pulley Assembly without applying any external force.

NOTE:

You can run the frequency analysis with or without applying the fixtures and loads. However, it is recommended to apply the required fixtures to the model to represent its real operating conditions. Although, applying external loads to the model is optional but, if you do so, their effects are considered in the frequency analysis.

Learning Objectives

In this case study, you will learn the following:

1. Starting the Frequency Analysis

2. Defining Properties for the Frequency Analysis

3. Applying Materials and Fixtures

4. Generating the Mesh

5. Running the Frequency Analysis

6. Displaying Natural/Resonant Frequencies

7. Viewing Different Mode Shapes

8. Saving Results

Section 1: Starting the Frequency Analysis

1. Start SOLIDWORKS and then open the Pulley Assembly from the location

> SOLIDWORKS Simulation > Case Studies > C08 Case Studies > Case Study 2

.

NOTE:

You need to download the C08 Case Studies file which contains the files of this chapter by logging to the CADArtifex website (www.cadartifex.com), if not downloaded earlier.

2. Click on the

Simulation

tab in the

Simulation

CommandManager

. The tools of the

Simulation

CommandManager

appear.

3. Click on the

New Study

tool in the

Simulation

CommandManager

. The

Study

PropertyManager

appears on the left of the graphics area.

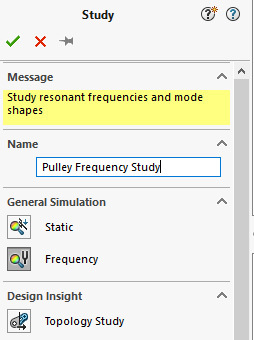

4. Click on the

Frequency

button in the

General

Simulation

rollout of the PropertyManager to perform the frequency analysis, see Figure 8.19.

5. Enter

Pulley

Frequency

Study

in the

Study

name

field of the

Name

rollout in the PropertyManager, see Figure 8.19.

Figure 8.19

6. Click on the green tick-mark button in the PropertyManager. The

Pulley Frequency Study

is

added in the

Simulation Study Tree.

Section 2: Defining Properties for the Frequency Analysis

Before you start performing the frequency analysis, you can define its properties.

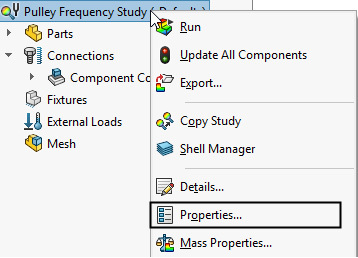

1. Right-click on the

Pulley Frequency Study

(

name of the study

)

in the Simulation Study Tree and then click on the

Properties

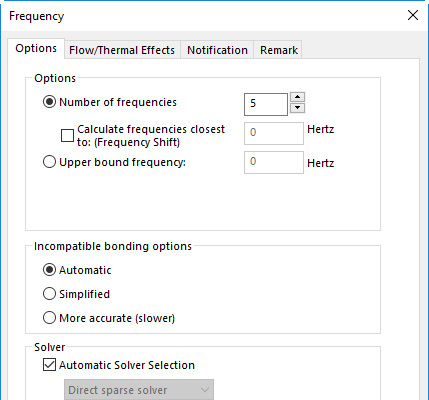

tool in the shortcut menu appeared, see Figure 8.20. The

Frequency

dialog box appears, see Figure 8.21.

Figure 8.20

Figure 8.21

2. Make sure that the

5

is entered in the

Number of frequencies

field of the

Options

area in the dialog box to calculate the first five natural frequencies of the Pulley Assembly.

3. Click on the

OK

button in the dialog box.

Section 3: Applying Materials and Fixtures

Now, you need to apply the materials and fixtures to the model.

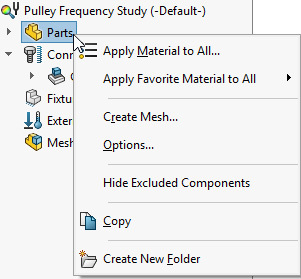

1. Right-click on the

Parts

folder in the Simulation Study Tree and then click on the

Apply

Material to All

tool in the shortcut menu appeared, see Figure 8.22. The

Material

dialog box appears.

Figure 8.22

2. Select the

Alloy Steel (SS)

material in the

Steel

category of the

SOLIDWORKS Materials

library in the dialog box.

3. Click on the

Apply

button and then the

Close

button in the

Material

dialog box. The Alloy Steel (SS) material is applied to all the components of the assembly.

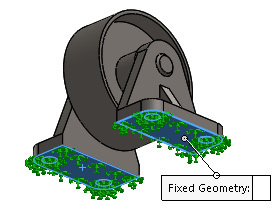

Now, you need to apply the Fixed Geometry fixture.

4. Right-click on the

Fixtures

option in the Simulation Study Tree and then click on the

Fixed Geometry

tool in the shortcut menu appeared. The

Fixture

PropertyManager

appears.

5. Rotate the assembly such that you can view its bottom faces. Next, select the bottom faces of both the Support components of the assembly to apply the Fixed Geometry fixture, see Figure 8.23.

Figure 8.23

6. Click on the green tick-mark button in the PropertyManager. The Fixed Geometry fixture is applied to the selected faces. Now, change the orientation of the assembly back to isometric.

Section 4: Generating the Mesh

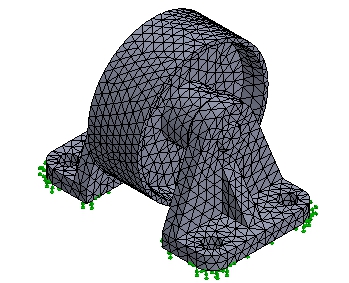

1. Generate the curvature-based mesh with default mesh parameters by using the

Create Mesh

tool. Figure 8.24 shows the meshed assembly.

Figure 8.24

Section 5: Running the Frequency Analysis

1. Click on the

Run This Study

tool in the

Simulation

CommandManager

. The

Pulley Frequency Study

(

name of the study

)

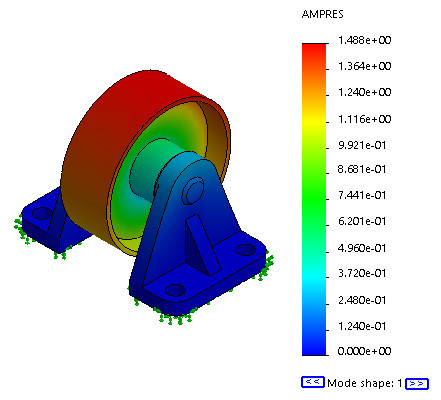

window appears which displays the progress of analysis. After the process of running the analysis is complete, the

Results

folder is added in the Simulation Study Tree. By default, the mode shape and the resultant amplitude plot of the first natural frequency appear in the graphics area, see Figure 8.25.

Figure 8.25

Section 6: Displaying Natural/Resonant Frequencies

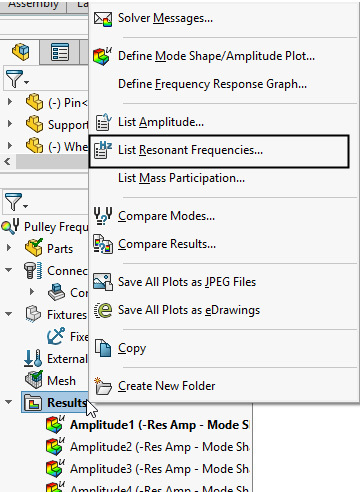

Now, you need to display the natural/resonant frequencies of the Pulley Assembly.

1. Right-click on the

Results

folder in the Simulation Study Tree and then click on the

List

Resonant

Frequencies

tool in shortcut menu appeared, see Figure 8.26. The

List

Modes

window appears, see Figure 8.27.

Figure 8.26

Figure 8.27

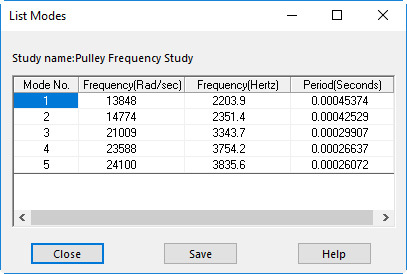

The

List Modes

window displays a list of calculated natural/resonant frequencies in Rad/sec and Hertz for each mode number. Besides, it displays the corresponding period in seconds for each mode number, see Figure 8.27.

2. Review the calculated natural frequency of the Pulley Assembly for each mode number. The mode number 1 has the frequency of approximate 2203.9 hertz and the mode number 2 has the frequency of approximate 2351.4 hertz. You need to ensure that the Pulley Assembly does not operate in the frequency which matches with any of its calculated natural frequencies to avoid the failure due to the resonance. Next, close the

List Modes

window.

Section 7: Viewing Different Mode Shapes

1. By default, the

Amplitude1 (-Res Amp - Mode Shape 1-)

result

is activated in the

Results

folder of the Simulation Study Tree. As a result, the mode shape 1 of the Pulley Assembly appears in the graphics area, see Figure 8.28. To display the other mode shapes, double-click on the respective results in the Simulation Study Tree. Figure 8.29 shows the mode shape 2 of the assembly.

Figure 8.28

Figure 8.29

Section 8: Saving Results

1. Click on the

Save

tool in the

Standard

toolbar. The model and its results are saved in the location

> SOLIDWORKS Simulation > Case Studies > C08 Case Studies > Case Study 2

.

2. Close the SOLIDWORKS session.

Hands-on Test Drive 1: Frequency Analysis of a Cantilever Beam

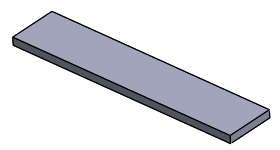

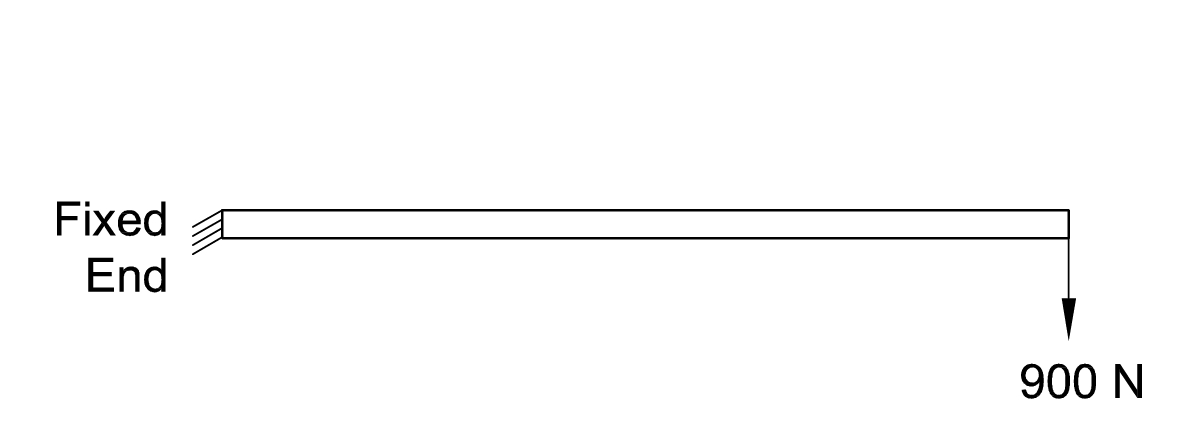

Perform the frequency analysis of a Cantilever Beam, see Figure 8.30 and determine its first five natural/resonant frequencies and their associated mode shapes.

Figure 8.30

Project Description

The Cantilever Beam is fixed at its left end and the downward load of 900 N is acting on its free end (right), see Figure 8.31. The Cantilever Beam is made up of

AISI 1035 Steel (SS)

material.

Figure 8.31

Project Summary

In this case study, you will run the frequency analysis on a Cantilever Beam with 900 N download load on its right end.

Summary

In this chapter, you have learned how to perform the frequency analysis to calculate the natural/resonant frequencies, the mode shapes associated to each natural frequencies, and the mass participations in X, Y, and Z directions.

Questions

•

The natural frequencies of an object are also known as

________

frequencies.

•

Every object has different natural frequencies depending on its

________

,

________, and ________

.

•

Each natural frequency of an object is associated with a shape called

________

shape.

•

When an object vibrates due to an external force with a frequency which matches with one of its natural frequencies, the object undergoes large displacements and stresses due to

________

.

•

The

________

tool is used to invoke the

List Modes

window, which displays the list of calculated natural frequencies.

•

The

________

tool is used to invoke the

Mass Participation

window, which displays the list of natural frequencies and the mass participation in the X, Y, and Z directions.

•

You can save the results of the natural frequencies in an external file having

________

file extension.