Chapter 9

Drop Test Analysis

In this chapter, you will learn the following:

• Introduction to Drop Test Analysis

• Drop Test Analysis of a Cylinder

• Drop Test Analysis of a Helmet

• Drop Test Analysis of a Hard Drive

In earlier chapters, you have learned about the failure of a design due to the stresses developed beyond the yield strength of the material, which is also known as the material failure of a design. You have also learned about the failure of a design due to buckling and fatigue. In this chapter, you will learn about the failure of a design due to falling on a floor. In real-world conditions, the most common failure of many products are due to the accidental drop during transport, installation, repairing, or handling. Therefore, it is important to design a product that is impact resistant by performing the drop test from specific height or velocity.

Introduction to Drop Test Analysis

The drop test analysis is used to analyze the effect of dropping an object (part or assembly) on a rigid or flexible floor. In this analysis, SOLIDWORKS Simulation calculates the impact of a part or an assembly with the floor.

Case Study 1: Drop Test Analysis of a Cylinder

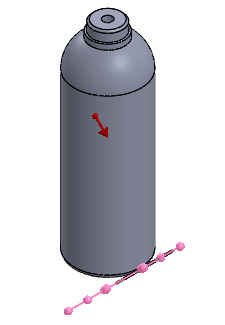

In this case study, you will perform the drop test analysis of a Cylinder, see Figure 9.1 and evaluate its effect of dropping on a rigid floor from the height of 2 feet.

Figure 9.1

Project Description

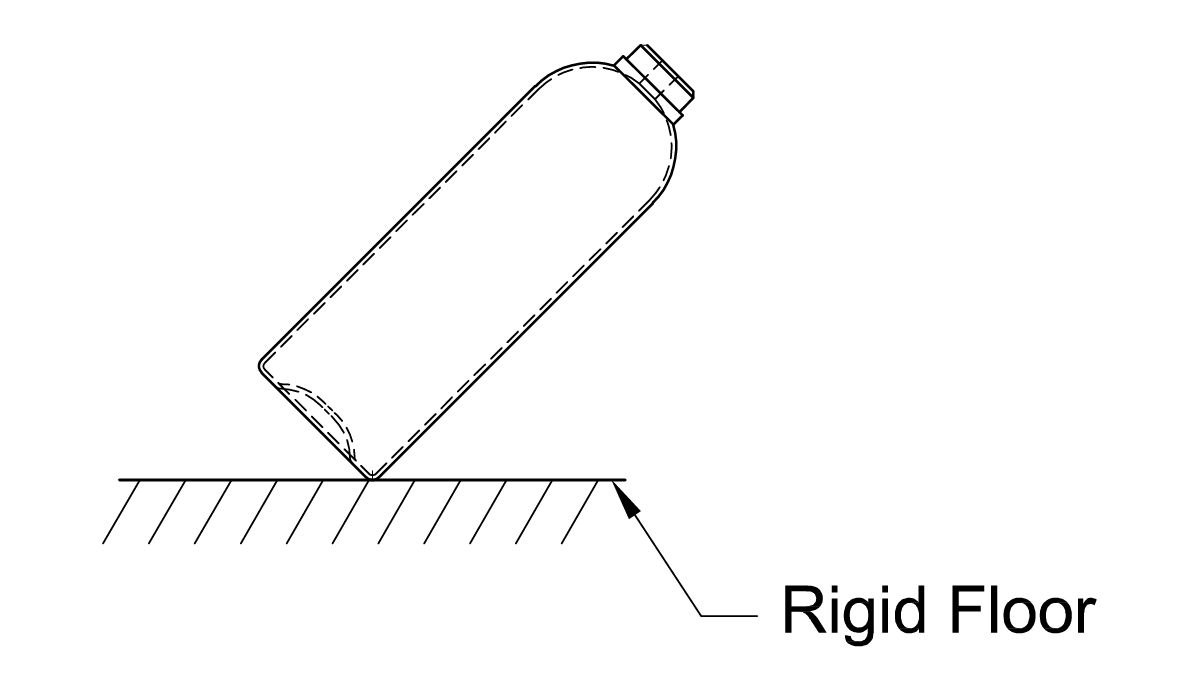

Determine the impact of the Cylinder with the rigid floor when falling from the height of 2 feet at an angle, see Figure 9.2. Note that the 2 feet height is measured from the lowest point of the Cylinder. The Cylinder is made up of

Plain Carbon Steel

material.

Figure 9.2

Project Summary

In this case study, you will run the drop test analysis on a Cylinder. In drop test, you no need to define any boundary conditions (fixtures and loads).

Learning Objectives

In this case study, you will learn the following:

1. Downloading Files of Chapter 9

2. Opening the Cylinder

3. Starting the Drop Test Analysis

4. Defining Drop Test Setup

5. Applying the Material

6. Defining Result Options

7. Generating the Mesh

8. Running the Drop Test Study

9. Animating the Stress Result

10. Saving Results

Section 1: Downloading Files of Chapter 9

1. Login to the

CADArtifex

website

(www.cadartifex.com)

with your user name and password.

2. After login to the CADArtifex website, click on

SOLIDWORKS Simulation > SOLIDWORKS Simulation 2018

. All resource files of this textbook appear in the respective drop-down lists.

3. Click on

Case Studies > C09 Case Studies

. The downloading of

Co9 Case Studies

file gets started. Once the downloading completed, you need to unzip the downloaded file.

4. Save the unzipped

C09 Case Studies

file in the

Case Studies

folder inside the

SOLIDWORKS Simulation

folder.

Section 2: Opening the Cylinder

1. Start SOLIDWORKS, if not already started.

2. Click on the

Open

button in the

Welcome

dialog box or the

Open

tool in the

Standard

toolbar. The

Open

dialog box appears.

3. Browse to the location

> SOLIDWORKS Simulation > Case Studies > C09 Case Studies > Case Study 1

of the local drive of your system. Next, select the

Cylinder

and then click on the

Open

button in the dialog box. The Cylinder model is opened in SOLIDWORKS.

Section 3: Starting the Drop Test Analysis

1. Click on the

Simulation

tab in the

Simulation

CommandManager

. The

tools

of the

Simulation

CommandManager

appear.

2. Click on the

New

Study

tool in the

Simulation

CommandManager

. The

Study

PropertyManager

appears at the left of the graphics area.

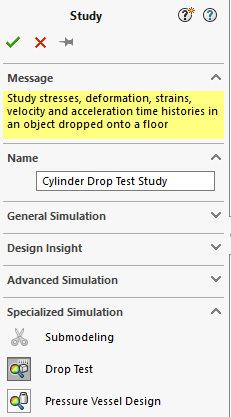

3. Click on the

Drop

Test

button in the

Specialized

Simulation

rollout of the PropertyManager to perform the drop test analysis.

4. Enter

Cylinder Drop Test Study

in the

Study

name

field of the

Name

rollout in the PropertyManager, see Figure 9.3.

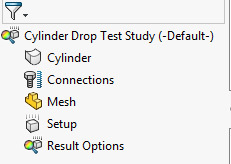

5. Click on the green tick-mark button in the PropertyManager. The

Cylinder Drop Test Study

is

added in the

Simulation Study Tree, see Figure 9.4.

Figure 9.4

Tip:

It is evident from the Simulation Study Tree that the loads and fixtures (restraints) are not required to perform the drop test.

Section 4: Defining Drop Test Setup

Before you start performing the drop test analysis, you need to define the drop test setup.

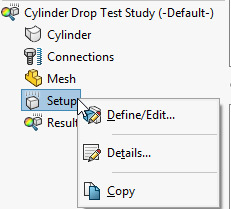

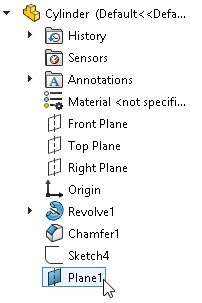

1. Right-click on the

Setup

option in the Simulation Study Tree and then click on the

Define/Edit

tool in the shortcut menu appeared, see Figure 9.5. The

Drop Test Setup PropertyManager

appears, see Figure 9.6.

Figure 9.5

Figure 9.6

The

Specify

rollout of the PropertyManager is used to specify the type of drop test setup. By default, the

Drop

height

radio button is selected in this rollout. As a result, you can specify the drop test setup for an object dropping from an height on a floor. On selecting the

Velocity at impact

radio button, you can specify the drop test setup for an object falling with a velocity on a floor.

2. Make sure that the

Drop height

radio button is selected in the

Specify

rollout of the PropertyManager, see Figure 9.6.

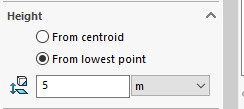

The options in the

Height

rollout are used to specify the height from which the object is dropped from rest. On selecting the

From centroid

radio button, the height is measured from the centroid of the object to the floor in the direction of gravity. On selecting the

From lowest point

radio button, the height is measured from the lowest point of the object to the floor.

3. Select the

From lowest point

radio button in the

Height

rollout of the PropertyManager.

4. Select the

ft

(feet)

option in the

Unit

drop-down list and then enter

2

in the

Drop

height

field of the

Height

rollout, see Figure 9.7.

Figure 9.7

The

Gravity

rollout is used to define the direction and acceleration value of gravity. You can select a reference plane, an edge, or a planar face to define the direction of gravity. Note that if you select a reference plane or a planar face as the direction of gravity then the gravity will be applied in the direction normal to the selection.

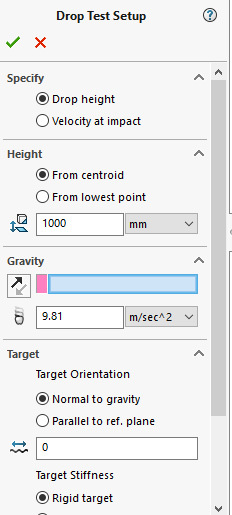

5. Expand the FeatureManager Design Tree, which is now at the top left corner of the graphics area and then click on the

Plane1

to define the direction of gravity, see Figure 9.8. The direction of gravity is defined normal to the plane selected. Also, an arrow pointing towards the direction of gravity appears in the graphics area, see Figure 9.9.

Figure 9.8

Figure 9.9

NOTE:

If needed, you can flip the direction of gravity by clicking on the

Reverse Gravity Reference

button in the

Gravity

rollout of the PropertyManager.

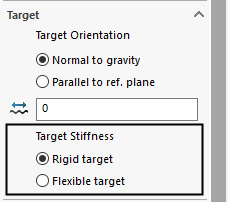

The options in the

Target

rollout are used to define the orientation and type of impact (target) plane. By default, the

Normal to gravity

radio button is selected in this rollout. As a result, the impact (target) plane is defined normal to the direction of gravity. You can also define the impact (target) plane, parallel to a reference plane. For doing so, select the

Parallel to ref. plane

radio button. The

Target orientation reference

field appears in this rollout. Next, select a reference plane. On doing so, the impact (target) plane is defined parallel to the selected reference plane.

6. Make sure that the

Normal to gravity

radio button is selected in this rollout to define the target plane normal to the direction of gravity.

Figure 9.10

The

Target Stiffness

area of the

Target

rollout is used to define the type of target plane, see Figure 9.10. By default, the

Rigid target

radio button is selected in this area. As a result, the rigid floor is used as the target. On selecting the

Flexible target

radio button, you can define the flexible target by specifying its properties such as stiffness, mass density, and thickness of the flexible target plane in the respective fields of the

Stiffness and thickness

rollout of the PropertyManager. Note that this rollout appears only when the

Flexible target

radio button is selected.

7. Make sure that the

Rigid target

radio button is selected in the

Target Stiffness

area of the

Target

rollout of the PropertyManager.

Tip:

You can also set the coefficient of friction between the object and the impact (target) plane by using the

Friction

Coefficient

field of the

Target

rollout in the PropertyManager.

8. Click on the green tick-mark button in the PropertyManager. The drop test setup is defined.

Section 5: Applying the Material

Now, you need to apply the material to the model.

1. Invoke the

Material

dialog box by clicking on the

Apply

Material

tool in the

Simulation

CommandManager

.

2. Apply the

Plain Carbon Steel

material to the Cylinder and then close the

Material

dialog box.

Section 6: Defining Result Options

Now, you need to define the result options such as how long you want to run the analysis after the impact and number of result plots to be saved.

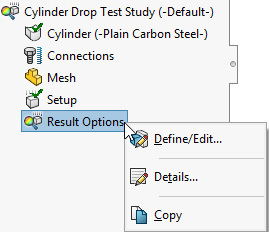

1. Right-click on the

Result

Options

option in the Simulation Study Tree and then click on the

Define/Edit

tool in the shortcut menu appeared, see Figure 9.11. The

Result

Options PropertyManager

appears, see Figure 9.12.

Figure 9.11

Figure 9.12

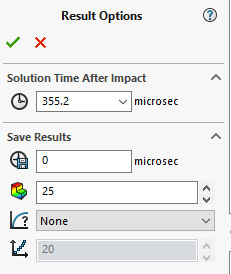

The

Solution Time After Impact

field of the

Result

Options

PropertyManager

is used to specify how long you want to run the analysis after the impact. By default, SOLIDWORKS Simulation automatically calculates the appropriate time by using the

3L/Ve

formula. Where,

L

is the largest length of the object boundary box size and

Ve

is the square root of the modulus of elasticity.

The

Save Results Starting From

field of the

Save

Result

rollout of the PropertyManager is used to specify the time from when program will start saving the results. By default, the

0

is specified in this field. As a result, the program start saving the results immediately from the moment of first impact. The

No. of Plots

field is used to specify the number of result plots, the program will save.

2. Accept the default specified options in the

Result Options PropertyManager

and then click on the green tick-mark button.

Section 7: Generating the Mesh

1. Generate the curvature-based mesh with the default mesh parameters by using the

Create Mesh

tool. Figure 9.13 shows the meshed model. In this figure, the reference plane is hide.

Figure 9.13

Section 8: Running the Drop Test Study

1. Click on the

Run This Study

tool in the

Simulation CommandManager

. The

Cylinder Drop Test Study

(

name of the study

)

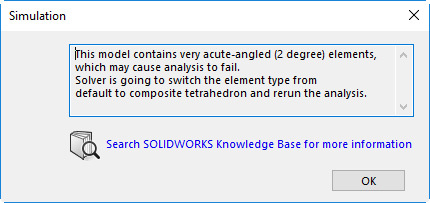

window appears which displays the progress of analysis. During the analysis, if the

Simulation

warning message appears, as shown in the Figure 9.14. Click on the

OK

button to continue with the analysis process.

Figure 9.14

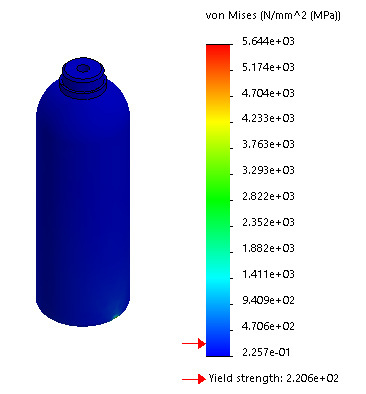

After the process of analysis completes, the

Results

folder is added in the Simulation Study Tree with the stress, displacement, and strain results. By default, the

Stress

result is activated in the

Results

folder. As a result, the stress distribution on the model after the impact and the von Mises stress plot appear in the graphics area, see Figure 9.15.

Figure 9.15

Notice that the maximum Von Mises stress in the model at impact is

5.644e+03

(5,644.486) N/mm^2 (MPa) which significantly exceeds the yield strength of the material that is

2.206e+02

(220.594) N/mm^2 (MPa). The yield strength of the material is indicated by the red pointer in the von Mises stress plot.

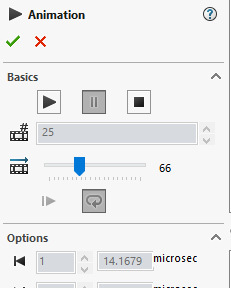

Section 9: Animating the Stress Result

Now, you need to animate the stress result to validate the impact with respect to time.

1. Right-click on the

Stress1 (-vonMises-)

option in the

Results

folder of the Simulation Study Tree. A shortcut menu appears. In this shortcut menu, click on the

Animate

option. The

Animation

PropertyManager

appears, see Figure 9.16. Also, the animated effect of the object dropping on a rigid floor appears in the graphics area.

Figure 9.16

2. Zoom to the impact portion of the Cylinder to view its impact with the rigid floor, closely.

3. To save the animation as AVI file, select the

Save as AVI

file

check box in the PropertyManager. Next, specify the path to save the file.

4. After reviewing the animated effects of the deformed shape, click on the green tick-mark button in the PropertyManager to exit the PropertyManager and save the AVI file in the specified location.

Section 10: Saving Results

Now, you need to save the model and its results.

1. Click on the

Save

tool in the

Standard

toolbar. The model and its results are saved in the location

> SOLIDWORKS Simulation > Case Studies > C09 Case Studies > Case Study 1

.

2. Close the SOLIDWORKS session.

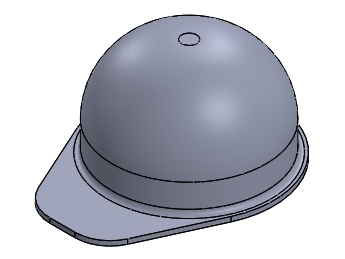

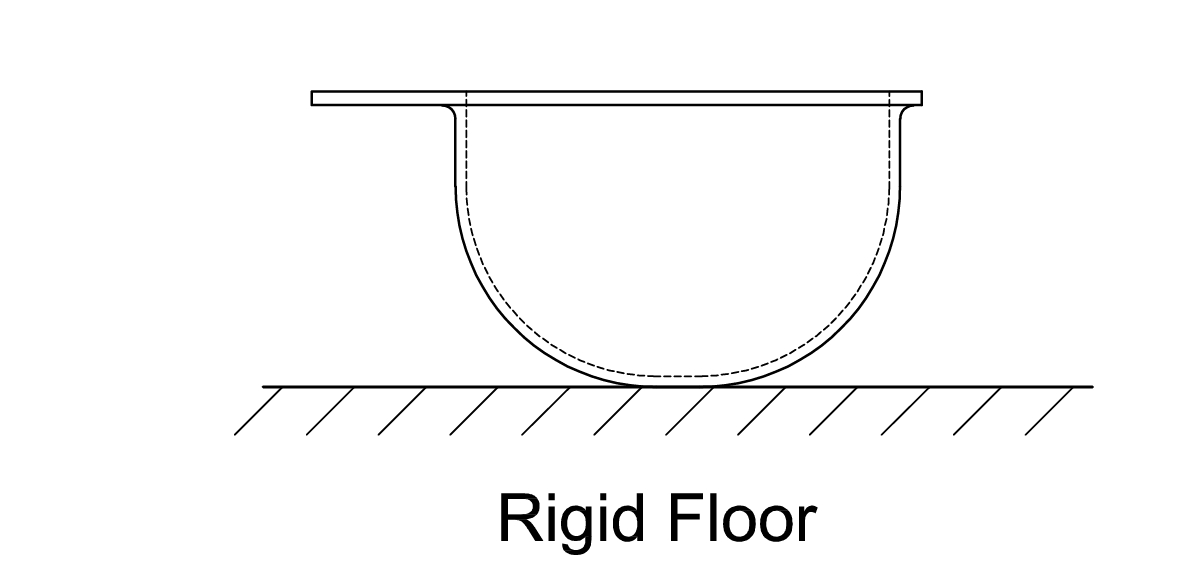

Case Study 2: Drop Test Analysis of a Helmet

In this case study, perform the drop test analysis of a Helmet, see Figure 9.17 and evaluate its effect of dropping on a rigid floor from the height of 5 meters.

Figure 9.17

Project Description

Determine the impact of the Helmet with the rigid floor when falling from the height of 5 meters, see Figure 9.18. Note that the 5 meters height is measured from the lowest point of the Helmet. The Helmet is made up of

ABS

material.

Figure 9.18

Project Summary

In this case study, you will run the drop test analysis on a Helmet.

Learning Objectives

In this case study, you will learn the following:

1. Starting the Drop Test Analysis

2. Defining Drop Test Setup

3. Applying the Material

4. Defining Result Options

5. Generating the Mesh

6. Running the Drop Test Study

7. Displaying the Time History Plot

8. Animating the Stress Result

9. Saving Results

Section 1: Starting the Drop Test Analysis

1. Start SOLIDWORKS and then open the Helmet from the location

> SOLIDWORKS Simulation > Case Studies > C09 Case Studies > Case Study 2

.

NOTE:

You need to download the C09 Case Studies file which contains the files of this chapter by logging to the CADArtifex website (www.cadartifex.com), if not downloaded earlier.

2. Click on the

Simulation

tab in the

Simulation

CommandManager

. The tools of the

Simulation

CommandManager

appear.

3. Click on the

New

Study

tool in the

Simulation

CommandManager

. The

Study

PropertyManager

appears at the left of the graphics area.

4. Click on the

Drop Test

button in the

Specialized

Simulation

rollout of the PropertyManager.

5. Enter

Helmet Drop

Test

Study

in the

Study

name

field of the

Name

rollout in the PropertyManager.

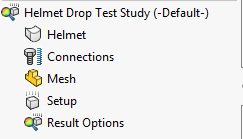

6. Click on the green tick-mark button in the PropertyManager. The

Helmet Drop Test Study

is

added in the

Simulation Study Tree, see Figure 9.19.

Figure 9.19

Section 2: Defining Drop Test Setup

Now, you need to define the drop test setup.

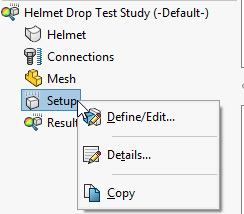

1. Right-click on the

Setup

option in the Simulation Study Tree and then click on the

Define/Edit

tool in the shortcut menu appeared, see Figure 9.20. The

Drop Test Setup PropertyManager

appears, see Figure 9.21.

Figure 9.20

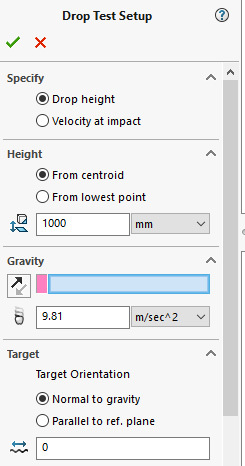

Figure 9.21

2. Make sure that the

Drop height

radio button is selected in the

Specify

rollout of the PropertyManager.

3. Select the

From lowest point

radio button in the

Height

rollout of the PropertyManager.

4. Select the

m

(meter)

option in the

Unit

drop-down list and then enter

5

in the

Drop

height

field of the

Height

rollout, see Figure 9.22.

Figure 9.22

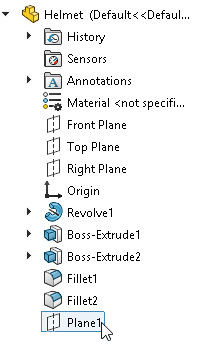

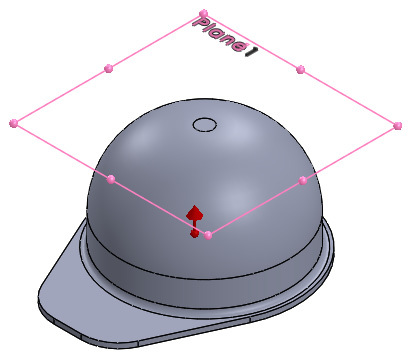

5. Expand the FeatureManager Design Tree, which is now at the top left corner of the graphics area and then click on the

Plane1

to define the direction of gravity, see Figure 9.23. The direction of gravity is defined normal to the plane selected. Also, an arrow pointing towards the direction of gravity appears in the graphics area, see Figure 9.24.

Figure 9.23

Figure 9.24

6. Make sure that the direction of gravity is towards the reference plane selected, see Figure 9.24. If needed, you can flip the direction of gravity by clicking on the

Reverse Gravity Reference

button in the

Gravity

rollout of the PropertyManager.

7. Make sure that the

Normal to gravity

radio button is selected in the

Target

rollout of the PropertyManager.

8. Make sure that the

Rigid target

radio button is selected in the

Target Stiffness

area of the

Target

rollout.

9. Click on the green tick-mark button in the PropertyManager. The drop test setup is defined.

Section 3: Applying the Material

Now, you need to apply the material to the model.

1. Invoke the

Material

dialog box by clicking on the

Apply

Material

tool in the

Simulation

CommandManager

.

2. Apply the

ABS

material to the Helmet and then close the

Material

dialog box.

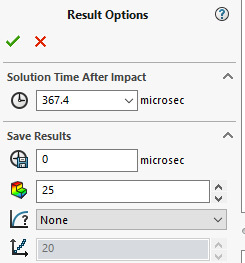

Section 4: Defining Result Options

Now, you need to define the result options such as how long you want to run the analysis after the impact and number of result plots to be saved.

1. Right-click on the

Result

Options

option in the Simulation Study Tree and then click on the

Define/Edit

tool in the shortcut menu appeared. The

Result

Options

PropertyManager

appears, see Figure 9.25.

Figure 9.25

2. Enter

30

in the

No. of Plots

field of the PropertyManager as the number of plots to be saved by program for all nodes.

3. Click on the green tick-mark button in the PropertyManager.

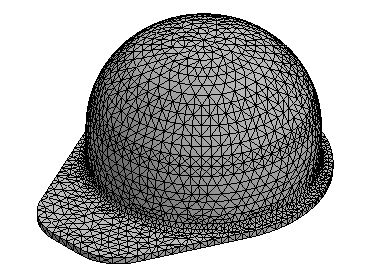

Section 5: Generating the Mesh

1. Generate the curvature-based mesh with the default mesh parameters by using the

Create Mesh

tool. Figure 9.26 shows the meshed model. In this figure, the reference plane is hide.

Figure 9.26

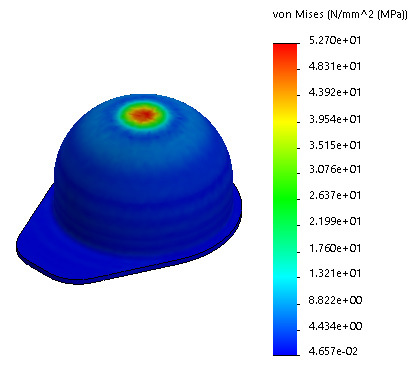

Section 6: Running the Drop Test Study

1. Click on the

Run This Study

tool in the

Simulation

CommandManager

. The

Cylinder Drop Test Study

(

name of the study

)

window appears which displays the progress of analysis. After the process of analysis completes, the

Results

folder is added in the Simulation Study Tree with the stress, displacement, and strain results. By default, the

Stress

result is activated in the

Results

folder. As a result, the stress distribution on the model after the impact and the von Mises stress plot appear in the graphics area, see Figure 9.27.

Notice that the maximum von Mises stress in the model at impact is

5.270e+01

(52.700) N/mm^2 (MPa).

Figure 9.27

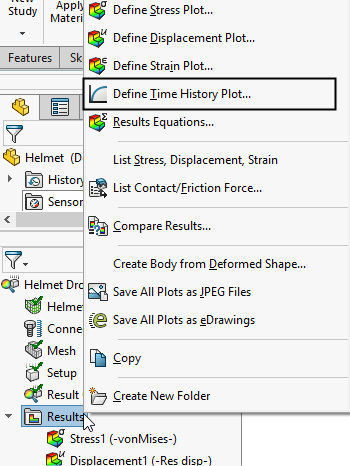

Section 7: Displaying the Time History Plot

1. Right-click on the

Results

folder in the Simulation Study Tree. A shortcut menu appears, see Figure 9.28.

Figure 9.28

2. Click on the

Define Time History Plot

tool in the shortcut menu. The

Time History Graph PropertyManager

appears, see Figure 9.29.

Figure 9.29

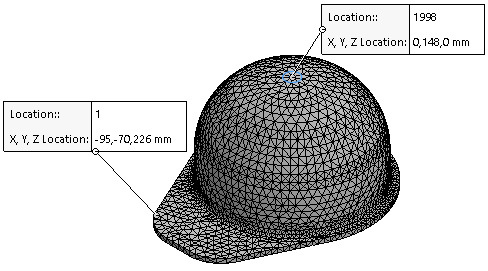

Notice that in the

Response

rollout of the PropertyManager, all the nodes of the model appear in a field. You can select a node or multiple nodes in this field, whose response graph is to be generated. Alternatively, you can click on a node or nodes in the graphics area.

3. Click on a node at the top center (impact area) of the model in the graphics area, see Figure 9.30. The node 1998 at the impact area get selected. Note that the selected node number of the impact area may differ in your case depending on your selection. Also, the node number 1 is selected, by default.

Figure 9.30

4. Make sure that the

Time

option is selected in the

X axis

drop-down list of the PropertyManager.

5. Make sure that the

Stress

and

VON: von Mises Stress

options are selected in the respective fields of the

Y axis

area in the PropertyManager.

6. Select the

N/mm^2 (MPa)

in the

Unit

drop-down list of the

Y-axis

area of the PropertyManager.

7. Click on the green tick-mark button in the PropertyManager. The

Time History Graph

window appears, see Figure 9.31. This window displays the response graphs of the selected nodes (1 and 1998) for the von Mises stress vs solution steps.

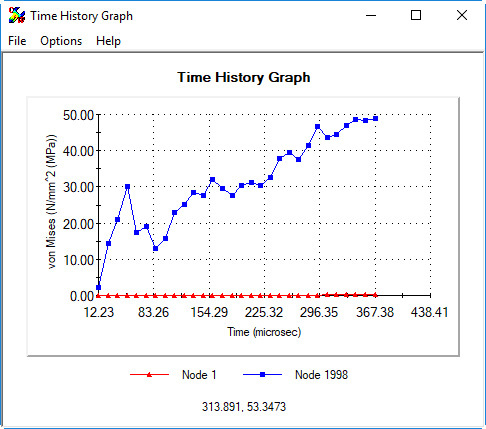

Figure 9.31

Notice that the maximum von Mises stress on the selected node (1998) is approximate

50

N/mm^2 (MPa), which occurs at time 367 microseconds from impact.

Section 8: Animating the Stress Result

Now, you need to animate the stress result to validate the impact with respect to time.

1. Right-click on the

Stress1 (-vonMises-)

option in the

Results

folder of the Simulation Study Tree. A shortcut menu appears. In this shortcut menu, click on the

Animate

option. The

Animation

PropertyManager

appears. Also, the animated effect of the object dropping on a rigid floor appears in the graphics area. You can zoom to the high stress area (impact area) of the object to views its effects closely.

2. After reviewing the animated effects, click on the green tick-mark button in the PropertyManager to exit the PropertyManager.

Section 9: Saving Results

1. Click on the

Save

tool in the

Standard

toolbar. The model and its results are saved in the location

> SOLIDWORKS Simulation > Case Studies > C09 Case Studies > Case Study 2

. Next, close the SOLIDWORKS session.

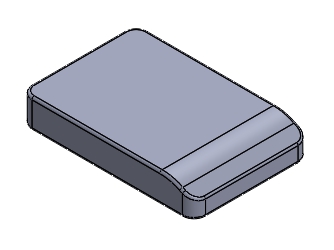

Hands-on Test Drive 1: Drop Test Analysis of a Hard Drive

In this case study, perform the drop test analysis of a external Hard Drive, see Figure 9.32 and evaluate its effect of dropping on a rigid floor from the height of 1 meter.

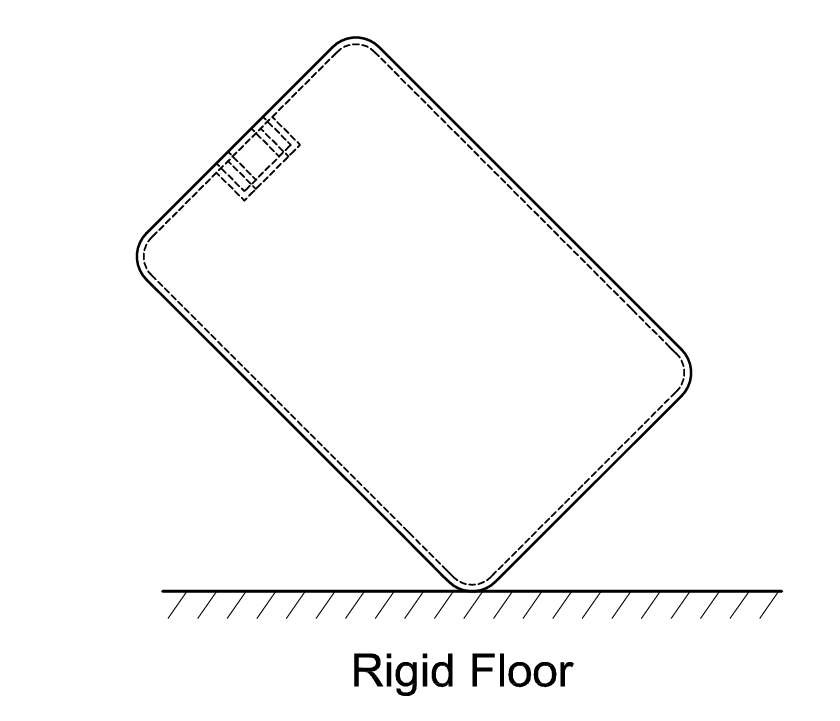

Project Description

Determine the impact of the Hard Drive with the rigid floor when falling from the height of 1 meter, see Figure 9.33. Note that the 1 meter height is measured from the lowest point of the object. The Hard Drive is made up of

PVC Rigid

plastics material.

Figure 9.32

Figure 9.33

Summary

In this chapter, you have learned how to perform the drop test analysis to calculate the impact of an object with floor.

Questions

•

The drop test analysis is used to analyze the effect of dropping an object on a

________

or a

________

floor.

•

The

________

radio button of the

Drop Test Setup PropertyManager

is used to measure the drop height from the centroid of the object to the floor in the direction of gravity.

•

The

________

radio button of the

Drop Test Setup PropertyManager

is used to define the impact (target) plane, parallel to a reference plane.

•

The

________

radio button of the

Drop Test Setup PropertyManager

is used to specify the drop test setup for an object dropping from an height on a floor.

•

The

________

radio button of the

Drop Test Setup PropertyManager

is used to specify the drop test setup for an object falling with a velocity on a floor.