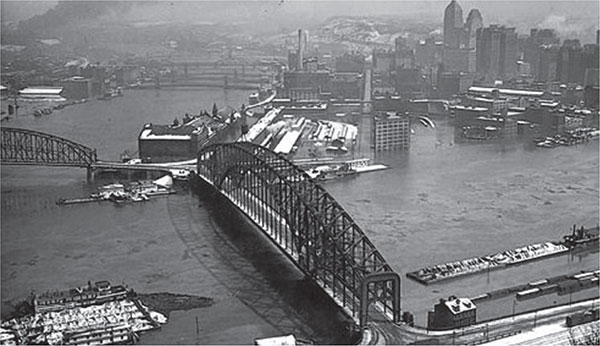

March 1936 flood in Pittsburgh, Pennsylvania. From www.postgazette.com.

NAVIGATION AND FLOOD CONTROL ON THE THREE RIVERS

By Brian Greene, PhD, PG; Anton Krysa, PE; Werner Loehlein, PE; Stephen Stoltz, PE; and Patrick J. Sullivan Jr., PE

INTRODUCTION

This chapter deals with the history of navigation on Pittsburgh’s three rivers and the history of past floods and efforts to mitigate future flooding of the city. In their natural, pre-1760 state, the Allegheny, Monongahela and Ohio Rivers (i.e., the “Three Rivers”) were very dynamic, reacting to the forces of nature. For most of the year, the river levels were low, but these periods were punctuated by brief, swiftly rising levels with high velocities greatly hindering navigation and urban development. Civil engineers have long been at the heart of providing systems and structures that permit the rivers to serve as a major means of transportation in support of the industrial core of Pittsburgh. Initially, the area’s rivers were a key means of transportation, but they were unreliable due to spring floods and summer low-water stages. In 1866, Congress authorized the Rivers and Harbors Act to seek a means to permit year-round, reliable navigation for commercial river towboats and barge traffic.

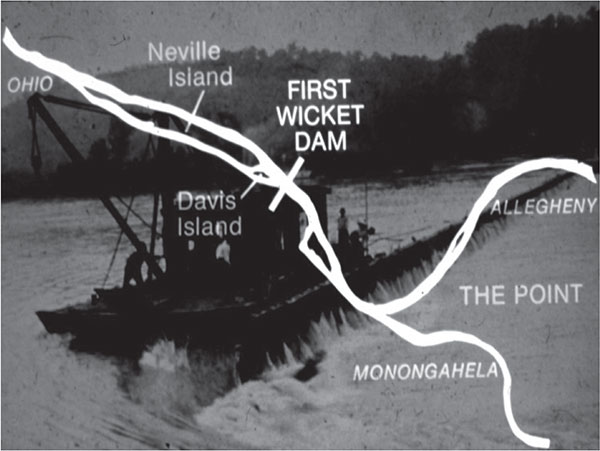

The act resulted in far-sighted civil engineers, including William Milnor Roberts and Colonel William Merrill, performing detailed surveys to develop a comprehensive plan for a slackwater canalization of the Ohio River. Completed in 1869, the surveys offered indispensable engineering and hydrological data later used to plan navigation projects, as M.C. Robinson noted in his 1983 national waterways study. Completed in the late 1800s, Davis Island Lock and Dam (L/D) was built about five miles downstream from the Point of Pittsburgh and represented the first navigation project on the Ohio River. Following Davis Island L/D, a network of descending locks and dams made year-round navigation of bulk goods possible. In addition, many tributaries located upstream of Pittsburgh were dammed so that floodwaters could be stored for future planned release. The added benefits of the dams and reservoirs in the Pittsburgh’s Ohio River drainage basin include water for public consumption, irrigation, recreation, reliable navigation and hydropower. The Three Rivers represent the lifeblood of Pittsburgh, both historically and in the present. The benefits of the system of locks and dams are immeasurable and clearly result in the most economical means to move bulk commodities throughout the region. There has been an ongoing investment in the repair and replacement of navigation locks of Pittsburgh, as well as improvements to key upstream flood-control dams. The term “flood control” has been replaced with “flood risk management” in recent years.

OVERVIEW OF DAMS IN PENNSYLVANIA

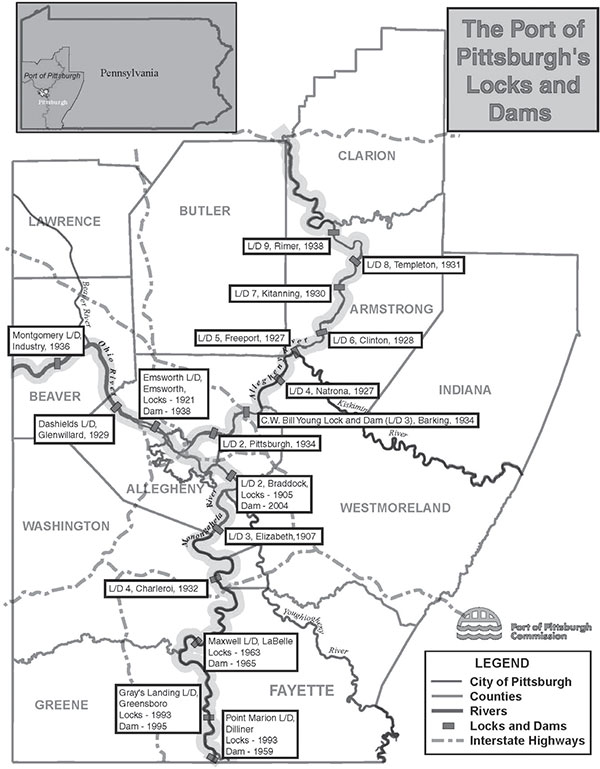

The Commonwealth of Pennsylvania has a variety of dams that vary in their construction materials, including earthen embankments, concrete gravity dams and combination dams. The most recent survey by the Pennsylvania Department of Environmental Protection, Division of Dam Safety and the American Association of State Dam Safety Officials indicates that as of 2015, there are 3,373 state-regulated dams located in the commonwealth. Existing dams, with their associated reservoirs, are used for multiple purposes: flood mitigation, navigation, hydropower, irrigation, water quality and recreation. Flood-control dams in Pennsylvania date back to the 1800s, although few have been built since 2000. The Pittsburgh District of the U.S. Army Corps of Engineers operates and maintains 23 locks and dams on the Allegheny, Monongahela and Ohio Rivers. The first navigation dams were built on the Monongahela River and were paid for by user tolls. Later, the Corps of Engineers took over the responsibility for the dams and locks to provide reliable navigation. Many of the existing locks and dams were built in the 1930s and are operating well beyond their estimated fifty-year service lives. The 2014 ASCE Report Card on Pennsylvania’s Infrastructure grades dams low and indicates a compelling need for reinvestment to maintain these structures.

FLOOD-CONTROL DAMS

The Upper Ohio River Basin has seen its share of major floods since the construction of Fort Pitt in the 1760s. Since that time, the Greater Pittsburgh area has experienced many severe flooding incidents created by a variety of events. Beginning in March 1763, floodwaters inundated Fort Pitt. As Pittsburgh grew, so did the city’s and region’s experiences with overbank flooding. Downtown Pittsburgh, at the confluence of the Allegheny and Monongahela Rivers, flooded an average of twice per year. Overbank flooding was such an issue for the region that in 1907, the Pittsburgh Chamber of Commerce organized the Pittsburgh Flood Commission under the leadership of H.J. Heinz. In 1912, the commission published the so-called Heinz Report. The report detailed the impact of flooding in the region and outlined a system of upstream flood protection dams in the Allegheny, Monongahela and Beaver River Basins of the Upper Ohio River Valley to protect the residents from damaging floodwaters. Unfortunately, the plan failed to gather much federal support following the Great Flood of 1913 and through the 1920s.

March 1936 flood in Pittsburgh, Pennsylvania. From www.postgazette.com.

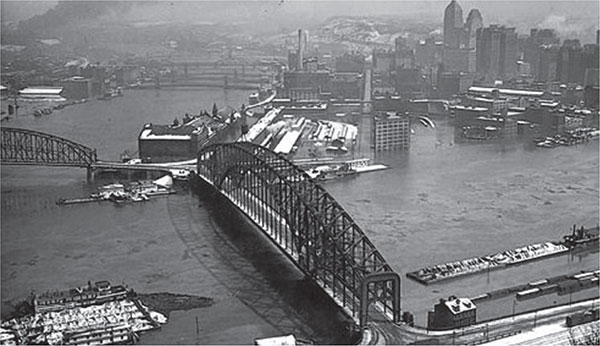

Federal flood damage reduction projects, Upper Ohio River Basin. U.S. Army Corps of Engineers, Pittsburgh District.

It was not until the region and country experienced the severe droughts of the early 1930s, followed by the March 1936 St. Patrick’s Day Flood, the largest flood of record in the Upper Ohio River Valley, that action was finally taken. This flood prompted the passage of the Flood Control Act of 1936 by Congress. Following record floods along the middle Ohio River in January 1937 and the lower Ohio River in March 1937, the 1936 act was amended with more projects and in 1938 funded the construction of most of flood protection projects east of the Mississippi River. The result in the Upper Ohio River Basin was a system that currently consists of sixteen federally built flood-control and multipurpose dams. This reservoir system has substantially reduced flood damages since the dams were constructed. For example, these projects combined to reduce the 1972 Hurricane Agnes flood by an estimated 12 feet at Pittsburgh. Without the upstream reservoirs, this flood would have been 2 feet higher than the record flood level recorded in March 1936, which crested at 46 feet. The January 1996 flood, which crested at 34.6 feet, was reduced by 10 feet at Pittsburgh—otherwise, it would have nearly equaled the flood elevations recorded during the March 1936 flood.

MULTIPURPOSE DAMS

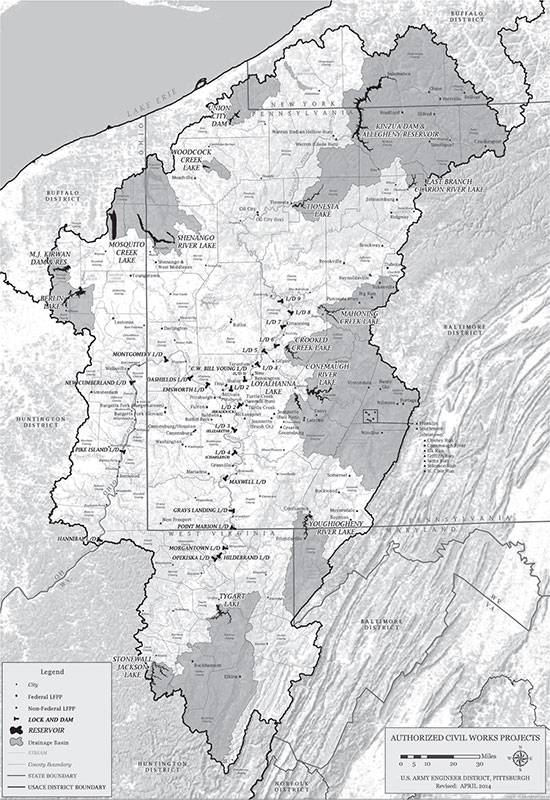

Following passage of the Flood Control Act of 1936, several of the dams in the Upper Ohio Basin were authorized for design and construction. Two prominent Corps of Engineers dams were Youghiogheny Dam, completed in 1944 and located on the Youghiogheny River, a tributary of the Monongahela River, and Kinzua Dam, completed in 1965 and located on the main stem of the Allegheny River.

Youghiogheny Dam

Youghiogheny Dam is located on the Youghiogheny River upstream from Confluence, Pennsylvania. The dam is an earthen structure, 184 feet high and 1,610 feet long at its crest. The reservoir extends 16 miles into Western Maryland and has a normal surface area of about 4.4 square miles.

Boaters consider Youghiogheny River Lake, with channels up to half a mile wide, the best powerboat and water-skiing lake in southwestern Pennsylvania. The tail waters of the dam are some of the few in Pennsylvania that open for trout fishing year round and are stocked by the Pennsylvania Fish and Boat Commission on a regular basis throughout the spring and summer.

An interesting fact associated with the construction of the dam is that the former town of Somerfield, Pennsylvania, located about three miles from the dam crest, was abandoned, razed and inundated when the reservoir was filled. The town was formed in 1818 and existed until the dam was constructed in 1942. Every so often, during extremely low water levels, former sidewalks of the town and the old stone arch Great Crossings Bridge of the National Road, which was the original Route 40, will appear.

Kinzua Dam

Kinzua Dam, located 6 miles east of Warren, Pennsylvania, is one of the largest dams in the United States east of the Mississippi River and the only flood-control dam on the main stem of the Allegheny River. The dam is a 179-foot-high and 1,877-foot-long combination concrete gravity/ embankment dam that impounds a reservoir having a total length of 24.2 miles at normal pool. The dam is located within the 500,000-acre Allegheny National Forest. The dam created Pennsylvania’s second-deepest lake, the Allegheny Reservoir, also known as Kinzua Lake. The lake extends north, nearly to Salamanca, New York, which is within the Allegany Reservation of the Seneca Nation of New York. Federal condemnation of tribal lands to be flooded for the project displaced more than six hundred Seneca members and cost the reservation 10,000 acres. The relocation is still a contentious issue within the Seneca Nation.

In 1966, the Pittsburgh Section of ASCE bestowed its first Civil Engineering Achievement Award to the Kinzua Dam Project. The primary purpose of the Kinzua Dam and Reservoir project is flood mitigation, but it is also used for navigation, pollution abatement, recreation and hydropower, all which are carefully balanced to optimize the use of the available water. Immediately above the downstream side of the dam is the Seneca Pumped Storage Generating Station. The pumped storage facility has a circular reservoir located on the left hillside, well above the dam. The pumped storage hydroelectric power plant distributes electricity to the power grid across the region.

Photograph of Kinzua Dam soon after completion in 1966. U.S. Army Corps of Engineers, Pittsburgh District.

RIVER NAVIGATION STRUCTURES

Since the early settlement of Western Pennsylvania, the Allegheny, Monongahela and Ohio Rivers have served the region for basic transportation and shipment of goods and cargo using barges pushed by towboats. The amount of coal transported downriver from Pittsburgh by these tows greatly increased following the Civil War, according to Johnson’s Headwaters District. The size of the tows/number of barges also grew with the amount of coal hauled against its increasing downriver demand. Due to the growing coal trade, the federal government began studying methods to produce a reliable navigation depth on the Ohio River. In 1866, Congress authorized the Rivers and Harbors Act, which launched a study to analyze a comprehensive plan for a slackwater canalization of the Ohio River. The study led to a determination that construction of an integrated system of locks and dams, each forming an upstream pool (defined as a slackwater lake, or a reach of artificially deepened river), was the best solution to meet the demands of the growing navigation industry. The increased storage capacity of each pool increased the amount of river water that could be managed by sequential release from each pool of a dam proceeding downriver.

DAVIS ISLAND LOCK AND DAM

The opening of the first lock and dam on the Ohio River at Davis Island in 1885 proved to be a significant technologic advance for the civil engineering profession at large. When completed, the Davis Island project incorporated the world’s first rolling lock gate and, at 600 feet long and 110 feet wide, was the widest lock chamber ever built at the time of its construction in 1878–85. The Davis Island navigation project incorporated a wooden timber wicket dam almost 1,900 feet long. Wicket dams were composed of moveable slab sections that were hinged at the bottom and held upright by adjustable props. Davis Island served as a prototype for the subsequent fifty locks to be built on the Ohio River. Davis Island Lock and Dam was removed in 1922 and replaced with Emsworth Locks and Dam, located downstream.

Map and photograph of Davis Island Lock and Dam. U.S. Army Corps of Engineers, Pittsburgh District.

LOCKS AND DAMS (1900 THROUGH 2000)

In 1910, the Rivers and Harbors Act was authorized by Congress, providing for the systematic construction of a system of locks and dams along the Ohio River. This project was completed in 1929 and produced fifty-one wooden wicket dams and typical lock chambers with dimensions of 600 feet long by 110 feet wide along the length of the river, starting at Pittsburgh. Wicket dams in the Pittsburgh region were the earliest structures to be replaced by mass concrete dams.

Taken together, the systems of locks and dams on the three rivers of the Pittsburgh region have been described as “rivers that are highways.” Even today, they are the most efficient means to move bulk commodities such as coal and construction aggregates compared to rail or truck transport. Throughout the late nineteenth and early twentieth centuries, the Monongahela River has carried a greater tonnage of bulk commodities than any other inland river in America, as Johnson noted in Headwaters District. In comparison with the Ohio and Mississippi Rivers, the Monongahela River was called the “Little Giant” because of the tonnage transported on it annually. Moving coal mined in Pennsylvania and West Virginia to steel mills in the Western Pennsylvania towns upstream and downstream of Pittsburgh was especially important, especially to the war effort in the late 1930s and early 1940s.

During the 1940s, a shift from steam-propelled to diesel-powered towboats allowed for more barges/larger tows on the river. However, due to the size of the lock chambers, the tows had to be disassembled upstream, and a select number of barges were “locked” through the lock chambers in multiple lockages. Once in the downstream pool, the tow was then reassembled before continuing downstream. This functional inconvenience backed up river traffic and increased expenses for the river towboat industry. Even as modernization of locks in the lower Ohio River was initiated in the 1950s to handle the larger tows/more barges, the locks in the Pittsburgh region remained unchanged. In the upper Ohio River, nearest Pittsburgh, each river navigation dam, either a gated type or a simple concrete weir structure, has two parallel, adjoining lock chambers— one a 600-foot-long by 110-foot-wide main lock and the other a 360-footlong by 56-foot-wide auxiliary lock.

Map of USACE locks and dams on the Three Rivers. Port of Pittsburgh Commission.

The Pittsburgh District, Corps of Engineers, currently operates and maintains twenty-three locks and dams on the three rivers. This operation represents the largest number of navigation projects in any district of the Corps of Engineers, and it systematically provides a nine-foot minimum depth navigation “pool” depth. In the 1990s, a new locks and dam project was built on the Monongahela River. The project, Grays Landing Locks and Dam, located eighty-two river miles south of Pittsburgh, involved traditional cofferdam construction. Steel sheet piles were used to form a series of interconnecting coffer cells. Once completed, the inner cofferdam area was pumped dry. Excavation of alluvial sediments, removal of rock, preparation of the foundation and placement of concrete was then performed.

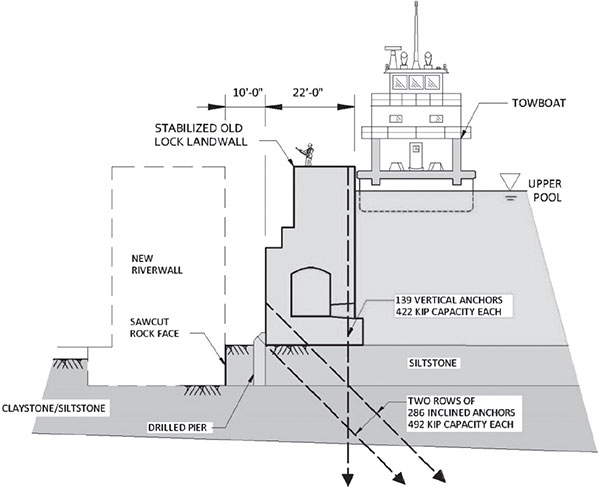

POINT MARION LOCK COFFERDAM

In 1990, work began on a replacement lock chamber at Point Marion Lock and Dam, located on the Monongahela River about seventy-five miles south of Pittsburgh and one mile above the confluence of the Monongahela and Cheat Rivers. The new lock chamber measured 84 feet by 720 feet, eliminating the traffic bottleneck of the old smaller 56- by 360-foot lock chamber. A larger lock chamber avoided reconfiguring barges into smaller components to lock through and then returning the configuration back to the original series of interconnected barges before continuing downriver. This inefficient double lockage procedure added about an additional hour to a typical lockage of about a half hour. Plans called for the new lock to be constructed landward of the existing lock, which would be incorporated as part of the river arm of the cofferdam. An important requirement was that the existing lock had to remain open during construction to avoid shutting down all traffic in the river. This required extensive stabilization of the existing wall since the proposed excavation for the new lock typically was within 10 feet of the existing landwall and extended up to 13 feet below its foundation. The new upper approach was extended and broadened for a distance of nearly one mile, which required removal and disposal of approximately 1 million cubic yards of material excavated from the left bank.

Existing walls had been incorporated into cofferdams in the past. In 1961, an existing lock landwall was incorporated as part of a cofferdam at the Tennessee Valley Authority’s General Joe Wheeler Lock and Dam, but the approach proved disastrous. The lock wall moved about thirty feet into the dewatered excavation, killing two people and suspending navigation on the Tennessee River for years until the lock was reconstructed. The cause of the failure was sliding of the existing lock wall on an undetected weak clay seam in the foundation rock.

Foundation explorations at Point Marion identified weak clay seams within the underlying rock. To avoid a sliding failure similar to that experienced at Wheeler Lock, 425 large-capacity post-tensioned rock anchors were installed in three rows to ensure the required stability of the existing land wall. The image here depicts a typical section through old lock wall showing rock anchor locations. Even more rock anchors were required for the coffercells making up the remaining portion of the cofferdam.

Typical section through old lock wall showing rock anchor locations. Anton Krysa.

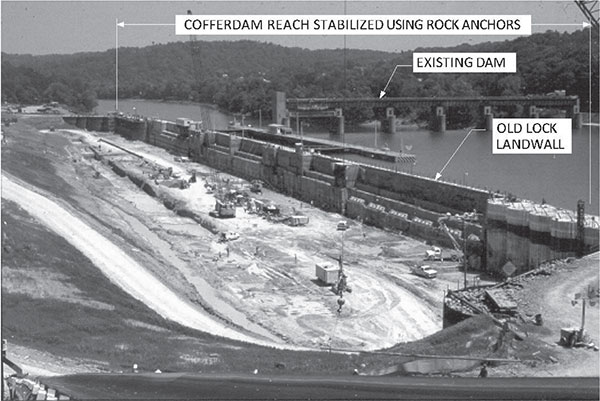

Construction phase with anchors installed and cofferdam dewatered. U.S. Army Corps of Engineers, Pittsburgh District.

For the landwall proper, 139 vertical anchors were installed to prevent overturning. Two rows of 286 inclined anchors were placed to resist sliding of the landwall monoliths along the top, as well as within the underlying weak rock. Excavation proceeded in stages and was closely linked to the installation and stressing of each row of anchors. An assortment of sensors linked to computers allowed real-time monitoring of the performance of the cofferdam throughout construction.

The image here is an aerial photograph taken during the construction phase of the project, with anchors installed and cofferdam dewatered. Even with the extensive stabilization measures, the response of the existing lock walls to the removal of the supporting backfill material was noticeable. The instrumentation proved to be invaluable in allowing quick modifications to the construction.

The Point Marion Lock Cofferdam Project was the recipient of the 1993 Civil Engineering Achievement Award by the Pittsburgh Section of ASCE. The new lock at Point Marion improved navigation on the Monongahela River and extended the project life of this important structure. The new larger lock chamber provided by the new construction resulted in more efficient lockages, thus eliminating a bottleneck to commercial barge traffic in this section of the river.

BRADDOCK DAM: THE FIRST FLOAT-IN DAM

Braddock Dam (Dam No. 2), located twelve miles upstream from Pittsburgh on the Monongahela River, was put into operation in 1906, and a pair of lock chambers was added in 1953. The land chamber is 110 feet wide by 720 feet long, and the river chamber is 56 feet wide by 360 feet long. By the late 1990s, replacement of the nearly one-hundred-year-old Braddock Dam had become necessary because as a fixed weir structure, the level of the upstream pool could not be regulated above the crest elevation, and locks were too small to permit long tows to pass through. To overcome these deficiencies, planning commenced for a replacement dam. Taking lessons learned from projects in Europe and Japan, the Corps of Engineers decided to use for the first time in the United States the innovative “in-the-wet” methods to expedite the construction schedule, improve construction quality control and reduce cost, among other reasons.

Construction of the new Braddock Dam consisted of two reinforced concrete shell segments set on eighty-nine drilled shafts founded in bedrock. The new gated structure was built about five hundred feet upstream of the almost one-hundred-year-old fixed crest dam that it replaced. Having a gated dam permitted control of the upper pool elevation and made river navigation more efficient. Braddock Dam introduced a new type of in-river construction that did not employ the use of cofferdams, which represented a first for dam construction worldwide. This project employed the most recent innovative construction techniques and was a major departure from the proven method of dam construction within a dewatered cofferdam that had been used for decades. The replacement Braddock Dam employed “float-in” or “in-the-wet” construction. The project began in 1999 and was completed in 2004. It was the first time in the history of an inland navigation system that a precast concrete dam had been floated into place.

As opposed to traditional “in-the-dry” methods of cofferdam construction, the “in-the-wet” method involved foundation preparation and construction of drilled shaft foundations at the site, while two dam segments, composed of a combination of precast concrete panels and conventional concrete that would be the visible above water portion of the dam, were fabricated at an offsite casting basin located downstream of Pittsburgh. While the dam segments were being assembled, eighty-nine reinforced concrete drilled shafts were constructed within the footprint of the dam. Each shaft was seventy-eight inches in diameter and forty feet long, which included a fifteen- to twenty-foot-long drilled rock socket. About 20 percent of the drilled shafts were affixed with circular-form, hydraulic flat jacks at the top of the shaft to level the segments of the dam once they were aligned and placed over the shafts. Once the drilled shafts were completed, the two precast concrete dam segments were separately floated upriver to an outfitting area (located upstream of Braddock Locks and Dam), passing through three locks (Dashields and Emsworth Locks on the Ohio River and Braddock Locks on the Monongahela River) to the location of the new dam site, as noted by Edwardo, Karaffa and Greene.

Dam Segment 1 was a 11,600-ton, 330-foot- by 104-foot-wide concrete section of the dam. The size of the dam segment allowed it to be towed and “locked” through the Dashields, Emsworth and Braddock Locks. The segment was lowered onto the drilled shaft foundations by filling the structure with water and sinking it. The segment-shaft connections were grouted underwater, and the interior of the segment was filled with tremie concrete to displace the water. A neat cement grout was used to fill the 1-foot void that remained between the base of the dam and a pre-placed graded gravel base under the footprint of the dam after the segment was submerged. As part of the foundation preparation, steel sheet piles were driven to rock at both the upstream and downstream limits of the dam segments to serve as an additional barrier to prevent seepage under the dam. Dam Segment 2, measuring 265 feet by 104 feet and weighing 9,000 tons, was installed in the same manner as Segment 1. There was a cellular closure section that connected Segment 2 to the left abutment of the dam.

Braddock Dam Segment 1 being towed toward the Point of Pittsburgh. U.S. Army Corps of Engineers, Pittsburgh District.

To complete the Braddock Dam project, the existing one-hundred-year-old fixed crest dam, located about six hundred feet downstream, was completely removed to the riverbed, and the demolished concrete was used to create underwater simulated reefs to promote fish habitat. Another environmental aspect of the project involved the riverside disposal of material dredged from the footprint of the new dam that was deemed suitable for disposal. Some 400,000 cubic yards of dredged material provided cover for the restoration of a nearby Brownfield site that had been an abandoned steel mill property.

The Braddock Dam Project was recognized in 2004 when selected as the Civil Engineering Project of the Year Award by the Pittsburgh Section of ASCE.

CURRENT IMPROVEMENT ACTIVITIES: LOWER MON PROJECT

Braddock Locks and Dam (or L/D 2); Locks and Dam 3, in Elizabeth, Pennsylvania; and Charleroi Locks and Dam (or L/D 4), in Charleroi, Pennsylvania, are all located on the Monongahela River. They are the three oldest locks currently operating navigation facilities on the Monongahela River in the Pittsburgh District, Army Corps of Engineers. Former Locks and Dam No. 1 was located in Pittsburgh but no longer exists. These locks experience the highest volume of commercial traffic on the entire Monongahela River Navigation System. The pools created by these locks provide industrial and municipal water to local users and are popular with recreational boaters.

As described in the previous section, the Lower Mon Project recently replaced the nearly one-hundred-year-old fixed-crest dam at Braddock Locks and Dam with a gated dam, and in the future, it will involve removal of Locks and Dam 3 in Elizabeth, Pennsylvania, and with the construction of two new 720-foot-long by 84-foot-wide lock chambers at Charleroi Locks located in Monessen, Pennsylvania. The removal of Locks and Dam 3 will create a single pool, between Braddock and Elizabeth, and having a newer gated dam at Braddock Locks and Dam will permit the pool to rise a nominal 5 feet within this reach of the river. With Locks and Dam 3 removed, from Elizabeth to Charleroi, the river pool will drop a nominal 3.2 feet. Even though familiar river/pool levels will change, there will be no increase in flooding events along the Monongahela River.

Photograph of current new Charleroi Locks construction. U.S. Army Corps of Engineers, Pittsburgh District.

Current work at the new Charleroi Locks employs innovative construction features such as precast, post-tensioned box beams founded on drilled shaft piers for the upper guard wall and precast concrete wall panels supported by drilled shafts for the lower guard wall. The new river wall is a combination of cast-in-place monoliths constructed within internally braced cofferboxes and tremie placed concrete monoliths in a non-cofferbox wall constructed in-the-wet using reusable forming system founded on drilled shafts and an emptying basin composed of seven precast segments lifted and placed in-the-wet on concrete pedestals. The new middle wall will be composed of cast-in-place monoliths constructed in internally braced cofferboxes founded on drilled shafts and innovative through-the-sill filling and emptying system located in the upper sill of the new chamber.

FUTURE NAVIGATION IMPROVEMENTS: UPPER OHIO PROJECT

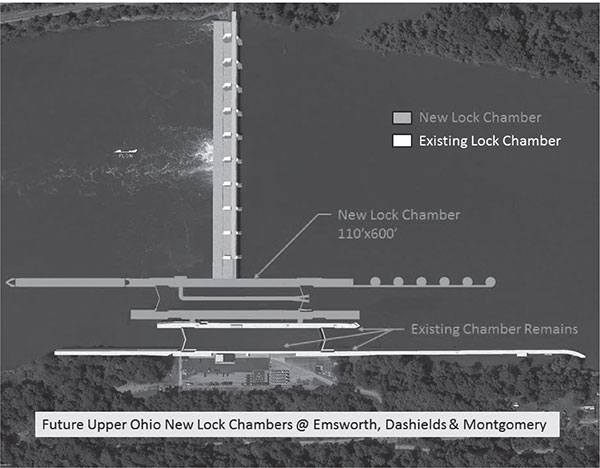

The Upper Ohio Navigation Study (October 2014, revised October 2016) recommends Congressional authorization of the National Economic Development (NED) plan for improving the upper Ohio River Navigation System. The navigation structures in this reach include Emsworth, Dashields and Montgomery Locks and Dams. Emsworth, Dashields and Montgomery, all constructed before 1936, are the first three locks and dams on the Ohio River downstream from Pittsburgh. Montgomery Locks and Dam is located thirty-two miles downstream from Pittsburgh, with the locks near Monaca, Pennsylvania. These facilities have the oldest and smallest lock chambers in the entire Ohio River Navigation System. Built before use of air-entrained concrete, all three lock structures have experienced severe concrete deterioration and are nearing the end of their service lives. The study report recommends construction of one new 110-foot-wide by 600-foot-long lock chamber at each facility, in the footprint of the existing 56- by 360-foot auxiliary lock chambers.

The wider replacement lock chambers will necessitate removal of one gate bay at Emsworth Main Channel Dam and at the Montgomery Dam. At the fixed-crest Dashields Dam, the recommended plan includes shortening the fixed-crest dam and installing one hydraulically operated gate and appurtenant facilities. The recommended new lock will be constructed using in-the-wet construction methods, including a combination of fixed and floating approach walls and a through-thesill filling and emptying system. The total project cost for all three new chambers is approximately $2.3 billion (October 2014 cost level). The recommended plan’s incremental benefit to cost ratio is approximately 4.3:1. This study determined the best plan for maintaining efficient and reliable navigation on the Upper Ohio River over a fifty-year period. The navigation project improvements will maximize economic development benefits consistent with protecting the environment. The three locks and dam facilities were constructed in the 1920s and 1930s, and their reliability exceeds what was the projected service life of all three projects; none of the structures meets modern design criteria. At each navigation structure, there is deteriorated structural concrete and antiquated operating systems.

However, early design efforts are underway to plan for the replacement of the three navigation projects. Foundation explorations at Montgomery Locks and Dam were initiated in March 2018, which is an important initial design step in the overall Upper Ohio Navigation Study.

Future Upper Ohio new locks project (rendering). U.S. Army Corps of Engineers, Pittsburgh District.

With the Lower Monongahela Project being brought to completion in 2024, if efficiently funded, and with the Upper Ohio Navigation Study leading to future improvements of the three navigation projects located downstream of Pittsburgh, the region will realize needed infrastructure upgrades.