CHAPTER 1

ROOFING SYSTEMS

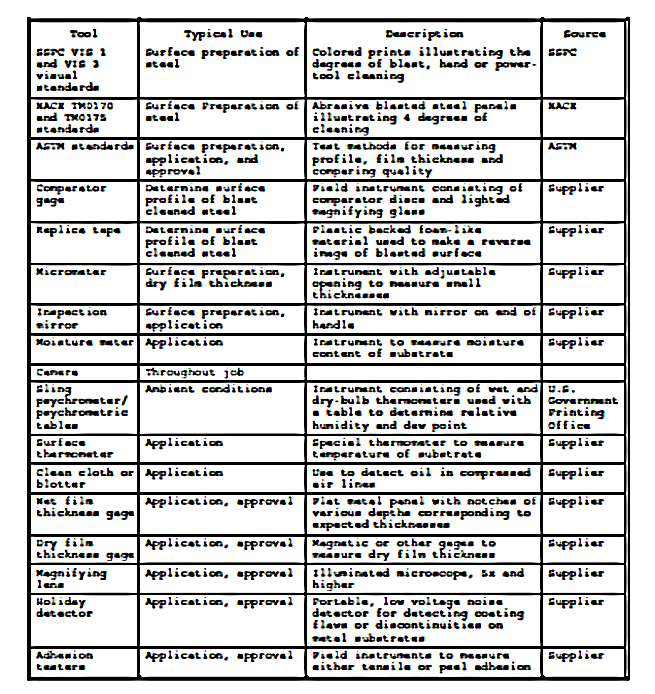

1. STARTING

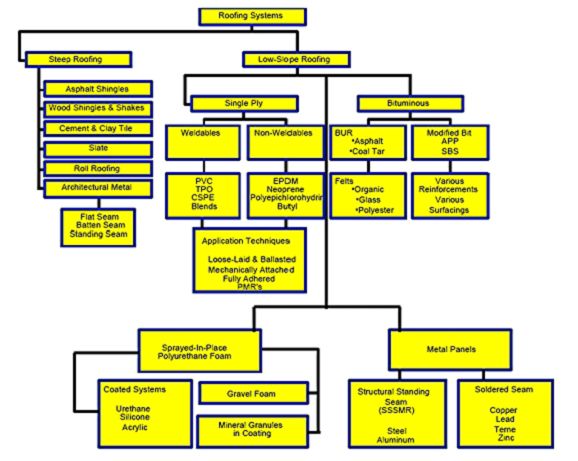

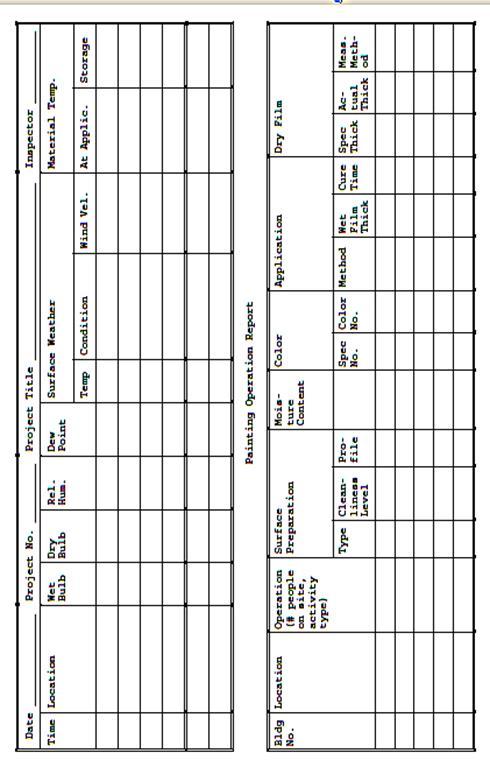

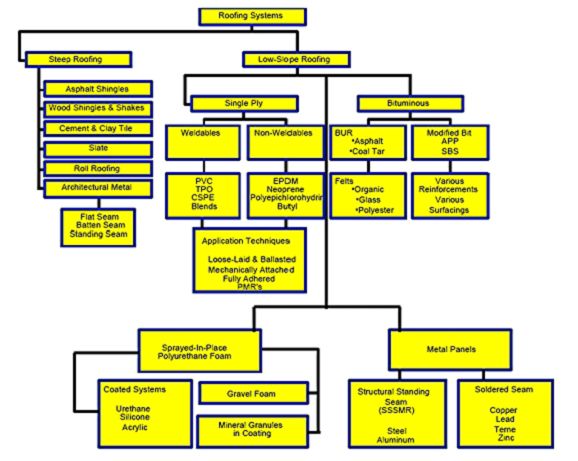

POINTS FOR ROOF SYSTEM SELECTION. This Chapter is intended to introduce the

major considerations in selecting a roofing system. Figure 1 depicts the

various alternative roofing systems and how they relate. When commencing the

selection process there are two different starting points.

Material and Roofing System Options

Figure 1

1.1 New vs.

Reroofing. The roof may be part of a new building design; or, it may

involve the reroofing of an existing structure (replacement or re-cover).

Today, approximately 75% of roofing activity is reroofing.

1.2 Steep-Slope

vs. Low-Slope. In new construction the designer is very likely to have a preconceived

notion as to whether a highly visible sloped-roof is wanted, or whether

a less visible low-slope roof design is acceptable. Positive drainage is

a very important design criterion. When reroofing, it may be feasible to

improve drainage by using tapered insulation or sloped deck fills.

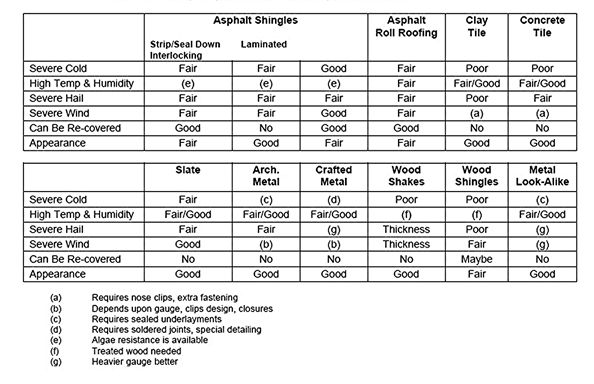

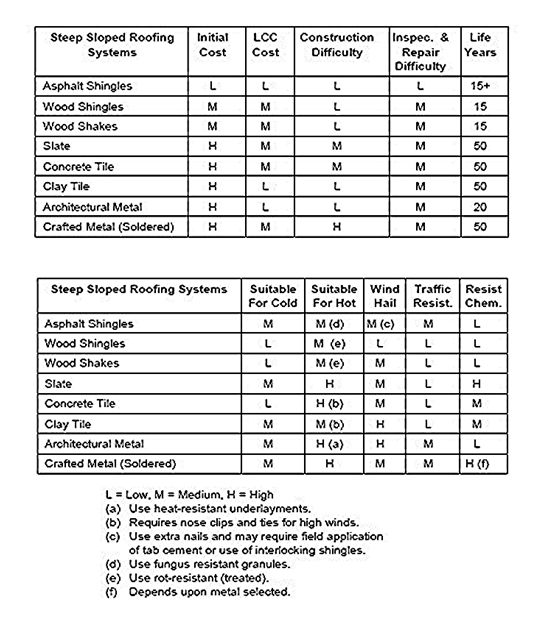

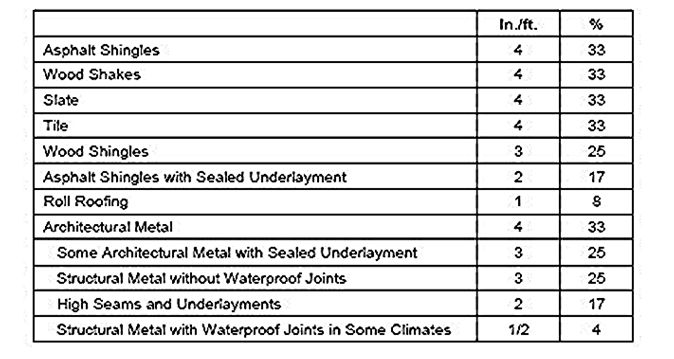

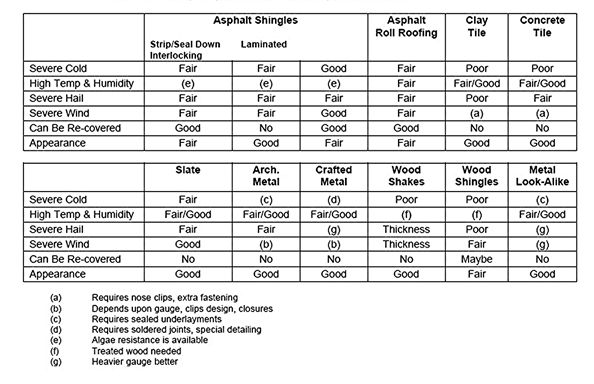

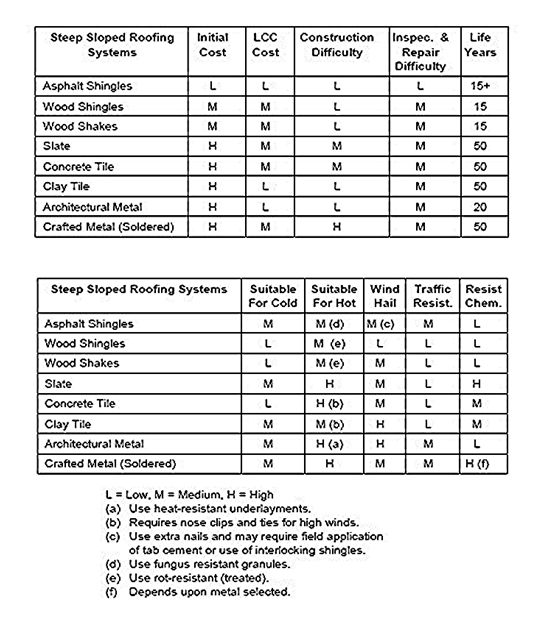

2. SELECTION

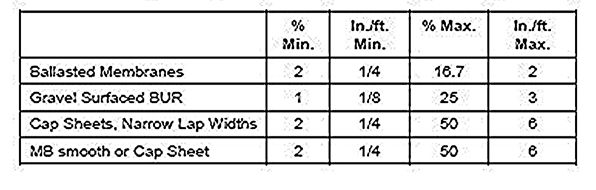

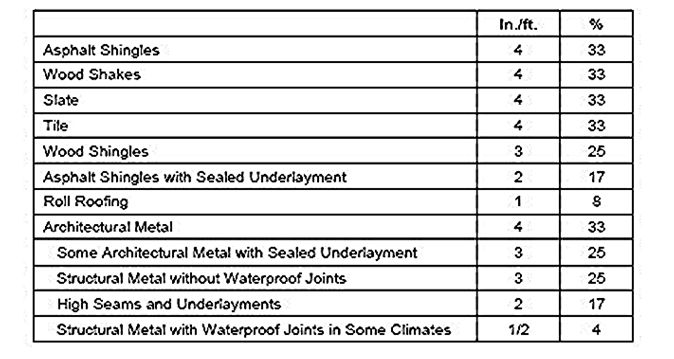

CONSIDERATIONS FOR STEEP ROOFING SYSTEMS. Table 1 evaluates common steep

roofing systems based upon some use criteria.

2.1 Aesthetics.

Steep roof systems make a strong visible statement about a building. The texture,

shadow-line, and color are major factors in selection.

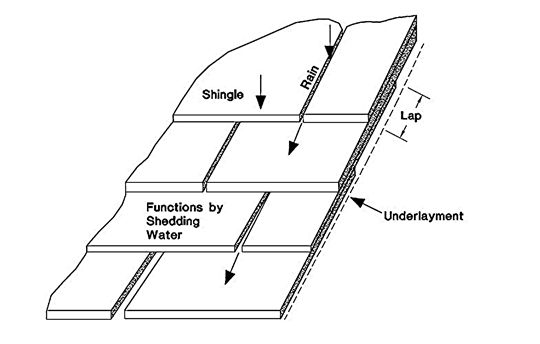

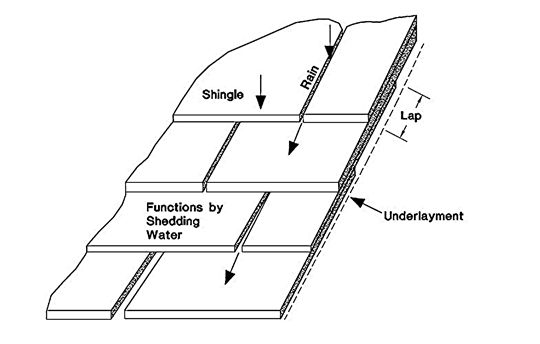

2.2 Minimum

Slope Requirements. Steep roofs function by shedding water rather than by being

waterproof (Figure 2). Minimum slopes as shown in Table 13, are required in order

to insure proper drainage.

2.3 Categories

of Steep Roofing. Major categories of steep roofing include asphalt

shingles, wood shingles and shakes, tile, slate, architectural metal, asphalt

roll roofing, and fabricated units of metal or plastic intended to look like

the others. Only asphalt roll roofing and asphalt or wood shingles may be

re-covered.

2.4 Snowshedding

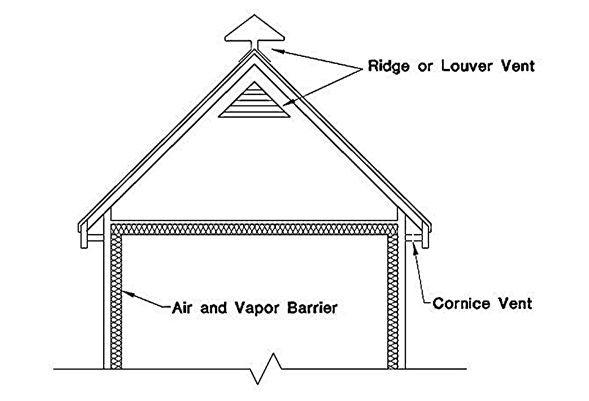

and Ventilation. Sloped roofs are effective snowshedders. In addition, the

attic space that accompanies steep roofing makes it easy to ventilate the

roofing system.

Steep Roofing (hydrokinetic)

Figure 2

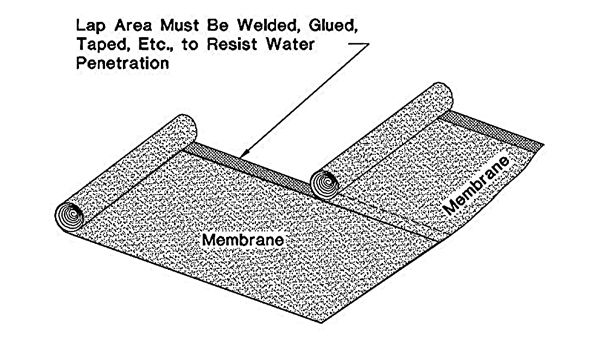

Low-Slope (hydrostatic)

Figure 3

2.5 Maintenance

Requirements. Sloped roofs in general, require less maintenance than flat roofing

systems.

2.6 Steep

Roof Conversions. When considering reroofing a flat roof, it may be

possible to convert the low-slope roofing system to a steeply sloped roof. This

may improve the appearance of the building while resolving drainage problems as

well. Steep roof conversions are a viable option for relatively narrow

buildings.

Steep Slope Selection Based Upon Use Criteria

Table 1

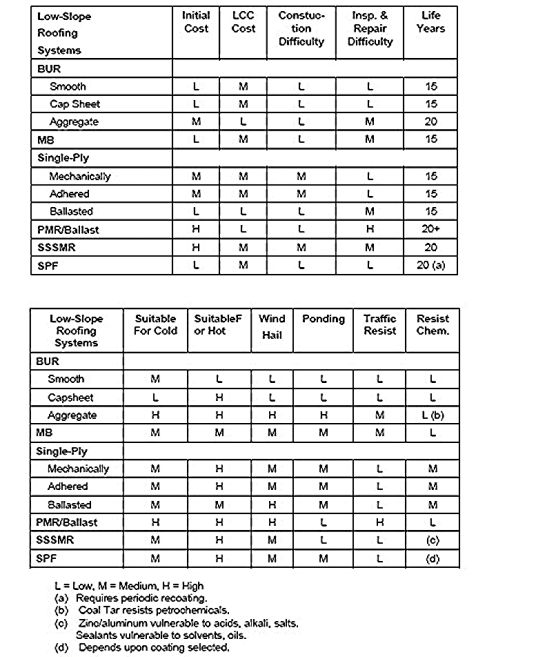

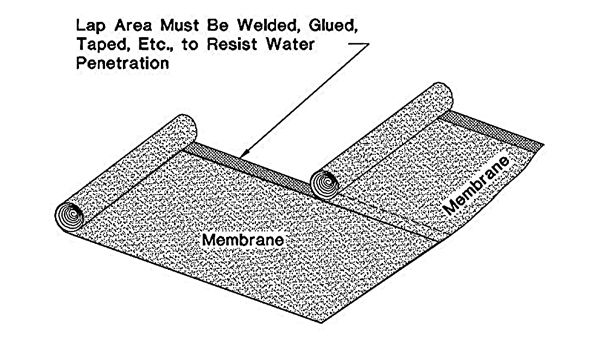

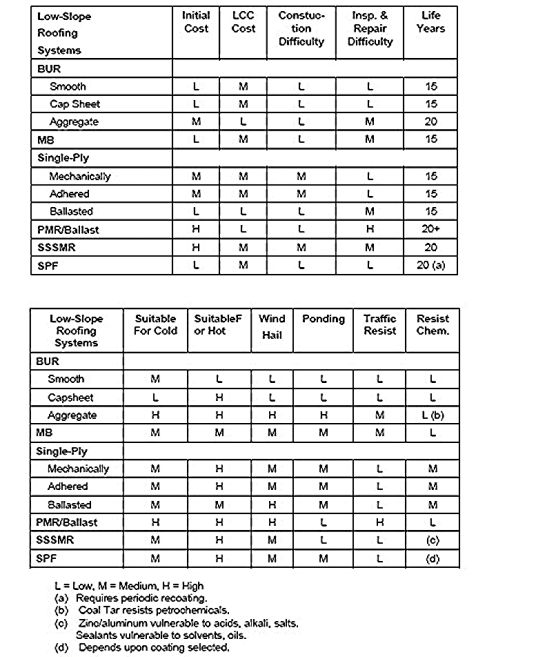

3. SELECTION

CONSIDERATIONS FOR LOW-SLOPE (MEMBRANE) ROOFING.

Membrane

roofing is typically used on commercial buildings where the minimum slopes

required by steep roofing render them impractical for larger buildings.

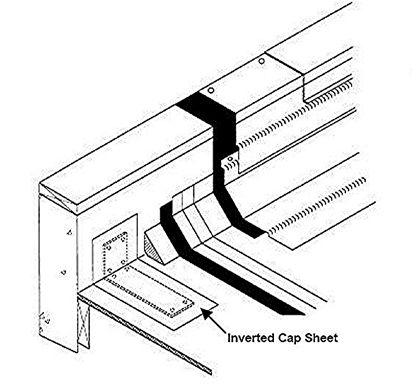

Low-slope membrane systems are completely sealed at laps and flashings (Figure 3)

and can temporarily resist standing water conditions. Choices for membrane

roofing include multi-ply bituminous built-up (BUR), polymer-modified bituminous

(MB), elastomeric single-ply systems (e.g., EPDM), thermoplastic single-ply systems

(e.g., PVC or TPO), sprayed-in-place polyurethane foam (SPF), and some metal (hydrostatic/low-slope/SSSMR)

systems. Designers frequently select low-slope roofs when the roof is expected

to accommodate rooftop equipment. With the exception of foam and metal, all low-slope

systems can be incorporated into Protected Membrane Roof (PMR) designs.

4. REROOFING

AND RE-COVERING.

4.1 Reroofing.

The term replacement is used when the existing roofing system is to be

either partially or totally removed and a new system installed. The designer

should consider any existing problems and whether drainage and thermal

performance needs to be improved. Existing surfaces such as walls and curbs

may be contaminated with bitumen, which might affect compatibility with some

reroofing options. Additional concerns (as compared to new roofing) include

whether the existing structure can handle a significantly heavier roof system

and whether construction activities of the reroof system will affect the

occupants of the building (i.e., fumes, falling debris, and noise).

4.2 Re-cover.

The term re-cover is used when a new roofing system is to be

superimposed directly over an existing system. In this case, underlying

conditions are obscured making assessment of their condition more difficult.

Additional concerns include how the re-cover system will be attached to the

existing membrane or roof deck, and compatibility with the substrate. The potential

for trapped water between the old and new membrane may suggest the use of

venting base sheets and/or roof vents.

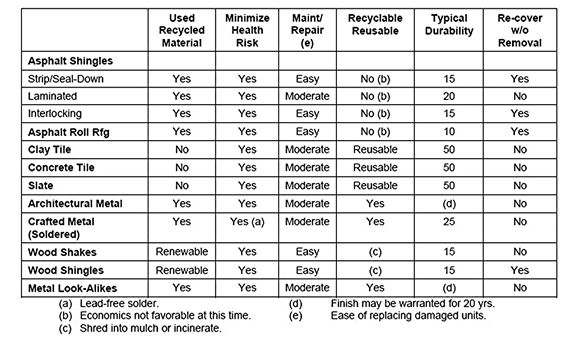

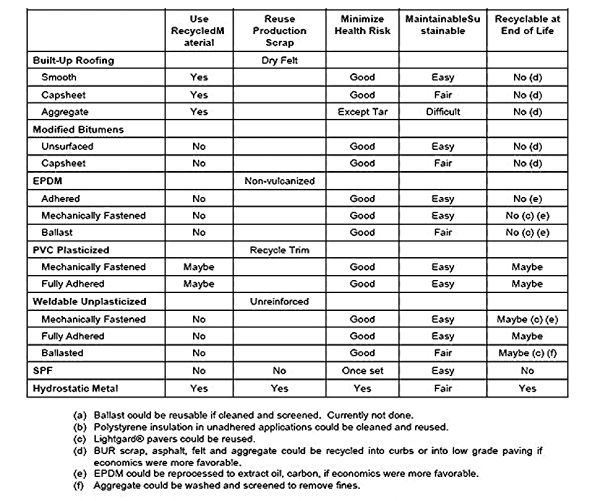

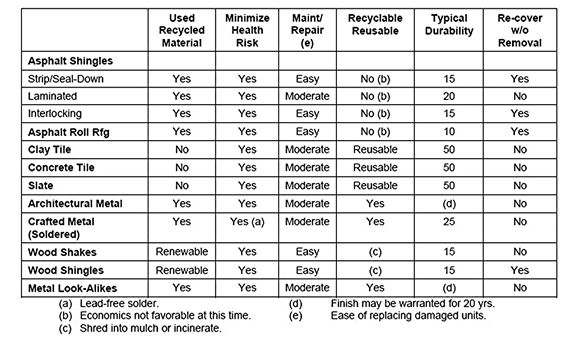

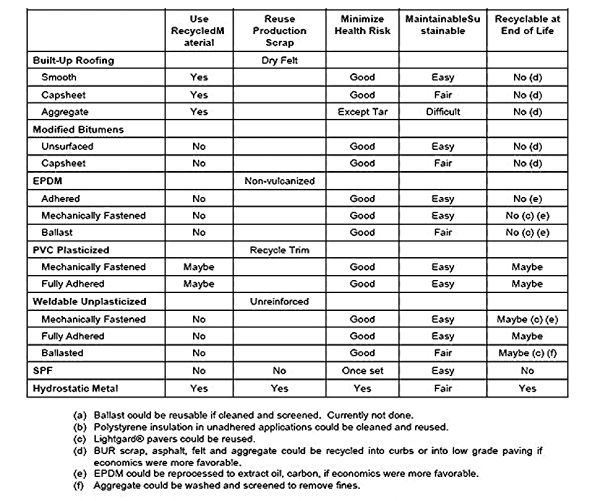

5. ENVIRONMENTAL

ISSUES. A relatively new design criterion is whether the roof system under

consideration meets green criteria, such as whether the system

incorporates postconsumer waste or is itself recyclable at the end of its

useful life. Roof system waste is bulky and puts a great strain on waste

disposal sites. Energy efficiency is also important in terms of raw materials

acquired, production of finished goods, and application of the roof system.

Thermal performance in service and retention of thermal value with age are

equally important. A sustainable or robust roof is highly

desirable as extension of the life of the roof contributes to overall

conservation. High albedo (reflective) roofs may improve localized climate

conditions. The felt used in asphalt organic shingles consists primarily of

recycled wastepaper, wood chips, and sawdust. Asphalt itself is a by-product of

petroleum refining. Wood fiber and perlite roof insulation contain waste paper.

Glass fiber and asphalt organic shingles have been recycled into asphalt

curbing and the like. Wood shingles and shakes can be recycled into garden

mulch. Steel and aluminum contain recycled scrap and at the end of their life,

metal panels can be recycled back into scrap. Tables 2 and 3 compare

environmental considerations for steep and low-slope roofing systems.

Preserving the Environment – Steep Roofing

Table 2

Preserving the Environment – Low-Slope Roofing

Table 3

6. DETAILED

INFORMATION. Once a tentative roofing system selection has been made using

information provided by this discussion.

7. USING

PRINCIPAL DESIGN CONSIDERATIONS TO REDUCE THE NUMBER OF POSSIBLE ROOF SYSTEMS.

7.1 Principal

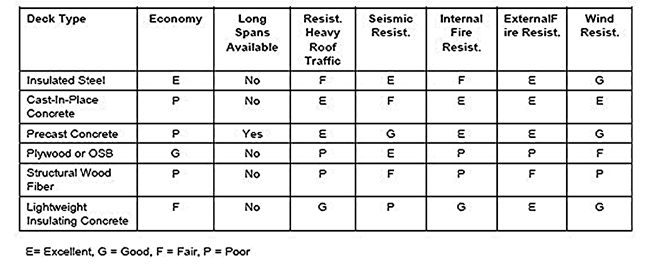

Design Considerations. Tables 4 and 5 list some of the principal design considerations

in roof system selection. An explanation of the headings follows the tables.

These tables are not all-inclusive but contain many criteria that the designer

can consider to reduce the myriad of choices. Systems that fail to meet the

principal project design criteria can be quickly disqualified from further

consideration. For example, if an existing structure has reached its design

load limit, then heavier roofs (such as ballasted single-ply roofs or concrete

tiles) would have to be disqualified (or the structure would have to be

strengthened at significant cost).

Principal Design Considerations—Steep Roofing

Table 4

Principal Design Considerations—Low-Slope Roofing

Table 5

7.2 Discussion

of Headers in Tables 4 and 5.

7.2.1 Initial

Cost. This may include materials, labor, and special set-up for

construction.

Initial cost

may determine if the roof, as designed, is affordable. Perhaps a somewhat less expensive

system should be considered if it does not incur significantly increased maintenance

costs or have a shortened life.

7.2.2 Life

Cycle Cost. LCC considers durability but also presumes that routine

maintenance

will be performed to achieve the projected life. Consider whether the building

is temporary or permanent. It would be hard to justify an expensive copper or

slate roof on a building scheduled for demolition in the near future. Also

consider the mission of the building. There are levels of quality in many systems.

For example, while 45 mil EPDM is the standard, for little extra cost 90 mil

material with greater puncture resistance, or conversion to a PMR system, could

be specified for a building with a critical mission.

7.2.3 Construction

Difficulty. Some systems require more clearance to accommodate

application

methods and equipment. Large prefabricated roof sheets (i.e., 50 ft. by 200

ft.) may be fine on a large roof with few penetrations, but are impractical on

a roof area that is broken up by many curbs and equipment supports. On multiple

penetration surfaces, relatively narrow sheets (e.g., BUR, MB, thermoplastic

single-ply) or sprayed-in-place polyurethane foam should be considered.

Penetrations through standing seam metal roofing need to accommodate the

expected thermal movement of the metal panels. Thermal movement is cumulative, increasing

with distance from the point where the panels are restrained (typically the

eaves). Penetrations in SSSMR panels must pass through the flat portion of the

panel, not through the standing seam. Penetrations wider than a single panel require

a diverter to carry water around the obstruction. Water must flow parallel to

the raised seams, never over them.

7.2.4 Periodic

Maintenance—(The need for periodic maintenance and difficulty of

inspection

or maintenance.) Some roof systems require periodic recoating for weather

protection. Aggregate surfaced roofs are more difficult to inspect and patch

than smooth surfaced roofs.

7.2.5 Life

Expectancy. A mean life is listed but the actual life is affected by

drainage,

maintenance,

and extreme use or abuse.

7.2.6 Suitability

in Severe Cold. Effects of freeze-thaw, hail, ice scrubbing, and traffic

while cold (i.e., snow removal) is considered. Some materials embrittle

dramatically at low temperatures (i.e., have a relatively high glass transition

temperature); others may embrittle as they weather and lose plasticizer or are

degraded by UV or thermal load. H indicates highly suitable; L indicates

less suitable.

7.2.7 Suitability

in Extremely Hot or Humid Conditions. Effects of thermal expansion and algae

growth are considered. H indicates more suitable, L indicates

less suitable.

7.2.8 Wind

Resistance. Roofs are vulnerable to wind scour and blow-off. While

arbitrary ratings are provided here, the resistance is affected by building

height, terrain, parapet height and measures taken to upgrade perimeter and

corner attachment. H indicates highly wind resistant (when properly

designed). For membrane roofing, impermeable roof decks such as cast-in-place concrete

are best. Air retarders are needed with loose laid and mechanically fastened

single-ply systems as they may otherwise balloon from interior air leakage.

Perimeter wood blocking must be well anchored to prevent peeling of the

membrane or loss of fascia metal. Avoid the use of small aggregate (e.g., pea

gravel) near tarmacs and on skyscrapers due to the damage it can cause if blown

off the roof by high wind. Asphalt shingles may require manual application of

tab adhesive. Interlocking asphalt shingles provide excellent wind resistance.

Metal panel systems are wind resistant only when all components including

clips, fasteners, and secondary structural members are installed as

wind-tested. SPF has outstanding resistance to wind and to wind-blown missiles.

SPF roofs performed well in hurricane Andrew, especially when they were

spray-applied

directly to

concrete roof decks.

7.2.9 Resistance

to Ponding Water. Membrane roof systems rely upon sealed seams to resist

hydrostatic pressure. Water absorption may result in root or algae growth or

cause rot. H infers highly resistant to these conditions.

7.2.10 Traffic

Wear Resistance. Roofs that have a lot of rooftop equipment will have foot traffic

that can cause punctures or abrasion. Most roof systems are available with

traffic protective overlayers, such as walkways. H indicates highly

resistant to abuse assuming protective courses have been used.

7.2.11 Resistance

to Chemicals (resistance to oils, fats, grease, metal ions). Some roof surfaces

are vulnerable to exhausted fumes or liquids. Thermoplastic polyolefins (TPO’s)

and Hypalon® (CSPE) may be better than bituminous materials in resistance to

oils, greases, and solvents. Copper-containing runoff water from condensate

coils or flashings will corrode zinc and zinc-aluminum SSSMR roofing. H indicates

better than average resistance to attack.

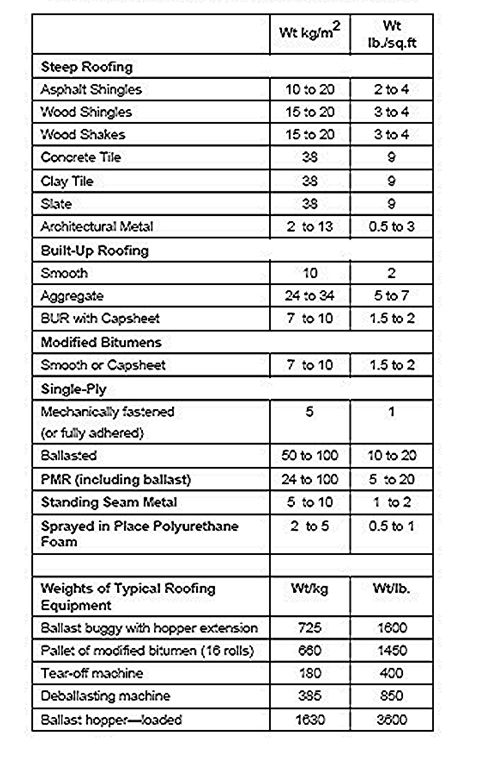

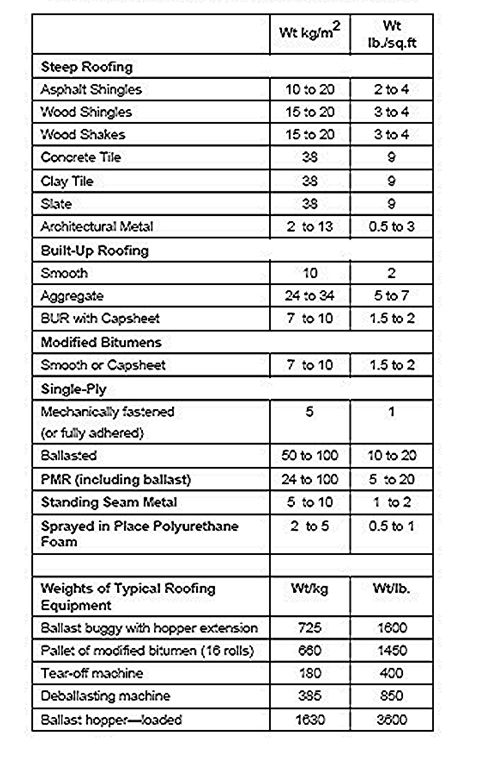

7.3 Weight

Factor. Consider the total number of roofs already installed, the weight of

the proposed roof system possible, and construction loads. The unit weight of

membrane systems vary dramatically, ranging from less than 0.5 psf for a 2 in. thickness

of SPF, to more than 20 psf for ballasted single-ply systems. Typical roof

system weights and construction loads are shown in Table 6.

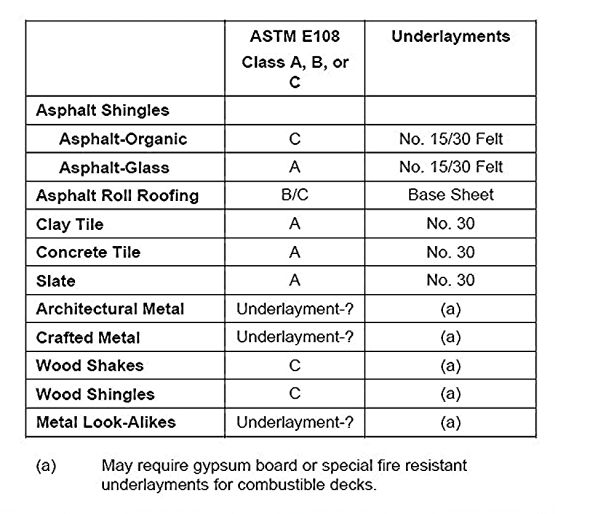

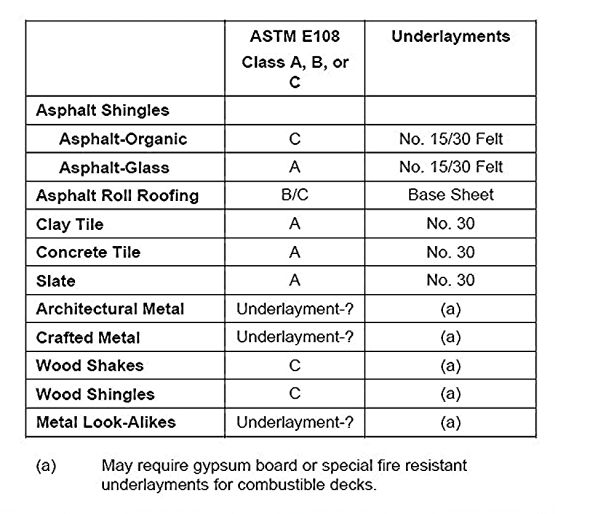

7.4 Compliance

with Fire & Wind Requirements. Roofing systems are rated as entire systems,

including the roof deck, method of attachment to the deck (e.g., fasteners, hot

bitumen, cold adhesives), vapor retarder (if used), thermal insulation, roof

membrane, and surfacing. Typical External Fire Ratings (ASTM E-108, Class A, B

or C) are shown in Tables 7 and 8. Combustible decks (wood/plywood/OSB)

require selected combinations of underlayments, insulation, roofing, and

surfacing to resist burning brands and intermittent flame as described in ASTM

E108.

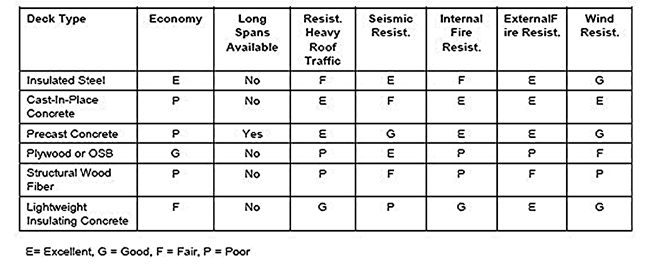

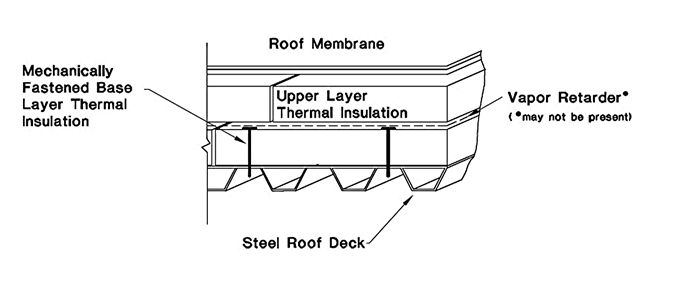

7.5 Roof

Decking. Principle roof decks for membrane roofing include steel,

cast-in-place concrete, precast concrete, wood, plywood, OSB, and structural

wood fiber. Variations of cast-in-place concrete include lightweight structural

concrete (typically 1680 kg/m3)(105 psf) and lightweight insulating

concrete(480 kg/m3)(30 psf). In new design, the roof deck is generally selected

based upon construction considerations and materials. Steel is by far the most

popular, followed by concrete and plywood/OSB. Table 9 lists some criteria for

deck selection for new construction. Table 9 lists methods of attachment to the

roof deck. Attachment options include full adhesion, mechanical fastening, and

loose-laid/ballasted roofing. Steel decking requires a

bridging course

typically mechanically fastened roof insulation. For steep roofing, plywood and

OSB roof decks are most common. They generally utilize flexible batts as

underdeck roof insulation although architectural metal and cathedral ceiling

constructions may use rigid insulation above the deck.

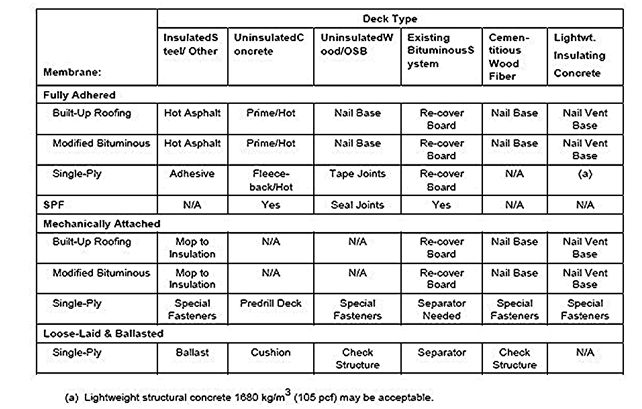

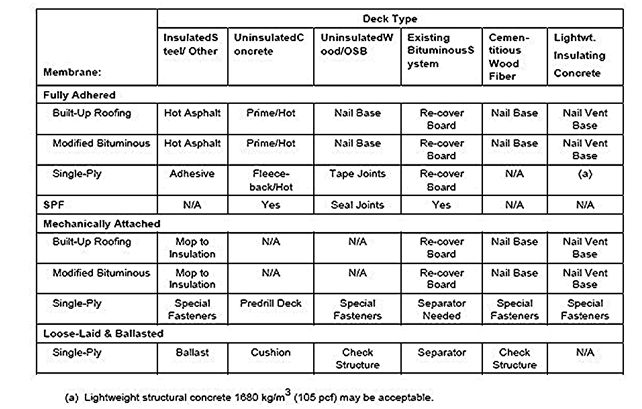

7.6 Suitability

of the Membrane for the Substrate. Table 10 lists some possible

combinations.

Typical Weights of Material and Equipment

Table 6

Fire Ratings and Required Underlayments for

Steep-Sloped Roof Systems

Table 7

Fire Ratings and Required Underlayments for Low-Slope

Roof Systems

Table 8

Suitability of the Roof Deck for Various Conditions

Table 9

Membrane/Substrate Compatibility/Attachment Methods

Table 10

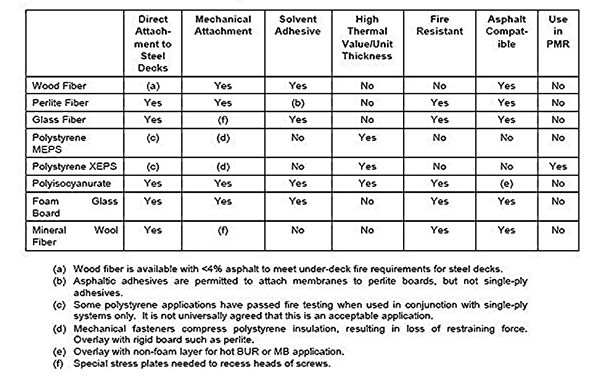

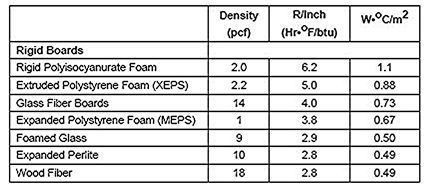

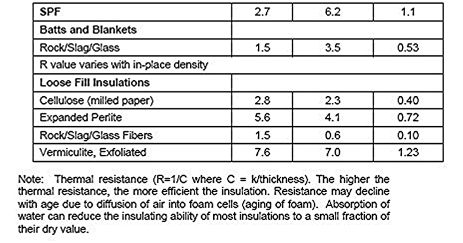

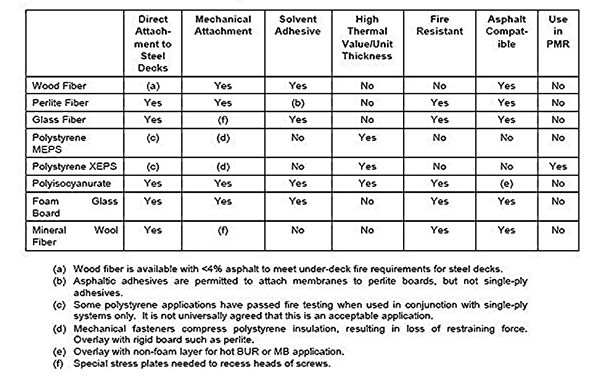

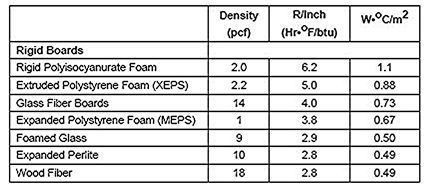

7.7 Thermal

Insulation. Rigid thermal insulations used under membrane roofing include

wood fiber, perlite fiber, glass fiber, foamed glass, polystyrene (extruded or

expanded), and polyisocyanurate (isoboards). Non-structural thermal insulations

include glass fiber and mineral wool batts, blown loose insulations such as

cellulose fiber, glass fiber, mineral fiber, and expanded vermiculite. Table 11

indicates suitability of rigid roof insulations for membrane roofing based upon

intended method of use.

Suitability of Roof Insulation for Method of Use

Table 11

7.7.1 Thickness

of Insulation. If thick layers of insulation are needed to meet a high

therm resistance, thicker wood nailers and deeper fascia metal will be

required. Foam plastics such as polyisocyanurate and polystyrene have the

highest R values per unit thickness.

7.7.2 Clearance

of Metal Panels. In standing seam metal roof systems, the permissible

thickness of blanket insulation may be limited by the clearance provided by the

supporting clip design.

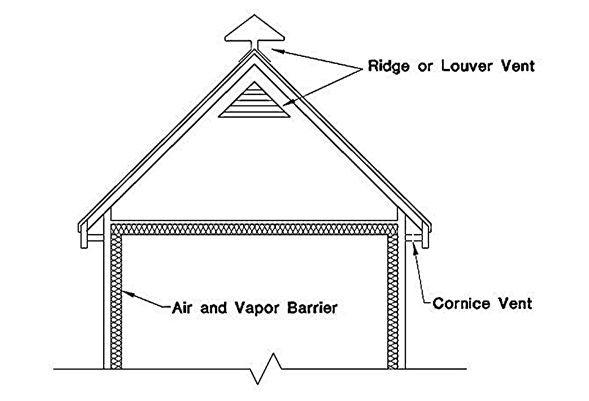

7.7.3 Insulated

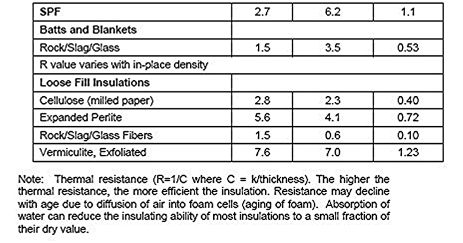

Attic. Blanket insulation used in steep roofing systems is frequently

placed on the

floor of the attic where R-values of 30 (RSI = 5.4) or more may be possible (Figure

13).

7.7.4 Ceiling

Insulation. Dropped ceilings are sometimes insulated by placing batts

directly above

the ceiling panels. This practice is not recommended as subsequent access to underdeck

equipment or phone wires is blocked. When the insulation is displaced to gain

access it is rarely put back in place correctly, if at all.

7.8 Suitability

for Extreme Climates. Protected membrane systems (PMRs) are very well suited

to extremely cold climates and have been successfully used in all climates. For

extreme conditions of snow and ice, a cold (ventilated) roof should be

considered. For most steep roofing this is achieved by allowing a flow of outdoor

air between the insulation and the roofing system. This air cools the roof in

summer, dries out any moisture that condenses in the roof, and greatly reduces

the formation of icicles and ice dams along eaves. For regions prone to severe

hail, ballasted EPDM roofs are very good and PMRs are excellent. Tiles,

shingles, bare BUR, and metal systems are easily damaged by hail. In regions of

semitropical climate (high temperatures and humidity), asphalt shingles should

be treated to be fungus resistant and wood shakes/shingles should be pressure

treated for rot resistance.

7.9 Installation

in Cold or Wet Weather. Most membrane systems are difficult to install in subfreezing

weather. If frequent precipitation during construction is a problem, factory

fabricated single-ply systems with field welded seams may have advantages over

systems where field application of adhesives or hot bitumen is needed. Torch

applied modified bitumens are one of the few systems that can be applied,

albeit slowly, in wet windy conditions.

7.10 Warranties.

The NRCA Commercial Low-Slope Roofing Materials Guide contains a comprehensive

side-by-side comparison of commercial roof warranties. The roofing industry offers

two general types of warranties: Materials Only and Materials & Workmanship.

Carefully read exclusions and limits. Note: The longest warranties are not

necessarily the best, nor does the length of the warranty directly relate to

roof durability. In many cases, manufacturers may restrict their warranties.

7.11 Maintenance

Considerations. Sloped roofs require less routine maintenance and may be preferred

when the facilities management is incapable of providing routine inspections

and minor repairs. Modified bituminous and BUR systems may be superior in abuse

resistance to thin single-ply systems. Various protection boards/walkways can

be used around equipment where traffic is anticipated. Protected membrane roof

systems (PMR’s) are abuse resistant but more difficult to inspect and repair.

7.12 Roof

Access, Fumes and Property Protection When Reroofing.

7.12.1 Fumes.

In reroofing situations fumes from kettles and solvents may be objectionable.

Hot coal tar pitch is especially objectionable; hot asphalt is also noticeable

but less noxious. Cold applied systems with taped or welded seams and metal

roof systems generate few odors. It may be necessary to coordinate

air-conditioning shutdown to avoid taking fumes into the occupied building.

7.12.2 Ease

of Construction Access. If the area around the construction site is congested

it may make heating and hoisting of roofing materials difficult.

7.12.3 Specifying

Construction Procedures. Site access, material storage area, layout area,

building and landscape protection should be identified on drawings.

7.12.4 Safety

and Disturbance to Occupants. The presence of occupants, vehicles, and pedestrians

may be of concern. Reroofing is noisy. Dust and overspray may affect those

nearby.

7.13 Installation.

Roofing requires skilled installers. Qualified contractors and inspectors are more

likely to be available if the system is customarily used in the region. It

should be determined whether there are several manufacturer-approved installers

capable of bidding the work.

7.14 Owner

Preferences. Verify that the contemplated system is acceptable to the

owner, occupants, and maintenance personnel.

8. CONSIDERATIONS

WHEN SPECIFYING LOW-SLOPE (HYDROSTATIC) MEMBRANE ROOFING. With the

exception of SSSMR, membrane roofing requires a suitable roof deck. Most constructions

will also use thermal insulation. Vapor retarders are sometimes required to

protect the roofing system from attack by interior moisture.

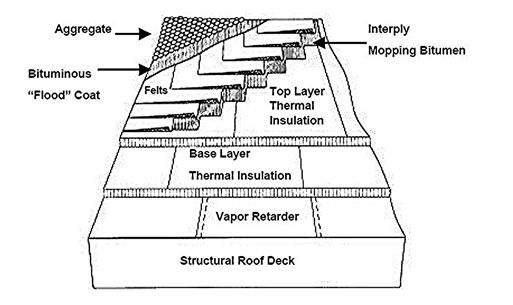

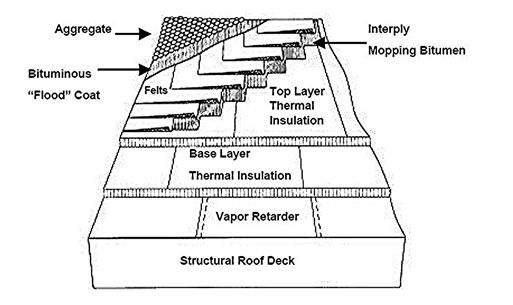

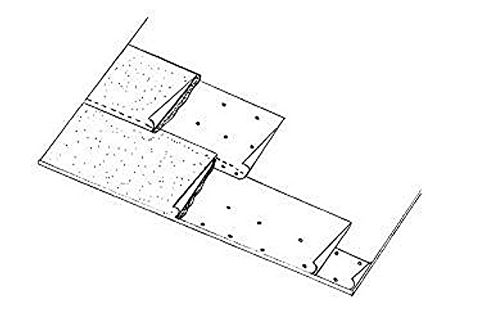

8.1 Built-up

Roofing (BUR). BUR Consists of multiple reinforcements such as asphalt

treated glass or organic felt laminated together with hot-applied bitumen

(asphalt or coal tar pitch) or cold adhesives (Figure 4). Surfacings include

aggregate, coatings, capsheets, and sprayed roofing granules. A typical system

includes thermal insulation and may include a vapor retarder.

Typical BUR System

Figure 4

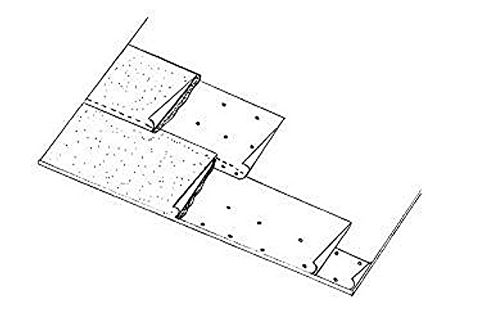

8.2 Polymer

Modified Bitumen. MB consists of reinforcing sheets factory-coated with

polymer modified bitumen. They may be laminated in the field using hot bitumen,

heat fusion, or by cold adhesives (Figure 5). Surfacings include capsheets with

mineral granules, metal foil, and field applied coatings.

Polymer-Modified Cap Sheet Adhered to Mechanically

Fastened Base Sheet

Figure 5

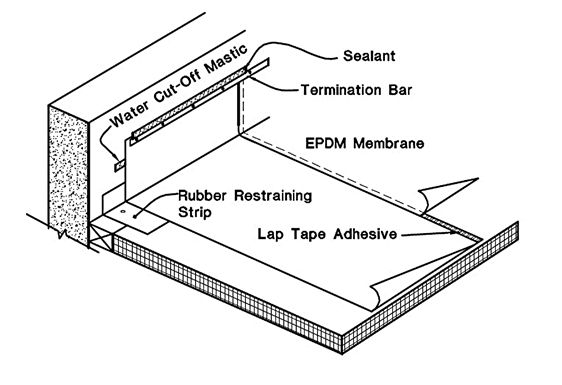

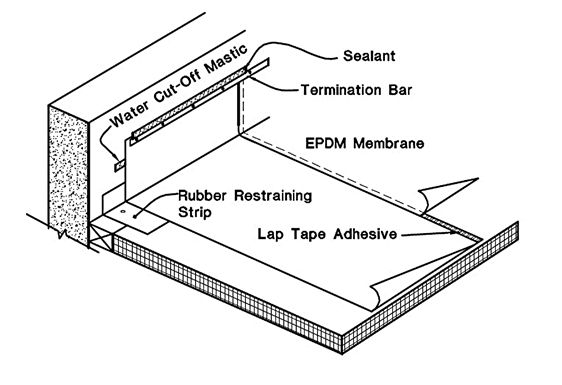

8.3 Elastomeric

(Single-Ply) Membranes. Elastomeric membranes consist of a factory produced

sheet generally of EPDM rubber with seams field-sealed with adhesive or tape (Figure

6). Sheets are unsurfaced unless ballast is used. Elastomers are vulcanized

(thermoset), and usually non-reinforced except when used in mechanically

fastened systems. A fleece-backed sheet is also available for fully adhered

systems when it is desired to use hot bitumen as an adhesive (e.g., for

re-covering an asphalt-contaminated deck or old BUR).

EPDM Roof System

Figure 6

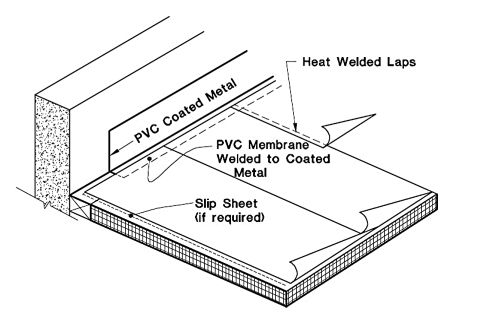

PVC Roof System

Figure 7

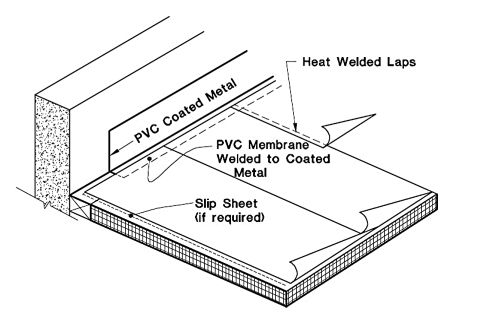

8.4 Weldable

Thermoplastic Membranes. These membranes consist of a sheet of reinforced thermoplastic

material such as PVC or TPO. Sheets are unsurfaced or ballasted. Seams are generally

heat fused although solvent welding and adhesive bonding are also possible (Figure

7).

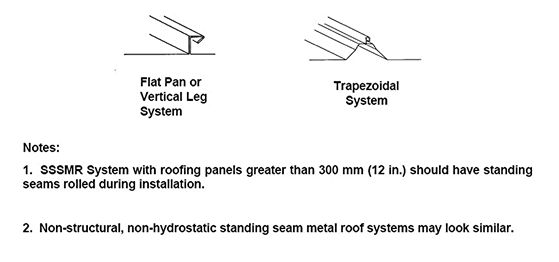

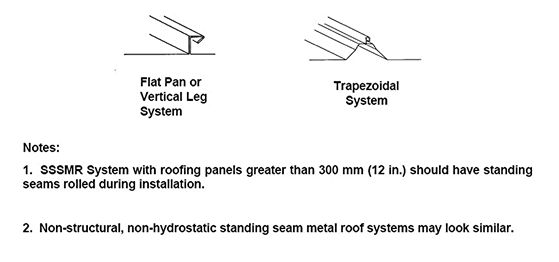

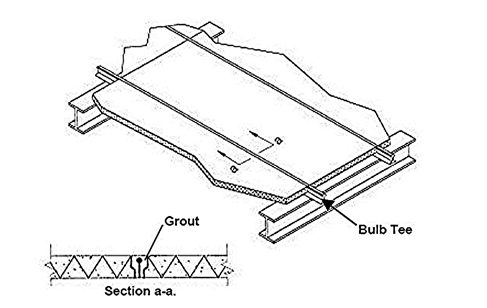

8.5 Structural

Standing Seam Metal Roofing. SSSMR consists of metal panels with raised seams

more than 1-1/2 in. high (Figure 8). Sealants are utilized at side seams and endlaps

to provide waterproofing. Most are considered hydrostatic, resisting standing

snow and occasional ponding. Caution: ridges and valleys of a SSSMR may not be

as watertight as the seams.

Structural Standing Seam Metal Roofing

Figure 8

8.6 Sprayed-in-Place

Polyurethane Foam. SPF is a thermoset rigid foam, field-formed by the reaction

of liquid components (in the presence of a foaming agent) sprayed onto the

substrate. SPF is protected by liquid-applied elastomeric coatings or an

application of loose gravel (on slopes < 4%).

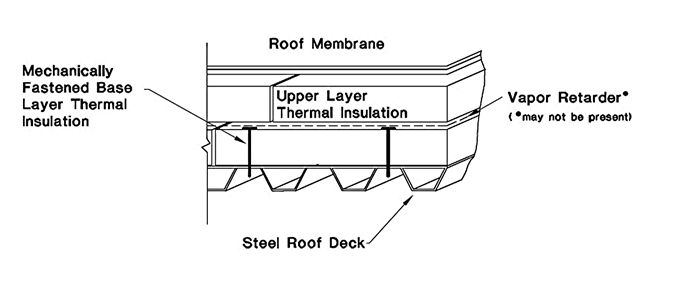

Components of Membrane Roofing System

Figure 9

8.7 Components

of Membrane Roofing Systems (Figure 9).

8.7.1 The

deck supports roofing loads and is selected to conform to fire resistant

design classifications. Not all systems require a deck (e.g., structural

standing seam metal roofing).

8.7.2 A

vapor retarder protects the insulation against moisture vapor attack from

the

warm, high

vapor pressure side of the roof assembly. Not all buildings require a vapor

retarder.

8.7.3 An

air barrier prevents air movement (infiltration or exfiltration) through

the roofing system.

8.7.4 Thermal

insulation provides thermal resistance and prevents condensation on

components

beneath the insulation. It also furnishes support and a smooth, continuous

substrate for the membrane.

8.7.5 The

membrane is intended to keep water out of the components below (as well as out

of the building). The membrane system affects fire resistance.

8.7.6 Individual

roofing components may be held in place by adhesives, fasteners, ballast, or

a combination of these methods.

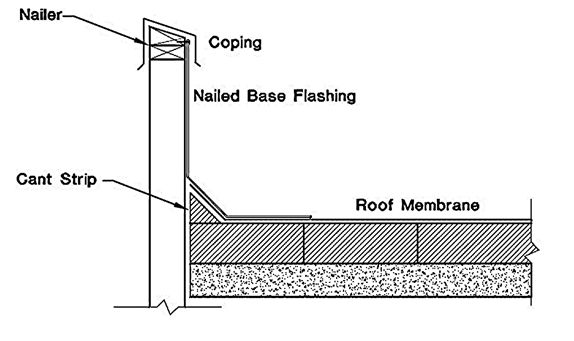

8.7.7 Perimeter

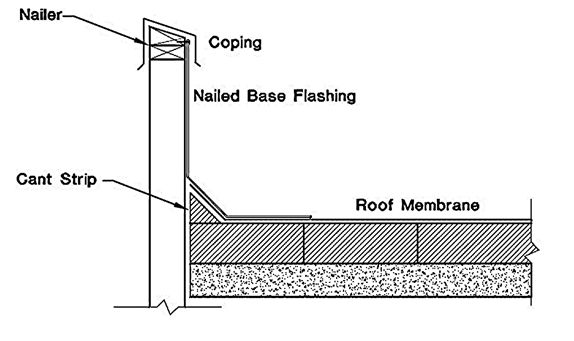

flashings are waterproof vertical terminations of the membrane (perimeter

flashing) (Figure 10).

Wall Base and Cap Flashing

Figure 10

8.7.8 Roof

edging and fascia are usually low profile roof edge terminations and side

trim.

8.7.9 Roof

penetrations include drains, vents, curbs, equipment supports, and the

like.

8.7.10 Surfacing

materials screen UV light, improve fire ratings, and may improve water and/or

hail resistance.

8.8 Attachment

for Low-Slope Roof Systems.

8.8.1 Full

Anchorage. For relatively inelastic roof membranes such as BUR and MB,

solid adhesion helps restrain the roof membrane and uniformly distribute

thermal stresses. When insulation is used, it is fastened or adhered to the

deck. The membrane is fully adhered to the thermal insulation using hot asphalt

or cold adhesive. Polyurethane foam is sprayed directly to the substrate,

especially in re-cover of existing BUR thereby being fully adhered as well.

8.8.2 Partial

Attachment. In partially attached systems the membrane is mechanically

anchored

through the insulation into the deck, or in a few cases, partially adhered with

strips or spots of adhesive. This is common with flexible single-ply roof

membranes. Fasteners are typically placed in the seams area where by can be

covered by the overlapping sheet.

8.8.3 Loose-Laid

Attachment. For loose-laid systems the membrane is unattached to the substrate

and is held in place by ballast. Restraint is required only at perimeters and

curbs. Loose-laid roofs are used with elastomeric (EPDM) and some thermoplastic

(e.g., TPO) systems. These are very inexpensive roof systems if the

structure can handle the ballast weight.

Caution:

In positive pressure buildings air

barriers should be used with loose laid and partially attached membranes to

avoid billowing and peeling.

8.9 Labor.

8.9.1 Highly

Intensive: BUR, MB

8.9.2 Moderately

Intensive: SSSMR—The system is very unforgiving of installation defects.

8.9.3 Medium

Intensity: Fully adhered and mechanically fastened single-ply.

8.9.4 Low

Intensity: Spray Foam requires the smallest crew (but is the most machine

intensive and

weather sensitive).

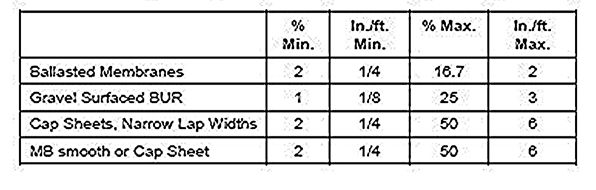

8.10 Slope.

Some Typical Slope Limitations for Low-Slope Roof

Systems

Table 12

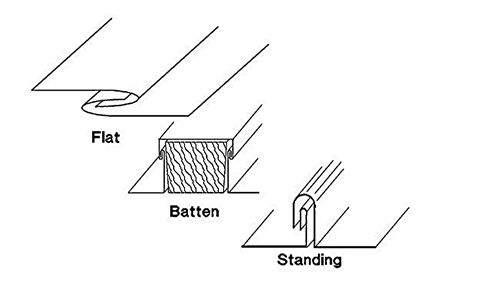

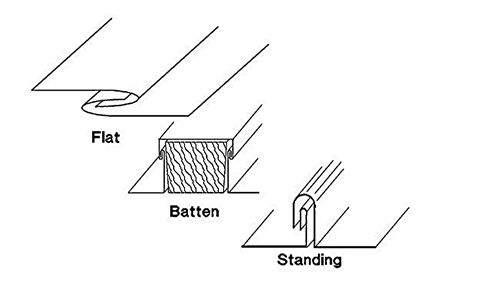

9. PRINCIPAL

CONSIDERATIONS WHEN SPECIFYING STEEP-SLOPE (WATERSHEDDING) ROOFING. This

category covers systems that range from asphalt shingles, wood shingles and

shakes, clay and concrete tile, slate, and metal look-a-likes. Also included

are architectural metal panels with a variety of seams (Figure 11). Slopes are generally

25% (3:12) or greater. Most must be continuously supported on a solid deck

(e.g., plywood or oriented strand board [OSB]). However, some varieties (e.g.,

clay and concrete tiles) may be supported on spaced horizontal batten boards. Underlayments

such as roofing felt, self-adhering MB or plastic film are usually required

over the entire roof to provide a secondary line of defense against driving

rain and blowing snow. In cold regions, a completely sealed MB underlayment is

needed along eaves, in valleys, and at dormers, skylights, chimneys and such to

resist leaks from water ponded behind ice dams.

Architectural Metal Seams

Figure 11

9.1 Aesthetics.

By their very nature steep roofing is highly visible. Appearance may be of primary

concern to the designer. Regional preferences exist. For example, red tile

roofing is very common and highly desirable in the Southwest, while light gray

concrete tile is preferred in Florida. Wood shakes give a textured natural look

preferred in the Pacific Northwest.

9.2 Labor

Intensity and Labor Skill.

9.2.1 High

Intensity. Heavy brittle units of clay, tile or slate.

9.2.2 Medium

Intensity. Architectural metal, wood shakes.

9.2.3 Low

Intensity. Shingles.

9.3 Watershedding.

Steep roofs rely on gravity to cause water to flow away from headlaps. Recommended

minimum slopes are shown in Table 13. Lower slopes are sometime permissible by

increasing overlap or enhancing the waterproofness of the underlayment.

Minimum Slopes for Typical Steep Roofing Systems

Table 13

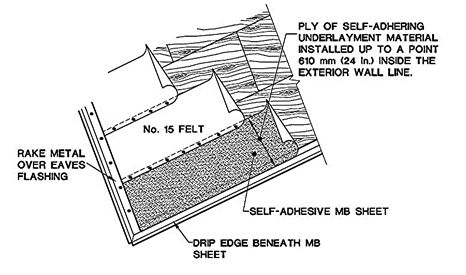

9.3.1 Valleys

and Eaves. Valleys must be well constructed. The slope of a valley will be less

than that of the intersecting planes that form it. Exterior drainage over the

roof edge or to a gutter is typical but may be troublesome in cold regions

since ice dams may form there.

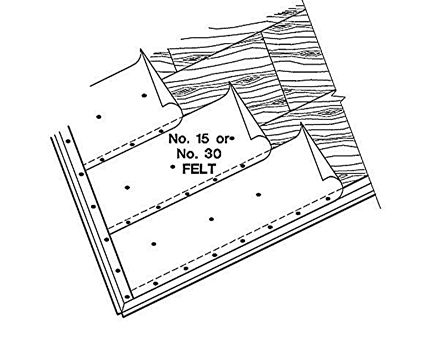

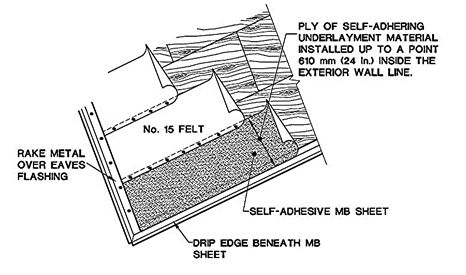

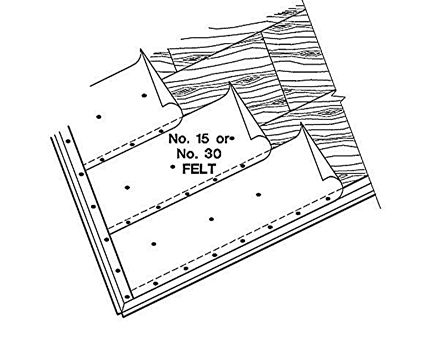

9.3.2 Underlayments.

Sealed underlayments of self-adhering modified bitumen are typically used

along the eaves to at least 24” beyond the interior wall line (Figure 12a) and

as valley lining. Occasionally the entire roof deck is covered with such a

membrane. Note that this can lead to problems if indoor moisture is not

isolated from the roof by well made vapor and air barriers. Underlayments are

used in steep roofing as a secondary defense against water penetration (Figure 12b).

These include No. 15 felt, No. 30 felt, and self-adhering MB sheets. For

hydrokinetic and crafted metal, self-adhering MB sheets are essential as a

secondary water barrier.

Self-Adhesive Eaves Flashing

(Underlayment is sealed from eave to 24” within wall

line.)

Figure 12a

Underlayment for Steep Roofing

(Underlay felt is unsealed)

Figure 12b

9.3.3 Energy

Efficiency. Steep roofs generally cover an attic space (figure 2-13) (with

the exception of cathedral ceilings). The floor of an attic can be

inexpensively insulated with nonstructural insulations such as fiberglass

batts, mineral wool, expanded vermiculite, or treated cellulose. Where the

thickness of the insulation is not limited by clearance problems, very high thermal

resistances (e.g., Rsi > 5.56, R > 30) can be achieved. If a vapor

retarder is required for a cold arctic climate the retarder needs to be placed

on the interior (warm side) of the insulation. The attic space above this

insulation should be ventilated to remove moisture and to keep the attic

relatively cold; this minimizes ice damming at eaves.

Vented Attic Space

Figure 13

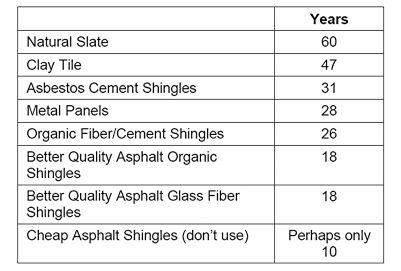

9.3.4 Durability.

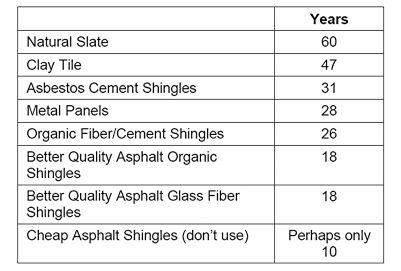

Mean durability of common steep roofing has been estimated in one survey as:

Mean Durability of Common Steep Roofing

Table 14

10. ADDITIONAL

CRITERIA AND DISCUSSION.

10.1 Wind. Maximum

wind speeds associated with locality and storm type determine needed resistance.

ANSI/ASCE 7-95 and EI01S010 provide design information.

10.1.1 Adhered

Systems. Air impermeable roof decks such as poured concrete, with adhered or

mechanically fastened insulation and fully adhered membranes, are highly wind resistant.

Tests conducted by the Factory Mutual System have determined that BUR systems installed

this way have resisted 8.6 kilopascals (180 psf).

10.1.2 Metal

Panel Systems. Metal panels are generally rated by the Underwriters 580 procedure,

with UL 90 ratings considered excellent. However, because some SSSMR panel systems

with UL 90 ratings have failed in service, structural standing seam metal roof

systems must pass the ASTM E1592 test method.

10.1.3 Ballasted

Systems. Ballasted single-ply systems rely on heavier and larger ballast in

more wind prone exposures. SPRI has developed wind guidelines in their

ANSI-SPRI RP-4 document based upon ANSI/ASCE 7-95 guidelines. Higher parapets

have a beneficial effect on ballasted systems. Above certain building heights,

SPRI recommends against the use of ballast.

10.1.4 Mechanically

Fastened Systems. Mechanically fastened single-ply systems use narrower

starter sheets and increased fastener density in high wind areas. Examples of

layout can be found in Factory Mutual Loss Prevention Data Sheet 1-29.

10.1.5 Foam

Systems. Sprayed-in-Place Polyurethane Foam (SPF) systems have proven very

wind resistant and are effective in protecting the structure against wind

hurled missiles.

10.1.6 Problems

with Small Roof Aggregate. Roofs adjacent to airport tarmac activities should

avoid aggregate surfacing as loose aggregate may be blown off the roof and

sucked into engines. Loose stone ballast which is much larger, is used

successfully at many airports.

10.1.7 Wind

Rated Roofs. Underwriters Laboratories lists wind rated systems in their Roofing

Materials and Systems Directory as Class 30, 60 or 90. Factory Mutual Research Corporation

lists wind rated systems in their Approval Guide with ratings ranging

from 60 to 210 psf.

10.1.8 Steep

Roofing. For most steep roofing systems, additional fastening is required

for

high wind areas

(e.g., six fasteners per asphalt shingle instead of four, addition of nose

clips for tiles, etc.).

10.2 Ice

and Hail. The formation of ice can cause the roof membrane to split. Ice

can also affect roofing performance by scrubbing the membrane and eroding the

surface. This can be especially detrimental to materials with a relatively high

glass transition temperature (Tg). Bituminous materials have a Tg of

approximately 32°F. Modified bituminous materials with an SBS modifier can have

a Tg as low as minus -30°F. EPDM membranes report a Tg less than -40°F. The Tg

of thermoplastics may increase with age (i.e., loss of plasticizer in PVC). Ponding

promotes ice damage; drainage avoids it.

10.2.1 Impact

Damage. Falling ice, such as from overhead towers, causes impact damage. Ballasted

EPDM provides some protection. Protected membrane roofs in which both

polystyrene insulation and ballast are placed over the finished roof membrane

provide excellent impact resistance.

10.2.2 Perimeter

Icing. Ice formation at eaves, scuppers, and gutters is a major design concern.

For low-slope roofing selection of internal drainage where building heat keeps

the drain lines unfrozen is recommended.

10.2.3 Minimizing

Icing Problems. For metal and steep roofing heating cables are sometimes

necessary but not especially reliable. In cold regions use of a cold roof in

which the roof is ventilated to prevent formation of icicles and ice dams is

preferred. Self-adhering waterproof membranes are needed to avoid leaks from

ice damming (Figure 10).

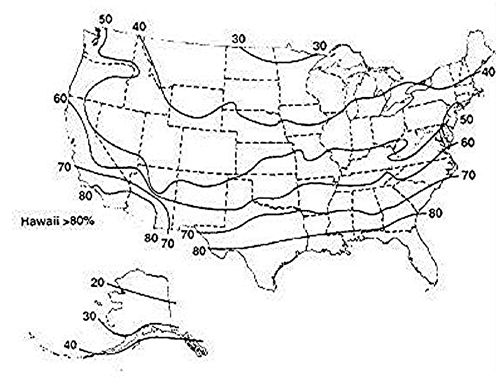

10.2.4 Hail

Damage. Weather maps are available that generally divide the U.S. into regions

that require resistance to severe hail (2 in. dia.), moderate hail (1-1/2 in.

dia.), and areas of low hail probability. Hail resistance is affected by the

compressive strength of the substrate, thickness of the membrane, tensile

strength, and age/brittleness of the material.

10.3 Snow.

Snow removal operations in which shovels or snow blowers are used can cause

severe damage especially to cold, brittle membranes. Smooth single-ply

membranes and metal roofing are extremely slippery when wet or when a thin ice

film covers melt water. Roof walkways consisting of compatible materials are

essential when it is necessary to walk on wet or frozen roofs.

10.3.1 Metal

Roofs. TI 809-52 recommends that SSSMRs should have a minimum slope of 8.3%

in cold regions.

10.3.2 Snow

Loads. Snow load information is available in ANSI/ASCE 7-95, TI 809-01, and

TI 809-52.

10.4 Slope.

Drainage is essential on all roofing systems. For hydrokinetic roofing the

drainage must be positive and rapid. Shingles, tiles, and the like,

generally have industry minimum recommended slopes of 33% to 42%. Sometimes

a lower slope option is available if waterproof underlayments are used.

10.4.1 Metal

Roofs. Minimum slopes for metal roofs vary from 4% to 33%, depending upon roof

type.

10.4.2 Membrane

Slope. Low-slope membranes should also comply with a minimum slope of 2%

(1/4 in./ft.). Where ponding is unavoidable such as in spray ponds, a BUR with

double poured aggregate and bitumen is sometimes used. Coal tar pitch membranes

are used at slopes as low as dead level and to a maximum slope of 2% (1/4

in/ft.). drainage is also needed. However, small puddles are inevitable as SPF

is never completely smooth. Small puddles should dry out within 24-48 hours after

inclement weather. Additional elastomeric coating is recommended where ponding

is anticipated.

10.4.3 Foam

Slope. For Sprayed-in-Place Polyurethane Foam (SPF) systems positive drainage

is also needed. However, small puddles are inevitable as SPF is never

completely smooth. Small puddles should dry out within 24-48 hours after

inclement weather. Additional elastomeric coating is recommended where ponding

is anticipated.

10.4.4 Reroofing.

In reroofing and re-covering applications, correcting the slope to 2% (1/4 in./ft.)

is sometimes unfeasible because of low windows, flashings, etc. In these cases,

tapered insulation at 1.5% (3/16 in./ft.) slope may be an acceptable

compromise.

10.4.5 Steep

Roof Conversion. Conversion of a poorly draining roof to a steep roofing system

may be accomplished on a relatively narrow roof system building by installing

new sloped joists.

10.5 Vapor,

Humidity, Moisture and Condensation. Moisture can be carried through

materials by diffusion or by the movement of air. Air barriers are needed to

reduce air movement. They can be located anywhere within the building envelope.

Vapor retarders, when needed, must be placed within the warm portion of the

thermal insulation.

10.5.1

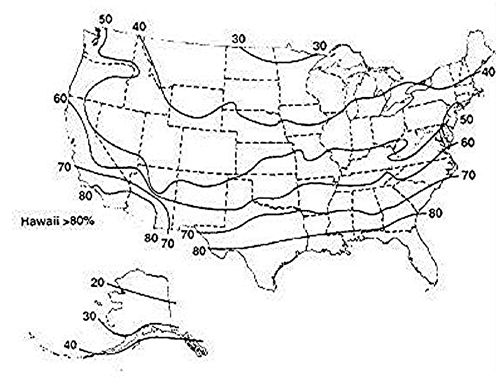

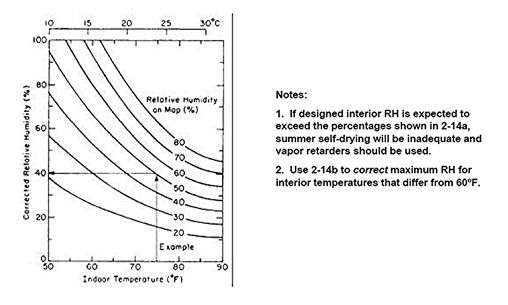

Self-Drying Systems. In cold weather, warm moist indoor air driven from

within the building towards the colder exterior may accumulate during the

winter then dry back out again during the summer months. Guidelines for the use

of vapor retarders in roofs are presented in CRREL Misc. Paper 2489, Vapor

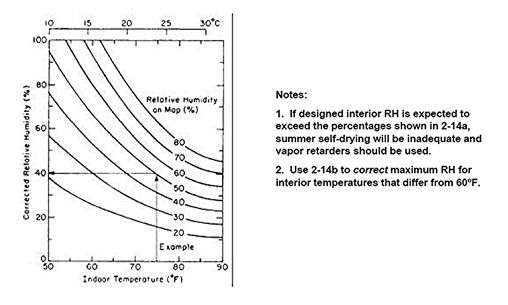

Retarders for Membrane Roofing Systems. Figure 14a indicates suggested

maximum allowable relative humidities where summer dry-out should be adequate. Figure

14b is used to adjust Figure 14a for temperatures other than 60oF.

10.5.2 Reverse

Vapor Drive. For hot humid climates a reverse vapor drive may occur especially

in cooler and freezer buildings. In this case the membrane and wall retarder

sealed and continuous. Roof vents and breathing edge details must be avoided.

For freezer buildings, consider separating the roof system from the freezer.

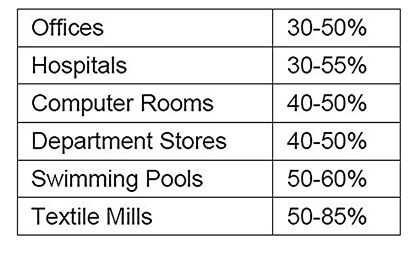

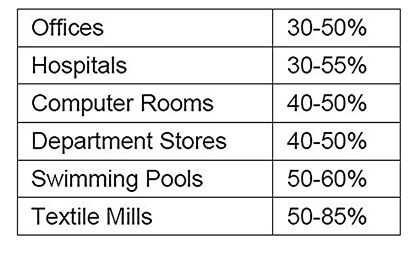

10.5.3 High

Humidity Occupancies. For buildings with high interior relative humidity including

bakeries, laundries, pools, kitchens, dining halls with serving lines and the

like, vapor retarders are considered essential.

Interior Relative Humidities (%) with Interior

Temperature of 68oF)

Figure 14a

Temperature Conversion When Temperatures Differ from 68o

F

Figure 14b

Typical Indoor Relative Humidity in Winter

Table 15

10.5.4 Bituminous

Vapor Retarders. Bituminous retarders are installed over solid fire barrier

substrates such as concrete, gypsum board, or a fire resistant insulation. Bituminous

retarders have near zero perm ratings. For most membrane roofing systems vapor

retarder permeance should be below 0.5 perms (28.6 ng/s•sq m•Pa). Perm ratings

for various vapor retarder materials can be found in the ASHRAE Handbook of

Fundamentals as well as in industry literature.

10.5.5 Non-bituminous

Vapor Retarders. Non-bituminous single-ply systems may use plastic films as

vapor retarders. These can be successful if the seams and penetrations are carefully

sealed with tape. Puncturing the retarder, either accidentally or by installing

mechanical fasteners lessens its resistance to moisture.

10.5.6 PMRs.

Protected Membrane Roofing systems (PMR’s) are very effective against vapor

drive from within the building. The roof membrane itself serves as the vapor

retarder as most, if not all, of the thermal insulation is located above it.

Self-drying of the insulation (extruded polystyrene) to the atmosphere

maintains the thermal resistance.

10.5.7 SPF

Systems. SPF systems are commonly installed on re-cover installations where

the old

bituminous membrane can be sealed to form a retarder. Dew point calculations

are necessary to insure the dew point is within the upper SPF layer.

10.5.8 Steep

Roofing. In steep roofing systems the retarder is usually a plastic film

(poly), treated kraft paper or foil facing on batt insulation installed with

the retarder facing the interior. When an attic or cathedral ceiling is

present, ventilation of the space above the insulation is essential since

retarders are rarely completely sealed and some moisture accumulation would otherwise

occur. Most codes recommend at least 1:150 net free ventilation area (total at

eave and ridge) when a retarder is not installed to 1:300 when a retarder is in

place. In cathedral ceiling construction larger net free areas are needed since

friction losses in the narrow airway reduce ventilation.

10.5.9 Metal

Systems. In structural metal systems where draped batt insulation is

used, it is

difficult to completely seal the retarder facer even if tape is used. When high

interior vapor conditions exist the use of a subdeck to support a retarder film

may be necessary. Other roofing systems should also be considered as such

systems are not good at resisting high internal relative humidities.

10.6 Considerations

When Using Thermal Insulation. Thermal insulation is important in modern

buildings both for energy conservation and human comfort and may impact roof membrane

performance.

10.6.1 Thermal

Resistance. Resistance to heat flow through the entire roof structure (characterized

by the R factor) should be as high as is both practicable and cost effective.

In general an R factor of > 20 (Rsi > 3.57) is recommended. Note: U = 1/R

therefore, the

U factor should be < 0.05 Btu/hr•ft2 oF.

Unit Resistances (i.e., Resistivity) of Common Roof

Insulations

Table 16

10.6.2 Installation

Locations. Thermal insulation may be installed in four locations.

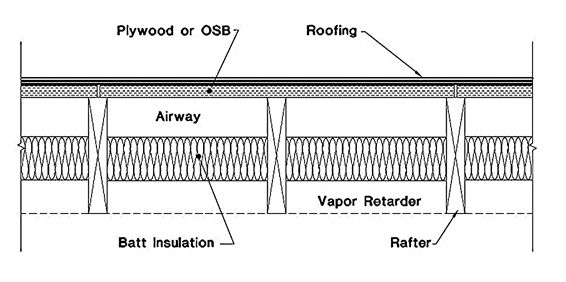

10.6.2.1 Underdeck

insulation (Figure 15).

- Wood frame

structures with steep roofing often utilize batt insulation placed between

the rafters. Vapor retarders of foil, kraft, or plastic film are located

on the inside face of the insulation. With structural standing seam metal

systems, batts are draped over the purlins. In attics, the insulation is

usually positioned between ceiling joists.

- An advantage

of underdeck insulation is that inexpensive nonstructural insulations such

as batts may be used.

Under Deck Insulation

Figure 2-15

- A

disadvantage is that the roof deck suffers greater thermal stress than

when it is overlaid with insulation. Another disadvantage is that it is

difficult to vapor seal such construction and make it resist air

exfiltration and as a result moisture problems are prone to occur.

Ventilation is usually required but ventilating low-slope framed roofs

lacking tight air barriers is apt to increase moisture problems, not

eliminate them.

- Common

underdeck materials include compressible batts of glass fiber and mineral

wool. Thermal spacers of rigid plastic foam are placed over the purlins of

SSSMR systems to maintain the thermal resistance where the batts are

compressed.

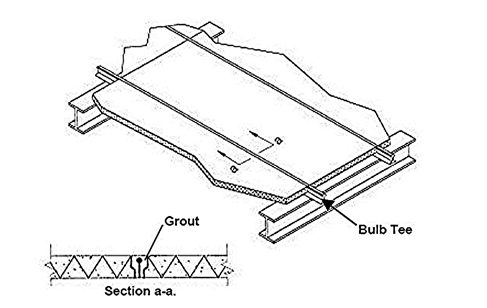

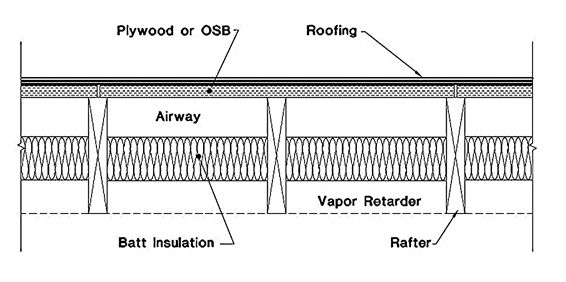

10.6.2.2 Self-insulating

roof deck (Figure 16):

Self-Insulating Roof Deck

Figure 16

- Insulating

decks such as structural wood fiber are less popular today because it is

difficult to achieve high R values within the deck itself. In reroofing

situations supplemental insulation would often be added on top of such a

deck. In some new assemblies a composite of structural wood fiber topped

with plastic foam is used. The underside of these self-insulating decks

can be exposed to the interior and serves as an attractive acoustical

ceiling.

10.6.2.3 Thermal

insulation within the roofing sandwich (Figure 9).

- Insulation on

top of the roof deck is the most common configuration for membrane

roofing. For adhered membrane systems the thermal insulation restrains the

membrane against wind loss or shrinkage and must have adequate structural

strength. For mechanically anchored and ballasted systems compressive

strength and stability are important. If hot asphalt or solvents are used

in construction of the membrane, the insulation must resist degradation by

these agents.

- Common

materials for adhered systems include faced polyisocyanurate foam

(ASTM C1289), perlite (ASTM C728), rigid glass fiber boards (ASTM C726),

wood fiber (ASTM C208), and cellular glass (ASTM C552). Verify that the

combination of membrane and roof insulation/facer are Fire and Wind Rated.

- For

mechanically fastened and ballasted systems expanded and extruded polystyrene

(ASTM C578) are added to the above list. (They could melt or dissolve if

placed in contact with hot bitumen or solvent-based adhesives).

- Some decay of

R value is observed with HCFC blown foams (urethanes and

isoboards) due to diffusion of air and moisture into the cells of the

foam. Manufacturers publish aged R values to reflect this decay. Always used

aged R-values for these materials. Since diffusion starts at the surface of the

foam, thicker foams are more thermally stable.

- Wood fiber

boards should be manufactured to use as roof insulation (meeting

ASTM C208), not sheathing boards, and should be limited to 4 ft. in length

and width.

- When

mechanical fasteners are used to secure thermal insulation, it is recommended

that the nail-one, mop-one technique be used. This minimizes a thermal

bridging and avoids nail-popping of the membrane. When multiple layers of

insulation are used, vertical joints should be offset to reduce heat

losses. Straight-through joints can take away 10% of a roof’s insulating

ability.

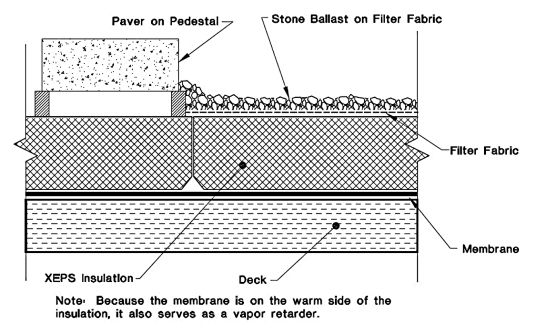

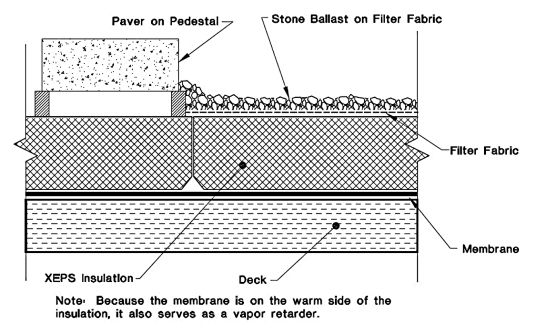

10.6.2.4 Protected

membrane systems (Figure 17).

- In PMR

systems only extruded polystyrene is suitable in the sometimes wet environment

above the completed roof membrane. This insulation protects the membrane

from thermal stress and abuse.

- Ballast and

filter fabric is needed to hold the loose-laid insulation in place.

Protected Roof Membrane System (PMR)

Figure 17

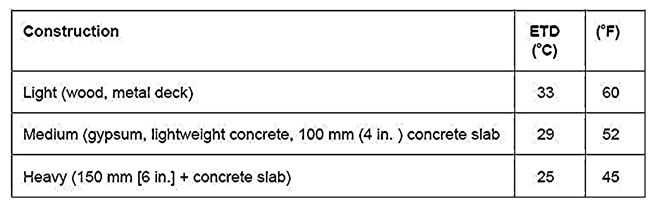

10.7 Energy

and Solar Radiation. The ratio of roof area on a low-rise commercial

building is high relative to wall area. Such roofs can provide a great

opportunity for energy conservation. This can be accomplished by using well

insulated, high thermal mass structures to reduce summer cooling loads, garden

roofs, or high albedo roof coatings.

10.7.1 Heat

Gain. For roofs in hot or temperate climates, light colored roof surfaces

reduce heat gain. For membrane roof systems, light colored aggregate (gravel surfaced

roofs) or mineral granules (capsheets [ASTM D249, D371, D3909] and MB capsheets

[ASTM D6162, D6163, D6164, D6222, D6223]) will reduce heat maximum surface

temperatures by up to 35°F over black membranes. Aluminum coatings (ASTM D2824)

are approximately the same, while white coatings (ASTM D6083) have been

observed to reduce temperatures by more than 45°F (provided that the roof stays

clean). The use of pavers and heavy ballast reduce heat gain through thermal

lag; that is, the high heat capacity stores some of the gained heat delaying

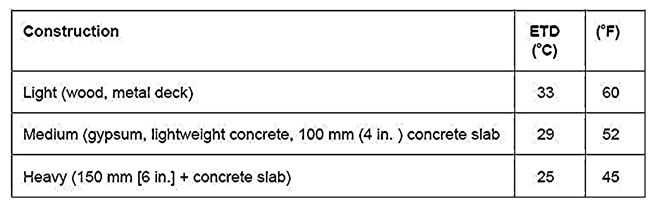

the startup of the building’s air conditioning system. The ASHRAE Handbook

of Fundamentals uses the term Equivalent Temperature Difference (ETD) in

energy calculations. The smaller the ETD, the better the system is at reducing

peak solar loads.

Equivalent Temperature Difference

Table 2-17

reflective roof

surfacing materials (e.g., white granules on shingles). Radiant barriers (reflective

foils) placed in attics are also effective.

10.8 Fire

Considerations.

10.8.1 Topside

Fire Ratings. Because of its large surface area, roofing plays an important

role in fire protection. Fire hazards can be defined as:

10.8.1.1

External, where the source is outside the building such as from wind blown flaming

debris. Tests for external fire resistance are referred to in building codes as

Class A, B and C.

- An external

fire rating is established by constructing and testing roofing assemblies

by methods described in ASTM procedure E108 (also known as UL790). In this

method relative degrees of fire resistance are established.

o Class A roof

coverings are effective against severe fire exposures. Under such exposures

roof coverings of this class are not readily flammable and do not carry or communicate

fire; afford a fairly high degree of fire protection to the roof deck; do not

slip from position; possess no flying brand hazard; and, do not require

frequent repairs in order to maintain their fire-resistant properties.

o Class B roof

coverings are effective against moderate fire exposures. Under such exposures

roof coverings of this class are not readily flammable and do not readily carry

or communicate fire; afford a moderate degree of fire protection to the roof

deck; do not slip from position; possess no flying brand hazard; but, may require

infrequent repairs in order to maintain their fire-resistant properties.

o Class C roof

coverings are effective against light fire exposures. Under such exposures roof

coverings of this class are not readily flammable and do not readily carry or communicate

fire; afford some degree of fire protection to the roof deck; do not slip from

position; possess no flying brand hazard; and, may require occasional repairs

or renewals in order to maintain their fire-resistant properties.

- Class A does

not mean Grade A! Note: In this classification only fire performance

is considered. A specifier should select the degree of fire resistance

required but recognize that selecting a higher rating does not assure

better waterproofing nor longer life. In fact, some compromise in

durability may have been made to meet the higher fire rating.

- ASTM E108

fire tests may be conducted on steep roofing, membrane roofing, SPF, and

metal panels. Listings of systems that meet these requirements are found

in the Underwriters Laboratories Roofing Materials and Systems

Directory, the Factory Mutual

- Approval

Guide, and reports/directories published by several other qualified

testing agencies.

o If a roofing

assembly fails to meet burn-through requirements of ASTM

E108 it may still be listed for use with non-combustible decks such as

steel, concrete, and gypsum.

o Roofing

assemblies are listed at the maximum incline to which the rating applies. As

long as the structure under consideration is at a lower or equal incline to

that listed it complies with the fire rating.

o If a listing is

intended for use as a roof superimposed over an existing roof, it should be

listed in the UL Roofing Materials and Systems Directory under the

category Maintenance and Repair Systems. In the FM Approval Guide it

will be listed as a Re-cover.

o In general,

only the materials listed qualify and only when used in the manner described in

the directories. Additional insulation, for example, might worsen the flame spread.

10.8.1.2 An

internal (underdeck) fire is when the flame spread is underneath the roof

deck. Listings

are referred to by the Approval Rating, usually Factory Mutual Class 1 or

Underwriters

Laboratories Insulated Metal Deck or Non-metallic Decks Constructions.

- Background—In

1953, a large insulated steel roof deck building suffered an unexpected,

catastrophic fire loss due to an underdeck fire exposure. The roofing

components above the deck contributed fuel to spread the fire. Tests

conducted on full scale test buildings confirmed the hazard. In the late

1950’s, laboratory tests were established and correlated to the full scale

data. Factory Mutual uses a calorimeter to establish fire performance

while Underwriters Laboratories uses a modified Steiner Tunnel test.

Successful systems are listed by FM as Class 1 while Underwriters lists

them as either Rated Metal Deck or Rated Non-Metallic Assemblies.

- The

underdeck ratings do not assure zero risk. The ratings assume an acceptable

risk assuming normal fire detection and fire control procedures are

available. If an insulated steel deck system fails to comply with the

requirements of FM Class 1, it is designated Class 2. Class 2

constructions may be converted to Class 1 by the addition of underdeck fireproofing.

Class 2 constructions may also be acceptable if an approved sprinkler

system is used.

- Fire

endurance tests. These are time-temperature tests (ASTM E119) in which

the roof-ceiling assembly is subjected to a rising heat load until either

the interior structural elements yield, or the temperature on the exterior

roof system reaches 139oC (250oF) above the ambient.

o The minimum

elapsed time required before the end point is reached is

usually established by building code or occupancy (e.g., 1-hour, 1-1/2

hour, etc.).

o Rated

assemblies are listed by UL in their Fire Resistance Directory and by FM

in their Approval Guide. Other testing agencies list rated assemblies in

their directories as well.

·

Assure that fire compliance (ratings) pertain to the entire

assembly. Each component of the system must be listed in the above directories.

Materials delivered to the job site should bear labels indicating compliance

with the construction intended. The label also provides third party assurance

that the products delivered to the construction site are essentially unchanged

from those tested and listed.

10.9 Seismic

Requirements. While membrane roofing materials in general do not affect seismic

stability of a structure, components of the roof system may be important. Roof

decks, for example, usually serve as a diaphragm increasing lateral stability.

10.9.1 Bracing

for SSSMRs. Structural metal systems with floating clips require bracing since

the structural standing seam metal panels do not provide diaphragm action. An

alternative to bracing is to use a steel subdeck to serve as the shear

diaphragm.

10.9.2 Inertia

Effect. Heavy roofing materials such as ballast or pavers may result in an inertia

effect that should be included in the design. This may be beneficial or

detrimental.

10.9.3 Lateral

Motion of Tiles. In steep roofing, seismic motion may shatter materials

such as cement and clay tile. Correct use of mechanical anchors may prevent

damage. Twisted wire systems are recommended for earthquake zones. The National

Tile Roofing Manufacturers Association requires two nails or a nail and a clip

on every tile to resist seismic damage.

10.9.4 Restraining

Roof Tiles. IR-32-1 (9/89), a Title 24 California code addresses the attachment

of tile, and allows the combination of wire tie and nose clips (wind locks or

tile locks). Nails or wire ties are to be copper, brass, or stainless steel 11

ga. minimum with two per tile. Nails are to penetrate roof sheathing, battens,

or support members 3/4 in. min. Ring shanked nails may be used when sheathing

thickness is less than 3/4 in.

10.9.5 Parapet

Walls. Parapet walls must be used with care. Through-wall flashings or

cut reglets

must be avoided as they reduce the wall’s resistance to lateral forces.

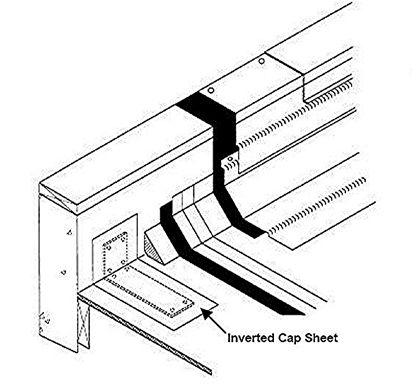

10.9.6 Roofing

Over Seismic Straps. Seismic straps (heavy metal plates) are sometimes installed

over plywood roof decks and between decks and walls. Where roof insulation is

not used (i.e., west coast capsheet construction), use construction details

provided by the Western States Roofing Contractors Association on how to roof

over the straps (Figure 18).

Roofing Over Thick Seismic Strap

Figure 18

10.10 Adequate

Design Details. Complete sectional views of every location where the roof changes

plane or there is a roof penetration or attachment should be provided on

contract drawings. Sections and design details should be drawn to a legible

scale with each element of the roofing system identified.

CHAPTER

2

COATINGS

AND PAINTS

1.

SELECTION OF COATINGS

1.1

Selection Criteria. The best selection of a coating system for a particular

service is determined by a variety of factors. These include desired

properties, work requirements and

limitations,

safety and environmental restrictions, compatibilities, and costs.

1.1.1

Desired Film Properties. In selecting a coating system, the first

consideration is the desired properties of the system for the particular

service. Desired properties may include one or more of the following aspects:

- Resistance

to exterior weathering (chalking; color and gloss retention)

- Water,

fuel, or chemical resistance

- Abrasion,

heat or mildew resistance

- Appearance

(color, gloss, and texture)

- Drying

time

- Ease

of application and maintenance

1.1.2

Work Requirements or Limitations. The following work requirements or

limitations may have to be considered:

- Type

of surface preparation

- Access

to work

- Drying

times

- Necessary

applicator skills

- Necessary

equipment

- Scaffolding

for access to work

1.1.3

Safety and Environmental Restrictions. It will be necessary to conform to

all prevailing safety and environmental regulations concerning materials and

processes to be used for surface preparation and for coating application.

1.1.4

Compatibilities. Coating systems must be compatible with the surfaces to

which they are applied. Coating incompatibility can cause failures at or just

after application or after a much longer time. Failures occurring just after

application are due to solvent incompatibility or wetting problems. Failures

associated with slow chemical reactions, such as those occurring between alkaline

surfaces (e.g., concrete and galvanized steel) and oil-based paints or

mechanical property mismatches (e.g., a rigid coating applied over a more

flexible one) cause failure in a longer timeframe. The failure more often is

peeling. For existing coatings being repainted, compatibility generally means

that topcoats should be of the same generic type or curing mechanism as

undercoats. One exception to this rule is inorganic zinc coatings. Since

inorganic zinc coatings frequently do not bond well to themselves, it is safest

to repair them with zinc-rich organic coatings. A simple test to classify

coatings is to determine solvent sensitivity using an methylethyl ketone (MEK)

or acetone rub test. To do this, soak a cloth in MEK or acetone, rub it against

the existing paint, and visually check for pick up of paint. The paint is

classified as "solvent soluble" if paint is picked up, and as

"solvent insoluble" if not. Another practical method of ensuring

topcoat solvent compatibility is to coat a small test area of the existing

coating with the paint selected for the work. If situations permit, this test

is preferred over the MEK rub test because it is specific for the surface to be

repainted. The test area should be visually inspected the following day (or

preferably after 3 or more days) for bleeding of undercoat, wrinkling, loss of

adhesion, or other coating defects. Although most incompatibility problems are

apparent in a couple of days, some types of incompatibility may not become

apparent for several months or until after a change of seasons. These types are

usually associated with mechanical film properties.

1.1.5

Costs. Life cycle cost has always been one of the most important

considerations in selection of coating systems. Life cycle costs include

original surface preparation, materials, and application and necessary

maintenance throughout the life of the coating system. Today, the expense of

containment of old paint during its removal and disposal of debris that is

often

considered

to constitute hazardous waste must be included. This usually means that the

system with the maximum maintainable life is the best choice.

1.2

Specifications for Lead- and Chromate-Free Coatings with VOC Limits. The

coating specifications listed below in Table 1 are lead- and chromate-free and

have limitations on their contents of VOC.

Table 1

Lead- and Chromate-Free Coating

Specifications With VOC Limits

|

Latex Coatings

|

|

|

Listed latex coatings are available

with a VOC content of no more than 250

grams per liter unless otherwise

specified

|

|

|

TT-P-19

|

Exterior acrylic emulsion coating,

available in a wide variety of colors and flat gloss finishes

|

|

|

TT-P-29

|

Interior latex paint, flat,

available in white and tints

|

|

|

TT-P-650

|

Interior latex primer coating for

gypsum board or plaster

|

|

|

TT-P-1510

|

Latex exterior flat finish

coating, available in a variety of colors

|

|

|

TT-P-1511

|

Latex interior coating, available

in gloss and semigloss in white and tints

|

|

|

TT-P-1728

|

Latex, interior, flat, deep-tone

coating

|

|

|

TT-P-001984

|

Primer, latex, for wood

|

|

|

TT-P-002119

|

Latex high-traffic coating,

available in flat and eggshell and a variety of colors

|

|

|

TT-E-2784

|

Acrylic emulsion exterior enamel,

gloss and semigloss, available in a wide variety of colors

|

|

|

MIL-E-24763

|

Acrylic water-emulsion coating

intended for shipboard use, available in 275 and 340 grams per liter VOC

classes; high, medium, low, and flat glosses; and a limited number of colors

|

|

|

MIL-P-28577

|

Corrosion-resistant latex primer

for metals

|

|

|

Stains

|

|

|

MIL-P-28578

|

Waterborne acrylic semigloss

finish, available in a wide variety of colors

|

|

|

TT-S-001992

|

Exterior latex stain,

semi-transparent and opaque, available in a variety of colors

|

|

|

Clear Floor Finishes

|

|

|

A variety of clear floor finishes

are available from the Maple Flooring Manufacturers Association (MFMA)

specifications, Heavy-Duty and Gymnasium Finishes for Maple, Beech, and Birch

Floors. Suppliers must be contacted to determine VOC content.

|

|

Table 1 (continued)

Lead- and Chromate-Free Coating

Specifications With VOC Limits

|

Oil and Alkyd Coatings

|

|

|

SSPC PAINT-25

|

Corrosion-resistant raw linseed oil

and alkyd primer, usually available at 300 grams per liter VOC but no

requirement listed

|

|

|

TT-P-25

|

Oil-based primer for wood,

normally available with a VOC content less than 350 grams per liter

|

|

|

TT-P-31

|

Red and brown oil ("roof and

barn") paint, usually available with 250 grams per liter VOC content but

no requirement specified

|

|

|

TT-E-489

|

Alkyd enamel, with 420 grams per

liter VOC limitation, available only in gloss, but in a wide variety of

colors

|

|

|

TT-P-645

|

Corrosion-resistant alkyd primer,

with a 340 VOC limitation

|

|

|

TT-P-664

|

Corrosion-inhibiting alkyd

quick-dry primer, with a 420 grams per liter VOC limitation

|

|

|

MIL-E-24635

|

Silicone alkyd enamel, available

in limited colors, 275, 340, and 420 grams per liter VOC types, and high,

medium, low, and flat gloss classes

|

|

|

MIL-P-28582

|

Alkyd primer normally available at

less than 350 grams per liter

|

|

Table 1 (continued)

Lead- and Chromate-Free Coating

Specifications With VOC Limits

|

Epoxy Coatings

|

|

|

MIL-P-24441

|

Epoxy-polyamide, two- and

three-coat systems, available in types with 340 VOC and limited colors

|

|

|

MIL-P-53022

|

Fast-dry epoxy primer with 420

grams per liter maximum VOC content

|

|

|

MIL-P-85582

|

Waterborne epoxy primer with 340

grams per liter maximum VOC content

|

|

|

Textured Coatings

|

|

|

TT-C-555

|

Waterborne or oil- or rubber-based

textured coating available at 250 grams per liter

|

|

|

Urethane Coatings

|

|

|

MIL-C-85285

|

High-solids aliphatic urethane

coating, with 340 and 420 grams per liter VOC types, available in a variety

of colors and in glass and semigloss

|

|

|

Zinc-Rich Coatings

|

|

|

MIL-P-24648

|

Zinc-rich coating, aqueous and

organic solvent types, self-curing and post-curing classes, organic and

inorganic

|

|

1.3

Recommendations for Different Substrates. This discussion provides general

recommendations for wood, concrete and masonry, steel, galvanized steel, and

aluminum surfaces. The recommended dry film thickness (dft) in mils is provided

for coating specification recommended for a particular substrate. Referenced

standards for coatings

provide

for lead- and chromate-free products that are low in VOCs. Although such

requirements may not be necessary at all projects currently, such requirements

may occur in the near future.

In

making local repairs of damaged coatings, loose paint should be removed by

scraping with a putty knife before lightly sanding or abrasive blasting any

exposed substrate and feather-edging existing sound paint to obtain a smooth

transition with the repaired area. Coats of repair material should be extended

1 inch onto the surrounding sound coating.

1.3.1

Recommendations for Wood. Oil-based and waterborne coatings and stains

(frequently called latex) perform quite well on new wood. A two-coat system,

paint or stain, is normally applied. However, as additional coats are applied

to resurface or repair weathered paint, the film thickness may become

sufficient to reduce the total flexibility to the point that

results

in disbonding of the total paint system from the surface. Thus, when

topcoating or making localized repairs, no more coating should be applied than

necessary to accomplish the desired goal.

Surface

preparation of new wood normally consists of lightly hand sanding or power

sanding, carefully controlled so that it does not damage the wood. Sanding is

also appropriate for preparing weathered surfaces for refinishing and for spot

repairing areas of localized damage.

1.3.1.1

Oil-Based Paints. Historically, wood has been successfully painted with

oil-based products that penetrate the surface well. These coatings are very

easy to apply.

|

Oil-Based

Paint System for Wood

|

|

|

Surface Preparation

|

Primer

|

Topcoat

|

|

|

Sand

|

one coat TT-P-25

or MIL-P-28582, 2 mils dft,

|

one-two coats

MIL-E-24635

or TT-P-102, 2

mils dft per coat

|

|

1.3.1.2

Water-Emulsion Paints. More recently, latex coatings have been found to be

very effective in providing attractive, protective finishes. They are also less

affected by moisture

than

are oil-based finishes and are generally more flexible and thus less

susceptible to cracking as the wood swells and contracts with moisture

changes. A problem sometimes arises when repairing or topcoating existing

smooth alkyd coatings with latex paints. To obtain good intercoat adhesion, it

may be necessary to lightly sand the existing paint and/or apply a surface

conditioner containing tung oil or some other oil that wets surfaces well before

applying the first coat of latex paint.

|

Waterborne Paint System for Wood

|

|

|

Surface Preparation

|

Primer

|

Topcoat

|

|

|

Sand

|

One coat

TT-P-001984, 1.5 mils dft

|

One-two

coats TT-E-2784 or other appropriate latex paint in Table 1, 1.5 mils dft per

coat

|

|

1.3.1.3

Semi-Transparent Stains. Because oil-based and waterborne paints form

continuous films, they may form blisters or disbond because of moisture in the

wood attempting to escape. Semi-transparent stains do not form continuous

films on wood and so do not have this problem. Thus, they are a good

alternative on new wood. Additional coats applied over the years or heavybodied

stains will, however, form continuous films.

|

Stains for Wood

|

|

|

Surface

Preparation

|

Primer

|

Topcoat

|

|

|

Sand

|

One coat

TT-S-001992, 1.5 mils dft

|

One coat

TT-S-001992, 1.5 mils dft

|

|

1.3.1.4

Clear Floor Finishes. A variety of clear floor finishes are available from

MFMA Heavy-Duty and Gymnasium Finishes for Maple, Beech, and Birch Floors.

Suppliers on the attached list must be contacted to determine VOC content.

1.3.2

Recommendations for Concrete and Masonry Surfaces. Concrete and masonry

surfaces, as well as those of stucco, plaster, wallboard, and brick, can be

coated with a variety of systems depending upon the desired purpose and

appearance. Surface preparation is usually accomplished by power washing with

aqueous detergent solution to remove dirt and other loose materials. Any oil or

grease will have to be removed by solvent or steam cleaning; any mildew, by

scrubbing with bleach; and any efflorescence or laitance, by brushing, followed

by acid treatment.

1.3.2.1

Waterborne Coatings. A two-coat waterborne (latex) system provides an

attractive breathing film that is normally less affected by moisture in the

concrete than non-breathing systems. The latex material is a self-primer in this

service, unless otherwise stated. Alkyd and other oil-based coatings should not

be applied directly to concrete or masonry surfaces, because the alkalinity in

the concrete will hydrolyze the oil in the binder and cause the coating to

peel. However, they can be applied over concrete or masonry surfaces primed

with waterborne coatings to produce a tougher, more washable finish.

1.3.2.2 Elastomeric Coatings. Elastomeric, waterborne

acrylic coating systems also perform well to seal and protect concrete/masonry

surfaces and are normally very low in VOCs. They can successfully bridge fine

or larger caulked cracks. There are no federal specifications for them.

|

Elastomeric Waterborne Acrylic System for

Concrete or Masonry

|

|

|

Surface Preparation

|

Primer

|

Topcoat

|

|

|

Power wash

|

One coat primer

recommended by supplier of elastomeric coating, dft varies with supplier

|

One coat

elastomeric acrylic coating, 10 -20 mils dft

|

|

1.3.2.3

Textured Coatings. Textured coatings system can bridge fine cracks and

waterproof from wind-driven rain. They are normally applied over a primer

recommended by the supplier to insure good adhesion. They are available in a

variety of textures and may be waterborne or oil or rubber-based products with

a VOC limit of 250 grams per liter.

|

Textured Coating System for Concrete

or Masonry

|

|

|

Surface Preparation

|

Primer

|

Topcoat

|

|

|

Power

wash

|

One coat

primer recommended by supplier of textured coating, dft varies with supplier

|

One coat

TT-C-555, 20 – 30 mils dft

|

|

1.3.2.4

Epoxy Coatings. A two-coat epoxy system will seal and protect

concrete/masonry surfaces well. An aliphatic urethane finish coat should be

used rather than the second epoxy coat on exterior surfaces to improve the

weatherability.

|

Exterior Epoxy/Urethane System for Concrete

or Masonry

|

|

|

Surface Preparation

|

Primer

|

Topcoat

|

|

|

Power

wash

|

One coat

MIL-P-24441

Formula

15, 3 mils dft

|

MIL-C-85285,

Type II, 2 mils dft

|

|

|

Interior Epoxy System for Concrete or

Masonry

|

|

|

Surface Preparation

|

Primer

|

Topcoat

|

|

|

Power

wash

|

One coat

MIL-P-24441, Formula 150, 3 mils dft

|

One coat

MIL-P-24441, of another color, 2 mils dft

|

|

1.3.3

Recommendations for Steel. Presently, a high-performance coating system is

recommended to prolong the service before it becomes necessary to remove and

replace it. Costs in coating removal, especially where there are restrictions

on abrasive blasting, are very high. Abrasive blasting is always preferred to

alternative methods of preparing steel surfaces for painting. It cleans the

steel and provides a textured surface to promote good primer adhesion. A

commercial blast specified by the Steel Structures Painting Council [re-named

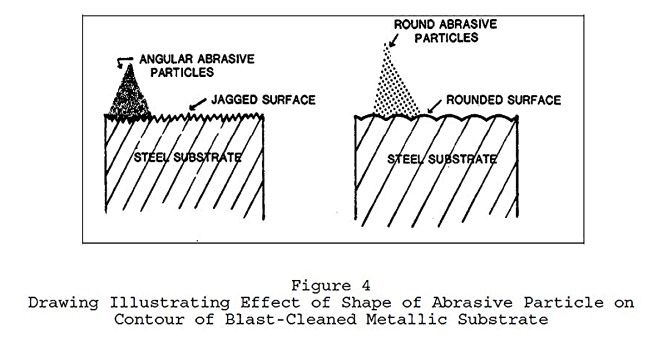

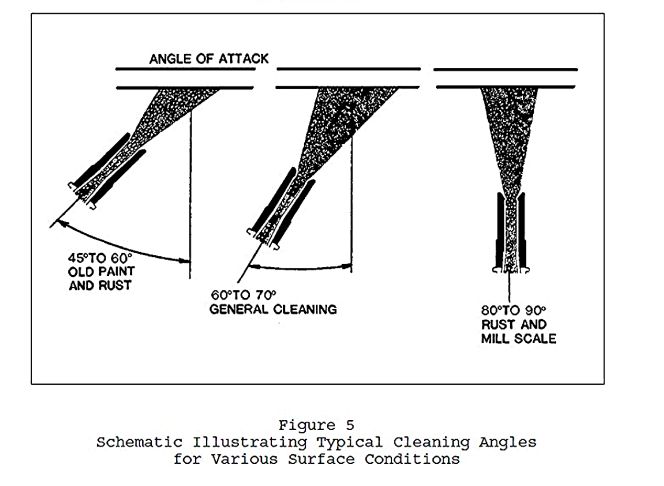

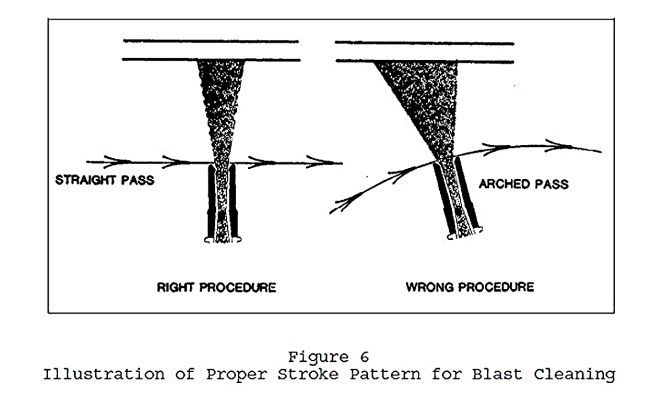

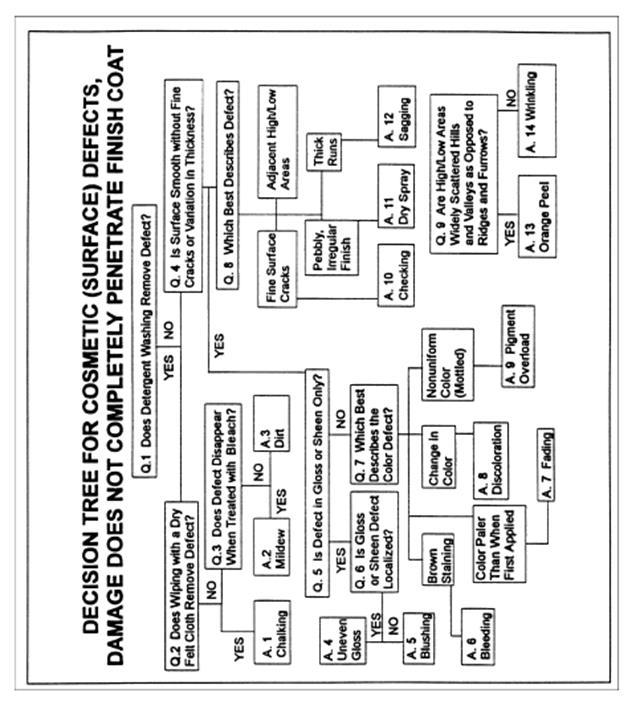

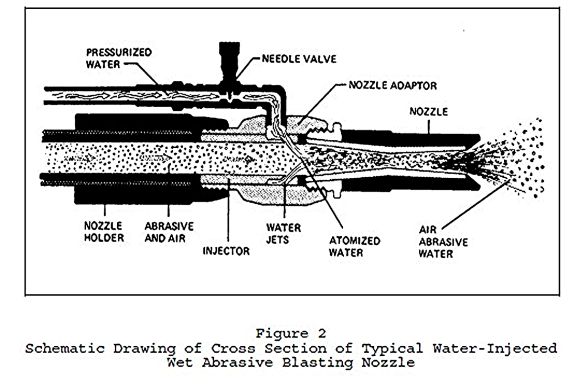

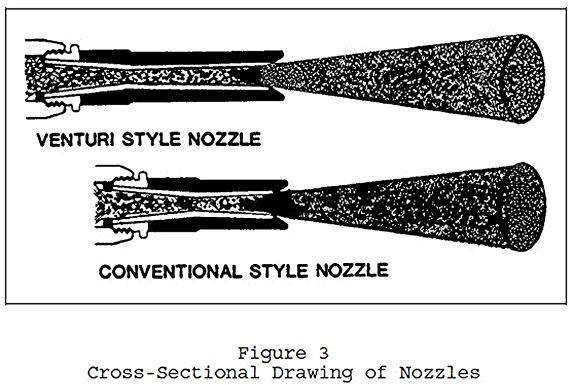

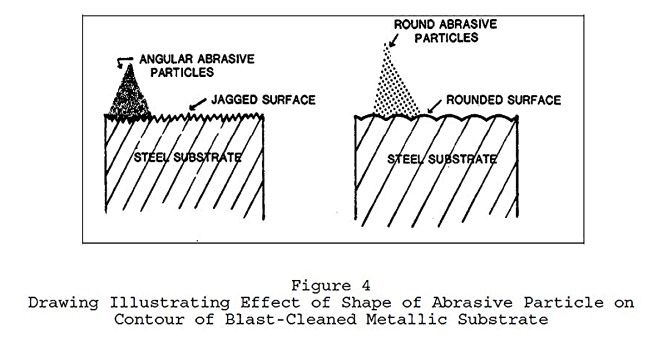

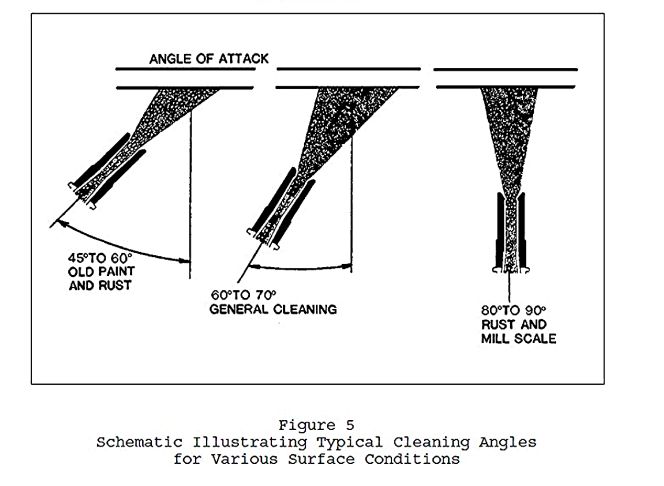

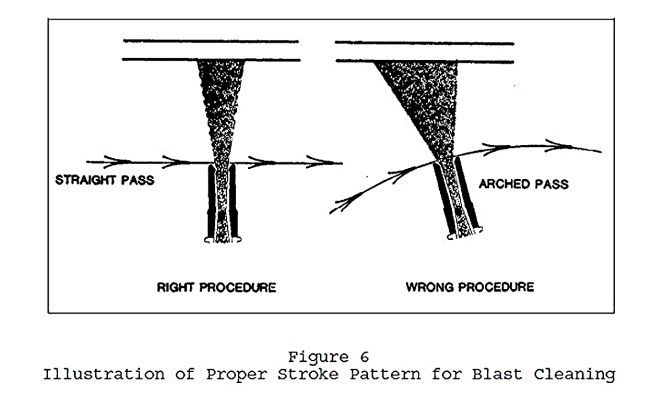

the Society for Protective Coatings in 1997] (SSPC) is (SSPC SP 6) is normally