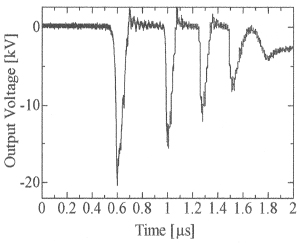

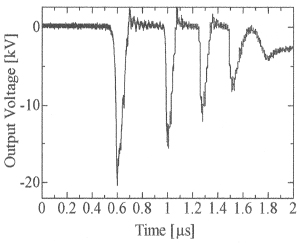

Figure 1. Output wave pattern of nanosecond pulses

Recently, micro power generation using electrets has attracted much attention due to its large power output at a low frequency range. Since the theoretical power output is proportional to the square of the surface charge density of the electret, the development of a high-performance electret is required. Conventionally, electrets have been mainly manufactured by corona discharge generated using a direct current (DC) source. However, dielectric breakdown usually occurs when high voltage is applied to a material due to the increased surface charge density of the electret. Here, we focus on the nanosecond pulse (70 ns pulse width) that has ability to apply higher voltages to materials than when DC is used. A series of measurements of surface potential and thermally stimulated discharge current (TSDC) spectra is made for various polytetrafluoroethylene (PTFE) electrets, which were manufactured by DC and nanosecond pulses. It is found that the surface charge density and thermal resistibility of electric charges are improved by using nanosecond pulses. A surface charge density using a nanosecond pulse of 0.59 mC/m2 is larger than that of using DC by 59%. In addition, the thermal stability of the electret manufactured by nanosecond pulses is superior to that of by DC. Moreover, discharge energy of nanosecond pulse generator is greater than that of DC power source. Therefore, we conclude that nanosecond pulse will be more useful for manufacturing electrets than DC.

In recent years, energy harvesting attracts much attention all over the world1. Especially, micro power generator using electret is studied actively2, 3 Since the theoretical power output of generator is proportional to the square of the surface charge density of the electret4, the development of a high-performance electret is required. Conventionally, electrets are manufactured by corona discharge using DC power source. However, dielectric breakdown usually occurs when a high voltage is applied to materials due to the increased surface charge density of electrets. Here, we focus on the nanosecond pulse (70 ns pulse width) that has ability to apply higher voltages to materials without inducing dielectric breakdown. Nanosecond pulse has a potential to produce more strongly charged electret than DC, because it can apply higher voltage than DC to materials.

The objective of the present study is to develop a fabrication method for a new electret using nanosecond pulse for higher surface charge density and thermal stability.

Figure 1 shows output wave pattern of a nanosecond pulse generator. Nanosecond pulse discharge generates an extremely short pulse width and because the voltage falls before the generation of insulation breakdown, which is induced by the application of a high voltage, it is possible to apply the higher voltages than when DC is used.

Figure 1. Output wave pattern of nanosecond pulses

Electrets were manufactured by applying a high voltage to a needle and injecting ions using a corona discharge under condition given in Table I. Polytetrafluoroethylene (PTFE or Teflon) was used as an electret material because PTFE is highly insulating and is a typical electret material. A 6 × 6 cm2 of 50-μm-thick PTFE was installed on an earth electrode, and electrification was performed using a corona discharge by applying a high voltage to a needle electrode at a fixed distance from the earth electrode. Fabrication conditions are shown in Table II. −6 kV DC is the maximum voltage that can be applied to the sample without being damaged.

Table I. Capacity of nanosecond pulse generator

| Pulse width | 70 ns |

| Output voltage(max) | -30 kV |

| Pulse risetime | 10 ns |

| Repetition frequency(max) | 500 Hz |

| Output current(max) | -30 A |

| Input voltage | 24 V |

Table II. Electret fabrication conditions

| DC | Nanosecond Pulse | |

| Output voltage | −6 kV | |

| −20 kV | ||

| −15 kV | ||

| −10 kV | ||

| Pulse repetition frequency | − | 200 Hz |

| Distance between electrode | 10 mm | |

| Discharge time | 30 min | |

| Heat temperature | 250 °C | |

Figure 2. Electret fabrication by corona discharge

In order to evaluate the performance of nanosecond pulses as a new fabrication method for electret, the temporal change of the surface potential was examined. The samples were stored at 23°C with 75% of humidity. The surface potential was measured with a surface voltmeter (Statiron DS3H, Shishido Electrostatic, Lid).

Thermally stimulated discharge current (TSDC) was measured while applying heat to the electret, as shown in Figure 3 (a). By measuring the TSDC, it is possible to estimate parameters such as the trapped charge concentration, the depth of charge injection, and the electret lifetime. Conditions for temperature increase is shown in Figure 3 (b).

Figure 3. Measurement of TSDC

The discharge energy was measured by observing the voltage and current waveforms. Figure 4 (a) & (b) show the measurement systems used for DC and nanosecond pulses.

Figure 4. Schematics of measurement system of discharge energy

Discharge energy of DC power source was calculated as described below.

Discharge energy of a nanosecond pulse generator was calculated as described below.

Figure 5 shows the surface potential as a function of discharging time under application of electrets −6 kV DC and −20 kV nanosecond pulses (repetition frequency: 200 Hz). It shows that surface potential of −2500 V (equal to surface charge density of 0.59 mC/m2) by nanosecond pulses is higher than that of DC by 59 % after discharge for 200h. This is mainly considered to be because the high voltage nanosecond pulses inject more charge into the electret.

Figure 5. Surface potential of electret

Figure 6 shows the surface potential measured after 150 h since they have been charged for 5 and 30 minutes. Comparison of the results for the DC and the nanosecond pulses reveals that by increasing the discharge times from 5 to 30 minutes for nanosecond pulses, the sample was charged at least 500 V higher. This is thought to occur due to the voltage application time being intermittent in the case of nanosecond pulse discharge so that it takes time to inject sufficient ions into the electret.

Figure 6. Surface potential of electret (after 150 h)

Figure 7 shows the results of TSDC measurement of PTFE made into an electret by applying −6 kV DC and −20 kV nanosecond pulses (repetition frequency: 200 Hz). It shows that a peak appears at near 175°C after application of DC and at around 210°C after application of nanosecond pulses. It is conjectured that when the current peak occurs at a high temperature, the thermal stability goes high, ions are injected deeply, and which results in the longer lifetime of the electret. With application of nanosecond pulses, it is believed that because a high voltage was used, ions were deeply injected and the thermal stability was high.

Figure 7. TSDC spectra of electret

Figure 8 shows the TSDC of electrets charged at various output voltages using nanosecond pulses. It has been previously reported that, in the case of DC, the TSDC increased with increasing output voltage. The same trend, in which current peaks increase and the amount of injected charge increases, was also observed during application of nanosecond pulses. Since nanosecond pulse generator has ability to apply the higher voltage than DC without generating dielectric breakdown to applied materials, it can be expected that the electrets, manufactured by nanosecond pulse would be more strongly charged according to the increased voltage by nanosecond pulse power generator.

Figure 8. TSDC spectra of electret

Figure 9 shows the discharge energy per second for DC and the discharge energy per pulse for nanosecond pulses. The product of the discharge energy per pulse and the pulse repetition frequency equals the discharge energy per second. The discharge energy using nanosecond pulses at −20 kV was higher than the discharge energy at −8 kV, which is near the limit for DC (when the repetition frequency was 50 Hz or greater). It suggests that nanosecond pulse generator has ability to produce larger amount of ions than the DC power source.

Figure 9. Discharge energy of power source

Varying the distance between the needle and earth electrodes for DC and nanosecond pulses and measuring the discharge energy revealed that, whereas the discharge energy varied greatly with the distance between the electrodes for DC, the variation was small for nanosecond pulses. This demonstrates that nanosecond pulses enable stabilizing the discharge without being affected by the distance variation between the electrodes.

In order to evaluate the performance of nanosecond pulses as a new fabrication method of electret, the surface potential and thermal stability of electrets charged by nanosecond pulse and DC, discharge energies of nanosecond pulse generator and DC were examined and compared. As for the surface potential, we have found that surface potential of −2500 V(equal to surface charge density of 0.59 mC/m2) by nanosecond pulses is higher than that of by DC after 200h from discharge by 59 %. This is mainly considered to be because the high voltage nanosecond pulses inject more charge into the electret. For the thermal stability, we have found that a peak of TSDC appears near at 175°C in the case of DC and at around 210°C in the case of nanosecond pulses. It would imply that in the case of nanosecond pulses, ions were deeply injected and the thermal stability of electret was high, because a high voltage was used. In terms of the discharge energy, we have found that the discharge energy using nanosecond pulses at −20 kV was higher than that using DC at −8 kV (when the repetition frequency was 50 Hz or greater). Moreover, variation of discharge energy depending on the distance between the electrodes of nanosecond pulse generator was smaller than that of DC. These demonstrate that nanosecond pulse generator produce more ions than DC and stable discharge is possible by using nanosecond pulses without being greatly affected by the distance between the electrodes.

Therefore, we conclude that nanosecond pulse will be more useful for manufacturing electrets than DC.

1R.J.M. Vullers, R.van Schaijk, I.Doms, C.Van Hoof, R.Mertens: Micropower energy harvesting, Solid-State Electronics, 53, 684–693 (2009)

2Hua-Bin Fanga, Jing-Quan Liua, Zheng-Yi Xub, Lu Donga, Li Wangb, Di Chena, Bing-Chu Caia, Yue Liub: Fabrication and performance of MEMS-based piezoelectric powergenerator for vibration energy harvesting, Microelectronics Journal, 37, 1280–1284 (2006)

3M. Nifuku, Y. Zhou, A. Kisiel, T. Kobayashi, H. Katoh: Charging characteristics for electret filter Materials, Journal of Electrostatics, 51–52, 200–205 (2001)

4Boland J, Chao C-H, Suzuki Y and Tai Y-C: Micro electret power generator, 16th IEEE Int. Conf. MEMS(Kyoto) 538–41 (2003)