Chapter 5: Understanding Steel

What is Steel?

Steel is an alloy of iron, which comprises a few percent of carbon to improve its fracture resistance and strength. Iron exists in different crystal shapes at different temperatures. At room temperature, steel is a mixture of cementite and ferrite.

The ability of steel to maintain different structures makes it an incredibly useful and versatile metal. Steel can be heat treated and cooled in a way that makes it hard. By manipulating the composition of steel, a Knifemaker can bring out specific characteristics from the steel. The combination of these factors will significantly impact the overall outcome of the final knife.

Tips to look out for before choosing particular steel

There are over three thousand, five hundred grades of steel globally, and because of this, trying to choose the best kind of steel might seem like an impossible task. Most beginners start their Knife-making career using whatever piece of steel they come across.

Although it is possible to make knives out of some of those steel, it

can be confusing because you don't know what you are working with exactly. Knowing the type and properties of the steel you are working with is worth spending a little cash. Knowing what type of steel you are working with will help you carry out the right steps you need to bring out the steel qualities to make the perfect knife.

One crucial factor to look for in steel is the carbon percent. The amount of carbon in steel ranges from (0.6 - 1.6) percent. Steel near the (0.6 - 0.9) percent carbon range will be more resilient, while steel near the (1.3 - 1.6) percent carbon range can obtain a higher level of hardness.

As a Knifemaker, another property you should be looking out for in your steel is its toughness and hardness. Your knife should be hard enough to hold an edge but also be tough enough to a point not to break easily. The primary key to making a splendid knife is finding a balance between toughness and hardness.

Apart from toughness and hardness, other things to consider about your steel are edge retention, corrosion-resistant, forge ability, ductility, hardenability, workability, and lastly, your skill level!

A common system of numbering steels

The SAE steel system:

There is a common system for numbering steel, and if you are planning on becoming a professional knifemaker, you will have to know how to interpret this system.

Digits usually distinguish steel. For instance, (1045 steel).

●

The first digit in the number is a code representing the primary alloying element.

●

The second digit represents the secondary alloying element.

●

The last two digits show the carbon content of the steel in hundredths of a percent by weight.

So 1045 steel has only carbon (represented by 1 and 0) and a (0.45 percent carbon.)

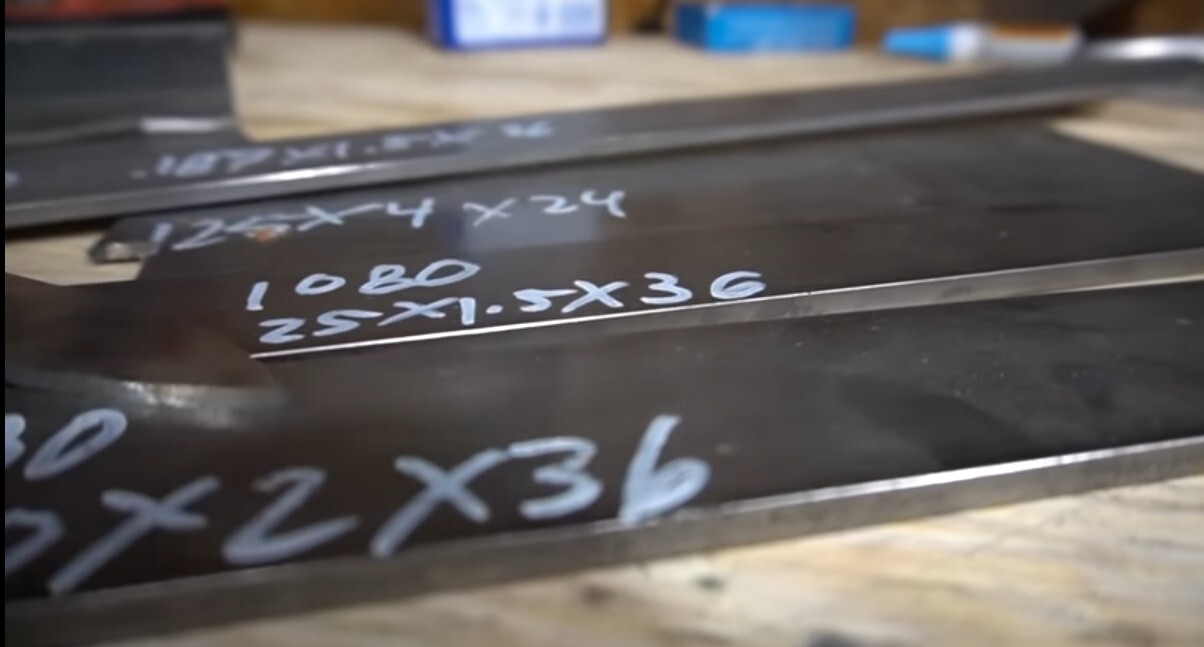

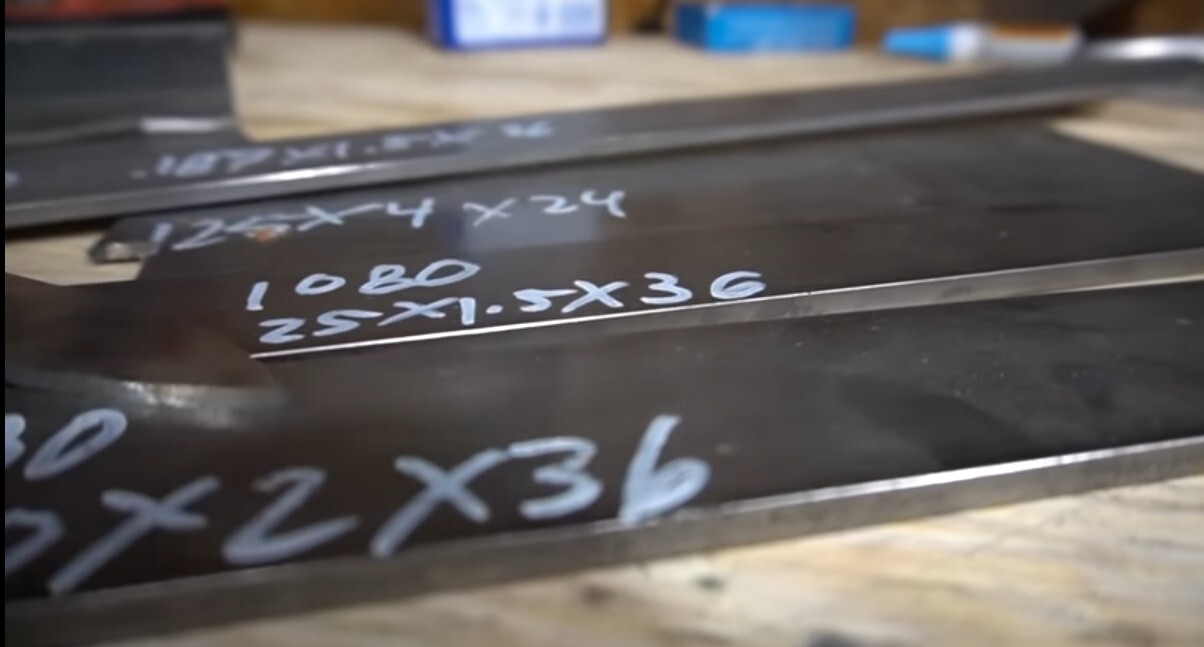

Common Steels for Knife-making

Here are some common steels you will need in your Knife-making journey;

High Carbon Steel:

Just as the name implies, they are a steel group that mainly contains carbon and steel with very few additional elements added. The high carbon steel has a high carbon percentage, which gives the steel strength and hardness, and they tend to hold a great edge! However, the negative side to the steel containing mainly carbon is that they don't have enough added elements in their alloy to make them corrosion-resistant, which can be an issue. They are susceptible to rust!

The High carbon steel, also known as 'the ten series,' is extremely common for pro-knifemakers. Of all the different types of high carbon steel, the best is the (1095 steel). It contains a (0.95 carbon percent). Any steel between (1045 and 1095) would be recommended for knife-making. Also, 'High Carbon Steels' are mostly seen with a coating on its exterior to prevent rust.

Alloy Steels:

This steel group is similar to high carbon steel because they also contain a high percentage of carbon. The difference between them is that Alloy steel typically has more added elements to cause specific characteristics in the steel. The added elements can make certain kinds of alloy steels a bit trickier to heat-treat.

Examples of Alloy steels are:

●

5160 steel:

It is very easy to heat-treat, making it great for forging.

●

6150 steel

: This steel is very pleasant to work with because it performs well even with less than the ideal temperature control during forging. It doesn't hold an edge like other steels, but it is quite tough and effortless to sharpen.

●

52100 steel

: This steel holds a high amount of carbon in it, making it very hard. It is a good choice for hunting knives.

●

A2 steel

: It is very flexible steel, but it is tough, so it can be difficult to grind. However, it has less wear resistance than other steels. It is often used for making combat knives basically because of its toughness.

●

D2 steel

: If you are particularly bothered about rust, and you want to use a steel that is resistant to rust, then the D2 steel is right for the job. This steel has good edge retention; however, it

can be difficult to sharpen. For this reason, it is considered as good steel for experts.

●

O-1 steel

: This steel tends to rust quickly. Although, it is a hard material and has good edge retention.

Stainless Steel:

Stainless steel is popularly known for its ability to resist corrosion. You might wonder why stainless steel can resist corrosion and why carbon steel does not. Stainless steel contains chromium in it which creates a thin oxide layer on the surface of the steel. This oxide layer covers the steel's whole surface area, which prevents the iron from oxidizing and can not rust, making stainless steel an ideal choice for making knives to be used in a wet environment.

Also, knives that are not used frequently might rust in their sheath, so they should be made using stainless steel. When making a knife using stainless steel, it is best to use the stock removal method, as stainless steel can be unforgiving and hard to work within the forge.