American farming experienced a great metamorphosis during the first few decades of the nineteenth century. Prior to that time, farming was largely a semisubsistence activity in which food and fiber grown on farms were used there as well. Things like tea and teakettles were imported, whereas things like cheese and beef were exported in limited quantities. The need to "shop in town" was so weak that itinerant peddlers, hauling their wares from door to distant door, became a commercial success.

Subsistence farms were still being established at the turn of the century in the rough country far from colonial villages, especially in Vermont, New Hampshire, and Maine. But farming towns to the south, especially near nascent industrial cities, began to export more and more—vegetable produce, dairy products, and poultry—to an enlarging urban market. The roads were still quite terrible, scarcely passable with more than a slow wagon. Under this circumstance, products that could be most easily carried to market—those that had the highest value per unit of weight—made the best profits. The alternative was forcing the animals to "walk" themselves to market and made even more sense. In this case, those animals with the largest weight per unit were the most profitable. Yankee drovers goaded their products toward principal cities from the most remote corners of New England, leaving great clouds of dust in dry weather, mired, impassable, manure-blessed ribbons of mud in wet. They were the first authentic American cowboys.

Stone-faced dam for a clover mill at Schoolhouse Brook Park.

Regional specialty crops also emerged, notably wool from Vermont, cranberries from the sandy bogs of Cape Cod, hops from near Boston, cheese from the Berkshire hills, and tobacco and onions from the Connecticut River Valley.

The British trade embargo of 1808 and high tariffs on imported goods after the War of 1812 stimulated those manufacturing enterprises that were already present on a small scale. Yankee industry flourished as it specialized and increased in scale; shoes were made in one place, clocks, axes, gunpowder,pistols, etc., in another.

Without imported British wool, sheep farming exploded in popularity, leading to the growth of textile mills that would eventually make southern New England the cloth-manufacturing capital of the world. High tariffs on iron tools also stimulated a tool-making industrial culture centered in Worcester, Massachusetts. Agricultural byproducts, particularly leather, precipitated the tanneries and shoemaking factories that would make Lynn, Massachusetts, world famous. All of these urban workers required that food be driven to them; market roads radiated outward from the densely populated mill cities like the spokes on a wheel.

The success of these "mill" industries had much to do with the geology of New England. Mills could be profitably "seated" only in narrow, constricted sections of streams, usually where a perennial stream was flanked by bedrock. Many other well-watered regions have sufficient water but lack a solid bedrock valley, having broad, winding, muddy channels instead. Although streams in drier regions often have the requisite bedrock channels, they lack the continuous flow of water. But New England has thousands of sites where both criteria are met. The uplift of the plateau had forced the streams to cut bedrock valleys that were narrow where the rocks were hard and wide where they were less resistant. It was the copious fill of well-washed sand and gravel in the broader reaches of valleys that created the aquifers that absorbed spring f loodwater and released it more slowly all year, ensuring an adequate flow to industry.1 Countless dams, all of which needed stone facing, appeared all over New England at this time, taking some of the waste stone previously stored in crude walls.

McCormick reaper and mower.

Farming became a more technical, commercial enterprise in the nineteenth century. Nitrate, or guano (seabird excrement), from the Atacama dessert—then in Bolivia, now in northern Chile—was available to fertilize crops depleted of nitrogen. Something they called "plaister of paris," now known as the mineral gypsum, provided sulfur, which was needed to make plant proteins. It was imported from all over the world. Lime, made of calcium carbonate, was bagged and hauled in wagons to neutralize acidity; oyster shells were an inexpensive source of lime. Potash production—the making of potassium salts and oxides for fertilizer use—surged; farmers who still had plenty of wood started small "pot-ash" factories.

The tools of farming changed as well.2 Implements for every task became more mechanized, automated, laborsaving. For example, the horse-drawn hay rake became widespread in the 1820s; before that, hay was gathered by hand. In the 1830s came multibottomed metal plows and specialized seed drills. These developments culminated in Cyrus McCormick's mechanical reaper, first marketed in 1834. With so many changes, agriculture was becoming less a way of life than a specialized trade taught at the college level; the first agricultural college, the Dariner Lyceum in Gardiner, Maine, opened in 1822. Specialty trade journals for eastern farming were published, notably the American Farmer (1819) and the Albany Cultivator (1834).

The switch from self-sufficient to market farming took place when America was still a largely rural, agricultural nation, its people spread out all over the land surface on freeholding farms. It was an era of improvement and optimism, one without parallel in our history. The rapid urban growth of eastern cities fueled the demand for agricultural products, raising commodity prices and producing a broadly distributed pattern of wealth for rural New England farmers that would never come again. Yankee Sturbridge Village—a living museum in Stur-bridge, Massachusetts, in the heart of the New England Plateau—captures the good times of the late 1820s and early 1830s. In 1825, the great New England orator Daniel Webster intoned, "Our proper business is improvement. Let our age be the age of improvement. In a day of peace, let us advance the arts of people and the works of peace."3

Tens of thousands of stone walls were built during this era of stable population, peace, and prosperity. Labor was available, there were no wars to fight, and the draining effort of deforesting the New England Plateau had been largely expended. Farmers throughout the region began to look inward at their farms, not as safe havens from war, but out of pride in being an American. A visible manifestation of this pride was the transformation of stone piles and primitive field-edge tossed walls into classical double walls that once surrounded productive farms, but which now thread their way through our woodlands. This didn't happen all at once, nor did it happen at the same time in all districts. In fact, some farms, such as the slave-operated estates in Rhode Island, had well-built stone walls from nearly the beginning. But in general, the primitive tossed walls and stone accumulations of the preceding epoch were either built up and leveled off or disassembled and rebuilt into their well-ordered early- to mid-nineteenth-century counterparts.

How such crews went about upgrading walls was seldom described. At least two men, a team of oxen, and a stone boat were typically used. The labor involved in such a transformation was extremely high. Modern masons often lay about twenty feet per day. An expert on British walls, Lawrence Garner, estimates that a good "waller" there can lay 5 to 6 yards a day. The agricultural historian Howard Russell concludes that "a good man with a good team might build four rods a day," or sixty-four feet of basic New England wall. Using the average of these estimates for the rate of wall construction and the estimated length of New England's stone walls from the 1871 fencing census (240,000 miles = 819,088,710 feet), forty million man days of effort would have been required to build them.4 This is an awesome amount of manual labor by modern standards, but it is trivial when compared to the much larger effort of getting stones to the edges of the fields in the first place. That job usually had been done stone by stone, and load by load, by the previous generation.

Most of the time the stonework on a farm was just another mundane chore, no more exciting than chopping wood, flinging manure, or shoveling snow, and no more costly in terms of labor, since it could be done during slack times. Other statistics can also help put this seemingly Herculean task into its proper perspective. The United States poptilation in the early nineteenth century was about 10 million souls. Assuming that only one person in three was young enough and strong enough to move stone, and that only one person in three lived in New England, each woiild have been responsible for biiilding 248 feet of stone wall, scarcely a few weeks' worth of effort during a lifetime.

Data from the national 1871 Census of Fences indicate that the average length of stone wall around an average 107-acre New England farm could have been built with a two-man crew in less than two days per year. Two days out of three hundred sixty-five would have been devoted to clearing stone.5 When compared with the equally mundane task of chopping and hauling wood, the average farmer probably spent twenty-two times as much effort to heat his home as to clear his fields of stone.6 (Based on the amount of energy they used, I once calculated that a single college football team could wall in twenty farms per year.")

Converting the ragged wall into an acceptable one was done in conjunction with the final clearing of stones from a valued field. This often involved removing the largest glacial erratics, which had been left in place up to then. Farmers, with more time on their hands, and greater literacy, actually wrote about the challenge of moving big boulders. Some of them were blown up with explosives. Others were pushed sideways into deep excavations dug beside them, then covered by dirt. Inventive farmers created and patented fancy contraptions—rock lifters and grippers, slings from tripods, jointed levers—to wage war against those persistent big stones that blemished their otherwise flawless fields.

A few stone walls were built above well-drained, frost-free foundations. Here, the recommended procedure was to lay out a straight line, excavate a shallow trench to remove the fine-grained material that wicked water beneath the stones during freezing, and backfill it with gravel before skidding or rolling the basal stones into place. Usually, however, only the loose organic debris was stripped away. Then the actual stonework could begin.

When building walls, New England farmers used simple rules governed by the laws of mechanics, a branch of physics dealing with mass and motion. The field of mechanics includes both statics, the stability of materials at rest (which governs the shape of stone walls and the internal arrangement of its stones), and dynamics (the forces and movements associated with moving the stones). Both were equally important in the construction of stone walls, regardless of when or where.

With respect to "statics," the most important principle was to lay the stones down in horizontal tiers with their edges butted together. Each successive tier of stones was laid so that the gaps in one tier did not coincide with the gaps in the one above it. This principle, known as one-on-two and two-on-one, is perfectly expressed by brickwork. A second principle was to place the largest stones (especially if they were irregular) near the base of a wall where they could serve as a foundation for the smaller stones above them. Finally, walls were tapered upward, or "battered," to keep them from tipping over.8

The majority of a farmer's walls were little more than stacks of stones perched precariously upon one another. Closer to the house and barn, and nearly always around cemeteries, stone walls were usually built, from the start, with some care. Most often, they were built of both sides, forming a "double-faced wall." WTienever possible, the straightest and thickest edge of each stone was placed on the outside, and each was positioned so that it slanted inward toward the center of the wall. This technique helped make walls stronger with time because the stones pressed more tightly together as the wall settled. The center of each double wall, where the thin and irregular edges of both sides met, was usually filled with rubble and pebbles. As the walls were built upward from their boulder foundations, they were leveled off to create a roughly rectangular cross section, upon which a final tier of "capstones" was placed.

Capstones were slabs large enough to span both sides of a double-faced wall, heavy enough to press them together, and flat enough to be attractive; often they were culled from stone piles and reserved for the final tier, especially at gates and corners. Another specialty stone was called a thrufter. These elongated, almost spindle-shaped stones were placed inside a wall to help bind its two sides together. This was especially important at corners, where the stones from one wall could be overlapped with those of the other, like the logs of a log cabin or the dovetails in a wooden drawer. Sometimes, the stones were arranged in a decorative pattern—blocks and slabs, dark and light, big and small—if the raw materials allowed it.

Stonework often is more carefully done near the end of a wall segment, regardless of whether it meets a corner or not; gaps between stones become fewer and smaller, the stones are chinked more tightly, the edges are aligned more carefully, and the top is laid flatter. Freestanding ends of wall segments are constructed as if they were "triple-walls," with the stones slanting in from both sides as well as in from the end. They are especially common at "bar-ways," places where primitive gates once stood before they rotted away. There, wooden rails called bars were raised or lowered and inserted into slots in the butt end of a wall to form a fence without the need for hinges. A stone stairway called a stile was sometimes built into a wall when a barway wasn't desired, but where pedestrian traffic warranted it. These were constructed most simply by letting the ends of a few strongly supported stones stick out from the wall.

The walls near barways and other primitive gates were built better, partly because there was a greater need for strength, but also for aesthetic reasons. It was here that the wall was seen most often by passing vehicles, flocks and herds of animals, and people—farmers, peddlers, children, evangelists, and strolling lovers.

Two segments merging at right angles form a corner. Many an imposing square corner quickly degraded to a pile of rubble with increasing distance. Solid corners were sometimes required after parcels of land had been resurveyed with the more precise surveying instruments available in the early nineteenth century—transits, theodolites, and levels. Conflicts over property boundaries needed permanent resolution, which often came in the form of a stone wall. Eventually, even well-defined wall corners would fall out of favor as more precise survey markers of iron pipes and concrete posts became the convention.9

Endless variations on these basic construction principles and techniques were woven into the stonework of Yankee villages. A door sill required little more than a single large stone and something to prop it up with. At the other extreme were the walls around churchyard cemeteries, which often exhibit the most elaborate stonework, often capped with a top layer of quarried stone. A barn or outbuilding foundation required little more than a row of large slabs raised to the same elevation. The most evocative type of drystone wall is the house-size square surrounding old cellar holes. Stone cellars were built to support the basal timbers of a wooden house and to create an artificial cave below it, one that could be used to store food and that kept it cool in the summer and unfrozen in the winter.

In addition to stone walls and foundations, there were other, more unusual stone structures. Freestanding root cellars were built aboveground in the shape of igloos, a design that offered a tightly sealed chamber without the need for other materials. Stacks of stone set upon farmyard erratics sometimes rose upward into columnar structures as the stone kept coming, year after year. Short segments of walls occasionally begin and end for no apparent reason; they were most often upgraded piles of fence-line stone. Crescent-shaped segments of walls curved into the prevailing wind may have been sheep folds, where a huddled flock could wait out a passing storm. Isolated circles thirty to forty feet in diameter were stone-lined charcoal pits, where heaps of wood twenty feet high smoldered for days; their stones are usually oxidized to the brick-red color of fired pottery. Smaller circles with red-tinged, fire-cracked rock were the remains of campfires, which have been constructed on and off for millennia by Native Americans and by runaways and homeless travelers during the Yankee era. When such fire pits are densely concentrated, they are probably the remains of temporary encampments for war soldiers. Some stone structures were built for the sake of art, some for no discernible reason at all.

The American model of an upgraded wall was distinctly different from its British counterpart.10 Many of the walls of western Britain are high enough to be legal fences, which is clearly not the case in New England, where most walls are thick and low. In Britain, they also usually have a top tier of stones—called copestones (not to be confused with capstones)—that are deliberately set on edge, like books on a shelf. This technique is extremely rare in the woodland walls of North America, and is typically present only in wealthy, old, thoroughly English communities like Newport, Rhode Island. Per unit weight, copestones exert greater stress on the flat-lying stones beneath them, bonding the underlying stones more firmly, making the top part of the wall more stable. They also provide painful footing for any animal jumping upon them, a function equivalent to iron spikes on top of a masonry wall. Finally, copestones look less natural, and less stable than when laid flat, sending a message of imminent collapse, one that might deter a recalcitrant sheep, filly, or calf from the prospect of jumping. Had stand-alone agricultural fencing been the paramount objective of stone walls in New England, many more would have approached the higher, more intimidating style of their Old World counterparts.

Nearly all of the walls in New England were built of unshaped fieldstone, stones simply picked up, moved from the field, then tossed or laid into a wall without mortar. In contrast, the walls in old villages or near houses and barnyards were often deliberately shaped, sometimes with little more than the whack of a hammer. Many stones still bear the marks of their shaping in the form of a lighter-colored patch where the stain, or patina, of the original stone was broken away. Chisels, wedges, and sledges were used for larger jobs such as splitting boulders to make capstones. Enormous blocks—especially those plucked from ledges for doorsills, capstones, and thrufters—usually required shaping with a primitive, handheld, spike-shaped, hammer-driven drill. After the right number of holes had been drilled to just the right depth in just the right orientation, a large slab could be broken, sometimes with fire, sometimes by hoisting and dropping it, sometimes with the blow of a heavy object. The telltale evidence of this type of quarrying can still be seen in the broken, cigar-diameter drill holes—called pin and feather marks—on the capstones of many ornamental walls. They are often spaced about ten inches apart.

Every slab of New England fieldstone contains a tiny remnant of the original tectonic stress imparted to it when the stone first became cool enough to behave as a brittle solid. The direction of this force is from the inside of a stone to its outside, and is concentrated at right angles to foliation. This "inside-pushing-outside" force is the fatal flaw_the Achilles' heel—of all rocks. Exposed stones have no alternative but to break into smaller pieces, for there is nothing except the pressure of the atmosphere to push stones together. The glacier exploited this inside-to-outside force when it lifted the bedrock in large quarried blocks, and used this force to break the blocks apart. The weather exploits this force when it breaks large fieldstones in half as they rest quietly in the woods. Quarrymen exploited this force when they converted New England's rough ledges and boulders into tons of straight-edged building stone.

Illustration of a Redding, Connecticut, farm.

Walking in the woods of New England today, one could get the erroneous impression that most of its fences were made of stone. Wooden fences, which were always more common than stone ones, simply vanished after the land was abandoned. This was true even during the early-nineteenth-century epoch of agricultural wealth, available labor, and Federalist optimism. The problem wasn't a limited supply of stone, for many areas had been deforested for nearly a century, giving plenty of time for stones to be concentrated by heaving and erosion. The problem was that a well-built stone wall was an expensive proposition, relative to a wooden fence, even then. We tend to underestimate the importance of wooden fencing in the nineteenth century simply because the wood has disappeared, whereas the stone has not. Wooden fence posts rotted at ground level, tipping their rails into the soil, where they were rapidly digested by soil microbes. Stone fences fall apart as well, but do so on a geological time scale rather than a biological one. Hence, they are still around.

The lithographs of John Warner Barber's "Connecticut Historical Collections" prove this point.11 Seventy-four of his engravings "executed from drawings taken on the spot" show rural agriciiltural scenes typical of southern New England. Of these images, forty-five show solely wooden fencing, usually of the post-and-rail variety, and with the fourth rail as high as a horse's shoulder. Twenty-one of the scenes show some combination of stone and wood fencing, usually with one or more rails placed above the stone, and held in place by an A-frame of poles. Only 11 percent (8 out of 94) of his illustrations showed stone walls without wood, and these were always lower in height than wooden fences. As a fencing material, stone without wood was very rare.

More detailed data can be found in a document produced by the U.S. Commission of Agriculture in 1872, the first and last national census of fences.12 At the time, fencing was an important factor in federal land-use policy, which was struggling to ameliorate disagreements, even bloodshed, between cattlemen, railroaders, and farmers over who bore the responsibility, and the privilege, of fencing the land. Essentially, the ranchers wanted the farmers to fence in their lands, whereas the farmers wanted the ranchers to fence in their cattle. This was a replay of the problem New Englanders had faced a century earlier during the transition from common herding to privatization of enclosure as the communal, Puritan style gave way to a distinctly American one. Questionnaires were sent to officially designated agricultural correspondents in every state and territory, 846 of whom responded. An anonymous statistician and author then compiled the report. It remains today as the best hard data on the phenomenon of stone walls at the time when they were most widespread, before many would be chewed up by rock crushers, buried to make way for larger fields, and poached for the suburbs of a subsequent century.

According to the census, the heights of fences in New England were typical of those elsewhere in the nation, ranging from three and a half to five feet. Stone fences were included in a category labeled "other," which included "worm, rail, cap-and-bunk, board, wire, hedge, log, brush, picket, and woven fence." The census also made it clear what nineteenth-century New England farmers meant when they said the word "wall" or "fence." To them, a stone wall was any accumulation that reached a height of two and a half feet, regardless of whether it was part of a fence or not. A stone fence, in contrast, had to reach the legal height of four to four and a half feet without any help from rails. The hybrid fence—part stone on the bottom, part wood on the top—was very, very common. In Plymouth County, Massachusetts (an area the size of Rhode Island), fully 60 percent of the fences were "stone and wood combined," with only 10 percent as true stone fences. Thus, most stone walls were never legal fences, in and of themselves.

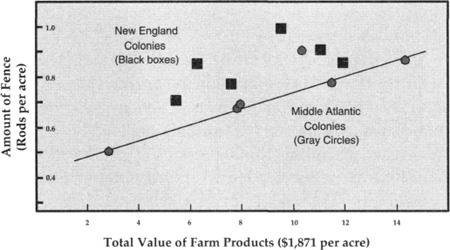

Graph based on data from the 1871 Census of Fences by the U.S. Dept. of Agriculture showing the strong correlation between farm productivity and the amount of fencing for the mid-Atlantic colonies (gray circles) and the New England states (black squares), where fences are more abundant and are unrelated to farm productivity.

Within greater New England, the maximum concentration of stone walls varied widely. Rhode Island, with up to 78 percent of its fences being made (or partly made) of stone, had the greatest proportion of stone walls, followed by Massachusetts (60 percent), New Hampshire (51 percent), Connecticut (33 percent), Vermont (32 percent), and Maine (20 percent). The average price of a stone fence bore little, if any, relationship to either the price of wood or to the average population density on farms, which was related to availability of labor. These hard facts and statistical data refute the argument that stone walls were built primarily because labor finally became available, or because stone replaced wood when the latter was in short supply.

With respect to monetary value (the cost of stone versus wood), a stone fence made the most economic sense in New Hampshire, followed by Vermont, Maine, Rhode Island, Connecticut, and, finally, Massachusetts. Curiously, stone walls were most abundant where they were most expensive to build and rarest where they were least expensive. This is the opposite of what would be expected if material costs for fencing were the primary determinant. Something else was going on.

George Washington had spotted the problem. He may have been the first to recognize that "in the New England States . . . landed property is more divided than it is in the states south of them."13 A comparison of twelve northeastern states, six in New England and six to the south (New York, Pennsylvania, Maryland, Virginia, Delaware, and New Jersey), showed that he was right; New England had far more "fences" than it needed, at least based on farm economics. Because fencing was usually the single biggest investment on a farm, often exceeding that of the land and buildings combined, the amount of fencing on any farm should correlate strongly with the combined value of stock and crops, even when the proportionately smaller sizes of New England fields are taken into account. This was certainly true in the states just south of New England; of these six states, only Pennsylvania, with its Dutch-German tradition of dense settlement, seemed off trend. In the six New England states, however, there was hardly any relationship between the amount of fencing and the value of farm products.14

The inevitable conclusion that must be drawn from this anomaly in the agricultural value of fences is that many of New England's so-called fences had little to do with agricultural production. The extra fences discovered by the 1872 census were, instead, walls built to hold stone. More than anything else, they were linear landfills, packed full of agricultural refuse that would not decompose. This claim is supported by an early-nineteenth-century analysis regarding the cost of constructing a fence made of stone in Farmington, Connecticut, relative to other types of fencing.15 This study took into account the lifetime cost of erecting and maintaining a rod of fence for a period of fifty years.

Many stone walls have lasted quite well, especially those that were actually built, rather than merely tossed; those that

were placed on firm, dry soils; and those that have escaped the ravages of falling trees. They seem to have survived everything

else that nature has dished out during the last two centuries: heaving soil, drenching rain, and dissolution. In his autobiography,

a nineteenth-century farmer-mechanic-tradesman named Asa Sheldon gave specific instructions on how to build a good two-sided

stone wall.

If you want to build your wall five feet high, and have it stand centuries, as I am sure you do, then make the base half the

thickness of the height, and batter it on front at least one and one-half inch to the foot. Mind and never put so small stones

on the top that a dog running over them will knock them off. If the soil be clay, take it out a few inches wider than the

wall and fill in back with good gravel stones, othemvise the clay will run in among the stones, freeze, and heave them, and

thus injure the wall.16

Mr. Sheldon's recipe was effective because each procedure he used interfered with one or more of the physical mechanisms that bring down a wall. Gravel helps because it doesn't wick moisture downward to the frost line, and doesn't compact unevenly. Battering (narrowing the width of the wall upward) ensures that the center of gravity for the wall stays low, preventing collapse by toppling. The blunt, pyramidal shape in cross section distributes the weight evenly. Avoiding stones too small for a dog to kick down prevents a chain reaction of the kinetic energy associated with falling stones. Early-nineteenth-century wall builders knew their practical physics.

Mr. Sheldon's rules for wall construction are similar to the natural laws of the formation of mountains, which mimic the structure of carefully laid walls. The relationship between the strength of a mountain and its internal structure is especially clear in the high part of the central Appalachians, where the tallest mountains have the widest bases, and are also those where resistant strata have been slanted inward, toward the center of the highland from both sides, and those capped by a thick layer of hard rock.17 This mountain form is identical to that of the properly built double wall, complete with capstone.

Many features of stone walls mimic nature, perhaps because stone walls, although constructed by humans, contain a large component

of naturalness. The Native American author William Least Heat Moon experienced the hidden, persuasive force of nature as he

passed through the northeastern United States, and recounts this in Blue Highways. There, while building a stone wall with a friend:

. . . a strange things began to happen. We could feel an urging in the rocks, a behest to be put in just so, to be set where

they would hold against the shifts of the earth, against the twists of the roots. They fit one way and not other ways. It

was as if the stones were, as Indians believed, alive. The rocks were moving us We just followed the will of the wall, whatever

came from the stones.18

Choosing the right stone, structure, place, and height for a wall are partly subconscious actions that take place when humans allow themselves to be guided by natural laws, when they follow the "will of the wall."

Stone walls "willed" the farm fields of New England to be small because of the amount of energy required to remove stone to

the edges of fields. Sam Deane, as early as 1790, advised against small fields because they interfered with cross-plowing

and became seriously compacted by confined livestock. Yet, at the same time, he recommended small fields for what he called

"disposing of the stones." The historian John Stilgoe was more specific.

Rock clearing explains in part the small size of colonial fields. Men understood the great effort required to clear fields

larger than one or two acres, and slowly—especially in New England—they learned how much longer they spent clearing one eight-acre field than eight one-acre ones.19

I have tested this simple idea quantitatively by writing simple computer models based on geometric considerations and by assuming reasonable distributions and concentrations of fieldstone, and reasonable dimensions for stone walls. Fields came in a variety of rectangular and triangular shapes, but most were made as square as possible. Assuming a square field in which rocks were hauled off by hand, one at a time, and assuming a hundred rocks per acre needing transport, clearing an eight-acre field of stone would require fifty-eight miles of walking, whereas eight one-acre fields would require less than twenty miles.

Subsequent computer models were used to investigate how other variables might have influenced the spacing of walls. A model called RimWidth calculated that the stone walls around enclosures smaller than two to four acres would waste too much space just to hold the stones on their edges. One called PlowTurn computed the time wasted in turning a plow and its draft horse around; for field sizes larger than two acres, the amount of wasted time diminishes rapidly. WallWalk computed the distance needed to transport the stone from fields of various sizes with, or without, a stone boat. Experimentation with these and several other theoretical models made it clear that the optimum trade-off between these conflicting needs was a square field between two and four acres in size.20

It is surprisingly difficult to determine the average actual size of New England's fields. Historic sources contain good data on farm size, and the proportion of improved and unimproved land, because this was an important issue for taxation. But the size of fields was too variable, too idiosyncratic, for good statistics to be kept. There is excellent data from Harvard Forest in Petersham, Massachusetts, where the pattern of stone walls was mapped accurately during the 1930s as part of a forestry disease research project attempting to understand how white pine blister rust spread from tree to tree. The walls had been mapped to create a base map for separate tree clusters.21 A sampling was done of two hundred fields within an area of densely settled farmsteads. The median size of a field was two and a half acres; 80 percent were smaller than five acres; 30 percent were smaller than two.

The same calculus governing field size was solved intuitively by the farmer George Platt of Milford, Connecticut. A transcript of his comments to the 1872 annual meeting of the Connecticut Board of Agriculture survives.22 Mr. Platt was so experienced with the concentration of stones in the soil that he deduced that the size of fields should be "about three acres," based on the number and spacing of the walls needed to hold the stone.

The geometric pattern of enclosures within enclosures, each rimmed in with stone, are also consistent with a partly natural origin. When settlement began, the field stones were more evenly distributed, at least statistically, as a consequence of the natural mechanisms that put most of the stones there. But over time, the initially more uniform distribution of stones became a segregated one in which stony edges (walls) surrounded stone-free centers (fields). If the walls around a field filled up with stone before the supply of fieldstone was exhausted, a good alternative for holding the excess stone was to create another wall, usually at right angles to the first, in order to maintain square fields. This subdivision process sometimes took place over and over, until the arrival of stones slowed down sufficiently. Thoreau mirthfully commented on this tight division of land by stone wall in his journals. "I am amused to see from my window here how busily man has divided and staked off his domain. God must smile at his puny [stone wall] fences running hither and thither everywhere over the land."23

The way walls grow around a field is also constrained by natural laws. For a square field, there must always be a band around the edge of every field where it makes sense to move the stones to the edge, rather than to any pile. Something similar happens when autumn leaves are raked from a yard bordered by woodland. I always start by scraping those leaves nearest the edge into the trees, then continue by making piles that I later haul to the nearest edge of the woods. Similarly, stones hauled from the zone nearest the edge of a field form an initial concentration around the perimeter, one that will increase with time as more stone is added. A load of stones from anywhere else in the field is a more complicated problem. As was the case with the piles of leaves, the shortest hauling distance between the load of stones and any fence line must be perpendicular to the nearest edge. But the incentive to move stone in that direction diminishes as one gets nearer the center of the field. There, at the midpoint of a square field, all fences are equidistant. At the midpoint of a rectangular field, the two closest sides are equidistant. Corners will be the hardest places to get stone to, because they must always be farther away than any side.24

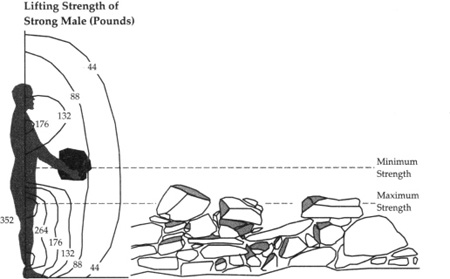

Diagram showing a typical stone wall and why it is thigh high.

Stone walls in New England are the height of a man's thigh because of several ergonomic factors.25 Lifting a heavy stone to an overhead position—say, to the top of the refrigerator—is not a smooth motion, but a series of three discrete steps. Using the terminology of weight lifters, there is the dead lift to the thighs, the curl to the chest, and the overhead press to a straight-arm's length. Once the stone has been lifted, person and stone become a single mechanical entity with a common center of gravity. If the stone is held overhead, the spine can remain straight. Otherwise, the person must hug the stone in the front, against his stomach, or hold it sideways on the hip. This places considerable stress on the spine, which must bend either backward for a stomach-held stone, or sideways for a hip-held one.

In carrying a stone, the ideal position with respect to the vertebrae—straight above the head—is not only dangerous for the back but is the most wasteful in terms of lift energy. The lifting strength of the human skeleton reaches a maximum midway between the knees and the hips. This height corresponds to the thickest bone in our bodies, the femur—the height wheelbarrows are designed to be lifted, a stretcher is to be carried, and where handles are placed on large suitcases. At this height, a stone held at arm's length can be swung in a gentle upward arc like a simple pendulum hung from the shoulders. This gives the stone momentum in the direction of its arc, allowing it to move past the face of a knee-high wall. Before it descends to the top of the wall, however, the stone passes through a vertical position where it is momentarily weightless, allowing its final positioning to be achieved almost effortlessly.

Large, slabby stones can most easily be held by their ends, and can be swung efficiently only in front of the body. This means that they will be most efficiently tossed across the wall, an orientation that is also best for structural stability. Stones that are more chunk shaped have a greater concentration of mass and fewer convenient hand holds; hence they are more easily pushed outward from waist height as they fall into place. Placing any large stone in a position higher than a person's hips is both difficult and dangerous. It was typically done only when the stonework was part of a construction project, rather than a fieldstone wall.

Slabs are the most convenient stones to clear and to stack. Moving a slab frees up more arable space than its round counterpart, and slabs are easier to lift because their edges make good handholds. They are also easier to carry because the stone can be held tightly against the body. This bring's the combined center of mass closer to the legs that are transporting it, which makes it more stable. But most important, the slab shape, like that of bricks or books, is easier to stack. Given all these incentives, it is no surprise that New England towns dominated by slab-shaped rocks are also those where the walls are the most common and the best built. The stone demanded it to be so.

In the early years of the nineteenth century, an era of optimism and improvements, the vast majority of Americans were still farmers, using their muscles and livestock to create a human-dominated landscape. In New England, a small proportion of this energy was expended to create the beautiful stone walls now found throughout the region today. The placement of walls on the landscape coincides with nature's placement of the stones. The height, width, and simple structure of walls were determined by the mechanical constraints of the human frame, whereas the quality of the walls was relative to the quality of the stone for building (slabs versus boulders). For areas of similar geology, the similarity in the physical form of the walls left behind by Yankee farmers—from Burlington, Vermont, to New Bedford, Massachusetts—is principally an expression of natural forces. Cultural forces also accounted for wall variation, but they were usually subdued beneath the economic mandate to move so much stone.