Folk Engineering

The next few chapters deal with the ironmongery, and in these I have gone into rather more detail, for it is upon detail that the success or failure of the hardware depends.

—SIR HARRY RICARDO

Before we lose patience we would do well to recall the words of Marshal de Saxe: “Although those who concern themselves with details are regarded as folk of limited intelligence, it seems to me that this part is essential, because it is the foundation . . . . It is not enough to have a liking for architecture. One must also know stone-cutting.”

—MICHEL FOUCAULT

When a red ’75 Beetle started showing up in the parking lot of a building I frequent, and it emerged that Carl was looking to unload the car, my middle-aged life of automotive self-denial was put to the test, and immediately crumbled. He let me sit in the driver’s seat, and it was like coming home. The cockpit of these cars is contained and intimate. Everything is within easy, natural reach. Merely resting my hands on the steering wheel and shifter, my feet on the pedals, summoned some dormant mechanical habits long forgotten by my conscious mind, but stored somehow in my body. With memories of downshifting into a slide, that body now said, “Oh. Yes.” There is a distinctive smell to the interior made of cheap German vinyl. Or maybe what I smelled is the horsehair that is stuffed above the headliner, and in the ancient seats amidst the talkative springs. It is not a stretch to say that there is an organic, indeed horsey quality to old cars. A car from 1975 is a product of the industrial economy at its zenith, yet you can imagine (however accurately) the homely provenance of the car’s materials, and the processes by which it was made. Because it is accessible to your imagination in this way, you may find that you want to do stuff to it. That is, you may be tempted to become a folk engineer.

If you’re like me and get all worked up about the possibilities, prematurely, you might make a bad mistake. For example, you might neglect to pull the carpet up from your prospective purchase and look for rust.

As I write this, it is eight years since I bought the car, and all that remains of the original is the central spine, the rear torsion housing, and the upper portion of the body shell. The rest was iron oxide powder held in the shape of a Volkswagen merely by habit, aided by carpet mastic. In the time I have invested during this interval, a person of more cultivated tastes could have learned Chinese, or made good progress toward mastering the violin.

Why devote myself to such a project? I may be the wrong person to answer that question—obsession isn’t very conducive to self-knowledge. But in the preceding chapters, I hope I have shown why one might look to an earlier stage of the automobile’s development to try to reclaim the excitement of driving.

The fetish of automaticity and disconnection looks to me like a cultural spiral into Promethean shame: the very opposite of the mentality of mastery that we usually associate with technology. By way of contrast, and paradoxically, the Bug I am building will be an emphatically “modern” car, in that good old-fashioned sense of modern. In fact, I am giving it state-of-the-art digital engine management, using the do-it-yourself platform MegaSquirt. I think a fully free relationship to technology would be one that neither shuns it as alienating magic nor accepts uncritically the agenda that is sealed inside the black box.

The design principles I am adopting in building the Bug are straightforward: lightness, rigidity, and directness of control. And, of course, horsepower—plenty of it. The result I am hoping for is a driving experience of suppleness and finesse, in which the car comes to feel like a well-fit prosthetic.

Such, at any rate, is my fantasy. For the first five years the project went entirely backward, and this for one reason: rust. Rust is the opposite of fantasy. As I disassembled the car, I kept finding more rust in the hidden hollows, leading me to cut out more sections of sheet metal to fully expose the rot to view. I quite literally cut the car into little pieces. While my fantasy life was taking place on the internet forums devoted to building something new and bitchin’, my actual life in the shop spiraled into an ever more intimate involvement with corrosion.

From 2011 through 2017, I would lie awake at night visualizing the capillary creep of moisture into seams where two panels of sheet metal overlap, and it would give me an itchy feeling. The insidious genius of corrosion is that the more you know of its creeping ways, the more it colonizes your mind with schemes for defeating it. Corruption must be rooted out. I never wanted to become an amateur chemist, but it cannot be helped when you are trying to disentangle the various claims made for rust inhibitor, rust dissolver, rust encapsulator, rust converter, and all the wishful thinking that such terms convey.1 Fatalism is the only truly rational response to the oxidative process; anyone who has spent years restoring an old car has failed to hear the words of the apostle who said, “Lay not up for yourselves treasures upon earth, where moth and rust doth corrupt.”

Such wisdom is easier to state than to heed. In a burst of hope and inspiration I attached a skinny hose to a long stick for shooting epoxy coatings deep into heater channels that I had spent weeks rebuilding. I found copper-heavy primers that can withstand the heat of welding, to use in places that will be inaccessible to full corrosion treatment once I have welded a panel into place. I rigged up a siphon that allows me to use a pressure washer as a media blaster; imagine a jet of water at 3,000 psi that is full of crushed glass. I use it to remove the accumulated layers of road grime, undercoating, paint, primer, body filler, seam sealer, and—there it is!—rust. The irony is that most of this crap was deposited by previous owners in a vain effort to prevent rust, and now it stands in the way of my effort to seek and destroy the cancer. In Greek, “truth” is aletheia, that which is uncovered. A lust for seeing bare metal takes over; one wants to dispel all the sediments of confusion that have been laid down by others who didn’t do their homework (obviously). Getting to the bottom of things, a tabula rasa that will lie fully exposed to my inspection and my will: restoring an old car becomes a metaphysical obsession that defies any honest cost-benefit analysis.

My wife is fond of reminding me of the concept of “sunk costs.” It is meant to be a liberating idea: sometimes it makes sense to just walk away from something that you are invested in. You have sat through an hour of a bad movie, but there is no point in remaining till the end (though you feel like you should, because of your investment). In a purely theoretical mood, without reference to any particular eyesore in the driveway, she’ll muse aloud that sometimes one has to step back and look at a project with the fresh eyes of someone who is noncommittal. Because she is so rational, she has no concept of being loyal to a heap of rusted metal.

INTERNAL COMBUSTION: THE ULTIMATE WIKI

The internal combustion engine is a miracle. The basic idea is simple enough: a piston moves down through a cylinder, increasing the unoccupied volume and thereby creating a vacuum. This vacuum draws a mixture of air and atomized fuel into the cylinder through an open hole. Then the hole is sealed up and the piston reverses course, moving up and compressing the air-fuel mixture into a much smaller volume (that is the combustion chamber, about one-tenth as large as the cylinder). Shortly before the moment of maximum compression, a spark is introduced. If all goes well, what ensues is a slow-motion explosion (gasoline has more energy per unit of mass than TNT), a pressure wave that is just shy of moving fast enough to count as “detonation.” This forces the piston back down. Because the piston is connected to a crankshaft, its reciprocating motion in a straight line is converted into a rotary motion (imagine the wheel of an old locomotive being driven by a shaft attached near the wheel’s circumference). The explosive energy that forced the piston down has been transformed into torque: the ability to exert force in a circular motion. Some of that energy is used to turn the wheels of the car and some is stored in a flywheel, attached to the end of the crankshaft, and that energy is going to be used now. The piston at this point is lifeless, having spent its energy. But the flywheel returns the favor, and the momentum of the rotating assembly carries the piston back up to the top. For this upward stroke, we’re going to open a different hole at the top of the cylinder, to allow the burnt air-fuel mixture to escape. That’s exhaust. Then that hole closes and the first hole opens again, and we’re ready to repeat the whole process. These are the four cycles of a “four-stroke” engine: intake, compression, power, exhaust. In the course of the four cycles, the crankshaft has made two complete rotations and the piston has gone down, up, down, up.

The more you know of the details of its operation, and how many things must go exactly right for it to do what it does, the more preposterous it seems that such a thing should be possible, much less that an individual motor might do this unobtrusively for two hundred thousand miles with little maintenance or complaint. By my rough calculation, this adds up to something in the neighborhood of one billion revolutions over the lifetime of a motor.2 For a six cylinder, four-stroke engine, that’s three billion little explosions. For a person whose primary acquaintance is with things digital, this may be an abstraction—a mere string of nine zeroes, no more impressive than the zeroes that make up a gigabyte. But the reciprocating, rotating, flexing, abrading, burning, pounding components of an engine do this while inhaling dusty air, getting cooked out on the highway. What is more, all of these components are fully inspectable things that you can hold in your hand, draw a picture of, nick with a file, or chuck across the room in a fit. They have heft and shape. The whole ensemble operates without summoning inscrutable entities that are said to live in the Cloud. The homey, nonmagical thingness of a motor invites the basic human drive to understand; I can think of no more effective ally of enlightenment.

The development of the internal combustion engine offers a singular story of engineering progress. It has been an object of mathematical science since its inception, but it has likewise been the beneficiary of perhaps the most sustained and widely dispersed project of practical experimentation in human history, the ultimate wiki.3 Today’s state of the art is the result of more than a century of back-and-forth between trained engineers and shade tree mechanics, illicit street racers and environmental regulators, high-dollar motor sports and cost-oriented automakers.

IN 1885, HARRY RICARDO was born in London to an architect father and a mother from an aristocratic family (his family name is of Portuguese origin, from the Sephardic Jews on his father’s side). In 1898 his grandfather purchased an automobile, and we can suppose that young Harry was one of the first people in England to see one. He attended the elite Rugby School and began building engines at the age of ten. After his first year at Cambridge University he entered a competition put on by the University Automobile Club, which he won by designing and building the machine that could travel the farthest on one imperial quart of petrol. Ricardo built a single-cylinder motorcycle that went forty miles, which would give it a fuel economy of 133 miles per U.S. gallon. In 1904. One wonders what Ricardo’s fellow toffs made of the ungentlemanly odors that must have emanated from the very pores of one so deeply immersed in engine work.

One of the most consequential engine developments of the twenty-first century is the use of “direct injection” to accomplish a stratified air-fuel charge, meaning that the ratio of air to atomized fuel is not homogeneous throughout the volume of intake charge admitted to the combustion chamber. A small area of richer mixture is ignited first by the spark, creating a fast-moving flame front that in turn ignites a much leaner mixture that fills the larger volume of the chamber. The result is better fuel economy, and greater thermal efficiency. While still a teenager, Ricardo built an engine that utilized this concept, a full century before its wide commercialization.

After university he set up shop, and during the First World War he took on the challenge of developing an engine for tanks that would emit less smoke. The smoke was a serious problem, because it would give away a tank’s position. His first attempt, a six-cylinder engine, solved the smoke problem. He also increased power output from 105 horsepower to 150, climbing to 260 HP in later iterations over the course of the war. During the Second World War he turned to aircraft engines, with similarly spectacular results. Elected a Fellow of the Royal Society for his wartime accomplishments, he would enter the peerage as Knight Commander of the Most Excellent Order of the British Empire. I wonder if Sir Harry still smelled of carb cleaner as he kneeled before the queen, to be touched upon the shoulders with the ancient sword.

Ricardo’s magisterial work, The High-Speed Internal-Combustion Engine, was first published in 1923 and rewritten in 1953. It opens with an interesting observation about the role of chance in the process by which certain designs beat out others.

When we review the progress of mechanical engineering in the past we find that each new line of development starts with a period of experiment and groping, during which a wide range of types is evolved. By a process of elimination this range is very soon whittled down to one or two survivors; in the final choice of these survivors, chance plays often quite as important a part as merit. We are too fond of crediting a few particular individuals with a monopoly of inventive genius. Ripe seeds of invention everywhere abound, and it awaits only a certain combination of need, of circumstance and, above all, perhaps, of chance, to decide which shall germinate.

On the one or two survivors, not necessarily the best, the attention of the whole engineering world is then concentrated, with the result that step by step they are improved out of all recognition and reign supreme, until they reach almost the very limit of their capacity, when new and fundamentally better types eventually replace them.4

What Ricardo didn’t anticipate is that some people would never get the memo about the obsolescence of some earlier engine architecture, and keep pushing forward with it. When I was in high school in the early 1980s, Top Fuel dragsters were making 3,000 horsepower. Nobody could have imagined that early in the twenty-first century, the same 500 cubic-inch, two-valve-per-cylinder, push-rod V8, based on a 1950 Chrysler design, would be making 10,000 horsepower. That’s greater by a factor of fifty-five over the first iteration from the Chrysler Corporation which made 180 horsepower, considered a demonic figure at the time.

Human beings are often bullheaded in their attachment to something suboptimal. Call it loyalty, call it perversity, or call it a cultural inheritance, this conservatism has at times been responsible for amazing leaps forward, paradoxically enough. Ricardo’s “ripe seeds of invention” that “everywhere abound” begin to germinate around some settled platform, “not necessarily the best,” allowing a body of communal expertise to develop. The impatient optimizer may see such an inheritance as an obstacle, something to be swept away in the name of forward progress. But tradition can itself be an engine of progress. It organizes the transmission of knowledge. It also provides an idiom for some shared endeavor, and a set of historical benchmarks, such that one can imagine oneself outdoing particular human beings who came before, and who worked within the same basic limitations. Tradition thus provides a venue for rivalry in excellence, the kind that sometimes brings a whole community to new and unexpected places.

In this respect, I think it is fair to call hot-rodding an art form. I’m not referring to the candy-flake paint jobs, chopped roofs, and such officially “creative” stuff—I mean the engineering side of things. In art, the limitations imposed by one’s materials are not simply limitations, they set the boundaries that give shape to an artist’s imagination, structuring the possibilities she sees for invention. Further, the fixed qualities inherent in her medium connect her to the efforts of those who came before. If she is a sculptor, she cannot escape her awareness of what Michelangelo did with marble. She can pursue such escape—into the realm of ex nihilo freedom—but knows that in doing so she risks triviality.

I’ll concede that I may be reaching a bit with this analogy to art. I am motivated by a felt need to justify, or at least understand, why I have spent a colossal amount of time and money building a high-performance, air-cooled Volkswagen engine when, for a fraction of the cost, I could have swapped a Subaru engine into my Bug and gotten comparable performance with greater reliability. There is a recipe for that swap; it has all been worked out. And I considered it. But I was afraid it would feel trivial, or that the project of building such a car wouldn’t feel like going further on a storied trail of invention.

For the last thirty-five years (and especially the last ten) I have been working out in minute detail the mental construction of my ultimate VW motor. To say that I am invested in the form begs the question, why? Middle-aged nostalgia is surely playing a role. As I related in Shop Class as Soulcraft, a certain deeply countercultural VW mechanic had a formative influence on me as a teenager. But that’s not the whole story, as I feel myself pulled into a history that reaches back before I was born, continues today as a vibrant and often heated quarrel on the VW forums, and inspires wonder at what might be possible in the future with these little magnesium-cased jewels. I am building this motor in two iterations. The first, normally aspirated, will make about 180 horsepower. The second, turbocharged and fuel injected, will make about 300.

THE PEOPLE’S CAR: A BIT OF HISTORY

In 1902, a young worker in the present-day Czech Republic, then part of the Austro-Hungarian empire, got drafted into the military. He had grown up working in the shop of his father, Anton Porsche, a master panel beater. (Panel beating is the art of putting compound curves in sheet metal by hand. It is how carriage and aircraft bodies were made in the early days and remains one of the crucial skills in making custom bodywork. Today we call it metal shaping.) Young Ferdinand Porsche landed a pretty good gig in the military, as chauffeur to Archduke Franz Ferdinand. You probably remember that name from a high school history lesson: he was the crown prince of Austria who got assassinated, a seemingly random spark that ignited the First World War.

By the time he got drafted, Ferdinand had left his father’s shop and been working in Vienna for a few years, first at an electrical manufacturer and then for the carriage maker Jakob Lohner & Company. After work, he would sometimes sneak into the local university and sit in on classes. Beyond this, and some night classes at his hometown technical school while still living at home, Ferdinand Porsche never received any higher education as an engineer. Yet at the close of the twentieth century he would be named Car Engineer of the Century by the Global Automotive Elections Foundation.

While at Lohner, Porsche worked on the first automobile the firm would make, unveiled in 1898. The twenty-two-year-old took the liberty of discreetly engraving “P1” on all the key components, standing for Porsche design number one. It was a bit of youthful audacity that looks justified in retrospect. His second design to be built by the firm was a hybrid, with electric hub motors and throttle by wire. The year was 1901.

Ferdinand Porsche would go on to put his talents in the service of the Third Reich and serve time in a French jail for his contribution to the German war effort. One reason the automotive history of this period is so fascinating is that its ugly political currents are inseparable from the genuinely volksy character of Volkswagen, the people’s car.

The 1930s were a strange and terrible time in Germany, following the wholesale social breakdown of the Weimar years. The political passions then circulating are hard to disentangle from our present vantage, particularly the affinities that then appeared natural—on both sides of the Atlantic—between socialism and nationalism, two ideas that we now quarantine across a left–right divide. In the United States, Herbert Croly’s “new nationalism” ideas were highly influential in conceiving the New Deal. In Germany, the party that came to dominate politics was called the National Socialist German Workers’ Party—Nazis to you and me. The Nazis’ relationship to socialism was basically fraudulent and opportunistic.5 But a worthwhile thought experiment in counterfactual history could begin by asking what the twentieth century might have looked like if the German labor movement of the 1920s hadn’t gotten yoked to anti-Semitism, industrialized murder, and world conquest. What if the emerging amalgam of nationalism and socialism hadn’t allowed itself to be co-opted, as it did, by a man so patently deranged? Such questions are not entirely idle for us today.

Imagine, if you will, a workers’ leisure organization that brings libraries, affordable holidays, concerts, plays, and day trips to workers and their families. It would take families hiking, to the movies, to fitness clubs and sporting events. Imagine it has as one of its missions the mixing of different classes. For example, in sponsoring cruises it would allocate cabins based on a lottery, without reference to social status. This is not a utopian proposal of Bernie Sanders; it was actually accomplished by KdF, the leisure organization of the German Labor Front. KdF had more than seven thousand paid employees and 135,000 volunteers by 1939, and had sent about 25 million Germans on vacations. The initials stand for “Kraft durch Freude,” which means “strength through joy.”

At the Berlin Auto Show in 1933, the new chancellor (soon to be Führer) announced that Germany would build a car that is economical to purchase and to operate, and thereby “motorize the people.” It would be called the KdF-Wagen: a reliable, no-frills family car. Jacko Werlin, a former Mercedes-Benz dealer, arranged for Hitler to meet with Ferdinand Porsche, who had recently hung out a shingle as an independent designer and automotive consultant, and had his own engineering firm in Stuttgart. By his own initiative, largely self-financed by borrowing against his life insurance, Porsche had already been working on prototypes that more or less fit the bill, with halting support from the firm Zündapp (soon to become famous for their motorcycles) and then NSU Motorenwerke. In this first meeting, “Hitler put forward demands that stunned Porsche: The car had to be able to cruise at 60 mph, fuel consumption was not to exceed 40 mpg, the engine was to be air-cooled, the body was to provide room for five people and the complete car was to be priced at less than 1,000 marks, retail.”6 This seemed “utterly unrealistic” to Porsche. But that was not the response the Führer was looking for.

According to Edward Eves, writing in the VW Supplement to the May 1, 1969, issue of Autocar, “When Porsche showed his proposals for the power unit for the KdF-Wagen in 1936, established German manufacturers threw up their hands and said ‘this aircraft engine’ could never be made for the price. Any production engineer would say the same today.”7 The air-cooled VW motor is commonly regarded as “simple,” but outward appearances are a bit deceptive. It is a marvel of precision manufacturing compared to, say, the small-block Chevy V8, which has a similarly stubborn place in its own world of enthusiasts. In crucial respects, the split-cased, magnesium and aluminum VW motor of 1939 is closer to a modern Japanese motorcycle engine than it is to the cast-iron crudities of midcentury Detroit.

What accounts for the screwy economics of the Volkswagen engine? O. G. W. Fersen was an automotive journalist who visited the Berlin Auto Show of 1939, where the KdF-Wagen was unveiled, and took the car for a spin on the track. Recollecting thirty years later, in the same 1969 issue of Autocar, he reports that “the little car did look very ‘cheap’ with quite a lot of exposed sheetmetal in the interior and an engine that no one could call refined. But after all it was a full-sized car and it cost less than 1,000 marks, or as much as a medium-sized motorbike.” Fersen explains the economics plainly enough: “The people’s car was born by order of a dictator—disregarding cost and commercial reason—and it would be built by the [German Labor Front], a kind of stage-managed union.”

Because the German auto industry didn’t think the car was feasible, the German Labor Front itself took command of the project, under the direction of Ferdinand Porsche. The result is the VW Beetle.

It was a socialist car, then. Its low cost and folksy back story was surely part of the appeal it would come to have for peace-loving American hippies of the 1960s counterculture. But it was also a fascist car, in the precise economic meaning of fascism: its low cost was due to dictatorial power, state-directed investment, and the outlawing of independent labor organizations not controlled by the Party. Nazi perversion of the ideal of free labor, or mockery of it, are well expressed in the fact that the phrase “Labor sets you free” was posted over the entrances to several of the death camps. The making of the “people’s car” relied heavily on slave labor at Volkswagen during the war (mostly Czechs and other Slavic peoples who were marked out as racial defectives in Hitler’s scheme). Once built, the plant at Wolfsburg mainly produced not the KdF-Wagen for consumers but the Jeep-like Kübelwagen and the amphibious, four-wheel drive Schwimmwagen for military use. (These were based on the same platform as the KdF-Wagen. During the war, the “people’s car” was produced only in numbers adequate to serve the needs of Party dignitaries and diplomats.) In retrospect, Hitler’s demands that the KdF-Wagen have such a fuel efficient, air-cooled engine were clearly motivated less by a concern for household economy than by his plan for far-flung conquests in regions sparse of fuel and water.

In a sense, the whole twisted ideological mess of 1930s German politics, with its mismatch between cultivated socialist image and underlying tendency to violence, is condensed into the air-cooled, flat-four VW motor. Twenty years after the war’s conclusion, hot-rodders in southern California discovered for themselves that the people’s engine, beloved by millions of peace-loving hippies, carried a vein of hidden Sturm und Drang that can be turned to warlike purposes.

It is a conflicted motor, then, and for that reason is ideally suited to the sleeper.

WHAT IS A SLEEPER?

Aristotle defined “irony” as a posture of concealing one’s superiority. He called it a vice. He found this vice in Socrates, that notoriously ugly and penniless man who would go around Athens asking innocent-sounding questions of high-status men. If they took the bait, the ensuing exchange would reveal their confusion to all competent bystanders. This was not a very nice thing to do.

A rusty, decrepit-looking old Volkswagen with 300 horsepower could be taken as an instrument of Socratic inquiry, then. Let us pose a question at the stoplight, and see if the men of high repute deserve their standing in the city.

This is the basic dynamic explored in the Netflix show Fastest Car, in which high-dollar supercars are pitted against owner-built cars (some of them genuine sleepers) in the quarter mile. “Built not bought.” This is the motto of the kind of man who looks at a Lamborghini and thinks “douchebag.” How sweet it would be to give that car, and the man who drives it, a proper spanking.

SQUISHY, DRY-SUMPED 2276 BUILD

To understand the mental life of the gearhead, we are going to have to get into the ironmongery, as Ricardo would say. What follows may be too down in the technical weeds for all but the initiated. If metallurgy and measurement techniques are of no interest to you, just sit back, breathe in the aromatic hydrocarbons, and allow your eyes to glaze over as I reproduce a few entries from the build journal for this motor and try to explain what I am doing.

Crankshaft built by Jose Alvarez.

Illustration by the author.

May 25, 2017

With crank on precision V-blocks at main bearing journals 1 and 3, run-out is barely observable (approx. 0.0003 inch at main 2 and 0.0004 at main 4), using dial indicator. Jose rocks!

The stroke of the stock 1600 cc VW motor—the distance traveled by the piston from the bottom of its travel in the cylinder to the top—is 69 mm. This distance is determined by the dimensions of the crankshaft. My crank was welded up from one of these stock units that had been chopped into bits by a fellow named Jose Alvarez, who has a business called DPR Machine in Santa Ana, California. This area is the Orange County epicenter of the air-cooled VW speed scene that began developing in southern California after the war, and remains one of those now-rare concentrations of engineering know-how that once dotted the American landscape.

Jose is the go-to guy for custom cranks. Speaking to him on the phone, I requested a longer stroke of 82 mm to increase the displacement of the engine, with counterweights added to smooth out the rotation (to allow the motor to rev higher), and rod journals made to the Chevy standard rather than the VW standard. Chevy rods are slightly smaller on the big end. Using them, I wouldn’t have to remove as much metal from the crankcase to create clearance for this oversized rotating assembly.

Amazingly, this hand-built crank made to a “triple-o” standard (meaning tolerances within 0.000X inch of spec) cost no more than a mass-produced Chinese crank offered for the VW enthusiast: about four hundred dollars. The Chinese cranks you can get without waiting for months, and they are made of chrome-moly steel, which is supposed to be stronger. On paper. But the stock VW crank is made of German steel, and among those who push these little buggers to stratospheric torque and rpm numbers, it is often the preferred stuff. There has always been a bit of mysticism that swirls around metallurgy; it is truly an arcane science that goes back to the quasi-religious guild secrets surrounding Damascus steel and samurai swords. In medieval times, to a significant degree it was the state of metallurgy in a sovereign’s realm that conferred military advantage, or not. But even in the industrial era, the knowledge and skill required for making good steel have not quite been reduced to following a recipe that can be fully spelled out. Like Walter White’s meth, it’s all about the cook.8

I also told Jose I wanted a larger than standard center main journal, to reduce flexing of the crank at high rpm. The inertial forces trying to flex the crank increase exponentially with rpm, and I intend to spin this motor to 7,000 rpm, whereas the stock motor risks grenading if pushed beyond about 4,500 rpm. As Sir Harry put it:

In the low-speed engine the dynamic forces set up by the inertia of the pistons and other moving parts are relatively small, hence these parts can be made very robust without imposing any undue stresses on the structure or the bearings, but dynamic forces increase as the square of the revolution speed and in a high-speed engine become the dominating factor. The essence then of high-speed engine design is the use of as rigid and compact a structure as possible containing the lightest possible moving parts.9

When Volkswagen introduced their “type 4” motor in 1968 for their heavier vehicles, later used also to power the Porsche 914, they increased the diameter of the crankshaft main bearing journals, with a crankcase machined to match. I was adopting this later standard in an earlier motor architecture. Back in the mists of time, some gearhead discovered that there is a particular bearing—made by BMW, not Volkswagen—that can be used to accomplish this adaptation.

Digging this information out of the community had not been a trivial accomplishment. It required hours of reading through extraneous rants and years-old quarrels on the forums. But then again, I had been wasting large chunks of my life reading through this stuff anyway. Some of the threads are like detective stories, and you can’t bear to stop until you’ve gotten to the end. Sometimes the technical mystery is resolved, but just as often the story peters out in a miasma of contradiction, seven pages in. Somebody changes the topic. There has been no book written on the subject since Bill Fisher’s seminal How to Hot Rod Volkswagen Engines, published in 1970. The state of the art has progressed quite a bit in the intervening half century, but the knowledge hasn’t been organized.

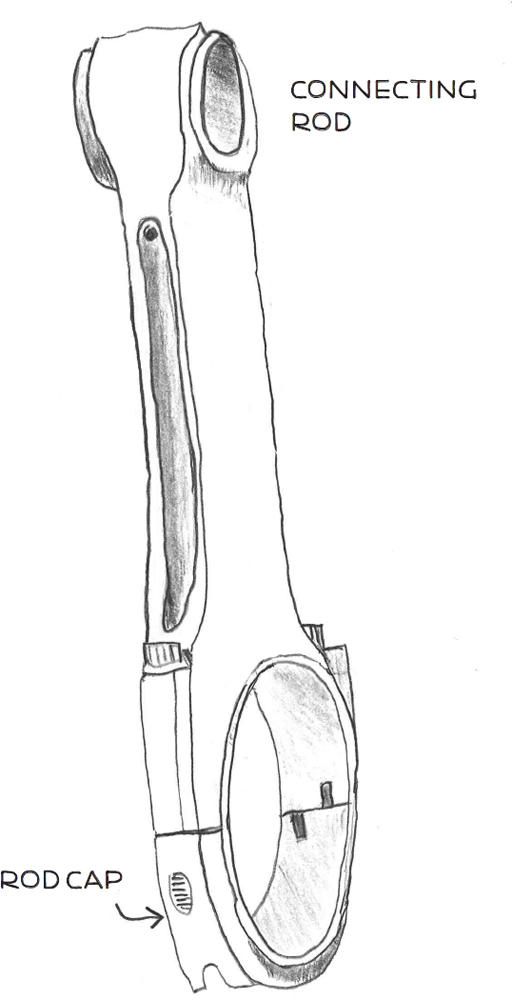

Connecting rod joins piston to crankshaft.

Illustration by the author

One of the lesser-known improvements of the last twenty years is John Connolly’s development of the “Super Squish” piston for the air-cooled VW motor. You have to sign a nondisclosure agreement to acquire a set of these from John, and agree never to post a picture showing the top of the piston. I am using these pistons and could describe them to you, but then I would have to kill you, dear reader. The main advantage is that they allow one to run higher compression without detonation. Allow Sir Harry to explain:

It has long been realized that it is the incidence of detonation, and of detonation alone, which, in the past, has set a limit to the power output and efficiency of the spark-ignition engine when running on volatile petroleum fuels . . . .

The mechanism of detonation is the setting-up within the cylinder of a pressure wave travelling at so high a velocity as, by its impact against the cylinder walls, to set them in vibration and thus give rise to a high-pitched ‘ping’.10

The tendency to detonation is reduced by increasing turbulence in the combustion chamber. This can be accomplished through “squish.” Ricardo explains that squish is “the rapid ejection of gas trapped between the piston and some flat or corresponding surface in the cylinder head.”11 Squish is achieved by manipulating the shape of the space left open between the top of the piston and the cylinder head.

I can say no more, for your own safety. Suffice to say that these arcane arts must be used for good and not evil.

May 27, 2017

Calibrated torque wrench.

Rod caps torqued to 24 ft-lbs with oil on threads.

#3 rod had zero side clearance, was binding, and the rod bolts gave me a queasy feeling upon torqueing. Something is amiss. Careful inspection found a little blob of weld protruding on the crank throw next to the rod journal. Fucking Jose!

I studied the situation with a magnifying glass and decided I should be able to remove the unwanted blob of metal with a file. I would be filing just a few millimeters from the polished surface of the rod journal, so first I protected it by wrapping a thin piece of soft aluminum around it, secured with a hose clamp.

With rod caps torqued, oil clearances of the rod bearings (measured with plastiguage) are all 0.002, side clearances (measured with feeler gauges) are as follows: #1 0.015, #2 0.016, #3 0.014, #4 0.009.

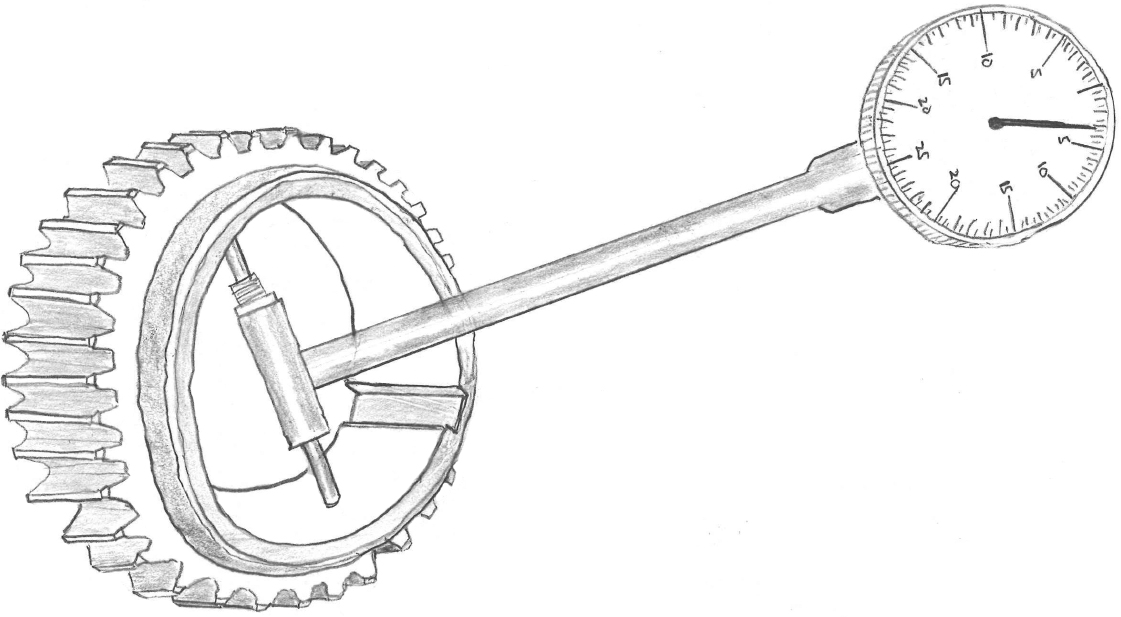

With the basic okay-ness of the crank and rod set now established, I used a bore gauge to determine the internal diameter of the timing gear, a micrometer to determine the external diameter of the snout of the crank, a small hole gauge to determine the width of the keyway, and a micrometer to determine the width of the key. Were all these items meant to work together? Yes, in theory. Then why bother measuring everything? In doing this kind of work, what you learn—the hard way, if necessary—is to trust nobody. The more you work with “high-performance,” aftermarket and boutique parts, or even original factory parts, the more hardened you become in adopting this attitude. You can call it an ethic of suspicion, or you can call it empiricism. One develops a low regard for the testimony of others, for representations by interested parties, for reputations earned years ago. You trust your own instruments. Such a skeptical mentality comes hard to anyone in the grip of a fantasy budget for his fantasy motor, who merely adds up the prices of all the parts he sees in the magazines and thinks that is what the parts cost. Better to regard the thing you buy as a first draft, an approximation of the final part. Your job, then, is to bring this hodgepodge of metal up to the highest standards. As the “mechanic in charge,” you will be integrating parts made by dozens of different manufacturers according to some plan that was never their plan. There will be interference and incompatibility all over the place.

I digress on this because often if a hot-rodder tells a noninitiate that he is building a motor, his conversation partner will get a quizzical look and say, “You mean rebuilding a motor?” Not really. “You mean you’re building it from scratch?” Well, no again. What we do is called “blueprinting” an engine. This has an ambiguous origin. To have a blueprint is to have a master plan, in which the dimensions of everything are fully specified to within some acceptable tolerance. But the term probably comes more directly from the fact that machinists use blue dye to mark clean metal, such that any light scratching or scuffing leaves a witness mark that allows you to see where contact is occurring between two parts—how evenly a valve makes contact with its seat, for example, or how some flat surface deviates from a perfect plane (revealed by sanding the surface on a piece of glass and seeing where the dye remains), or the depth of engagement of the teeth of two gears that mesh. Such use of dye is an extremely sensitive technique for revealing irregularities that cannot be seen, nor measured with common machinist’s instruments.

Measuring the internal diameter of the timing gear. This one is straight-cut.

Illustration by the author

I put the crank in my freezer overnight. This caused some confusion in my household. The next day I took the timing gear that goes on the end of the crank, set it in a pot, covered it with vegetable oil, and put it on the stove in my kitchen until the oil began to smoke. Cooking up a motor often involves an excursion into the kitchen: baking, deep-frying, what have you. This dish was all about presentation. With a drizzle of motor oil on the snout of the chilled crank, I lifted the timing gear out of the hot vegetable oil with a screwdriver, grasped it with thick welding gloves, and immediately presented it to the crank. It slid on effortlessly. After a few seconds of heat transfer, the gear was immobile on the crank, with a room temperature clearance of about .0005 inch as measured beforehand. I would have preferred an interference fit of about .0005 (interference is the opposite of clearance), but this was acceptable. The hardened key would keep the two from rotating in relation to one another.

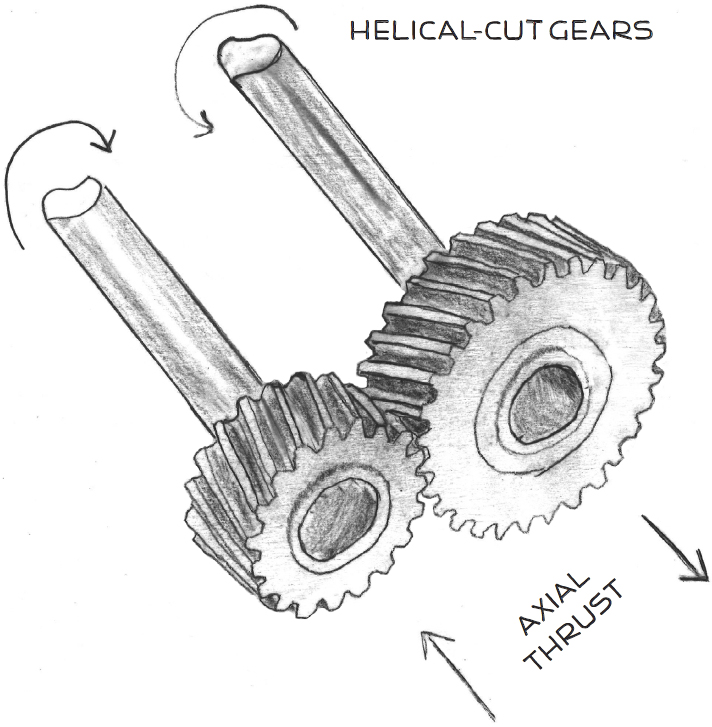

Here’s the thing about timing gears. First, what are they? They mate the crankshaft to the camshaft. The one on the crank is small, the one on the cam is big, which makes the cam turn at half the speed of the crank. On a stock VW motor, they are helical-cut. This makes the gears less noisy (think of it as two objects—in this case gear teeth—colliding at a glancing angle rather than head-on. The teeth make contact gradually along their width rather than all at once). But because of the angle at which the teeth mesh, there is a thrust force introduced. That is, the gears are not only making the cam turn, they are also trying to push the cam along its length. This isn’t something to worry about in a stock motor. But in a motor designed to turn higher rpms, you need to use stiffer valve springs (to keep the valves from floating due to their own inertia, i.e., losing contact with the springs that are meant to control them), and this increased spring pressure gets transmitted through the valve train to the gears, creating more thrust force, which wears out cam bearings. Dig? So, what one does is use gears that are straight-cut rather than helical-cut. This eliminates the thrust. Yes, they are noisier. The looser the mesh of the gears, the noisier they are. So, one would like to make the mesh nice and tight.

This is not simple. How tightly they mesh will be determined by how far the cam bore is from the crank bore in the case. This is not something you can adjust. That is why VW made cam gears in various over and under sizes, to compensate for minute variations in the spacing. But if you are using aftermarket, straight-cut gears, there is no variety of sizes. You get what you get. The ideal gear lash (empty space between adjacent teeth) is .000–.002. I measured mine at about .0045.

Helical-cut gears try to move along their axis of rotation. This is called thrust and it’s bad.

Illustration by the author

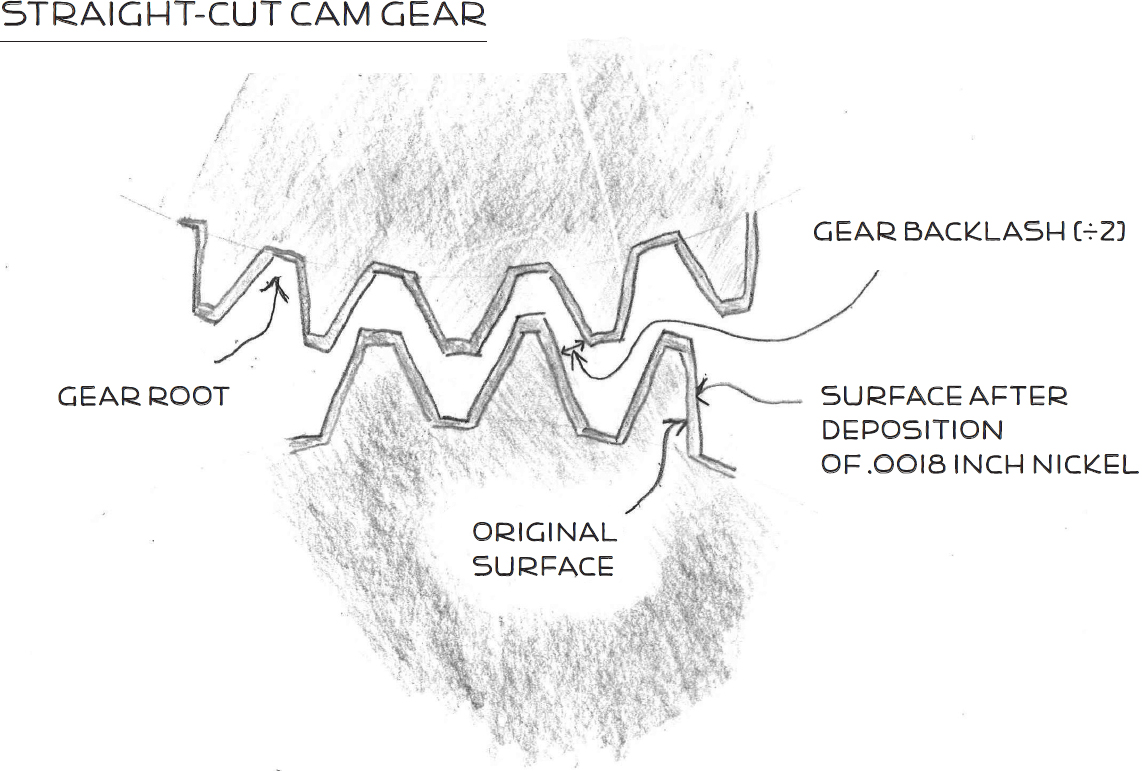

I know what you’re thinking: Life is short, let it go. But once you break the spell of complacency and take responsibility for a motor, it is hard to accept parts that aren’t perfect. Could I deposit some material on the cam gears to build up the surface, and thereby close up the gap between teeth? Nobody on the forums seemed to have tried this, as far as I could find. If the material were to flake off into the oil, the result could be catastrophic.

The mentality of being in charge spurs attempts at innovation and improvement. You feel emboldened. But you also feel the need for circumspection: if nobody else has tried this, there might be a good reason. Or maybe somebody did try it, and we never heard about it because they were too embarrassed by the result to report it. One must beware “the idiot tax,” the risk of failure that leads gearheads to adopt a kind of precautionary principle abbreviated as KISS: “keep it simple, stupid.” Departing from convention, one is more likely to screw up than make a lasting contribution. But this is a lesson that usually becomes clear only in hindsight.

Building up the surface of a gear set with plating, to reduce lash.

Illustration by the author

I considered electroplating the gears to build up the surface. Googling around, I learned that with electroplating it is difficult to control the thickness of the plating in small-radius surface features, such as the root of a gear tooth. But there is a process called “electroless nickel plating,” the practitioners of which claim to have minute control over the thickness. I sent my cam gear off with a request for a nickel coating of .0018 inches, with a 6–10 percent phosphorous content to get the proper hardness. With that extra layer on each side of a gear tooth, I should reduce my lash by twice that number, or .0036, putting me at a hoped-for .001 lash, right in the middle of the spec. When I got the gear back, I baked it in a toaster oven at 550˚F for two hours, per the instructions of the plater. He said this would raise the surface hardness to about 56 on the Rockwell C scale.

This was one episode in what became a prolonged education in various industrial processes, which became necessary once I no longer took for granted the adequacy of available parts. In the course of this education, which is ongoing (the car is not yet finished), I bought a metal lathe, gained access to a milling machine, and found it incredible that I had ever gotten by without these things. Measure everything, trust nobody, and make it from scratch if need be.

Such a mentality reminds me of that moment that is so often catechized in the story of modernity, when Galileo rejected received authority and believed his own eyes, aided by instruments he had built himself. To go deep into any technical field is to make progress in independence of mind, and feel a freedom to maneuver that grows in proportion with one’s powers. It is to become modern again, as against the heavy blanket of magic that weighs us down with Promethean shame.

One can’t quintuple the horsepower that a car was designed for and leave it at that, without rethinking every aspect of the car. Since finishing the rust repair, my time has gone into building a roll cage, seam-welding the body for greater rigidity (as opposed to the factory spot welds), bracing and triangulating in various places subject to new forces, building a hydraulic system for the brakes and clutch that uses four separate master cylinders (the car originally had just one), having custom axles made up, using heavier CV joints—the list goes on. I made custom rear hubs on my lathe, starting from an old pair of brake drums that had been lying around my shop for years. (Lesson learned: Cast iron is a disgusting metal to machine. It is dirty, dusty, and eats through tool bits like crazy.) I designed the hubs to mate to brake rotors from a Porsche 914, which I paired with brake calipers from a VW Golf (sourced from eBay) and caliper brackets from a VW Passat, in a process that John Lucsko aptly called “high-performance bricolage.”

Such a cobbled-together system requires research, lots of it. For all the apparent infinity of the internet, there is one very basic kind of information that is rarely to be found anywhere on it: the dimensions of objects. And this reveals something interesting about contemporary material culture. Any object can be represented in various ways, according to the purpose served by the representation. On the web, what you will find is photographs of parts, prices of parts, and parts numbers. These are all you need, if you are simply replacing one part with an identical copy. Parts numbers are a system for managing inventory in an automobile manufacturer’s vast catalogue. It is a way of bringing order to a universe of parts, many of which are made by subcontractors spread all over the planet, and these in turn are subject to changing ownership as they are merged and acquired in the churn of global capitalism. If he is of long tenure, the parts manager at a car dealership (who can be hailed from behind the parts counter if you are lucky) is a savant of this system, a philologist of parts numbers. He may be able to read a twelve-digit parts number and tell you not only what the part is, and for what model of car, but for what range of years. Of course, all of this should be in the computer that sits in front of each clerk at the parts counter. If the clerk is stumped (and this happens with some regularity, in my experience) and summons the manager, the manager may stare at the blown-up parts diagram for a moment and then stare off into space for a while, accessing some synaptic tether deep in his cortex and reeling it in. And then he will say something that makes sense only within his arcane world. “Wrong prefix. In 1993 they changed to a letter code, and the Camry had a mid-model-year production change.” Or something like that.

This is the deepest level of institutional knowledge that one can access, and it generally requires a trip to the parts counter: people who know things don’t spend their time answering telephones.

But this sort of information counts as knowledge only if one stays within the prescribed world of the institution. Try asking the parts manager a question like the following: “what is the center-to-center spacing of the mounting holes on the bracket where it mates to the spindle?” What you will get is a long silence. It is like you just asked the most erudite mandarin in the court of the Chinese emperor which variety of saffron to use for an authentic Spanish paella, in tones suggesting he ought to know the answer. He has never been addressed in this manner. It’s not the sort of question he has entertained before. If you follow up with “Well, do you have a set of calipers?” (for measuring) you reveal yourself as a troublemaker.

To engage in high-performance bricolage is to depart the world of parts numbers entirely and enter the world of dimensions, expressed in universal units. The thing about dimensions is, they are accessible to anyone with a few rudimentary measuring tools. Yet these dimensions are absent from inventory systems; they are not included in the systems of knowledge we have to pass through in dealing with material things. This is why you end up buying a metal lathe and a milling machine. It’s just easier to make some parts than it is to hack a bureaucracy. Plus, you get to replace a frustrating activity with an enjoyable one.

This idea, “accessible to anyone,” and the related idea of a universal standard (such as a unit of measurement), are at the very heart of the Enlightenment idea of knowledge. The whole point was to bypass the proprietary systems maintained by priests and scribes that kept the people in darkness, more easily controlled. This is the story we tell ourselves about what it means to be modern. What we have failed to notice is that we have constructed systems of knowledge, ostensibly hypermodern, that more closely resemble the medieval.12

Let me tell you about the transmission, if I may presume upon your patience. It needed to handle five times the horsepower of the original motor, and be able to transmit that power to the ground via sticky race tires without breaking in half. I also wanted a five-speed rather than the original four-speed, and a limited slip differential to put the power down in corners with a minimum of wheel spin. It also needed to fit, more or less. A transmission from a late-model Subaru seemed to be the ticket. It just needed to be shortened by a few inches. And it needed to be converted from all-wheel drive to two-wheel drive. Also, in an old VW, the engine is in the rear. In a Subaru, the engine is in the front. If you were to simply swap the Subaru transmission into a Beetle, you would have one forward gear and five reverse gears. That could make for some interesting parking lot shenanigans, but isn’t very practical. The transmission output needed to be made to turn in the opposite direction (relative to its input) than its designers intended. Thankfully, all of these issues have been solved by a transmission guru in Australia named Todd Triebler. He manufactures a reversed ring and pinion gear set, and has a recipe for doing the swap more or less worked out.

More or less. The issue was the flywheel. The flywheel is where the engine, the transmission, the clutch, and the starter motor come together, and must be made to play nicely with each other. What was required was a flywheel that was fluent in both German and Japanese, and could serve as a go-between for these power trains with no natural basis for friendship.

This became an eighteen-month saga that unfolded over three continents. I made careful pencil drawings with dimensions labeled in tenths of millimeters rather than thousandths of inches, as preferred by my man in Australia, who used my drawings to make a computer model of the whole assembly. (In the U.S., machinists speak in inches, even when working on metric parts, because their tooling and instruments are calibrated in inches, and also because long use of these gives rise to embodied expertise: an experienced machinist knows what a step of two or three “thou” feels like as he drags a fingernail across it.) After much back and forth, he sent me a 3-D printed plastic prototype of the flywheel. The model needed some adjustment, and we went through another round of measuring and designing. Finally he sent me a flywheel machined from his computer model out of steel, somewhere in Asia, which I could tell by its surface finish, color, and the fact it arrived already badly rusted: due to the boat trip, but also due to the fact that this clearly wasn’t “chrome vanadium” steel, like the original German flywheels.

After some further machining at my lathe and drill press, as well as some welding, grinding, the use of marking dye, and some unkind words for the whole nation of people Down Under, I had a working assembly. Almost. I still needed something so trivial it had escaped my attention until now: dowel pins to locate the clutch pressure plate on the flywheel. I measured the diameter of the holes in the flywheel where the dowels needed to go, using a small hole gauge and a micrometer: 0.315 inches, or eight millimeters. The corresponding holes on the pressure plate (an aftermarket unit to fit a 2014 Subaru WRX, whence my transmission came) were six millimeters. So the dowels I needed would have a step in them, measuring eight millimeters on one end and six millimeters on the other. Do such dowels exist? Did Todd make this flywheel with dowel holes the same size as those on a Subaru flywheel, so I could simply use the stock dowels? I looked online to see if I could learn that dimension, to check against my measured holes. Again, I found only pictures, prices, and parts numbers. So I went to the Subaru parts counter and asked to see some dowel pins.

“Model and year, please.”

“Umm, for my imaginary car?”

“Eight millimeters on one end, six on the other” wasn’t going to get us anywhere. I spoke to the parts manager and to a service tech, the guy who actually does clutch work. Neither of them had ever noticed any stepped dowel pins of the sort I described. This led me to conclude that Todd had not made the holes according to a Subaru standard.

I was truly on my own now. I drove home, resolved to make some dowel pins. But as a last-ditch effort before departing society and going full Unabomber, I called the maker of my aftermarket clutch. I managed to get a technical person on the phone, and had an extraordinary conversation. What made it extraordinary was that this person knew things. And because he sits at the crossroads of many different makes of automobile, he knew things from a universal perspective, independent of the internal designations of the various manufacturers. Here is what he knew in particular, God bless him: Ford Mustangs from 2001 through 2014 that have the V8 option, but not one of the really crazy V8 options, have dowel pins that are eight millimeters on one end and six millimeters on the other. Wow!

I felt I was in the presence of greatness, and told him as much. We talked parts, we talked managerial capitalism. A nugget stored in his brain had solved my problem, and he had been duly recognized for this (by me), outside the incentives of his employer. Sometimes a real human connection happens in the most unexpected setting. He seemed reluctant to get off the phone. In me he had a conversation partner who understood the value that someone like him provides, and which so rarely shows up in an organizational flow chart: deep, specific, nonarbitrary knowledge. The kind that can be stated without the use of special nomenclature, or a system of signs internal to a bureaucracy.

It felt almost subversive, this conversation, like we belonged to a cell of saboteurs. We were the ones who would survive the collapse of the System—parts numbers—like the feral horsepower freaks depicted in Road Warrior. Those improvisational folk engineers of the Outback were a bit depraved, but they also preserved the seeds for civilization, and in watching them one could hope civilization might rise again.

In this they had to rely on one another. Here we get to a major complication in the story I have told thus far. You can’t measure things for yourself, most of the time, because the objects you are wondering about (can they be made to fit?) aren’t in front of you. I learned the recipe for my cobbled-together brake system from people on the forums. We stand on the shoulders of giants. Such shoulder standing is what civilization is; we learn from one another.

A monopoly of knowledge, guarded by a system of arbitrary symbols such as parts numbers, isolates us from one another and suffocates the human drive to innovate, those “rich seeds of invention that everywhere abound,” as Ricardo named it. Such monopoly is what gearheads dissent from.