Letter 10 The Ethics of Engineering

Dear Natasha and Nick,

Let me start this letter by asking you a question. Did you ever wonder why it sometimes may seem tough to optimize competence and character in our engineering careers? This is humorously illustrated in the television comedy series The Big Bang Theory by the devious engineer Howard Wolowitz. In one episode, he tries to impress a friend whom he sneaks into a government-run Mars Rover control room, but then accidentally gets the vehicle stuck in a ditch. Instead of admitting his mistake, he recruits his colleagues to help him in a comical series of deceptions.

But, more seriously, competence and character are both especially important for engineers, since our work can positively or negatively affect the health, safety, happiness, and prosperity of society at large. Unfortunately, just like everyone else, we engineers can think, say, and do things we regret later. Ideally, we’ll have the chance sooner or later to take responsibility, learn some lessons, make amends, and never repeat those errors again. And that’s what this letter is about, namely, the ethics of engineering.

Now, the word “ethics” could be reasonably defined as the study of what people think is either morally acceptable or unacceptable human behavior. Of course, this topic is a murky one, since how this works out in people’s daily lives has been debated for centuries by philosophers and theologians. Even so, when it comes to engineering, there are concepts and tools that can help us do our work ethically.

Before I really get into the subject, let me state a few caveats. First off, I readily admit that I haven’t personally figured this out, or even lived it out, fully and perfectly, but I’m still learning. Also, each region, country, and professional engineering society (PES) that legally certifies a professional engineer (PE) has slightly different philosophies, policies, and laws to make sure engineers do their work ethically. And, there are comprehensive resources specifically on engineering ethics that you should get your hands on. With that said, I hope what I write below inspires you to dig into this topic even more.

The Wheel of Engineering Ethics

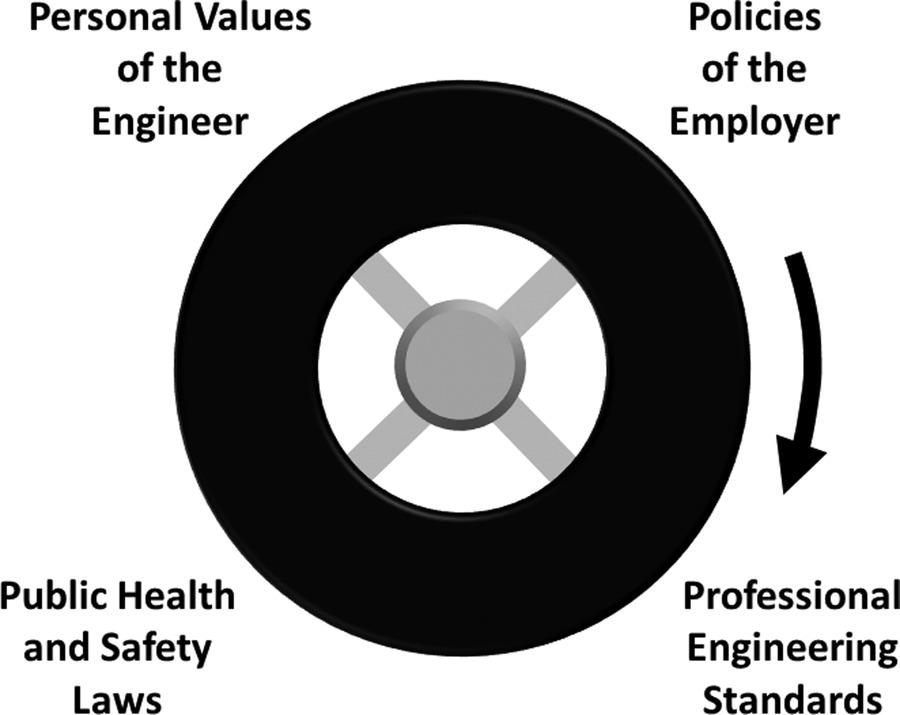

Let’s start by discussing some ideas that should be kept in mind by every engineer who wants to work ethically in order to benefit their customer, client, employer, profession, and society at large. Since metaphors and visuals have always helped me grasp concepts that might otherwise be fuzzy, I’d like you to picture what I like to call the “Wheel of Engineering Ethics” (see Figure 10.1). Each of its 4 spokes symbolizes an equally important aspect of engineering ethics. So, ideally, all 4 spokes will be in good shape so the wheel can turn and go forward at full speed. But, these 4 spokes also function like a system of checks and balances. Even if just one spoke is broken (i.e., something’s unethical based on just this criterion), the wheel will warp and have difficulty turning and moving forward (i.e., the unethical project will have difficulty getting done).

Figure 10.1 The wheel of engineering ethics.

The first spoke represents personal values of the engineer. In our personal and professional lives, most of us recognize that our attitudes lead to our actions, our beliefs determine our behaviors, and our principles inform our plans. We don’t always painstakingly take the time and effort to analyze and reanalyze every little daily decision we make to uncover the underlying core reason for it. If we did, we’d never get anything done. We may not always be consciously aware of why we think, say, or do certain things, but there are core values that undergird it all. But, how many of us have actually taken the time to think about, write down, thoroughly analyze, and even adjust our core values as engineers? Our values could be influenced by certain philosophical or religious ideas or just by our own life experiences. Whatever the case may be, it can be a useful exercise for all of us to do at least once in a while, since it can help us say “yes” or “no” to the various engineering questions we need to answer with more ease and conviction: Should I take that job? Will I accept that project? Should I report those results? Am I truly qualified to design, build, inspect, repair, or dispose of this product? Shall I express my concerns about the health and safety of this technology? etc. After all, even if the whole world says it’s okay to do something, but we think it’s unethical and just don’t feel right about it, then we have an extremely tough question to answer—will we follow the world or will we follow our conscience?

The second spoke refers to policies of the employer. The 3 primary places of employment for engineers are the university, industry, and government. At some point after hiring an engineer, a responsible employer will provide the engineer with information—such as a website, computer files, or some booklets—about the employer’s policies regarding both the employer’s and the engineer’s duties. And this includes the employer’s and engineer’s duties to behave ethically in the workplace towards others, but it also involves employee health and safety and the engineer’s technical work itself. If this information isn’t given right away, the engineer should approach the employer—say, the human resources (HR) officer or department—to get the information, so they know about the employer’s policies. Of course, if the employer is a small business, they might not have an HR officer or department or even a comprehensive information package that includes a code of conduct dealing with ethics. In this case, the engineer can request the employer to provide a simple document on ethics, ask the employer if they’d be willing to adopt the code of conduct from a PES, or some other idea. The point is that the engineer needs to get something in writing to clarify the employer’s and their own duties; don’t just rely on a verbal agreement. On the one hand, if the engineer fails to abide by the employer’s policies, of course, they could be demoted in position or dismissed from work altogether. On the other hand, many employers are so driven by financial profits, impending deadlines, or commercial rivalries that an engineer may feel forced to engage in behaviors or projects that seriously breach their own personal values, the employer’s own policies, professional engineering standards, and/or public health and safety laws. If appealing to the HR officer or department, the team or department leader, the president of the company, etc., doesn’t resolve these issues, then the engineer has other options—just get back to work, quit the job, or become a “whistleblower.” A whistleblower is someone who bypasses their employer and reports the problem directly to their PES, the public media, the legal system, and the government to discourage the employer from continuing the unethical behavior.

The third spoke signifies professional engineering standards. If you’ve been formally certified as a PE by a PES in your region or country, then you’re an ambassador of the PES and, thus, are obligated to understand and abide by its standards, such as its code of conduct. A code of conduct typically emphasizes an engineer’s responsibility to do their work using concepts like accountability, confidentiality, compassion, competency, fairness, honesty, legality, loyalty, objectivity, respect, and trustworthiness. If you deliberately or ignorantly fail to comply with the PES code of conduct, you could be temporarily or permanently stripped of your legal PE certification. Now, even if you’re not a PE, but you are a working engineer, it’s good to become familiar with a code of conduct to help you decide whether something is ethical or not, as well as to understand the views of your peers in the engineering profession. Moreover, technical competency is also a vital part of being an ethical engineer. So, you should be aware of, understand, and incorporate, whenever possible, the widely recognized international engineering standards that describe the technical specifications required for material quality, experimental testing, product performance, health and safety levels, and so on. The most commonly used standards are the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO), although there may be some local standards that are frequently used in a particular country. If the ASTM and ISO don’t have documents that address your need, then consider looking to manufacturer guidelines, journal articles, textbooks, handbooks, manuals, and codes to provide a precedent or guideline for formulas, procedures, standards, and so forth.

The fourth spoke means public health and safety laws. It’s often said that technology can either help or hinder the health and safety of human society and the ecology. Although that’s easy to see in many cases, often it’s not a binary choice and it’s more complicated than that. So, for instance, maybe technology is greatly beneficial in one way, but it also has some serious negative side effects. What should be done in that case? Should the technology be permitted as it is, banned outright, or only used in certain situations? Or, perhaps, is it worth the time, effort, cost, and resources to improve or replace that technology? How and when will these issues be resolved? And who will decide? etc. These and other philosophical questions are faced by engineers and society all the time. And the answers that are given in response to these questions can have serious consequences in the here and now, as well as to the future survival of human civilization and our planet. Consequently, most developing societies have local or regional laws (e.g., building codes for structural integrity, electrical wiring, plumbing systems, waste disposal, etc.) and nationwide laws (e.g., government regulatory agencies that approve or reject applications for patenting, marketing, and selling of technologies) that address public health and safety. Obviously, these laws need to be balanced with other factors like financial prosperity, personal choice, public opinion, cultural tradition, and so forth. The ethical engineer and engineering organization need to know and abide by these laws because they affect how they do their work, otherwise, they could face boycotts, closures, dismissals, fines, lawsuits, or prison.

True Tales of Engineering Gone Wrong

The short vignettes below are meant to illustrate how an engineer’s poor ethics can have bad and sad consequences. Through negligence, incompetence, or malevolence, an engineer’s shoddy work, an engineer’s conscious decision to develop or misuse technologies, or the misuse of technologies by others can cause illness, injury, discomfort, death, or destruction. In many cases, the engineer, their employer, and other participants can potentially face bad reputations, stripped credentials, financial penalties, lawsuits, or prison. It’s disturbing that many similar cases have happened in history. Each event, whether quiet or dramatic, is a poignant reminder to engineers about their moral obligations to themselves, their employers, their profession, and society at large.

The first story is about the explosion of a famous spaceship. I personally remember watching this tragic event on the television news. What happened? As reported in physicist Richard Feynman’s book The Pleasure of Finding Things Out, on January 28, 1986, a short time after NASA launched the Space Shuttle Challenger, it exploded in mid-air killing all 7 passengers. The cause was later identified as the failure of important O-rings (i.e., gaskets) on the shuttle’s solid rocket booster. Here’s how this was discovered. Following the calamity, an official Commission was set up to determine the cause of the disaster and to recommend changes to prevent future ones. The only scientist assigned to the Commission was Richard Feynman himself, who was a Nobel Prize-winning physicist. After a thorough investigation, which also involved interviewing the engineers who worked on the project, Feynman wrote a summary that was almost excluded from the Commission’s final official report. He noted several important things. First, prior successful Space Shuttle flights showed O-rings with erosion depths of one-third the radius, so it was assumed that the deeper erosion to one-half the radius that was known to cause O-ring failure would not occur for the upcoming Challenger flight. Second, pre-launch mathematical modeling of O-ring erosion was done, but only the best-fit-curve running through the center of the scattered experimental data points was considered when making decisions about safety; however, experimental data points that were far above or below the best-fit-curve, as realistic extreme cases, were ignored. Third, the mathematical modeling was based on a material that was similar to, but not exactly the same as, the material from which the O-rings were made. It’s disturbing to know that engineers had warned the mission’s management team that the O-rings might fail due to the low temperatures on the shuttle’s outside, yet the launch went ahead with terrible consequences. At a live press conference later organized by the Commission, Feynman clearly illustrated the problem when he dipped one of the shuttle’s O-rings into a cup of ice water, pulled it out, and then easily broke it apart. And so, were the engineers unethical for not being more forceful with management, was management unethical for going ahead with the mission regardless of safety concerns, or both?

The next tale concerns the orthopedic implant industry. I’m quite familiar with this topic because of my many years working as a hospital-based and university-affiliated mechanical/biomedical engineer. Orthopedic implants are used to replace bad joints (e.g., prostheses for shoulders, elbows, hips, knees) or repair broken bones (e.g., plates, rods, screws, cables). They are made from metals, plastics, and/or fiber-reinforced composite materials. The companies that design, make, and sell implants often do some in-house stress testing to ensure they work as expected, they obtain official approval from a government regulatory agency, and then they sell the implants to doctors, clinics, and hospitals for use in patients. But, a major problem exists, namely, that the proprietary nature of design and testing data, as well as the rivalry between companies, prevents this information from being published openly in peer-reviewed engineering or medical journals. Sadly, without much publicly available scientific evidence available to them, surgeons sometimes choose, buy, and insert unproven implants into patients. And so, mechanical and biomedical engineers like my colleagues and me—who have no formal connection to these companies whatsoever—have to rush to perform computational analyses, experimental stress tests, and patient trials in our labs on these unproven implants and publish our findings in academic journals for all to read. We want our articles to finally provide comprehensive engineering data about the quality and performance of those previously unproven implants. Only then can surgeons make good clinical decisions for their patients. As a consequence of this somewhat backward system (i.e., implants are approved and used before they’re fully proven), many implants have caused pain, discomfort, infection, wear debris, and bone fracture in patients. Not surprisingly, there have been many highly publicized lawsuits against implant companies resulting in millions of dollars in fines and banning of particular implants from the marketplace. So, who’s at fault here? Is it the scientists and engineers who design the implants but don’t convince their employers to allow them to publish the results openly, the government regulatory agencies who approve the implants before they’re totally validated, the implant companies who sell the implants that haven’t been fully proven yet, the surgeons who insert the implants in patients without comprehensive evidence, or all of them?

The final example is about an engineering student who cheated. Many years ago, I was a teaching assistant helping a professor to run a university engineering course that was composed purely of lab exercises. The students worked in small groups, yet each student was asked to submit their own individual written lab report for grading. When I started to grade the lab reports, it was very obvious to me that one student group didn’t write individual lab reports, but they copied from each other often word for word. They cheated. So, I gave each of those particular students the lowest possible passing grade of 50%. I told this to the course professor, who said I was too lenient; the professor would have divided the grade by the number of students in the group or just given them each a zero. Then one—and only one—of the cheating students came to me to complain about the 50% grade. After some discussion, the student admitted he cheated. But, what was quite disturbing, was that he didn’t think cheating was a serious issue. He didn’t express any regret. His justification was that the university really wouldn’t care about him after he graduated anyway, so engineers like him and me needed to stick together. I was mildly shocked that he tried to recruit me for his unethical attitudes and actions. I kindly told him he was wrong and that I was perhaps too generous in giving him a 50% grade since the course professor wanted to give him an even lower grade. He went away unconvinced and unhappy. What eventually became of him in later years, I don’t know. But, I can only hope that my little conversation with him somehow changed his mind before he became an engineer in the workforce who could affect the health, safety, happiness, and prosperity of society at large. So, who’s to blame in cases like this? Is it the engineering educational programs that pressurize engineering students with overly busy schedules and yet expects them to perform well, the professors and teaching assistants who don’t communicate persuasively enough about engineering ethics to their students, the individual engineering students who don’t take personal responsibility for their own actions, or all of them?

So, What’s the “Take Home” Message of This Letter?

To bring balance to technical competence, which is the major focus of engineering education and training, it’s necessary to add the element of moral character. But, since the personal values of an individual engineer cannot be solely relied upon by society, it’s vital for an engineer to also consider and comply with the policies of the employer, professional engineering standards, and public health and safety laws. When these 4 spokes are in place on the “Wheel of Engineering Ethics,” then the profession of engineering can more confidently be relied upon to deliver products and services for everyone’s benefit.

All for now,

R.Z.