Traditionally the starting date for the industrial revolution that was to transform British society is 1760. One reason that date was selected is closely tied to an important development in the world of canals. The story begins with young Francis Egerton, who had an unhappy childhood. His father, the Duke of Bridgewater, died in 1745 when the boy was just 9 years old and his mother soon remarried. He was seen by the family as insignificant and rather stupid. As a younger brother with few prospects, no one bothered much about him and his education was neglected. Then, in 1748, his brother died and Francis was now heir to the dukedom. The family were not happy and even tried to get him declared unfit to take the title but the courts decided otherwise. It became a matter of urgency to fill in the gaps in his education to prepare him for his new role as the third Duke of Bridgewater, hence the suddenly arranged trip to Europe on which he visited the Canal du Midi. The object was to preen him into courtly manners by taking him to Paris, where he was expected to learn the finer points of life in polite society. As a teenager having his first trip abroad he showed more interest in pursuing actresses, a polite name for young ladies who seldom performed on any public stage. He was rapidly whisked off to Italy and the circuit of antique sites and encouraged by his tutor to buy large quantities of statues and artefacts that were then packed up and sent back to England. It is said the crates were never opened.

Back in England as a young man he wooed one of the great beauties of the day, Maria Gunning, young widow of the Earl of Coventry. All was going well, but rumours spread that Maria’s sister, the Duchess of Hamilton, was not behaving as she should. The young Duke announced to Maria that she must make a choice: cut her sister out of her life forever or end her relationship with him. Faced with this ludicrous and pompous request, she sensibly chose the latter course. The love affair was at an end and the Duke abandoned the London court forever and vowed never again to have anything to do with women. It was said that he even refused to have female servants. He now devoted himself to improving his estates near Manchester.

Changes were already apparent by the middle of the eighteenth century in Britain. There was a steady movement from country to town and a new demand for basic commodities. The town dwellers could no longer gather firewood from the commons and woodland to heat their homes and now bought coal. And a major new industrial use had been found for the fuel. Early in the century Abraham Darby, the iron master of Coalbrookdale in Shropshire, had succeeded in using coal for smelting the ore, by turning it into coke before using it to fire the furnaces. This was good news for the young Duke whose estate included mines at Worsley, only a few miles from the rapidly growing town of Manchester. He could make a handsome profit provided he could get it from pit to customer easily and cheaply. And, of course, he knew the answer already from his trip through France. What he needed was a canal.

There is a well-known and much reproduced illustration of the young Duke of Bridgewater, looking every inch the Georgian dandy, pointing with pride at the Barton aqueduct. In later years, he dressed so plainly that he was often mistaken for one of his own workmen. This sign was photographed outside a pub close to the junction of the Trent & Mersey and Caldon Canals and shows him as he appeared in his later years, but still with the Barton aqueduct in the background. (Anthony Burton)

The Duke was still in his early twenties and relied heavily on two employees: the brothers Thomas and John Gilbert. Together they laid their plans. To build any canal or upgrade a waterway it was first necessary to obtain an Act of Parliament. This they succeeded in doing, but their proposal was heavily amended. It got them as far as the navigable River Irwell and there it stopped. The Duke applied to the Irwell Navigation for permission to connect his canal to their waterway, but was refused point blank. The old company had a profitable monopoly and saw any addition to the system as a threat. He needed a new plan and he needed help from someone with experience of this sort of work. He was recommended to approach a Derbyshire millwright, James Brindley, who had experience in handling water management problems having recently designed a complex drainage system for the all too appropriately named Wet Earth Colliery.

It is tempting to think of the Duke and Brindley as the British equivalent of Riquet and Andréossy, but the contrasts are more obvious than the similarities. The Duke was a young man, just 23 when he began planning his canal, with no practical experience of running any enterprise. Riquet had reached the end of a highly successful career in businesses of various kinds. This did not necessarily mean that either was prepared for the problems that would arise during canal construction: both men were practically bankrupted at one time. The young Duke was once reported to have been found hiding in a barn from a creditor. Andréossy had studied both science and engineering at university and had travelled widely to gain first-hand knowledge of the latest thinking about the technology of canal construction. Brindley had only a rudimentary education. He remained semi-literate throughout his life. His notebooks show him spelling words phonetically, and with hints at his own Derbyshire accent, so ‘luck’ became ‘louk’ and an engine was an ‘engon’. His experience was all practical, and not necessarily the worse for that. He was used to working things out for himself, and it was said that when faced with a difficult problem he would retire to a darkened room and lie down until he had it solved in his head. There was no question of making calculations on paper. He was undoubtedly a success in his new career as canal engineer, but there is also a very good case for saying that much of the credit for the successful construction of the Bridgewater Canal lay with the two Gilbert brothers.

In 1760 a new Bridgewater Canal Act was passed, in spite of fierce opposition from the older Irwell Navigation Company. Instead of joining the Irwell, this canal would stride across it on an aqueduct. It is a mark of British insularity that one eminent engineer, when shown the plans, remarked that he had often heard of castles in the air, but this was the first time he had heard of anyone actually trying to build one. The critics were confounded. The canal was built and included what was considered a wholly new invention of Brindley’s – the use of puddled clay to keep the bed watertight. As we have seen, this had actually been used in the previous century on the Canal du Midi. The canal was lock free and there was no water supply problem as it was used to help drain the mines at Worsley. There were, however, a few last minute worries. When the water was let into the substantial stone aqueduct, there were worrying signs of cracks. The problem was located. Brindley had been over-cautious and had put in so much puddle that the structure was overstressed. The water was drained out, much of the heavy puddle removed and the problem was solved.

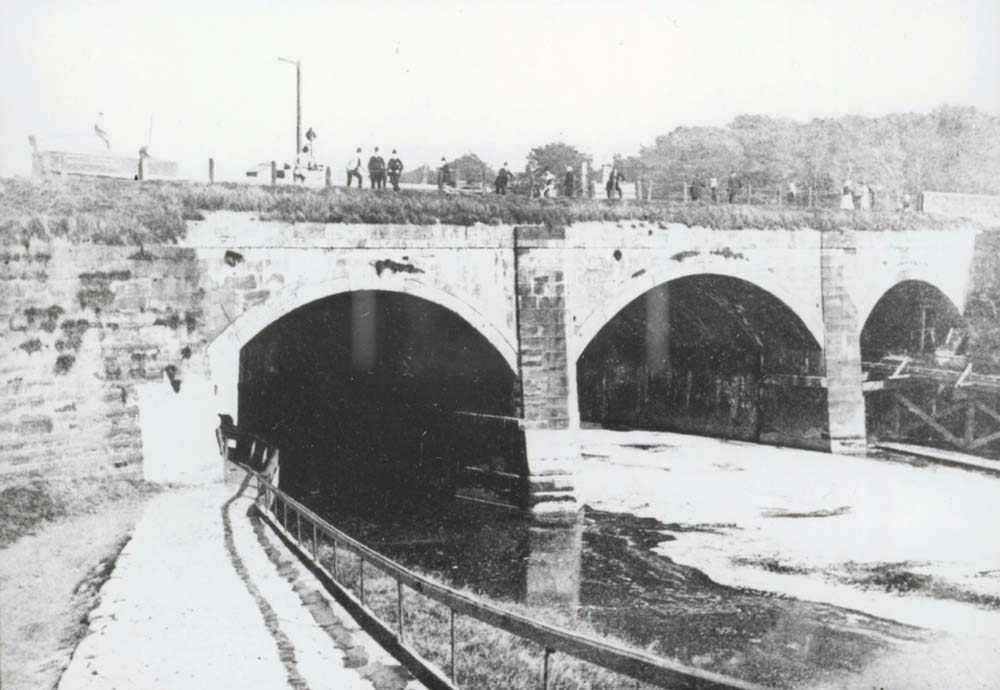

Although river navigations had been improved for many decades and the Sankey Brook Navigation, completed in 1755, was an independent canal in all but name, the Bridgewater created a sensation. The sight of boats on the canal passing over boats on the river was considered so strange that it became a regular stopping off point for sightseeing tours. One tourist, Samuel Curwen, was overwhelmed and declared that he hardly dared walk over the towpath. We can no longer walk over the original aqueduct. It was demolished at the end of the nineteenth century, when the Irwell was incorporated into the Manchester Ship Canal. The original aqueduct did, however, survive long enough to be photographed and we can see that it was a less graceful structure than it appears in contemporary prints and modest compared with later structures.

The Barton aqueduct that carried the Bridgewater Canal across the Irwell Navigation, photographed in 1891, shortly before it was demolished to make way for the Manchester Ship Canal. It is difficult now to see this plain structure as awe inspiring, but when it opened in 1761 it was the wonder of the age and tourists rushed to see the boats on a canal crossing over boats on a river. (Waterways Archive Gloucester)

Meanwhile, an extension of the Bridgewater Canal was to be built that would take it south, down to the Mersey at Runcorn. Brindley was again the man in charge and in planning the route he chose a method that was to be a trademark of his canals. Just as Riquet had done when building the rigoles for his canal, Brindley took the line of least resistance, preferring to go around obstacles, rather than through or over them, by following the natural contours. However, when it came to joining the Mersey he had no option: he had to build a flight of locks to join the two waterways. As the basic idea was to make the canal accessible to the traditional trading vessels already in use on the river, the Mersey flats, it was necessary to make each lock large enough to accommodate a single boat. They were made 72ft by 15ft, soundly built of massive stones that, according to one visitor, weighed up to 12 tonnes each.

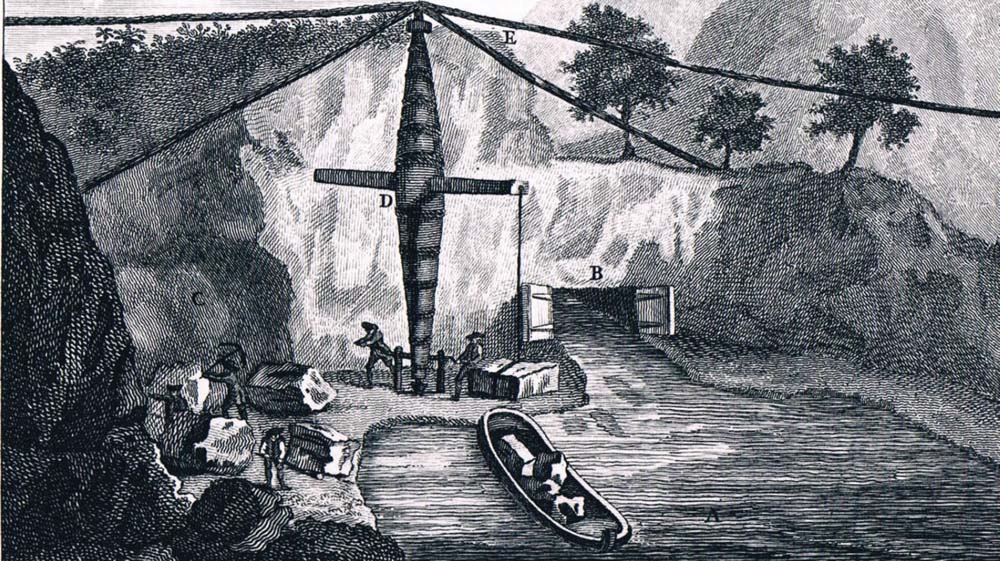

What visitors to the canal did not realise was that they were only seeing a portion of the whole. Behind the narrow mine entrance at Worsley Delph lay a network of underground canals. Carts brought coal from the face to be loaded into long thin vessels, just 4ft 6in wide. Because of their shape and the prominent ribs they were known as ‘starvationers’. Once out of the mine, the vessels were linked together and towed away on the main canal. There was an ingenious method used for unloading the vessels at the Castlefield wharf at the Manchester end of the canal. To raise the cargo to street level, boats were floated under the bottom of a shaft and a water-powered crane lifted the coal to the top.

The Bridgewater Canal began underground in the Duke’s mines at Worsley, just outside Manchester. This crude illustration shows the entrance to the mines and the immense crane used to load stone into a boat. The simple vessels originally used on the canals were long and narrow, known as starvationers, and they could be floated right into the workings to be loaded near the coal face. (British Museum)

Whereas the general public came to stare at the engineering marvel, others were much more impressed by a simple statistic – the price paid for Worsley coal in Manchester was halved. Britain was just starting on a great period of transformation. It started in the cotton textile industry, where the preparatory processes of carding and spinning were being taken out of the workers’ homes. New machines were installed in mills, powered by water wheels that, by the end of the century, would be replaced by steam engines. The changes created an even greater demand for coal, a fact that famously resulted in the Duke of Bridgewater remarking that a successful canal must have ‘coal at the heel of it’. Other traditional industries were also undergoing profound changes and creating their own demands for the new transport system.

Until the middle of the eighteenth century, the Staffordshire potteries, based in and around Stoke-on-Trent, mostly made earthenware using the local dark clay. The only way to produce a white plate, for example, was to cover it with a heavy, opaque glaze. Each item would be made by an individual potter, a skilled craftsman who was in charge of everything from throwing a pot on a wheel to fixing on the handle and finishing with a suitable pattern and glaze. One man who changed all that was Josiah Wedgwood. He wanted to appeal to the aristocracy and the new, rapidly developing middle class market. There was a growing enthusiasm for imported porcelain from the Far East and Wedgwood set out to emulate it in earthenware. That would never have been possible with the local clays, so he brought in a much paler clay, available in Devon and Cornwall. To whiten it he mixed the clay with flint that had been heated to a high temperature to make it friable after which it was ground to a fine powder. So he had two new sources of raw material: clay from the West Country and flint from East Anglia. Bringing them overland to Staffordshire would have been ruinously expensive. He was also making delicate ware unsuitable for transportation along the bumpy roads of the time. This was only a part of his innovation: he no longer relied on craftsmen making a single pot then starting work on another. He set up what was, in effect, a primitive version of a production line: one potter throwing, another worker adding handles, someone else doing the decoration and so on. To organise this new workforce he wanted to build a factory designed specifically to streamline the new processes. Obviously the new works would need an efficient transport system to bring in raw materials and take out finished ware. He needed a canal.

James Brindley, the former millwright from Derbyshire, was employed by the Duke of Bridgewater as engineer for the Duke’s canals. The success of this pioneering venture made him the first choice for new canal companies begun in the 1760s. Here he looks relaxed, with his arm resting on his surveying instrument, but in reality he was leading a highly stressed and active life, moving from project to project. He died in 1772 with several important projects still unfinished. (City Museum, Stoke-on-Trent)

Wedgwood became the main promoter for a canal that would cross the country, connecting two great navigable rivers. It would be the Trent & Mersey Canal, with a direct connection with the Trent and joining the Mersey via the Bridgewater Canal. His flints could be shipped round the coast to the Humber and then into the Trent; his clay from the West Country could be brought to the Mersey. He turned inevitably to the man of the moment, James Brindley. This was a canal on a scale never attempted in Britain before, but it was not the only canal for which he had been signed up as chief engineer. He was also in charge of the Staffs & Worcester that was to link the Trent & Mersey to the River Severn. But it was the Trent & Mersey that gave him his biggest headache.

The most important canal on which Brindley was involved after completing the Bridgewater was the Trent & Mersey. The chief promoter was the famous potter, Josiah Wedgwood, who built a new factory alongside the canal at a spot that he named Etruria, after antique pottery that he admired and that he believed, incorrectly, was made by the Etruscans. The site is now part of Stoke-on-Trent. The sketch shows the factory and a working boat out on the water. The factory was later moved and most of the original site was cleared, leaving only the circular domed building in the foreground of this picture. (Wedgwood P.R. dept.)

As well as the factory, Wedgwood built a new house for himself and his family, looking out over the canal and the works, Etruria Hall. The enamelled plaque shows the house and canal and the extensive parkland in between. Wedgwood tried to persuade Brindley to provide a sweeping curve at that point, but the engineer would have none of it. Wedgwood declared him an ‘inflexible vandal’, but the argument did not spoil their genuine friendship. (Wedgwood P.R. dept.)

Ideally the new canals would, like the Bridgewater, be available for the barges already in use on the rivers they connected. The Trent & Mersey, however, had to cross a line of low hills. It was not possible to go around, and there would have been far too many problems, not least water supply, to go over the ridge. The only solution was to go through in a tunnel. But, unlike that at Malpas on the Canal du Midi, this would not be a few hundred yards long: it would have to be about a mile and a half. Brindley baulked at digging a tunnel that would need to be 15ft wide to take the river barges. One has to bear in mind that geology had not yet developed as a science. He had no idea what the ground inside the hill would be like – and he was, in fact, to have some unpleasant surprises. So he simply halved the width, effectively quartering the amount of material to excavate. If you think of the tunnel as being basically circular in cross section, the area is determined by the square of the radius, not as a straightforward multiple of it. The resulting tunnel was low and narrow, with just enough space for one boat and no room left for a towpath. Traffic had to be regulated, with certain hours allocated for travel in each direction. The boats had to be moved by ‘legging’, the boatman lying on his back and walking his feet against the roof.

The greatest challenge faced by Brindley was Harecastle Hill that lay right across the route of the Trent & Mersey. The only solution was to build a tunnel. The first canal tunnel at Malpas had been modest, but this would have to be more than a mile long. The first Brindley locks on the Bridgewater had taken vessels of 14ft beam, but building a tunnel to such dimensions was too much. It was designed instead to take vessels just half that width and with a one-way traffic. The photograph shows the low, narrow opening to the now disused Brindley tunnel on the left and the new, improved tunnel built by Thomas Telford to the right. Originally both were used to allow two-way traffic; today only the Telford tunnel is open and traffic is again one-way at a time. (Anthony Burton)

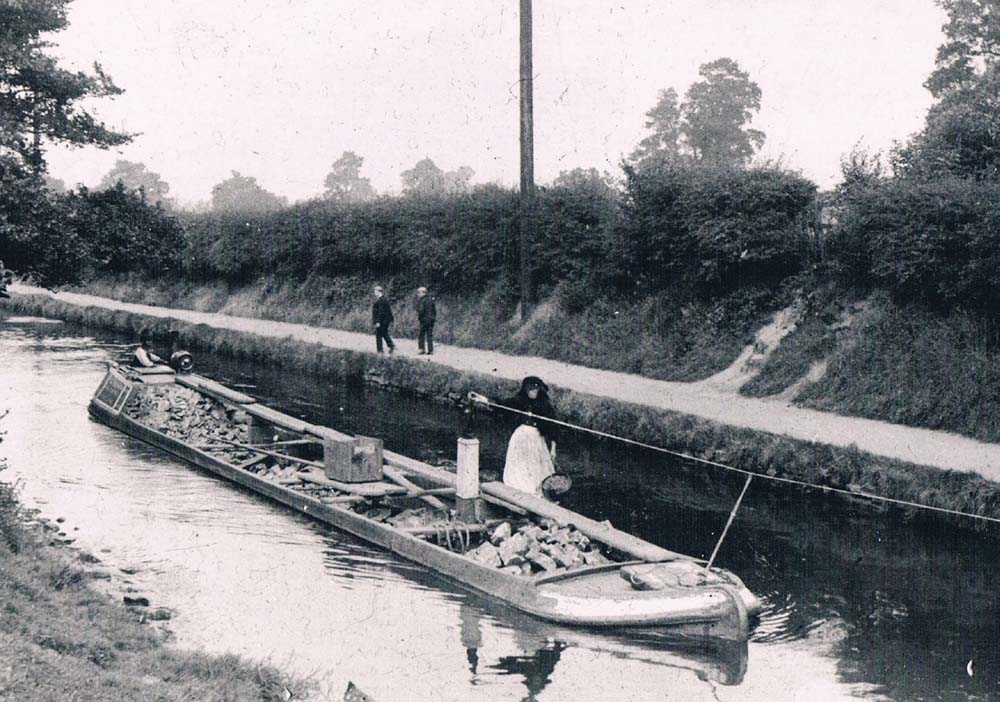

Having taken this momentous decision, he now had to decide how the canal would be operated. As the wide barges could not use the tunnel, there were two possible solutions: set up a system in which barges would arrive at either end and then tranship their load to smaller vessels, or not have barges on the canal at all. The latter meant Brindley could save himself a lot of expensive construction. He could halve the width of the locks. His new locks would be half the width of those he had built at Runcorn and a new type of boat was developed for the canal, the narrow boat, roughly 7ft beam and 70ft in length.

As work got under way, Brindley was in demand for still more canals: the Birmingham Canal (from Wolverhampton to Birmingham) and the Coventry Canal were both approved in 1768 and the following year the Oxford Canal Act was passed. Together they would form a cross linking the four great rivers of England: Thames, Severn, Trent and Mersey. As this was to be an interconnected system, Brindley decreed that all should be narrow canals, and a pattern was set for canal development in much of Britain. No one was unduly concerned: it still meant that canals were much more efficient than any other transport system known at that time.

Once it was decided to build Harecastle tunnel so that it could only be used by vessels roughly 7ft wide, it seemed pointless to build other structures, such as locks, to take wider vessels. As a result, all these early canals were built with narrow locks and a new type of canal boat was born – the narrow boat. This heavily laden narrow boat is being towed on another canal for which Brindley was the chief engineer, the Coventry. (Miss E. M. Waine)

Brindley also set his mark on the canals in other ways. He followed his favoured method of contour cutting. For much of the way the routes of these canals wandered apparently aimlessly. Anyone travelling north of Banbury on the Oxford Canal, for example, will at one point find themselves at Wormleighton with a view of an attractive house on a hill in front of them; many minutes later, they will have almost circled the hill and finish up staring at the back door of the same house. The northern section of the canal was subsequently straightened, but in its original form it was said that boatmen could travel all day and still hear Brinklow clock striking. An even more dramatic example of Brindley’s methods is on the Birmingham Canal. This too was straightened, and if you travel it today then you will see several side branches that loop round and rejoin the main canal much further on. These were not built as loops: they are the curving lines of the original waterway.

The Brindley canals were all built on the same basic principle. To avoid expensive earthworks, such as cuttings and embankments, they followed the natural contours of the land. In undulating country this could mean a wayward route of extravagant curves, as seen in this aerial view of the Oxford Canal at Wormleighton, north of Banbury. The marks in the field in the foreground are the remains of the moated manor and medieval village. (Cambridge University Collection of Air Photographs)

Brindley led an exhausting life, travelling round all the canals he was being paid to supervise, and often infuriating the companies that felt they were not getting enough of his time. Nothing gave him more trouble than the great tunnel through Harecastle Hill. The act for construction was approved in 1766 and, the following year, the engineer blithely announced that the whole works would be finished in five years. In the event he did not live to see its completion: he died in 1772 and the tunnel finally opened to traffic in 1777; the five years had become eleven. The delays are not too surprising, for nothing on this scale had been attempted on any canal anywhere in the world.

The first stage was to survey the route, setting out the line and using a theodolite to measure the height above the level of the canal bed at various points over the hill. It was then possible to sink a series of shafts from the surface to canal level. Compass directions taken at the surface were transferred to the underground workings, so that men could work from the bottom of the shafts as well as from the two ends. Theoretically, they would then all join together in a straight line. The original tunnel has long since been closed but there are other tunnels on the line and the one at Preston Brook, which is three quarters of a mile long, is still in use. Travelling through it by boat reveals that is very definitely not straight. Thomas Telford was called on in 1822 to inspect the Harecastle tunnel and his report was scathing:

‘ In many places the roof is not more than 6 feet above the ordinary level of the water … in some places it is too narrow, in others crooked, and generally speaking the brickwork which forms the bottom, side & top of the Tunnel is not more than 9 inches thick, it has throughout been made with bad mortar, so that in all the brickwork under water … the mortar is as soft as clay.’

No doubt the criticism is justified, but Brindley and his team were pioneers, struggling under difficult conditions. In some places they met hard rock, which had to be drilled by hand and then blasted with gunpowder; in other spots they met soft ground little better than quicksand. In places the canal ran through coal measures that gave off ‘fire damp’, the potentially lethal methane gas. Ventilation was supplied by means of a stove and a pipe that sucked out the gas and released it at the surface.Water flooding into the workings was a constant problem. At first, pumps driven by water wheels and a wind pump were used for drainage. When they proved insufficient, Brindley installed a Newcomen engine to do the job. This was an early form of steam engine, but one that used atmospheric pressure rather than actual steam pressure to do its work. The pump rods descending into the workings were suspended from one end of an overhead beam, balanced at its centre. The weight of the rods dragged that end of the beam down. At the other end was a piston suspended from a chain that fitted snugly inside an open-topped cylinder. Steam from a boiler was let into the cylinder and then condensed by spraying it with cold water. This condensed the steam, creating a partial vacuum below the piston. Air pressure now pushed the piston down and, lowering that end of the beam, lifted the pump rods at the other end at the same time. Pressure equalised, the rods dropped again. So the beam bobbed up and down, the pump rods rose and fell and the water was removed. Engines such as this were huge, cumbersome devices and, in terms of the energy that had to be put into the system in the form of heat to raise steam, incredibly inefficient. But they represented the latest in technology at that time, although they were soon made obsolete by the true steam engines designed by James Watt.

This first generation of British canals introduced no specifically new technological advances, although the tunnelling was on a scale never previously attempted. It did, however, differ in several important aspects. The way in which the canals were funded was unlike that used in continental Europe. Apart from the Bridgewater Canal, for which the Duke of Bridgewater himself put up the money, the rest raised the finance by setting up private companies and selling shares. The promoters of these early companies were often men who were more interested in the advantages to their own businesses than in possible dividends, not that they were averse to the latter. Wedgwood acted as treasurer for the Trent & Mersey, a post of considerable importance, but not profitable as he wryly noted when setting out details of the main official appointments:

‘James Brindley, Surveyor general £200 per ann.

Hugh Henshall, Clerk of the Works £150 per ann. for self & clerk

T.Sparrow Clerk, to the Proprietors £100 per ann.

Jos. Wedgwood, treasurer at £000 per ann. out of which he bears his own expenses.’

One striking effect of the development was new inland ports where the canals met the major rivers, and goods had to be stored for transhipments between the narrow boats and the river barges. The best known of these new towns is Stourport. An old story repeated in many early canal histories states that the citizens of Bewdley, a thriving port on the Severn, were approached by Brindley who wanted to make the town the terminus of the Staffs & Worcester Canal. They rudely told him to take his ‘stinking ditch’ elsewhere. So he did. It’s a good tale but unfortunately untrue. Documents show that all the petitioning was the other way round: Bewdley wanted the canal, seeing it as increasing their trade. Brindley, however, was much more concerned in finding the easiest route to dig the canal, and that meant following the line of the little River Stour to a point on the Severn downstream from Bewdley. And it was here that Stourport developed. A wide basin was constructed, with river access through both wide barge locks and narrow canal locks. Warehouses were built, with houses for the staff, and traders could be entertained at a new hotel, The Tontine. The name derives from the curious custom in which a group of investors put their money into the tontine and the last surviving member of the group got the lot, and the descendants of the other investors got nothing. The other notable new town that grew up at the time was Shardlow, at the Trent end of the Trent & Mersey. One of the most striking features is the former Trent Corn Mill. This was built over a wide arch that spans a spur of the canal so that boats could be loaded and unloaded under cover. Similar buildings were constructed throughout the canal building period in Britain.

New towns were not the only developments. The new industrialists now favoured canalside sites. Wedgwood, the chief promoter of the Trent & Mersey, built a new factory at Etruria together with workers’ houses. The only trace of the original works is a small circular domed building near the canal bridge. His own new house, Etruria Hall, looks down on the canal and the works. He tried to persuade Brindley to make an elegant curve in the canal at that point to create a picturesque effect, but the engineer was having none of it. Wedgwood jokingly called him a vandal, but the engineer insisted reasonably on the direct line. Later, when Boulton & Watt began a new factory designed for building steam engines, they did not build it next to Matthew Boulton’s existing works on the outskirts of Birmingham, but right alongside the original Brindley canal. It was called the Soho factory and when the new straight line Birmingham Canal was built, this section was bypassed and became known as the Soho Loop.

One of the most important, and financially successful, canals was the Birmingham. It attracted industrialists to set up in business along its banks. The most famous was Boulton & Watt who established their new Soho factory for making steam engines alongside the canal, with a short branch leading to an extensive basin. This part of the system is now rarely used, as the new main line was built by Telford on a more direct line, leaving this part as the Soho Loop. (Jennifer Tann)

Brindley was not the only canal engineer at work during the 1760s and 1770s, nor were all built to his ideas as contour canals with narrow locks. The Forth & Clyde Canal did just what its name suggests: it joined those two great Scottish rivers. The engineer was John Smeaton, the man who enthused about Dutch canals, a fact that in itself shows he was more travelled and experienced than Brindley. In fact their backgrounds could hardly have been less similar. Smeaton’s father was a lawyer in Yorkshire and, after a grammar school education, he joined his father in the business. He was much happier in his workshop at home than in the office, and taught himself the skills to become a maker of scientific instruments. His interest in science, however, went further than that: he undertook the first scientific examination of wind and water power, studies that won him a Fellowship of the Royal Society. In 1755 he paid the visit to Holland mentioned earlier and soon after that began the move from instrument making to engineering. His best-known early work was the building of the Eddystone lighthouse, which has subsequently been replaced, but the original Smeaton tower has been re-erected on Plymouth Hoe. By the 1760s he had considerable experience of river navigation and drainage schemes when he was invited to visit Scotland to consider building a canal. Inevitably Brindley was also consulted and the pair were at work in 1768. Brindley was already heavily engaged in a large number of projects in England and seems to have rushed to a conclusion that earned a scathing report from Smeaton:

Other famous engineers working on canals during this period included John Smeaton. He is often described as the father of civil engineering in Britain, responsible for many prestigious structures, including the Eddystone lighthouse, completed in 1759. He was the chief engineer on a canal which, like the Leeds & Liverpool, ran from coast to coast, but this time across Scotland – the Forth & Clyde. (National Portrait Gallery, London)

‘ Mr Brindley recommends to begin at the point of partition, [the summit] because, he says, it is his “constant” practice to do so, and, in the present undertaking, it seems particularly advisable “on many accounts”; but pray, Mr Brindley, is there no way to do a thing right but the way you do? I wish you had been a little more explicit on many accounts: I think you only mention one, and that is to give more time to examine the ends; but pray, Mr Brindley, if you were in a hurry, and the weather happened to be bad, are the works to be immediately stopped when you blow the whistle, till you can come again, and make a more mature examination?’

The work was entrusted to Smeaton and it was a major undertaking, with a summit 150ft above sea level. There was no opportunity for contour canal construction here, and Smeaton showed his mastery by planning a route with a 16 mile long summit, reached by twenty locks from the Forth and nineteen from the Clyde. Like the Canal du Midi, the Forth & Clyde linked two seas and was intended for use by coastal craft up to 68ft 6in long and 19ft 8in beam. The most imposing structure was the Kelvin aqueduct that dwarfed the Barton aqueduct over the Irwell. It is 445ft long and is carried 62ft above the river on four arches. Visitors in the early days witnessed the amazing sight of tall masted ships sailing across it or being bow hauled by a large team of men. The canal work was actually held up for many years because of a lack of funds, so the aqueduct itself was actually the work of Smeaton’s successor, Robert Whitworth, and opened in 1790. The ‘new town’ of Port Dundas was established on the canal approximately 1 mile north of the centre of Glasgow. It was the showpiece of the canal and the company built suitably imposing offices there. One of the first canalside industries to arrive was an equally imposing whisky distillery.

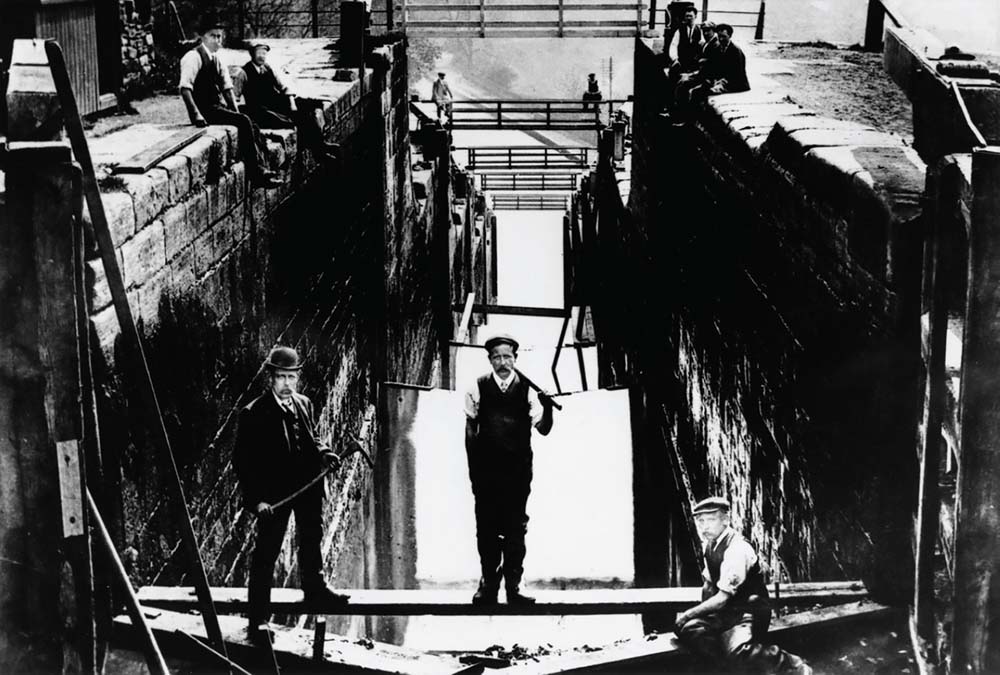

One other important canal that was built to a different standard from that of the Midland network was the Leeds & Liverpool, authorised in 1770. Work began at the Leeds end under the direction of John Longbotham. Brindley once again was involved in the early days, but was far too busy to take over the demanding role of chief engineer for such a vast enterprise. As no one contemplated any sort of unified canal system for the country, no one cared very much about what anyone else was doing, and it was designed to take vessels up to 14ft 3in beam, but just 60ft in length. It began by following the Aire valley but then, as the way steepened, the canal climbed at first through single locks, then by a double lock, a three-lock staircase and reached a climax at Bingley, where the canal was lifted 60ft by the famous five-lock staircase. Having climbed out of the Aire valley, the canal now stayed with the contours taking a serpentine course through the hillocks but with 19 miles to the next lock. It didn’t, however, reach that far during Longbotham’s time as chief engineer. It had only got as far as Skipton when the money ran out. It finally opened throughout in 1816.

The most majestic structure on the Forth & Clyde was, until very recently, the Kelvin aqueduct. Construction work was frequently delayed, but when the aqueduct was finally completed in 1790 it was the largest in the country, at 445ft long. The etching by James Hopkirk clearly shows that this was a ship canal, and originally had a water depth of 8ft, sufficient even for large vessels. Imposing as it is, it has been surpassed by the breathtaking Falkirk Wheel, a boat lift linking this canal to the Union Canal. (Waterways Archive Gloucester)

Few canals show more clearly just what a boon the new transport system was to the Industrial Revolution. In its passage through the major towns met along the way, the canal is lined with mills. Skipton, for example, was a market town that grew up in the protective shade of its castle, but now it developed a whole new canalside area of mills and back-to-back terraces. And a short branch line was dug alongside the castle that ended in a wharf designed to take stone from nearby quarries. By far the most impressive site is Saltaire. The industrialist Sir Titus Salt built a vast mill complex and an early example of a model town here, named after himself and the river valley. It had a rich variety of amenities – a church, a school, library, hospital, almshouses – but no pub. Salt was no teetotaller, but he saw pubs as places where workers could get together and lay plans to get pay rises.

Brindley was not the only engineer working on canals in Britain in the early days, nor were all built to take narrow boats. One of the most ambitious undertakings was for a canal across the Pennines – the Leeds and Liverpool. It was built to connect the Mersey to the Aire & Calder and to take the barges already in use on those river navigations. The locks took vessels up to 62ft long and 14ft 3in wide. The photograph shows two of the typical Leeds & Liverpool barges, generally known as ‘Short Boats’ to distinguish them from the narrow boats. They are being loaded with stone at Church Wharf, just outside Accrington. (Waterways Archive Gloucester)

Canal construction seemed to be galloping ahead in Britain in the years following the opening of the Bridgewater, but external events brought the whole process grinding to a halt. Across the Atlantic in 1776 American states declared their independence and France at once allied itself with the infant nation. The resulting War of American Independence had a disastrous effect on British trade: profits slumped and no one wanted to invest in anything, least of all canals. The first phase had ended and when construction restarted after the war, it did so with new men and new ideas.

Elsewhere in Europe there was progress in canal construction during these years. One obvious candidate was the narrow neck of land in the south of Denmark that separated the North Sea from the Baltic. In 1777 work started on improving the tidal River Eider as far as Rendsburg. A lock then gave access to a canal that covered the 32km section as far as Kiel. In 1785 an edict made the canal an open waterway for vessels of every nation, and it brought immense traffic with more than 3,000 vessels a year using it by the middle of the nineteenth century. It was such a valuable waterway that it was replaced by the more modern, far larger Kiel Canal at the end of the century.

The Leeds & Liverpool Canal rose through the Aire valley from Leeds in a series of locks, culminating in the five-lock staircase at Bingley. Once boats had reached the top of the staircase the crew could relax as they had reached the long summit level and the next locks to start the journey down to the Mersey were 17 miles away. The photograph, taken some time between 1910 and 1920, shows the locks being repaired. It is a rare opportunity to appreciate the full scale of the system. It was clearly taken at a time when safety at work was not an issue. (Waterways Archive Gloucester)

France also started an ambitious programme for new canals. One of these was intended to reduce the cost of coal imports from Flanders, now Belgium. It would link the River Scheldt to the Oise and through the latter to the Seine and Paris. The major problem was a high ridge between St. Quentin and Cambrai. The proposal, approved in 1769, was certainly bold. It called for a tunnel of generous proportions, with a width of 6.5m, but it had to be nearly 14km long. Bear in mind that at much the same time Brindley had baulked at creating a tunnel less than half as wide and a sixth as long and you can imagine just how daring this project was. It was so daunting that a more modest start was made with a 3.25m wide pilot tunnel. That had still only reached a length of just under 10km when the money ran out. More than a million livres, roughly 6 million modern euros today, had been spent and it was calculated it would take another 2.6 million livres to complete it. Work was abandoned and a canal link would not re-emerge as a practical proposition for many years.

At the same time as Britain was developing its canal system, new projects were also being brought forward in France. Among them was the Canal de Bourgogne, running as the name suggests through the heart of Burgundy. It was an immense undertaking, 242km long with 189 locks. As the photograph clearly shows, the locks were built to generous dimensions to take vessels such as this barge, converted into a hotel boat. (Anthony Burton)

When Louis XIV came to the throne in 1774, he proved to be a great enthusiast for canal construction as a way of moving France into an industrial future. The most promising scheme was to link the Saône and Yonne through Burgundy. This major undertaking had the highest summit level of any French canal at 378m, 189 locks in 242km and a tunnel at Pouilly-en-Auxois that was to be almost 3.5km long. But that lay in the future. The King had hoped for an industrial revolution in France, but what he got was a political revolution instead. As a result, works such as canal construction simply stopped, and the Canal de Bourgogne was not opened until 1832. It remains, however, one of the most attractive of all French canals and today enjoys a thriving tourist trade. Thanks to the huge political upheavals in Europe and across the Atlantic in the latter part of the eighteenth century, few canals of importance were built for many years. When work restarted, new men appeared with fresh ideas about how they should be built and the materials that could be used.