A great turning point in the industrial history of the eighteenth century came when Abraham Darby of Coalbrookdale, in Shropshire, made iron using coke as a fuel for his furnace instead of charcoal. It may not sound significant, but it had two dramatic effects. Charcoal has to be made from a limited resource – timber – and the forests of Britain also had to provide wood for all kinds of other uses, especially for building ships. Coal was abundantly available, so there were no longer the same restraints on expanding the industry. The other major difference lay in the sort of iron the different furnaces produced. The older works turned out wrought iron, a very pure form of the metal that, as its name suggests, is malleable. Darby produced cast iron with a higher carbon content. Again the name tells you a lot: it could be cast in moulds to replicate the shape of a wooden pattern. It also has very different characteristics from wrought iron: the former is very strong in tension, but buckles under pressure; the latter is strong in compression, but cannot be bent without fracturing. The two forms of the metal are both useful, but in very different ways.

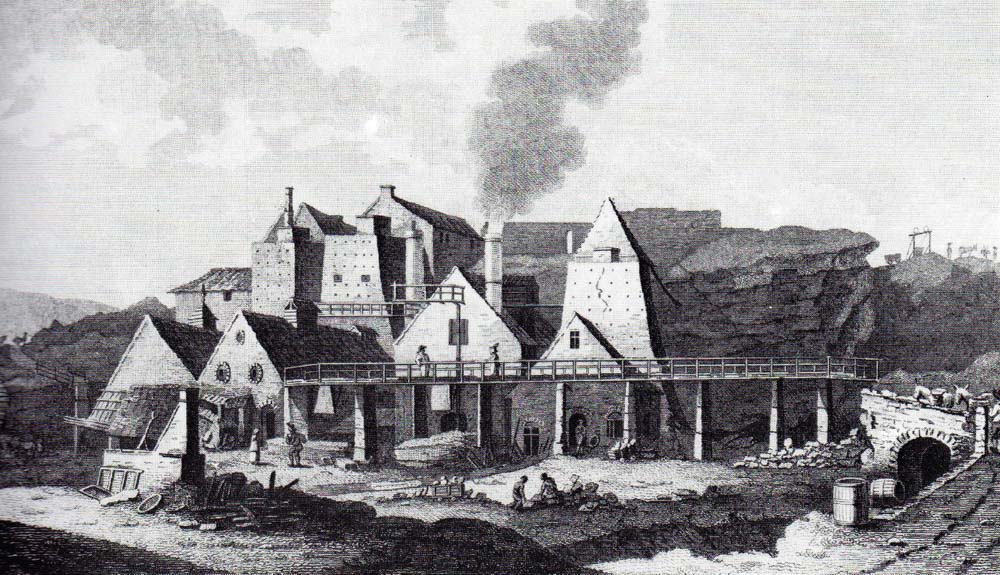

Following the success of Abraham Darby’s smelting of iron ore with coke instead of charcoal, new ironworks were developed in the regions where ore and coal were both readily available. One important site, the extensive remains of which can still be seen, was at Blaenavon in South Wales. The illustration shows the rows of furnaces, with the casting houses at the foot. The works were connected via a tramway to the Brecon & Abergavenny Canal. From there, the pig iron could be taken via a direct end-to-end connection down the Monmouthshire Canal to Newport for transhipment.

At first, the Darby works specialised in making cooking pots, but gradually they extended the use of iron to construction. It was Abraham Darby III who designed the famous bridge across the Severn that gives the town of Ironbridge its name. Opened in 1777, it is a curious structure. Nothing like it had ever been attempted, so it was designed by treating the iron elements that went into its construction as if they were timber. So the bridge is a complex mixture of curved iron segments, either passing through each other or joined by what are, in effect, woodworking joints. It was essentially a one-off, but it was the starting point for a new age of bridge building that spread to the canal world.

On all the early canals, fixed bridges had been built of either brick or stone, depending on the material most readily available close to the working site. When money was running short, engineers would cut costs by using moveable bridges. The simplest type, seen for example on the Oxford Canal, consists of wooden platforms, moved by means of a long balance beam – rather like a lock gate laid on its side. The more complex versions have a superstructure, with a horizontal balance beam at the top that could be pulled down by a chain. This type of bridge is common on Dutch canals and is on some British canals, such as the Ellesmere. The alternative was the more sophisticated swing bridge. Moveable bridges were satisfactory when they were merely carrying tracks, for example where a canal cut off one part of a farmer’s land from the rest. They suited the farmer, but boat crews had to stop and open and close them. Mostly, they were simple arches, striding across canal and towpath, providing a hump for the road or track up above. Occasionally, they had to be more complex, for example where the towpath changed sides. As the horse could not simply cross a conventional bridge, dragging a boat behind it, an alternative design was needed. The simplest structures had long ramps up from the towpath and then equally long ramps leading back on the opposite side in the same direction. This allowed the towrope to pass safely under the arch. More sophisticated versions were used on the Macclesfield Canal, where the towpath curls under the bridge – earning them the name of ‘snake bridges’. Conventional bridges depend on the complete arch being in place, but with iron you could make a bridge with a gap in the middle, by building two cantilevered sections that don’t meet. The towrope can pass through the gap as the horse walks across the bridge. Examples can be seen on the Stratford Canal.

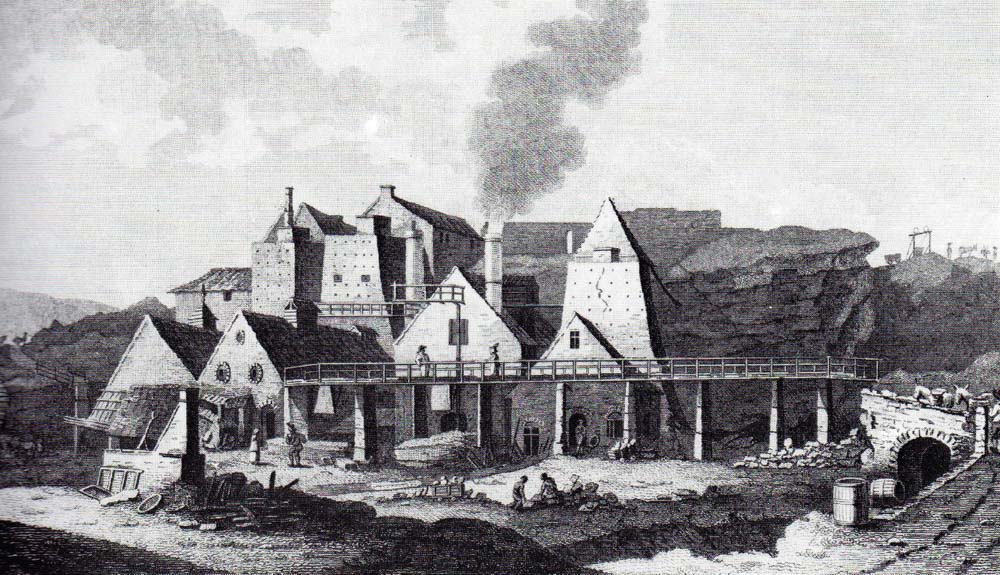

Many canals had moveable bridges, largely because they were cheaper to install than conventional bridges of brick or stone – although maintenance costs were always higher. The most common type were the swing bridges, such as this designed by Thomas Telford. The mechanism is straightforward, the platform being pivoted at one end above a turntable. What is not shown is a balance beam to allow it to be moved, much as the beams are used to open and close lock gates. (Hugh McKnight)

A rather more complex bridge is the lift bridge. This example is on the Ellesmere Canal, now generally known as the Llangollen Canal, at Whixall. The superstructure supports a balance beam, one end of which is connected to the platform of the bridge, and the other end has a dangling chain that can be pulled for lifting. This type of bridge was common in Holland long before it came into use in Britain. (Anthony Burton)

Cast iron also offered a new option for conventional bridges. Canals are generally designed to be the same width throughout their length, which means that bridges can all be the same design and dimensions. Jessop designed standard conventional bridges for the Grand Junction, building them in brick or stone, depending on the best material available locally, but others recognised that standardisation was perfect for iron. Once you have created a pattern, it can be used over and over again to produce a set of identical components.

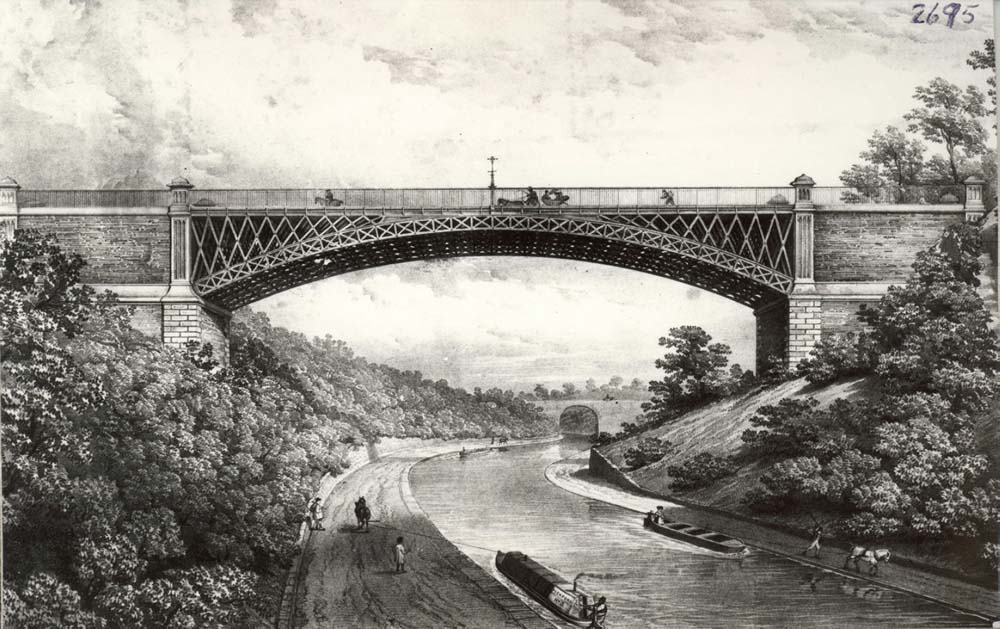

In 1704 the Horseley Iron Works was established on a branch of the Birmingham Canal. The development of the Birmingham system into what became known collectively as the Birmingham Canal Navigations (BCN) required the construction of many new bridges. As the canals were of a uniform width it was possible to cast the parts for what became standardised bridges that could be assembled on site. This example is in Birmingham near the top of the Farmer’s Bridge flight of locks. (Anthony Burton)

One of the problems canal engineers faced was building a bridge at a point where the towpath changed from one side of the canal to the other – a turnover bridge. The options were at first limited. The boatmen could be made to unhitch the tow rope, lead the horse over the bridge and reattach the rope on the other side, or a bridge could be built with a complex of ramps going up one side, and turning back under the arch on the other. With cast iron, the job became simpler. You could make a bridge that would be in effect a pair of cantilevers with a small gap between them, through which the rope could be passed. This example is on the Stratford-on-Avon Canal at Lapworth. (Anthony Burton)

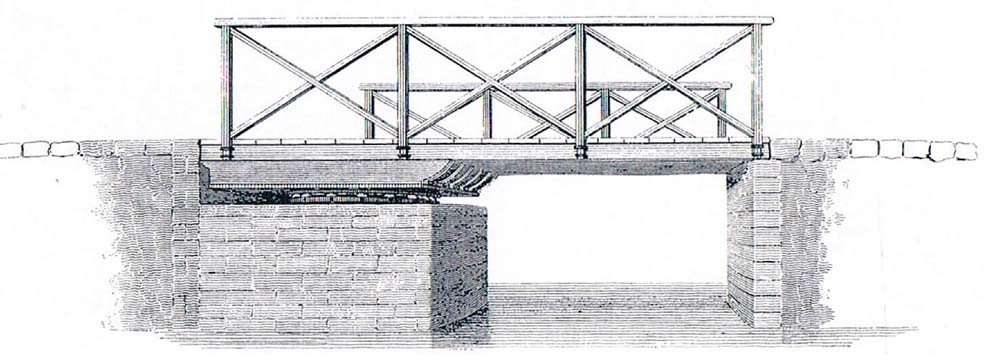

One company in particular is associated with producing standardised cast-iron bridges for Midlands canals. The Horseley Iron Works had its foundry on a branch off the Birmingham Canal and many of its bridges were designed for the complex of canals in that region known as the Birmingham Canal Navigations (the BCN). The bridge is cast in sections. Each side section consists of a flat arch with integral handrail. The two sides can then be linked by locking plates, above which smaller iron plates are laid to create the roadway. They are simple but elegant. Not all iron bridges came in standard sizes. When Thomas Telford was appointed to improve the canal system in Birmingham, he realised that Brindley’s old wandering line needed to be replaced by a more direct route. This involved, in places, carving through the rising ground that the older engineer had avoided. One of these deep cuttings needed to be crossed by a high-level bridge, and a very handsome arch was built to carry the roadway. Known as Galton Bridge, it demonstrated how far design had come since Darby’s day. No one any longer thought of iron as simply a replacement for timber, but recognised that it called for new construction methods. The main 150ft span arch comprises six ribs, each consisting of seven segments bolted together. These are joined to the roadway above by a lattice of diagonal struts. Iron could also solve the problem of turnover bridges.

A far more daring use of iron appeared in 1787 on the Severn at Ironbridge. In the middle of the sixteenth century, a strange woman, known as Mother Shipton, lived in a riverside cave in Knaresborough, Yorkshire. She gathered her prophecies in a poem that included the lines:

‘On water iron then shall float

As easy as a wooden boat.’

Because of outlandish ideas such as this she was generally thought mad. ‘Mad’ was also applied to John Wilkinson, not in the sense that he was deranged but because he was besotted with using iron in previously unthought of ways – he even had his own iron coffin propped up in a corner of his office. ‘Iron Mad’ Wilkinson made Old Mother Shipton’s prophecies a reality. He built an iron barge, The Trial, that launched on the Severn at Coalbrookdale in July 1787. ‘It answers all my expectations’, he wrote, ‘and it has convinced the unbelievers, who were 999 in a thousand’. Iron boats were particularly useful for tub-boat canals, variations on the theme we saw developed at Coalisland.

The Horseley works not only provided bridges in Birmingham. To improve communications between the northern end of the Grand Junction Canal at Braunston and Birmingham, it was decided to improve the next section of the route along the northern section of the Oxford canal. This was a typically wandering Brindley canal and it was decided to create a new, straighter route. This wintry scene shows one of the new bridges near Newbold-on-Avon. It displays how the Horseley bridges were assembled: the main structure consists of a pair of iron arches, which are then joined together by metal plates to form the roadway. (Anthony Burton)

Another iron master, William Reynolds, who was anxious to join his works to the River Severn, further developed improved ways for using inclined planes for canals in very hilly country. He needed large supplies of ironstone and coal for his foundry at Ketley. These were available just a mile and a half away and could be brought by canal, but at the end there was a 73ft drop. It would have been impossible to build locks, as there was no adequate water supply. Instead he built an inclined plane. This consisted of two parallel sets of iron rails leading down the slope. The little tub boat would be floated into a lock, which was then drained, the water passing into a reservoir, from which it could be pumped back by steam engine. As the water level dropped, the boat settled on a carriage, with different sized wheels to keep it level. The carriage was fastened by chains that passed round a drum to connect with a second carriage on the opposite track. As the cargo was only moving down the slope, the weight would be sufficient to haul the empty boat back from the bottom. Completed in 1787, the system worked well as Reynolds wrote in a letter to James Watt. He said it had met his ‘most sanguine expectations … we have already let down more than forty boats per day each carrying 8 tons … and have not yet had an accident’.

The most splendid iron bridge across a canal was designed by Thomas Telford when he was chief engineer developing the new main line for the Birmingham Canal. Galton Street Bridge crosses the canal, at a point where it lies in a deep cutting, in a single, elegant arch. Sadly, although the bridge still exists, this open view has been lost. A new road bridge has been built at a lower level and the canal passes under it in a tunnel that is basically a concrete tube. (Waterways Archive Gloucester)

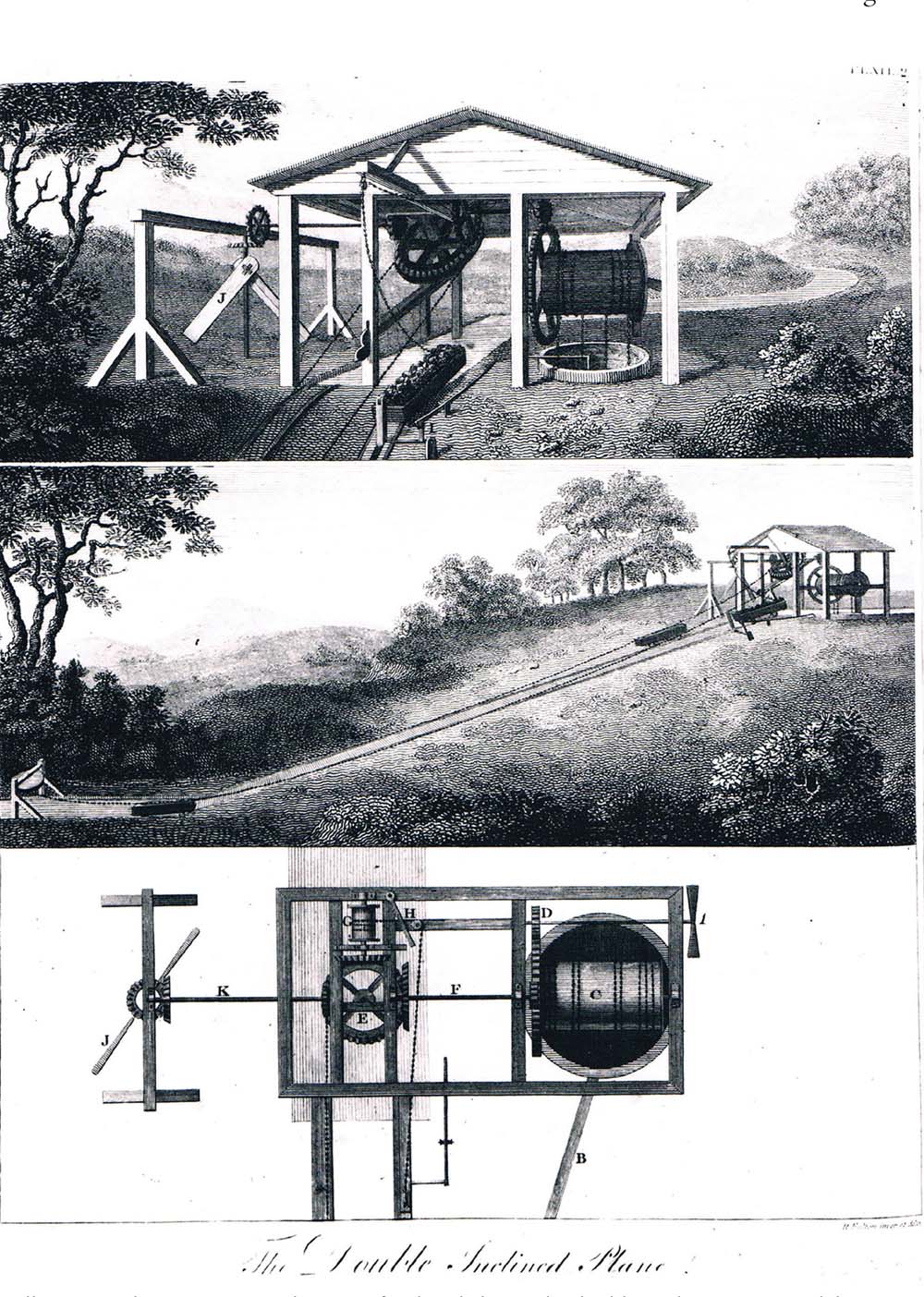

This illustration shows one particular type of inclined plane. The double track carries two tub boats, so that there is a counterbalancing effect. The boats are moved by means of chains and the motive power comes from the weight of a large bucket full of water dropping down the well to the right of the framework. When the bucket reaches the bottom, a valve connects with a projection to empty the water. A boat going down the slope would then raise the bucket again. One of the most impressive uses of this system was on the Bude Canal. This was mainly used to bring beach sand inland for fertilising and had a series of inclines. The largest, which was worked in this way, was at Hobbacott Down: it was 995ft long and raised the boats by a vertical height of 220ft. (Bodleian Library, University of Oxford)

This was just the first of many inclined planes built in the area. The Shropshire Canal was authorised in 1788, a modest affair in length at 7½ miles long, but the country was seemingly impossible for conventional canal technology. The summit of this short waterway would be more than 300ft above the river. Once again the answer was found with inclined planes. There were three: the first, the Hay incline, lifted the boats for 207ft from the Severn at Coalport; the next was a lift of a further 126ft to the summit; and a third dropped the canal by 120ft to join the Donnington Wood Canal. Few traces remain of the pioneering Ketley incline, but the Hay incline has not only survived but also been restored as part of the Ironbridge Museum site at Blists Hill. Parts of the canal are in water and one can also see the simple iron tub boats that were used. The Trench Incline on the old Shrewsbury Canal was the last to remain in use, only going out of service in 1921, which meant it survived long enough to be photographed in its working days.

Inclined planes also found a use in the West Country, notably on the Bude Canal. The main reason for building the canal was to carry the sand from Bude on the coast, inland to the farms of Cornwall. The sand was largely composed of shells, so had a very high calcium content and could be used instead of lime as a fertiliser. This was a huge trade – records show 4,000 cart loads of sand being removed in a single day. The entrance to the canal is through a sea lock, then the canal follows the line of the river, until it meets the hills that stand between it and the upland farms. The answer lay with inclines and the site of the first, the Hobbacott Down incline, can still be traced. It was immense, 935ft long and rising 225ft, and the working of the incline was described in a travel handbook published in 1865. The system was rather different from that of the Shropshire inclines. On the Bude Canal, the barges themselves were fitted with wheels. The rails dipped into the water, the wheels were set in place and a chain attached. At the top of the incline was a massive bucket filled with water that was attached to the opposite end of the chain fastened to the boat. The bucket then dropped down a deep well, dragging the boat up the slope. When the bucket hit the bottom, a plug in the bucket connected with a stake, opening a valve to release the water. There were two tracks, and the empty bucket was connected to another in a second well, so that as one descended the other was raised. There was a steam engine on hand, but was only used where necessary. This effective technology once again had its origins in the work of iron masters.

The Trench inclined plane on the Shrewsbury Canal, photographed c.1900. The wooden tub boat has been floated onto the carriage. On this incline the power is supplied by a steam engine housed at the top of the incline. (Waterways Archive Gloucester)

Many structures associated with canals and rivers benefitted from the new technology. Jessop’s early work on the Albion Mill in London went up in flames in a fire, and such accidents were all too common in buildings that relied on wooden pillars and beams. By the end of the eighteenth century, buildings with a cast-iron frame were common. And the iron was not only used structurally. Many canalside warehouses have standardised cast-iron window frames. The material even made its way into a broadsheet ballad of the period:

Canals were generally required to provide mileposts along the route. Originally they would have been individually carved from stone blocks, but with cast iron a standard design could be made, and only small adjustments to the numbers were needed between castings. This milepost stands at the junction of the Montgomery and Ellesmere Canals. (Anthony Burton)

‘Since cast-iron has got all the rage,

And scarce anything’s now made without it;

As I live in this cast-iron age,

I mean to say something about it.

There’s cast-iron coffins and carts,

There’s cast-iron bridges and boats,

Corn-factors with cast-iron hearts,

That I’d hang up in cast-iron coats.’

By far the most dramatic use of iron in the canal story comes with the building of aqueducts. To find out how it began we have to turn back to William Jessop and his busy life and commitments.

During the mania years of the 1790s, the demands on Jessop were extreme. Just like Brindley before him, he was the man of the moment and all the scheme promoters wanted him. Although he could do the initial work on a number of canals, he could not give all of them his full attention: he needed to establish priorities and a reliable man to act in his place. One canal on which he was the chief engineer was the Ellesmere. It had its origins in the need to make a useful connection with the existing Chester Canal. This had been built to run south from Chester to end at a point near Nantwich and, without extra connections, it served no obvious purpose. What was needed was a link to an area that would provide trade. The selected area was North Wales, with its mines and ironworks, together with an extension northwards to the Mersey. It took its name from the little market town along the route and it is doubtful if Jessop considered this his most important commission. He had hoped to appoint a trusted assistant, William Turner, to the post but he was overruled by the Committee of Proprietors who wanted the job to go to their own man, even though he had no experience in canal work. His name was Thomas Telford.

Telford was born in Eskdale in the Southern Upland hills of Scotland in 1757. His father, a shepherd, died when he was an infant and his mother had to leave the cottage where he was born to settle in a single room with the baby. It was not a promising start, but Telford acquired an education and, thanks to a local lady, Elizabeth Pasley, he took an interest in literature. In later life he claimed that the first book that enthralled him was Milton’s Paradise Lost, scarcely typical reading for a teenager of any generation. Schooling was necessarily brief, for the family were desperate for money. He was apprenticed to a local stonemason and learned his craft well. But he was ambitious and knew he could never prosper if he remained in rural Eskdale. His first foray away from home took him to Edinburgh, where great building works were in progress, with the construction of the New Town in the shadow of the castle. It was not long, however, before he headed for London, where he got engaged on one of the most prestigious projects of the day – Somerset House. His natural talents were considerable and in his spare time he studied all kinds of subjects – in one letter to a friend in Scotland he declared himself ‘deep in Chemistry’. He was clearly no ordinary stonemason.

His gifts were recognised by the newly appointed MP for Shrewsbury, William Pulteney. He planned to make a new residence for himself in the dilapidated Shrewsbury Castle, and invited Telford to Shropshire to look after the restoration. It was a decisive moment for he was soon offered an even more prestigious position as county surveyor for Shropshire. The post offered all kinds of opportunity, including the building of the first of many bridges he designed over the years, this one crossing the Severn at Montford. He also tried architecture, designing two churches at Bridgnorth and Madeley. He even became involved in archaeology with excavations at the Roman town of Wroxeter. He had established himself in the area as an intelligent man and capable of working in different disciplines. The main subscribers to the Ellesmere Canal were Shropshire men and they insisted their protégé got the job.

Jessop had planned the canal with his usual care, using contour cutting where appropriate and driving a straight line where that represented the ideal solution. He had ensured water supplies by building a weir across the River Dee near Llangollen to feed the main canal through a narrow, but navigable, branch. Because Llangollen is now seen as the end of the navigable canal, it is generally known by that name today. Problems included crossing marshy land at Whixall Moss, but that probably seemed a minor inconvenience to the man who had struggled with the Bog of Allen. The biggest obstacle was how to cross the River Dee, which ran at a level far below that of the canal. The most promising idea was to build locks down either side of the valley to reduce the height above the river and the length between the banks. This could then be bridged by a conventional aqueduct. There was, of course, a problem. With water coming down both sides, the aqueduct would act as a sump, and a pumping system would have had to be introduced to return water to the higher levels. But before this could be tackled, Telford was called away on another task.

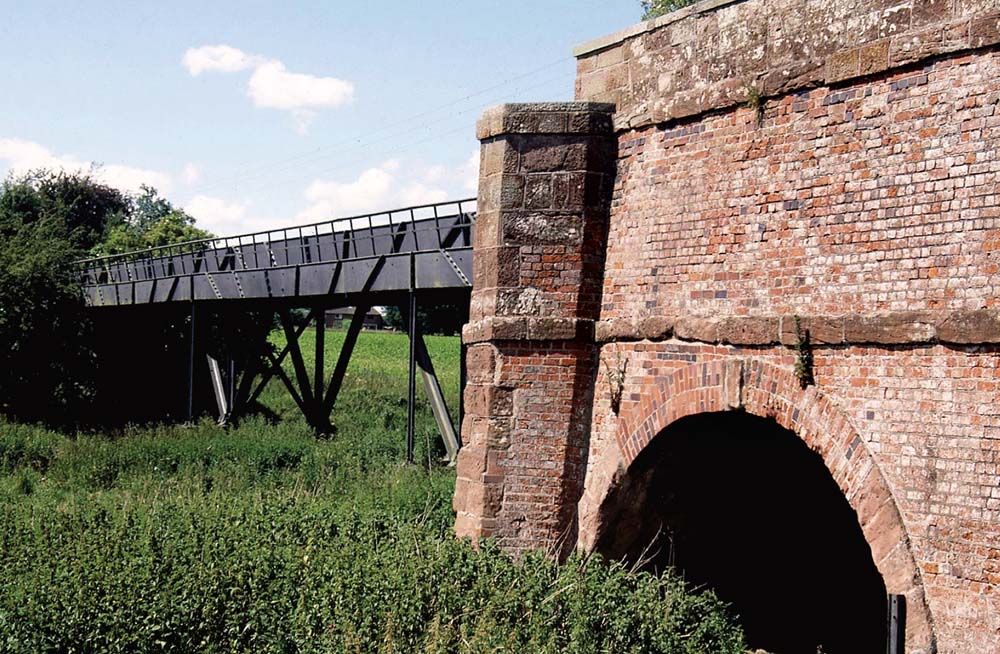

The Longdon aqueduct carried the now derelict Shrewsbury Canal over the little River Tern. It represents a pioneering use of the iron trough and is a comparatively simple structure, with the triangular iron supports set into stone blocks. The towpath is outside the water-filled trough. The light iron trough contrasts with the bulky stone abutments that were built for what was meant to be a conventional masonry canal. Designed by Thomas Telford and the ironmaster William Reynolds, it was one of two aqueducts that were the first to use an iron trough, the other being Benjamin Outram’s structure on the Derby Canal. The latter was demolished, and although it was carefully dismantled with a view to preservation, the parts were lost. (Anthony Burton)

Work had already begun on the Shrewsbury Canal, a modest waterway just 18 miles long, when the engineer, Josiah Clowes, died suddenly, leaving it unfinished. The one engineering work of note was an aqueduct over the River Tern at Longden. The river was not navigable so a typical low masonry structure was planned. Work had actually begun when a flood carried away much of the unfinished masonry. The obvious next step was simply to rebuild it as originally designed, but the chief promoter of the canal was the iron master William Reynolds. He was always looking for new ideas and for new ways of using the iron he manufactured. He and Telford came up with a radical new proposal: they would rebuild the aqueduct with an iron trough. The existing stone abutments were cut back, and the 187ft gap closed with the trough, consisting of twenty-six sections bolted together. An iron walkway on the outside of the trough acted as a towpath for the horses. The advantages of the system were obvious: the ironwork was much lighter than masonry and there was no need to line it with puddle clay. The other iron-trough aqueduct designed at that time was on the Derby Canal, designed by Jessop’s partner, Benjamin Outram.

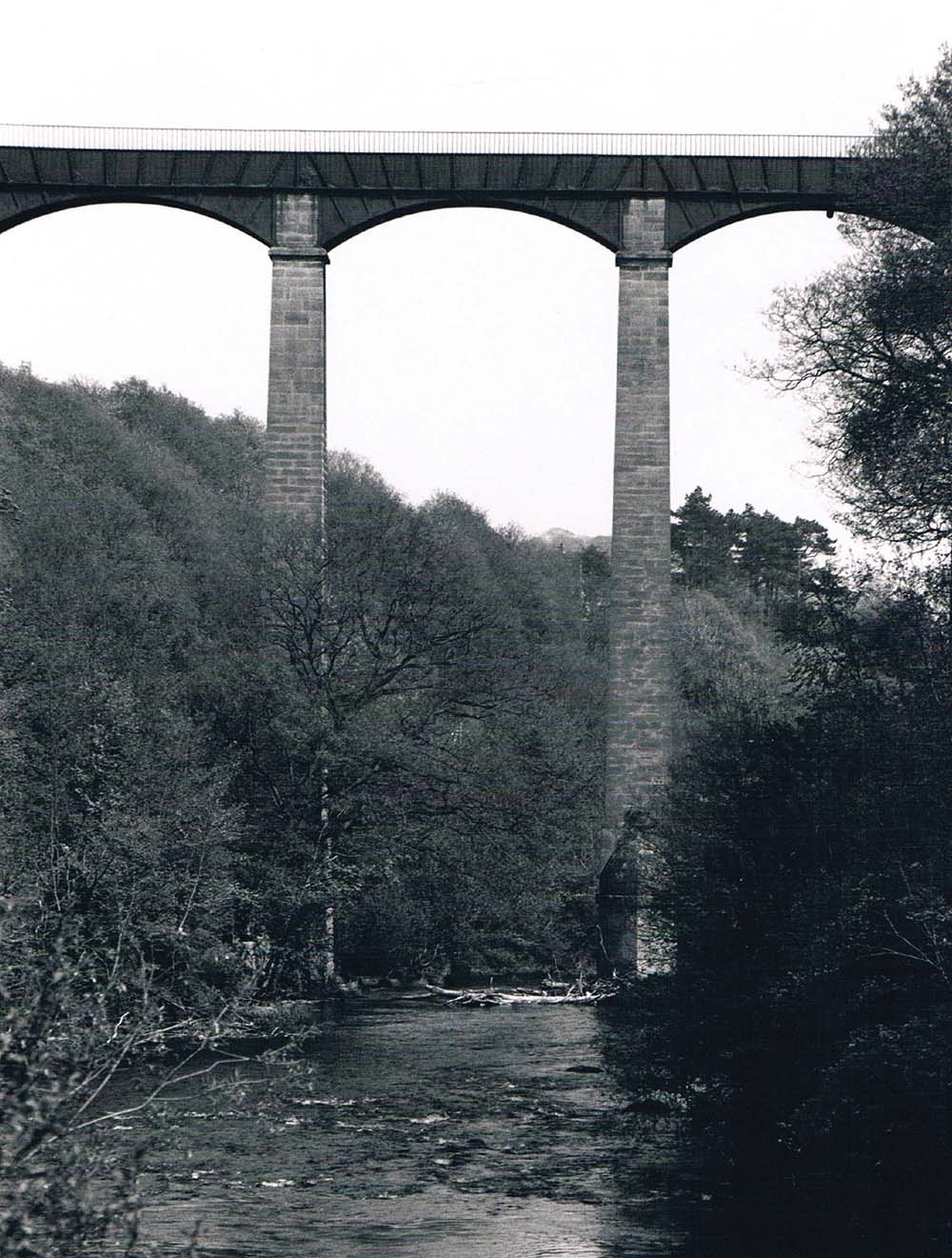

Telford now realised that this new type of structure offered a far more elegant solution to the problem of the Dee crossing on the Ellesmere Canal. In March 1795 he proposed an iron aqueduct that could be built at the height of the canal and so would not require either locks or expensive pumps. The plan was accepted and the result was the most spectacular canal aqueduct ever built – Pontcysyllte. The structure would be 1,007ft long and 120ft above the River Dee. The trough was to be carried on eighteen piers that were built solid at the bottom, and hollow with cross-bracing nearer the top. The ironwork was provided by the nearby Plas Kynaston ironworks. The trough itself was made out of a complex of metal plates bolted together. Where at Longden the towpath was set outside the trough, here it is cantilevered out over the water, allowing a free flow underneath, while the narrow boats fit snugly between the opposite side and the path. Crossing the great aqueduct is an interesting experience, particularly for the steerer standing at the back, unable to see the edge of the trough. It is the nearest you can get to the sensation of flying in a canal boat.

There has been controversy over who should take the credit for Pontcysyllte. Traditionally the credit belongs to the chief engineer on the project, in this case Jessop. He certainly showed a continued interest in cast-iron aqueducts, including the impressive Iron Trunk that carried the Grand Junction across the Great Ouse. But the idea originated with Telford and was executed under his control. It is safest to share the honours, but contemporaries shower praise on Telford, and it did wonders for his reputation. He went on to be chief engineer in his own right on many important projects. One of these canals, the Birmingham and Liverpool Junction, begun in 1826, also features cast-iron aqueducts, but is notable for the almost aggressively straight line it takes, using the modern technique of ‘cut and fill’. Very deep cuttings were made through the hills, and the spoil used to build up equally imposing embankments in the valleys.

Following the success of the Longdon aqueduct, Telford proposed an iron-trough aqueduct as the best solution for carrying the Ellesmere Canal across the deep, wide Dee valley near Llangollen. Jessop, chief engineer for the canal, accepted the suggestion and the result is Pontcysyllte, arguably the most famous structure on the British canal system, which has now been awarded World Heritage status. The photograph shows the central section, rising an imposing 120ft above the River Dee. (Anthony Burton)

It might seem that building up a bank would be easier than digging a cutting, but on the Birmingham and Liverpool Junction the banks caused the greatest problem. This was especially true at Shelmore where the bank stretched for a full mile above the surrounding fields. At the beginning of 1831, there were between 300 and 400 men at work on the site, and 70 horses were kept busy bringing the soil to the site. In Telford’s own words, ‘the rich marl of which this mound is composed was crushed and dissolved by its own weight, which in some places squeezed out the sides to a considerable extent.’ He was convinced drier soil would solve the problem, but a year later the bank was still slipping. Telford was now elderly, and he suggested a new engineer, William Cubitt, should take over. Cubitt diagnosed a different cause: the soil at the bottom was too weak, so when more earth was piled on top it simply gave way. He put even heavier soil on top, hoping this would force out the weaker material and produce a more solid structure. Nothing, however, seemed to work. The work was holding up the opening of the canal, but all Cubitt could say was that the completion date ‘has hitherto defied all our calculations’. It took four years to complete and stabilise the great bank.

More than seventy years had gone by since Brindley began his career as a canal engineer. Now one of his greatest successors at the end of his life was still struggling to complete a canal, albeit one built to a very different pattern. And the technology had scarcely changed: it still relied on men armed with nothing more sophisticated than pickaxe and spade. There was, however, one new addition to the canal landscape that came out of this network of canals. When the Ellesmere had been extended north of Chester to reach the Mersey, the important junction between canal and river involved a transhipment point between barges and narrow boats. As at other similar junctions the site was developed as a new town, Ellesmere Port. Here Telford designed a large basin, surrounded by warehouses, built to the very latest design on iron frames, with arched entrances at water level that allowed boats under the buildings for loading and unloading. Much of the complex was destroyed in a twentieth-century fire, but enough remains to give some idea of the scale. The site now houses an important canal boat museum.

The Birmingham and Liverpool Junction Canal marked the end of narrow canal construction in Britain, but canals on a far larger scale had already been built both here and in other European countries.