The steam engine evolved as a response to a pressing problem. Mines, especially the tin and copper mines of the south west of England, needed to go ever deeper to reach the ore, but the available pumps couldn’t cope with removing water from such depths. The first successful solution was provided by a Dartmouth man, Thomas Newcomen, who had supplied miners with tools and was aware of the problem, as described on p.69. The first Newcomen engine worked at a colliery at Dudley in the Midlands in 1712. Collieries were the main beneficiaries of the invention, and its inherent inefficiency was no problem where coal was so readily obtainable. But as its use spread to other areas, notably the metal mines of Devon and Cornwall, the situation was different. There coal, mainly brought in by sea from South Wales, was very expensive. Attempts were made to improve the engine, but very little changed for half a century. It was this machine, however, that led directly to a true steam engine.

James Watt was an instrument maker at Glasgow University when he was sent a model of a Newcomen engine that wasn’t working. He realised there was an inherent inefficiency caused by constantly cooling and then reheating the cylinder. His solution was to condense the steam in a separate vessel so that the cylinder could be kept permanently hot. To solve the problem of heat escaping from the open top, he closed off the top of the cylinder and, instead of air pressure, used the pressure of steam to push down the piston. The atmospheric engine had become a far more efficient true steam engine.

Watt went into partnership with the Birmingham industrialist Mathew Boulton. They established a new works to manufacture steam engines on a site beside the Birmingham Canal. Boulton’s other factory was the Soho works a few miles away, so this became the Soho Engine Works. This was still the meandering Birmingham Canal as laid out by James Brindley. Early in the nineteenth century, Telford made major improvements, slicing through the old wobbly route in a new straight line canal. There was no question of closing off the original canal, simply because there were so many businesses, including important customers, lining the banks. So the bends were left as loops off the main line, and the one containing the Boulton & Watt factory remains the Soho loop to this day.

The steam engine came into use on the canals as a pumping engine for water supply. There are old engine houses on many canals around the country, including one on the Birmingham Canal. A few still have their old engines in place, including one on the Cromford Canal, but there is only one place where a pumping engine can, and still does, work exactly as it did when first installed, and that is on the Kennet & Avon at Crofton. The water source is a lake below the level of the canal. The engine house itself contains two massive engines, one of which is a Boulton & Watt of 1812. It is remarkable to think that this magnificent machine started its working life when Napoleon was setting off on the long, dismal trudge with his defeated army back from Russia. The machines may look archaic, great lumbering, slowly nodding beam engines, but they are still powerful, able when working together to pump a million gallons an hour. It is one of those sights that inspires awe, as water gushes into the leat that carries it away to the canal summit. But for all their power, these are still engines working at low steam pressure, and can do so much work simply because of their size.

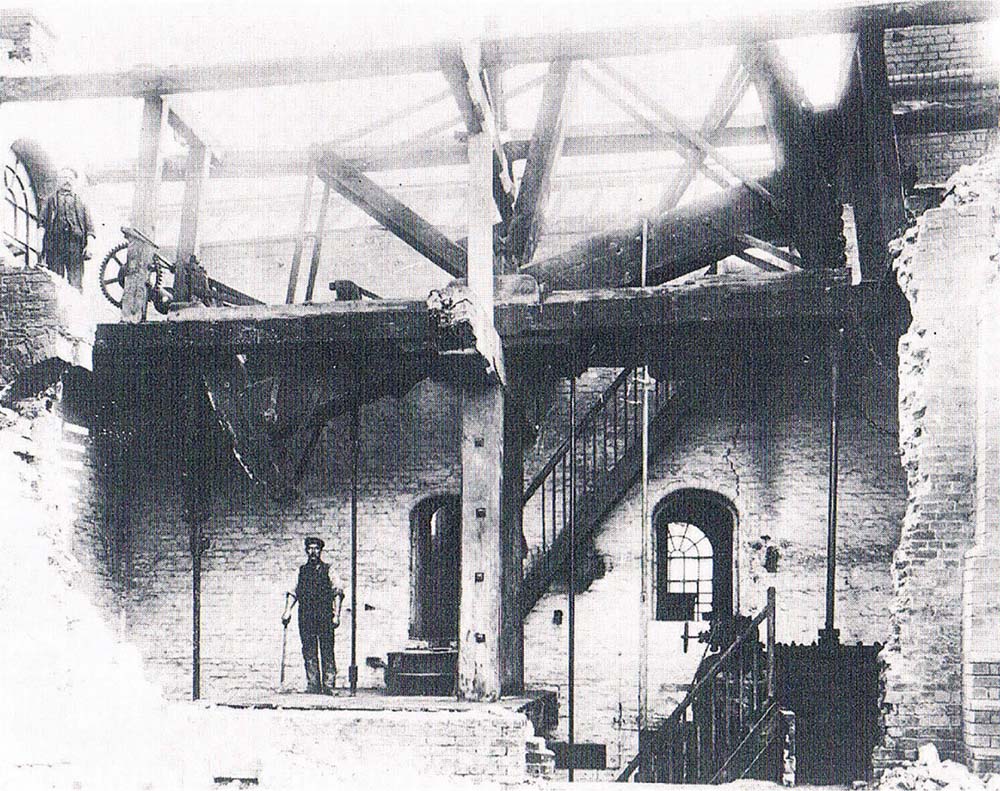

This Boulton & Watt engine of 1776 was built to supply water for the summit level of the Birmingham Canal. The photograph was taken as the building was being demolished. It is typical of early pumping engines, with the pump rods suspended from one end of the beam, and with the piston rising above the steam cylinder attached to the opposite end of the beam. James Watt’s engines were massive and worked at very low pressures, and it is difficult to imagine such a cumbersome machine being adapted for any form of transport. (Science and Society)

Watt had a virtual monopoly on all steam engine construction until the end of the eighteenth century thanks to an all-embracing patent. He did make one significant improvement. Originally, as in the Newcomen engine, the piston was hung from the beam by a chain, which meant it still needed a weight at the other end of the beam: you can pull a chain but can’t push it. Making a rigid connection was problematic as the end of the beam moves along a circular path. Watt solved this by attaching the top end of the piston rod to a shifting parallelogram of rods. Now steam pressure could move the piston in both directions – and that meant it could be used, via a crank, or some similar device, to turn a shaft. It could drive machinery. The steam age was about to enter a second, vital period of development. In the latter part of the eighteenth century, several ideas had been put forward for applying steam power to moving boats: some were practical, others less so. It might have been expected that the first success would have come in Britain, where steam power had been developed, but it is generally agreed that the first successful steamer appeared across the Channel in France.

The story of canals has largely been one of practical, working men, often with very little formal education, who learned by experience rather than theory. The next developer in the steam world definitely does not fit that mould – Claude-Françoise-Dorothée, Marquis de Jouffroy d’Abbans. Born in 1751, he entered the army at 20, was involved in a duel and then exiled from Paris. He took an interest in steam power, starting by studying pumps. He experimented with using steam to power a boat. His first experiment on the River Doubs in 1778 was not a success, largely because he tried to use the engine to work ‘duck feet’ paddles. He then embarked on a much more ambitious project, when in 1782 he designed the 182 tonne Pyroscaphe for which he developed a double-ratchet system, to turn continuously rotating paddle wheels on each side of the vessel. He applied for a patent, and produced a model of his vessel for inspection, now preserved in the Musée de la Marine in Paris. The vessel underwent trials on the Saône near Lyon in 1783. The French academicians prevaricated over the patent and before anything more could be done, the country was convulsed by revolution. The Marquis abandoned his schemes, although he did write a treatise on steamships. It was a bold beginning, but it is uncertain how many people outside France were aware of the events.

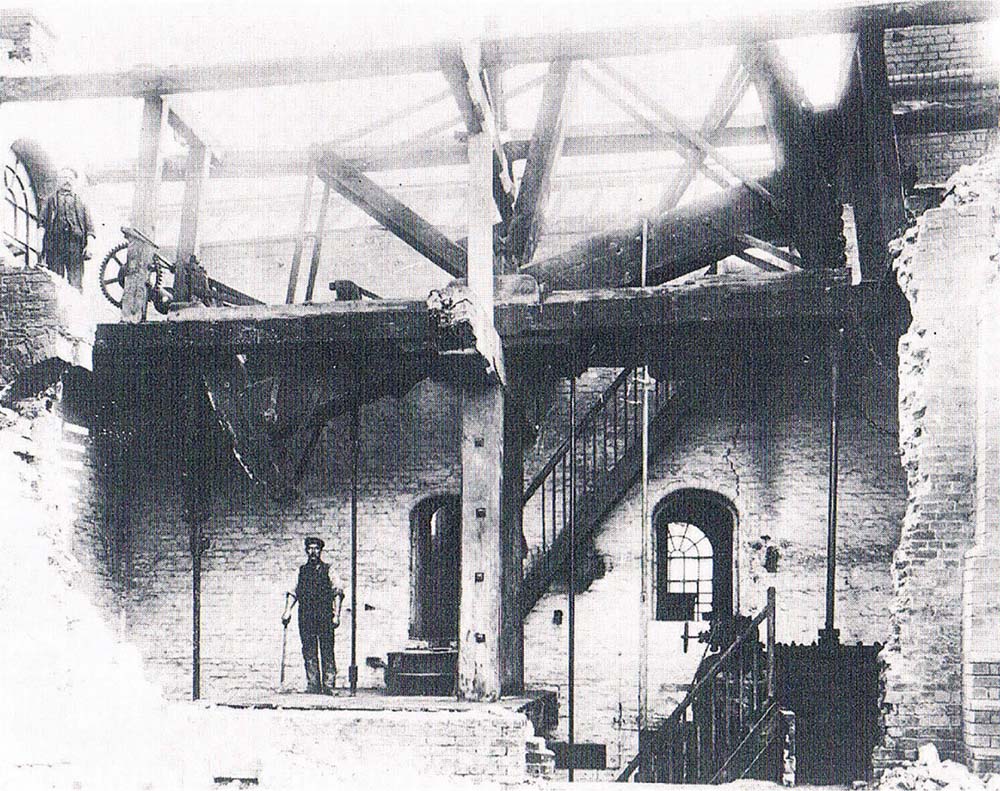

A model presented to the French Académie de Science by the Marquis Jouffroy d’Abbans to persuade them to allow him to build a full-size paddle steamer and test it on the Seine in Paris. He was refused permission. In the event, his trials took place on the River Saône near Lyons, starting in 1775 and were eventually successfully completed with his vessel, the Pyroscaphe, launched in 1783. Unfortunately further developments in France were halted by the great political revolution. (Musée de la Marine)

An alternative to the paddle steamer was tried in America in the 1780s. A steam pump drew in water at the bows and fired it out at the stern, but the technology of the time was not up to it. The next successful experiment took place in Britain. William Symington was born at Leadhills in Scotland in 1764, a spot that as its name suggests was at the heart of a lead mining district, where his father worked as an engineer. The local school recommended that he should train for the clergy, but instead he followed his father’s profession. He soon showed a strongly inventive mind and thought of ways to improve the Boulton & Watt engine at the local mine. He also tinkered with building a steam carriage to go on the road. In 1787, an Edinburgh banker, Patrick Miller, invited Symington to design the engine for a paddle steamer.

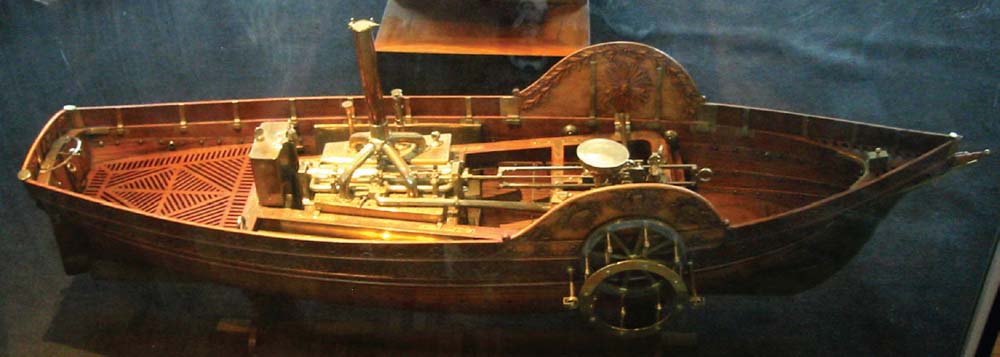

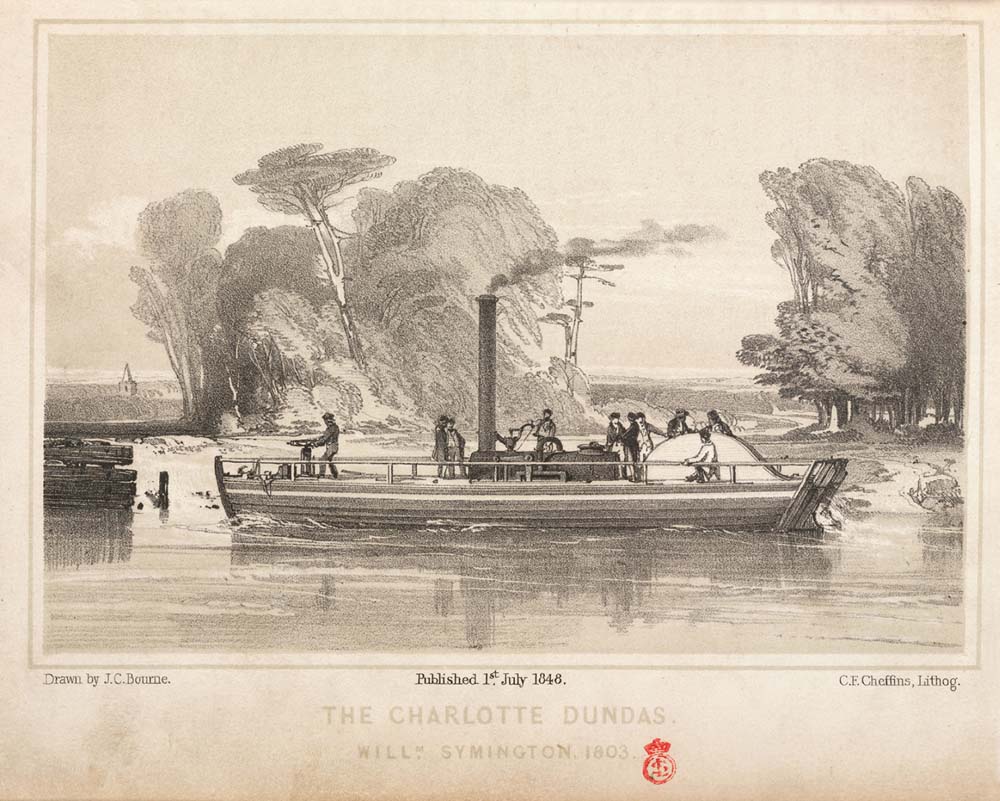

The steamer Charlotte Dundas was designed by William Symington as a tug to haul barges on the Forth & Clyde Canal. At its trials in 1802 it proved successful in hauling two 70 tonne barges at an average speed of slightly over 3mph. The authorities, however, were worried that the wash from the paddle wheels would damage the banks. The experiment was abandoned. (Science and Society)

The vessel was a double-hulled 25ft vessel with a small engine made in a local brass foundry. It was tried out on Dalswinton Loch in Dumfries in 1788, achieving a speed of 5mph. Among those invited to try out the novel system was the poet Robert Burns. Unfortunately he left no record of his adventure, but he could at least claim to be the first poet to be moved by steam. Encouraged by this success, Symington made arrangements for a much larger engine to be built at the famous Carron Ironworks. In 1789, there was a fresh trial on the Forth & Clyde Canal, but the paddle wheels broke. Miller was furious and blamed Symington, who he described as a vain fool. The steamboat experiment was abandoned, and Symington returned to more conventional engineering projects.

Symington, however, never abandoned his steam ideas and continued experimenting with different types of rotary engines. Then, in 1800, Lord Dundas, one of the directors of the Forth & Clyde Canal Company, asked him to build an engine for a boat designed by Captain John Shank, for use on the canal. The vessel was named Charlotte Dundas after the director’s daughter. It proved underpowered, but a second version, Charlotte Dundas II, was soon completed. It was very simple, with steam provided by a rough waggon-boiler, with the flues encased in brick. The single 22 inch diameter cylinder was set horizontally, with the piston connected directly to a crank to drive the wheel. In tests on the canal in 1802, it towed two 70 tonne barges against a strong headwind for 20 miles at an average speed of about 3mph. In that respect, it was a success, but a new problem appeared. Boulton & Watt were always jealous of anyone else developing any form of steam power, and their engineer James Lawson reported, rather gleefully, on the outcome: ‘The Engine is made by Symington & turns a Wheel – which made so much Splashing that they were affraid of washing down the Canal Banks … the papers say Lord Dundas is the great Patroniser of the scheme – which I rather think will Die without further noise.’ Lawson was almost right. The canal company did indeed decide that the vessel was likely to cause too much damage to the canal banks and abandoned the scheme. The Duke of Bridgewater was impressed, and ordered eight similar craft for his canal. Sadly, he died before the order was completed, and his successors showed no further interest. The pioneering canal tug was left to rot and Symington’s boat building days were ended. The scene moved across the Atlantic for the next stage of development.

Developing steamboats for American waterways had begun early. John Fitch was born in Windsor, Connecticut, in 1743 and had a varied career. He had little formal schooling and was apprenticed to a clock maker, then he tried to set up in business as a brass founder and, when that failed, began a brass and silversmith business. The American Revolution ended that and he worked as a gunsmith for the New Jersey militia during the war years. He also set up a profitable business supplying beer and rum to the troops. By 1780 he was acting as a land surveyor in Kentucky when he was captured by Indians and handed over to the British. On his release he settled in Pennsylvania, where he developed his ideas for building a steamboat.

The most remarkable part of the Fitch story is that when he started he had never seen an actual steam engine, only an illustration of a Newcomen engine in a book.How he thought that monstrous machine could ever take to the water is a mystery. He had, however, heard that a man called Watt had made improvements. With this scanty information he designed and built his engine with the help of a clockmaker, Henry Voigt. In 1787 the vessel Perseverance was given its trial. It was an extraordinary affair, driven along by banks of three oars, set on either side of the hull, powered by the engine. It was not a great success, and a new version appeared that now had the oars mounted in the stern, paddling along like ducks’ feet, similar to the system first tried and soon abandoned by the French duke. In 1790, Fitch had established a regular steamboat service between Philadelphia and Burlington, New Jersey. He had hoped to get a monopoly in steamboat construction, but when that was denied his investors lost faith. Several other attempts to build steamboats in both Europe and America all came to nothing, and his latter years saw him deeply involved in litigation over land he had originally surveyed in Kentucky. When he died in 1798, America still had no steamboat services on its rivers and canals and his name slipped into obscurity. Yet he was a man of bold imagination: it is hard to conceive just how difficult it must have been to make any kind of working steam engine without having seen one, let alone one capable of driving a boat. It was the next American inventor who went down in the history books as the first really successful steamboat pioneer.

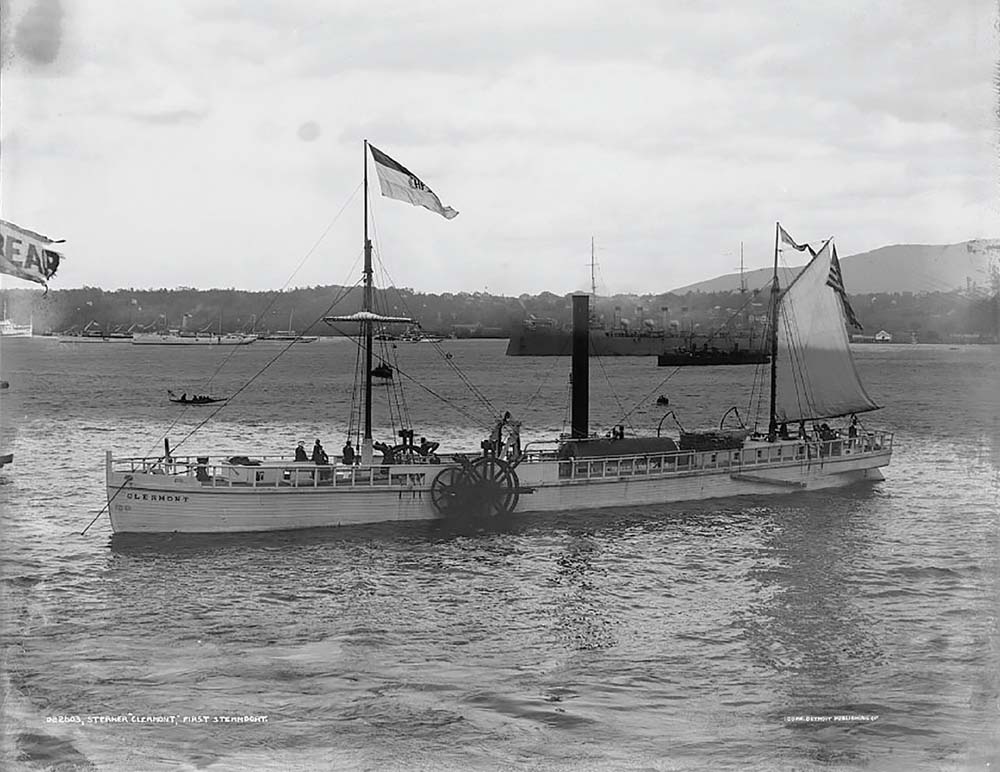

The Clermont, designed by the American engineer Robert Fulton, was the first paddle steamer to enter into regular service. Built in 1807 it carried passengers on the Hudson River between Albany and New York. Although always known as Clermont, it was actually launched under the more prosaic name North River Steamer. The photograph shows a replica built in 1909. (Library of Congress)

Robert Fulton was born in Pennsylvania in 1765, the son of Irish immigrants, whose farm failed in 1771. By 1774 his father was dead. After a necessarily brief education, Fulton was apprenticed to a jeweller in Philadelphia, where he showed a talent for painting miniature portraits for lockets. This set him off on a career as an artist and, in 1787, local merchants raised money to send him to London to improve his art. He had a modest success, but the competition was far greater in cosmopolitan London than in the still provincial city of Philadelphia. Nevertheless he stayed in Britain at the start of the Canal Mania years, and developed a new enthusiasm for transport. He wrote a book, advocating a system of short, local canals, linked by inclines, with no locks. The idea was never taken up.

He may have spent ten years in Britain, but in 1797 he moved to France, where he proposed building a new type of vessel to attack the British fleet – a submarine. He even built a craft at his own expense, but it had no effect on naval warfare. But it was in Paris that he met the American minister in France, Robert R. Livingston, who had acquired a monopoly for running steamboats in the state of New York – even though he had no steamboats to run. The two men joined forces to make a steamboat that was tried out on the Seine, using an 8-horse power French engine. It was not entirely successful, but showed enough promise to continue the experiments. By 1804, Fulton was back in London, now trying to sell to the British the idea of building a submarine with which to attack the French. But with the Royal Navy’s domination of the seaways there was no interest. So, by 1805, he was back with the original idea of steamboats, this time using a Boulton & Watt engine, which he had shipped back to America in parts.

By 1807 the vessel, originally just known as Steamboat but later as the Clermont, was ready. The vessel was 150ft long and its single cylinder engine drove paddle wheels on either side of the vessel. Boulton & Watt were still committed to low pressure steam, and the use of a separate condenser, so the wood-burning boiler was only needed to produce steam at a decidedly modest 3 pounds per square inch (psi). On her trial run she completed the 150 mile journey along the Hudson, between Albany and New York in thirty-two hours, which might not seem like rapid progress, but the existing horse-drawn boat service took four days. Modifications were made and by September she was in regular service. The owners of the sloops that had monopolised traffic up to then, were less than pleased by the rival, and a suspiciously large number of ‘accidental’ encounters occurred between their vessels and the vulnerable paddle wheels. Guards over the wheels alleviated that problem and regular commercial steamboat runs were finally established.

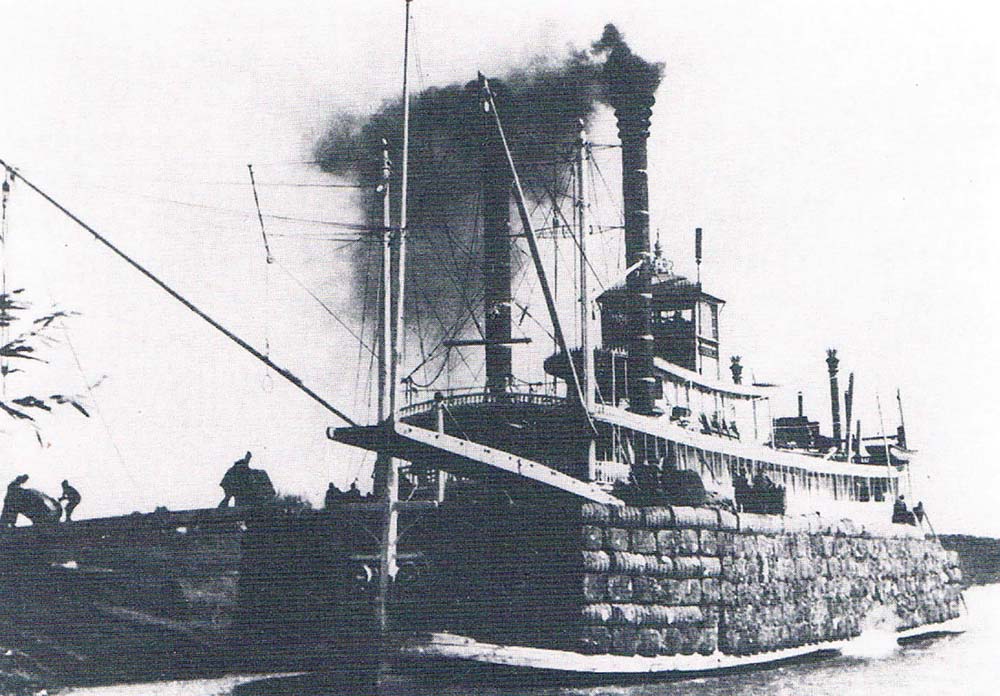

The paddle steamer became a vital link in the American transport system, especially on the Mississippi. In popular imagination the typical Mississippi steamer was a showboat, inhabited by gamblers and ladies of dubious virtue; in reality most of the traffic was the vital carriage of cotton from the fields to the main port of New Orleans. This illustration shows a stern wheeler in which every space has been crammed full of bales of cotton. (Public Library of Cincinnati & Hamilton County)

The paddle steamer was ideal for the major rivers of America, and the Mississippi steamers became legendary. Today, we see them as they have appeared in films, as exotic floating pleasure houses where professional gamblers fleeced the unwary. In practice, most of the river traffic was less glamorous. There was an immense trade in the nineteenth century, bringing cotton from the plantations of the South down to New Orleans for shipment to the mills of Lancashire. These boats not only carried cotton in the hold but also bales were heaped up all along the decks, so that the whole vessel looked like a pile of bales on the move. The other passenger boats did and do exist. One of the few Mississippi paddle boats, still actually worked by a steam engine, the Natchez, still takes passengers for trips on the river at New Orleans. Along the way they are regaled by music from the steam calliope, an organ in which steam is blown through the pipes instead of air.

Suitable as they might have been for the vast reaches of the Mississippi, American canal authorities were no more enthusiastic than their counterparts on the Forth & Clyde had been. The same problems of the wash eroding the banks led to them being banned. It seemed that steam was destined to be limited first to rivers, then ocean-going vessels or to canals specifically designed to take ships rather than narrow boats and barges. One of the first actual canals to use steam power on the water was the Göta Canal in Sweden. The works that had been started beside the canal at Motala not only built structures for the canal, such as locks and bridges, but also even before it was completed they were building paddle steamers for use on the waterway. The work continued after the canal was opened and one vessel, named after the Swedish engineer, Eric Nordwall, was built in 1835. It foundered twenty years later, but the remains were found and a replica was recently completed. It steams again down the canal.

Regular steamer services were introduced onto the Göta Canal from an early date. One of these was named after Erik Nordewall, the engineer in charge of the first section of canal linking Gôtenborg to Lake Varna. It sank, but its remains were discovered at the bottom of a lake. Now a full-scale replica of the paddle steamer has been built and steams again on the canal. (Paddlesteamer, Sweden)

In Britain, where so much pioneering work had been done on both canals and steam engines, movement towards uniting the two was painfully slow. The major difficulty was with the narrow canals. There was never any question of using side paddles: boats would have been unable to fit into the locks, and stern paddles would have been vulnerable to damage in the locks. Even if that had not been the case, when your boat size is limited you cannot give over extra space for paddle wheels, an engine and its fuel, nor can you pay extra crew to look after the machinery. It was only in the 1860s that steam narrow boats came into limited use, mostly run by the carrying company Fellows, Morton & Clayton (F.M.C.) on the Grand Junction Canal. To save on space, they needed small, powerful engines. By this date, high-pressure engines were common, and these were worked at 140psi, a huge increase from the 3psi of Clermont. There was also another factor that made a huge difference. Back in the 1830s an Englishman, Francis Pettit Smith, had devised a different way of moving a vessel through water – the screw propeller. It was an immediate success. Brunel changed his plans for his second steamship, the iron-hulled Great Britain, abandoning the original paddle wheel design in favour of the screw propeller. The big advantage, as far as use on canals was concerned, was that instead of being stuck either out at the side or behind the stern, as the paddle wheels needed to be, the propeller could be tucked away under a counter stern.

The introduction of steam power to British canals only developed slowly. At the end of the nineteenth century, steam-powered narrow boats were introduced, which worked both as cargo carriers and tugs, hauling an unpowered narrow boat, the butty, behind them. One company that specialised in this type of craft was Fellows, Morton & Clayton and one of their steamers, Sultan, is shown here with the crew. To maximise their profits, these boats were worked ‘fly’ on non-stop runs. (Waterways Archive Gloucester)

The system worked because the steamer was powerful enough to tow a second narrow boat, the unpowered ‘butty’ behind it, and the locks on the Grand Junction were wide enough to take in the two vessels side by side. The great advantage the steam engine has over the horse is that it never gets tired, so the boats were run ‘fly’ travelling day and night. To work to a strict timetable, they had to carry change crews: usually five men on the steamer and three on the butty. Working the steamer must have been an interesting exercise in communication: the steerer couldn’t see or control the engine, and the engine driver couldn’t see where they were going. Communication was through coded signals on a lanyard. But they were undoubtedly efficient: a timetable for a run from Limehouse Basin at the end of the Regent’s Canal to Fazeley, near Birmingham, was scheduled to take just forty-four hours, during which time the crew would have travelled 151 miles and passed through 161 locks. The men were considered elite and were smartly dressed in white uniforms; not the most practical colour for a coal-fired steamer. One of these craft has been preserved and restored to full working order, and President can regularly be seen out on the water in the old FMC livery.

One much appreciated steam innovation on the narrow canals was tugs for tunnels. Many had no towpaths, so the vessels had to be legged through. Life was easier for crews when they could be towed along as part of a string of boats. The only ones who would have regretted their arrivals were the professional leggers, who had done the job at some of the country’s longer tunnels.

The main use for steam on British canals was on the broad waterways of the north of England and Scotland. The owners of the Forth & Clyde Canal, having turned their back on the original steam tugs, tried again in the middle of the nineteenth century. They installed an engine in an 80 tonne lighter, Thomas, and trialled it on the canal in 1856. It was a success and from this simple beginning a distinctive vessel was born – the Clyde Puffer. The popular name was given because in the original version, exhaust steam was sent straight up the funnel, sending out a puff of smoke and steam with every stroke. The vessel was still recognisably derived from the old lighters. It had to be built to fit the locks and maximise the cargo space, so it was flat bottomed, bluff in the bows with a rounded stern. The captain had a cabin aft and the crew had their accommodation in the foc’s’le up in the bows. In between there was just one large hold, covered in hatches. Originally there was an open steering position, but this was soon changed with the addition of a wheelhouse immediately behind the funnel. This makes steering interesting. The engine was developed as a compound. That is, steam under high pressure enters one small cylinder, and then exhausts into a second larger cylinder. The difference in size balances out the power – high pressure acting on a small piston, the lower pressure on the larger area. The puffers were soon freed from the confines of the canal and became the workhorses of the Highlands and islands of the Scottish west coast. The little craft were made famous in the Para Handy tales of the puffer Vital Spark and her crew.

One very successful use of steam on British canals was tugs to pull narrow boats through tunnels that had no towpaths. This photograph taken c.1910 shows a large number of horse-drawn boats waiting to be towed through Blisworth Tunnel. The tug can just be seen to the left of the picture. At this date the Grand Union had not yet been formed, hence the initials on the tug for the Grand Junction Canal Company. (Waterways Archive Gloucester)

The Forth & Clyde Canal Company had rejected steam at the beginning of the nineteenth century. They finally succumbed by the end of it, introducing small cargo steamers that became known as ‘Puffers’. The name derived from the exhaust steam that passed up the funnel with smoke from the boiler in a series of regular puffs. This Puffer was working on the canal in the twentieth century and is seen here loading up with whisky from a warehouse at Port Dundas. In later years the Puffers spread out from the canal, trading up and down the west coast of Scotland and out to the islands. (Waterways Archive Gloucester)

Attempts in America to introduce steam on the canals moved at much the same pace as they had in Britain. Taking one canal as an example, the Chesapeake & Ohio, one finds a string of trials, failures and false starts. A committee had been set up in 1831 to examine the whole question, but always with the proviso that nothing could be done that might damage the banks. Nothing materialised at first. There was, however, one promising development. Pettit Smith was not the only man working on screw propulsion. John Ericsson, a Swedish-born engineer who had earlier designed a locomotive in Britain but then moved to America, had the same idea at much the same time, and one of his craft was tried on the canal in the 1840s. There was a period of experiment with steam tugs, but their use was severely limited by rules that they should not travel faster than 4 miles per hour and not draw more than 4ft of water.

The company was still wrestling with the problem in the 1860s. A report in the Alleganian newspaper on 7 July 1868, after commenting on the fact that ‘the several attempts heretofore made to introduce steam propulsion upon our Canal have proved unsatisfactory’, went on to praise an invention by Captain James L. Catheart. His device had been successfully tested by the Philadelphia Transportation & Freight Co. It worked ‘in such a manner that the banks of the canal will not be washed away as they are liable to be now by the ordinary screw, which makes so great a commotion in the water that its use is strictly prohibited’. The propeller was attached to a flexible knuckle joint from the drive shaft and also to a rudder, so that both could be moved together –much as a modern outboard motor is swivelled by the tiller. It was claimed that whereas ‘the old lumbering boats’ were run at a cost of 23 cents a mile, with the new steamers this was cut to 9 cents, and the vessels could move at 6mph without causing damage. The Pennsylvania Company was reported as having changed all their vessels to the new system at a cost of $8,000 per boat.

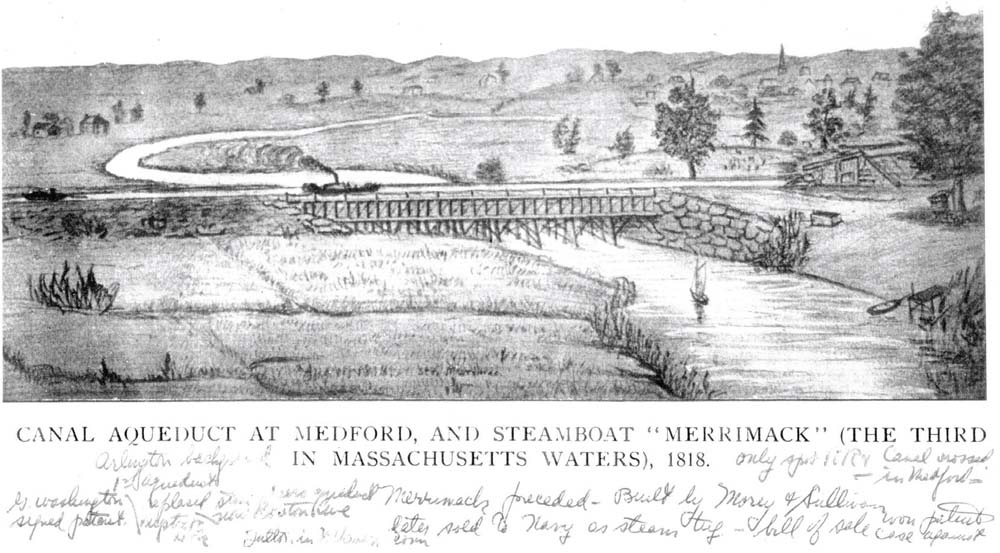

This illustration shows the steam tug Merrimack on the Middlesex Canal at Medford in 1818. It is crossing the Medford aqueduct over the Mystic River. This appears to be the oldest known record of steam being used on American canals. They seem, nevertheless, to have been very little used on canals, yet finding much greater use on rivers and river navigations. (Middlesex Canal Association)

There was a short period of use of steam packets on the Chesapeake & Ohio canal, but in general the steam engine never had any great impact on canal traffic anywhere in the world. Horses and mules trudged towpaths well into the twentieth century. One type of steam engine, however, did have a huge effect on the canals and that will be the subject of the next chapter.