>

>Shaving Cabinet

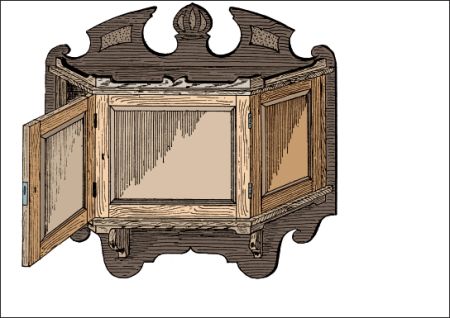

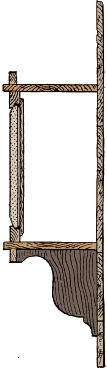

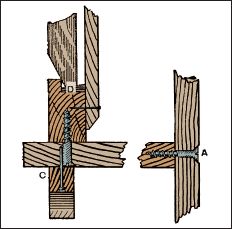

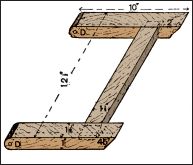

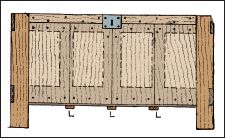

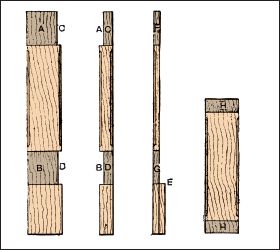

The shaving cabinet illustrated in Figure 1 is arranged so that when you open the doors the light is reflected on each side of the face. You should begin by making the back of the cabinet. It is of ½-inch material, 2 feet, 7 inches by 2 feet, 5 inches, and is either jointed up, as shown in section by Figure 2, or framed, a ¼-inch board forming its center. Cut it out with a bow-saw; the ornamental panels at the top have the outlines cut in about ⅛ inch, the centers being beveled down and punched with the point of a wire nail. The top and bottom boards at the back are ½ inch thick and 2 feet, 6½ inches by 7½ inches The ends form an angle of 45º with the back. The front edge has a length of 1 foot, 3½ inches These boards are 1 foot apart, and are fixed with screws through the back as at a (Figure 3). Frame up the front 1 foot, 3 inches by 1 foot, the rails and stiles being 1¼ inches by ¾ inch, rebated for the glass, and the back edge of the stiles being beveled off at an angle of 67.5º. Cut and fit the brackets as shown in Figure 2. They are glued and screwed through the bottom board and back. Get out the ornamental rails at the top and bottom, miter them, and glue and brad them in place, ½ inch within each edge, and they will then cover up the screws used to secure the front, as at C (Figure 3). Fasten A slip cut to the section of B in each angle at the back; with these slips the doors will come flush. Frame the doors 1 foot by 9 ⅛ inches of similar section to the front, with the hinge stile beveled to 67.5º, and hand the door in place. This can be fitted either with locks or with hanging handles and catches. Stain and polish, or otherwise finish to your taste, and, finally, insert the mirrors. These should be securely wedged like at D (Figure 3), and covered at the back with thin wood to protect them from scratches.

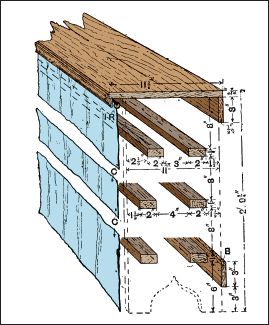

Boot and Shoe Rack

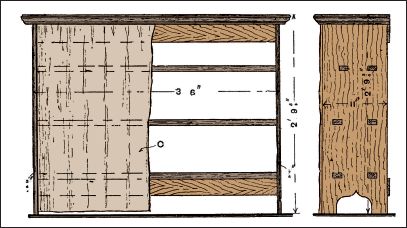

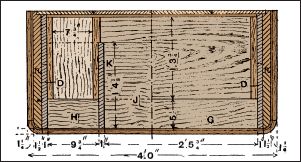

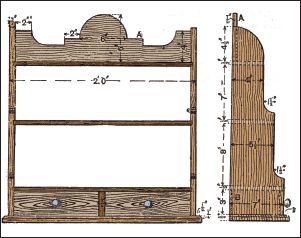

Figures 4 and 5 show a rack for boots, shoes, and slippers, which you will find useful in almost any part of your house. The rack can be made of ¾-inch yellow pine or sound red deal, and requires two ends, 2 feet, 9 inches by 11 inches by ¾ inch; one top, 4 feet by 11¾ inches by ¾ inch two braces, 3 feet, 6 inches by 3 inches by ½ inch; six rails for shelves, 3 feet, 7 inches by 2 inches by 1 inch; and one molding, 6 feet by 1½ inches by ⅞ inch. First prepare the rails, then plane them square, and take off the sharp corner to form a slight chamfer. Shoulder and tenon each end ready for the ends, which can then be prepared with the mortises. Space them out as shown in Figure 6, the top two rails for children’s boots and slippers.

After you cut the mortises, gently drive on the ends and wedge the rail tenons.

Across the back, screw two braces b (Figure 6), and then screw on the top from the under-side. Make sure to gouge the ends and braces for the screws. at the front, immediately below the top, place a  inch diameter iron rod i r (Figure 6) suspended by brass hooks, on which to fix a curtain c (Figures 4 and 6) to cover the boots. The finishing molding along the top can be fixed next, and the rack is then often ready for painting, or staining and varnishing. rails are preferable to solid shelves, as they admit of a free current of air to dry the soles of the boots.

inch diameter iron rod i r (Figure 6) suspended by brass hooks, on which to fix a curtain c (Figures 4 and 6) to cover the boots. The finishing molding along the top can be fixed next, and the rack is then often ready for painting, or staining and varnishing. rails are preferable to solid shelves, as they admit of a free current of air to dry the soles of the boots.

>

>

Figure 1—General View of Shaving Cabinet.

>

>

Figure 2—Vertical Section of Shaving Cabinet

>

>

Figure 3—Joints of Shaving Cabinet

>

>

Figures 4 and 5—Elevations of Boot and Shoe Rack

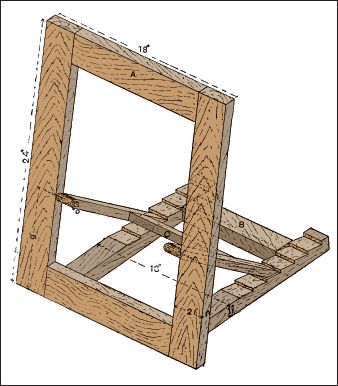

Bed Rest

For the bed rest illustrated by Figure 7 the following materials will be required: For the frame a (Figure 7), two pieces 2 feet, 1 inch by 3 inches by 1 inch, planed to 2¾ inches by ⅞ inch. For the frame b, two pieces 1 foot, 4½ inches, planed to 1¾ inches by 1⅛ inches. For the frame c, two pieces 10½ inches by 1¾ inches by 1¼ inches, planed to 1½ inches by 1 inch; and one piece 11½ inches by 1¾ inches by 1¼ inches, planed to 1½ inches by 1 inch. There will also be required between 5 yd. and 6 yd. of webbing, one pair of 1¼-inches back flaps, some ¾-inch screws, and two coach-screws, 3 inches by ¼ inch. The wood must first be planed to true. Begin by planing true the face side and face edge of each piece of wood, afterwards gauging to the several widths and thickness, taking care that in each measurement the gauge is set quite  inch full to allow for smoothing off when glued up. When this is true, lay it on the bench, face up, and as the other pieces are planed lay them on the prepared piece, and if each piece does not lie perfectly flat, plane off the part where it touches, that being the highest part. The face edge of each piece can be done in a similar manner.

To test with the eye alone, hold up a piece of wood to your line of sight, then slowly turn up the further edge into your line of sight. notice which corner comes into view first—that will be the highest part. plane this side down, and the opposite corner of the diagonal. This is because if one corner curls up ⅛ inch, taking

inch full to allow for smoothing off when glued up. When this is true, lay it on the bench, face up, and as the other pieces are planed lay them on the prepared piece, and if each piece does not lie perfectly flat, plane off the part where it touches, that being the highest part. The face edge of each piece can be done in a similar manner.

To test with the eye alone, hold up a piece of wood to your line of sight, then slowly turn up the further edge into your line of sight. notice which corner comes into view first—that will be the highest part. plane this side down, and the opposite corner of the diagonal. This is because if one corner curls up ⅛ inch, taking  inch off the opposite corner will make it equally true and the material will hold thicker that if ⅛ inch was planed off one corner. Having planed all the material on the face sides and edges, set the gauge for the width. as each piece is gauged, plane down to the line, taking care that the edge is exactly square before the line is reached; if two gauges are to hand, then the other gauge can be set to the thickness, and the planing of each piece; plan down to the gauge line on each edge, testing for level by placing the back edge of the try-square across the grain.

inch off the opposite corner will make it equally true and the material will hold thicker that if ⅛ inch was planed off one corner. Having planed all the material on the face sides and edges, set the gauge for the width. as each piece is gauged, plane down to the line, taking care that the edge is exactly square before the line is reached; if two gauges are to hand, then the other gauge can be set to the thickness, and the planing of each piece; plan down to the gauge line on each edge, testing for level by placing the back edge of the try-square across the grain.

>

>

Figure 6—General Sectional View of Boot Rack

>

>

Figure 7—Bed Rest

Setting out Bed Rest

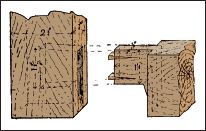

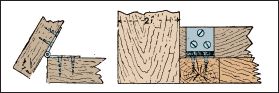

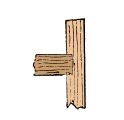

Now proceed to set out, remembering that in setting out work the face sides and face edges must always pair. For example, take the frame marked a (Figure 7). take one of the sides, 2 feet, 1 inch long, 2¾ inches by ⅞ inch, and, keeping the face side to the worker and the face edge uppermost, find the center of length; mark off 1 foot (half the height) on each side of this, and square lines across the edge. Then from these lines mark 2¾ inches inwards, being the width of rail at top and bottom of frame, and set out 1⅝ inches width of tenon. note that the tenon does not go through, only entering 1⅝ inches, which is quite sufficient, the joint being fastened by fox-wedging, which is here shown by Figure 8, but which has already been described. Thus, setting-out lines will only be needed on the face edge. Having set out one side of frame a, take the other side and place it beside the one set out, so that the two sides pair—that is, both face sides are outside and both face edges uppermost. Having squared lines across, set the mortise gauge to the chisel that is nearest one-third the thickness of material, adjusting the one teeth of the mortise gauge so that the chisel just rests comfortably between the points of the teeth, then set the gauge head so that the teeth are exactly in the center, trying first one side and then the other by pricking in the points of the teeth until the points coincide; then tighten up, and holding the stock of the gauge close to the face side, mark the mortises and continue gauge lines for the haunching, running the lines on to the end. next proceed to set out top and bottom rail of frame a (Figure 7). take one rail, find the center of its length, and set off half-width of frame less 2¾ inches (width of stile) on each side of center. Square all these lines, taking great care, for it is very important that these, being shoulder lines, should be marked true. Note that the try-square should always be applied to either a face side or face edge. The lines must next be squared to the other rail, it having been first noted in placing the rails together that they pair. Then with the mortise gauge mark the tenons all round the end from shoulder to shoulder.Now set out frame b (Figure 7). The material should be ½ inch longer than the finished lengths. Set out one side, starting ¼ inch from one end, and marking off 1 foot, 4 inches, thus leaving a little waste to be sawn off, and enabling a square end to be cut, which can also be shot just before the gluing together. From the first line set off 2 inches (Figure 9). On the face side of one of the 1-foot, 6-inches pieces, commencing ¾ inch from the rail end, set out successively six spaces of 1½ inches each; place the other side so that they pair. Square lines across the two pieces by means of the try-square; you should also square down each edge a little way, and with a marking gauge set to ¼ inch just make a mark on the line; mark the slope with a striking knife, using the edge of the try-square as a straight-edge; then set out the rails 9 ½ inches between shoulders, the tenons 1 inch longer, prepared for fox-wedging, as in frame a. Frame c (Figure 7) frame together the wedges are driven in,

side and proceeding to set it out as in the case of frame b. For dimensions of c, see Figure 10. note that one end of frame c is semicircular, and that at the center of this portion a  inch hole must be bored through each piece (see d d, Figure 10), so as to enable the coach-screw (the head of which is shown in Figure 11) to pass through for the purpose of hanging frame C to frame A, and allowing it to hinge easily. The other ends of the frame c must be cut at an angle of 45°, to obtain which it is not necessary to have a bevel, for if the thickness of the stuff is set off from the end and a line joined diagonally from this point to the top edge, the angle will be 45º. The cross-rail is set out similarly to frame b; it is 9 ½ inches between the shoulders, and the tenons are 1 inch longer. The setting-out is not complete.

inch hole must be bored through each piece (see d d, Figure 10), so as to enable the coach-screw (the head of which is shown in Figure 11) to pass through for the purpose of hanging frame C to frame A, and allowing it to hinge easily. The other ends of the frame c must be cut at an angle of 45°, to obtain which it is not necessary to have a bevel, for if the thickness of the stuff is set off from the end and a line joined diagonally from this point to the top edge, the angle will be 45º. The cross-rail is set out similarly to frame b; it is 9 ½ inches between the shoulders, and the tenons are 1 inch longer. The setting-out is not complete.

>

>

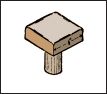

Figure 8—Joint at Corner of Bed Rest Frame

>

>

Figure 9—Horizontal Frame of Bed Rest

>

>

Figure 10—Bed Rest Strut

>

>

Figure 11—Head of Coach-screw

>

>

Figures 12 and 13—Side and Back Views of Corner of Bed Rest Frame

Making a Bed Rest

Begin the actual work by mortising the sides for frame a (Figure 7). The mortises are 1 ⅝ inches, and are widest at bottom for fox-wedging (see Figure 8); note also that the haunching (see Figure 8) tapers from nothing at the end to ⅜ inch at the tenon. great care must be used in mortising, because if the hole is not perpendicular it will cause the frames to twist, as the tenons will follow the holes, and so tend to take the stuff with it. After mortising, cut the tenons, ripping down first, then sawing the shoulders, after-wards marking width of tenons 1⅝ inches from face edges, and the haunched part of tenon ⅜ inch to nothing (see Figure 8). next make two cuts in each tenon about ¼ inch from the side and 1 inch long, and prepare and insert in each cut a small wedge of the same thickness as the tenon, ¾ inch long, and tapered  > inch to nothing, leaving the wedge projecting at the tenon end. on driving or cramping the frame together the wedges are driven in, and the end of each tenon is widened so that, with the glue, it is impossible to pull it out.

A hole should now be bored in the center of each face edge of stiles 9 inches from the bottom, the hole to be a little less than ¼-inch diameter for the coach-screw to fasten in tight when hanging. It is best done before gluing up, for when together it would be found awkward to bore except with a rather large gimlet. Smooth the edges of the frame so as to leave it clean, and the frame is ready for gluing. The frames b and c can be served in a similar manner. In gluing up the frames, be sure the glue is hot. Get the cramp or cramps together before you begin, and make sure the fox-wedges are right. When the frames are glued up, test them with a large square while applying the cramp; a slight movement of the cramp will correct any error.

In frame a, if the diagonals are the same length it is square. If an iron cramp is not to hand, a wooden one can be constructed by screwing cleats of wood on a piece of board, 2 inches or 3 inches wide, and allowing for a pair of wood between the frame and the hammer to avoid dents. When the glue is set, the frames can be smoothed over and the fixing together can begin. A pair of 1¼-inch back flaps and ¾-inch screws will be required to hinge frame b to a (see Figures 12 and 13); about half the knuckle of the hinge projects. The drawings will fully explain the position of the hinges.

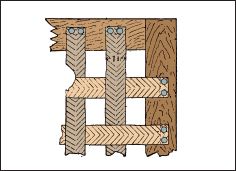

Two coach-screws, 3 inches by ¼ inch, are needed to hang frame c in position in frame a (see Figure 7); these can be turned in with a pair of pincers. The front should now be covered with webbing. The lengths are cut to the dimensions of frame A, about ¾ inch at each end being turned under and fastened by two ¾-inch clout nails at each end. The spaces between webs should be no more than the width of the webbing, as shown in Figure 14, where it will be noticed that the webbing is interlaced; 5 yd. Will suffice, though a little more would certainly make the whole a little stiffer. Finish with a light stain and a coat of varnish.

> inch to nothing, leaving the wedge projecting at the tenon end. on driving or cramping the frame together the wedges are driven in, and the end of each tenon is widened so that, with the glue, it is impossible to pull it out.

A hole should now be bored in the center of each face edge of stiles 9 inches from the bottom, the hole to be a little less than ¼-inch diameter for the coach-screw to fasten in tight when hanging. It is best done before gluing up, for when together it would be found awkward to bore except with a rather large gimlet. Smooth the edges of the frame so as to leave it clean, and the frame is ready for gluing. The frames b and c can be served in a similar manner. In gluing up the frames, be sure the glue is hot. Get the cramp or cramps together before you begin, and make sure the fox-wedges are right. When the frames are glued up, test them with a large square while applying the cramp; a slight movement of the cramp will correct any error.

In frame a, if the diagonals are the same length it is square. If an iron cramp is not to hand, a wooden one can be constructed by screwing cleats of wood on a piece of board, 2 inches or 3 inches wide, and allowing for a pair of wood between the frame and the hammer to avoid dents. When the glue is set, the frames can be smoothed over and the fixing together can begin. A pair of 1¼-inch back flaps and ¾-inch screws will be required to hinge frame b to a (see Figures 12 and 13); about half the knuckle of the hinge projects. The drawings will fully explain the position of the hinges.

Two coach-screws, 3 inches by ¼ inch, are needed to hang frame c in position in frame a (see Figure 7); these can be turned in with a pair of pincers. The front should now be covered with webbing. The lengths are cut to the dimensions of frame A, about ¾ inch at each end being turned under and fastened by two ¾-inch clout nails at each end. The spaces between webs should be no more than the width of the webbing, as shown in Figure 14, where it will be noticed that the webbing is interlaced; 5 yd. Will suffice, though a little more would certainly make the whole a little stiffer. Finish with a light stain and a coat of varnish.

>

>

Figure 14—Webbing on Bed Rest Frame

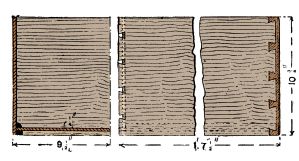

Linen Chest

Deal is the best material probably with which to make the linen chest illustrated by Figure 15. The elevations and inside view of the chest, which is 2 feet, 3 inches high, 4 feet long, and 1 foot 10 inches wide, are represented by Figures 15 to 17. The two uprights at the front corners are strips of 1 ½-inch material, 2 feet, 3 inches long by 4 inches wide. Figure 18 shows a front and Figure 19 a side view of that to the right hand. In both figures, a denotes where the upper 4 inches is cut away from the front to a depth of ½ inch to receive the end of the upper front rail; while b is a similar cut to take the end of the lower front rail. At c and d are other cuts for the end rails, all being ½ inch deep. A side view of the right-hand back upright is shown by Figure 24. Its length and breadth are those of its fellow at the front, but it is of ¾-inch board only; 1 ½-inch wood may be used, to make the job stronger, but one half will have to be sawn away as far as e to receive the ends of the back-boards. Below e, where the double thickness is needed to form the leg, a second piece of ¾-inches material should be screwed on. at f and g this upright is cut away ½ inch to receive the ends of the rails. The rails are all of ¾-inches board and 4 inches wide. The front ones are 4 feet long. The ends of these are cut away behind for a distance of 4 inches and to the depth of ¼ inch to fit the corresponding cuts in the uprights. To these they are fastened with round-headed screws, as shown. The stiles are also of ¾-inches material, 1 foot, 4 inches long and 3 inches wide, with the exception of the middle one of the front, which is 4 inches. Their tops and bottoms are halved in front for 1½ inches (See h h, Figure 21), corresponding cuts being made in the rails above and below to receive them. Their front edges, as well as those of the rails against the panels, are chamfered off. The paneling of the front is done with ½-inches board, cut to 1-foot, 7-inch lengths. These reach from the bottom of the lower rail to the middle of the upper one, above which is a longitudinal strip of the same board. This may be seen in Figure 17, which shows the inner side of the chest front. This arrangement will make a neater finish than could be gained by carrying the upright boards to the top. In Figure 17 the position of the stiles is shown by dotted lines, and the joints of the paneling should be set up so that it is covered by them.

>

>

>

>

Figures 15 and 16—Elevations of Linen Chest

>

>

Figure 17—Inside View of Chest Front

The panels which have been thus made are 1 foot, 1 inch by 7½ inches at sight; and, before leaving them, it will be well to finish them by adding the small ornamental span-drils, one of which is illustrated by Figure 22. These are of ¼-inch board, and the curved edge of each is worked to a hollow molding with the gorge. The length of the end rails is 1 foot, 9½ inches. The backs of their ends are cut away ¼ inch deep to fit the openings in the uprights—the front end for 1 inch and the back end for 1½ inches. The end of the chest (Figure 16) has a 3-inches stile, and is paneled like the front. The back is of ¾-inches boarding, the pieces being 4 feet long and (together) 1 foot, 9 inches wide. At the corners, openings will have to be cut, 4 inches by ½ inch, to admit the ends of the rails. The back-boards are screwed to the uprights, and should also be doweled together. For the bottom ½-inches matchboarding will be best, the pieces being 4 feet long and (together) 1 foot, 10 inches wide. Openings are cut at the corners, 4 inches by 1½ inches, to admit the uprights. These boards are screwed to the lower end rails, also to the lower front rail and to the back-board. For their further support, three ledgers (l l, l, Figure 17), 2 inches by 1½ inches, are placed beneath them and screwed to the back and front rail. The ledgers are placed in line with the middle of the stiles.

>

>

Figures 18 and 19—Front Corner Upright of Linen Chest

Figure 20—Back Corner Upright

Figure 21—Front Middle Stile

>

>

Figure 22—Spandril for Linen Chest Panels

Linen Chest Base-boards, and Lids

You may prefer to add to the chest the ornamental base-boards and moldings shown in Figures 15 and 16, running along the front and ends. These boards are ¾ inch thick and 4 inches wide. The front one is 4 feet, 1½ inches long; those at the ends are 1 foot, 10¾ inches long. They are mitered where they meet at the corners, and their lower edges are so shaped as to hide the ends of the ledgers. Their tops overlap the lower rails 1 inch, and they are screwed to the uprights. place a strip of molding on these, ¾ inches square, with its front edges simply rounded off. These strips, like the boards below, are mitered at the corners; the front strip is 4 feet, 3 inches long, the end strips 1 foot, 11½ inches. The lid is made of ¾-inch boards, 4 feet, 6 inches long and (together) 2 feet wide. oak color.

Figure 23—Oak Bedstead

>

>

Oak Bedstead

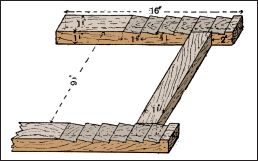

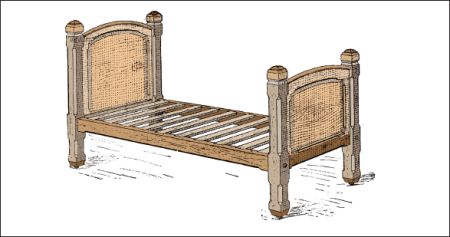

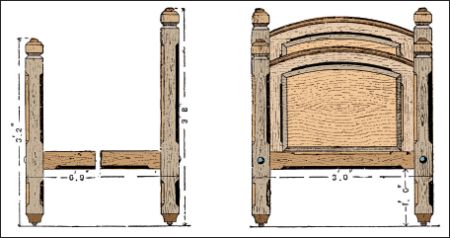

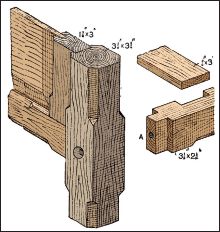

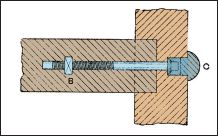

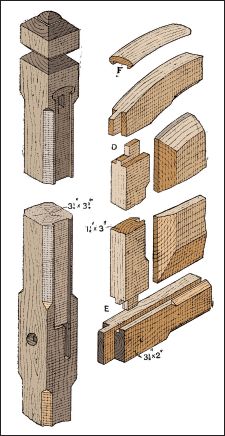

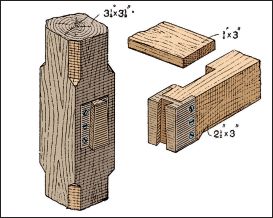

Figure 23 shows a beautiful oak bedstead. Leading dimensions are given on Figures 24 and 25, but these dimensions can be varied to your own requirements. Alternative methods of connecting the sides to the foot and head as shown, Figures 26 and 27 illustrating the old bed-screw method of connecting by means of nuts and bolts. In this case a hole A (Figure 26) is bored from the end of the tenon longitudinally in the rail; a mortise is made from the inside of the rail, and a nut B (Figure 27) is inserted, the bolt-head being hidden by the turned wooden button C. A method that is not being generally used is illustrated in Figure 29, the principle being that used on iron bedsteads. A dovetail piece with flanges is screwed to the post, the flanges being let in, and a corresponding dovetail socket piece is fitted and screwed to each end of the rails. The illustration shows the construction fully. The pieces of timber having been cut to their several sizes, each should be planed to finished dimensions. Then the posts and rails should be set out and the mortising and tenoning done. The forms of joints for connecting the stiles and rails of the head and foot are clearly shown at d and e (Figure 28), and the top rails of the head and foot are curved for a better appearance. The curved top rail has a stub-tenon at each end to enter corresponding mortises in each post. The stiles and rails are ploughed to receive a panel, which is shown in Figures 26 and 28, with splayed margins. Cut an oval-sectioned piece f (Figure 28) to proper sweep and sink out the under-side to fit on to the curved rail, the posts being recessed so as to receive the ends of the capping. After you fit the joints properly, the posts, rails, and stiles need to be stop-chamfered and the tops and bottoms of the posts worked to shape. The joints of the head and foot framings can then be glued together, and when the glue is dry the stiles and rails can be smoothed off. Then the top and bottom rails and stiles are ready to be fit into the posts, which can also be glued together. Four castors should be fixed on the bottom of each post to complete the bedstead.

>

>

Figures 24 and 25—Side and End Elevations of Oak Bedstead

>

>

Figure 26—Part of Bedstead Post and Panel

>

>

Figure 27—Bed-screw Joint

>

>

28—Jointing Bedstead Framework

>

>

Figures 29—Metal Dovetail for Bed Rails

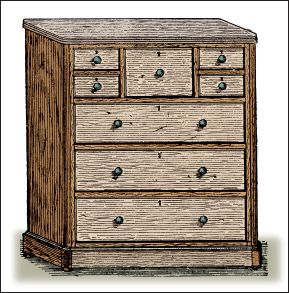

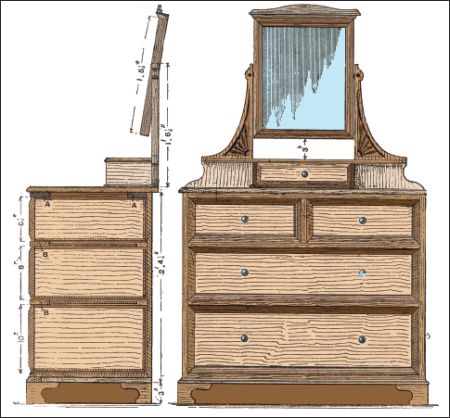

Framework of Chest of Drawers

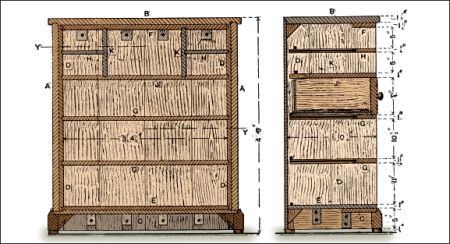

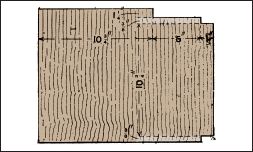

The chest of drawers illustrated by Figure 30 is 4 feet wide, 4 feet, 6 inches high, and 2 feet deep outside. The two sides a, 1¼ inches thick, 1 foot, 10¾ inches wide, and 3 feet, 11 ⅛ inches high, support the top B, which is 1½ inches thick, 2 feet wide, and 4 feet long, the grooves being ½ inch deep. Two inner pieces d, 1 foot, 10 ¼ inches wide and 3 feet, 5 ¼ inches long, rest on piece C (see Figures 31 and 32). The top piece f and the two lower partitions G are 5 ½ inches wide and 3 feet, 5 ¼ inches long, the shorter partitions H being 5 ½ inches wide and 10½ inches long. The partition J is 1 foot, 4 ¾ inches wide and 3 feet, 5 ¼ inches long, and the vertical partitions K are 1 foot, ¾ inch deep by 1 foot, 4 ¾ inches long, cut to the shape shown by Figure 33, to rest in ⅜-inch grooves in the pieces B, F, and J. Cut all the partitions, including F and bottom E, as shown in Figure 34, and rest, as shown in Figure 31, in ⅜-inch grooves in the partitions D and K, are put in at each side of the drawer spaces for the drawers to run on (see Figures 32 and 35). A ¼-inch boarding separates the drawers, as seen by the black lines in Figure 32. The plinth is 2½ inches thick and 5 inches deep, and should be cut out to receive the bottom and sides, as shown. The whole is raised slightly from the ground by means of buttons, 1 inch thick, screwed to the plinth. The framework should be strengthened where necessary by triangular blocks.

>

>

Figure 30—Chest of Drawers

>

>

Figures 31 and 32—Longitudinal and Cross Sections of Chest of Drawers

>

>

Figures 33—Vertical Partition for Chest of Drawers

>

>

Figures 34—Horizontal Partition for Chest of Drawers

>

>

Figure 35—Horizontal Section of Chest of Drawers

>

>

Figures 36 and 37—Drawer Details

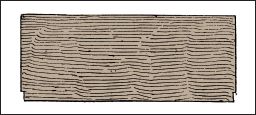

The Drawers

Fit the drawers together as shown in Figures 36 and 37, but the bottoms of the long drawers are strengthened with two bat-tens. Make the drawer fronts 1 inch thick, the sides ⅜ inch thick, and the bottom and back ¼ inch thick; the smaller drawers can be made of thinner material. The clear spaces for the drawers are as follows:

1. Bottom drawer, 11 inches deep, 3 feet, 4 ½ inches wide, by 1 foot, 9¾ inches.

>

>

Figures 38 and 39—Section and Elevation of Chest of Drawers and Dressing Glass

2. Bonnet drawer, 1 foot, 10¾ inches deep, 1 foot, 7 inches wide, by 1 foot, 7½ inches;

3. Four short drawers, 5 inches deep, 9¾ inches wide by 1 foot, 7½ inches

Drawer stops should be fixed on the runners. You can make the handles of either wood or brass. The back should be ½ inch thick, and is strengthened vertically by two battens, and rests in a groove in the top B (see Figure 32). You can make the bottom long drawer deeper than the rest, and, instead of the four small drawers and center bonnet drawer, two short drawers can be put in if you desire. Figure 35 is a section on y y (Figure 31).

Chest of Drawers and Dressing Glass

Figure 38 shows the front elevation of a chest of drawers, with a dressing glass and jewel drawer at the top. This chest contains four drawers, one 10 inches deep, one 8 inches deep, and two short drawers 6½ inches deep. The chest measures 3 feet over the gables. Plane and square up the two gables 2 feet, 3½ inches in length by 1 foot, 6 inches in width by ⅞ inch thick. The back edges have to be rebated to receive the back, which consists of ⅝-inch matchboarding. Make the bottom from pine ¾ inch thick and lap-dovetail it to the gable ends. Two pieces a (Figure 39), 3 inches wide by ¾ inch thick, are fixed to the gable ends in the same way as the bottom, the object of one being to allow the back to overlap. The front piece may be of pine, with a thin slip of walnut glued to the edge. The two fore-edges B are also fixed to the gables by grooving the latter to form a dovetail (Figure 40). The fore-edges are slid in from the back. Stop the grooves at the front, and rebate the fore-edges to bring them flush there.

>

>

Figure 40—Dovetail Joint in Gable

Bedroom Bookshelves

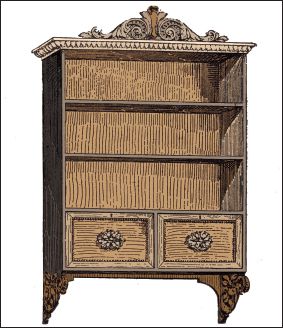

Figure 41 shows the front view and Figure 42 the side elevation of a bookshelf which may stand on a table or be hung on the wall. The drawers are of the usual pattern and make. a wooden back would strengthen the bookshelf, but for ordinary use the ornamental top a and the piece of backing b behind the drawers is enough. Figure 43 shows a larger and highly ornamented set of small shelves with lockers beneath. The shelves and sides can be made of ⅝-inch deal, the outer frame being 3 feet, 4 inches by 2 feet, 4 inches by 6 inches deep, and the pieces may be screwed together for simplicity of construction. The back and top should be of well-seasoned ½-inch boards, glued and clamped up together. The outlines of the ornament at the top (Figure 44) and at the lower ends of the side pieces (Figure 45) should be roughly shaped out, and the ornament applied in gesso. The whole of the ornament may be applied this way or it can be carved. The doors of the lockers should be paneled and hinged at the bottom to open downwards. add a coat of white enamel to finish the work.

>

>

Figures 41 and 42

>

>

Figure 43—Ornamented Bedroom Bookshelf

>

>

Figures 44 and 45—Gesso Ornaments for Bookshelf

>

>