CHAPTER SIX

THE ICONIC BRITISH SPORTS CAR

E-Type

The E-Type has become the benchmark by which all other sports cars in the world have been measured. As Enzo Ferrari once said, “It is the best looking car in the world.”

Nothing has approached the E-Type in terms of purity of style or world appreciation. Its overall package of performance, practicality, comfort, and good looks plus value for money when new, and investment potential in recent years, shows that it has stood the test of time, a true icon.

1961: A New GT is Born

Jaguar’s E-Type was so revolutionary in many ways. At the heart of its success was William Lyons’s ability to know when something was right. At its launch at the Geneva Motor Show in March 1961, it left the world speechless for a moment, then unable to keep quiet, creating more rapture than even the XK120 had done in 1948. Although the E-Type retained the XK engine and gearbox, virtually everything else was new, a lot of which had come about through racing experience.

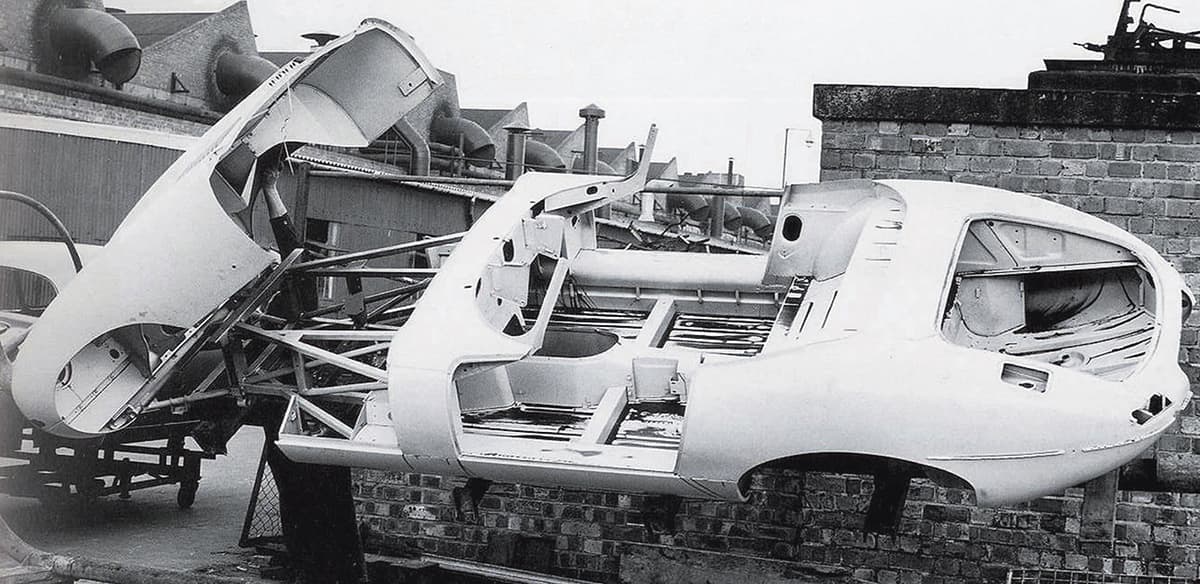

Describing the E-Type, one must start with the ravishing and aerodynamic body, a monocoque of advanced design. The bonnet was made up of a huge center section, flanked by separate wings. The front section led down to an aerodynamic “nose” with a mouth instead of a radiator grille. The bonnet hinged from the front, lifting in one piece to give unobstructed access to the engine and front suspension. A framework of Reynolds 541 square tubing bolted to the bulkhead extended forward to carry the engine and front suspension, with a further frame to carry the radiator and bonnet anchorage/hinging.

A curved single-piece, quite shallow windscreen required no fewer than three windscreen wipers to clear it without rising over the top edge.

The whole of the passenger area from the bulkhead back to the rear quarters was made up of welded steel panels. Large hollow sills started just behind the front wheels, continued under the bulkhead and doors to the rear wing area to mate with a transverse hollow section before the rear suspension. In the floor the propshaft tunnel provided extra strength with a further transverse member running across under the seats. Two more longitudinal members ran under the floor from the bulkhead to the rear crossmember. The boot floor, with its two longitudinal box sections either side, joined up with that rear crossmember, all of which took the rear suspension subframe. On to all this the exterior curvaceous paneling was welded to form an exceptionally strong structure for both roadster and fixed head coupe styles.

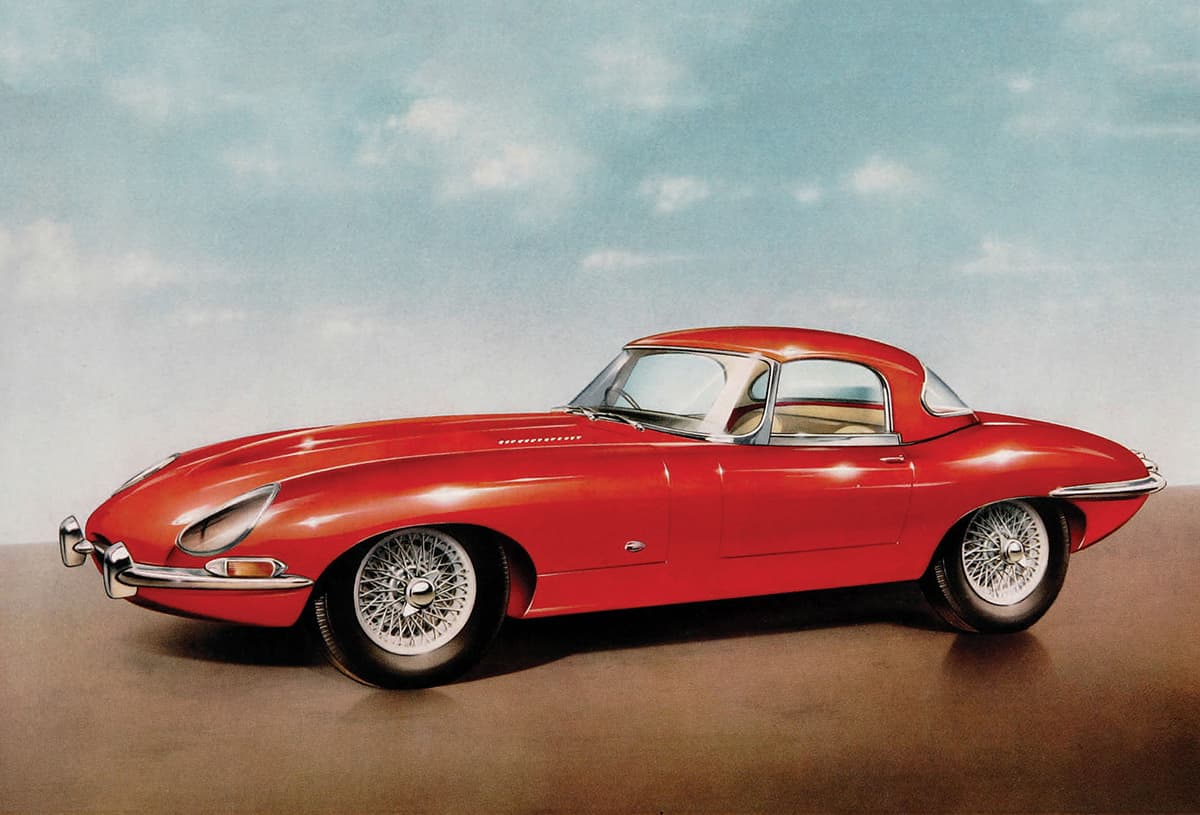

A well-known image of the original E-Type taken from the launch brochure for the model—an artist’s interpretation adapted from a real car photographed in the studio. This roadster displays the fiberglass hardtop that could be ordered from the factory and painted to body color.

Stylistically different from any previous production Jaguar, it followed the basic lines of the racing D-Types. The exceptionally long bonnet housed flared-in headlights with glass covers and chromed curved surrounds with side lights/indicator units set underneath, wrapping around the wing corners. The mouth in the nose was fitted with a horizontal chromed splitter bar with a center badge. Two chromed quarter-bumper bars curved around with the bonnet line under the lights, with twin overriders at the center, meeting the mouth of the bonnet. For most markets, the registration plate was by way of a sticker attached to the leading edge of the bonnet; where necessary a separate mounting plate under a bumper was used for some overseas markets. A bulge ran the center length of the bonnet to accommodate the camshaft covers of the XK engine. This was flanked by bonnet louvres either side to aid engine-bay cooling. A further vent exited from the rear of the bonnet’s power bulge.

From the sideview, the extensive bonnet and integral wings appeared to form 50 percent of the entire length of the car. For the fixed head, doors still incorporated Jaguar’s traditional chromed surrounds to the glass, and there was a large rear side window area formed to follow the line of the sloping roof and the upswing of the body over the rear wings.

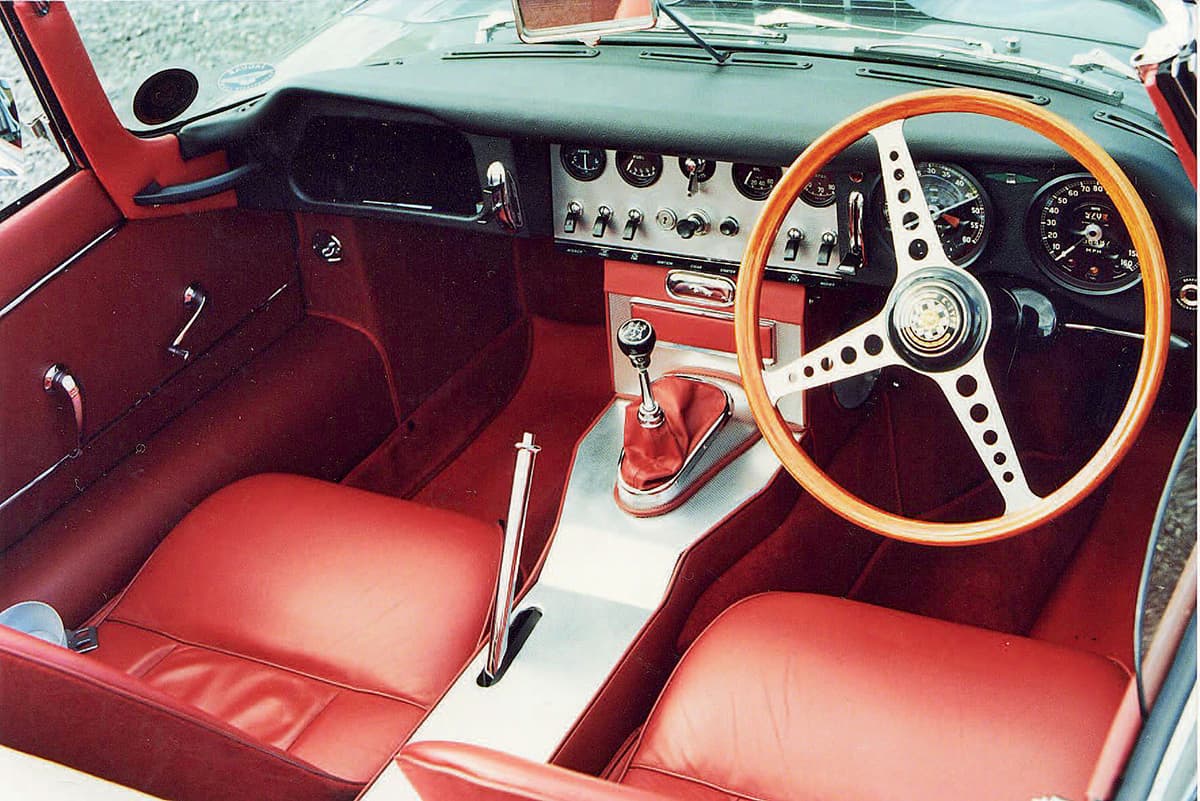

The famous E-Type three-spoke wood-rim steering wheel, only ever seen on the E-Type, formed a signature part of the car, even taking pride of place on the sales brochure.

At the rear, the fixed head sloping roof ran down to meet the rear light units, again curving around the sides of the wings above rear quarter bumps and overriders. The bumpers extended around the sides to meet the rear wheel arches. Registration plates were mounted centrally, set into the bodywork, and the large under-body valance extended up to meet it, under which the twin exhaust pipes were mounted together in the center.

Both fixed head and roadster were two-seaters, the only styling differences being that for the latter the door glass was frameless and there was a chromed strip at the top of the doors running the width. The roadster also had a flat boot area with a rear hinged lid (the lock released from a pull lever inside the car behind the driver’s seat). The boot interior was limited in space but was Hardura covered and housed underneath a spare wheel well, flanked by the fuel tank. A single-piece hood, attached to the rear, could be easily erected or taken down in one operation from the driver’s seat. When raised, it secured to the windscreen on each side. Jaguar supplied a tonneau cover for the hood when down providing a cleaner line to the car.

Externally, nothing was carried over from the outgoing XK150. The E-Type was significantly lighter, the fixed head 24 hundredweight compared to 29, a couple of inches shorter and 7 inches lower.

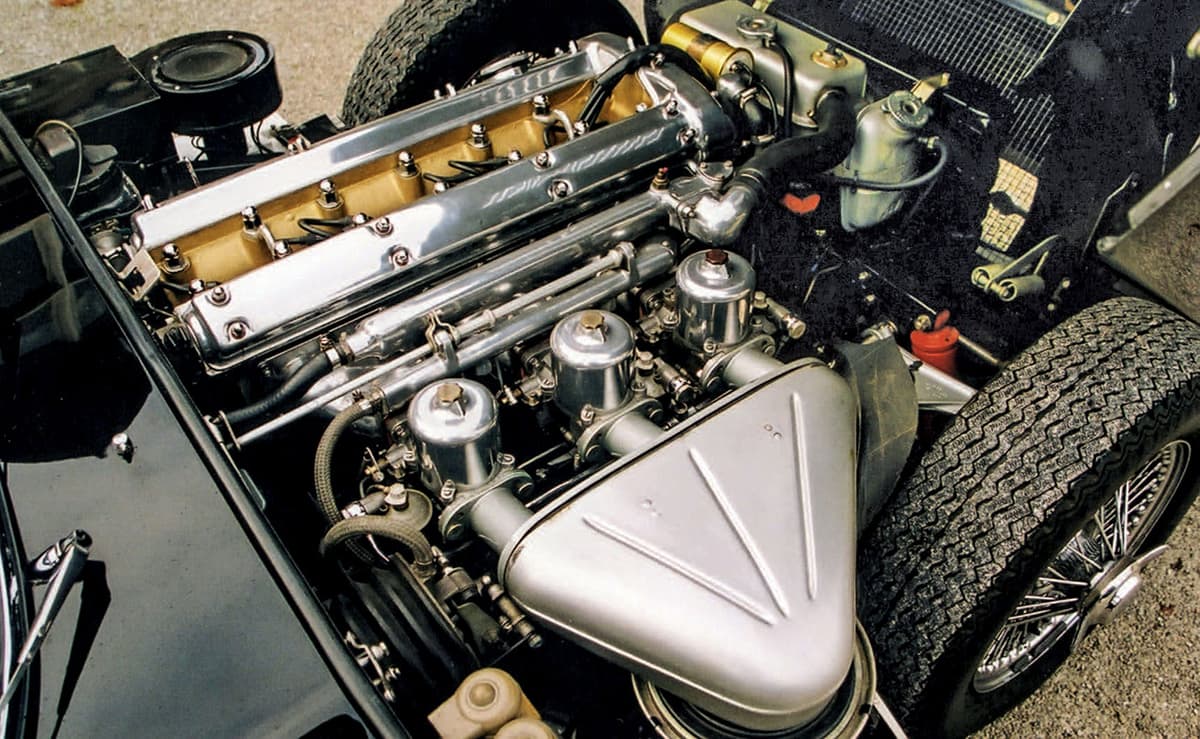

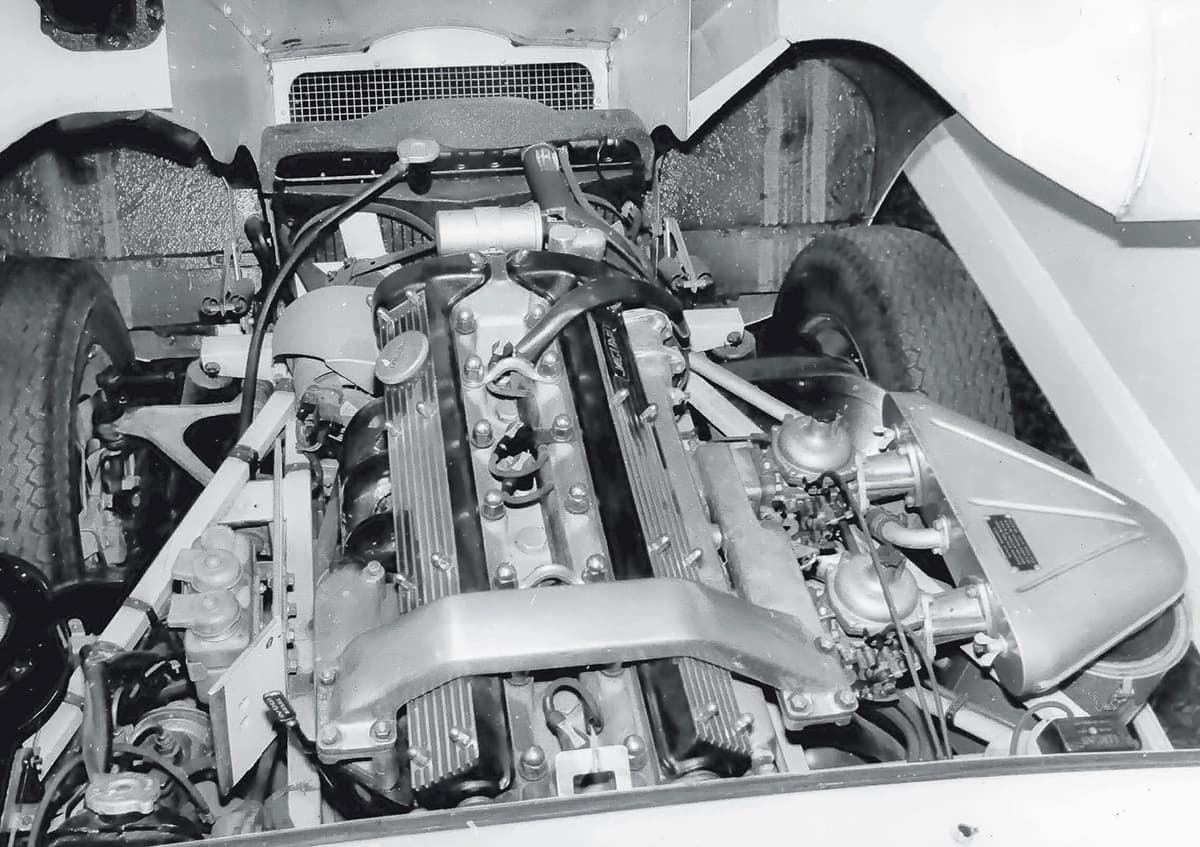

With everything new externally, the E-Type was a 50/50 mix of old and new under the skin. It retained the XK engine, now in 3.8-liter S form, complete with triple SU carburetors. A new drum air cleaner arrangement was fitted. Cooling was provided by the front-mounted radiator, but due to height restrictions, there was a separate header tank and the engine-mounted cooling fan was replaced by a thermostatically controlled electric fan. The E-Type also carried over the four-speed Moss gearbox from the XK. What was new, however, was an incredibly sophisticated independent rear suspension.

The whole of the rear suspension, plus the braking system and differential, were fitted to a detachable steel cage frame attached to the body by four rubber mountings. The design incorporated two quite small coil spring/damper units on each side, mounted on projecting lugs on lower suspension links, located at the top on the subframe. Large diameter half-shafts extended from the differential to the wheel hubs in light alloy castings, forming the top link of the system. These castings continued down to pivots on which were attached the lower suspension links, with forked ends, one attached to the wheel hub casting and the other to mounts at the bottom of the cage. A Salisbury rear axle was still used and solidly fixed to the subframe. Only two suspension members were not directly part of the cage frame—”U” section trailing radius arms, which located the suspension longitudinally and were fixed to the body with rubber mountings.

For the rear braking system, Jaguar fitted 10-inch inboard discs mounted directly on the output shafts of the differential, with special silicon rubber oil seals to guard against the extreme heat that could be generated in that area. There was a single caliper per disc, operated by two pistons. The handbrake operated on an extra caliper on one rear disc.

The E-Type’s extremely complex and well-executed monocoque was a major move forward for Jaguar.

The whole independent suspension subframe was a masterpiece of engineering and could be easily detached from the car for major work. The design first seen in the E-Type went on to appear in future Jaguar models for many years.

Returning to the braking system, conventional outboard discs of 11-inch diameter were fitted at the front. The brake pedal was connected by a balance bar to two master cylinders, each with its own fluid reservoir, and also to the brake booster bellows unit (servo). This was an unusual system designed by the Kelsey-Hayes company in America and adapted and made in the UK by Dunlop; its first car installation was in the E-Type. Depressing the brake pedal activated the master cylinders, simultaneously closing an air valve and opening a vacuum valve in the servo, vacuum being taken from the engine’s induction system. The unusual bellows then started to contract, resulting in a load applying through the balance bar to the master cylinders.

The E-Type was only available with 72-spoke wire wheels of a smaller 15-inch diameter, fitted with Dunlop tires.

Internally, the E-Type was again a mix of old and new. The dashboard and instrument layout first seen in the Mark 2 saloon was continued, and like the XK150 before it, there was no wood to be seen anywhere. Instead the E-Type relied primarily on black finishes for the top rail and surround, and black crackle finished metal for the dashboard area, except for the center section containing the auxiliary gauges and switchgear, which was finished in a figured silver alloy. This center panel was flanked by two slider controls, one on the passenger side for the heater control, the other on the driver’s side controlling the manually operated choke. On the passenger side, there was an open glove box and a grab handle built into the top rail.

A center console ran down vertically from the dashboard and horizontally between the front seats featuring the gear lever, radio controls, and ashtray. The sides were trimmed to match the rest of the car and the top in figured silver alloy. There was a “fly-off” handbrake fitted to the passenger side (right-hand drive cars) of the console.

A new style of steering wheel, only ever used on the E-Type, became a styling feature, even on the front cover of the original brochure. Held by three spokes, it was a drilled design in alloy with a wood rim and center horn boss featuring a checkered flag. The steering column was adjustable for reach and contained the usual stalk to control the flashing indicators and headlight flashers.

New style bucket seats were fitted, and the car was trimmed to the usual Jaguar standard with quality carpeting. The fixed head coupe headlining was now foam backed.

The launch of the E-Type at Geneva was a hasty affair, but the panic was well worth the end result as the orders rolled in and Jaguar was in the embarrassing position of being unable to meet the incredible demand. Not only was the E-Type so special in terms of its looks and performance, but at an original cost of just over £2,000 including UK taxes, there was nothing in the world that could touch it for value for money. When the road testers got hold of the car, they sang its praises as not just a highly credible and fast sports car that handled so well, but entirely practical for everyday use—quite happy sauntering along in dense traffic one minute, and the next accelerating from 0 to 60 miles per hour in under 7 seconds without hesitation.

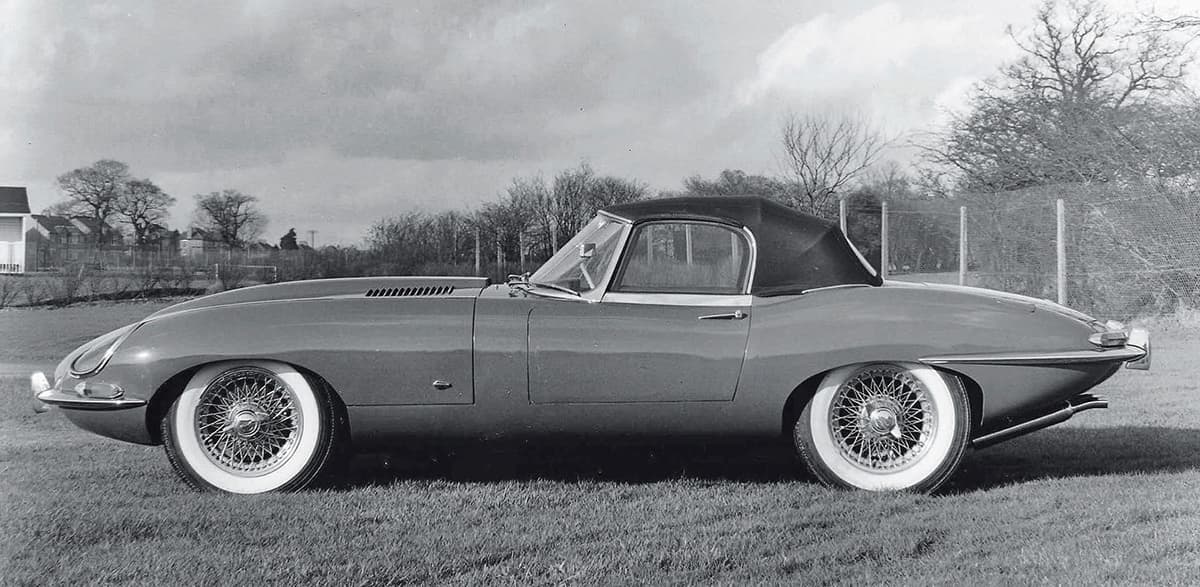

The original 3.8-liter roadster with the hood erect and displaying whitewall tires and wire wheels, common on cars destined for the US. The early 3.8-liter cars had external bonnet locks on each side that required a T-key to unlock, shown here covered with chromed escutcheons.

An early 3.8-liter fixed head coupe, arguably the prettiest of the two styles with its swept back roofline.

One could say that the E-Type was one of the first “hatchbacks” with this very useful luggage area in the fixed head and the wide-opening rear door. The spare wheel, tools, and fuel tank are underneath the boot floor and are easily accessible from a lift-up panel.

In contrast, luggage accommodation in the roadster was minimal and once you included space for the hood tonneau cover (seen here), you really needed an after-market luggage rack on the boot lid!

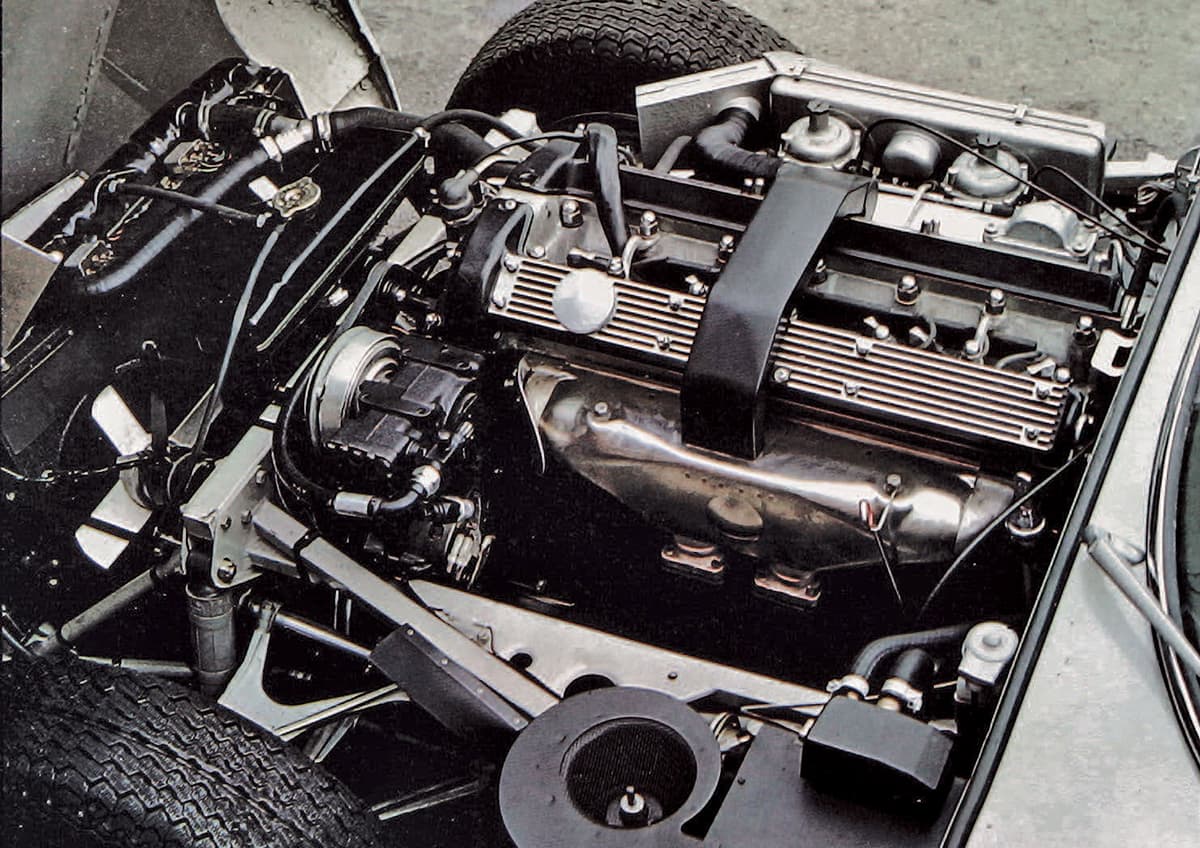

The legendary XK six-cylinder in triple carburetor E-Type form. The forward hinged bonnet provided excellent access for maintenance. At the bottom left, near the firewall, can be seen the bellows unit for the Kelsey-Hayes brake servo.

1962–1963: Minor Improvements

In 1962, driver/passenger accommodation was improved. The footwells were modified to provide extra space, the rear bulkhead was altered to provide greater seat travel, and the foam seat fillings were thicker to give greater support, plus the position of the pedals was altered.

The only changes mechanically involved the fitting of shields over the rear universal joints for protection, increased thickness of the brake discs and new brake pad material.

From a starting sales figure of 2,182 in 1961, 6,266 E-Types came off the assembly line in 1962 and 4,065 in 1963.

1964–1965: More Flexibility and a Tidy-up

Some major mechanical upgrades took place towards the end of 1964 that affected not only the E-Type but the big brother Mark X as well. The most significant was a 4,235cc version of the XK engine. The increase in capacity was achieved with a new engine block, the two middle cylinders moved closer together and one and six moved further out and the bore increased by 5.07 millimeters. The block remained of the same dimensions.

The 3.8-liter “cockpit” area with instrumentation similar to the saloons but a distinct lack of the wood veneer for which Jaguar was well known. Black and alloy was considered sportier. This later 3.8 shows one of the chromed internal bonnet locks forward of the front door area. Although a very well-equipped car, a radio was still extra in those days!

Very early on, the E-Type was campaigned in racing. Even later, world champions like Jackie Stewart cut their teeth racing them, in his case, “borrowing” a new E-Type from his parents’ showroom to compete!

The 4.2-liter E-Type Series 1 fixed head was virtually indistinguishable externally from the early model.

The interior of the 4.2-liter E-Type with larger, more comfortable seating, black finish replacing alloy, and even a center armrest/glove box on the console.

There was also a new crankshaft with thicker webs for the extra torque and a new vibration damper. The water jacket was altered to improve flow of coolant. New pistons with chromed-plated tops and oil-control rings improved oil consumption over the 3.8-liter engine. The induction manifold was cast as a single piece and the exhaust system was also revised. The main advantage of the new engine was to increase the torque figure by 43 pounds-feet, which improved midrange flexibility.

There were other, more minor changes in the engine bay. An alternator replaced the dynamo for better charging and the radiator was made of copper instead of alloy.

With the 4.2-liter engine came a new four-speed all-synchromesh gearbox with inertia-lock baulk rings preventing the engagement of a gear until the synchromesh was complete. This was a significant improvement noted by owners as it allowed smoother changes, with less noise and removed the long “throw” from first to second gear of the old Moss gearbox.

The Kelsey-Hayes brake booster system was abandoned in favor of a conventional Lockheed brake servo, and the front discs received heat shields. With better sealing, the steering and front suspension didn’t need so much maintenance, and mileage suggestions increased from 2,500 to a massive 12,000 miles.

Externally, the new E-Type was only identifiable by the “4.2” badging at the rear and for the keen-eyed, sealed beam headlights were now fitted.

Inside there were more changes. Firstly, the bucket seating had gone (often criticized for not being that comfortable), replaced with more conventional, flatter seats, also now adjustable for rake. The perhaps rather “garish” silver alloy finish on the center dash panel and transmission tunnel was replaced by black vinyl and leather. There was now also an armrest/glove box on the console between the seats. For the roadster model, the boot lid could be locked.

There was only a slight increase in the price of the 4.2-liter car over the equivalent 3.8-liter model. The new car was 1 hundredweight heavier and the performance was virtually the same. The 3.8-liter model did continue in production throughout 1964 until the introduction of the 4.2, the total number of the earlier models being 15,481.

During 1965, little changed except for the availability of radial ply tires, and water sealing in various areas was improved. There was also a new windscreen washer system.

1966: Getting a Stretch

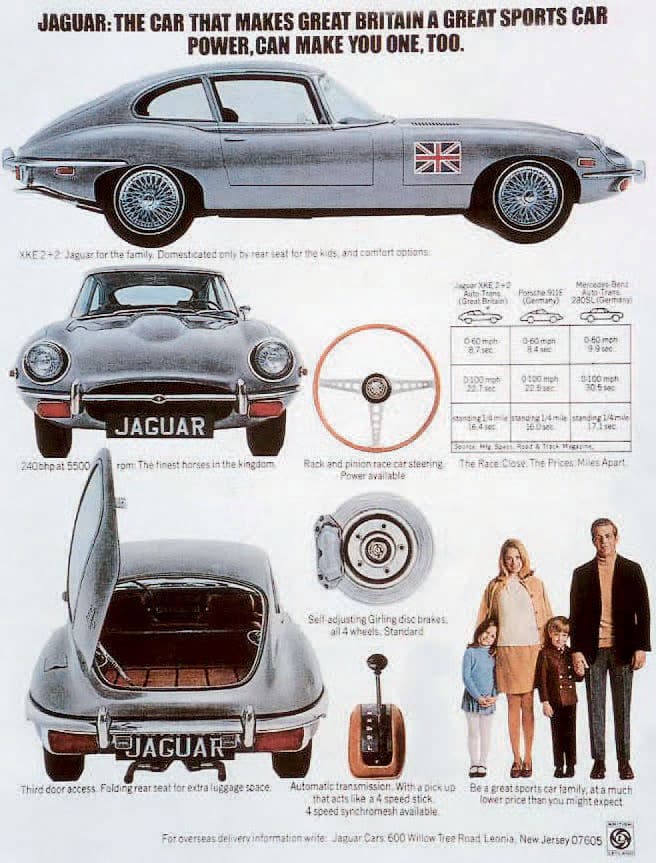

March 1966 brought a third variant on the E-Type theme. Alongside the fixed head there was now a 2+2 model. This had the advantage of widening the customer appeal for the E-Type and allowed the fitment of an automatic transmission for the first time.

The change was achieved with surgery to the bodyshell, adding 9 inches to the wheelbase and 2 inches to the overall height. The extra length in the body had all been achieved in the mid area. The doors were now 81/2 inches wider with a larger glass area, chromed surround, and even a horizontal chrome strip across the top finishing at a spear on the rear wing. To achieve the extra height in the roof, the windscreen was more severely raked. The overall effect was very well executed, and the car still didn’t look out of proportion.

A new third model introduced in 1966, the 2+2. The “stretched” body and raised height have not compromised the style of the car. This is an early preproduction example without the chromed stripe above the door, below the window level that appeared on all production 2+2s.

This illustrates the differences between the Series 1 fixed head and 2+2 models.

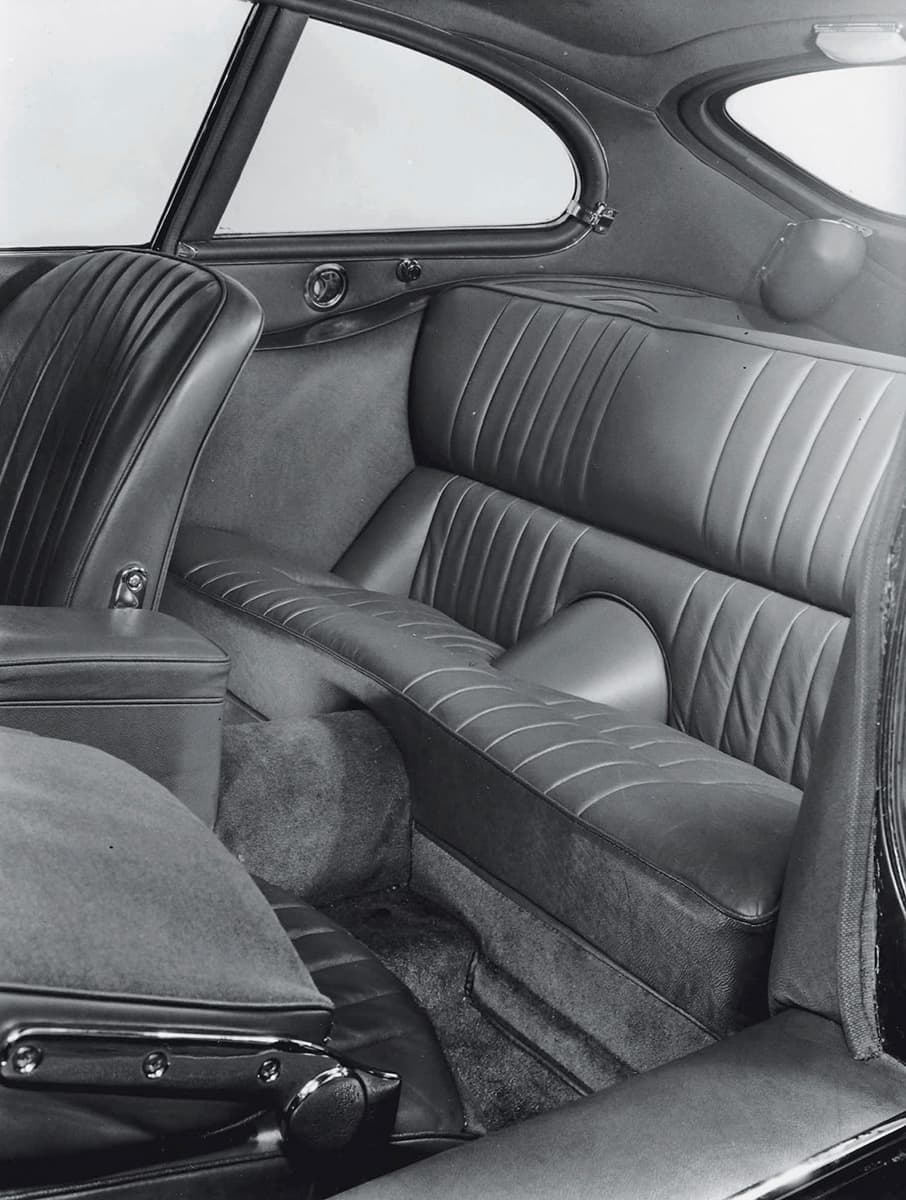

Changes internally amounted to the fitting of a rear bench-type seat upholstered to match the front. Legroom and width were limited so these were very much “occasional” seats but served a useful purpose for those with a growing family or when necessary to carry adults. The seat back could fold down to allow for extra luggage in the rear. A benefit for the front seat occupants was that the seats could now travel further backwards when no one was sitting in the rear. The 2+2 model also featured a full-width parcel shelf below the dashboard and there was a larger glove box with a lockable lid. The heater system now had variable direction outlets and the doors had burst-proof catches.

The new version weighed in at an extra 2 hundredweight over the fixed-head. Minor mechanical changes were necessary, which included revised spring and damper rates for the extra weight. Internal cooling was improved with better heat shielding underneath the car.

For the first time, an automatic transmission was available on an E-Type due to the extra length afforded by a 2+2 bodyshell. The control occupied the center console just like a conventional gear lever, with both D1 and D2 operational modes. The 2+2 of course was still available with the manual gearbox as well.

The 2+2 model was well received in the States as it was the first E-Type to be equipped with automatic transmission.

The occasional rear seating made the E-Type more appealing to families and those seats could be folded down to provide extra luggage space.

1967: Halfway House

By the end of 1966, over 13,000 E-Types had been sold worldwide and a facelifted car was already under development at Jaguar. There would be a brief period during 1967 when some design features of the E-Type would change unannounced before the new model would be seen the following year. Effectively these were still 4.2-liter (Series 1) models in all three body types, but afterwards became unofficially known as Series 11/2.

Because of the need to improve the rather dim lighting of the E-Type, this model now displayed open headlights (without the covers). This meant a new chromed surround and finisher. Other identifiable changes included door-mounted rearview mirrors and non-eared spinners retaining the wire wheels. This was a move brought about by overseas legislation.

Interior trim changes came about in dribs and drabs. Some of these interim cars featured new rocker switches on the center dashboard panel replacing the old toggle switches, and with flush fitting choke and heater controls. The cigarette lighter was repositioned, and the indicator stalk activated the horn as well. Some cars featured different door panels and seats with adjustable rake and adaptable to take head restraints.

Some of these “Series 11/2” models also featured engine modifications to suit the North American market.

To comply with new emissions regulations, considerable changes were made to the engine. The most economic and cost-effective way to modify the exiting 4.2-liter engine was by fitting twin Zenith-Stromberg 175CD2 carburetors. There was also a new inlet manifolding arrangement crossing over the top of the engine and connected to the exhaust manifold. The way the system worked was with a small-diameter choke tube. At low engine speeds, the mixture was ducted through the new manifolding, heated by the exhaust, and then fed back to the inlet side.

An interim car that later became unofficially known as the Series 11/2 model. Specification varied according to what was on the production line at the time, but all featured the open headlights with new surrounds, but retained the above bumper side/indicator lighting.

E-Type engine equipped to meet US federal emissions regulations with the cross-over trunking and two Stromberg carburetors.

1968–1970: Enter the Series 2

Jaguar’s E-Type Series 2 was announced at the October 1968 British Motor Show and there were lots of changes, some of which have been identified previously with the interim Series 11/2 models.

Stylistically the Series 2 featured a new bonnet with a much larger (by 68 percent) mouth area to eliminate cooling problems in hotter climates. This necessitated a new chromed horizontal cross bar in the mouth. The open headlights mentioned earlier were a part of the new package, but they were fitted 2 inches further forward to minimize scatter, so the surrounds and fillet above the lights was different again to those seen on the Series 11/2. New lighting treatment continued with much larger side light/indicator lens units set below the bumper bar on a revised bonnet valance, with side repeaters for most markets fitted to the side of the front and rear wings. The bumper bars looked, but weren’t, the same and the bumper heights were changed to suit new legislation.

At the rear, the bumper bar continued to a center section with the registration plate now fitted below on a satin alloy finished panel with reversing lights either side. The rear lighting units also formed part of this under-bumper panel of a new, larger design. To accommodate a square type of registration plate, the exhaust pipes were more widely separated.

From the sideview, nothing had changed except for the 2+2, which got a new wraparound windscreen with an increased rake to the vertical; the bottom of the screen came further out taking up much of the space previously occupied for the scuttle area, and there were now only two wipers fitted to this model, with a stronger motor. The screen change enhanced the look of the 2+2. A driver’s door rearview mirror became a standard feature. Although still available with wire wheels, for the first time E-Types were offered with 15-inch steel wheels as well, either in silver finish or chrome plated, fitted with standard Jaguar hubcaps but with black centers.

The Series 2 model with larger air intake mouth, open headlights with different surrounds from those on the Series 1/2, and larger side/indicator lightings below bumper level.

Series 2 cockpit area with a nod to safety with extra padding, recessed door handles, and rocker switchgear.

US promotional material for the Series 2 2+2 model showing off the extra space, automatic transmission, and favorable performance compared to the competition.

Rear styling of the Series 2 with full-width bumper bar, under-bumper lighting attached to an alloy finished panel, and revised exhaust pipe exit. This is a 2+2 model.

US federal regulations dictated changes to the interior. The rocker switches replaced toggles, there was a combined ignition and starter switch, and flush-fitted choke and heater controls. The door trims were new, simpler in design in a recessed area to accommodate the new style flush-mounted door handles, and there were rounded knobs to the window winders and better anti-burst door locks.

New seating with a positive locking system so they wouldn’t tip forward in an accident were fitted along with new seat belts.

The braking system now incorporated three pistons at the front, two at the rear to meet the new US requirements for safety. The engine followed the practice first seen on the Series 11/2, standardized for all US-destined cars, while the UK and other markets still received the triple carburetor arrangement. All engines by now got the ribbed cam covers.

For 1970, the US emissions equipment was amended, whereby the crossover manifolding was replaced by a water-heated chamber. On part throttle, the mixture was warmed in the chamber and then fed to the inlet manifold. At higher speed, a bypass allowed the full flow of the mixture directly into the manifold. Another addition for the US market was a charcoal canister to absorb gasoline vapor.

To simplify manufacture later in the year, the twin Stromberg arrangement and manifolding was standardized for all markets, so no further triple SU carbureted cars would be made.

Production of Series 2 models ran out towards the end of 1970 with development finished on its replacement model, the Series 3. A total of 18,848 cars were produced with the roadster being the most popular, followed by the 2+2.

A few E-Types, primarily for the US market, were fitted with an air conditioning system with the controls and outlets below the center dash area.

Series 2 engine bay with revised emissions equipment and ribbed cam covers.

1971: Series 3—The Final Fling

By this time, the Jaguar E-Type was losing out, particularly in the States where homegrown V-8s were the order of the day and could deliver huge performance. Jaguar could no longer address this with changes to the XK six-cylinder engine. Jaguar had previous experience with a V-12 engine, fitted to the XJ13 sports/prototype, and although it would have been much simpler and less costly to produce a V-8, Sir William Lyons was concerned about the refinement and wanted to create a major impact on the market. A road-going V-12 would give Jaguar a step-up from the numerous American V-8s and even out-shine European machinery from the likes of Ferrari and others.

The V-12 engine had a single overhead camshaft on each bank of six cylinders operating in-line valves working in a flat cylinder head, with the combustion chamber formed in the recessed piston crowns. The new engine had a capacity of 5,343cc with a bore and stroke of 90×70 millimeters. The crankcase was carried well below the level of the seven-bearing crankshaft. Wet liners were used in the block with upper flanges machined so that they left a narrow water passage between adjacent liners in the hottest part of the cylinders.

The Series 3 roadster with its longer (2+2) wheelbase, flared wheel arches and revised frontal treatment with a larger air intake and, for the first time on an E-Type, a grille.

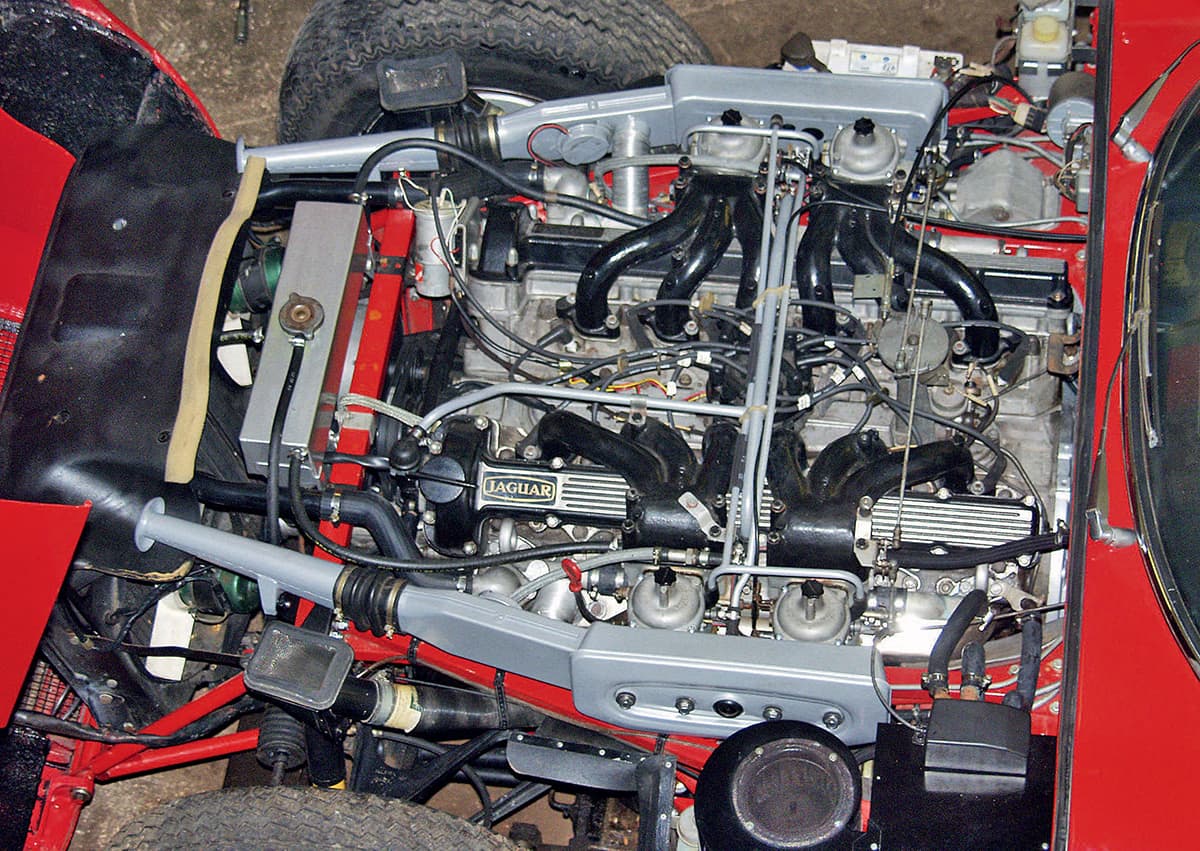

Only the second new Jaguar engine since the end of World War II, the 5.3-liter V-12 was fitted to the E-Type Series 3 from 1971, requiring significant changes to the front subframe.

With the advantage of an aluminum block and cylinder heads, this large engine was only 80 pounds heavier than the XK unit. For lubrication, there was a crescent-type oil pump incorporating an oil cooler. Chain-driven camshafts remained like the XK engine.

Carburetion again used the Zenith Stromberg 175CD SE carburetors, but now four of them, located in pairs outside the engine’s “V” formation. The beautifully engineered throttle linkage picked up on all four carburetors with rods leading to a centrally mounted capstan and then on to the acceleration cable.

Jaguar was the first company to fit the Lucas Opus (Oscillating Pick up System) ignition, with an electro-magnetic pickup and solid-state electronics.

With a quoted maximum power of 272 brake horsepower at 5,850 rpm, and maximum torque of 349 pounds-feet at 3,600 rpm, the Jaguar V-12 was a fantastic marketing tool for the company. It was well engineered, exceptionally refined, and could be updated over time to a larger capacity or even to accept fuel injection.

The V-12 engine was longer and wider and slightly heavier than the XK, so the front subframes of the E-Type were redesigned, incorporating triangular strengthening plates at the top. The bulkhead onto which the frames were located was also strengthened and enlarged to take the extra weight and stress. Also, to handle the increase in torque there was a substantial tie-bar arrangement under the engine.

The front suspension was fitted with the anti-dive geometry from the XJ6 saloon by repositioning the upper and lower wishbone mountings, with the upper wishbones provided with sealed-for-life bearings. Torsion bar adjustment was now by means of a cam plate. The track was widened at the front by 41/4 inches and 3 inches at the rear. Wider 6-inch wheel rims were fitted with Dunlop tires.

Jaguar proudly fitted this badging to the boot lid/tailgate of all Series 3 models.

The braking system was virtually the same as the Series 2 models but with ventilated discs at the front. The rear brakes were still mounted inboard, but cooling was improved with the fitment of an under-floor air scoop.

Power-assisted steering was now standard, and the rack was modified to reduce compliance. Jaguar four-speed manual transmission was still available with a larger 101/2-inch-diameter clutch. Automatic transmission was by BorgWarner but now the Model 12 box instead of the Model 8.

Bodily, the new V-12 models used only the 2+2 shell and so were effectively long wheelbase cars. There were therefore only two models, the fixed head 2+2 and the roadster, still just a two-seater. At the front, the mouth was enlarged yet again, now incorporating a grille with a chromed surround. There was also an air scoop underneath to move more air into the engine bay for cooling.

From the side, the wheel arches were flared to accommodate the wider track and tires. Both cars used the wider doors with chromed strips at the top and the windscreen rake followed that of the Series 2.

At the rear, the fixed head’s tailgate displayed a prominent “V-12” badge and chromed vent panel. The rest of the rear below bumper level was as the Series 2, although the V-12 now sported a four branch “finned” tailpipe arrangement.

The interior was still very much existing E-Type. The floor was lowered slightly to improve legroom, and the seat backrests reclined further and got headrests as standard. For the first time since the E-Type was launched in 1961, there was a new steering wheel of a smaller diameter and leather trimmed instead of wood. It retained the three-spoke arrangement but was now dished for safety, with a simpler embossed growler featured on the black center boss.

A Series 3 with fitted hardtop and conventional steel wheels with hubcaps.

For the US market, E-Types had to be adapted with Nordel bumper over-riders.

A Series 3 interior, with a parcel shelf below the dashboard and the new style steering wheel.

Having the wider opening doors made entry and exit easier, particularly for the roadster with the top up. Jaguar also produced a revised fiberglass hardtop as an extra-cost option, with a larger rear screen and chromed side ventilator panels.

Although a few Series 3s came off the production line in 1970, full-scale production started early in 1971 with 3,833 available for sale, nearly twice the quantity of either the Series 1 or 2 in their first full year of production.

1972: More of the Same

For 1972, several minor changes took place to aid production and keep costs down. The handbrake assembly was changed so that the same parts could be used for left- or right-hand drive models. A revised starter motor was fitted and a simpler coolant hose system and water pump. Later in the year, a sealed fuel system was added.

On the comfort side, the heater and choke controls were redesigned and fresh-air vents with control levers were fitted. To meet new safety legislation in the States, a seat belt alarm system was fitted and rear seating in the 2+2 had to be fixed in the upright position. There was now remote-control operation for the door rearview mirrors.

It was good year for Series 3 sales with another 4,000 leaving the production lines.

1973: Fixed Head Finale

The big news for 1973 was the deletion of the fixed head model due to safety legislation. New US law required coupes be equipped with rollover bars, which could not be factory fitted by Jaguar. Surprisingly, although the model had often been criticized for its styling with the wider wheel arches, the fixed head outsold the roadster with a total of 5,789 produced, compared to 2,058 roadsters up to that point.

Roadster sales continued. Jaguar had already been offering an air conditioning system for US customers and this was made available for the home market.

Minor changes during the year included revisions to the rack-and-pinion steering assembly, the fitting of a thermostatic vacuum switch to the right-hand rear coolant branch pipe eliminating associated hoses, and new needle roller bearings in the gearbox.

The Series 3 fixed head was a short-lived model.

Addressing US federal emissions regulations meant a loss of power for the V-12 engine. A new air injection system using a rotary-vane pump driven by a V belt off the water-pump pulley pushed air through the individual air injection pipes into the exhaust gases to ensure efficient burning. There was also a new fuel filler dispensing with the fuel stop tap.

The cooling ducts for the rear brakes had to be modified, as they got too easily damaged; there was a modified BorgWarner automatic transmission, first seen in the XJ12 saloon; and there was a modified synchromesh for the manual gearbox.

1974: End of the Line

1974 was the final year of E-Type production. Despite this, January was a banner sales month with 580 cars, a record for Jaguar in a single month for any E-Type variant.

One of the reasons for the impending demise of the E-Type was more legislation coming from the States relating to safety and emissions. One such regulation meant that all cars had to sustain a 5-mile-per-hour impact at the front or rear. The only economic option for Jaguar was to fit US cars with Nordel rubber “buffers,” extending forward from the framework, while at the rear adding a pressed steel reinforcing plate to the monocoque to distribute impact.

It was also during this final year of production that the exhaust system was amended with a twin “fin” tailpipe.

With the last E-Type leaving the line a total of 7,982 roadsters had been completed. It truly was the end of a very special era in Jaguar’s history.

SPECIFICATIONS

MODEL |

3.8 Series 1 |

4.2 Series 1 |

Series 1 2+2 |

ENGINE SIZE |

3,781cc |

4,235cc |

4,235cc |

CARBURETION |

3 x SU |

3 x SU |

3 x SU |

MAXIMUM BHP |

265@5,500 |

265@5,400 |

265@5,400 |

MAXIMUM TORQUE |

260@4,000 |

283@4,000 |

283@4,000 |

GEARBOX |

4-speed |

4-speed |

4-speed |

AUTOMATIC |

n/a |

n/a |

BW 3-speed |

0 TO 60 MPH |

7.1 sec. |

7 sec. |

8.9 sec. |

STANDING 1/4 MILE |

15 sec. |

14.9 sec. |

16.4 sec. |

TOP SPEED |

149 mph |

150 mph |

136 mph |

AVERAGE FUEL CONSUMPTION |

19.7 mpg |

18.5 mpg |

18.3 mpg |

MODEL |

4.2 Series 2 |

5.3 Series 3 |

ENGINE SIZE |

4,235cc |

5,343cc |

CARBURETION |

3 x SU (later 2 Strombergs) |

4 x Stromberg |

MAXIMUM BHP |

265@5,400 |

272@5,850 |

MAXIMUM TORQUE |

283@4,000 |

304@3,600 |

GEARBOX |

4-speed |

4-speed |

AUTOMATIC |

BW 3-speed |

BW 3-speed |

0 TO 60 MPH |

8 sec. |

6.4 sec. |

STANDING 1/4 MILE |

15 sec. |

14.2 sec. |

TOP SPEED |

150 mph |

146 mph |

AVERAGE FUEL CONSUMPTION |

18 mpg |

14.5 mpg |