CHAPTER SEVEN

ONE-MODEL POLICY

The XJ Series

Jaguar’s postwar success was attributed to a fine range of quality saloons and sports cars, developed through a racing heritage, all based around the XK twin-cam engine. The large saloons were the backbone of the range and justifiably carried the slogan “Grace … Space … and Pace.” Although the Mark X from the 1960s had been relatively well received, it didn’t generate the sales intended, so Sir William Lyons and his team set about creating what would be, for him, the pinnacle of his styling ability, the XJ.

To confirm this model’s success, one only has to look at the number of years it was in production and the quantity produced, as well as the increasing interest in the model still today.

A Family Resemblance

The XJ6, at first glance, carried over many of the styling features of the Mark X/420G, but in reality, every single body panel was new. Lyons had created a more balanced look with larger wheels in proportion to the body.

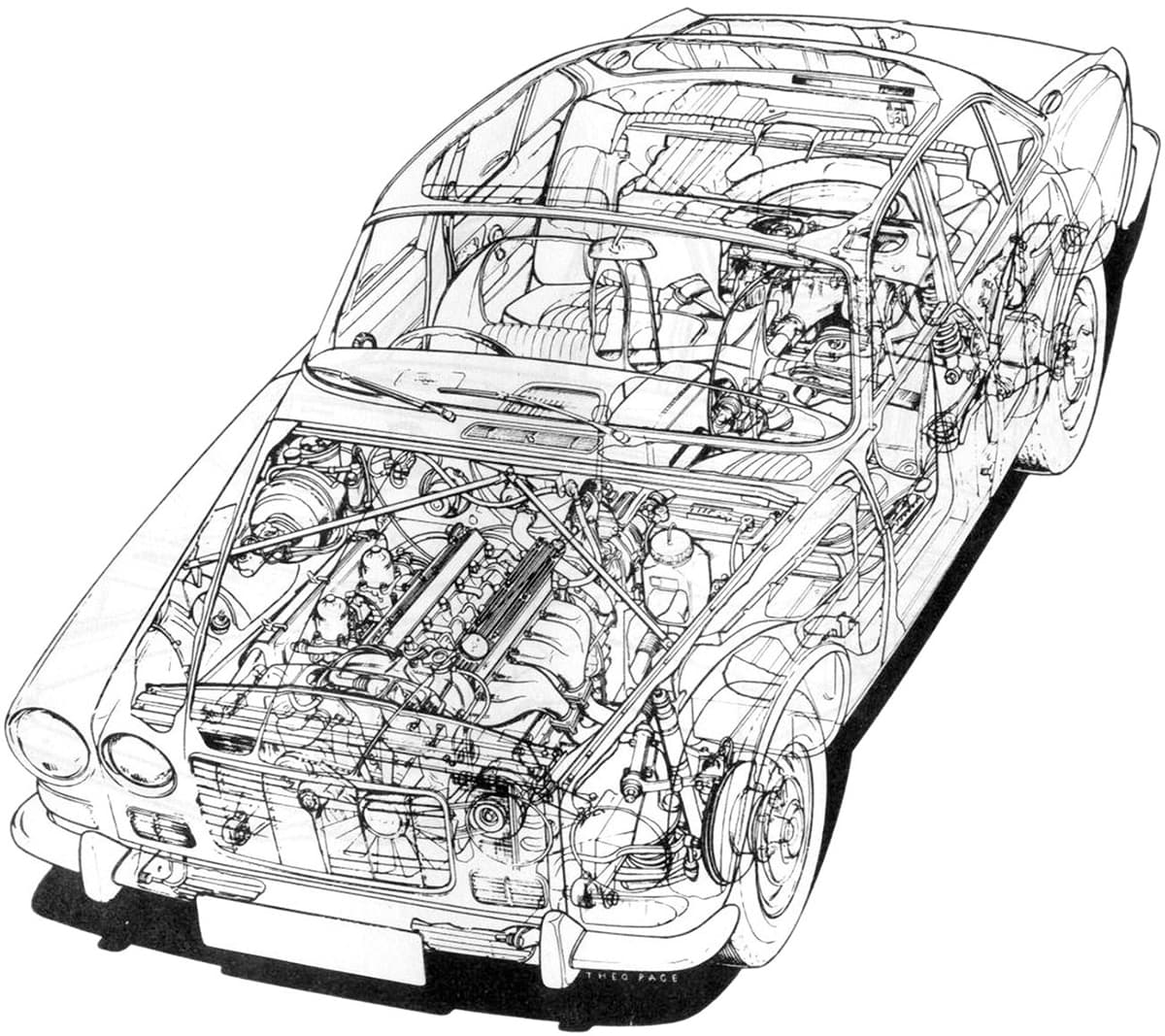

A new anti-dive feature improved the ride. The upper wishbone pivot was inclined at 3.5 degrees to the horizontal and the lower one angled downward by 4 degrees, causing the king pin to rotate under braking and push the body up. The effect kept the car level on deceleration. Girling dampers were fitted outside of the springs.

The new front subframe carried the engine mountings and rack-and-pinion steering with Varamatic power assist. Front brakes incorporated three-wheel cylinders operating two smaller pads on the outside of each disc with one larger pad on the inside. This improved pad life and reduced brake fade.

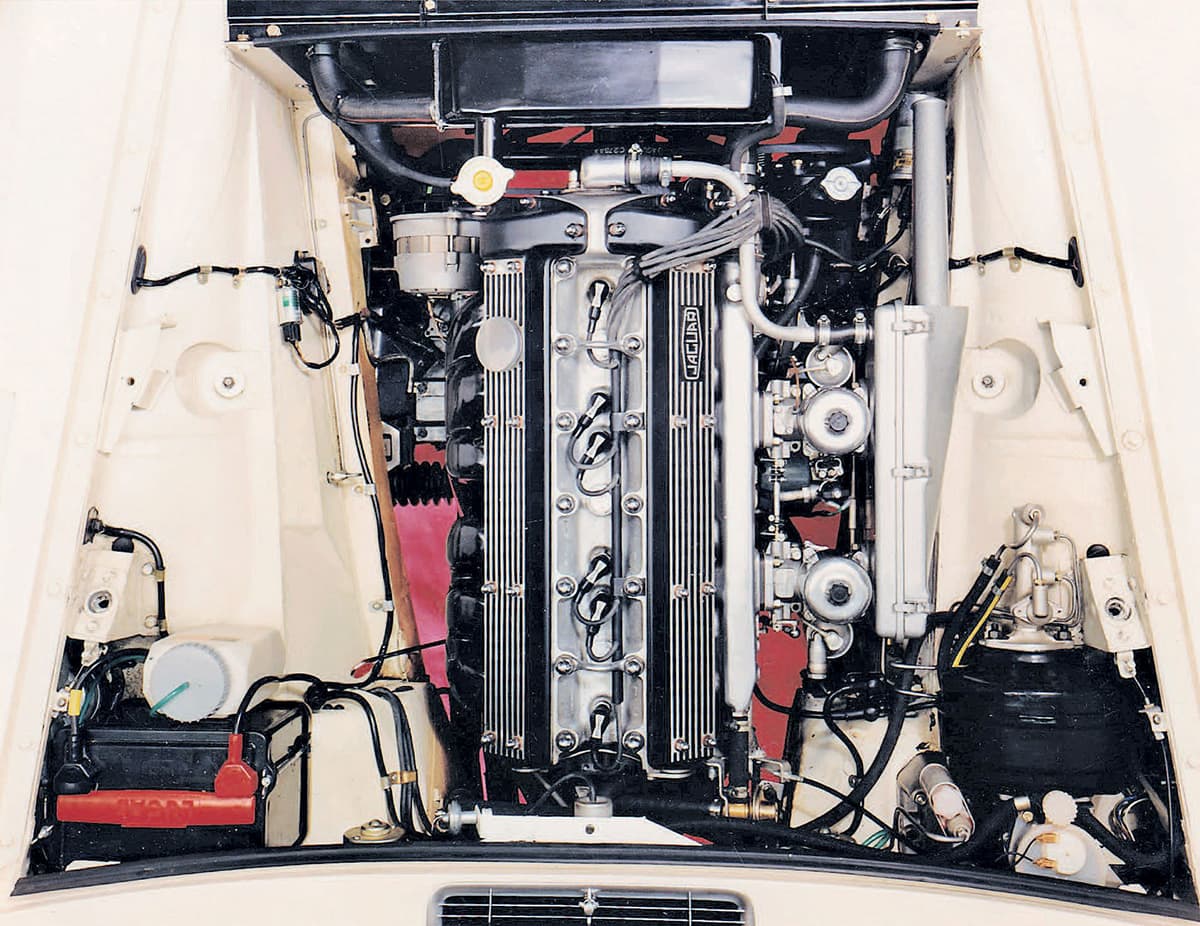

The conventional 4.2-liter XK engine powered the car, either with twin 2-inch SU HD8 carburetors or twin Stromberg 175CDs in the US. The engine used a larger impellor in the water pump, and a larger bypass hose fitted in the cylinder head, eliminating the water gallery. A cross-flow radiator with separate header tank fitted behind the core kept the height down. The XJ6 bonnet had a bulge to clear the cam covers.

Sir William Lyons was justifiably proud of his XJ creation, here seen at Browns Lane where the cars were produced at the time of the model’s launch.

A new engine of 2,791cc (2.8 liters) was introduced for the XJ6, with a bore and stroke of 82×86 millimeters. This configuration would help sales in some European countries where there was a tax tied to capacity. With a cylinder head identical to the 4.2-liter engine, it too featured the twin SU carburetors.

For the manual transmission models, Laycock de Normanville overdrive was again offered and the 4.2-liter engine retained the BorgWarner Model 8 automatic transmission; the 2.8-liter engine used the smaller BorgWarner Model 35.

Wheels were 15 inches in diameter with 6-inch wide rims. Dunlop developed special E70 VR15 tires for the XJ, derived from their SP range.

Instantly recognizable as a Jaguar, even though the radiator grille was somewhat nondescript, the lines and proportions were more popular than the previous model.

The XK six-cylinder engine installation was very similar to that in the earlier 420, although the under-bonnet space had always been planned for a larger unit.

Main mechanical aspects were unchanged from the previous model—4.2-liter XK straight-six engine and independent rear suspension cage but with tweaks to the suspension and braking.

Larger wheels filled wheel arches better, while early cars bore no mention of the name Jaguar. The straight exhaust tailpipes were later curved to eliminate fumes entering the cabin when windows were open.

Although having that strong family resemblance to the Mark X, the styling of the XJ was less flamboyant, smoother, slightly smaller, and much lighter. With the roof supplying more strength, similar assembly methods were employed but with greater “crushability” in the design to better absorb impact in an accident. The front wings and lower rear wing panels were bolted for ease of removal and repair.

At the front was a similar four-headlight treatment with wraparound side lighting with mock horn grilles similar to the 420 and revised full-width bumper bar and overriders. The radiator grille was “egg-crate” style without a prominent surround, merely a jaguar-head design within the center badge. Gone was any recognition of the Jaguar name and, because of legislation, no mascot appeared on the bonnet. There was no center chrome strip along the bonnet. A large curved one-piece windscreen was raked quite sharply into the roof and from the side the whole window area was larger.

The sides were flatter with a waist swage line running the whole length of the body. Behind the rear door there was a discreet “kick up” in the panel. Window frames were lighter and of a simpler design and the door handles came from a standard supplier, common to many other British cars.

The boot lid was much flatter than before with a raised floor accommodating the spare wheel. The rear was more upright with entirely new lighting and a large under-bumper valance with cut-outs for the twin exhaust pipes.

Badging was restricted to a plastic leaper badge at the base of each front wing, the jaguar head in the grille and the engine size on the boot lid.

Internally, although the dashboard layout was the same as early 1960s Jaguars, the instruments were of a new, clearer style. Auxiliary gauges in the center were fitted on a black ribbed plastic backing set into the veneer. Rocker switches, first used on the E-Type Series 2, operated all the central controls, including the main lights. A set of warning lights was set within a binnacle between the speedometer and rev counter. The dashboard had a padded top roll in black.

The interior retained a traditional look with walnut veneer, yet better, more supportive seating, “safety” switchgear, and extra storage space in the doors. This early car with manual transmission features the chromed bezels to the instruments.

Below dash level was a parcel shelf on each side with occasional tray in the center. The center console contained heater/air conditioning controls and radio, along with gear lever/transmission selector, two chromed ashtrays and cigar lighter, all set into a figured alloy backing. A lockable glove box on the passenger side of the dashboard and a center-console storage area within the armrest provide secure storage. Finally, there was a new steering wheel with twin spokes and half horn ring.

Seating was new and smaller, providing better lateral support and Posture Springing. The front seats reclined. A bench seat served rear passengers. Foam-backed headlining was used, and new door trims incorporated a slim wood fillet and combined armrests/storage areas. Recessed chromed door handles were used, plus either hand window winders or switches on the center console and at the rear for individual occupants if the car had power windows.

Some differences were tied to the engine chosen. The standard-trim 2.8 used Ambla instead of leather upholstery, with no rear-seat armrest and no rear-door storage pockets. Power assisted steering was not fitted. But one could specify a De Luxe version of the 2.8, appointed like the costlier 4.2-liter model.

The most prominent change to the interior came with the entirely new heating/ventilation and air conditioning system. Designed by Delaney Galley, it provided substantially greater output and airflow than any previous system used by Jaguar. Better temperature regulation was provided via controls on the center console and stale air was extracted via a one-way vent in the rear parcel shelf. A combined air conditioning option was available at extra cost that didn’t require any substantial changes to the other system or take up extra space. All cars had fresh-air ventilation outlets, one each side of the dashboard.

1968: Launch Time

The XJ6 was launched in September 1968 with its first public appearance at the British Motor Show a month later. Priced at a mere £1,797 including tax for a 2.8-liter model, and £2,397 for a 4.2-liter automatic, these represented exceptional value for money. Comparative examples included the Mercedes-Benz equivalent at £3,000 more and the Oldsmobile Cutlass at £1,200 more.

Despite the marketing plan to sell the 2.8-liter as a base model to attract business from other lesser brands and to help tax conscious markets, the car never sold that well. Jaguar never even offered an example for the press to road test.

1969: Daimlerization

Gas fumes were an initial common problem, apparently caused by twin fuel fillers. An antisurge flap in the fillers solved the problem. The cars were also improved with heat shields fitted between the exhaust and the body under the front seat areas to prevent heat build-up. Quieter running camshafts were fitted to all engines from the end of the year. Stiffer springs and revised anti-roll bars and mountings provided a better ride.

Inside, front seat backs were modified to take optional headrests, and inertia reel seat belts were offered also as another extra-cost option.

The biggest news in 1969 was a new model in the XJ range, the Daimler Sovereign. With the run down in production of the Daimler 420 Sovereign in August, its replacement was announced in October.

The new model was identical to the Jaguar XJ6 externally except for a traditional fluted radiator grille, similar treatment on the boot lid and badging. Internally, it was also much the same except for the black fabric finishing to the center console and more badging.

At a marginally higher price, the Daimler was supplied standard with certain options one paid extra for on a Jaguar, like overdrive.

Good sales totaled 13,172 Jaguar XJ6s and 597 Daimler Sovereigns for 1969.

Series 1 models in both Jaguar and Daimler forms, the latter with the more prominent radiator grille and center chromed strip along the bonnet.

1970–1971: Ongoing Improvements

The XJs proved to be a phenomenal success and sales in 1970 for all models amounted to a staggering 21,833. By the end of 1971, another 27,517 XJs had been sold, resulting in an amazing 63,758 in a little over two years, a record for the company.

The cars were so good that few changes were necessary. Despite modified spring pans being fitted to the front suspension early on in an attempt to provide better tire clearance, it was only when the front wing wheel arches were modified in 1970 that the problem was cured.

Front seat occupants now had controlled fresh-air vents, supplied by air taken in from the outer headlight surrounds. The surrounds to the instruments, previously chromed, were from 1970 finished in matte black to avoid glare, accompanied by a satin finish to the exterior scuttle ventilator (replacing chrome). Aluminum door treadplates were also fitted and there were improved door locks.

Mechanically, emissions exhaust manifolds were now fitted to all engines along with an improved crankshaft rear oil seal. The brake fluid reservoir was also repositioned.

The biggest single change in 1970 was a new BorgWarner Model 12 automatic transmission offering a D2 position and part-throttle down changes without flooring the accelerator.

External changes meant new lighting to suit European regulations and a three-piece rear bumper to replace the previous one piece to save on replacement costs.

1972: 12 into 6 Will Go

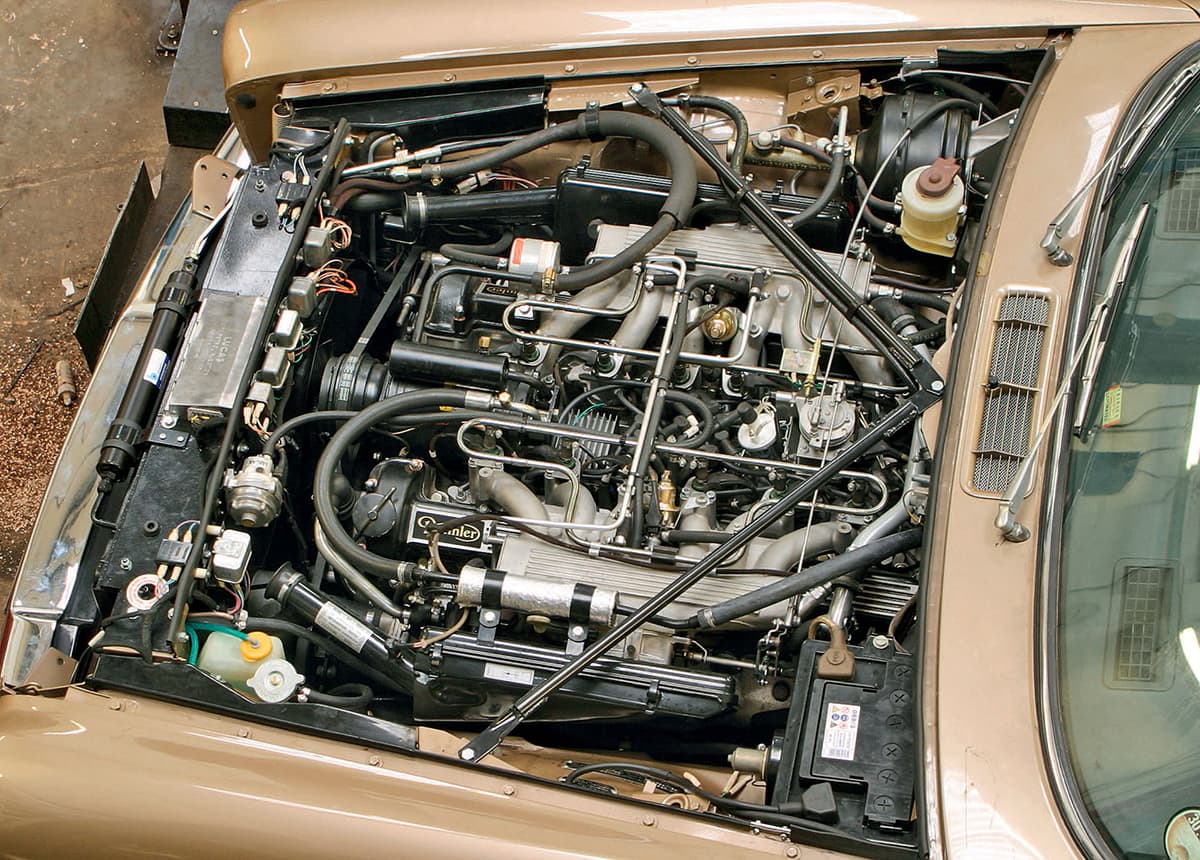

The XJ body had been designed to accept another Jaguar engine, the V-12, first seen in the E-Type Series 3. As that engine was not yet in production during the XJ’s development, many adjustments were necessary to fit the much bulkier engine and its ancillaries in the bodyshell.

Part of the problem was excessive heat generated in the engine compartment to the point that the battery, situated at the firewall, had to be fitted with its own cooling fan! The crossflow radiator was redesigned with two areas to ensure an even temperature across the V’s two cylinder banks. An electric fan supplemented the conventional engine driven fan. Heat shielding was provided to protect areas like the steering rack and engine mountings, and the exhaust downpipes were double skinned to reduce noise. Heat shields were even fitted to the underbody to reflect heat generated by the exhaust system.

The V-12s were available only with the new BorgWarner Model 12 automatic transmission.

Front spring rates were increased due to the extra weight of the engine and its ancillaries (129 pounds). For a more efficient braking system, ventilated front discs were fitted with a Girling Supervac servo with an additional vacuum reservoir. Dunlop’s special tires were upgraded for all V-12 cars, incorporating a steel breaker strip because of the car’s weight and speed potential, fitted to ventilated road wheels.

Externally, apart from the revised wheels, changes were minimal. The “egg-crate” radiator grille was replaced with a more attractive one with vertical slats and incorporating a “V12” badge. On the boot lid, another “V12” emblem appeared and for the first time a Jaguar badge was fitted on the opposite side of the number plate area.

Inside, subtle changes appeared. Like Daimler six-cylinder models, a black finish replaced alloy on the console, which now incorporated a gold finished “V-12” badge. Similar door trims with pull handles were also used. Calibration of the main instruments changed, including a new 7,000 rpm rev counter. There was also a manual choke control fitted under the dash near the driver’s door.

The XJ12, as it was called, was launched in July 1972. Shortly afterwards, the inevitable Daimler-badged version, the Daimler Double Six, was announced. In September, yet another model was announced, the Daimler Double Six Vanden Plas.

The “VDP” was a stretched-bodyshell version of the XJ, lengthened 4 inches for more rear-seat room and with wider rear doors. The model was built as a conventional Daimler Double Six at the Jaguar factory, without final paint or interior trim. The semifinished cars were then shipped down to the Vanden Plas Coachworks in London, where they were treated to final painting in a bespoke range of colors, fitted with chrome trim including auxiliary lighting at the front and a swage line, given “Vanden Plas” badging on the boot lid, and received a vinyl roof covering.

Internally, there were bigger improvements. The VDP model was fitted out more luxuriously with the best leather trim throughout to a different design, individual rear seating, and burr walnut veneer with boxwood inlays.

The most expensive model in the Jaguar/Daimler range, the Vanden Plas cost £5,363 at launch.

Later that year at the British Motor Show in October, the longer wheelbase bodyshell from the VDP became an option on other XJ models.

Apart from badging and the different profile tires, the XJ12 was identified by its vertical slatted radiator grille.

Even though the under-bonnet area was “made” for the V-12 engine, it was a tight installation. Note on the top right the cooling fan in the battery casing to dissipate heat and the well-engineered throttle capstan unit in the center of the “V.”

1973–1974: More Than a Facelift

In September 1973, the Series 1 cars, as they later became known, were replaced by the Series 2 XJ. The public had purchased over 98,500 of the first iteration, an absolute record for Jaguar at the time. Jaguar announced the new version at the 1973 Frankfurt Motor Show.

Stylistically they were instantly identifiable from the raised bumper bar level at the front, necessary to meet new US regulations. This meant new “underiders” instead of overriders with a larger air intake below bumper level in the valance. Accompanied by new under-bumper side/indicator light units, the radiator grille was much shallower—and fluted for Daimlers.

The front wings and bonnet were adapted from the Series 1, but the doors and rear wings were unchanged. Rear lighting was revised.

The major change not easily noticeable was a substantial reworking of the firewall area, mostly to accommodate a new heating/air conditioning system. The normal double-skinned metal bulkhead was replaced by a single skin covered on the engine side by a full-width asbestos shield, and on the cockpit side with a mix of bitumen, felt, and PVC shaped coverings. A light alloy pedal box was fitted, sealed to reduce the ingress of heat and noise. Also, all drilled holes through the bulkhead were eliminated, replaced by multipin connectors taking the wiring connection from the engine bay through to the interior. Even the heating and air conditioning liquids were accommodated by sealed metal tubing set into the bulkhead.

The launch of the XJ12 at the London Motor Show, then the fastest production saloon car in the world.

The XJ Series 2 model easily identified from the front by the raised bumper bar treatment and new narrow grille. This is a V-12 model with appropriate badging and extra-cost auxiliary lighting. The leaping mascot was not a factory fit.

Rear view of the Series 2 with revised plinth now incorporating the registration lighting (previously in the bumper bar). New badging at this time incorporated “L” for long wheelbase where appropriate.

The purpose of the changes was to insulate the new heating/air conditioning system from interference by external airflow and temperature conditions. The controls for the new unit were electro-servo operated.

Substantial changes took place internally, including a completely new dashboard layout with all instruments in front of the driver. A large air vent appeared where the minor instruments were before. Many of the old rocker switches were replaced with either push-button controls on the center console beside a new clock or by stalks off the steering column. The under-dash parcel shelf was replaced with a larger glove box and door pockets. The center console incorporated larger switches for the electric windows, where fitted. Another new steering wheel design appeared, now without a half horn ring. Door trims were also altered, the rear incorporating ashtrays. Fiberoptic lighting, a first for any British car, eliminated the need for some individual dash bulbs.

The new model range was extensive, composed of short- and long-wheelbase bodyshells for XJ6 and Daimler variants, long wheelbase only for the XJ12 and DD6 models, plus new two-door coupe bodies also in Jaguar and Daimler 4.2- and 5.3-liter models. Known as the XJ6C and XJ12C, these additional models were well received, but not instantly available.

Using the standard wheelbase shell, the new coupes had doors that were 4 inches longer with frameless windows and no central “B” pillar. With the front windows and rear side windows wound down, this created an attractive pillarless style. The coupes had a black vinyl roof covering hiding a change at the rear of the roof with extra strengthening, and other extra strengthening was fitted behind the door shut face.

A completely new dash layout for the Series 2 models with all instruments in front of the driver, a new steering wheel, and extra ventilation in the center panel.

A long-wheelbase Series 2 showing the extra legroom in the rear compartment. This car is equipped with the then new cloth upholstery.

To many, the most attractive of all the XJ Series models, the two-door Coupe with wider doors, pillarless glass areas, and vinyl roof.

Series 2 models destined for the States had to be fitted with federal-style bumpers incorporating 5-mph impact beams. Note also the name Executive, which applies to certain markets only and, in this case, the discreet British Leyland badge, not always fitted, except in cases where cars were assembled abroad.

1975–1976: Improved Economy, Performance, and New Models

As the 2.8-liter engine continued to give problems, Jaguar finally deleted this option and in April 1975 introduced a new 3.4-liter (3,442cc) version of the XK unit.

The “new” engine used the existing 4.2-liter cylinder block and the straight-port cylinder head. Fitted with twin SU HS8 carburetors with the usual automatic cold-start enrichment device, the engine was rated at 161 bhp. The new model was available with the usual choice of manual/overdrive transmission plus the BorgWarner Model 65 automatic, with a 3.54 rear axle ratio.

The 3.4-liter car was an economy model available only with the four-door bodyshell and various trim changes, like narrow pleated cloth-trimmed seating in a minimal range of just five colors. Unavailable in the US, the new model was competitively priced in the UK at nearly £400 less than a 4.2.

A Bendix fuel-injection system adapted by Lucas was fitted to the V-12 engines, initially for the two-door coupes only. This improved economy, helped reduce emissions, and raised the brake horsepower figure to 285 at 250 rpm less. An electronic control unit monitored data from various sensors around the engine and its ancillaries, computing the engine’s fuel requirements, and sending the necessary information back to the injector solenoids.

In the engine bay, the installation looked more complex but was very efficient and easily maintained. At the same time, handling was improved with a revised steering rack, anti-roll bar, steering arms and upper wishbones. Finally, a rear axle ratio change to 3.07 improved economy.

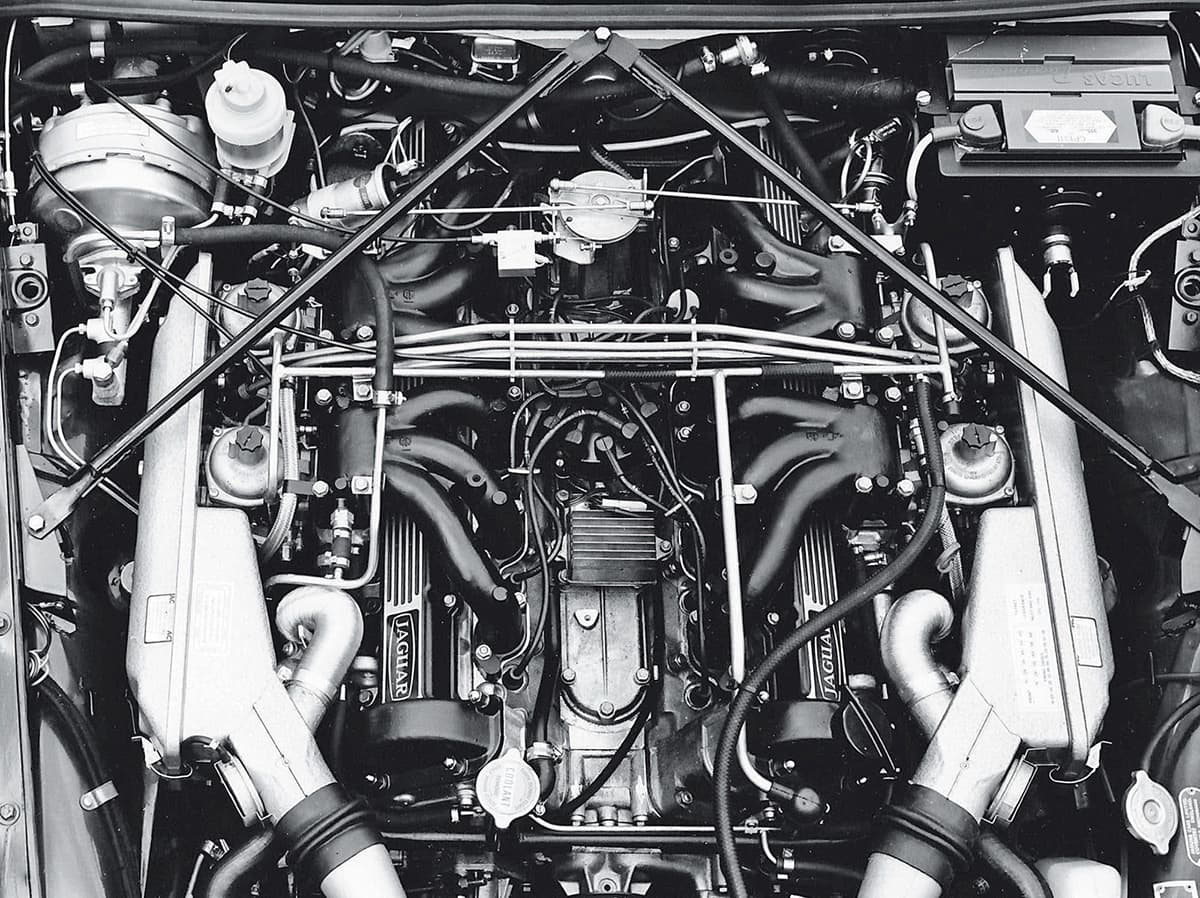

Series 2 XK engine with emissions systems.

The V-12 HE in the Series 2, now fitted with fuel injection.

Externally, a “Fuel Injected” badge appeared on the boot lid and a few months later fuel injection was standardized on all V-12-engined cars for all markets. There were also numerous trim changes throughout the life of the Series 2 cars. V-12s for example received the vinyl roof treatment and chromed swage line trim previously only on the VDP cars, and a new style Kent alloy wheel became available from GKN.

Another new model arrived on the scene, extending the Vanden Plas model offering with the 4.2-liter engine.

1977–1978: Final Changes and Improved Sales

For 1977, Jaguar replaced the aged BorgWarner Model 12 automatic with General Motors’ GM400 transmission in the V-12 cars. The new gearbox provided sportier gear-changes and acceleration with lower gearing on first and second that could be held for longer.

In May 1978, all 4.2-liter engines received Lucas-Bosch L-Jetronic fuel injection with a three-way catalytic converter, turning pollutants into harmless elements. To combat power loss, the fuel injection raised the compression ratio to 8:1 and, in conjunction with larger inlet valves, provided an extra 15 brake horsepower, plus better fuel economy. Although the fuel-injected 4.2 was originally destined for the US market, this engine was standardized for all production cars in that year. The 3.4-liter engine continued with carburetion.

In October 1978, Rover’s five-speed manual gearbox became available for the 4.2-liter XJ. This was a relatively new gearbox designed for Rover’s SD1 saloon, revised to reduce noise and with a new outer casing to make it fit. It replaced Jaguar’s now aging four-speed/overdrive unit but didn’t much improve economy or performance.

The last Coupe models were phased out in November 1977 due to continued quality problems and capacity needed to meet demand for saloons. The Series 2 saloon continued to sell well into 1979 when its replacement was announced.

1979: An Evolutionary, Rather than Revolutionary, Change

Total Series 2 sales had surpassed 100,000 when the Series 3 was announced in March.

Although carefully retaining the essence of the XJ design, the third version saw significant changes.

The first obvious shift was in the bumpers, now wraparound rubber-faced steel structures, which for the US market incorporated 5-mile-per-hour impact beams. A chrome blade sat atop the bumper and turn signals were into the front.

The Series 3 XJ with its larger glass area, flatter roofline, flush-mounted door handles, new wheel trims and bumpers.

Comparison between the Series 2 (left) and Series 3 clearly showing the many differences in body and trim.

The radiator grille had a flatter, more prominent surround, vertical slats with a center rib, and displayed a jaguar-head badge. Daimler models retained their ribbed style with a “D” motif. The twin headlights, now quartz halogen for all but 3.4s, also incorporated the side lighting.

With the front screen and pillars more vertical, a flatter roofline and the rear of the roof raised slightly, there was a sleeker look to the car with extra headroom inside. Marginally reducing the roof width and leaning the slightly larger glass area inward improved visibility. All models but the 3.4 now featured tinted glass, and the front door window quarterlights were eliminated. For the first time, Jaguar offered an electrically controlled flush-fitting sunroof.

Front and rear wings were subtly redesigned, and along the swage line there was a single coachline featured on XJ6 and a double on XJ12 models. The 3.4 was plain. The Series 3s now had flush-fitting door handles.

At the rear, the full-width wraparound bumper incorporated the rubber molding and inset high-intensity fog lights (not for US cars). Larger rear light clusters now incorporated the reverse lights and there was a new wider, flatter boot plinth incorporating the lock and illumination. Badging was amended according to model, but all of the same plastic, chromed faced style.

Road wheels remained of the same size but with a new style stainless steel trim with exposed wheel nuts. Alloy wheels were still an option on all models.

Although the basic elements of the mechanics of the cars remained the same, there were many refinements, like cruise control operated from one of the steering wheel stalks. Only available for the larger (4.2/5.3 liter) engines, cruise control was standard on US-bound cars.

Front seating was improved with lumbar support adjustment and power seats for the US market, optional elsewhere. New map pockets, hidden inertia-reel seat belts, and slightly altered rear seating improved comfort all round. A new molded headlining incorporated flush-fitted sun visors and there was a larger rearview mirror. Carpeting was also of a plusher type, which improved sound deadening.

Instruments had improved legends and all switchgear now incorporated symbols instead of words. The warning light display now incorporated extra warnings for low coolant level and fog lights on. Another warning light illuminated if there was a bulb failure. A new steering wheel provided better view of the instruments and the column stalks were swapped to meet internationally recognized positioning.

New driver aids included intermittent wipers and a headlight wash/wipe system standard on VDP models and those for the States. Power door mirrors were also standard on those models. As a final touch, reminiscent of classic Jaguars, there was a fitted briefcase containing tools in the boot.

The 4.2-liter engines retained fuel injection with the OPUS electronic ignition system and now developed 200 brake horsepower. For economy, fuel supply was cut off when the driver released the accelerator until revs dropped to 1,200. The 4.2-liter cars could still be fitted with the ex-Rover manual gearbox or BorgWarner Model 65 automatic.

Series 3 V-12s were fitted only with the GM 400 automatic transmission.

1980–1982: Economy Is King

At launch, service intervals had been set at 3,000, 6,000, and 12,000 miles, but were soon increased to 7,500 and 15,000 for the US market, and for all markets by May 1980.

In October 1980, Jaguar announced a revised 3.4-liter XJ6 to help compete in the important fleet market. Reduced in price by £500, the car came with a cheaper audio system, cloth upholstery, and straight-grained wood veneer.

Due to a changing climate over fuel economy, the V-12 engine was receiving bad publicity for its inefficiency. Jaguar worked with a Swiss engineer, Michael May, who had some radical ideas on combustion chamber design. A two-chamber combustion arrangement was devised with the inlet valve recessed in a collection zone, and the exhaust valve located higher up in a “bathtub” chamber into which the spark plug projected. The mixture was pushed by the piston from the inlet valve zone to the combustion chamber on its compression stroke. This meant low turbulence, concentrated the charge around the spark plug, and enabled rapid complete burning of the lean mixture. The new cylinder head had a much higher compression ratio of 12.5:1 and a revised Lucas-Bosch D-Jetronic fuel injection system was adopted. Although overall performance was little changed, fuel consumption was dramatically reduced.

A later 3.4-liter Series 3 XJ6 with cloth upholstery and the straight grain woodwork. This car also features the later center-console area with revised clock mounting. Better equipped models featured a combined clock and computer.

With this new engine, the cars were sold with “HE” appropriate badging. The V-12s also received standard alloy wheels, chromed side-moldings, electrically operated sunroof and door mirrors, and headlamp wash/wipe. Dunlop D7 tires with a larger 215 section provided better handling and feel.

For distinction, Daimler models didn’t get alloy wheels as standard, but did get electrically controlled height adjusted seats, improved carpets, rear seat headrests, and smoother leather facings. For Vanden Plas models (both engine sizes) standards were further enhanced with even plusher seating, cruise control, and further boxwood inlaying.

The six-cylinder engines received a V-12-sized cooling fan that was thermostatically controlled and an oil cooler.

Automatic transmission cars got a change in the positioning of the selector, removing the detent to allow smoother operation between D and the lower 1 and 2 positions. For the six-cylinder cars the later BorgWarner Model 66 gear was fitted.

For 1982, leather trim and an integrated radio/cassette system were standard on 4.2s, while 3.4s were upgraded with electric windows and central locking as standard.

1983–1992: Long Lasting

By the end of 1982, the Daimler name would be dropped from the European market and replaced by Jaguar Sovereign, a former Daimler model. The same approach was later adopted for the UK.

All models were updated with a new center-console area incorporating a switch panel and storage tray and wood veneer. The analog clock (or onboard computer where now fitted) were moved to the upper panel and appropriate Jaguar or Daimler badging added to the lower panel. A further new panel carried the radio and air conditioning controls on the console, finished in black. There was also a new thicker-rimmed steering wheel.

A Jaguar XJ12 Sovereign with Pepperpot alloy wheels, which continued in production until the end of 1991.

Revised better quality badging for the later models.

The later 4.2-liter six-cylinder XK engine equipped with fuel injection, fitted to Series 3 XJ6s.

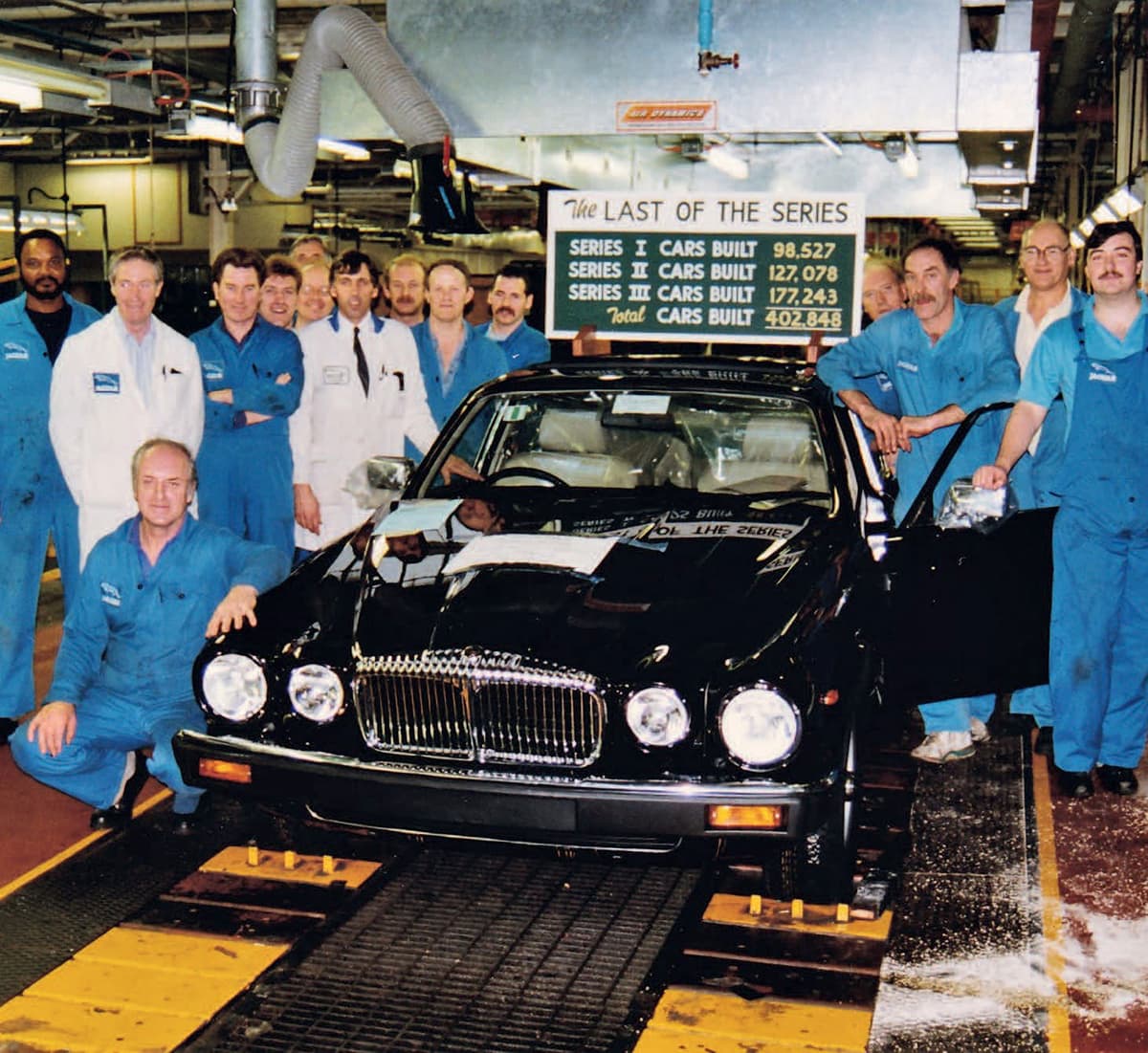

The end of the line as the very last Series 3 XJ (a Daimler Double Six) left production at the end of 1992.

Along with restyling of external badges, a new “Pepperpot” alloy wheels were fitted to Sovereign V-12 models. A single coachline was now applied to 3.4-liter models as were halogen headlights.

In 1984, the Sovereign XJ6 and HE (V-12) became available in the UK as the top-of-the-range Jaguar-badged models incorporating all the usual features and more. It was £1,000 cheaper than the equivalent Daimler Vanden Plas (or Jaguar Vanden Plas as it was called in the United States). The “VDP” designation continued in the United States but was dropped for the UK market. Daimler models continued elsewhere in just two variants: 4.2 and Double Six with all the features of the old VDP except for a vinyl roof covering.

There were other enhancements from 1986 on including a revised and enhanced air-conditioning system, ABS brakes, and catalytic converters, with the cars remaining relatively competitive in the marketplace despite the design’s age.

Although Jaguar introduced its all new replacement XJ in 1986, the Series 3 XJ6 continued in production until April 1987. The Jaguar Sovereign HE continued until November 1991 and the Daimler Double Six until December 1992. It was an incredible run, resulting in over 168,000 Series 3 cars and an astonishing 395,000 total Series 1, 2, and 3 models.

A top-of-the-range Daimler and Jaguar Sovereign model with the on-board computer. Controlled via the illuminated push-buttons, read-outs could be obtained for distance travelled and fuel consumption.

SPECIFICATIONS

MODEL |

2.8-liter Series 1 |

3.4-liter Series 2/3 |

4.2-liter Series 1 |

ENGINE SIZE |

2,791cc |

3,442cc |

4,235cc |

CARBURETION |

2 x SU |

2 x SU |

2 x SU |

MAXIMUM BHP |

180@6,000 |

161@5,000 |

245@5,500 |

MAXIMUM TORQUE |

182@3,750 |

189@3,500 |

283@3,750 |

GEARBOX |

4-speed |

4-speed |

4-speed |

AUTOMATIC |

BW 3-speed |

BW 3-speed |

BW 3-speed |

0 TO 60 MPH |

11 sec. |

10.9 sec. |

8.8 sec. |

STANDING 1/4 MILE |

18.1 sec. |

18 sec. |

16.5 sec. |

TOP SPEED |

117 mph |

117 mph |

124 mph |

AVERAGE FUEL CONSUMPTION |

18 mpg |

17 mpg |

15 mpg |

MODEL |

4.2-liter Series 2 |

4.2-liter Series 3 |

ENGINE SIZE |

4,235CC |

4,235cc |

CARBURETION |

2 x SU |

Fuel Injection |

MAXIMUM BHP |

170@4,500 |

200@5,000 |

MAXIMUM TORQUE |

231@3,500 |

236@3,750 |

GEARBOX |

4-speed |

4-speed |

AUTOMATIC |

BW 3-speed |

BW 3-speed |

0 TO 60 MPH |

9 sec. |

10.5 sec. |

STANDING 1/4 MILE |

17 sec. |

17.6 sec. |

TOP SPEED |

124 mph |

128 mph |

AVERAGE FUEL CONSUMPTION |

15 mpg |

16 mpg |

MODEL |

5.3-liter Series 1 |

5.3-liter HE Series 2/3 |

ENGINE SIZE |

5,343cc |

5,343cc |

CARBURETION |

4 x Stromberg |

Fuel Injection |

MAXIMUM BHP |

253@6,000 |

285@5,750 |

MAXIMUM TORQUE |

302@3,500 |

294@3,500 |

GEARBOX |

n/a |

n/a |

AUTOMATIC |

BW 3-speed |

GM 3-speed |

0 TO 60 MPH |

7.4 sec. |

7.8 sec. |

STANDING 1/4 MILE |

15.7 sec. |

15.7 sec. |

TOP SPEED |

150 mph |

147 mph |

AVERAGE FUEL CONSUMPTION |

11 mpg |

16 mpg |