CHARLES BRISCOE

“If you’ve got a job, there’s a way to do it. As a farm kid I didn’t have anyone to ask; I just had to figure it out. So when I went to Boeing, that’s just what I did.”

AMERICA WAS a modern industrial power when it entered the war, and so the machinery was already in place for converting production from domestic needs to the tools of war—tanks, jeeps, ships large and small, submarines, small-bore rifles, and artillery pieces large enough to launch a shell the size of a full-grown hog. No industry was as busy or as inventive as the airplane business. Aircraft designers were drafting new fighter planes and long-range bombers almost daily.

All this production required another kind of army—one of workers. There was no shortage of men and women ready to earn a steady wage after the long, lean years of the Great Depression. Moreover, most of them were used to hard work and long hours. Many had grown up on farms where the days ran from daybreak to past sundown, where work meant just that—work—the back-breaking, callus-making kind of work in hayfields and cattle barns, in primitive kitchens and rudimentary laundry rooms.

Charles Briscoe grew up as the son of an itinerant farmer who moved restlessly across the Great Plains, looking for work. Briscoe came of age in the Dust Bowl. “On the fourth of March, 1935,” he says, “I was in a car being pulled by my uncle’s car. It was a beautiful day. The sun was shining. Then it turned dark as quickly as you can clap your hands. I could see nothing. I got out of the car and felt my way to his car. My mother lit a coal-oil lamp and held it in the window of the house and we drove toward that.”

He tells another story about all that dust in those days. “My mother would hang wet sheets over a frame on our bed to keep the dust out of our lungs when we went to bed. The neighbors all around us lost children because they didn’t take the precautions my mother did.”

And two more stories of those days of poverty:

“One of the happiest days of my life—I was about in the seventh grade—we were farming in Kansas and I was trying to plow with a team of horses, walking behind, trying to keep the plow straight. My dad came home with wheels and a seat for the plow. I’ll never forget it.

“When my mother had to have work done on her teeth we had no money, so I went to the dentist and offered to work for him in exchange for the work she needed. I washed his car and I did such a good job he hired me to work around the office. I washed the floors and the windows, cleaned the bathroom—anything he wanted. He said I was the best help he’d ever had, and he gave me the keys to the office so I could come and go when I wanted. I told him my mother taught me to clean house.”

A neighbor had a John Deere tractor in need of an overhaul. He asked Charles whether he could handle the job. In fact, Charles had never worked on a John Deere, but that didn’t discourage him. The neighbor’s wife drove him to town to buy the parts. He took the tractor apart, installed the new parts, and put it back together again.

“I had a wonderful dad, but after any of us children got to a certain age we started working and never kept a paycheck. It all went into the family kitty. I could find a job at age fifteen when my father couldn’t. I just had natural skills. I got a job cutting broom-corn by hand. The rows were a mile long. The boss told the other men that if they couldn’t keep up with me, they could leave. My dad couldn’t keep up, so I’d cut his row, too.”

His father was having a more difficult time on his own farm, according to Briscoe. “We planted wheat five years straight and only one year the crop came in. We got twenty-five bushels an acre and sold them for twenty-five cents a bushel.”

By the time Briscoe was high school age, the family was living on a farm thirty-five miles from Arkansas City, Kansas, where his sister was teaching school. He wanted to complete his studies, so he hitchhiked to town to attend the high school. “I studied in the city library until they closed it,” he said, “and then I would pick up an abandoned newspaper and go to an abandoned house. I’d sleep on the newspapers. My main meal was salted peanuts because you could get them for a nickel. That went on for three weeks until we sold a pig. Then I could rent a room for a dollar and a half a week.”

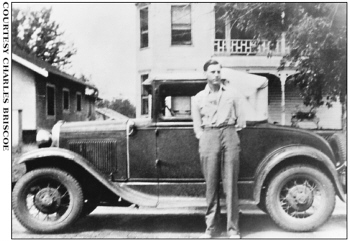

Charles Briscoe, junior college, 1938

After graduation Briscoe left for California, where he enrolled in a sheet metal school, learning the ways of this new trade that blended perfectly with his eye for design and his instinct for a job well done. He returned to Wichita, Kansas, in 1940 with his new craft, for a job at the Stearman Aircraft Division, a branch of Boeing. The plant was already gearing up for the possibility of war, turning out light training planes and working on a supersecret project: the development of the B-29, the Superfortress, the long-range bomber the Army Air Corps desperately needed.

Briscoe knew the mission was urgent. “We knew the B-17s and B-24s didn’t have the range to get to Japan. We had to have the B-29 to win the war and get the men home from over there. We worked seven days a week, often twelve to fourteen hours a day.” He says Boeing tried to find farm boys for their workforce “because we were used to long hours. Out on the farm we got up at four A.M. to milk the cows and then milked them again at eight-thirty that night. So hard work wasn’t anything.” There was another dividend for Boeing in hiring farm boys at a time when the aircraft industry was in a do-or-die creative phase. Farm boys were inventive and good with their hands. They were accustomed to finding solutions to mechanical and design problems on their own. There was no one else to ask when the tractor broke down or the threshing machine fouled, no 1-800-CALL HELP operators standing by in those days.

My father, Red Brokaw, was a blue-ribbon member of that fix-it generation. My mother learned not to say aloud that she needed, say, a new ironing board, because my father would immediately build her one. She liked to buy something from the store occasionally. When I was a young man in need of spending money I mentioned that I could mow many more lawns if I had a power mower. I had a snazzy new model from Sears Roebuck in mind. My father went to his workshop and built a mower using an old washing machine motor, welded pipes for handles, a hand-tooled blade, and discarded toy wagon wheels mounted on a plywood platform. He painted it all black and it was a formidable machine. At first I was embarrassed, but then as it drew admirers I was proud of its homespun place in a store-bought world.

During the war, Red and his pals made all of our Christmas toys. Later in life, when I took our daughters home for a Christmas visit, it snowed hard and we were determined to go sledding. By then my parents had gotten rid of all of our childhood sleds, so Grandpa Red took my daughters down to his workshop and turned out a wooden sled in less than an hour. It went down the hill as swiftly as any Wal-Mart model. My daughters, grown now, treasure the memory.

My father and his friends were like Charles Briscoe. They loved to make things work, and although they were not formally trained they had an instinct for design. Briscoe worked in tool design at Boeing. “I had to learn it all on the job because I had no experience like that whatsoever,” he says. “We couldn’t always get the materials we needed, so we’d make some tools out of Masonite or maple wood. They didn’t last long, but then we’d make another one using just a band saw.”

Briscoe’s parents were also used to hard work, so he got them jobs at the Boeing plant. His father was sixty-five at the time and his mother was in her late fifties.

They were all part of a team effort to build the new, long-range airplane. Nothing like it in aviation had ever been undertaken before. Just four years earlier, Boeing had produced a total of one hundred airplanes from its Seattle and Wichita plants. Now the military wanted more than five thousand a year, including this new, long-range bomber—the first mass-produced, pressurized heavy bomber. It had a wingspan almost fifty feet longer than a modern 737. It would be the single greatest airplane program during World War II.

It was America at its inventive best. “Today you have to have FAA approval,” Briscoe says, “but on the B-29 the engineers were drawing plans and we were making parts before it was approved by anyone. Some of what the engineers gave us were just pencil sketches—not even blueprints.

“We started putting beds in the B-29 because we figured the pilots would be in there a long time—but then we decided there wasn’t enough room, so we had to redesign and take the beds out.”

In February 1943, a prototype B-29 was tested near Seattle with tragic results. It caught fire and crashed, plowing into a building near Boeing Field. All twelve crew members and nineteen people on the ground were killed.

In June 1943 the first production B-29 rolled off the Wichita assembly line. Briscoe will never forget the moment. “All of us went out to the front of the hangar to watch the new B-29 take off, and as it took off, smoke started coming out! We thought we’d lost everything. But it turns out they’d left an O-ring off one of the oil lines.

“The next day it took off and it was beautiful. We knew we had a successful airplane. It looked as big as an apartment house—and I had built it.”

What he did not know at that moment was that the B-29 Superfortress would be the means of delivering the bomb that would bring Japan finally to its knees. It was a B-29 called the Enola Gay, named after the mother of the pilot, Colonel Paul Tibbets, who dropped the atomic bomb on Hiroshima—the beginning of the end for imperialist Japan.

Charles Briscoe was not on the job the day the news came of the bombing of Hiroshima. He was in the Navy. “I was twenty-nine years old and I had two sons and I wanted the world to be safe for them, so I volunteered for the Navy in 1945. I was in for just nine months before the war was over. I definitely knew it had to be a B-29 carrying the bomb, because that was the only airplane we had that could make it that far. I was thrilled. I realized it was sad that all those Japanese died, but how many Americans would have been killed without the atomic bomb?”

After the war and his short-lived Navy career Briscoe returned to Boeing and spent the rest of his working life there, helping develop parts for the new airliners that were rapidly filling the skies around the world. Briscoe was an invaluable troubleshooter for Boeing. Going back to the time when they were inventing the B-29 day by day, he had developed a knack for designing and producing airplane parts. After he retired at sixty-seven, Boeing brought him back at the age of seventy to work on special projects. The company tried to bring him back after his eightieth birthday as well, but there he drew the line.

He’s proud of the work he did on the Boeing 737, the world’s most popular airliner. The skin of the 737 was first formed by two sheets of metal that met the thickness specifications but exceeded the weight restrictions. So Briscoe and the Boeing experts designed a series of waffle-shaped cutouts on the inside to reduce the weight. It was one of many challenges the former farm boy relished during his long career at Boeing.

It’s been a much better life for Charles Briscoe than he expected when he was moving around the Dust Bowl with his parents as a teenager. What he learned then, however, served him well. He learned to work. As he says, “If you’ve got a job, there’s a way to do it. As a farm kid I didn’t have anyone to ask; I just had to figure it out. So when I went to Boeing, that’s just what I did.”

It’s a way of life for him. Now in his eighties, Briscoe is still fixing what’s broken. “I buy run-down houses and remodel them and rent them. Anything that needs to be done, I do it—the plumbing, the electrical. I roof ’em, I do the Sheetrock, patch the holes, all of that.”

Briscoe teaches his children and grandchildren by example. “The kids nowadays,” he says, “their parents buy them fancy cars and depend on someone else to keep them running. When all my grandchildren wanted cars I bought five hail-damaged cars—we get a lot of hail in Kansas. I got them for about three thousand dollars each instead of ten thousand or fifteen thousand dollars. I welded a finishing nail in each of the dents, bent it over, ground it smooth, and filled it in with body putty. By the time we finished, the cars looked brand-new. I had my grandchildren help me so they’d learn that if you want something badly there’s a way to get it.”