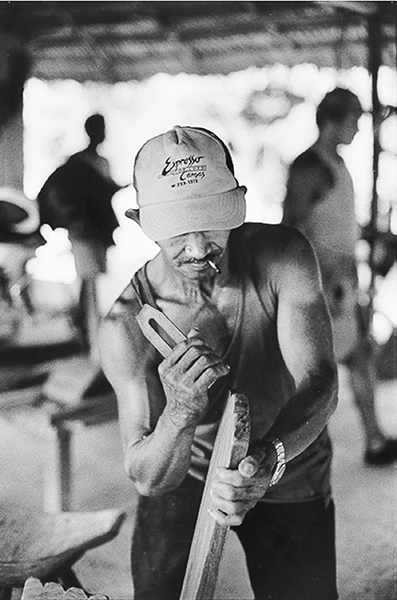

(Opposite) Woodworker from the village of Nuquini in the Tapajós-Arapiuns Extractive Reserve, Pará, Brazil, sculpting the back of a handcrafted chair. Photo by D. McGrath.

Tapajós-Arapiuns Extractive Reserve, western Pará, Brazil, 2002–2005

The logging companies, local business interests, and municipal authorities never wanted it to happen, but in 1998 a 650,000-hectare block of forest between the Tapajós and the Arapiuns Rivers in western Pará was turned into an extractive reserve, a controlled area in which the state allocates use rights, including resource extraction, to local communities. The caboclo communities—detribalized groups of mixed European, African, and indigenous descent that inhabit the floodplains of lowland Amazonia—living along the river had been fighting for years to oppose commercial logging in the forest, and aided by mounting political pressure, they had finally won. Three kilometers of land paralleling the rivers along the perimeter of the area was designated for settlements and agricultural activities; the remaining land was gazetted as a forest reserve. Resource use in the Tapajós-Arapiuns forest, one of the first examples of a new type of extractive reserve being created in Brazil, was not limited to rubber tapping and the collection of Brazil nuts. Communities were not allowed to sell whole logs, flitches (cross-sections), or rough-sawn timber from the reserve, but when value-added processing—and a written management plan—could be provided, they were permitted to fell a specified number of trees each year.

Three of the caboclo communities in the reserve, Nova Vista, Nuquini, and Surucuá, expressed an interest in developing a small, handcrafted furniture initiative. They had been making a few stools and tables using wood from dead trees in the agricultural zone, but to ramp up production and access timber growing in the forest reserve, they needed a formal management plan and a permit from the Brazilian Institute of the Environment and Natural Resources (IBAMA). Since they did not know how to go about doing this, I started collaborating with these communities in early 2002.

During my first meeting with the communities, I explained that we needed inventory and growth data from the reserve to develop a management plan. Without going into too many details, I described how we might collect this information. We made a list of the forty to fifty species of desirable furniture woods in the reserve and had a long discussion about sustainability and how forests could be conserved through wise use and compliance with the rules. As we were wrapping things up, I asked the representatives from each village how much of the extractive reserve they were thinking of including in their management plan. I was expecting them to suggest one or two hundred hectares of forest for each village—after all, they were making cutting boards and stools, not feeding a sawmill. The chatted among themselves for a minute, and then told me in a serious tone that they wanted to manage all of it. All 650,000 hectares. That’s a lot of stools.

I spent some time explaining what was involved in a forest inventory, after which it was unanimously agreed that a two hundred hectare intensive management area would produce more than enough wood to keep their furniture initiative going. (After the data from the inventory had been collected and analyzed, we calculated that one tree with a diameter of 1.5 meters and a height of 45 meters—of which there are many in the management area—contained enough wood to produce about fifty thousand cutting boards.) We started the inventory work in Nuquini. The management area was located about four kilometers from the village, and rather than walk there twice a day—especially in the late afternoon when we were exhausted—I suggested that we camp out in the forest until we finished. Nobody liked this idea. A group of women from the village agreed to make lunch for us each day, but we always had be back in time for dinner each night.

We first laid out a baseline of stakes every hundred meters along the southern boundary of the management area to mark the starting points of the inventory transects. We then divided ourselves into two teams and started slowly moving north using a compass and measuring tape, counting and measuring all the trees we encountered on the species list that were larger than five centimeters in diameter. Each of the transects was a kilometer long, but neither team got even half through the work the first day. Constant questions arose about using the clinometer, an optical device used to measure slope or tree height, determining whether a tree was in or out of the transect, measuring the diameter of a large tree with buttresses, and writing the data in the correct column on the tally sheet. The wasps’ nest in transect 1 that sent everybody running into the forest did not help things.

We grew progressively faster at the work as the days went on, and by the end of the inventory, the crews were doing a transect and a half or more a day. We were proud of what we had accomplished, and we had gained a much better idea of the distribution and abundance of furniture woods in the management area. Most evenings were spent animatedly sharing this information with the rest of the village, whether anyone wanted to hear it or not. The inventory work at Nuquini took a total of eight days to complete. Two teams of nine extremely motivated villagers sampled 1,000 plots, counted and measured 3,452 trees from 42 species, and encountered 5 poisonous snakes (Bothrops spp.) and one very large red-tailed boa constrictor.1

We had heard about the abundance of poisonous snakes in the forest and were determined to have a good supply of antivenin for the crews. This turned out to be more complicated than we had expected. We could not simply buy the antivenin and some disposable syringes and take them to the field. We had to contract with a nurse to administer the antivenin, and he would have to accompany us to the field carrying an ice chest. The young man we hired for this was wonderful, and after several days without having to open his ice chest or give anybody a shot, he started helping us count and measure trees. No one was bitten by a snake, but he was certainly prepared: he had fifty doses of antivenin in his ice chest—enough to treat up to six cases of snakebite a day for the entire inventory.

Several young women from Nuquini also helped with the inventory. They had the best handwriting and were the most careful about recording the measurements in the correct columns, so they were always chosen to carry the clipboard and tally the data. All these women had families and were expected to help with the dinner preparations at their houses each evening. I will never forget the sight of one of our most capable and trusted note takers handing her clipboard to another member of her team one afternoon so that she could pick up a large tortoise (Chelonoidis denticulate)2 that was slowly walking through the transect. She flipped the tortoise over on its shell, and carried it around, much like a waiter carrying a tray, for the rest of the day. Dinner solved.

I wanted to train the villagers to make dendrometer (growth) bands, which they could leave in the forest and periodically check to measure the diameter growth of important furniture woods. These bands are relatively easy to make, and since growth data ultimately determine how much wood can be harvested each year, I considered it important for the villagers to collect these data themselves. The government foresters I talked to, however, told me that extensive growth studies had been done several years earlier on the other side of the river in the Tapajós National Forest by university-trained foresters. They recommended that I use these data. There was the unstated, but nonetheless palpable, opinion embedded in this comment that the villagers would not be able to make the bands or do a growth study by themselves.

The last thing I wanted to do was simply give the community a number derived from somewhere else—like pulling a rabbit out of a hat—of the annual growth of their trees to combine with the inventory data they had worked so hard to collect so they could calculate an annual allowable harvest. They deserved the opportunity to take responsibility for gathering these data for themselves. Another advantage of having the villagers put growth bands on the trees in the management area was that the community could then measure the growth response of the residual stand after the harvest trees were removed. As the canopy was opened through tree felling, the remaining trees should grow more quickly. Faster-growing trees would mean greater wood production each year and larger volumes of wood that could be sustainably harvested from the forest.

It took a single morning to train the villagers to make the dendrometer bands. And once they learned how to make the bands, they wanted to put them on as many trees as possible. We ended up banding more than 250 trees from a variety of species, and the results from the first year of growth were invaluable. All the tree species measured in the management area were growing significantly faster than the same species across the river in the National Forest. A forest fire had swept through the area several years earlier. The fire had quickly been suppressed in the National Forest, where personnel and equipment were available to deal with it; it burned for a considerably longer period in the forests behind Nuquini. As a direct result of the fire, the canopy was more open in Nuquini’s management area than in the National Forest, light levels were higher, and, not surprisingly, the trees were growing faster. Everyone in the village was delighted with this finding.

Once the inventory and growth data were available, we had several productive meetings playing around with the data and assessing different scenarios for determining the sustainable annual harvest of wood from the management area. To do this, we first needed to calculate the wood volume of every tree recorded in the inventory, then group these data into species, expand the diameter of each tree using the average annual diameter increment of that species, and finally recalculate the volume based on the new diameter. By subtracting the original wood volume from the new volume calculated after a year of growth, and figuring out the sum of all these, we could estimate how much new wood a particular species had produced in one year. This result represents the inviolate limit of how much wood can be harvested from that species each year on a sustainable basis. It may not be rocket science, but forest management can get a bit complicated. I should point out that every member of the forestry team at Nuquini, some of whom could not read, stayed with me every step of the way as we did these calculations. There was much whispering back and forth as I wrote things on the blackboard, but based on the responses I got when I questioned them, the caboclos understood the procedure very well.

Combining the inventory and growth data yielded some fascinating results.3 For example, one cubic meter of wood contains about 1,000 cutting boards, 190 stools, or 50 coffee tables. Or, expressed in terms of growth and sustainable harvesting, the two-hundred-hectare management area at Nuquini produces 184,000 cutting boards, 35,000 stools, and 9,200 coffee tables each year. This bodes well for the sustainability of the venture, because these quantities exceed by a huge margin what the furniture makers can produce—or sell—each year. Suffice it to say that these figures leave a lot of room for the small furniture initiative to grow.

After finishing the inventory work at Nuquini, we moved to Surucuá and started counting trees in another piece of forest. The management area selected for the inventory was located ten kilometers from the village, but this time the field crews decided to build a basecamp so we could sleep and have our meals in the forest. The first day, a long line of us headed down the trail to the management area like a stream of ants: workers carrying pots and pans, sacks of food, hammocks and tarps, bags of field equipment, and a boombox. Everybody was on a bicycle. It was strangely reassuring to come back from the field each evening and see twenty-five bicycles parked next to the basecamp. My bike was bright red, all of the padding had come out of the seat, and the brakes didn’t work.

When I was not sleeping in a basecamp, I spent most of my evenings in the Tapajós-Arapiuns Extractive Reserve on a small boat with colleagues from the research institute in Santarem that was hosting my visit. We would take our meals on the boat, eating off a metal plate while rocking in a hammock, and then climb down off the boat into the river, usually in the late evening, to bathe and reflect on the day’s events. And this may be the best-kept secret of the reserve—white sand beaches and no bugs.

A final note: the furniture makers do not use large logs or long boards in their work; they prefer to work with small “bolts” of wood because these are easier to handle. Material of this size can be easily transported out of the management area across the seat and handlebars of a bicycle. The forests are essentially flat, with few rocks, and trails running all over them, so everybody has a bicycle. In a wonderful nod to combining logging technology with conservation of fossil fuels, the harvest trees at Nuquini are felled with a chainsaw and bucked into one-meter-long sections that are then wheeled out of the forest on a human-powered bicycle.