Chapter 2

Installing Cabinets

In This Chapter

Getting your tools together

Getting your tools together

Figuring out where to put your cabinets

Figuring out where to put your cabinets

Installing wall cabinets

Installing wall cabinets

Fitting base cabinets to the wall

Fitting base cabinets to the wall

C abinets are expensive. You’ll probably spend the biggest chunk of your remodeling budget on them, so you want to install them correctly.

Have your cabinet supplier assume the responsibility for measuring up your kitchen to determine the proper cabinets sizes and include in the order any prefinished filler strips that might be required. These narrow boards are installed between stock-size cabinets to make them fit a space, provide necessary clearance around appliances and sometimes to fill a gap between a cabinet that abuts a wall that is badly out of level.

Installing basic kitchen cabinets — those without a lot of prefinished molding — is a project that most intermediately skilled DIYers can handle. If you decide to tackle this project yourself, make sure that you allow your-self enough time — and don’t rush through any of the steps. Rushing leads to mistakes, and mistakes lead to frustration and dissatisfaction. Remember, these cabinets may be in your home for many, many years. And if you’re not happy with the installation or the cabinets’ operation, you’re reminded of your dissatisfaction every time you reach inside.

Gathering the Right Tools

Gather all the tools that you need before you start a project. You need them at various stages of the project; but it’s better and faster to be able to walk (or send a helper) to your tool area and grab what you need to keep the job moving. If you’re not familiar with a tool mentioned in this chapter, flip back to Chapter 2 in Book I for a quick review. Here’s a list of the tools you need to install new cabinets:

One 2-foot and one 4-foot level (the 2-footer is good for checking level and plumb in tight areas; use the 4-foot level for checking level and plumb and to determine the high point of your floor)

One 2-foot and one 4-foot level (the 2-footer is good for checking level and plumb in tight areas; use the 4-foot level for checking level and plumb and to determine the high point of your floor)

Straight, 6- or 8-foot 2 x 4 (used with the level for checking the floor’s level and high point)

Straight, 6- or 8-foot 2 x 4 (used with the level for checking the floor’s level and high point)

8-foot 1 x 4 pine board (used as a ledger support board when installing wall cabinets)

8-foot 1 x 4 pine board (used as a ledger support board when installing wall cabinets)

Chalk line

Chalk line

Tape measure (25 foot minimum)

Tape measure (25 foot minimum)

Stud finder

Stud finder

6-foot stepladder (a 4- or 5-foot ladder works, but I prefer a 6-footer)

6-foot stepladder (a 4- or 5-foot ladder works, but I prefer a 6-footer)

Variety of clamps — squeeze, wooden screw, and spring clamps of various sizes

Variety of clamps — squeeze, wooden screw, and spring clamps of various sizes

3/16-inch-diameter countersink drill bit

3/16-inch-diameter countersink drill bit

3-inch #10 cabinet screws

3-inch #10 cabinet screws

Several No. 2 Phillips screw bits

Several No. 2 Phillips screw bits

3/8-inch drill/driver (corded or cordless)

3/8-inch drill/driver (corded or cordless)

Hammer

Hammer

One or two packages of wood shims

One or two packages of wood shims

Jigsaw

Jigsaw

Heavy-duty extension cord for a corded drill or jigsaw (a 25-foot cord is best, especially if you need to draw power from another room)

Heavy-duty extension cord for a corded drill or jigsaw (a 25-foot cord is best, especially if you need to draw power from another room)

Marking Reference Lines and Mounting Locations

Marking reference lines is the first and most crucial step in installing cabinets. If you don’t have accurate reference lines, your cabinets likely become misaligned, which affects their operation and appearance.

Adding cabinets before flooring is the way to go

A lot of people ask, “Should I run my new floor from wall to wall and then install the cabinets on the new floor, or should I install the cabinets first and butt the new floor up to it?” Either method works, but installing new cabinets before new flooring is better. (See Book V, Chapter 1 for more on flooring.)

If you choose to install the cabinets first and then lay the floor, you save money by using less flooring material. Plus, you can work on the subfloor and not have to worry about damaging a new floor when you’re installing cabinets. And if you’re even moderately skilled, you can make your flooring cuts close enough to the cabinet so that you can cover any small gap by a toe-kick trim strip.

Checking your floor for level

Don’t assume that your floor is level. Most floors are off by a little bit, but not so much that cabinet installation is impossible for a DIYer. To check your floor for level, follow these steps:

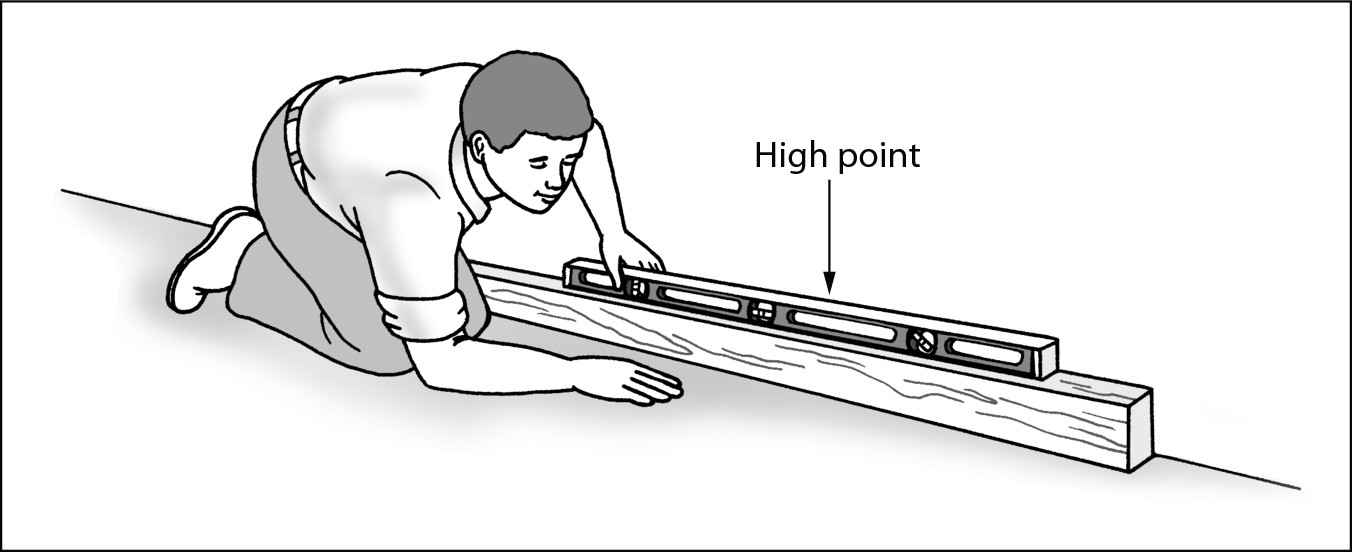

1. Lay a long 2 x 4 on edge against a wall where you will install the base cabinets and set a 4-foot level on it as shown in Figure 2-1.

The long 2 x 4 spans a greater distance of the floor, giving you a more accurate reading with the level. To determine if it is straight sight down one edge and the other, looking for any bends.

2. Determine the first high point. Lift one end or the board or the other as needed to center the bubble between the lines in the level’s vial.

If the vial already indicates level, there is no high point in this floor section. If an adjustment is needed, then the point where the level contacts the floor is your first high point.

3. Use the level/straightedge to determine if there is any point higher along that wall or an adjacent wall where base cabinets are to be installed.

Place an end of the board on the first high point and extend the board further along the wall or to any adjacent walls, checking for level as you did in Step 2. To make sure that the highest point along the wall is not lower than a point 2 feet off the wall (rare), check with a 2-foot level perpendicular to the wall. If it is you need to add the difference to the height of your reference line (see next section).

|

Figure 2-1: Use a straight 2 x 4 and a 4-foot level to find and mark the floor’s high point on the wall. |

|

Measuring cabinet heights

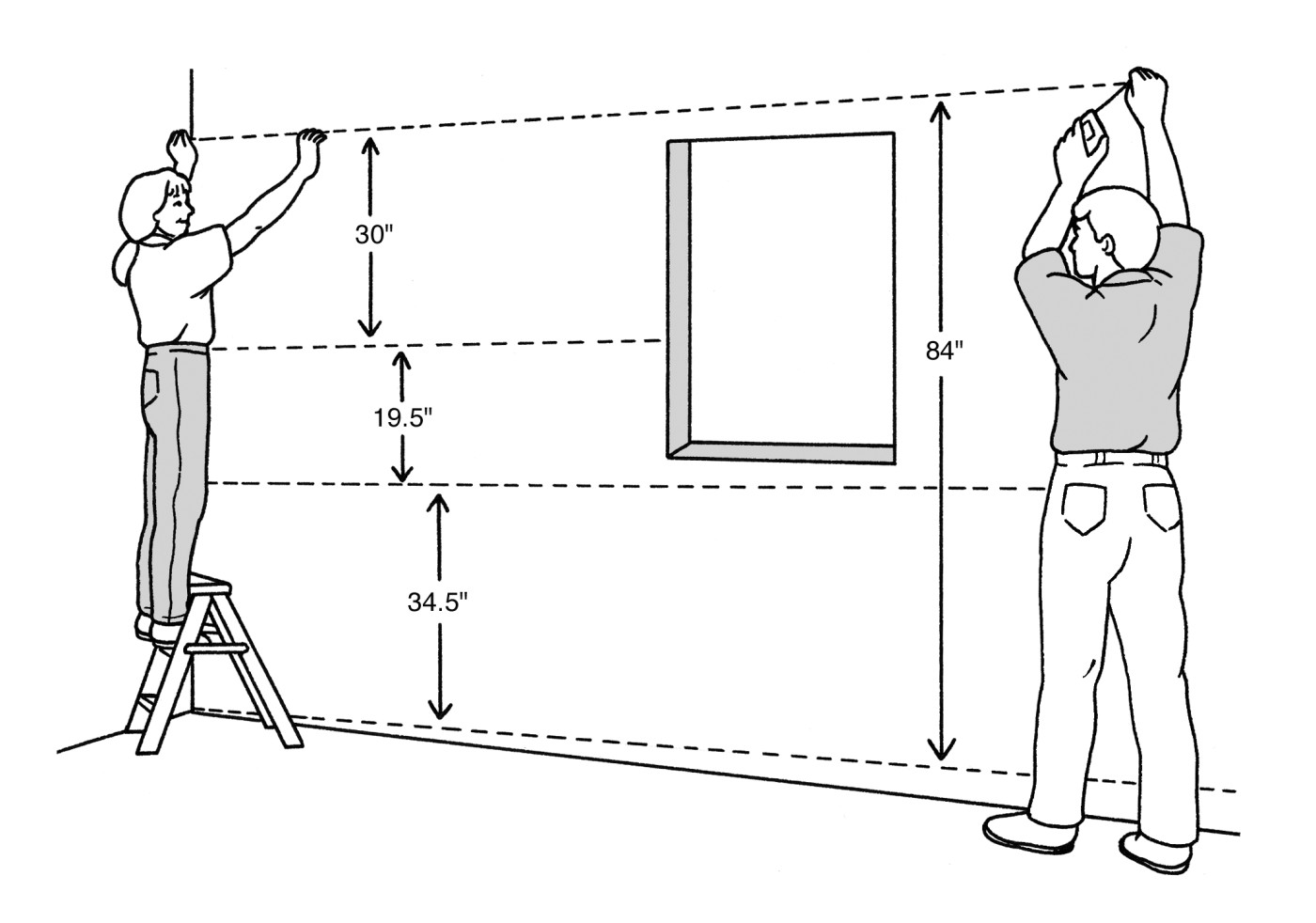

When you have your measurements marked on the wall, have a helper assist you and snap chalk lines at the top of your base cabinets and the bottom of your wall cabinets (see Figure 2-2). These lines give you your reference lines for installation. Perform this procedure on each wall where you plan to install cabinets. Be careful as you chalk the lines — make sure that your lines stay level around the entire room.

1. Measure up 34 1/2 inches from the highest point and mark the wall. Using a level, pencil a level reference line on the wall to represent the top of the base cabinets.

2. Measure up 49 1/2 inches from the reference line at both ends and mark the wall to represent the top of tall cabinets and wall cabinets.

3. Measure up 19 1/2 inches from the reference line at both ends to represent the bottom of 30 inch wall cabinets.

When you have your measurements marked on the wall, have a helper assist you and snap chalk lines that represent the bottom and top of your wall cabinets. If you have shorter wall cabinets, such as those over a range or refrigerator, measure down from the top line a distance equal to the height of the cabinet to determine the bottom edge. These lines are your reference lines for installation. Perform this procedure on each wall where cabinets will be installed. Be careful as you chalk the lines — make sure that your lines stay level around the entire room.

Standard height cabinets installed in a room with standard 8-foot ceiling leaves you approximately 12 inches of space above the cabinet for open storage or for a soffit — a nearly square, boxed-in shape that’s found above many kitchen cabinet installations.

|

Figure 2-2: Measure from the floor’s high point and mark reference lines for base and wall cabinets on the wall. |

|

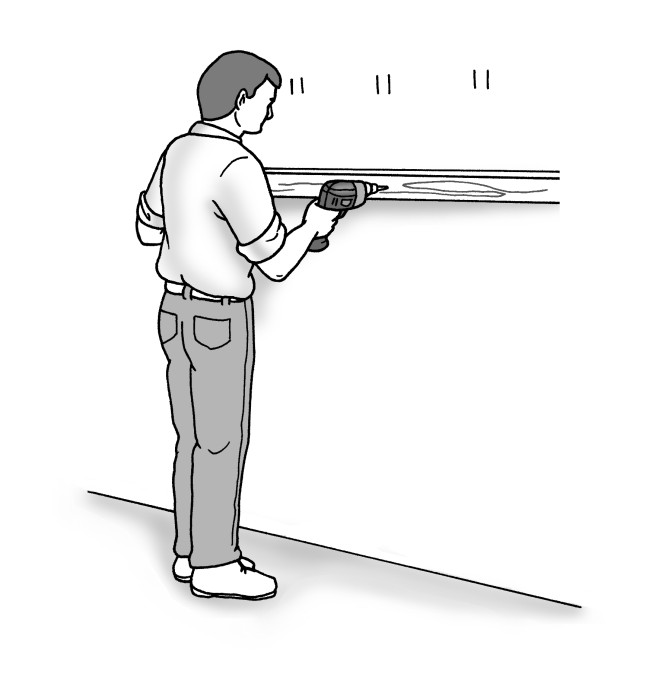

Locating the wall studs for mounting

You must secure wall cabinets to the walls with screws that you drive into wall studs. Hanging cabinets with hollow wall anchors is asking for a disaster! Even the most heavy-duty hollow wall anchor can’t support the weight of a cabinet plus the weight of all the items stored inside.

Use a stud finder to locate each wall stud. In most construction, especially in homes built after the 1960s, the wall studs are spaced every 16 inches or 16-inches-on-center (16-o.c.). In older homes, spacing can vary. Mark each wall stud along the three level lines wherever cabinets will be installed. You will use these marks to guide where you drive screws that secure the base cabinet, the ledger, and the top and bottom of the wall cabinets to the wall.

After you’ve marked the wall stud locations, attach a temporary ledger board to help support the wall cabinets during installation. I suggest using a long 1 x 4 pine board. Secure the ledger board along and below the line that marks the bottom of your wall cabinets. Drive a 2 1/2-inch-long drywall screw into every other stud to secure the ledger board to the wall (see Figure 2-3). Cut the ledger board to length as needed, depending on the length, or run, of your wall cabinet sections. After the wall cabinets are up and secured to the wall with #10 coarse thread cabinet screws at every stud location, and to each other, you remove the ledger board, patch the small screw holes, and paint the walls.

|

Figure 2-3: Attach a ledger board to support wall cabinets temporarily. |

|

Checking your walls for plumb

You need to check to see if your walls are plumb, or vertically level. The best way to check is to place a 4-foot level vertically on adjacent walls at an inside corner. If the wall against which the cabinet end butts is either in or out of plumb (walls can go in either direction), you will need to shim the cabinets (both base and wall cabinets) as you install them to make them plumb. Cabinets that butt an out-of-plumb wall will leave a tapered gap you will need to address. If the gap is not more than 1/4-inch wide and you are installing face-frame cabinets, you can plane the edge of the stile (the vertical member of the frame) as needed to close the gap. Larger gaps require that you install a tapered filler strip. Such a strip is best cut on a table saw so you may want help for this. Cabinets must be installed truly vertically and typically base cabinets must line up exactly with wall cabinets. To ensure that will be the case, especially when walls are out of plumb, it is essential to lay out cabinet positions on the wall before you start the installation.

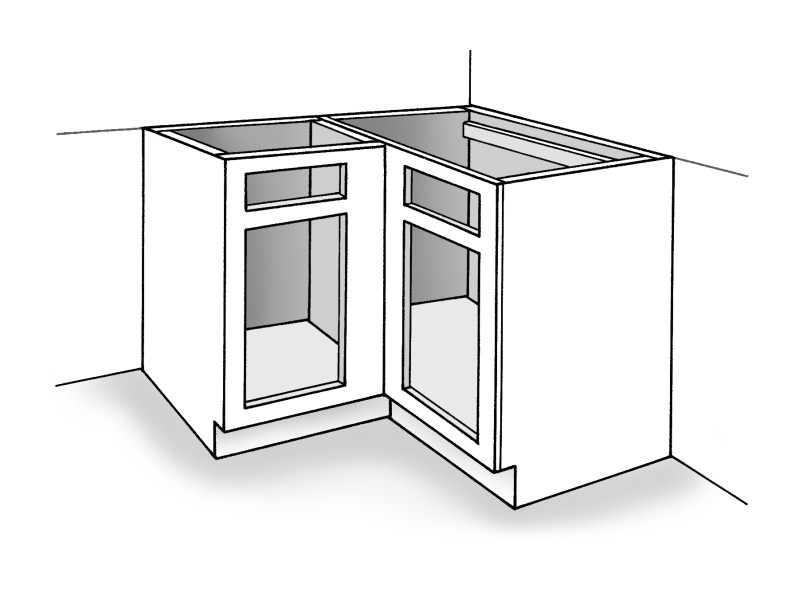

Noting cabinet position

Just as you establish a level horizontal reference line to determine cabinet heights, you must also establish a plumb vertical reference line to locate the cabinet sides. Walls are rarely perfectly plumb. Starting at an inside corner like the one shown in Figure 2-4, (assuming there is one), use a 4-foot level to check for plumb. If the top of a wall that the end of a cabinet butts into leans in, measure along the wall it will be installed on and mark a point that is equal to the width of the first cabinet. You can find this dimension on your cabinet order or by measuring the width at the front face of the cabinet. Then using your level, pencil a plumb line from that point to the floor. If the wall leans out, then measure out from the bottom of the wall to locate the reference line; and if it bows out at the middle, measure from the middle.

Repeat the procedure on the adjacent wall so in the end you have a line on each wall indicating the location of the first cabinet.

|

Figure 2-4: A blind inside corner cabinet unit. |

|

Hanging Wall Cabinets

We recommend installing wall cabinets first because you don’t have to work above the base cabinets. The open area of the floor allows you, your helper, and your stepladder clear access.

Note: This section describes installing framed cabinets. Installation instructions for frameless cabinets are similar except when connecting adjoining cabinets, as explained in the next section.

It’s time to install the first wall cabinet. Once you start, you’ll be amazed at the quick progress you’ll make by following these steps:

1. Transfer stud locations from the wall to the inside of each cabinet before you lift it into place; and drill clearance holes for the mounting screws.

Measure carefully and measure twice. Drill the holes in the upper and lower hanging rails of the cabinets (the two horizontal pieces of lumber along the top and bottom of the back of the cabinet). Clearance holes, which are the same diameter as the screw, ensure that the cabinet will be drawn tight to the wall by the head of the screw.

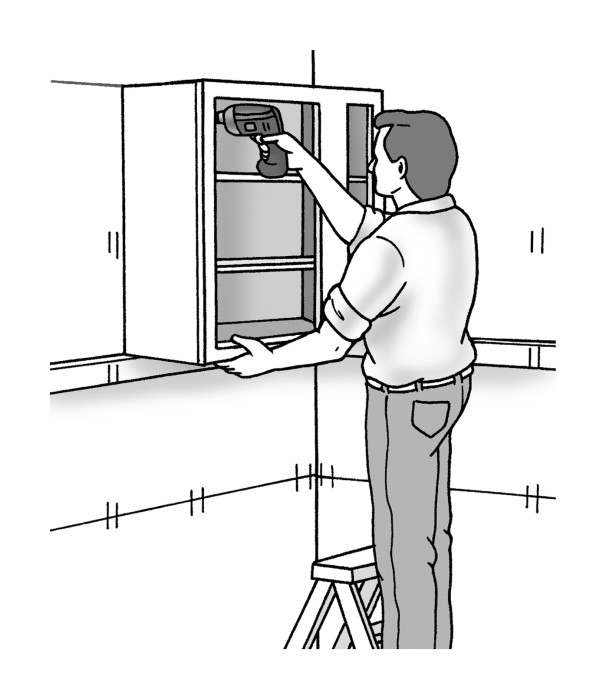

2. Set the first wall cabinet on the ledger strip and 1/4-inch away from its reference line on the wall; secure the top and bottom of the cabinet to the wall with 3-inch-long #10 cabinet screws, as shown in Figure 2-5.

Go ahead and snug up the screws as you go, but don’t tighten them completely. You’ll go back later for a final tightening of all the screws after cabinets are aligned with each other, joined together with screws and plumbed.

If you have a helper, have her hold the unit in place while you secure it with screws. If you’re working alone, cut some lengths of lumber and make a V-shaped notch in one end. Use these pieces as braces by placing the notch against the bottom of the cabinet and wedging the lumber up to hold the cabinet in place (see Figure 2-6). Put a rag or piece of cardboard over the cabinet where the notched lumber will go to protect the cabinet’s finish.

3. Position the second cabinet on the ledger and next to the installed cabinet. Attach it with screws as you did the first one.

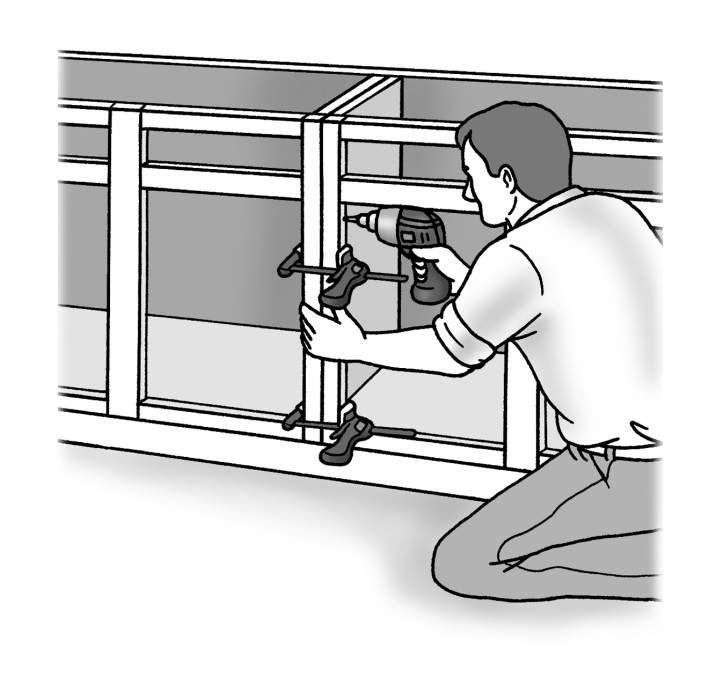

4. Join the two cabinets with two clamps, located about 1/4 the distance from the top and bottom. Use wooden screw clamps or short bar clamps with padded jaws that won’t mar the cabinets. Don’t position clamps at hinge locations because this is where you will join the cabinets with screws. As you tighten the clamp ensure that the face, top, and bottom of the two frames are all perfectly flush.

5. Drill clearance holes through the face frame, countersinks so that the screwheads will be flush with or below the surface, and pilot holes in the adjoining cabinet.

|

Figure 2-5: Position the wall cabinet on the ledger board and drive 3-inch-long cabinet screws through the top and bottom hanging rails and into wall studs. |

|

|

Figure 2-6: Use shims to make a cabinet plumb. |

|

Locate the holes at the hinge positions so when the hinges are installed, the screwheads will be concealed. The easiest way to drill these holes is all at once, using an adjustable combination bit.

6. Drive 2 1/4-inch drywall screws into each hole and remove the clamps.

.jpg)

If the holes are not properly sized or if you overdrive the screws, they can easily snap off. Use the proper bits and adjust the clutch on your drill/ driver to limit the torque to only what is necessary to drive the screws.

7. Install the remaining wall cabinets along this wall in the same manner and then remove the ledger.

8. If the plan calls for a filler strip at a particular location clamp it to the face frame and attach it as you would attach two cabinets together.

Often a filler strip must be ripped (cut to width along its length) to suit a particular space, and sometimes it must be tapered as well. As this task should be done on a table saw you may want to hire a carpenter to help with fillers.

9. Starting at the corner plumb the cabinets using the reference line on the adjacent wall and a 2-foot level, and insert shims as required.

Install shims behind the cabinet at the bottom or top as indicated until the cabinet is plumb and the proper distance from the reference line. Back out an installation screw, insert the shim until the cabinet is plumb and drive in the screw. When all cabinets are plumb, trim off the shims. Make numerous passes with a very sharp utility knife until it is scored enough to snap off or until you cut entirely through the shim.

10. Similarly complete the installation of cabinets first on adjoining walls and then other walls.

Clamp the filler strip in place and drill 3/16-inch pilot holes through the cabinet face frame and filler strip, using a countersink bit to recess the screw head into the face frame. Secure the strip with 3-inch drywall screws.

11. Reinstall the doors and check each one for smooth operation.

Doors have a tendency to misalign after they’ve been removed. However, many styles of hinges allow you to make minor adjustments to get doors operating smoothly. Be careful when redriving the screws for the hinges. The screws are generally made from a fairly soft metal, which makes the heads easy to strip and the shafts easy to snap off. A stripped screw can be replaced. A snapped off screw will need to be extracted, because you need to use the same hole that has the broken screw in it. To remove a broken screw, use a screw extractor. Extractor kits are available at home centers and hardware stores for less than $20.

Before moving on to the base cabinets, install a decorative valance over the sink, if your design includes one. You need to position the valance between the two cabinets that flank the sink, secure the valance temporarily with clamps, drill countersink, clearance and pilot holes through the adjacent cabinet stile into the ends of the valance, and then secure it with 2 1/4-inch screws.

Adding the Lower Level: Base Cabinets

Now you get to fill in the bottom half and install the base cabinets. You start the same way you did with the wall cabinets — unbox each cabinet and remove all doors and drawers, marking each one as you go, to make sure that you return the right door or drawer to its intended spot.

Installing the corner cabinet(s)

Start on the same wall and corner where you installed the wall cabinets. There are three ways to handle corners. You made this choice at the time you ordered your cabinets.

In the first option, a blind base installation, the cabinet on one wall (the blind base) extends almost to the corner, and then a standard base cabinet installed on the adjacent wall butts into it. Install these cabinets as a team and clamp them together as you level, plumb and attach them to the wall.

A corner base, often equipped with revolving “Lazy Susan” trays, is a single cabinet that extends 36-inches along adjacent walls. You must align it to reference lines on both walls as you level, plumb, and attach it to the wall.

In the third option, two standard base cabinets meet at their front corners creating a 2x2-foot dead (inaccessible) space in the corner. Install these cabinets in pairs to ensure that they meet precisely.

The steps that follow describe an installation that starts with a blind base:

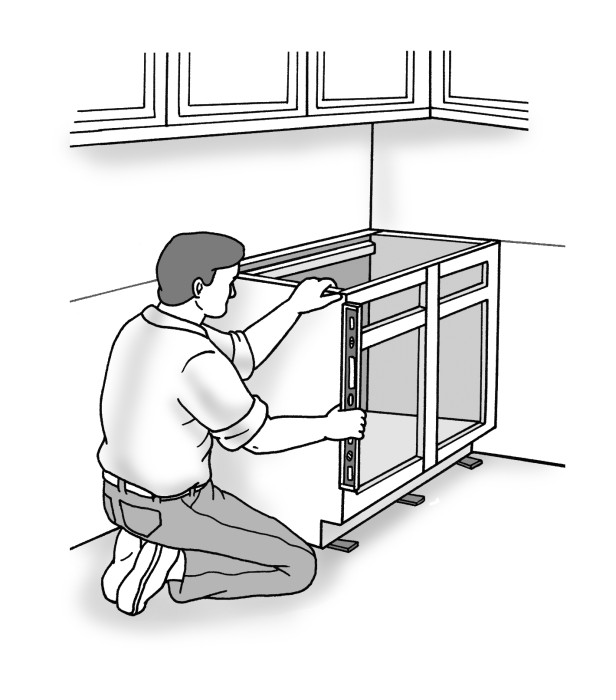

1. Position the blind base cabinet and then the standard base cabinet on the adjacent wall that butts into it, as shown in Figure 2-4.

2. Working on both cabinets, insert shims under the exposed ends and front edges until each cabinet is flush with the horizontal line and 1/4-inch away from the plumb reference line on its wall.

Use a level across the top, from front to back and on the face of the cabinet, while inserting tapered shims. Shim under exposed edges to raise the back to the line; shim under the front to level the front from side to side and back to front.

3. Clamp the top edges of the cabinets together.

Because the face frame overhangs the base cabinet by 1/4-inch, insert a 1/4-inch shim between the cabinets near the back edge to maintain that 1/4-inch space.

4. Attach the cabinets to the wall with 3-inch screws through the mounting rail at each wall stud location.

Drill clearance holes in the rails first and don’t drive the screw tight just yet. Chances are you’ll still need to spend time shimming the cabinets until they are just right.

5. Check the cabinets again to make sure that they are plumb and level in all directions, and that they still align properly with the two reference lines and with each other.

Back out an installation screw to insert a permanent shim behind the cabinet at each stud location as needed (see Figure 2-7). Reinstall the screw to secure the cabinet and keep the shim in place. Spend lots of time getting this corner perfect. Proper installation of the remaining cabinets all depend on it.

|

Figure 2-7: Use shims as needed to level the blind base cabinet. |

|

Finishing the base cabinet run

Finishing the base cabinet runs is less strenuous than hanging the wall cabinets because the cabinets rest on the floor and don’t need to be supported while you secure them to the wall. However, it’s still a good idea to have someone nearby to help make adjustments.

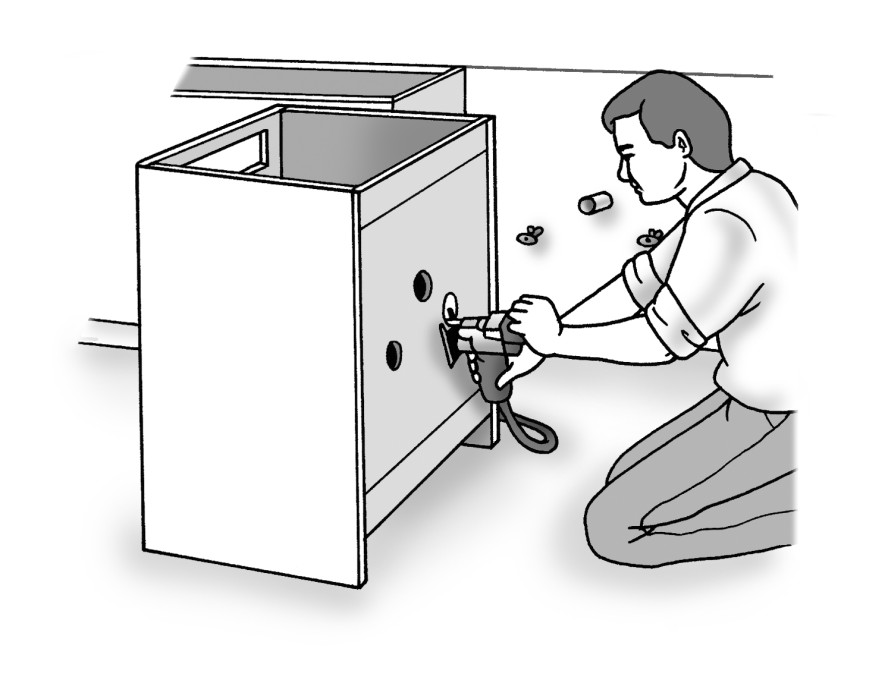

|

Figure 2-8: Cut openings in the back panel of the sink base cabinet for the drain line and water supply lines. |

|

Follow these steps to finish the base cabinet run:

1. Place the second cabinet in position and check it for plumb and level.

2. If shims are needed, gently tap them into place with a hammer.

Don’t trust your eye to check for level. Just because the two cabinets are flush along the top edge doesn’t mean that they’re both level and plumb. Check it and adjust as necessary. You may need to place shims under the front or exposed side of the cabinet and between the back of the cabinet and the wall.

3. Attach the cabinets together as you did the wall cabinets. (See the “Hanging Wall Cabinets” section, Steps 4, 5 and 6, earlier in this chapter, and check out Figure 2-9.)

|

Figure 2-9: Connect the base cabinets with 2 1/4-inch screws. |

|

4. Install the remaining cabinets and any required filler strips the same way, attaching each one to the previously installed cabinet.

Complete the installation of each cabinet and then check all installed cabinets for level, plumb, and alignment before moving on to the next cabinet.

If your new cabinets include a separate pantry unit, install it the same way you installed the first cabinet of either the wall or base run: Make sure that it’s level, plumb and that it aligns properly with horizontal and plumb reference lines before you secure it to the wall with 3-inch drywall screws.

After the cabinets are secured, score and break off all protruding portions of shims as you did for wall cabinets. You may find that you have a gap along an end panel and the wall or along the floor where shims may have been needed. Use a decorative trim molding to cover the gap between the end panel and the wall, as with the wall cabinets. To cover the gap at the floor along the area called the toe-kick, install a strip of matching hardwood or vinyl base molding, which can be cut with a utility knife and is adhered with special mastic.