Chapter 4

Fridges, Ranges, Disposals, and More: Installing Appliances

In This Chapter

Putting in a range, cooktop, or oven

Putting in a range, cooktop, or oven

Installing a fridge

Installing a fridge

Looking into installing a few other appliances

Looking into installing a few other appliances

I f you’ve decided that you’d like to include new appliances in your kitchen remodel, do your homework to make sure that the new units will fit properly. If you’re simply replacing your old range with a new one, chances are good that the new one will fit in the old space. But if you’re replacing the old range with one that’s larger or uses a different fuel source, you need to make some adjustments. You’re in luck! This chapter explains how to handle the situation should you need to make adjustments so that your new appliances fit in your remodeled kitchen. It also covers how to convert from gas appliances to electric and vice versa.

Installing Ranges, Ovens, and Cooktops

The two major questions to answer for this part of the remodel are

What is the fuel source: gas or electric?

What is the fuel source: gas or electric?

Where is the appliance going to be installed? In a row of base cabinets, in an island, or freestanding?

Where is the appliance going to be installed? In a row of base cabinets, in an island, or freestanding?

This section takes a look at installing a new cooking unit as well as converting your fuel source from gas to electric, including the basic installation steps for ranges, cooktops, and ovens. You don’t need many tools, because this job is best left to a pro.

Changing the power/fuel source

The most common fuel-source change is going from gas to electric. However, the last house we purchased came set up for an electric range and clothes dryer. We were raised using gas-fired appliances and, in our opinion, once a gas appliance user, always a gas appliance user. So we decided to run gas lines to both.

Gaining space in your electric service panel before converting to electrical appliances

Just because you want electric-powered appliances doesn’t always mean that your home’s electrical service can handle it. The best way to figure out whether your system can handle adding electric-powered appliances is to have an electrician or your electric service provider come out and inspect your main panel.

If your home has fuses, either the screw-in plug type or fuse blocks, you probably won’t be able to add electric appliances without upgrading to circuit breakers. If your home has circuit breakers, you may be able to add electric appliances without increasing the amperage to the house. However, just because the service panel has unused slots doesn’t mean that you can simply knock them out and add a few breakers. Homes with circuit breaker panels have at least 100 amps of power (100-amp service), which is considered the minimum standard for a medium-size home with no more than three major electric appliances, including central air conditioning. So, for example, if your home has 100-amp service, and it has central air, an electric water heater, and an electric clothes dryer, you probably won’t be able to add an electric range without upgrading your system. Many new homes have 150- or 200-amp service or more.

Making the move from gas to electric

Electric codes require an electric range and/or oven to be on a dedicated 40- or 50-amp circuit. Check with your electrical inspector as to which is required in your area. To do this job, you (or your contractor) need

Enough 6/3 cable to run from the service panel to the new receptacle in the kitchen. (See the sidebar “Wiring ID: It’s all in the numbers” for more on wire numbers.)

Enough 6/3 cable to run from the service panel to the new receptacle in the kitchen. (See the sidebar “Wiring ID: It’s all in the numbers” for more on wire numbers.)

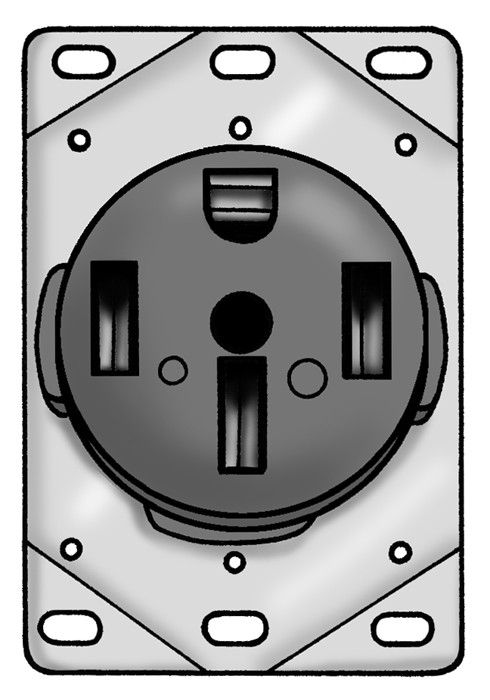

A 240-volt appliance receptacle, which has three plug prong holes and a ground prong hole. As you can see in Figure 4-1, the orientation of the prong holes is different than on a standard 120-volt receptacle.

A 240-volt appliance receptacle, which has three plug prong holes and a ground prong hole. As you can see in Figure 4-1, the orientation of the prong holes is different than on a standard 120-volt receptacle.

A double-pole, 40- or 50-amp breaker. A double-pole breaker consists of two individual breakers joined together to form a single unit and used on 240-volt circuits.

A double-pole, 40- or 50-amp breaker. A double-pole breaker consists of two individual breakers joined together to form a single unit and used on 240-volt circuits.

.jpg)

Make sure the new breaker is the same brand as your service panel. In most cases, brands are not interchangeable, and you could create a fire hazard by installing the wrong brand.

After the new circuit cable is run to the kitchen, it needs to be connected to the receptacle. And new ranges don’t come with plugs, so you’ll need to install one. Make sure to buy a four-wire appliance plug. Most ranges or the plug packaging have instructions for making the right connections.

If you’re replacing an existing electric range, it may have a three-wire setup; however, the current electrical code requires a four-wire setup. You can’t use a four-wire plug with a three-wire receptacle, so the old setup must be replaced.

|

Figure 4-1: A 240-volt receptacle has three prong holes and one ground prong hole. |

|

Wiring ID: It’s all in the numbers!

Understanding electric wire numbers isn’t difficult. For example, a 6/3 cable means that the wire thickness of all the individual wires is a #6 wire and that there are three individual wires (not including the ground wire) within the cable’s sheathing. Therefore, a 6/3 cable uses a #6 wire and has one black, one white, and one red wire, plus a bare or green wire for the ground. Some regions may require only an 8/3 cable for an electric range. The only difference is that the wires used are slightly thinner than the #6 wire, but three individual wires plus the ground wire are still there.

Just remember that as the first number of the wire designation gets bigger, the wire thickness or gauge gets smaller. The second number indicates the number of individual wires within the cable, excluding the ground wire.

Converting from electric to gas: Running a new gas line

If your home has one gas-fired appliance, you can add as many as you like. The only thing that you need is a gas line to each of the new gas appliances. For this job, you need

A roll (coil) of 1/2-inch outside diameter (O.D.) soft copper pipe (tubing). The beauty of running a gas line from an existing line is that most codes allow the use of soft copper from the main gas line pipe (which is usually black threaded pipe) to the appliance.

A roll (coil) of 1/2-inch outside diameter (O.D.) soft copper pipe (tubing). The beauty of running a gas line from an existing line is that most codes allow the use of soft copper from the main gas line pipe (which is usually black threaded pipe) to the appliance.

Assorted short lengths of threaded black pipe, usually from 3 to 8 inches long (in 1-inch increments). These short lengths are called nipples.

Assorted short lengths of threaded black pipe, usually from 3 to 8 inches long (in 1-inch increments). These short lengths are called nipples.

Union fittings, which connect the nipples to the main pipe.

Union fittings, which connect the nipples to the main pipe.

A Tee fitting for the nipple that will have the flexible copper line attached to it.

A Tee fitting for the nipple that will have the flexible copper line attached to it.

A separate shut-off valve for the range gas line supply. You must have this valve so that you can shut off the gas to the range without having to shut off the gas to other appliances.

A separate shut-off valve for the range gas line supply. You must have this valve so that you can shut off the gas to the range without having to shut off the gas to other appliances.

Pipe joint compound, often called pipe dope, for coating all threaded connections (required by code).

Pipe joint compound, often called pipe dope, for coating all threaded connections (required by code).

Flexible copper pipe uses flare fittings to connect to the gas pipe. What makes this type of fitting so good is that it’s easy to disassemble if you need to move the range for service or any other reason. You need a flaring tool kit to hold and form the flared end on the copper. The pipe is secured in the flaring tool base while you use a flaring tool to form the small lip or flare on the copper. If you work with flare fittings and don’t form the lip properly the first time, don’t try to reuse or reshape the lip. Cut off the flared lip by using a copper tube cutter and start over. After a lip is out of shape, it’s unsafe to use. The lip must be round to seal properly inside the flare nut and against the flare union.

If you do install a gas line yourself, be sure to check it for gas leaks. Here’s what to do:

1. Apply a soap-and-water solution to each connection. Never use a match!

Pros use much more reliable but very expensive electronic sensors.

2. Turn on the gas and look for bubbles.

3. If bubbles form, tighten the fitting slightly with a pipe wrench and recheck.

Be sure to wipe off the old solution and apply a new round of the mixture.

4. If you still see leaks, disassemble the fitting and check the flare shape.

You may need to redo the flare end of the copper pipe.

.jpg)

If you smell any gas odor, shut off the gas immediately! Open a window to help move the gas fumes out of the room. Don’t turn on a light or start an electric fan, either. Both have been known to cause a spark and ignite the gas fumes, causing a devastating and sometimes fatal explosion.

When working with flexible copper, be sure to leave two or three extra loops of copper behind the range before you attach it to the range and shut-off valve. The loops allow you to move the range in and out without putting stress on the connections. Repeated movement on the connections can cause them to leak. We’ve seen too many gas-fired ranges and clothes dryers with a straight line of soft copper pipe leading directly to the connection. The first time the owner moves the appliance, it puts a kink in the pipe, which then needs to be replaced.

.jpg)

Wrangling with a range

Assuming you purchased a range (a cooktop and oven combination unit) that uses the same fuel source as your old range, installing the new appliance should be as easy as sliding in or dropping in the unit. (You can also choose a freestanding range, but it’s the same as a slide-in model — only not surrounded by cabinets.)

A slide-in range is the easiest to install regardless of the fuel source. After the fuel source connection is made, you simply push or slide the range into position — hence the name “slide-in.”

Electrically powered slide-in ranges use either a heavy cord that’s plugged into a dedicated 240-volt/50-amp circuit or a length of flexible metal cable with individual wires inside, which is connected to an electrical box located behind the range. Gas-fired slide-in ranges use a flexible gas line that’s attached to the gas supply line’s shut-off valve, or gas cock, on one end and to the range’s gas connection on the other. Gas connections use flare nut fittings to attach the gas supply line to the main gas line. When installed properly, they provide the best seal for preventing gas leaks, and they can be taken apart easily if, for example, you need to move the range out to work on the area behind it.

Making a gas connection to an appliance isn’t difficult, but it must be done correctly to prevent a gas leak. Flare nut fittings are used on both ends of the flexible gas line. After the connections are made, check for leaks, as we explain in the “Converting from electric to gas: Running a new gas line” section, earlier in this chapter. If you detect a gas leak after testing and refitting the connection a couple of times, you may want to call a plumber to handle the hookup.

Both electric and gas ranges usually have a clock and other cooking accessories that run off of electrical power, but only 120 volts or a standard circuit is required. The ranges have a standard 120-volt power cord that’s plugged into a 120-volt receptacle located on the wall behind the range. An electric range needs two outlets behind it — a 240-volt for powering the cooking components and a 120-volt for the clock and timer(s).

A drop-in range requires a cutout cabinet and countertop area so that the range drops into the cabinet. This type of range often has a flange around the edge of the cooktop surface. The flange rests on the countertop and supports the entire range. Then the range itself is screwed to the cabinet. The fuel-source hookups are the same for a drop-in range as they are for a slide-in type.

Installing a cooktop

Cooktops come in either gas or electric models and are installed in a cutout area of the countertop or in an island. Fuel-source connections are the same as for a range. The main difference is in how each type is installed in the countertop.

Electric models typically have a flange around the cooktop (similar to a drop-in range) that supports the unit in the countertop. The weight of the cooktop is enough to keep it from shifting.

Electric models typically have a flange around the cooktop (similar to a drop-in range) that supports the unit in the countertop. The weight of the cooktop is enough to keep it from shifting.

Gas-fueled units are installed a little differently than their electric- powered counterparts. Gas cooktops do not have a flange around the edge for supporting the unit. Instead, they need to fit into a cutout or dropped section of the countertop and actually sit on the top of the cabinet frame. You (or your cabinet and countertop designer) should have figured this drop section into the plans so that the correct cabinets and countertop are ordered.

Gas-fueled units are installed a little differently than their electric- powered counterparts. Gas cooktops do not have a flange around the edge for supporting the unit. Instead, they need to fit into a cutout or dropped section of the countertop and actually sit on the top of the cabinet frame. You (or your cabinet and countertop designer) should have figured this drop section into the plans so that the correct cabinets and countertop are ordered.

Built-in baking: Installing a built-in oven

A built-in oven is installed in a similar manner to a slide-in range except that it slides into a cabinet or, in some upscale installations, into an opening in the wall. Built-in ovens come in gas and electric versions, so hookups are the same as for slide-in units.

Installing a New Fridge Complete with Dispenser Unit

The refrigerator is the easiest of all appliances to install. In many cases, when there’s no in-the-door water and ice dispenser, it’s as easy as sliding it into its designated space and plugging it in.

However, fridges today often come with popular extras that require more from you in the way of installation. The most popular of these extras is the in-the-door icemaker/water dispenser unit. For this feature, you need to run a water supply line to the back of the fridge. Fortunately, even the greenest of DIYers can handle this easy job.

You need the following tools:

Two adjustable wrenches

Two adjustable wrenches

A 3/8-inch power drill (electric or cordless)

A 3/8-inch power drill (electric or cordless)

A 1/2- to 3/4-inch diameter spade bit

A 1/2- to 3/4-inch diameter spade bit

An icemaker water supply kit (which usually includes a saddle Tee for tapping into the cold water supply line)

An icemaker water supply kit (which usually includes a saddle Tee for tapping into the cold water supply line)

A compression-fitting Tee kit (if a saddle Tee is not code-approved in your area)

A compression-fitting Tee kit (if a saddle Tee is not code-approved in your area)

Here’s how the installation is done

1. Determine which of the water supply pipes is the cold.

To find the cold water supply pipe, simply follow the two pipes that supply water to your kitchen sink. They should run parallel and be fairly close together. If the hookup is done correctly, the pipe on the right (as you’re looking at them and as they’re going to the sink) should be the cold. Believe it or not, we’ve been in a few houses where the hookups are backwards — hot on the left and cold on the right. If you’re still not sure which is which, turn on the hot water tap at the kitchen sink and grab the pipes. Whichever pipe turns warm is the hot water supply pipe, so you know the other pipe supplies cold water.

If you have a basement, tap into the cold water pipe down there. Doing so gives you easy access to the pipe and from the pipe to the floor area just behind the refrigerator. Also, it doesn’t take up space under the sink with another valve and the necessary supply pipe to the refrigerator. If your home doesn’t have a basement, tap into the cold water supply line that goes to the faucet.

2. Determine whether you can use a saddle valve in your area of the country.

Most icemaker kits come with a length of copper tubing and a saddle valve; however, in many areas a saddle valve doesn’t meet code.

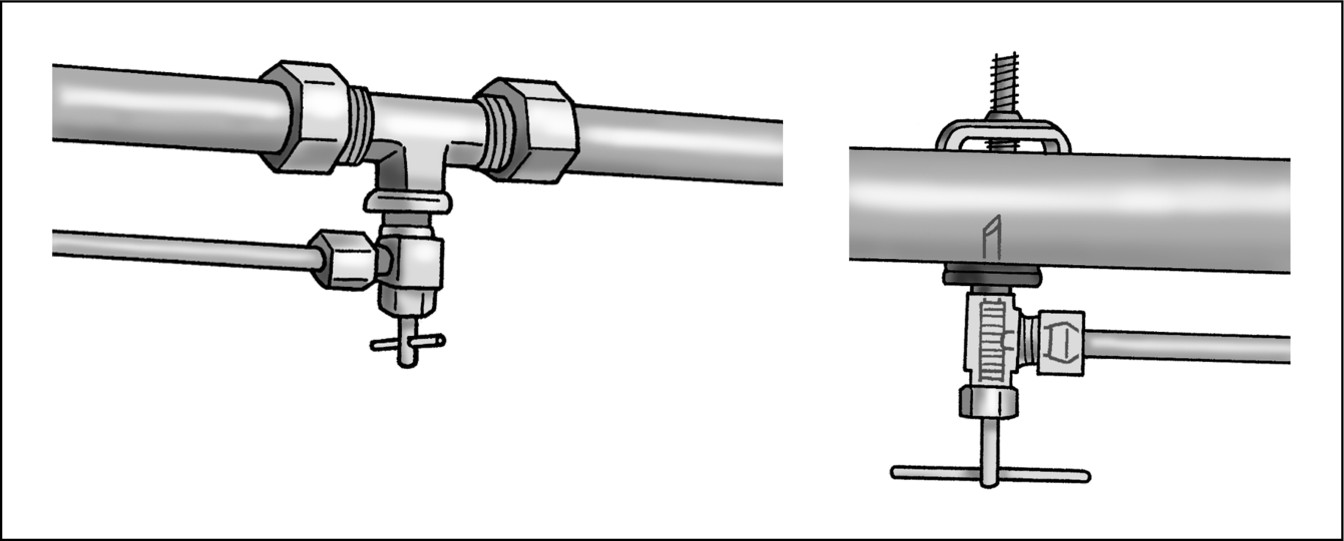

3. If you can’t use a saddle valve, you need to install a compression-fitting connected valve (see Figure 4-2). Simply cut out a short section of copper and install the compression-fitting valve.

Turn off the water before cutting into the water supply pipe!

If you can use a saddle valve, follow these steps:

a. Attach the two straps (saddles) over the cold water pipe and secure them with the supplied bolts and nuts.

The shaft or spike of the valve is hollow and pointed so that when you tighten or close the handle of the valve completely, the tip of the shaft pierces the copper pipe and water then flows through the hollow center.

b. Open the valve completely to allow water to flow through the tubing to the fridge.

The copper tubing uses a compression fitting to connect it to the tapping valve’s threaded end. Use an adjustable wrench to tighten the nut to the fitting.

.jpg)

Don’t reopen the saddle valve or the compression-fitting valve until you’ve attached the tubing to the refrigerator, or you’ll have a big, wet mess!

4. Drill a hole through the floor (if you’re coming up from the basement) so that you can feed the copper tubing up to the refrigerator.

Use a spade bit to drill up through the flooring. Remember to wear eye protection, as you’ll be drilling overhead, and it’s easy for something to fall in your eye.

If you’re working in your basement, a quick way to spot the hole location from below is to drive a nail through the kitchen floor from above. Then simply go in the basement and look for the tip of the nail — that’s where you drill the hole.

|

Figure 4-2: Compres-sion-fitting valve (left) and saddle valve (right). |

|

5. After the hole is drilled, feed the tubing up into the kitchen.

Don’t cut off any extra tubing; instead, bend two or three large coils behind the fridge so that you can move the fridge in and out for cleaning without putting any stress on the tubing or the connections.

6. Use a compression fitting to connect the kitchen end of the tubing to the back of the refrigerator’s water fill valve, usually located in the lower left corner.

7. After all the connections are made, open the water supply and check for leaks.

You shouldn’t have a leak at the refrigerator unless you didn’t connect the threaded fitting on the water inlet valve properly. If it leaks there, carefully remove the fitting and reconnect it, keeping the fitting straight with the threads. If the compression-fitting valve leaks, turn off the water and redo the compression fittings.

Make your icemaker work better and last longer

For pure, clean ice and better-tasting water, install an in-line water filter on the icemaker’s water supply tube. Adding a filter increases your icemaker’s life, because it removes particles and sediment from the water that would otherwise end up on the moving components of the icemaker and water dispenser. These hot dog-shaped filters get rid of particles and contaminants that can eventually clog the water inlet valve, the dispensing spout of the water dispenser, and the fill spout for the icemaker. Install the filter unit where you can access it easily. Otherwise, you may be discouraged from changing it because it’s a hassle to reach. I’ve seen them installed behind the refrigerator in the coiled tube section and in the basement, too, before the tubing goes up to the kitchen. Either place works fine. You’ll need to change the filter about every six months. (The actual length of time depends on your family’s water usage habits.) Adding a water filter costs less than $20, including the fittings. Replacement filters cost between $10 and $15, depending on whether you replace just the filtering material or the entire cartridge. All the materials are sold at appliance parts stores and at most home centers.

Doing the Dishes — Automatic Style

For most families, an automatic dishwasher is a must-have appliance. It not only cleans the dishes, glasses, silverware, and cookware, but it also keeps your counters cleaner and neater by preventing dirty dishes from piling up.

Gathering the right tools

Installing a dishwasher is pretty straightforward, and you don’t need much fancy tools and equipment. Simply gather the following common tools:

A power drill

A power drill

A bit for drilling a hole in the cabinet side wall (the correct size bit will be listed in your dishwasher’s installation instructions)

A bit for drilling a hole in the cabinet side wall (the correct size bit will be listed in your dishwasher’s installation instructions)

A straight-tip screwdriver

A straight-tip screwdriver

A 6-inch adjustable wrench

A 6-inch adjustable wrench

You’ll also need a hot water supply connection (which you get by tapping into the hot water supply line of your kitchen sink faucet), a drain connection, and a 120-volt receptacle or electrical box. Check with your city’s electrical inspector to find out which type of power hookup is allowed in your area. A dishwasher can drain directly into the sink’s drain line or into a food (garbage) disposer.

Some cities require that an air gap be installed if you drain the dishwasher directly into the disposal. The air gap prevents a clogged drain from backing up into the dishwasher by actually causing a break in the direction of the water flow. An air gap is a piece of plastic pipe with a V-shaped split at one end; the split ends are called nipples. This setup allows you to attach the dishwasher drain hose to the smaller straight nipple and a second, shorter length of pipe to the other air gap nipple and to the nipple on the disposer. Check with your city plumbing inspector to see what’s required for your installation.

If you do drain your dishwasher through your food disposer, be sure to remove the plug or knockout in the dishwasher nipple on the disposer before attaching the drain hose from the dishwasher or air gap, depending on your situation. If you don’t remove the plug, the dishwasher won’t drain, and you’ll be bathed in dirty, soapy water when you open the dishwasher door!

Installing the dishwasher unit

The basic steps for installing a dishwasher are listed as follows. Be sure to follow the manufacturer’s instructions as steps may vary slightly among brands.

1. If an air gap is required, mount it in one of your sink’s predrilled openings.

If you don’t have enough openings in your sink, drill a hole in the sink or in the countertop next to the sink.

2. Cut a hole in the side of the sink base cabinet right next to where the dishwasher will be installed.

This hole is for the dishwasher drain hose and the water supply line. Consult the manufacturer’s instructions for the exact size and location of the hole.

3. Remove the lower access panel from the front of the dishwasher.

This is where you’ll make the water and electrical connections to the dishwasher.

4. Attach a brass L-fitting to the water inlet valve.

This fitting is threaded and simply screwed on. Apply some pipe dope on the threads of the fitting that go into the inlet valve to make a leak-free connection. Consult the installation instructions for the location of the water inlet valve — it varies between manufacturers.

Again, your machine may or may not come supplied with a brass L-fitting. Dishwasher installation kits that do and L-fittings are sold at home centers and hardware stores. Check this out when you buy your machine.

5. Feed the drain line hose through the hole in the cabinet as you slide the dishwasher into place.

6. Level the dishwasher by following the installation instructions.

Most dishwashers have adjustable front feet that are threaded for easy adjustment. This is one time when it’s okay to eyeball the unit for level.

7. If your system has an air gap, attach the dishwasher drain hose to the smaller air gap nipple.

8. Attach a second hose to the other air gap nipple and then to the dishwasher nipple.

9. Secure all hose connections with screw hose clamps (often referred to as radiator hose clamps).

If your unit didn’t supply clamps, you can find them at home centers or auto parts stores. Buy a 2-inch or 3-inch clamp.

10. Connect the dishwasher water supply tube to the hot water shut-off valve and feed it through a hole in the cabinet to the underside of the dishwasher.

Get a supply tube that has a braided steel or nylon shell. This type of tube is very flexible, it doesn’t have to be cut to the exact length, and it lasts for years. You need a shut-off valve that has two outlets — one for the dishwasher and one for the faucet — which means that you have to replace the shut-off valve if there’s only one outlet for the faucet.

11. Attach the other end of the water supply tube to the other threads on the L-fitting.

12. Open the water supply valves and check for leaks.

13. If you don’t find any leaks, make the electric connections so that the unit will run, and reinstall the front panel.

Consult your owner’s manual for step-by-step instructions for this process because the steps vary among brands.

But one rule applies to all units: Turn off the power before making any electrical connections!

Taking Out the Trash — Sink Style

A food (garbage) disposer’s main job is to grind food waste so that it can be flushed down the drain, which cuts down on the amount of bagged garbage that goes into the local landfill. Yes, it does create more wastewater to be treated, but at least it can be treated and reused.

A food disposer takes the place of a sink basket and drain piece on one of the kitchen sink bowls. To install this appliance, consult the installation instructions that come with the unit, because the steps vary among brands.

Here are the basic steps for installing any food disposer:

1. Remove the sink basket (if one was installed).

2. Send the sink sleeve (which replaces the sink basket and secures the disposer to the sink bowl) through the hole in the sink bottom and secure the sleeve to the bowl by using the gasket and mounting rings, following the unit’s installation instructions.

The gaskets and mounting rings keep the sink sleeve from leaking when you run water. There are two mounting rings: the upper mounting ring and a backup mounting ring. There’s also a snap ring that goes into the groove on the backup mounting ring as extra security for keeping the unit in place.

3. Lift the disposer and align the mounting lugs (small, rolled curls of metal attached to the mounting ring) and mounting ears (90-degree angled metal cliplike pieces also attached to the mounting ring near the lugs) with the mounting screws located between the upper and backup mounting rings.

The mounting screws are threaded. The lugs and ears are located on the lower mounting ring, which is attached to the disposer housing (the main body of the unit).

Turn the disposer clockwise until it’s supported on the mounting assembly (sleeve and mounting rings).

4. Attach the discharge tube (a short, approximately 90-degree plastic elbow where the waste and water is discharged) to the discharge opening (the larger hole in the side of the housing) in the side of the disposer housing.

The tube uses a rubber gasket and metal flange to secure it and keep it from leaking.

5. If you’re draining your dishwasher through the disposer, remove the plug in the smaller dishwasher nipple and attach the dishwasher drain hose to the nipple with a hose clamp.

If you don’t have a dishwasher, do not remove the plug! If you remove the plug but don’t have a hose to connect to the nipple, the water will spew out the hole.

6. Connect the drain line pipe from the sink drain setup to the disposer’s discharge tube with a slip nut and washer.

You may need to cut either the discharge tube or the drain line pipe to fit.

7. Lock the disposer in place by using the disposer wrench (included with the unit).

Insert the wrench into one of the mounting lugs on the lower mounting ring and turn it clockwise until it locks.

8. Make the electrical connection.

A standard plug-end cord is the electrical power connection for most disposers. But you do need to connect the cord to the motor wires. Here’s how:

1. Remove the disposer’s bottom plate.

2. Strip off about 1/2 inch of insulation from each wire of the power cord.

3. Connect like color wires by using wire connectors.

4. To ground the unit, attach the green ground wire from the power supply to the green ground screw that will be on the disposer housing.

The screw is easy to spot, because it’s actually painted green.

5. Gently push all the wires in and reinstall the bottom plate.

6. Plug in the cord and you’re good to go!