Chapter 5

Go Flush! Selecting and Installing a Toilet

In This Chapter

Understanding the different types of toilets

Understanding the different types of toilets

Removing a toilet

Removing a toilet

Checking the floor around the toilet

Checking the floor around the toilet

Putting in a new toilet

Putting in a new toilet

I f you always took toilets for granted, you’re in for a big surprise when you find yourself in the toilet-buying market. Don’t be overwhelmed by the fact that you have hundreds to choose from. Consider this chapter Toilets 101, where you’ll find everything you need to know about choosing and installing the toilet that’s right for your home.

When it comes to a toilet, function follows form, so begin by pinpointing who the primary users are and how often it will be used. A good choice for an infrequently used powder room is a distant cousin from one that’s used in a family’s one-and-only hall bathroom. If you have large family members, you may want to consider elongated toilets, which are larger and more comfortable. Also available are elevated toilets, which are convenient for anyone who is physically challenged or has difficulty sitting down or rising. A standard toilet has a 15-inch rim height, but many of today’s toilet manufacturers are now offering 17-inch rim heights, which are more comfortable for most adults and meet the requirements of the Americans with Disabilities Act (ADA). Choose a toilet to fit the person who will use it.

You can buy a toilet for under $100 or over $1,000, and both of them can get the job done. But obviously, the durability, design, quality, and style are what account for the price difference. Figure an average price of $300 for a good-quality toilet that may outlive the people who installed it. Actually, the life expectancy of a toilet is 40-plus years. Set your budget first because it may limit the color selection, quality, quietness, flushing mechanism, water-conserving quality, and ease of cleaning.

Taking a Tour of Toilets

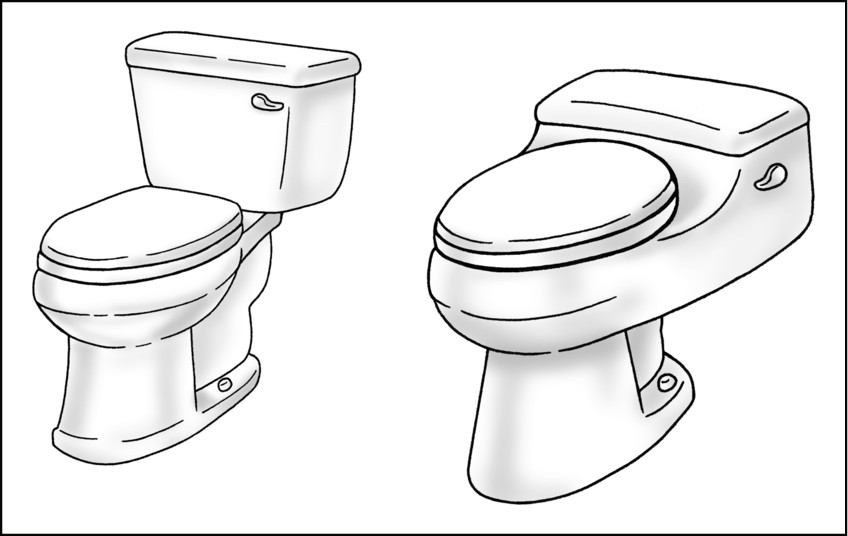

Most toilets are made of vitreous china, which means that they’re impervious to water. It’s a durable material that’s easy to clean, making it the obvious choice for a bathroom. Toilets come in two basic designs:

One-piece: This style is seamlessly molded together, has a streamlined look, and is, consequently, easy to clean.

One-piece: This style is seamlessly molded together, has a streamlined look, and is, consequently, easy to clean.

Two-piece: Less expensive than a one-piece unit but slightly more difficult to install, the more typical two-piece toilet has a separate water tank that hangs on the wall and rests on the toilet base or bowl.

Two-piece: Less expensive than a one-piece unit but slightly more difficult to install, the more typical two-piece toilet has a separate water tank that hangs on the wall and rests on the toilet base or bowl.

Check out Figure 5-1 to see the differences between one-piece and two-piece toilets.

|

Figure 5-1: Notice the differences between a two-piece toilet (L) and a one-piece toilet (R). |

|

Considering flushing mechanisms

The rush of the water moving through the toilet to remove the waste causes that whoosh that you hear when you press the flush lever. Good old gravity, water, or air pressure causes the water rush. Depending on where your toilet is located, one flushing method is better than the other. The types of flushing mechanisms are as follows:

Powered by gravity (the quiet flush): Gravity toilets are a lesson in basic physics: Press the lever to release water in the tank into the bowl. The weight of the water, located above the toilet’s drain, flushes the water and waste down the drain.

Powered by gravity (the quiet flush): Gravity toilets are a lesson in basic physics: Press the lever to release water in the tank into the bowl. The weight of the water, located above the toilet’s drain, flushes the water and waste down the drain.

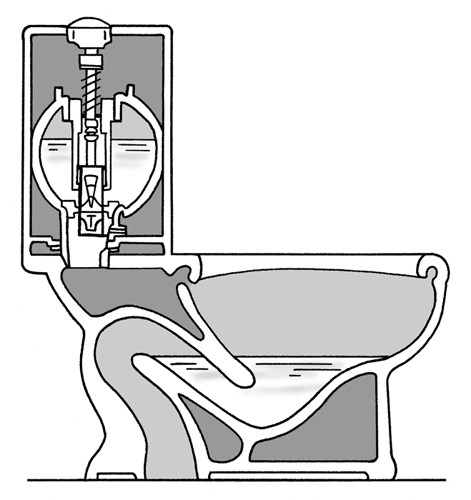

Pressure assisted (the big whoosh): Pressure-assisted toilets (see Fig- ure 5-2) use water pressure or compressed air to force water through the bowl and flush the water and waste down the drain. This type of toilet gets the job done, but because it’s sometimes noisy, everyone in the house may know just what you’re doing. The noise level also makes these toilets a bad choice near a bedroom or family room, but that may not be the case forever: Manufacturers are working on reducing the noise.

Pressure assisted (the big whoosh): Pressure-assisted toilets (see Fig- ure 5-2) use water pressure or compressed air to force water through the bowl and flush the water and waste down the drain. This type of toilet gets the job done, but because it’s sometimes noisy, everyone in the house may know just what you’re doing. The noise level also makes these toilets a bad choice near a bedroom or family room, but that may not be the case forever: Manufacturers are working on reducing the noise.

|

Figure 5-2: A pressure-assisted toilet. |

|

Getting a good fit

The typical height of a toilet is 14 to 15 inches, a convenient and comfortable height for most people. For tall or large people, elevated toilets are available that are up to 18 inches high. These elevated toilets are also convenient for anyone who is physically challenged and has difficulty sitting down or rising. You’ll also find ADA-compliant toilets that meet the standards of the Americans with Disabilities Act for wheelchair accessibility. And if parenthood is in your future, you may be interested to know that you can get a small toilet that’s scaled down for a child and designed for potty training.

The lowdown on low-flow toilets

In the early 1990s, a national law was passed to conserve water. It mandated that all new toilets sold in the United States require a maximum of 1.6 gallons of water per flush. The thinking was that by reducing the water from 3.5 gallons used by the old-style tanks, a lot of water would be saved. However, these early low-flow toilets were flawed in design and required two or sometimes, three flushes to empty the bowl. This, of course, gave credence to complaints of many homeowners, builders, and remodelers that low-flows nullify any water savings.

That’s all an unpleasant part of our history, and if you had one of those early low-flows, we hope you’ve replaced it. If you haven’t, do it now with one of today’s new and improved low-flow models.

Considering features and comfort

When you begin your personal survey of toilets, you’ll be amazed at the differences and nuances in comfort you’ll discover. Here are some things to notice in your quest for the perfect toilet for your remodeled bathroom:

Comfortable size: Is the toilet too small for a large person’s use? Consider an elongated toilet, which is usually about 2 inches deeper than a standard toilet and has an oversized seat, making it more comfortable and convenient to use.

Comfortable size: Is the toilet too small for a large person’s use? Consider an elongated toilet, which is usually about 2 inches deeper than a standard toilet and has an oversized seat, making it more comfortable and convenient to use.

Elevated height: For anyone who struggles while lowering and raising themselves, consider an elevated toilet, which is approximately two to four inches higher than a standard toilet.

Elevated height: For anyone who struggles while lowering and raising themselves, consider an elevated toilet, which is approximately two to four inches higher than a standard toilet.

Cleanability: Some people consider the ease of cleaning a toilet the most important feature. For them, a one-piece toilet with a smooth-sided bowl is the best choice. Another option is a toilet seat that pulls off without tools, so it’s easy to clean.

Cleanability: Some people consider the ease of cleaning a toilet the most important feature. For them, a one-piece toilet with a smooth-sided bowl is the best choice. Another option is a toilet seat that pulls off without tools, so it’s easy to clean.

Quiet flush: If your bathroom is next to living quarters, consider a toilet that offers a quiet flushing system. It’s much like a dishwasher: You want it to work, but you don’t want to hear it working.

Quiet flush: If your bathroom is next to living quarters, consider a toilet that offers a quiet flushing system. It’s much like a dishwasher: You want it to work, but you don’t want to hear it working.

Power flushing: Many toilet manufacturers have their own patented flushing systems designed to exceed performance standards. Most of these designs use water pressure to compress air in a chamber. When the toilet is flushed, the air pushes the water out of the chamber at high velocity, flushing the toilet with less water.

Power flushing: Many toilet manufacturers have their own patented flushing systems designed to exceed performance standards. Most of these designs use water pressure to compress air in a chamber. When the toilet is flushed, the air pushes the water out of the chamber at high velocity, flushing the toilet with less water.

Automatic seat closing: Some toilets are designed with a slow-moving hinge that gradually lowers both the seat and lid. Doesn’t this sound like the perfect solution for the lone woman in an all-male household?

Automatic seat closing: Some toilets are designed with a slow-moving hinge that gradually lowers both the seat and lid. Doesn’t this sound like the perfect solution for the lone woman in an all-male household?

Insulated water tank: To prevent a build-up of moisture on the outside of the tank (a breeding ground for mold and mildew), many toilets have an insulated water tank. The insulation prevents condensation by keeping the cold water inside. This feature is popular in humid climates.

Insulated water tank: To prevent a build-up of moisture on the outside of the tank (a breeding ground for mold and mildew), many toilets have an insulated water tank. The insulation prevents condensation by keeping the cold water inside. This feature is popular in humid climates.

Two-lever flush lever: To conserve water, many toilets offer a double-action flushing lever. You push the small lever to release less water for liquids or use the large lever to flush away solid waste.

Two-lever flush lever: To conserve water, many toilets offer a double-action flushing lever. You push the small lever to release less water for liquids or use the large lever to flush away solid waste.

Reinventing your bathroom with new fixtures

Decisions, decisions, decisions — that’s what you’ll face when you begin looking at toilets. Fortunately, the major manufacturers of plumbing fixtures have done some of the work for you by offering eye-catching suites or collections of fixture styles. You’ll find toilets and bidets, sinks, tubs, and faucets in a variety of styles that include contemporary, traditional, country, Victorian, and retro, just to name some of them.

If you’re remodeling a particularly small bathroom, you‘ll find compact-size toilets designed specifically to fit in small spaces. Some manufacturers offer a special corner toilet when that’s the only space available.

You can choose from a rainbow of colors for toilets and fixtures, as well as the more versatile white and off-white. If you’re choosing a colored fixture, make sure that you see a life-size floor model first — not just on a sample board. This isn’t wallpaper that you can just remove if you get tired of it. You can expect to live with a toilet, one of the more permanent fixtures in your home, for a long time.

Shopping for la toilette

Depending on where you live, you can shop for bathroom fixtures in several places. Many of the large home store chains have design centers within their stores, where a wide selection of toilets and related fixtures are installed in showroom settings. Kitchen and bathroom design centers feature extensive displays of bathrooms and a selection of fixtures and cabinetry. The more sources you can visit, the better. That way, you’re able to preview different types, styles, and colors of toilets, along with their related fixtures.

You can also purchase toilets and other bathroom fixtures from several sources on the Internet. But if you decide to buy online, do so only after you’ve done the footwork and know the toilet style, model, and color you want. Before placing an order online, investigate the cost of shipping and handling, as well as the return policy.

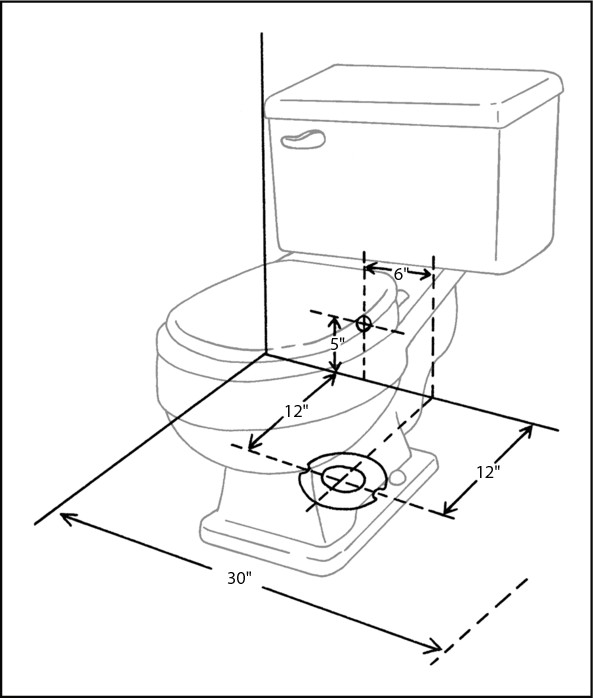

Roughing Dimension: Measuring Your Options

Installing pipes behind the walls or beneath the floor, called roughing in, is the first stage of a new plumbing job. In a remodeling project, the pipes are already there but may have to be altered. In either situation, the location of these pipes must match up with the fixtures that are installed later. To make sure that pipes and fixtures are properly aligned, manufacturers provide rough-in dimensions for each fixture. For a toilet, the important rough-in dimension is the distance from the wall to the center of the drainpipe in the floor and the height on the wall behind the toilet for the water supply line. If the drain isn’t the proper distance from the wall, the toilet could sit far from the wall and look silly. Even worse, if the drain is too close to the wall, the base of the toilet can’t be aligned over the drain. (See the section “Installing a New Toilet,” later in this chapter.)

If you’re replacing a really old toilet, measure the distance between the bolts that hold it to the floor and the wall. Prior to the mid-1930s, tanks were hung on the wall, and the bowl was attached to a sewer pipe with a mounting flange located either 10 inches or 14 inches from the wall. Today, toilets use a 12-inch roughing-in dimension, so if you’re replacing one of these good ol’ boys, you may have to hire a plumber to modify the drainpipe or install an offset toilet flange, which may give you the extra two inches that you need to install a 12-inch toilet on a 10-inch rough-in. Figure 5-3 illustrates a rough-in position for a toilet. Toilets are available on special order to fit the old dimensions, but the choice of styles is very limited.

|

Figure 5-3: The rough-in position for a typical toilet. |

|

Dethroning the Throne

Disconnecting an old toilet to prepare for the installation of a new one is nothing regal. The steps to install a toilet are the reverse of removing one, so you get a practice run before connecting the new one. Clear the floor and lay an old blanket or newspaper nearby so that you can rest the parts of the toilet on the paper as you disassemble it. You’ll also need a bucket, a large sponge, rags, rubber gloves, a wrench, and a scraper.

Follow these steps to remove an old toilet:

1. Pour 1/4 cup of toilet bowl cleaner or household bleach into the toilet and flush it a few times.

2. Turn off the water to the toilet and flush the toilet again, lift off the top of the tank, and set it aside so that it’s out of the way.

3. Mop water out of the tank with a sponge and disconnect the supply line to it at the bottom of the toilet tank.

The toilet bowl will have a small amount of water at the bottom.

4. Wearing rubber gloves to protect against bacteria, use a large sponge to soak up the water remaining in the bowl and squeeze it into a bucket. Continue until all the water is gone.

You can also use a wet-dry shop vacuum to remove the water left in the bottom of a toilet.

5. Remove the gloves and wash your hands thoroughly.

6. Look on the underside of the toilet base where the tank rests to find the tank mounting nuts and bolts. Use a wrench to loosen and unscrew them.

If the nuts and bolts are corroded and won’t budge with a wrench, give them a shot of WD-40 or Liquid Wrench, a spray lubricating oil. If that doesn’t loosen them, try a hacksaw, inserting the blade between the toilet base and the nut to cut through the bolts. Place masking tape on the surface of the toilet that’s near the bolts to protect the base.

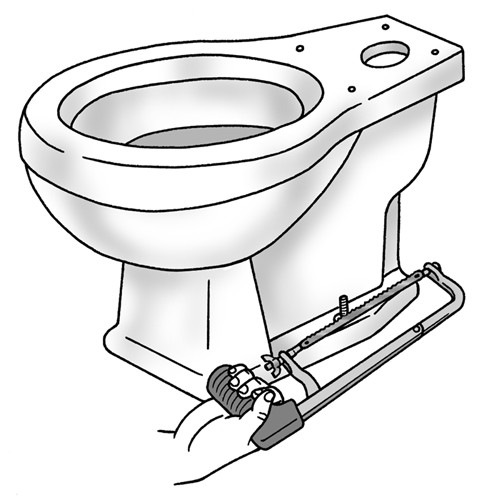

7. Find the nuts and bolts on either side of the base of the toilet that hold the toilet to the floor. If they’re covered with plastic caps, remove the caps and use a wrench to loosen and unscrew the nuts.

If the bolts are too corroded to unscrew, remove them with a hacksaw. (See Figure 5-4.) Keep a rag handy to wipe up any water that may seep out.

|

Figure 5-4: Use a hacksaw to cut through badly corroded closet hold-down bolts. |

|

8. Standing over the toilet bowl, gently rock it from side to side to break the seal of the wax ring; then lift it straight up and keep it level.

Water is likely to be left in the trap, and you’ll slosh it all over your feet and the floor if you tilt the toilet. Rest the toilet on an old blanket or newspapers.

9. Stuff an old rag in the hole in the floor, called the closet flange.

This hole is a direct path to the soil pipe that leads to the sewer or septic system. The rag prevents sewer gases from entering your home.

10. Find the old wax ring that sticks the base of the toilet to the floor and remove it.

11. Use a scraper or putty knife to thoroughly clean the floor of all the residue.

12. Wipe down the flange and surrounding area with a mixture of household bleach and water or use a disinfectant cleaning solution.

Preparing the Floor for a New Toilet

After you remove the toilet, inspect the underlayment for damage. The underlayment is a material that provides a flat, level surface for the finished flooring and toilet to rest on.

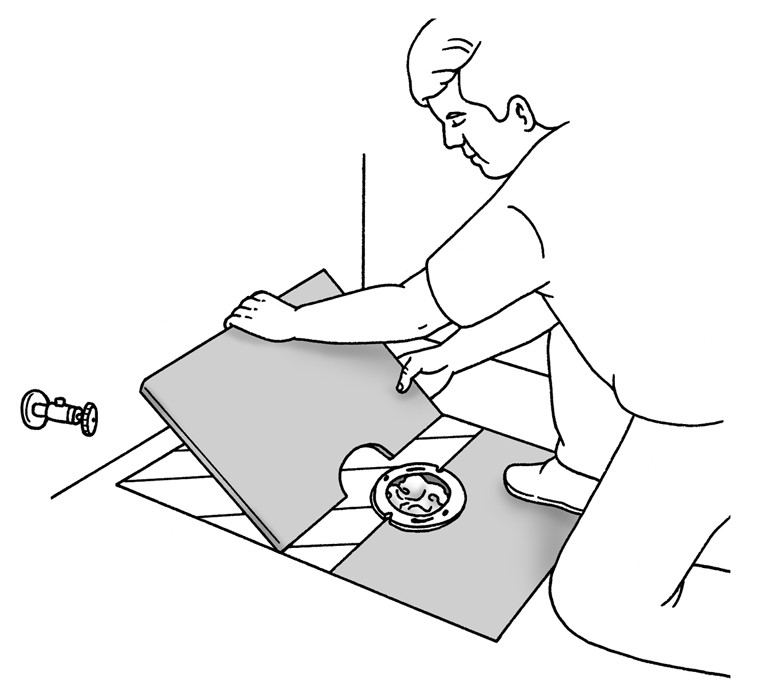

Look for telltale signs of moisture. Dark or discolored underlayment around a toilet indicates water damage. You can replace only the damaged sections, leaving in place what’s in good condition (see Figure 5-5). To make the repairs, cut away the damaged underlayment with a circular saw, setting the saw blade depth to match the thickness of the underlayment. Cut through the underlayment with the saw and remove the bad section around the toilet. Then cut a piece of underlayment of the same thickness as the old and replace the damaged pieces.

|

Figure 5-5: Before installing a new fixture, replace any damaged underlay-ment. |

|

If you’re installing a new floor over an existing one, plan to get an extension flange that raises the toilet up to align with the new flooring height.

Installing a New Toilet

You install a two-piece toilet in three phases: First, you secure the toilet base to the floor, then you fasten the tank to the base, and finally, you connect the water supply to fill the toilet with water.

A one-piece toilet is installed in the same way as a two-piece unit except that it’s more cumbersome and heavier to handle. Because it’s all in one piece, however, the installation goes faster, because you don’t need to install pieces separately. Use the basic instructions later in this section to install both types of toilets.

To install a two-piece toilet, you need the following:

Adjustable wrench

Adjustable wrench

Carpenter’s level

Carpenter’s level

Plumber’s putty

Plumber’s putty

Putty knife

Putty knife

Scrap of carpeting or heavy blanket

Scrap of carpeting or heavy blanket

Screwdriver

Screwdriver

Toilet and its mounting nuts and bolts

Toilet and its mounting nuts and bolts

Wax ring or bowl gasket

Wax ring or bowl gasket

Carefully read the installation instructions packaged with the toilet and identify the parts and then follow these steps to install a new toilet:

1. Remove the rag in the flange hole in the floor.

2. Prepare the floor for a wax ring.

If you haven’t already, scrape up any old wax and debris from the flange and surrounding area.

3. Locate the closet bolts and attach them to the toilet flange.

Turn the T-shaped head of each bolt so that it slips into the slot in the flange. Push the bolt into the slot and slide it into position so it’s parallel to the wall behind the toilet. Turn the bolt, so the head can’t be pulled out of the flange. Slide the plastic retainer washers down the threads to hold the bolts in place.

4. Turn the toilet upside down and rest it on a padded surface.

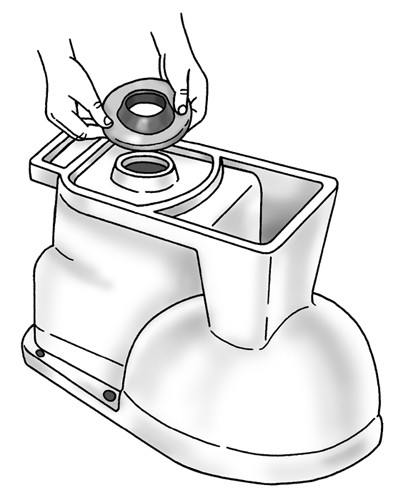

5. Locate the toilet horn, the short spout in the center of the toilet’s base. Place the wax ring and its sleeve onto the toilet horn and press it down firmly, as shown in Figure 5-6.

This wax ring fits around the toilet horn and compresses against the drain flange as you press it to the floor and then bolt it into place. The plastic spout must face up. You have a one-time shot with a wax ring, because after the ring is compressed, it won’t spring back. The key to a proper seal is to lower the toilet onto the flange without disturbing it.

|

Figure 5-6: Installing a new wax ring seal. |

|

6. Carefully lower the toilet base on the flange by lining up the closet bolts over the holes in the toilet base (see Figure 5-7).

It’s helpful to have another person on hand to line up the bolts with the holes in the base as you lower the toilet onto the floor. Keep the base level as you lower it to the floor.

Put plastic drinking straws over the bolts to lengthen them and act as guides as you lower the toilet onto the bolts.

7. Gently but firmly press the base down on the wax ring.

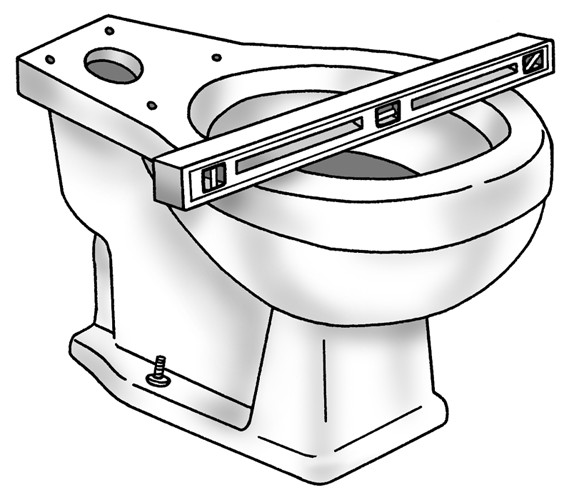

8. Put a carpenter’s level across the toilet base to assure that the bowl is level both side to side and front to back (see Figure 5-8), and then place the washers and nuts on the bolts, using an adjustable wrench to tighten them.

Alternate side to side as you tighten the nuts, checking that the bowl is still level side to side and front to back.

|

Figure 5-7: Lower the toilet bowl onto the bolts installed in the slots on the side of the toilet flange. |

|

|

Figure 5-8: Use a carpenter’s level to ensure that the bowl is level. |

|

.jpg)

Be careful not to overtighten the bolts. You don’t want to tighten them so hard that they crack the base of the toilet.

9. Cover the bolts with the trim caps.

If the bolts are too long for the trim caps to cover them, shorten them with a hacksaw. Snap the plastic trim caps in place to cover the bolts.

10. Install the flush mechanism (if necessary).

The fill and flush mechanism in a toilet tank regulates the flow of water into the tank when you push the lever. It opens a valve so that clean water in the tank flows into the toilet bowl, flushing out its contents. Most toilets come with the mechanism installed, but if yours does not, follow the instructions included with the toilet to install it.

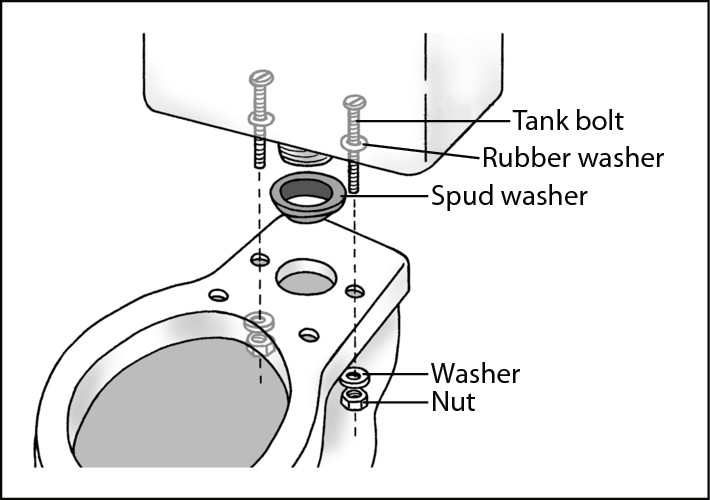

11. Turn the tank upside down and attach the rubber seal, called the spud washer, to the pipe that protrudes from the bottom of the tank.

12. Carefully turn the tank right side up and center the spud washer over the water intake opening, which is at the back edge of the bowl in the toilet base.

13. Lower the tank to the back of the bowl, align the tank bolts and rubber washers with the holes in the tank, and insert the tank mounting bolts through the holes in the bowl.

14. On the toilet bowl’s underside, thread on the washers and nuts, tightening by hand at first and then with a large screwdriver (see Figure 5-9).

Do so carefully and don’t overtighten. Be sure to turn the nut, not the bolt. Some toilet tanks have preinstalled mounting bolts, and others require that you preinstall the bolts. Follow the directions that come with the toilet.

|

Figure 5-9: Use a screwdriver to keep the tank bolts from turning while you tighten the nuts from below the tank. |

|

15. Connect the riser (supply) tube and shut-off valve by fastening the coupling nut to the tank fitting and the compression fitting to the shut-off valve, first by hand, and then with a wrench.

Reinforced flexible tubes available in various lengths in white or braided stainless steel are very reliable and easier to install than standard plastic or chromed brass tubes.

16. Turn on the water supply at the stop valve to fill the tank and toilet with water, checking for any leaks and watching the toilet as it begins to fill with water.

The water flow should begin to slow and stop at the fill line marked inside the tank. Tighten connections only as needed to stop leaks. Don’t overtighten.

17. Follow the manufacturer’s directions about adjusting the water level.

Some valves have a float arm that can be adjusted, and others have a setscrew to adjust.

18. Install the toilet seat by pushing the seat bolts through the holes in the toilet base and then holding the nuts on below while you tigheten the bolts with a large screwdriver.

That’s it! Enjoy your new throne.