Chapter 8

Bowled Over: Basins, Vanities, Medicine Cabinets, and Faucets

In This Chapter

Selecting a basin

Selecting a basin

Putting in a pedestal or wall-hung sink

Putting in a pedestal or wall-hung sink

Choosing and installing bathroom cabinets

Choosing and installing bathroom cabinets

Mastering Faucetry 101

Mastering Faucetry 101

D epending on what dictionary you consult, a lavatory is either a built-in washbasin, a room having one or more toilets and washbasins, or both. So don’t be confused when you order a sink and it comes in a box labeled “lavatory.” What makes today’s bathrooms interesting is the choices that you have when it comes to selecting a washbasin. Sure, you’ll find the traditional sink sunk into a nice countertop and the old-style pedestal sink, but you can also get a whole new breed of basins today.

Looking at Types and Styles of Basins

Before you walk into a design center to look at basins and faucets, do some noodling about who uses the bathroom and how often, what your priorities are, what style you like, and how maintenance-friendly you want the room to be. Yes, a snappy red pedestal sink would be a knockout, but in a family bathroom, a better choice is a countertop sink with a vanity for storage in a light color that doesn’t show soap scum and is easy to clean.

The range of basin styles is matched by the range in their prices. For example, a 19-inch-diameter sink made of vitreous china (which is fired to a hard, nonporous surface) sells for less than $100, and a cast-iron basin with a porcelain glaze goes for about $150. The price goes up to $1,000 if you want a fanciful pottery sink or a glass vessel that sits above a counter or in a metal bracket mounted on the wall. For a granite or marble bowl, the prices go into the $1,600 range.

Manufacturers sell both cast polymer and solid-surface sinks as one unit, called an integral sink, combining a sink and a countertop that you can install easily on top of a vanity base cabinet. They come in a range of sizes, from 25 to 49 inches wide, and are designed to fit the most popular vanity cabinets. The seamless design of these units makes them easy to clean and eliminates the need for caulk to seal a joint between the countertop and basin. A 36-inch-wide cast polymer countertop and sink, made of polyester resin and granite or crushed marble, costs less than $350. For under $700, you can get a solid-surface unit with color throughout its thickness, a popular choice for shaped and contoured edges.

Putting In a Pedestal Sink

What it lacks in storage space, a pedestal sink makes up for in high style. A small-bowl pedestal is a good choice in a powder room because it takes up little floor space, and a wider console style with a basin ledge for toiletries makes a handsome addition to any bathroom. If you’re replacing a wall-mounted sink, you can install a pedestal sink relatively easily. Just hook up the new sink to the old plumbing.

Before you purchase a pedestal sink, remove the old sink and measure the location of the plumbing lines so that you can choose a new sink that matches up with them. To get these rough-in dimensions, make a sketch of the wall and note the following measurements:

Distance from the floor (or wall) to where the drain enters the wall (or floor)

Distance from the floor (or wall) to where the drain enters the wall (or floor)

Distance between the floor and the water supply pipes

Distance between the floor and the water supply pipes

Distance right to left from each water supply pipe to the drain

Distance right to left from each water supply pipe to the drain

Sit on the floor with the sketch in hand and visualize how the back of the pedestal sink will match up with the supply lines. Also, check the sink’s specifications and rough-in dimensions. You can do this rough measuring by finding sinks that you like at a home center; note the manufacturer, style, and model number and then visit the manufacturer’s Web site. Most manufacturers provide specifications and rough-in dimensions online, so deciding what fits and what doesn’t is easy.

Of course, a plumber or knowledgeable salesperson in a home center can help you do the same thing, assuming that you have your sketch with you and your measurements are correct.

How you install a pedestal sink varies by style and manufacturer. Some use a wall bracket, although others are secured directly to the wall with lag screws or toggle bolts through holes in the back of the bowl. Most sinks rest on the pedestal but get major support from the wall mounting. The instructions in the following sections are for installing a pedestal sink with a mounting bracket. The project involves completing several individual tasks and then connecting everything. You purchase the faucet, drain, and pop-up assembly separately. Before you install the sink, install the drain, pop-up assembly, and faucet.

Installing the drain and pop-up assembly

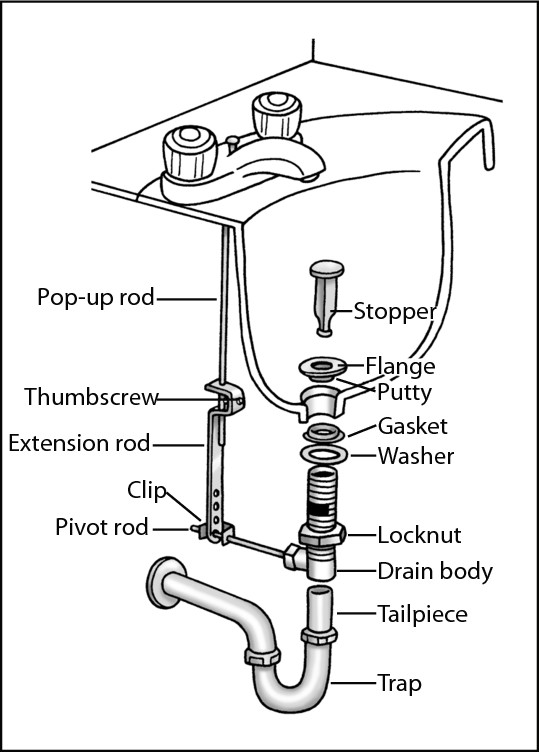

This section contains generic directions for installing a typical assembly. Carefully read the directions that come with the unit that you buy to familiarize yourself with the parts and how they fit together. Figure 8-1 introduces the major players in this process.

|

Figure 8-1: The main parts of a typical lavatory’s drain assembly. |

|

The drain consists of pipes that attach to the sink and lead to the trap. The following steps explain where the different metal and rubber washers go:

1. Thread the large locknut onto the drain body.

2. Slip the flat washer and then the wedge-shaped rubber gasket onto the drain body.

3. Place a thin bead of plumber’s putty around the underside of the drain flange.

4. Push the drain body up through the hole in the bottom of the sink.

5. Thread the drain flange into the body of the drain.

6. Turn the drain body so that the opening for the pivot rod mechanism faces the back of the sink.

7. Using groove-joint pliers, tighten the locknut on the drain from the underside of the sink until the plumber’s putty is compressed and the flange looks and feels tight.

The pivot rod operates the mechanism that opens and closes the drain. Most units have a rod with a ball on it that operates the drain plug. To assemble this mechanism, follow these steps:

1. If the retaining nut is screwed onto the valve body, remove it and the washers. If not, skip this step.

2. Slide the washer seal over the short end of the pivot rod.

3. Insert the short end of the pivot rod into the drain body and thread on the nut.

Don’t tighten it yet.

4. Insert the pop-up rod through the hole in the faucet’s body.

5. Push the pivot rod all the way down.

6. Connect the extension rod (the short arm through which the pivot rod extends) by placing the pivot rod in the first or second hole of the extension rod and sliding the pop-up rod into the extension rod.

7. Pull the rod all the way down and tighten the thumbscrew.

Installing the sink

Before a pedestal sink takes its place, you need to shore up the wall behind it to hold its weight. After you do that, you can install the sink easily.

Shoring up the wall

To provide a solid surface for mounting the sink, reinforce the wall with wood blocking, which we describe in Steps 1 through 6 of the section “Installing a Cast-Iron Wall-Hung Sink,” later in this chapter.

Mounting the sink to the wall

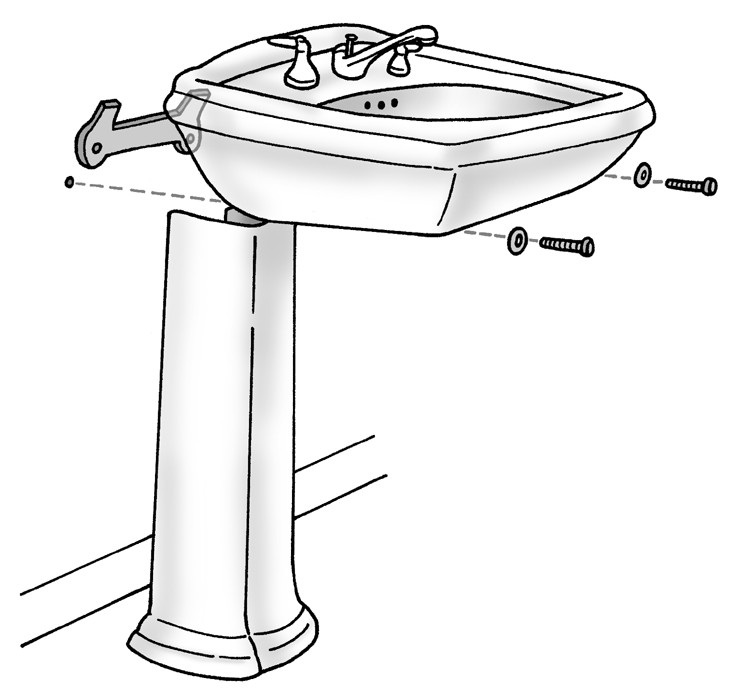

After reinforcing and repairing the wall, you can install the sink. Some sinks require you to install a separate bracket first, although others mount directly to the wall. The following directions are for a sink with a bracket, so you can skip them if the sink you’re installing doesn’t have a bracket. Figure 8-2 shows a typical installation.

|

Figure 8-2: You hang pedestal sinks on a wall bracket or secure them directly to the wall and support them with the pedestal. |

|

1. Position the bracket on the wall and use it as a template to mark the location for the mounting lag bolts (large screws with a square or hex head).

To determine the exact location of the mounting bracket, consult the roughing-in dimensions provided by the manufacturer. Make sure that the bracket is level.

2. Drill pilot holes through the layout marks on the wall into the wall reinforcement.

Make the holes about 1/8 inch smaller than the lag bolts that came with the sink.

3. Install the bracket with the lag bolts.

4. Hang the basin on the wall bracket and then install the mounting screws to hold the sink to the bracket and wall.

If the sink doesn’t have a mounting bracket, install it directly to the wall with the fasteners provided.

5. Test-fit the pedestal, mark its location, and then move it safely out of the way.

Installing the P-trap

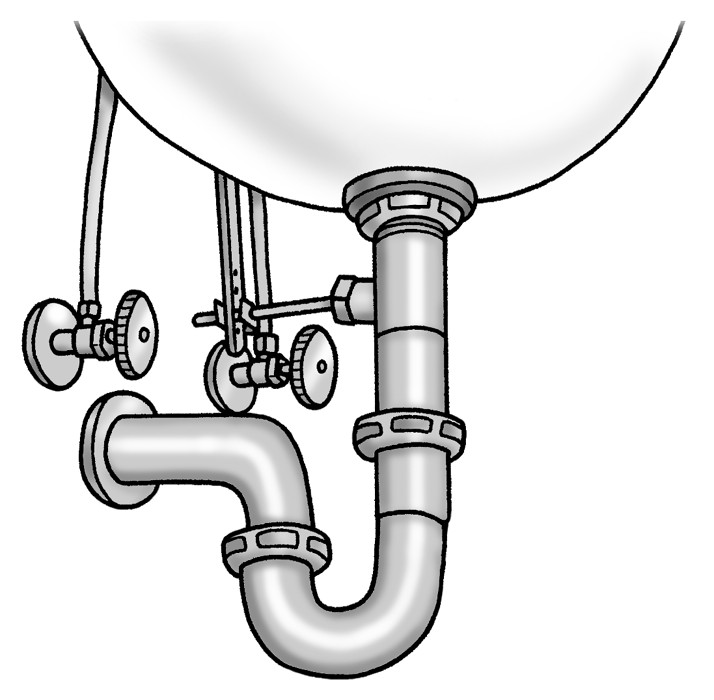

With the sink on the wall, you can install the P-trap, the pipe that connects the sink to the house drain. The U-shape of this pipe is the trap that retains enough water to prevent sewer gases from entering the bathroom. You can adjust the P-trap, sliding it up and down on the pipe that leaves the sink drain. The other end of the P-trap can slide into and out of the fitting on the wall.

Referring to Figure 8-3, follow these steps to install the P-trap:

1. Slide the short side of the P-trap onto the tailpiece that drops down from the sink drain. Move the P-trap up or down to align the trap arm with the opening in the wall.

Use a hacksaw to cut the tailpiece if you can’t move the P-trap higher up the tailpiece and the trap arm is below the wall drain fitting. Purchase a longer tailpiece if the P-trap lies above the wall drain fitting when attached to the end of the tailpiece.

2. Take the lower part of the P-trap apart and insert the trap arm into the wall drain fitting as far as it will go.

3. Pull the trap arm out of the wall fitting until it lines up with the top U-shaped portion of the trap.

If the trap arm comes completely out of the wall before it can be attached to the trap, purchase a longer trap arm. If the trap arm is in the wall fitting as far as it will go and extends past the U-shaped part of the trap, cut it with a hacksaw.

4. Insert the trap arm back into the wall drain, move it into alignment with the trap, and thread on (but don’t tighten) the slip nut.

5. After you’ve joined the trap parts together, tighten the slip nuts on the tailpiece and the wall drain fittings.

|

Figure 8-3: The P-trap and riser tubes. |

|

Attaching riser tubes to the faucet

After installing the P-trap, turn your attention to attaching the riser tubes (supply lines) to the faucet tailpieces, using the compression nuts that came with the faucet. The riser tubes connect the faucet to the stop valves. Here are a couple of pointers for attaching the tubes to the faucet:

Snug up the nuts by hand.

Snug up the nuts by hand.

Bend or loop the riser tubes so that they fit between the stop valves and the wall before tightening them with a wrench.

Bend or loop the riser tubes so that they fit between the stop valves and the wall before tightening them with a wrench.

Finishing up

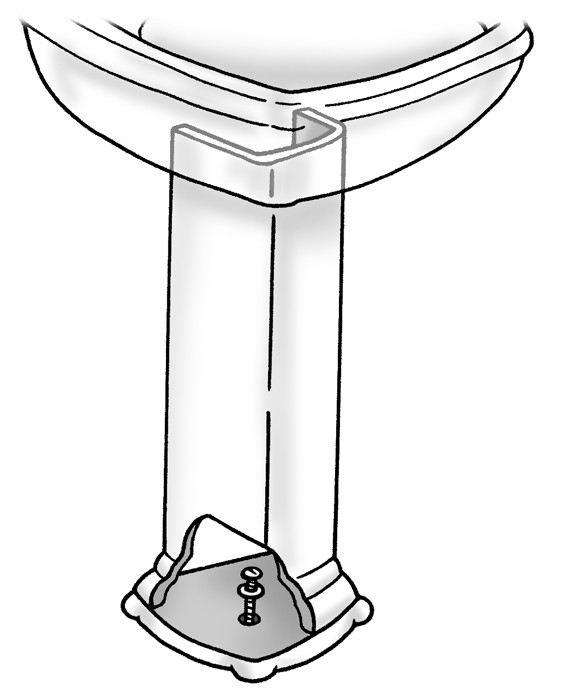

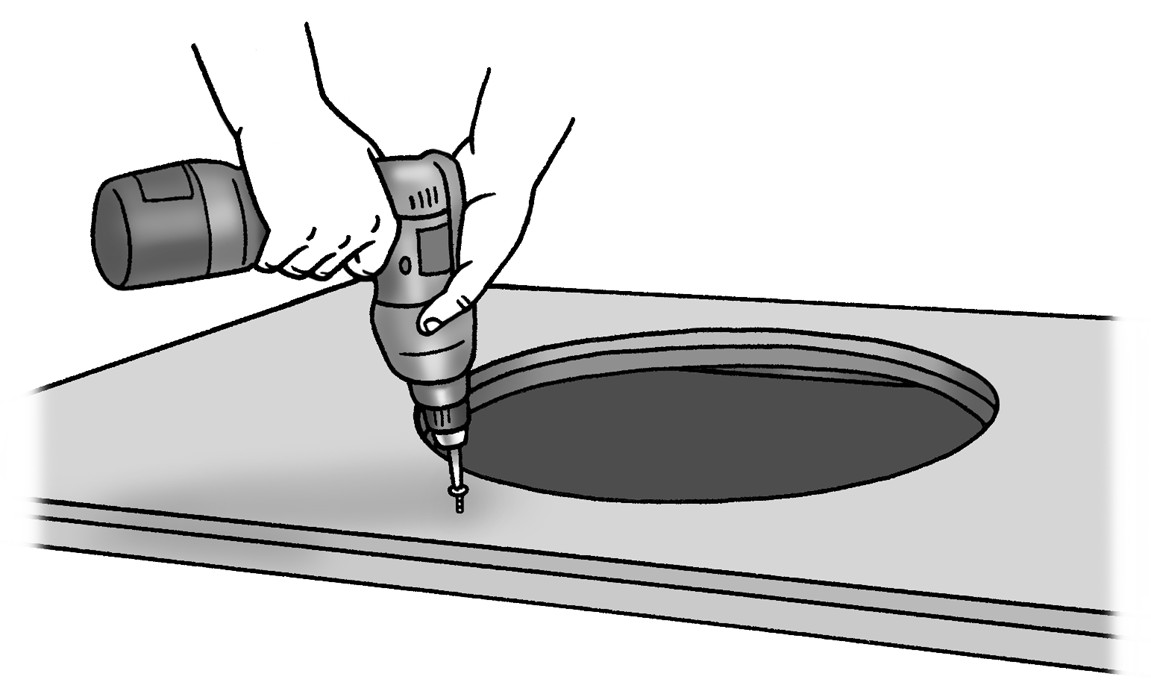

The moment of truth has arrived: You have to turn on the water at the shut-off valves and the faucet and test for leaks in the supply lines and fittings leading to the faucet and in the drain lines and fittings. When everything is drip free, install the pedestal by positioning it properly beneath the sink and securing it to the floor with a wood screw (see Figure 8-4). If the floor is tile drill a clearance hole through the tile with a masonry bit first.

.jpg)

Lastly, caulk any gaps or voids between the wall and the basin, removing any excess caulk with a wet rag.

|

Figure 8-4: The pedestal is held in place with a wood screw. |

|

Installing a Cast-Iron Wall-Hung Sink

Wall-hung sinks that you mount on the wall can be customized to the user’s height. It’s a nice way to personalize a bathroom for someone who’s particularly tall or short. A sink mounted on the wall is also ideal for a person in a wheelchair because the sink has access underneath it; however, be sure to slip an insulated cover over the trap so that the pipe (heated by hot water passing through) doesn’t burn the person’s legs. A wall-mounted sink also takes up less space in a small room than a traditional vanity with sink.

Preparing the supporting wall

When you’re going to install a sink in an existing bathroom, you have to remove the drywall in the area behind the sink to add blocking to provide the support needed for the sink. You have to open the wall to expose at least two studs, neither of which can be located directly behind the sink. If a wall stud happens to be centered directly behind the sink, you need to open the wall to three studs — the one behind the sink and the studs on either side of it. You have to support both ends of the blocking with a stud. Follow these steps to provide the necessary support:

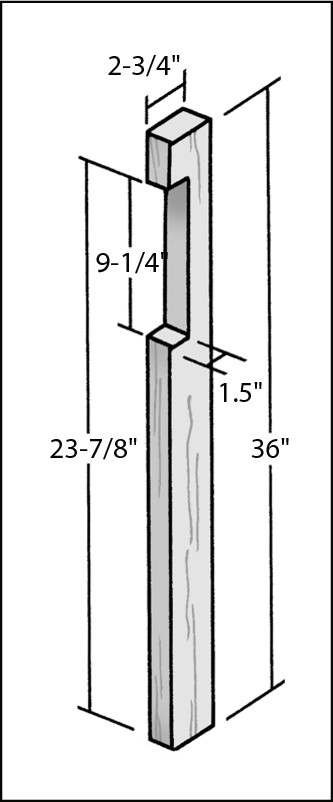

1. Cut a 2 x 4 into two 36-inch pieces.

2. Cut these two boards lengthwise to a 2 3/4-inch width.

3. In each board, cut a notch that’s 1 1/2 inches deep and 9 1/4 inches high.

Position the notches 23 7/8 inches from the end of the board, as shown in Figure 8-5.

|

Figure 8-5: The dimensions of the side braces cut from a 2 x 4. |

|

4. Nail or screw the boards to the studs.

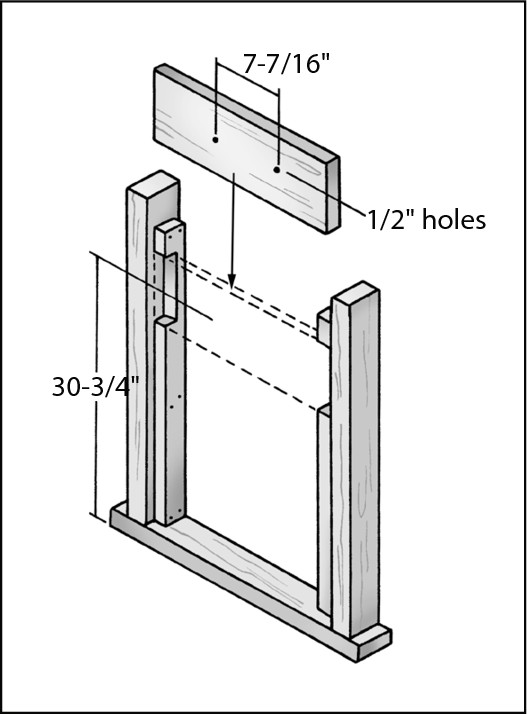

5. Cut a piece of 2 x 10 to fit between the notches and studs, as shown in Figure 8-6.

If the 2 x 10 spans a center stud, you must notch the stud to accept the board.

|

Figure 8-6: Screw 2 x 10 blocking to the side braces to support the sink. |

|

Setting the mounting bolts

Next, you need to set the mounting bolts into the support brace in the wall. Follow these steps:

1. Mark the location of the mounting bolts on the 2 x 10.

The bolts are located 30 3/4 inches from the floor and 7 7/16 inches apart. You have to place the bolts behind the sink, but they can’t line up exactly in the center of the 2 x 10 brace.

2. Remove the 2 x 10 from the wall and drill 1/2-inch holes through the layout marks.

3. Insert the mounting bolts.

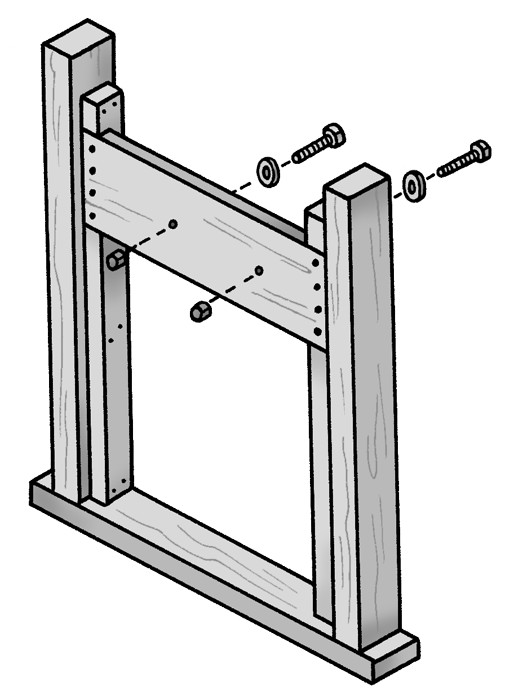

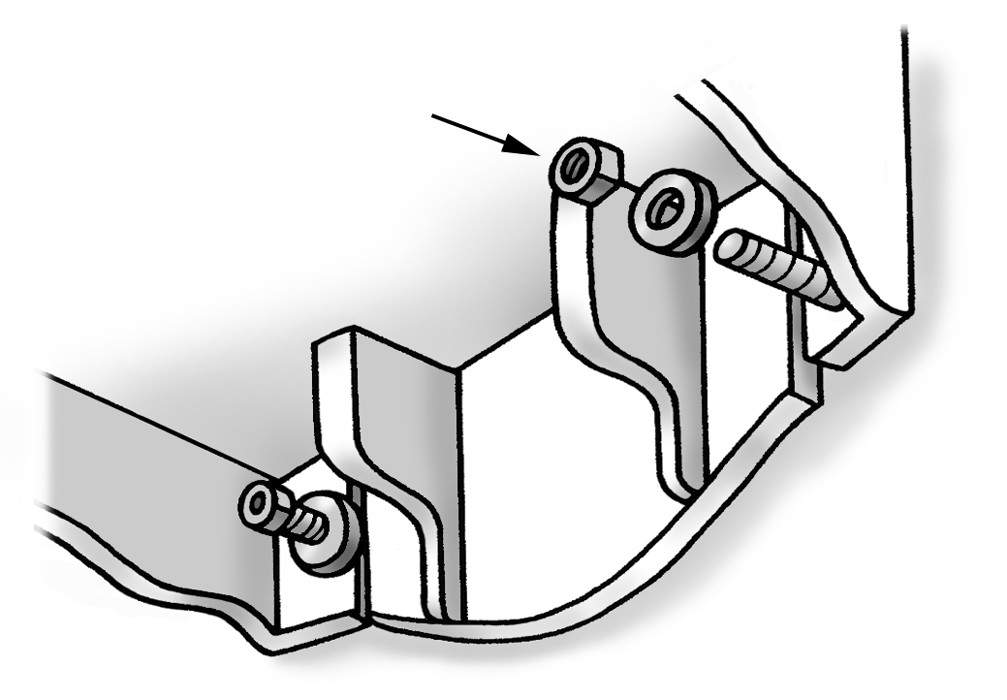

4. Install the threaded inserts to hold the bolts in place (see Figure 8-7).

|

Figure 8-7: Threaded inserts supplied with the sink hold the mounting bolts in place. |

|

5. Fasten the 2 x 10 brace to the wall studs by using 2 1/2-inch screws.

6. Cut a piece of 3/4-inch plywood to fit between the wall studs.

If the opening is three studs wide, you must remove 3/4 inch from the front edge of the center stud so that you can install the plywood flush with the wall studs on the outer sides of the opening. In this case, make several 3/4-inch-deep cuts in the edge of the center stud and use a wood chisel to knock off the wood between the cuts.

7. Drill holes in the plywood for the mounting bolts and plumbing pipes.

8. Screw the plywood to the support boards (see Figure 8-8).

|

Figure 8-8: Screw plywood filler to the side braces; it has to lie flush with the front of the studs so that you can cover it with drywall. |

|

9. Apply moisture-resistant drywall (green board) to cover the opening.

10. Tape and mud the joints between the existing wall and the new drywall with joint compound.

11. Sand the joints smooth and paint the wall.

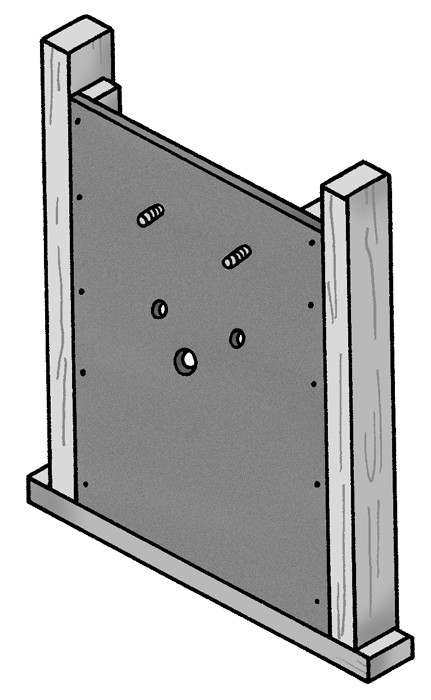

Bolting the sink to the wall

The last step is to mount the sink on the wall — it’s heavy, so get help.

1. Lift the sink onto the mounting bolts.

2. Slip on the washers and thread on the nuts (see Figure 8-9).

|

Figure 8-9: Two large bolts hold a wall-mounted sink to the wall. |

|

3. Use a carpenter’s level to position the sink so that it’s level.

4. Tighten the bolts with a wrench.

After you have the sink in place, see the earlier sections “Installing the drain and pop-up assembly” and “Installing the P-trap,” earlier in this chapter, and the section “Getting a Handle on Faucets,” later in this chapter.

You’re So Vain: Vanity Cabinets

A vanity cabinet is like any piece of furniture: The price goes up as the quality improves. You can find in-stock factory-made vanities in a range of sizes and styles, meaning that you can walk into a store and leave with the vanity of your choice. Or you can order a semicustom vanity that’s factory made and customized with specialty finishes and handy options like a pull-out tray, bins, and shelves. At the high end, you find a custom-made cabinet designed by you or a designer to specifications not available in stock or semicustom cabinets. Although a custom piece can be pricey, it can be a design solution that makes the most of a cut-up or tight floor plan. Remember to allow extra time if you purchase a vanity that’s made to order.

You get what you pay for when it comes to the construction of a vanity. Better-quality pieces have backs made with tongue-and-groove construction, a solid face frame, full-depth drawers, and thick shelving. Doors have substantial hinges that open and close easily, and drawers glide on their tracks.

Vanities are shorter than kitchen cabinets, which may work for kids and shorter adults, but you may get tired of bending down to wash your face. Manufacturers now make taller vanity cabinets, or you can use a kitchen cabinet as a base to create a higher vanity and make a new kickboard (the board under the front of the cabinet that covers the platform).

Looking at your options

You use the traditional vanity cabinet, which offers the most counter and storage space, with a single basin or pair of basins. You install it by fastening it to the wall. You can find several types of basins, and the installation methods vary:

A self-rimming sink is dropped into a cutout in the countertop. Its rim overlaps the surface, forming a seal.

A self-rimming sink is dropped into a cutout in the countertop. Its rim overlaps the surface, forming a seal.

A flush-mount sink is installed so that it’s level with the surface of the countertop. It’s also called a tile-in installation because the sink is designed to fit flush with a tiled countertop.

A flush-mount sink is installed so that it’s level with the surface of the countertop. It’s also called a tile-in installation because the sink is designed to fit flush with a tiled countertop.

An above-counter basin, also called a vanity top installation, is used for basins or vessels that are installed to rest on top of the counter.

An above-counter basin, also called a vanity top installation, is used for basins or vessels that are installed to rest on top of the counter.

An under-counter sink mount is used with stone or solid-surface countertops. The rim slips beneath the countertop and creates a seamless appearance.

An under-counter sink mount is used with stone or solid-surface countertops. The rim slips beneath the countertop and creates a seamless appearance.

Every vanity needs a countertop. The following are the most common countertop materials:

Laminate: This material comes in ready-made stock sizes or ordered in an endless number of colors and patterns.

Laminate: This material comes in ready-made stock sizes or ordered in an endless number of colors and patterns.

Solid surface: Like laminate, this man-made material is also available in a variety of colors and patterns. Pliability is its unique feature; you can configure it to be more versatile than laminate, particularly if you want edging details. It can also be ordered with an integral sink.

Solid surface: Like laminate, this man-made material is also available in a variety of colors and patterns. Pliability is its unique feature; you can configure it to be more versatile than laminate, particularly if you want edging details. It can also be ordered with an integral sink.

Ceramic, stone, slate, and marble tiles: You install these materials over a base and then lay them in intricate patterns on a counter surface or as a solid design. Like solid surface, tile makes an ideal backsplash, wall covering, and countertop in a bathroom. When installed over a base cabinet, you place the tile on a base of plywood and backerboard with thinset mortar and then grout it.

Ceramic, stone, slate, and marble tiles: You install these materials over a base and then lay them in intricate patterns on a counter surface or as a solid design. Like solid surface, tile makes an ideal backsplash, wall covering, and countertop in a bathroom. When installed over a base cabinet, you place the tile on a base of plywood and backerboard with thinset mortar and then grout it.

Installing a vanity

Carefully unpack the vanity from its box, check that its measurements are correct, and move it into position. Use a carpenter’s level to make sure that the floor is level so that the new vanity can rest on a sound, level surface.

If you find that the floor isn’t level, do the following:

1. Find the high point of the floor using a carpenters level. Lift one end of the level or the other, as needed, to center the bubble in the vial. The point that touches the floor is the high point.

2. Measure the height of the cabinet. Measuring up the wall from the high point on the floor, mark the height of the cabinet, and then draw a level line at that point.

3. Use the level to draw a vertical line where one edge of the cabinet will be located.

4. Slide the vanity in place and align it with the horizontal and vertical reference line on the wall.

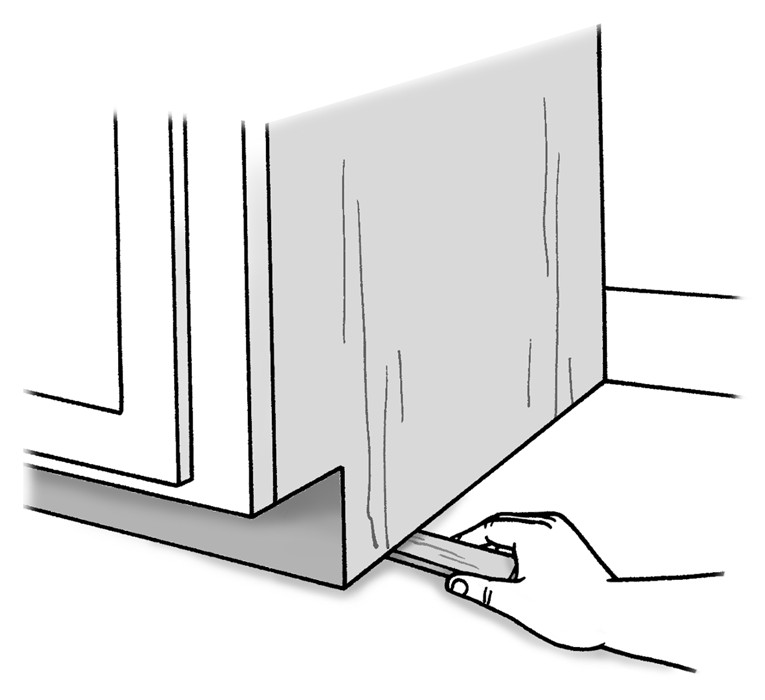

Drive tapered wood shims between the floor and the base as you need to adjust and level the vanity (see Figure 8-10).

|

Figure 8-10: Wood shims level the cabinet. |

|

Finding wall studs behind your vanity is important. You can use an electronic stud finder to accomplish this task. The original builders probably used the studs to secure the old unit, so old screw holes may point to the studs.

.jpg)

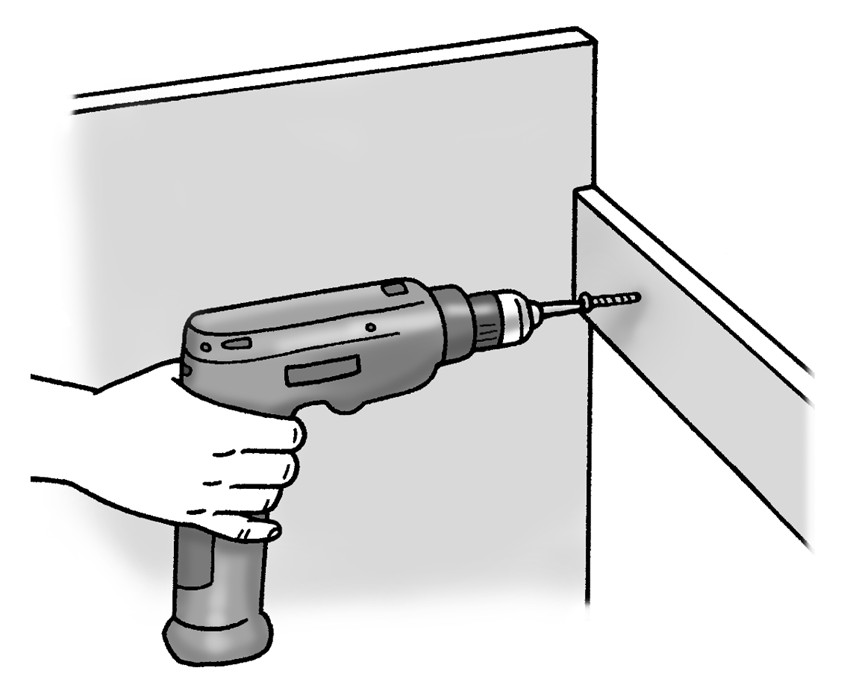

1. Use long drywall screws to fasten the vanity to the studs through clearance holes drilled through the mounting board. (see Figure 8-11).

2. Use a utility knife to cut off any shims that stick out.

3. Caulk small gaps between the vanity and the floor and wall.

|

Figure 8-11: Fasten the cabinet to the wall with screws driven through the back frame into the wall studs. |

|

Topping your vanity with stone

One of the hottest looks in bathrooms is a granite countertop on a wood vanity. You often only need a rich-looking countertop of stone — a durable, high-style material — to update a cabinet. At home centers, you find a range of colors and sizes. Typically, stone countertops come in widths of 25, 31, 37, and 49 inches, with a separate backsplash and bowl that you glue to the underside of the countertop before fastening it to the vanity base. The countertop is conveniently predrilled with three holes on either 4-inch or 8-inch centers for a faucet.

Positioning the sink

A stone countertop comes ready for sink installation. Follow these steps:

1. Lay the countertop polished side down on a work table or on 2 x 4s across a pair of sawhorses.

2. Unpack the sink and place it upside down over the sink hole in the countertop.

3. Line up the back edge of the sink so that it sits between the faucet holes and the inner edge of the sink hole in the top.

Make sure that the sink is centered over the sink hole. Feel around the edges underneath the countertop to ensure that the sink is centered.

4. With a felt pen, draw a line all around the sink on the bottom of the countertop.

5. Make alignment marks on the front and back of the sink and countertop.

Begin the line on the sink and continue it on the countertop. After removing the sink, you can replace it in the exact same position by matching the lines on the sink with those on the countertop.

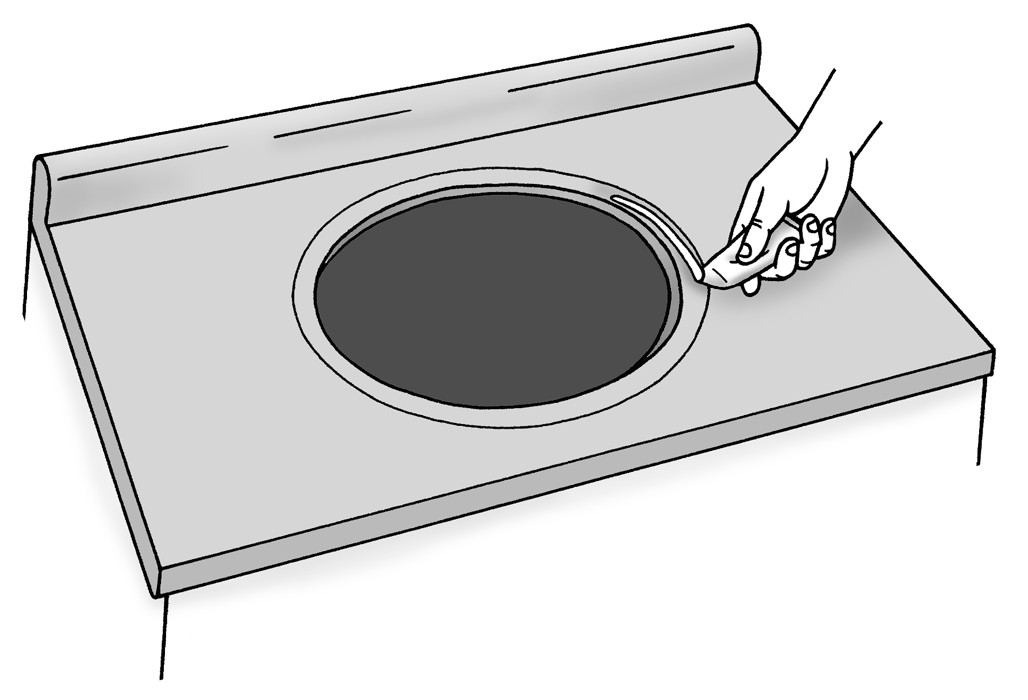

Sticking the sink to the stone

The sink is attached to the underside of the stone countertop with epoxy (see Figure 8-12). This step isn’t difficult, but you must set the sink in the right place. After the epoxy cures, you can’t change your mind! Here’s how you glue a sink to a countertop:

|

Figure 8-12: Apply epoxy around the perimeter of the sink opening. |

|

1. Lift the sink off the vanity top and set it down within easy reach of the countertop.

You don’t have much time to position the sink after you pour the epoxy.

2. Mix the epoxy by following the directions on the packet that came with the countertop.

To activate epoxy, you usually knead both sides of the packet together by hand or by sliding the packet up and down along the edge of the countertop to mix it thoroughly. Continue kneading the epoxy packet against the countertop edge until it begins to feel warm to the touch (about three minutes).

3. When the epoxy feels warm, immediately cut off one corner of the packet with scissors and squeeze the contents quickly and evenly onto the countertop around the inside of the line you drew.

Work quickly! After the epoxy begins to warm up, it continues to heat and hardens quickly. When finished (or if the epoxy gets too hot to handle), place the used epoxy packet in a metal can or on a nonflammable surface.

4. Quickly place the sink back on the underside of the countertop inside the outline you drew, making sure to place the back of the sink toward the faucet holes and line it up exactly with the front and back alignment marks that you made.

5. Move the sink back and forth for about five seconds, making sure that it’s within the layout circle.

Doing so ensures that you have the epoxy spread around as much as possible between the top and sink.

Before installing the countertop and sink on the vanity, install the faucet and drain body according to the manufacturer’s directions while you have easy access.

Installing a sink and countertop on your vanity

After the epoxy has dried for about 45 to 60 minutes, check whether the sink has adhered to the countertop by carefully lifting up the sink a few inches by the bottom drain hole. If the vanity top lifts with the sink, you’re ready to carry it into the bathroom and install it on the vanity.

Run a bead of silicone caulk around the top edge of the vanity, carefully lower the top in place, and center it over the vanity base. Clean up excess caulk with a damp rag.

To finish up, clean the surface of the stone countertop and sink thoroughly, let it dry, and then apply a stone sealer. Complete the supply and drain line connections as described for pedestal sinks earlier in this chapter.

Topping your vanity with tile

The selection of ceramic, slate, stone, and marble tile for bathroom countertops is vast, indeed. The choice of colors, textures, and patterns of ceramic tiles is awesome, and their hard finishes and durable quality make them good choices. Similarly, you may want to consider slate, stone, and marble tiles, which offer the same durability in more natural shades.

Tile comes in many shapes and sizes, but the specially shaped trim pieces are what make using tile so versatile. These preformed pieces make finishing off the edge of a counter or navigating an inside corner possible. Here’s a short list of trim that you can find at most outlets:

Edging or bullnose tiles with one rounded edge

Edging or bullnose tiles with one rounded edge

Inside-outside corners with four edges rounded

Inside-outside corners with four edges rounded

Inside and outside corner caps

Inside and outside corner caps

V-cap for edging

V-cap for edging

Bead for straight edges

Bead for straight edges

You can transform a bathroom with a new tile countertop and add years of service to an existing vanity (or replace the vanity, too). The emphasis here is on the countertop, so choose tiles with that fact in mind. For inspiration, visit a tile retailer, where you can find the widest selection and most displays of tile countertops. Bring along a sketch of the vanity cabinet on graph paper with dimensions, including the backsplash on the wall behind it.

A self-rimming sink is the best type of sink for a tile countertop because you install it after the tile is set, and you can easily seal the joint between the sink and tile with caulk.

A self-rimming sink is the best type of sink for a tile countertop because you install it after the tile is set, and you can easily seal the joint between the sink and tile with caulk.

Buy more tiles than you need, allowing yourself a few miscuts or tiles that break when you cut them.

Buy more tiles than you need, allowing yourself a few miscuts or tiles that break when you cut them.

Double-check your measurements and ask the tile dealer to check your dimensions so that you order the correct amount of tile and material.

Double-check your measurements and ask the tile dealer to check your dimensions so that you order the correct amount of tile and material.

Before beginning the job, open all the cartons and make sure that the tiles are the right size, color, and design.

Before beginning the job, open all the cartons and make sure that the tiles are the right size, color, and design.

Building the underlayer

The first stage in installing a tile countertop is preparing a sturdy, level surface to lay the tiles on. Before you can start, you need to measure the length and width of the vanity cabinet and build a backing made of 3/4-inch AC grade plywood and tile backerboard, such as cement board. If you’re replacing an old countertop, use it as a template to cut the backing and backerboard (see Figure 8-13). Otherwise, cut the plywood and cement board 1 to 2 inches larger than the cabinet (depending on how much overhang you want).

1. With the template that came with the sink, trace an outline for the cutout where the sink will be located onto the plywood and cement board.

2. Drill a starter hole in the plywood so that you can use a jigsaw to cut the hole for the sink in the plywood.

|

Figure 8-13: Cement board and plywood form a sturdy base for tiles. |

|

3. Using the plywood as a pattern, transfer the location of the sink to both sides of the backerboard in pencil.

Always flip the plywood when you mark the other side of the backerboard, even when the sink is centered.

4. Score the marked cutout on both sides with a scoring tool and knock out the waste piece (where the sink goes) with a hammer.

5. Place the plywood on the cabinet and drive screws through the cabinet’s corner blocks up into the plywood to secure it to the frame.

6. Mix and spread thinset adhesive on the plywood and comb with the notched edge of a trowel. Lay the backerboard in the thinset and secure with backerboard screws or roofing nails.

7. Fill joints between backerboard panels (if any) with thinset and fiberglass mesh tape.

The sink cutout should line up exactly on both pieces.

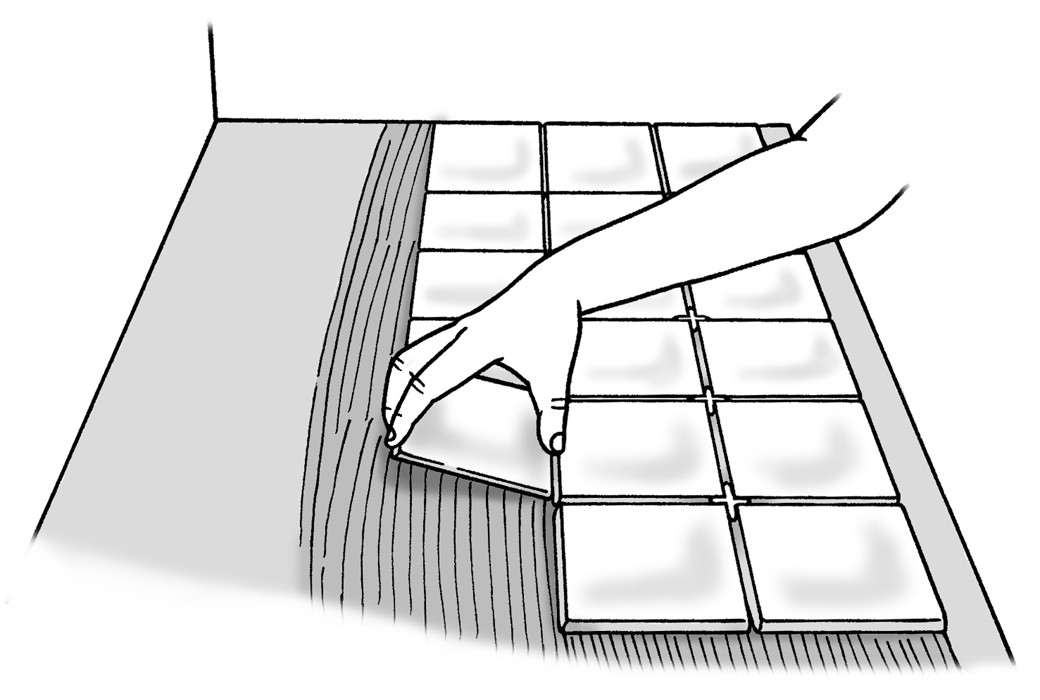

Placing the tile

Plan your layout with courses of full (uncut) tiles starting at the front edge; any rows of cut tiles will be at the ends and at the backsplash, where they will be less noticeable. To ensure that cut tiles at the ends are equal width and not too narrow, mark the left-to-right center of the counter and plan the first front-to-back row so it is either centered over this mark or a grout line between two rows of tiles will be. Choose whichever layout yields the largest cut tiles on the ends. Bend this rule on sink counters when the sink is not centered. Shift the layout so it is centered on the sink, which is typically a focal point.

If you plan to edge the front of the counter with trim tiles, dry-fit that trim and, if relevant, the tile that will face the countertop. Allowing for a grout line, pencil a layout line parallel to the front edge at this point to guide positioning the front edge of the first course of full tiles.

Follow these steps to lay the tiles:

1. Dry-fit the first course and the center row of tiles to verify your layout.

2. Using a framing square, mark a layout line perpendicular to the front edge along the edge of the row.

Your fits tile will be positioned adjacent to the two layout lines

3. Mix a small batch of thinset mortar with latex bonding additive according to directions.

4. Apply thinset to the backerboard up to the layout lines with the smooth side of a trowel. Then use the notched side of the trowel, held at a 45-degee angle, to comb the thinset.

Combing assures that the correct amount is applied and that the application is uniform. This, in turn, ensures a flat tile surface.

5. Continue to spread mortar and lay full tiles on one side of the layout line, using spacers between them if necessary.

Push each tile down to ensure full contact with the adhesive (see Figure 8-14), and lay a straight board across the set tiles to verify they are flat, check spacing and make needed adjustments as you go.

6. After all the full tiles are in place, cut the border tiles and fit them into place before moving on to the next section of the counter and beginning the process again.

Depending on the type of tile you are using, use a manual tile cutter, which scores and snaps the tile to size, or a wet saw, which cuts the tile with a circular diamond abrasive blade. Both can be rented. Ask your tile dealer for a recommendation and the rental store for instructions on using the tool.

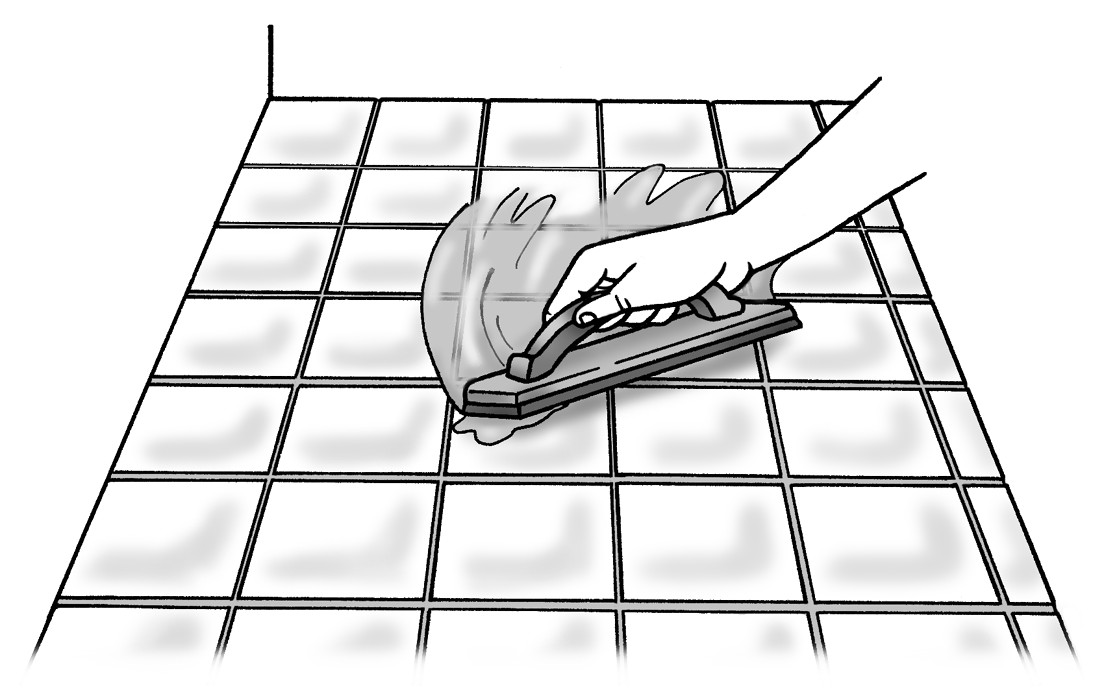

Grouting the tile

Read the grout manufacturer’s instructions for an overview of applying grout. Then follow these easy steps:

1. Spread the grout diagonally over area no more that 5 feet wide at a time Use a rubber float to push the grout into the spaces between the tiles (see Figure 8-15).

Start with the tool held at a 30-degree until joints are full then cut away the excess grout with the tool nearly perpendicular to the surface

|

Figure 8-14: Lay the tiles flat on the adhesive and then push them down to ensure full contact with the adhesive. |

|

|

Figure 8-15: Using a rubber float, push the grout between the tiles. |

|

2. Wait a few minutes and use a damp grout sponge to remove excess grout off the face of the tiles before it dries, trying not to disturb the grout lines. Wait a few more minutes and repeat until the tiles are clean.

3. Use cheesecloth or a dry soft cloth to buff off any haze that may remain after 15 or 20 minutes.

4. Follow the tile dealers advice and manufacturer’s instructions about whether, when and how to apply a sealer that will help prevent food stains.

Dropping in the sink

With the tile in place and grouted, the sink goes in next. Follow these steps:

1. Place a bead of silicone caulk along the underside of the sink’s rim.

2. Lower the sink into the cutout and secure it with the mounting hardware provided by the manufacturer.

3. Hook up the drain and pop-up assembly and the faucet. (See the sections “Installing the drain and pop-up assembly” and “Attaching riser tubes to the faucet,” earlier in this chapter, and “Putting in an easy-install faucet,” later in this chapter.)

That’s it!

Much Ado about Medicine Cabinets

You can’t store medicines and toiletries in any better place than right where you need them — in a convenient cabinet in the bathroom. Yes, you find boring antiseptic metal boxes faced with mirrors, but you also see inspired and appealing designs with intricate beveled glass and mirrors and colorful, whimsical designs.

Hanging a surface-mounted medicine cabinet

Manufacturers sell medicine cabinets preassembled except for the doors, with drywall anchors to fasten them to walls. Because of its weight, the best location for this cabinet is on the wall with a wall stud behind it. You don’t want it falling off the wall, so fasten it securely to the wall framing, which is much more secure than the wallboard alone. Because most wall studs are 16 inches on center, meaning that a space of 16 inches sits between the centers of two studs, and a cabinet is at least 15 inches wide, you should be able to adjust the position of the cabinet to center one of the mounting holes over the wall stud.

Follow these steps to hang a medicine cabinet:

1. Locate at least one wall stud within the mounting area of the cabinet with a stud finder.

2. Level and mount the medicine cabinet to the wall by driving a screw through the back of the cabinet at the top and bottom into at least one wall stud.

3. Drill at least two additional holes through the cabinet into the wall. Remove the cabinet to install wall anchors and reposition the cabinet to drive in all screws.

If another stud is not located behind the cabinet, use a winged or coarse-threaded wall anchor. Follow the directions that come with the medicine cabinet to ensure that it doesn’t require a different kind of mounting process.

Replacing a recessed medicine cabinet

To replace a recessed medicine cabinet, choose a replacement cabinet that’s the same or close to the same size as your original cabinet so that it fits in the existing wall cavity. Another good bet is to get a larger cabinet, which you can install after enlarging the opening. It’s relatively easy to measure the additional space needed and enlarge the opening by cutting the wallboard with a drywall saw and modifying the wall framing.

If you have a large hole left from an old recessed cabinet and you choose a smaller cabinet, the job becomes more complicated. You have to apply new wallboard, tape, and compound; let it dry; and then finish the wall with another application, followed by sanding.

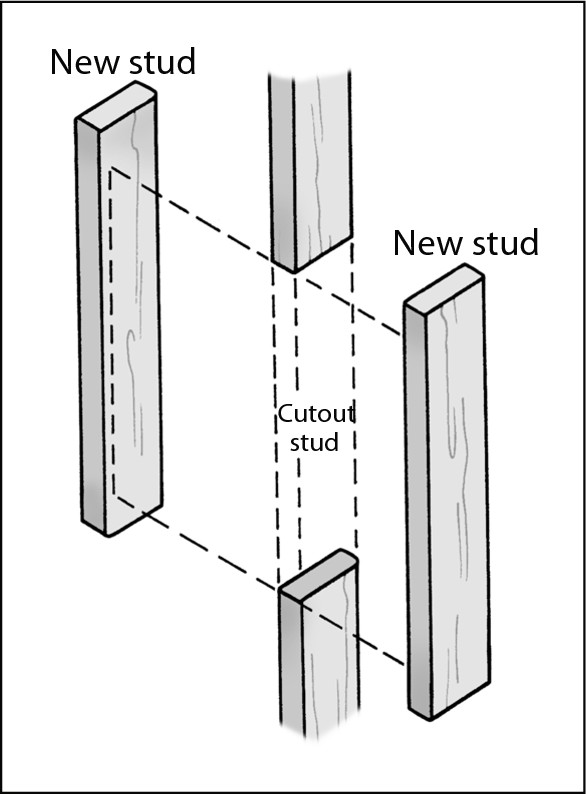

|

Figure 8-16: Adding support if you have to cut a stud. |

|

To replace a recessed medicine cabinet, you need a drywall saw, a recessed-mount medicine cabinet with fasteners, and shims. Follow these steps for a professional-looking installation:

1. Empty the old cabinet, take out the shelves and, in some cases, remove the door.

2. Find the fasteners that hold the cabinet in the wall cavity, remove them and pull out the old cabinet.

3. If the new cabinet came with the door attached, remove it if possible, following the manufacturer’s instructions.

Store the door carefully to prevent damaging it or any mirror.

4. Test-fit the cabinet body in the wall cavity.

You should be able to adjust the cabinet to make it level and plumb.

5. If necessary, remove the cabinet from the cavity and enlarge the opening by cutting the wallboard with a drywall saw.

6. Reinsert the cabinet into the wall opening and check again to ensure that the cabinet is level and plumb.

7. Insert the mounting screws in the mounting holes in the cabinet body, following the manufacturer’s instructions, and tighten the screws to secure the cabinet in the opening.

If the cabinet comes with screw covers, snap them in place.

8. Install the hinge mechanism for the door on the cabinet body and position the door so that it’s properly aligned.

9. Position the shelf brackets where appropriate and set the shelves on top of the brackets.

10. Check the door for proper alignment and make any necessary adjustments.

Getting a Handle on Faucets

When you’re selecting a faucet, make sure that it’s compatible with the sink you choose. Lavatory sinks are drilled for faucets with a distance of 4 inches (center set) or 8 inches (widespread) between the hot and cold faucet handles. A single hole accommodates most single-control faucets. Many sinks come with centered single holes, and some have no drillings for faucets mounted directly on the countertop or wall.

When it comes to faucet controls, some single-handle faucets have the handle mounted directly behind the spout, which can limit the space around the spout, making it challenging to keep clean. Short spouts don’t take up much room, but they also don’t always deliver water where you want it in the basin. The bottom line is to decide whether you’re happy with the faucet control and handles of the faucet you have, and then choose a new one based on that decision.

Many people wouldn’t consider a two-handle faucet because they enjoy the ease of operating a single-lever control, but many others love the two-handle look. Still other people swear that a pullout spout with a push-button spray in the bathroom is the handiest convenience because they like to wash their hair in the sink. Only you know what type of faucet and control gives you the convenience, comfort and look you want.

Finishes come in basic chrome and chrome brushed with polished brass and other finishes, including stainless steel, nickel, and accent colors and patterns. For design direction, consider choosing your bathroom fixtures and fittings from a manufacturer’s collection of products, which are all coordinated, but from different price categories, and which you can use together stylishly.

Putting in an easy-install faucet

Many of today’s faucet manufacturers have a line of easy-to-install single- control faucets designed for do-it-yourselfers. It’s easy to install because it’s accessible almost entirely above the countertop. No more lying on your back crammed into a dark cabinet. The manufacturers have figured out a way to preassemble the unit, which alone is revolutionary. Just knowing that you’re not going to face a bag of strange-looking unfamiliar parts and the challenge of installing them correctly makes the unit a godsend for DIYers.

The nastiest part of this job is emptying the stuff under the cabinet so that you can reach inside to hold the faucet while you tighten it. You need only two tools to install the faucet: an adjustable wrench and a screwdriver. Follow these steps:

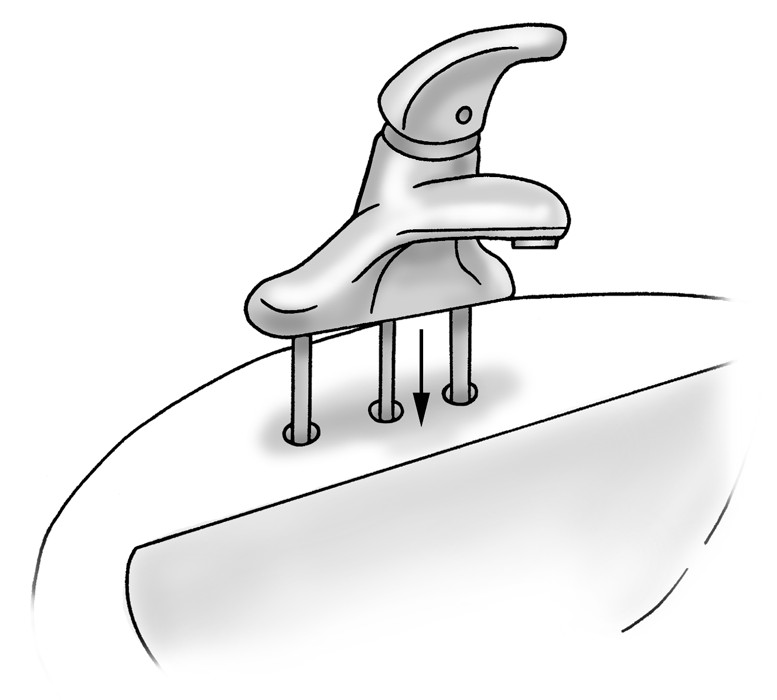

1. Drop the flexible supply lines through the holes in the sink.

2. Align the center toggle with the center hole in the sink and push the valve body down to force the toggle through the hole.

3. Use a standard screwdriver to tighten the setscrew in the back of the faucet body (see Figure 8-17).

You may have to hold the toggle that’s now underneath the sink to keep it from turning.

|

Figure 8-17: This faucet has preinstalled supply lines and installs with a screwdriver. |

|

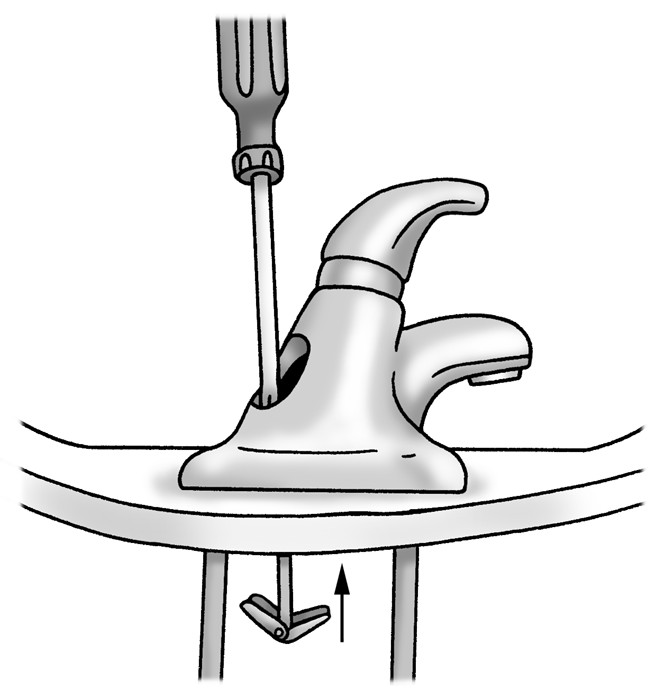

4. When the toggle reaches the underside of the sink, firmly tighten the screw to lock the faucet in place (see Figure 8-18).

|

Figure 8-18: Tightening the toggle. |

|

5. Thread the caps of the flexible supply lines onto the stop valves and tighten them with a wrench.

Installing a two-handle faucet

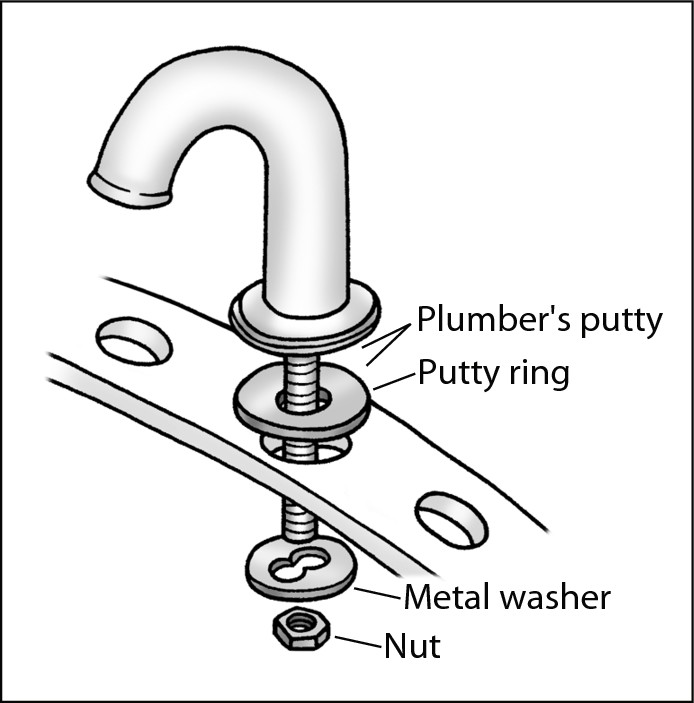

A hardworking bathroom faucet doesn’t have to be ordinary, but it does have to be installed properly. Some faucet designs use a rubber gasket to seal the joint between the base of the faucet and the sink. Others require that you place a bead of plumber’s putty around the perimeter of the faucet’s base. (See Figure 8-19.) Today’s designs of these two-handle faucets make installing one easier than ever.

|

Figure 8-19: This two-handle faucet has a separate spout and valves handles. |

|

You can find a wide selection of two-handle faucets on the market. You install them in basically the same way, but be sure to follow the instructions included with the unit. Generally, here’s what’s involved:

1. Unpack the faucet and check that it’s the model you want, fits the sink holes, and comes with all the parts needed for installation.

2. Follow the manufacturer’s directions and install the gasket or apply the plumber’s putty.

Many faucet designs have a rubber gasket that goes between the base of the valves and spout assembly and the countertop. Others require that you apply a bead of plumber’s putty to the underside of the unit.

3. Place the faucet spout on the sink or countertop.

If the spout has riser tubes already installed, align them with the hole in the sink and lower the spout body into place.

4. Place the faucet valve assemblies (hot and cold) into the holes in the countertop.

If these valves have riser tubes already installed, thread them through the holes in the countertop.

If the faucet isn’t equipped with built-in riser tubes, thread them onto the valve tailpieces and then jump ahead to Step 8.

5. From the underside of the sink, tighten the hold-down bolts.

Some models have large washers and nuts that screw on the valve tailpieces, although others are held in place with brackets that bolt to the underside of the valve body.

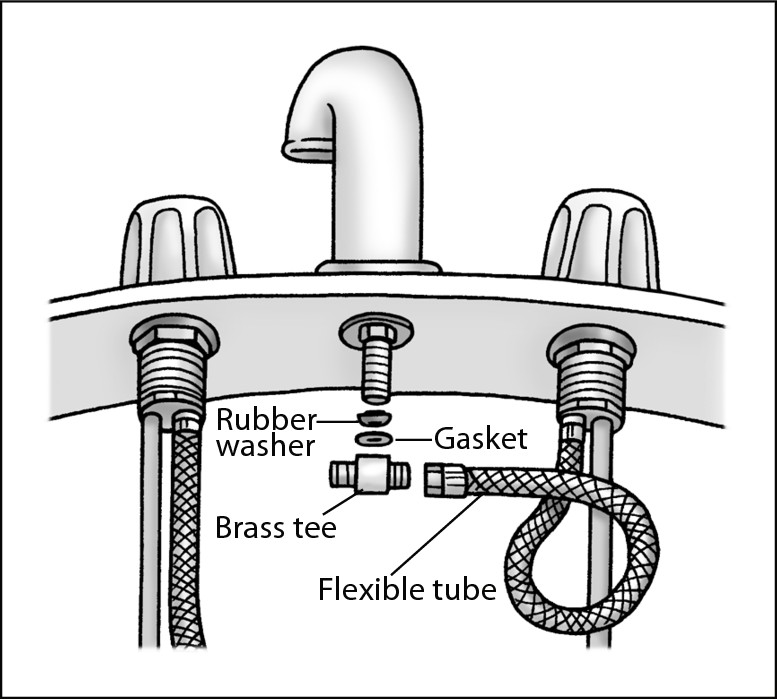

6. From under the sink, connect the flexible hoses from the hot and cold valves with the spout (see Figure 8-20).

|

Figure 8-20: Separate valves and spout allow this faucet to fit a wide variety of sinks. The valves are connected to the spout with flexible tubes. |

|

7. Connect the riser tubes from the hot and cold valves to the stop valves on the wall.

8. Turn on the water and check for leaks.

9. Remove the aerator screen from the spout and run water through the faucet to flush out any debris that may be in the pipes.

10. When the water runs clear, replace the aerator.