Chapter 2

Windows Don’t Have to Be a Pane

In This Chapter

Keeping your windows in good working order

Keeping your windows in good working order

Conserving energy with caulking and weather-stripping

Conserving energy with caulking and weather-stripping

Treating your windows to shades, blinds, and curtains

Treating your windows to shades, blinds, and curtains

T he windows in a house are designed to bring sunshine and fresh air inside. Unfortunately, in some homes, windows have broken glass panes and rotted wood, or they rattle like a bag of bones and let in cold drafts. This chapter is a crash course in the basics of window maintenance and repair. Read on to discover how to improve or upgrade your windows and even how to decorate them with shades and miniblinds.

Know Your Windows

Not all windows look and work alike. Some slide, crank, or swing open and closed; others, such as picture windows, have no working parts. The window frame, which encloses all the basic parts of the window, may be made of wood, vinyl, or metal. Wooden window frames require painting, but those made of vinyl or aluminum are nearly maintenance free. Because metal conducts cold, wood windows are preferred in climates with cold winters.

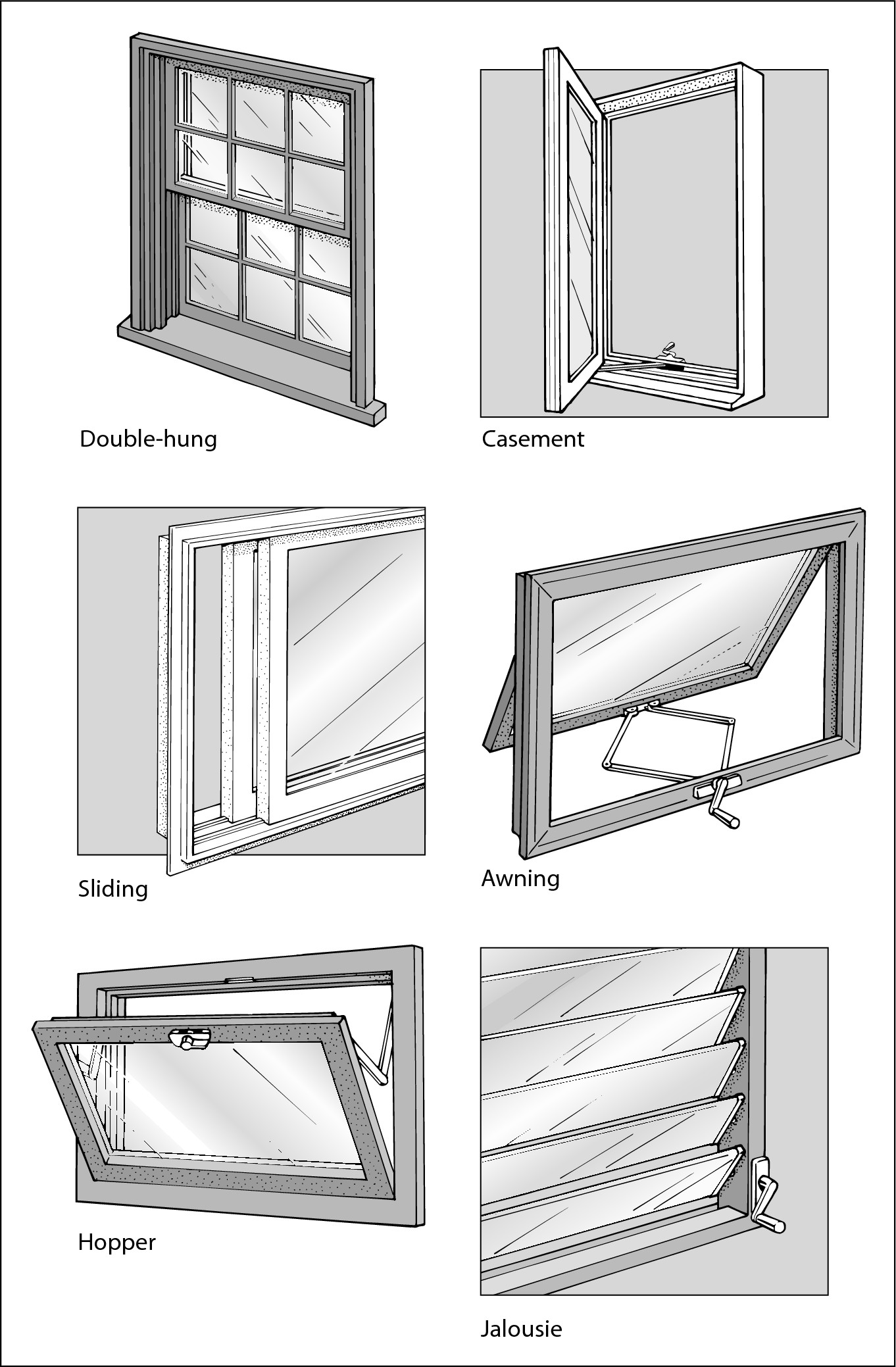

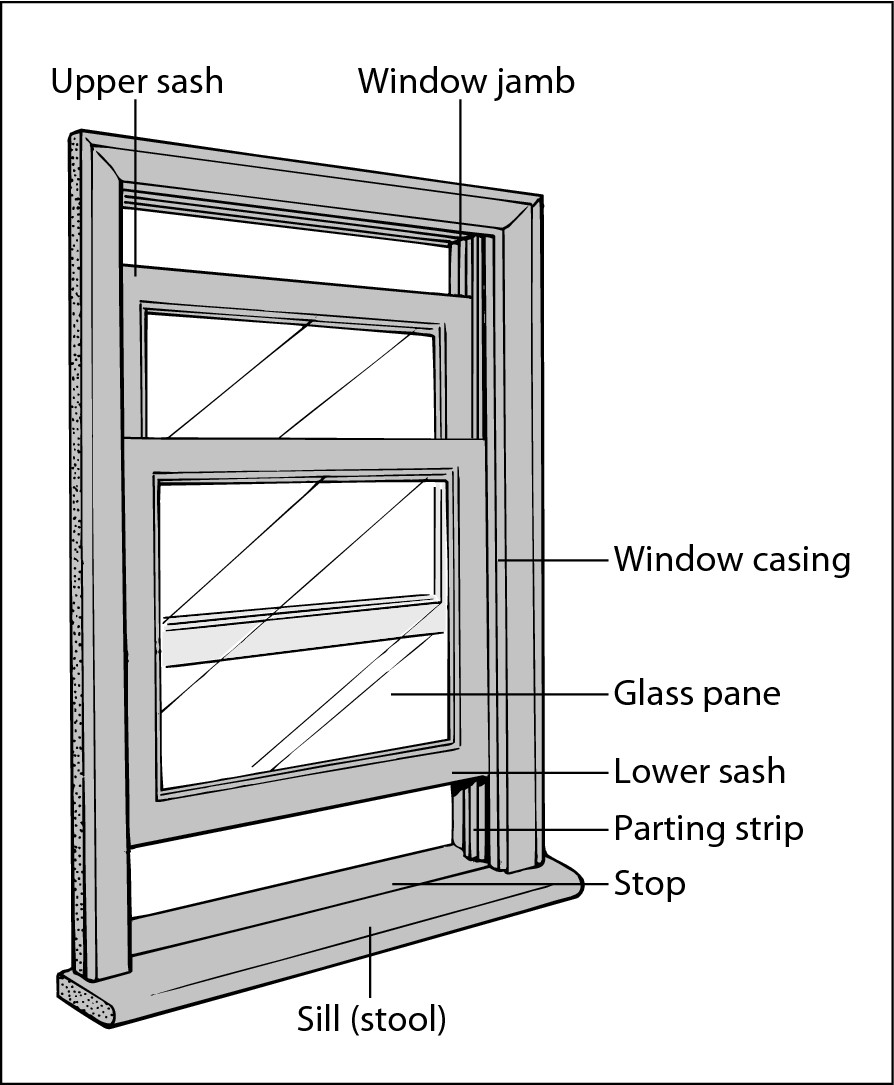

The most popular window style is the double-hung window, shown in Figure 2-1. Double-hung windows have an upper and a lower sash (the inner frame that holds the glass panes in place) that move vertically in separate channels. The sashes are separated by a small piece of wood called a parting strip. The upper and lower sashes have meeting rails — that is, the top rail of the bottom sash and the bottom rail of the upper sash meet and are slanted and weather stripped to form a tight seal between the rails. A locking mechanism secures the sashes together at the two parting rails to create a tight seal and to minimize air infiltration and heat loss.

|

Figure 2-1: Windows aren’t an open-and-shut case; some slide up and down, others side to side, some swing out, others open in slats. |

|

Other common window styles, shown in Figure 2-1, include the following:

Casement windows have hinges on one side of the sash and swing outward when you activate a lever or crank. Because the entire casement sash swings outward, these kinds of windows provide full ventilation and unobstructed views. Casement windows are easy to open, so they’re commonly used where humidity or heat can build up, such as above kitchen sinks, in bathrooms, and on walls that connect to porches.

Casement windows have hinges on one side of the sash and swing outward when you activate a lever or crank. Because the entire casement sash swings outward, these kinds of windows provide full ventilation and unobstructed views. Casement windows are easy to open, so they’re commonly used where humidity or heat can build up, such as above kitchen sinks, in bathrooms, and on walls that connect to porches.

Sliding windows open horizontally and bypass each other in separate tracks mounted on the header jamb and sill.

Sliding windows open horizontally and bypass each other in separate tracks mounted on the header jamb and sill.

Awning windows are hinged at the top and swing outward via a crank or lever.

Awning windows are hinged at the top and swing outward via a crank or lever.

Hopper windows are hinged at the bottom and swing inward.

Hopper windows are hinged at the bottom and swing inward.

Jalousie windows are made of a series of horizontal glass slats that are joined so that all the glass slats open or close together when the crank is turned. The drawback to jalousie windows is that the cracks between the slats offer an avenue for air infiltration.

Jalousie windows are made of a series of horizontal glass slats that are joined so that all the glass slats open or close together when the crank is turned. The drawback to jalousie windows is that the cracks between the slats offer an avenue for air infiltration.

Although they differ in design, basic maintenance is the same for all types of windows. By figuring out how your windows are supposed to work, you can keep them in tiptop shape and detect problems before they become serious.

Window Maintenance

At least once a year, put together a maintenance kit and inspect, lubricate, and clean each window. We admit that window duty isn’t a particularly pleasant way to spend a weekend, but annual maintenance adds years to the life of your windows. Be sure that your maintenance kit includes the following items:

A small paintbrush for cleaning dirt and debris from the window channels

A small paintbrush for cleaning dirt and debris from the window channels

A handheld, battery-powered vacuum for sucking up loose dirt

A handheld, battery-powered vacuum for sucking up loose dirt

A roll of paper towels

A roll of paper towels

An aerosol can of spray lubricant, such as WD-40, for lubricating channels and locks

An aerosol can of spray lubricant, such as WD-40, for lubricating channels and locks

A selection of both Phillips and flat-head screwdrivers for tightening any loose screws

A selection of both Phillips and flat-head screwdrivers for tightening any loose screws

First, open the window and use a hand vacuum or small paintbrush to clean the debris from the windowsill. Then wet a paper towel and wipe down the sill to remove any residual dust.

Inspect the window unit for any loose hardware. Metal window channels or guides are attached to the side frames via small brads or screws. Renail or tighten loose guides. Check the window locks to be sure that screws are tight: If they aren’t, retighten them. Lubricate the locks with a shot of spray lubricant.

If window locks are fouled with paint, remove the locks and soak them in paint remover; then clean, polish, lubricate, and replace the hardware. Use paper towels to wipe away any excess lubricant.

Casement or awning windows are operated with a crank or lever. The windows open via an arm, which may be a single linkage arm, double sliding arms, or a scissors arm. By opening the windows fully, you can disengage the arm from the track, which permits you to lubricate the arm and track or to free the window sash for easier washing.

If you have casement windows that are hinged on one side and swing out via levers or crank handles, open the windows fully and use spray lubricant to oil the hardware, including the crank or lever, the hinges, and the lock.

With the arm disengaged, you can also service the operator mechanism. Check the owners’ manual provided with the windows for instructions on removing the cranking mechanism cover. Of course, owners’ manuals, like able-bodied teenagers, have a way of disappearing when you need them. If you can’t find the official instructions, look for a couple of screws on the housing cover to which the crank or lever is attached and remove them. Lift off the cover, apply a bit of light grease to the crank gears or opening levers, and then replace the cover.

Unsticking a Stuck Window

If a window is stuck, the problem may be that the window channels need cleaning and lubrication, but the odds are that paint has run into the cracks between the window stops and the sash and is binding the window. Either problem usually yields to a simple solution.

First, check to be sure that the window is unlocked and that you’re not lifting up on the sill. If the window is unlocked, place a block of wood against the sash frame and, moving the block along the entire length of both stiles, tap the block lightly against the stiles with a hammer. This trick may loosen up the window so that you can open it. Whatever you do, don’t pound on the block, or you may crack the glass.

If your double-hung window still refuses to open, remove the stops along both side stiles of the sash with a small pry bar. You can then remove the window sash. Use fine sandpaper or a paint scraper to clean the edges of the sash and the edges of the stops. To lubricate the sash, rub a block of paraffin or a wax candle stub along the edges of the window sash and the stop.

If the window resists your best open-sesame efforts, check for paint in the crack between the window sash and stops. Insert a serrated tool, called a Paint Zipper, into the crack, as shown in Figure 2-2. Using a light sawing motion, move the Paint Zipper in the crack along the entire length of the window sash on both sides. Then use the tool to cut any paint bond between the bottom rail and the sill. Now try again to open the window. In most cases, the window will open. (A pizza cutter has been known to work just as well as a Paint Zipper; don’t hesitate to experiment!)

|

Figure 2-2: Use a special tool with a serrated blade or a putty knife with a thin, flexible blade to open painted-shut windows. |

|

Replacing Sash Cords

The sash weights in old double-hung windows are intended to provide balance so that, when the window is open to the desired position, it stays there. If the sash cord (or chain) breaks, the window can’t stay in place. If you have to prop open your double-hung window with a stick, chances are that the sash cord is broken and the window operates with all the controlled restraint of a guillotine.

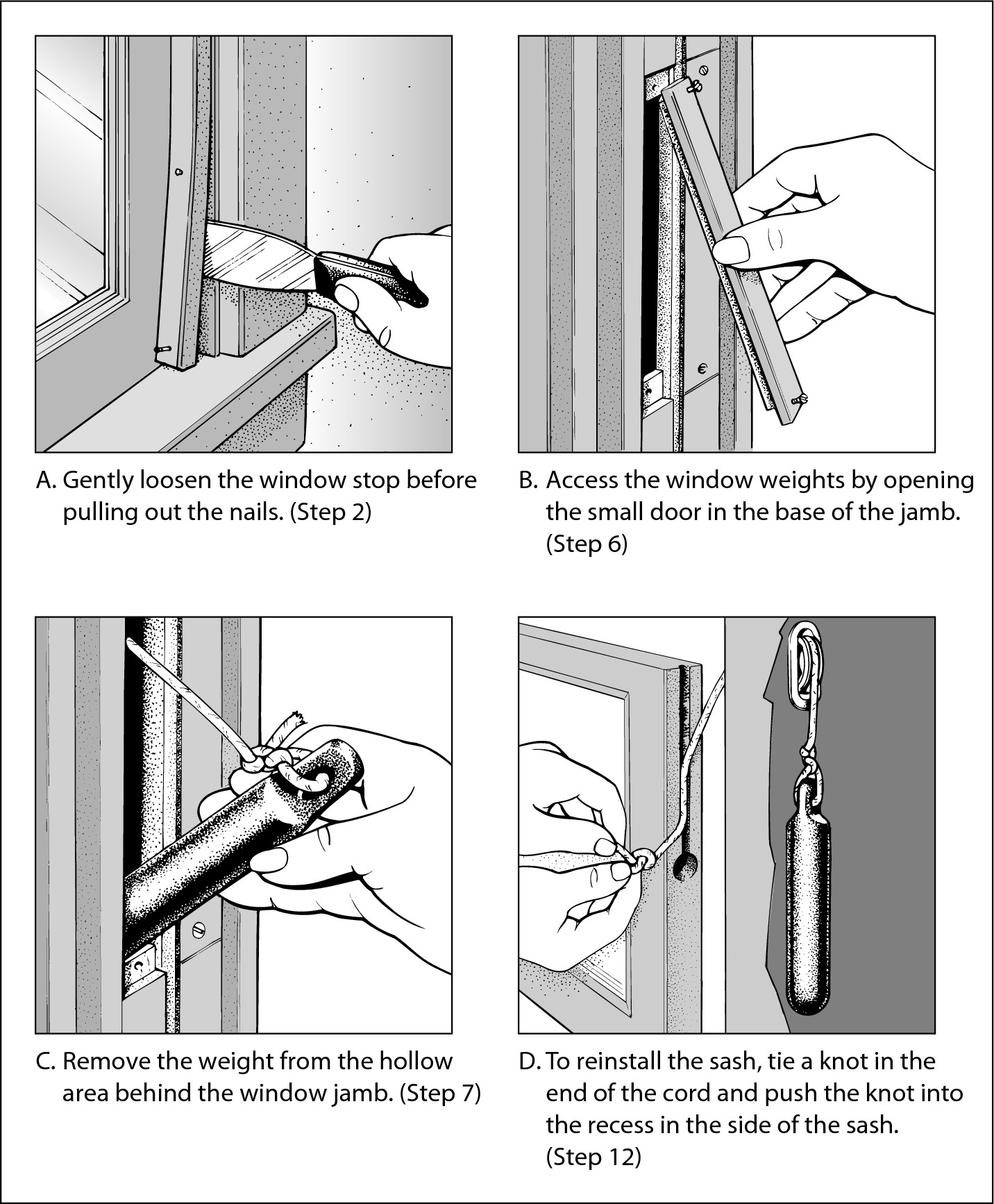

To replace the sash cord, follow these steps (illustrated in Figure 2-3):

1. Use a razor knife to cut the paint line where the stop is attached to the frame.

Cutting this paint seal keeps the stop from breaking when you pry it off.

2. Using a thin pry bar or a stiff putty knife, gently pry out the stop at each nail location.

3. At both sides of the frame along the upper sash, use the pry bar or putty knife to remove the parting strip.

4. Raise the lower sash so that it clears the sill; then swing out the sash.

5. Disconnect the sash cords from the slots at each side of the sash.

With the sash removed, you can see the sash weight access panels on either side of the jamb.

6. Use a screwdriver to remove the retaining screws and then pull off the panel cover.

7. Remove the sash weight from its space.

8. Use an aerosol lubricant such as WD-40 to lubricate the pulley above each access panel.

9. Feed the new sash cord over the pulley and downward until you can see the end of the cord through the hole at the access panel.

10. Tie the sash cord to the weight.

Pass the end of the cord through the hole in the top of the sash weight and then tie a figure-eight knot in the end of the rope.

11. Replace the weight in its compartment.

Pull the other end of the rope tight so that the sash weight stands up straight in the compartment.

12. Attach the sash rope to the sash.

The end of the rope that you have in your hand attaches to the window sash. Most sashes have a groove milled in the side that fits the diameter of the sash rope. At the end of the groove is a recess that holds the knot. Tie a knot in the cord so that the sash weight hangs about 3 inches above the bottom of the compartment when you put the knot into the recess and raise the sash all the way up.

|

Figure 2-3: Replacing a damaged sash cord in a double-hung window. |

|

Modern double-hung windows have metal channels in which the sash sides, or stiles, move. These channels are spring-loaded, and one channel has tension screws that can be adjusted to hold the window in any open position. If your double-hung window refuses to stay open at the chosen position, adjust the tension on the channel. Inspect the window channels to find the adjustment screws. To increase the tension on the stiles, turn the screws counterclockwise with a screwdriver. When properly adjusted, windows open easily but remain firmly in place at any open position.

Replacing a Broken Window Pane

Replacing window glass is not a difficult task. Repairing the damage is only slightly more difficult than breaking the glass in the first place. Just gather the appropriate materials and tools and follow the steps for the type of window you’re repairing.

You need the following materials to replace a broken pane:

Replacement glass: Ask a salesperson at a hardware store or home center to cut a piece of glass exactly to size. Follow the steps later in this section to make sure that your measurements are accurate.

Replacement glass: Ask a salesperson at a hardware store or home center to cut a piece of glass exactly to size. Follow the steps later in this section to make sure that your measurements are accurate.

Latex glazing putty: This material, available by the can in the glass and painting departments, forms an airtight, watertight seal while allowing the pane to expand and contract in changing temperatures.

Latex glazing putty: This material, available by the can in the glass and painting departments, forms an airtight, watertight seal while allowing the pane to expand and contract in changing temperatures.

A box of metal glazing points: Sometimes called glazier’s points, these tiny T-shaped metal pieces have pointed ends that you force into the frame and two small flaps that hold the pane of glass in place.

A box of metal glazing points: Sometimes called glazier’s points, these tiny T-shaped metal pieces have pointed ends that you force into the frame and two small flaps that hold the pane of glass in place.

You also need the following tools:

Heat gun (available from rental outlets) to soften the old glazing if it’s still intact and as tough as cement

Heat gun (available from rental outlets) to soften the old glazing if it’s still intact and as tough as cement

Flexible putty knife

Flexible putty knife

1- or 2-inch stiff steel putty knife

1- or 2-inch stiff steel putty knife

Flat-head screwdriver

Flat-head screwdriver

.jpg)

Wood-frame window

To replace a broken glass pane in a wood window, first measure the size of the pane. Measure the exact length and width of the grooves in which the pane will fit and then have a new piece of glass cut so that it measures 1/8 inch short of the exact dimensions in both the length and width, leaving a 1/16-inch gap on all four sides between the edges of the pane and the rabbet groove cut into the edge of the wood where the glass pane rests. This gap between the wood sash and glass is necessary because it allows room for the glass to expand when the weather changes.

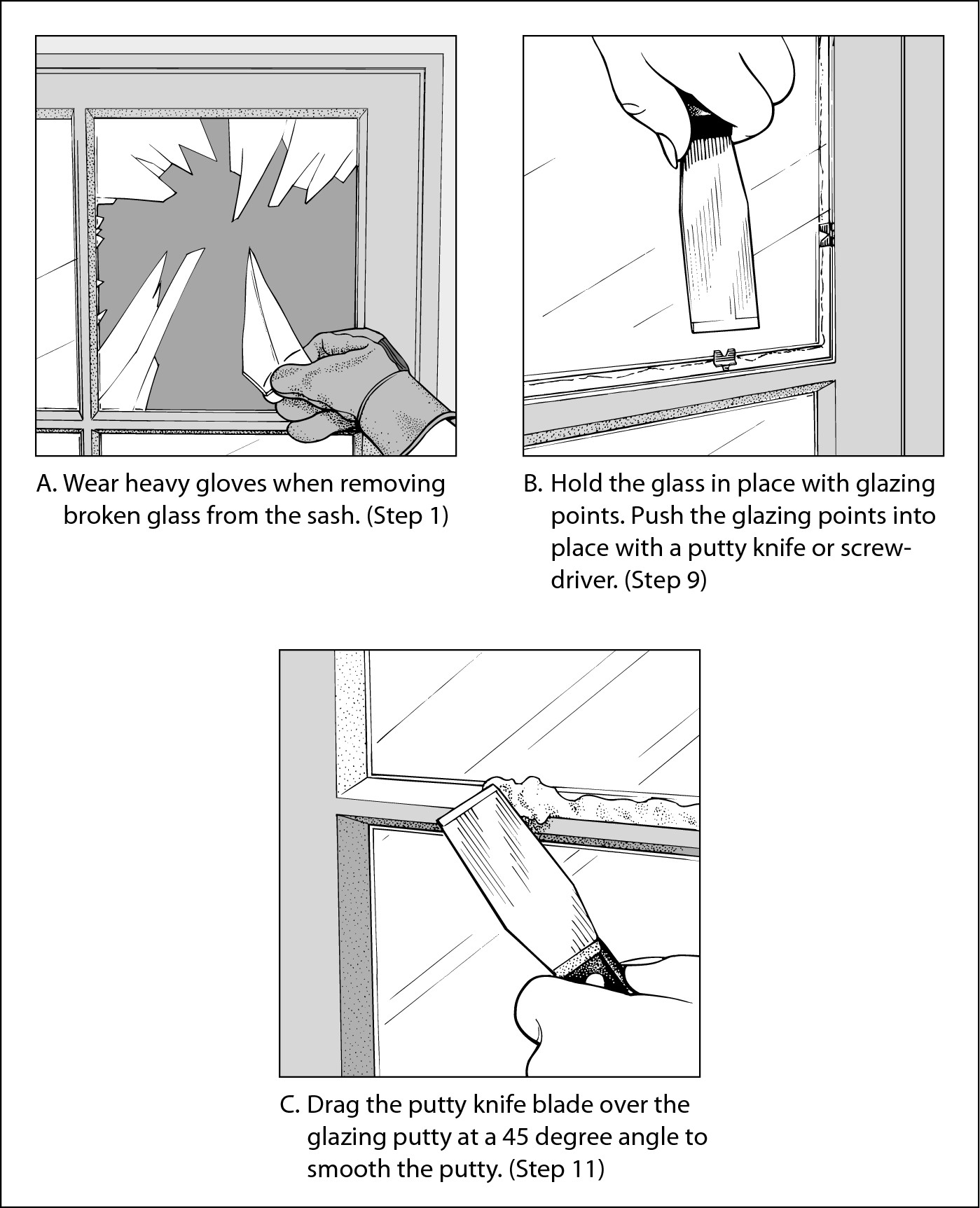

When you have your tools and supplies ready, follow these steps, illustrated in Figure 2-4:

1. Remove any remaining glass shards.

2. Use a heat gun to soften the old glazing putty.

Heat the glazing putty and try to scrape it away with a putty knife; if it doesn’t lift off easily, apply more heat and try again. You may find that the putty around really old windows is as hard as concrete. Be patient — the heat will eventually soften all putty. Don’t be tempted to chisel out the old putty unless you don’t mind wrecking the window and creating even more work for yourself!

As you remove the old glazing putty, you can see small triangular metal glazing points, which hold the glass in position until you apply the glazing putty.

3. Use a putty knife or the tip of a screwdriver to remove the old glazing points.

4. Clean and inspect the rabbet groove to ensure that no glazing putty, glass shards, or glazing points remain.

Wear safety goggles as well as gloves; small chips of glass can cause permanent eye damage.

5. Squeeze out a 1/16-inch bead of putty on the glass side of the rabbet groove between the edge of the glass and the window frame.

6. Press the glass down gently at the edges to bed the glass into the putty.

Allow the putty bed to spread out and form a moisture seal on the inside of the window between the glass and sash.

7. Position the new pane in the rabbets so that a 1/16-inch gap remains between pane and sash on all four sides.

8. Place at least two new glazing points in each section of the window sash surrounding the new glass.

Space the points evenly around the perimeter, about 6 inches apart.

|

Figure 2-4: Replacing a broken window pane. |

|

9. Using the flat side of a putty knife or a screwdriver blade, push one corner of each triangular glazing point into the wood sash.

10. Roll a glob of putty between your bare hands to form a 1/2-inch-thick rope and then press the length of putty along all four sides of the glass.

11. Holding the putty knife at a 45-degree angle, press and smooth the glazing putty against the glass and sash.

12. Allow the putty to dry and then repaint the putty and repair area.

Don’t use masking tape on the glass before painting because you want the paint to form a moisture seal between the glass pane and the sash. Allow the paint to overlap about 1/8 inch onto the glass.

Metal frame window

Some steel or aluminum window frames, such as those that you find in many basements, are welded together in one piece at the factory. The other common type of metal frame windows is storm windows. Glazing putty or some sort of gasket holds the glass in place. Except for some minor points, which we explain, replacing a broken pane of glass in either type of metal frame window is basically the same as for wood windows.

To replace the pane in a one-piece steel window, follow the instructions for replacing glass in a wood window with the exception of glazing points. The glass pane in steel casement windows is held in place with glazing putty and spring clips rather than glazing points. When you remove the broken glass from the metal frame, save these clips so that you can reinstall them later.

On some one-piece aluminum windows, such as metal storm windows, the glass is held in place by a vinyl strip called a spline. The spline acts as a seal between the metal and the glass, eliminating the need for glazing putty. Use a screwdriver or putty knife to pry out the spline. Carefully remove any broken pieces of glass from the frame and then replace the pane with new glass. Reverse the process and push the spline back into the frame with a putty knife or screwdriver.

Some metal window frames, including sliding sashes, are held together by screws placed at each corner of the frame. Remove the screws, slide out the broken pane, slide in a new pane, and redrive the corner screws.

Other metal frames are held together by L-brackets placed at the four corners. The faces of these frames are dimpled over the L-brackets. To take these frames apart, you have to remove only one side. To do so, follow these steps:

1. Drill a hole in the depression at both ends of one side of the frame.

Use a bit slightly larger than the diameter of the depression.

2. Pull the sides of the frame apart and carefully remove any broken glass from the frame.

3. Replace the pane, making sure that the new glass is fully seated into the gasket surrounding the glass.

4. Push the corners together so that the L-brackets are in place and the joint is tight.

5. Use a small nail set or a punch and hammer to dimple the metal back over the L-brackets and lock the frame together.

Repairing a Rotted Windowsill

Windowsills are sloped outward so that water can run off the sill. Brilliant, huh? Still, if the paint is peeling and the sill is left unprotected, the wood may rot. Although moisture causes this condition, it’s called dry rot. Go figure.

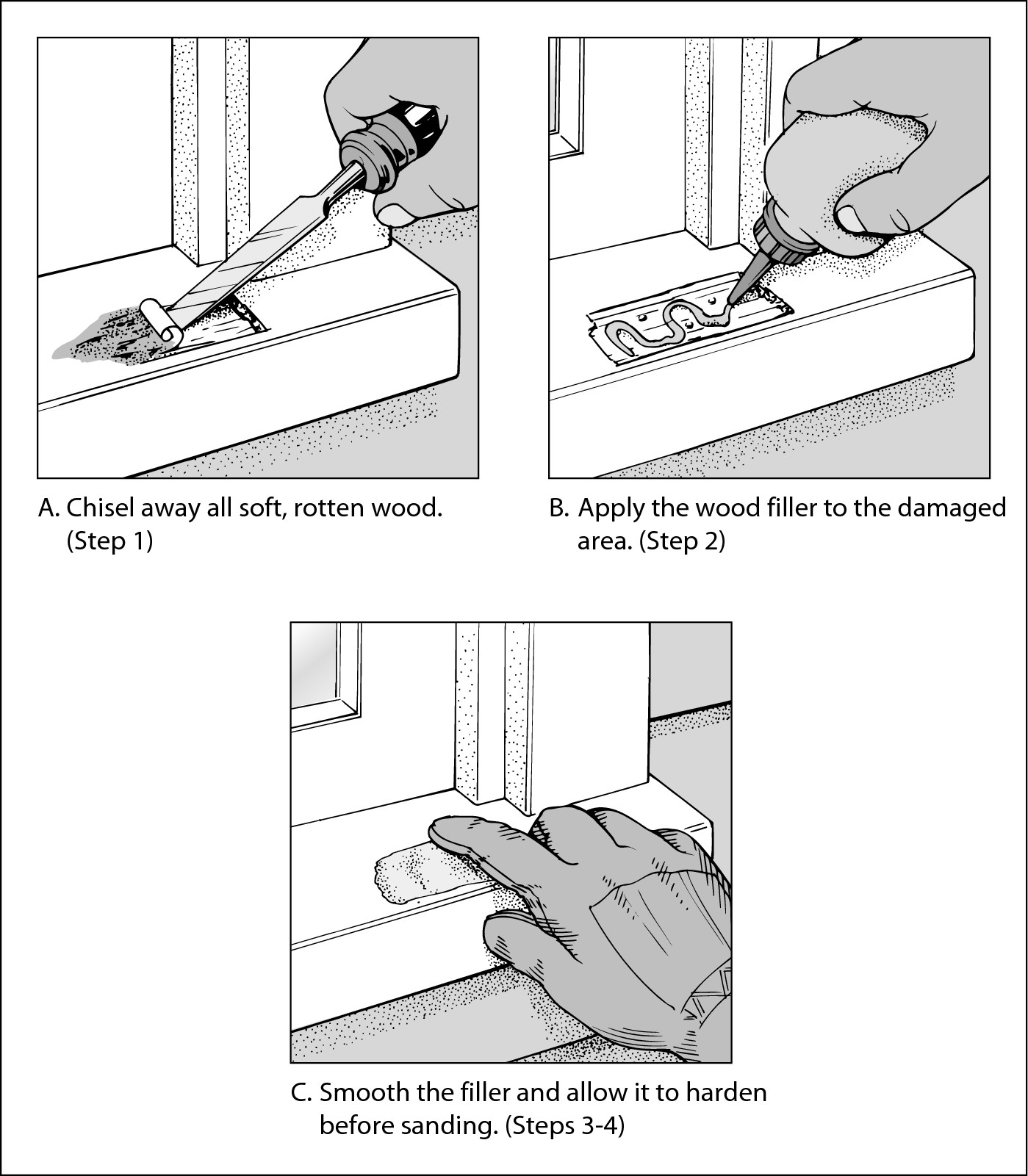

If you have a windowsill that’s rotted, probe the wood with an ice pick or carpenter’s awl. Wherever the awl penetrates easily, the wood is rotted. When you hit a point where the wood is difficult to penetrate, you’ve reached solid wood. If the wood is completely rotted, you’ll have to replace the entire sill with a new piece of wood — a job probably best left to a skilled carpenter. If the rot is limited to a small area, you can make repairs by following these steps (illustrated in Figure 2-5):

1. Using a wood chisel or sharp knife, cut away any soft wood.

Remove all the damaged wood down to the rot-free portion.

2. Fill the damaged area with epoxy or polyester wood filler.

Filler bonds to sound wood and is very durable.

3. Use a putty knife or small broad knife to shape the wood filler so that it matches the contours of the old sill.

4. Wait for the filler to set and then sand it smooth.

Follow the directions on the container; you want the filler to be rock-hard to the touch before sanding. Sand the repair area so that the new surface is smooth and level with the adjoining surface.

5. Apply wood primer and paint to the repair area to match the existing finish.

|

Figure 2-5: Use wood filler to repair small patches of rotted wood on the windowsill. |

|

Replacing Window Channels

If your sashes let in drafts and rattle in their channels, you may want to consider replacing windows. However, a less expensive solution is available: You can install replacement channels in your double-hung windows.

Replacing window channels is no walk on the beach, but it does give you an opportunity to clean and repair the windows while they’re apart. (Okay, so these jobs are no picnic, either.) By replacing the channels, you can have windows that operate more freely and waste less energy, and you save hundreds or thousands of dollars compared to the cost of buying new windows. A typical size channel kit costs less than $50.

Buy new channels at a home center or glass company. They’re sold in kits that range in sizes from 3 to 5 feet long, so they fit most sizes of windows. Measure the window opening from the top of the upper sash to the bottom of the lower sash for the correct dimension. Then choose a channel kit that’s slightly larger.

The following steps walk you through installing new window channels. Consult Figure 2-6 if you are unsure about what some of the terms mean.

1. Remove the window stops.

If the window stops are painted, use a razor knife to cut through the paint film along the line where the stops meet the jambs. To avoid breaking the stops, use a thin pry bar, pry only at nail locations, and work carefully.

2. Pull out the lower sash and then pry out the parting strip to remove the upper sash.

Set the sash aside for later, when you can clean it, repaint it, or install new weather-stripping.

|

Figure 2-6: All the bits and pieces that go into a window. |

|

3. Release the sash cords from the slots in the sash.

Pull the sash cord out of the groove in the edge of the sash. Sometimes, the knotted end is held in place by a small nail. If this is the case, pull out the nail to remove the sash cord.

If you’re replacing the channels in a double-hung window, this is a good time to replace the sash cords, as well. (See “Replacing the sash cords,” earlier in this chapter.) If your replacement channels are spring-loaded, the sash weights are no longer necessary. In this case, remove and discard the old sash weights and cord and stuff fiberglass insulation loosely into the cavities.

4. If necessary, cut the new channels to length with a hacksaw.

Remember: Old windows may not be square. Carefully measure each side of the window jamb and cut the channels to fit. Note that the bottom of the channel is cut at a slight angle to match the slope of the sill. If the precut angle matches the slope of your windowsill, trim the top of the channel; if the angle is different, cut the bottom of the channel to the same angle as your sill.

5. Inspect and clean the sash and stops.

If paint is peeling, now is the time to repaint the windows, while they’re out of the frame. To prevent paint runs, lay the sash flat on a workbench or across two sawhorses. Sand the sash carefully to remove any dried paint runs or other roughness from the frames and stops. You want to apply only a thin film of paint on the sash, so thin the paint a bit by adding a small amount of water (to latex paint) or mineral spirits (to alkyd paint).

.jpg)

Painted surfaces do not slide easily against each other. For this reason, some parts of the window sash, such as the backside of the meeting rails and the inside edges of the stops, are left unpainted. Because painting channels or the edges of the sash may cause them to stick, don’t paint any exposed bare wood.

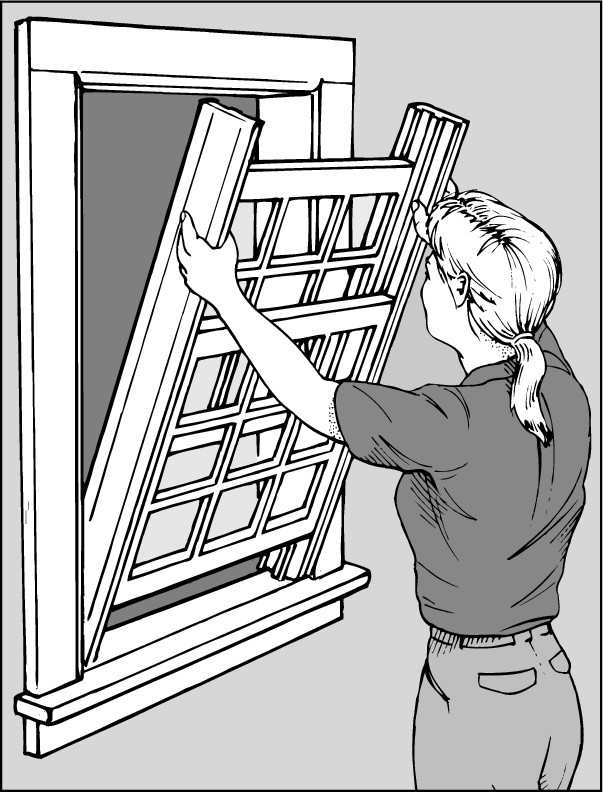

6. Reassemble the window, as shown in Figure 2-7.

Replace the upper sash first — it goes in the outside channel — and then place the lower sash in the inside channel. Hold the channels against the sashes and place the bottom of the channels into the window jamb. Then push the assembly into the jamb so that the channels rest against the outside window stop. The unit will stay in place while you install the inside stops.

Before you nail the stops permanently in place, test to make sure that the windows operate freely. Don’t push the stops too tight against the channels, or the windows will be hard to open.

|

Figure 2-7: Place the window sashes in the replace-ment channels and then slide the assembly into the jamb. |

|

Energy-Saving Projects

Two of the easiest projects that you can do around the house happen to shave your heating and cooling bills. Weather-stripping and caulking fill in gaps and holes around the doors, windows, and other places that leak air. Buttoning up the holes and plugging the leaks are must-do projects that couldn’t be easier.

Weather-stripping, step by step

Weather-stripping is material that seals the cracks between moving components, such as the crack where a window sash meets the frame or stop. In addition to saving energy, weather-stripping blocks drafts and keeps out dust and insects. The thin barrier also blocks outside noise.

Weather-stripping comes in many shapes. It’s available with a felt, vinyl, or foam-rubber edge on a wood or plastic strip that you attach to the edge of a door or window with small brads. Some versions have an adhesive back so that you can install them without nails.

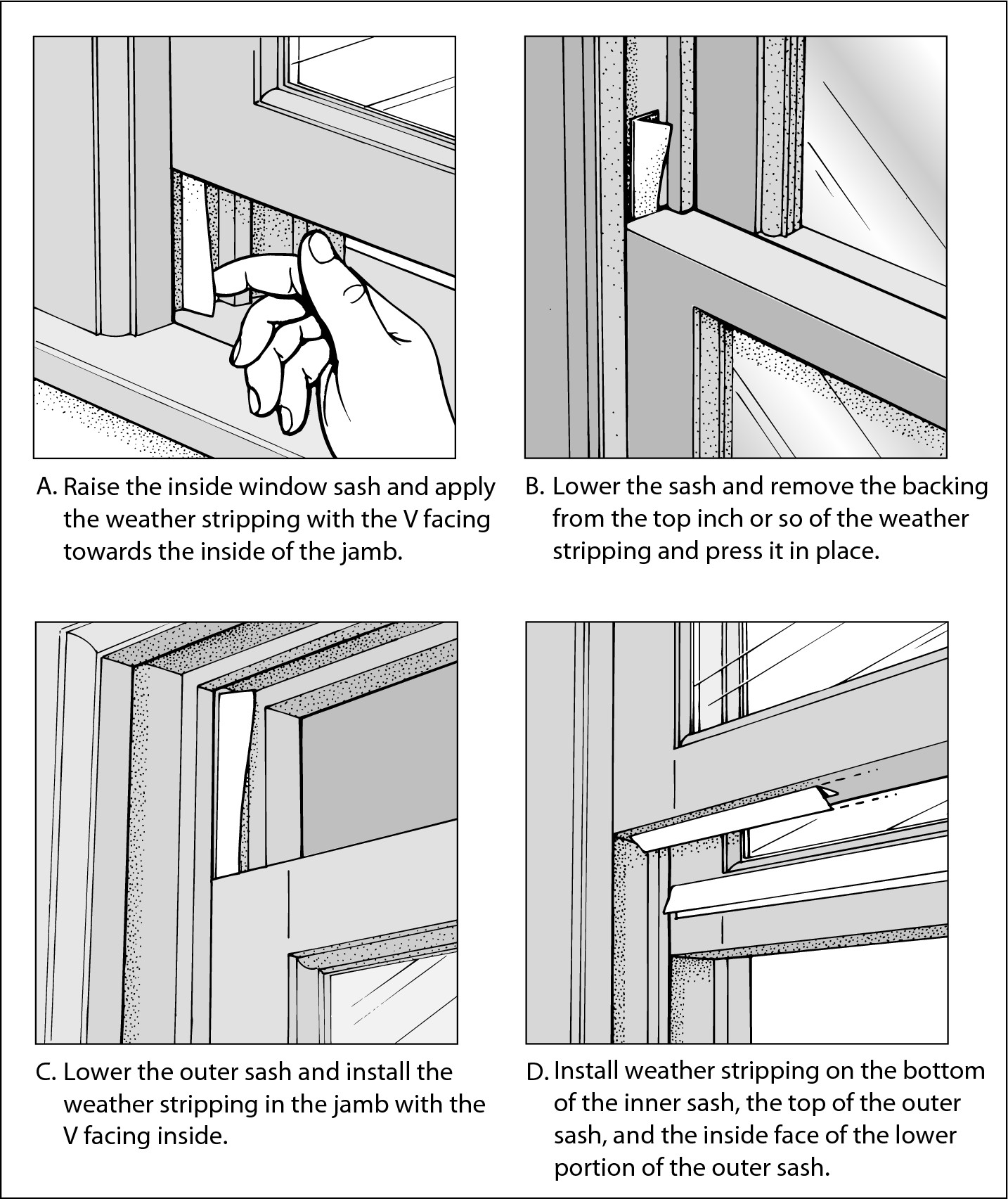

The easiest type of weather-stripping to install is the adhesive-backed V-seal type, available in a peel-and-stick roll. This type of weather-stripping is inexpensive and easy to install. To apply adhesive-backed weather-stripping to a double-hung window, follow these steps (illustrated in Figure 2-8):

1. With a damp rag, clean the window jamb or other surface where you plan to apply the weather-stripping and let dry completely.

2. Cut the strip to the length you want.

Use a measuring tape to find the length you need, or place the weather-stripping in position and cut a piece slightly longer. To fully seal the window, you need strips for each side of the inner and outer sash, the bottom of the inner sash, the top of the outer sash, and the outer meeting rail.

|

Figure 2-8: Installing adhesive-backed V-seal weather-stripping. |

|

3. Raise the inner sash as far as it will go.

4. Peel away the backing of the strip, except for an inch or so at the top.

Later, you have to push this part of the strip up between the sash and jamb, which is easier to do if you leave the backing in place.

5. Press the strip in place with the V facing inside.

6. Install the strip on the opposite side of the jamb in the same way and then close the window.

7. Remove the backing from the top of the weather-stripping that protrudes above the sash and press it in place.

8. Lower the outer sash as far as it will go and install the weather-stripping in this sash the same way that you did on the inner sash.

The only difference here is that you should leave the backing at the bottom of the strip in place until you raise the window.

9. Raise the inner sash and apply a strip of weather-stripping to the bottom of the sash; then lower the outer sash and put a strip on top.

10. Lower the outer sash far enough to expose the inside face of the bottom of the sash; clean this surface and then apply a strip of weather-stripping with the V facing down.

Modern windows often have a kerf — a slot into which the weather-stripping fits. The weather-stripping for these windows has a tubular edge on one side, with a felt or vinyl lip on the opposite side that closes and seals any crack. To replace this weather-stripping, pull or pry the tubular retaining edge from the slot in the window and then press the new weather-stripping into the slot.

Caulking, step by step

Caulk is a filler material that seals a crack where two nonmoving components meet, such as where a house’s siding meets the exterior window trim. Caulk seals the crack against air infiltration, prevents drafts, and keeps moisture from entering the crack and causes paint to peel or wood to rot.

Caulk is available in 10-ounce tubes, enough to caulk around the average door or window. At one end of the tube is a cone-shaped plastic nozzle. Because the nozzle gradually decreases in size from its base to the tip, you can squeeze out a bigger bead of caulk by cutting the nozzle shorter. How much coverage you get from a tube of caulk depends on the size of the caulk bead.

The caulk tube fits into a caulk gun. The gun has a trigger handle that you squeeze to apply pressure to the tube, forcing the caulk out the nozzle. Caulk guns are available at home centers, hardware stores, and paint outlets.

To seal the exterior of a window with caulk, follow these steps:

1. Use a putty knife or scraper to clean away any old caulk remaining on the outside of the window.

2. Cut the tip off the caulk tube nozzle at a point where it produces a bead large enough to fill the crack.

A 1/4-inch bead is large enough for most cracks. To avoid too large a bead, cut the nozzle tip near the end, test the bead for size, and then cut off more if you need a larger bead.

After you cut the tip, you have to puncture the seal in the end of the caulk tube before any caulk will flow. To puncture this seal, insert a stiff wire, such as a piece of metal clothes hanger or a long nail, into the nozzle and push it into the caulk tube until you feel it puncture the seal.

3. Apply a bead of caulk, moving the caulk gun at a measured pace along the crack and using continuous light pressure on the gun trigger.

Caulk on all four sides of the window trim to seal the crack between the trim and the siding.

4. Smooth the caulk.

You can use a Popsicle stick, plastic spoon, or wet finger to create a smooth surface.

5. Wash away caulk remaining on the gun, your hands, or other unwanted spots before it dries.

Window Enhancements and Add-ons

To avoid living in the proverbial fish bowl, most people want some kind of covering for their windows. For rooms where privacy is a prime concern, such as a bathroom or bedroom, window coverings are more important. In other rooms, you may need them mostly for protection from bright sunlight. Whatever the motivation, basic window coverings are easy to install, even for the not-so-handy.

Installing a window shade

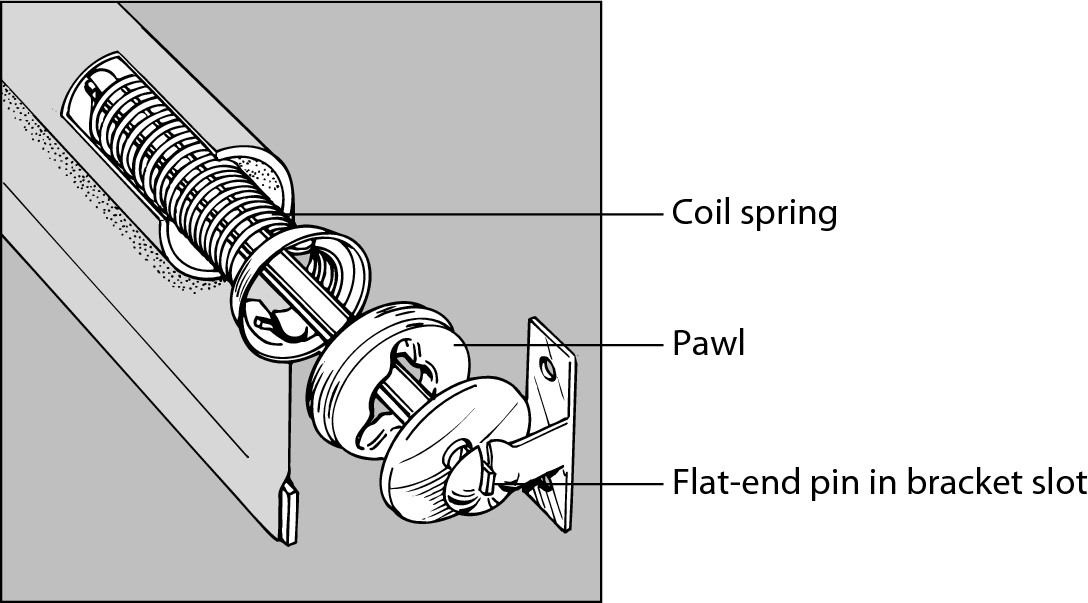

Window shades are spring-loaded so that they roll up or down and lock in the chosen position. The hardware consists of round support brackets at either end of the shade, as shown in Figure 2-9. You mount the brackets on the inside of the window stops. One bracket has a hole into which a round shade support is inserted; the opposite bracket has a slot to receive the flat support on the other end of the shade. Shades are so easy to install and remove that even a child can do the job; the problem is, a child is never around when you need one.

If you’re replacing an old shade, measure the width of the old roller from end to end, including the metal tips, and then measure the length of the shade fully extended. Order a new shade of the same width and length.

|

Figure 2-9: The mechanics of a window shade roller. |

|

To measure for a new shade, hold a rigid measuring stick across the top of the window. Place one end on the inside upper window stop and carefully extend the rule across to the stop on the other side. Order a shade 1/8 inch smaller than the measurement.

Measure the inside of the jamb and then subtract 1/8 inch to find the proper length. You can purchase shades that are easy to cut to the exact length that you need.

To install a shade, follow these simple steps:

1. Position the metal support brackets on the two window stops at opposite sides of the window. Mark the brad hole positions on the stops with a sharp pencil.

Allow enough room between the top of the window jamb and the shade for the roller to turn freely, remembering that when the shade is fully rolled up, it grows in diameter. Hold the shade up where you plan to install it. When you find the correct position for the first bracket position, make a pencil mark for the location of the brad hole. Measure the distance from the top and sides of the window frame and then use that measurement to locate the bracket on the opposite side.

2. Secure the shade brackets to the window stops with small brads.

With a carpenter’s awl or an ice pick and hammer, make starting holes in the stops. Hold the shade bracket in position with a tack hammer to drive in the brads.

3. Slide the ends of the shade into the slots in the brackets.

Make sure that the shade is fully wound up when you install it, or it may not retract properly. If you pull the shade down and it doesn’t fully roll up by itself, pull the shade down a foot or so and take it off the bracket. Rewind the shade on the shade roller and then reinstall it in the bracket.

To remove the shade, just push upward on the slotted end of the shade to free it from its bracket and then pull the round support from the hole in the opposite bracket.

Trim-to-fit shades

Many large retailers sell inexpensive window shades that you can cut to fit almost any window. These shades are lightweight and flimsy (what do you expect for about $8?), but they may be just right for a quick fix or when you’re on a tight budget.

You can’t do anything about the length of these shades, but you can custom-cut the width by using the score lines on the shade as guidelines. The steel shade roller slides together to fit the new width.

Install the brackets as we describe for regular shades. (See the “Installing a window shade” section in this chapter.) Insert the shade in the left bracket. Remove the plastic hem slat from the pocket and notice its score lines that match up with the score lines running the length of the shade. Hold the shade level under the right bracket, so you can determine the correct width. Then mark the width with a light pencil mark at the closest score line on the shade. Carefully begin to tear the length of the shade at its score line until the entire shade is done. Adjust the shade roller to fit the new width by pushing the end plug until it reaches the end of the shade. Then snap off the plastic hem slat to the same width and install it.

Installing a miniblind

Miniblinds are mounted in U-shaped brackets that have snap-on covers to provide a finished look. They’re a mainstream decorating choice for a window treatment because they coordinate with just about any decor. Use them alone or with a fabric valance or cornice board covering the top of the window.

You can mount most miniblinds outside the window frame (on the outer trim of the window), on the wall (so that they cover the window trim), or on the inside of the frame between the window stops. Because you have all these options, most mounting brackets have pre-drilled holes on both the ends and the backs of the mounting brackets. You use only one set of holes, depending on how you mount the miniblinds.

Before you purchase miniblinds, decide whether you want to mount the blind inside or outside the window frame and then measure your windows using a folding wooden measuring rule or wooden measuring stick. Manufacturers have specific directions for measuring on their packaging or brochures, but the general procedure is to measure the width at the top, middle, and bottom of the window and use the smallest dimension for its width. Measure the length of the window to get the correct extension of the blind.

If you order custom blinds, you can indicate the length you want the blinds to be. If you buy blinds off the rack, you have to cut the blind cords to the proper length; usually, you want the bottom edge of the blind to rest on or slightly above the windowsill. Directions for cutting the blind cords for length are included in the miniblind package.

You can install small clips on both sides of the window to act as hold-down brackets to secure the bottom of the blinds so that they don’t sway freely. These clips, secured with a small brad or finishing nail, are easy to reach but not noticeable.

To install a blind on the inside of the jamb, follow these steps:

1. Measure and mark the locations for the U-shaped mounting brackets.

Position the mounting brackets at the top corner of the window jamb. Hold the brackets in place (paying attention to which is the right and which is the left bracket) and use them as a template to mark the location of the mounting screws with a pencil.

2. Drill pilot holes for the mounting screws through the pencil marks on the window jamb.

Use a 1/16-inch drill or carpenter’s awl to make starter holes for the screws.

3. Use a screwdriver to install the mounting brackets with the screws provided.

4. Push the blind’s header bar into the brackets, as shown in Figure 2-10, and secure it by closing each bracket.

Some designs simply slide into the bracket.

5. If necessary, cut the blind cords to length.

|

Figure 2-10: To install miniblinds inside the jamb, screw the brackets to the top or side of the jamb. |

|

Installing curtain rods and hardware

Rod-mounting brackets are often nailed to the window trim or stops to hold the rods for lightweight curtains. To install curtain rods, refer to the “Installing a window shade” section for directions, earlier in this chapter.

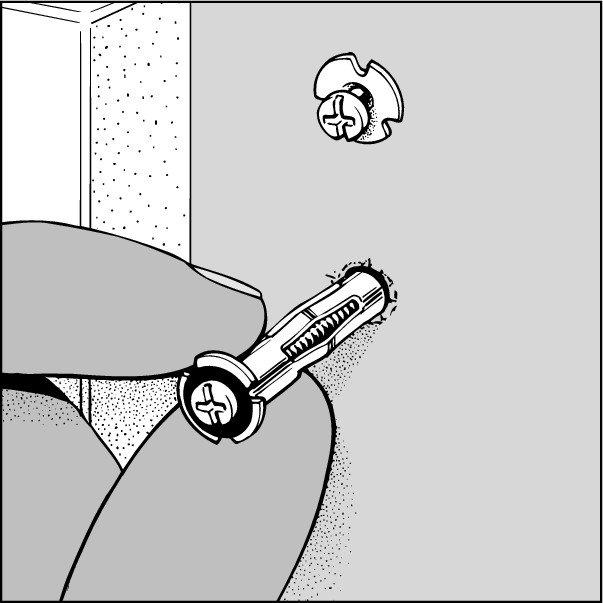

Installing rods to support heavy curtains or drapes can be a horse of a different color. If you’re mounting drapery hardware on the window trim or on the wall at the window edge, you can drive the hardware screws into wood. But you may encounter difficulties mounting rods that extend onto the walls if the @*!%&* builder failed to install nailing blocks beyond the header to provide something into which you can screw the rod brackets. In this case, you must install hollow-wall fasteners like Molly bolts in the walls and then secure the drapery hardware with the fasteners.

Molly bolts include a metal shaft or sleeve into which you can insert a small machine screw, as shown in Figure 2-11. As the machine screw turns in the Molly shaft, the shaft collapses against the back side of the plaster or wallboard, providing a secure support for the weight of the rods and the drapes. Other types of fasteners are available for this purpose: Ask your hardware or home center clerk to suggest a fastener for your project.

|

Figure 2-11: Molly bolts expand behind the wall and are a good choice for holding curtain rods securely in place. |

|

To install a Molly bolt, drill a hole at the rod hardware location through the wallboard or plaster. Insert the Molly screw into the hole and tap it lightly to seat it against the wall. Place the rod mounting bracket in position so that the screw holes line up with the Molly bolt(s) and use a screwdriver to drive the screw home. To test the installation, pull firmly on the mounting bracket. If the bracket moves, tighten the screw a bit more until you’re sure that the screw is securely anchored.