Chapter 3

Doors: An Open-and-Shut Case

In This Chapter

Caring for door hinges and locks

Caring for door hinges and locks

Unsticking bifold doors

Unsticking bifold doors

Juggling panels in combination screen/storm doors

Juggling panels in combination screen/storm doors

Keeping sliding storm and closet doors on track

Keeping sliding storm and closet doors on track

Installing and replacing door locks

Installing and replacing door locks

Keeping garage doors in tiptop shape

Keeping garage doors in tiptop shape

T hey swing open; they slide shut — simple acts you probably take for granted. But when they squeak or refuse to budge, you start to notice the doors in and around your house. To keep everything in good working order, perform the typical door maintenance and repair jobs in this chapter. They may be all you need to keep your home safe and secure.

Maintaining Locks and Hinges

You probably don’t spend much time thinking about your doors — and if you do, you may want to seek professional help — but consider that a family may open and close entry doors thousands of times each year. The hinges and locks on the doors can take a real pounding, so lubricate them at least once a year. To lubricate door hardware, you need a can of aerosol lubricant such as WD-40, paper towels, slot and Phillips-head screwdrivers, and a hammer.

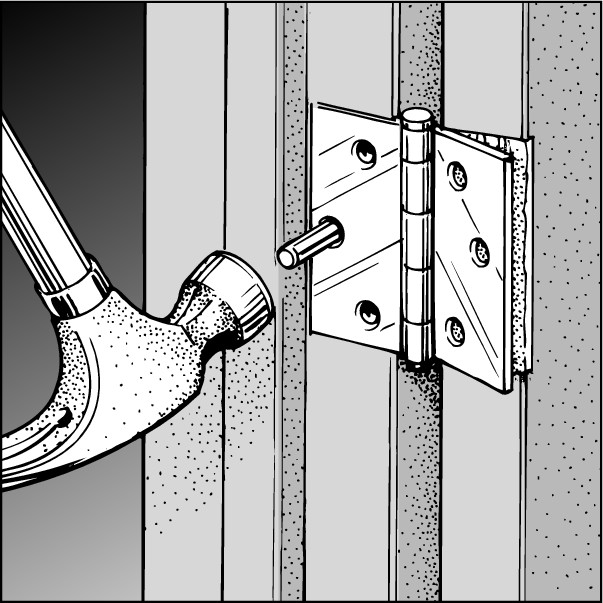

Lubricating hinges

Interior doors typically have two or three hinges. Exterior doors are heavier than interior doors, so they have three or four hinges. To lubricate door hinges, first remove one hinge pin. Some hinge pins extend through the hinges, so you can use a large nail to tap them up from the bottom, as shown in Figure 3-1. Other hinges may require you to insert the blade of a slot screwdriver under the head of the hinge pin and then tap the handle of the screwdriver with a hammer to drive the pin up and out of the hinge.

|

Figure 3-1: Hinges with an open bottom have hinge pins that you can remove by tapping a large nail into the bottom of the hinge, driving the pin up and out. |

|

After you remove one hinge pin, drop a large nail in the hinge to temporarily replace the removed pin and prevent the door from sagging off its hinges. Lay the hinge pin on paper towels and remove any dirt. Then spray the pin with a light coating of lubricant and replace the pin in the hinge. Repeat this procedure for all the hinges, one at a time.

Lubricating door locks

Many people put up with the aggravation of a sticking door lock for years — an annoyance that would try the patience even of Harry Houdini. Ironically, you can fix most stubborn locks in a matter of minutes.

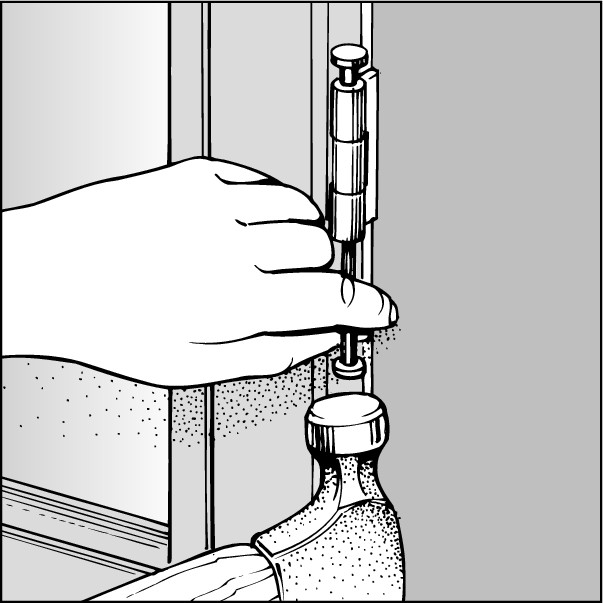

First, clean the keyhole with a penetrating lubricant like WD-40. (Don’t apply household oil to the key or cylinder because it attracts dirt and eventually would gum up the lock.) Spray the lubricant into the keyhole itself and then spray it on the key. Slide the key in and out of the lock several times to spread the lubricant.

If this superficial cleaning doesn’t free the lock, eliminate the aggravation altogether: Take about ten minutes to disassemble, clean, and reassemble the entire door lock. Here’s how to remove and clean the most common type of door lock:

1. With the door open, use a Phillips screwdriver to take out the two connecting screws that are located by the doorknob on the inside of the lock.

2. Remove the two screws that hold the lock faceplate on the edge of the door.

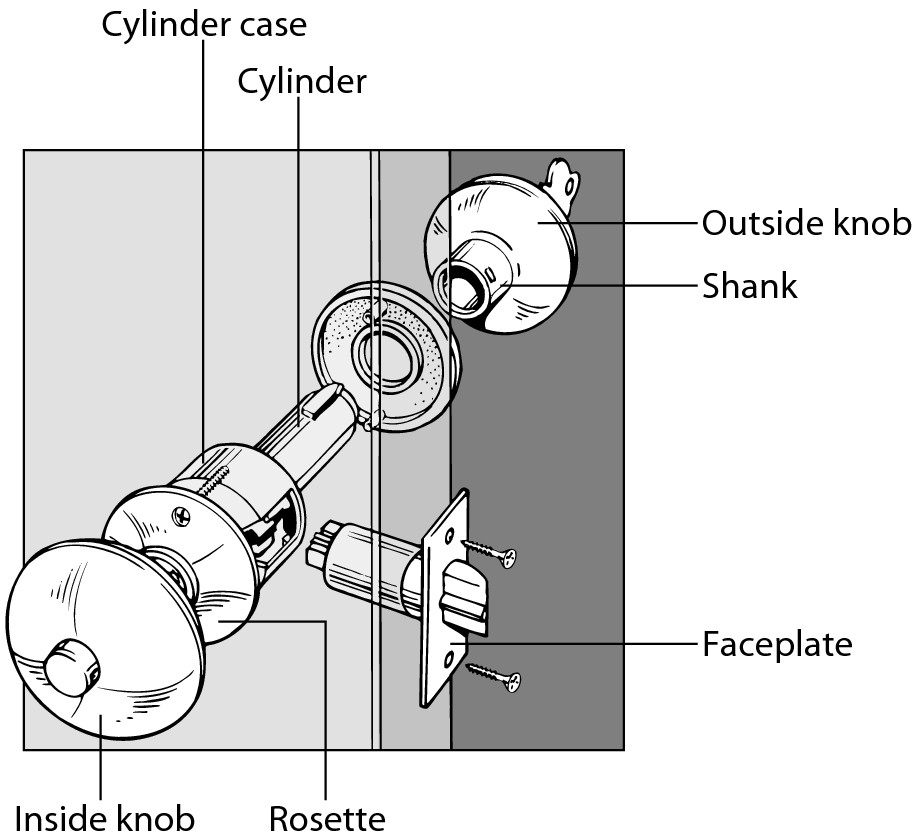

3. Slide the doorknob off the spindle, pull out the lock mechanism, and remove the latchbolt from its hole in the edge of the door, as shown in Figure 3-2.

|

Figure 3-2: You can easily remove, clean, and reassemble most modern door locks. |

|

4. Lay the disassembled lock parts on layers of newspaper or paper towels.

5. Spray a light all-purpose household lubricant or silicone lubricant on all moving parts of the lock, flushing out the latchbolt. Use powdered graphite to lubricate the lock cylinder.

Spray until all the dirt is flushed from the assembly and then let the latchbolt assembly lie on the newspaper or towels until all the excess lubricant has dripped off.

To reassemble the door lock after cleaning and lubricating it, follow these steps:

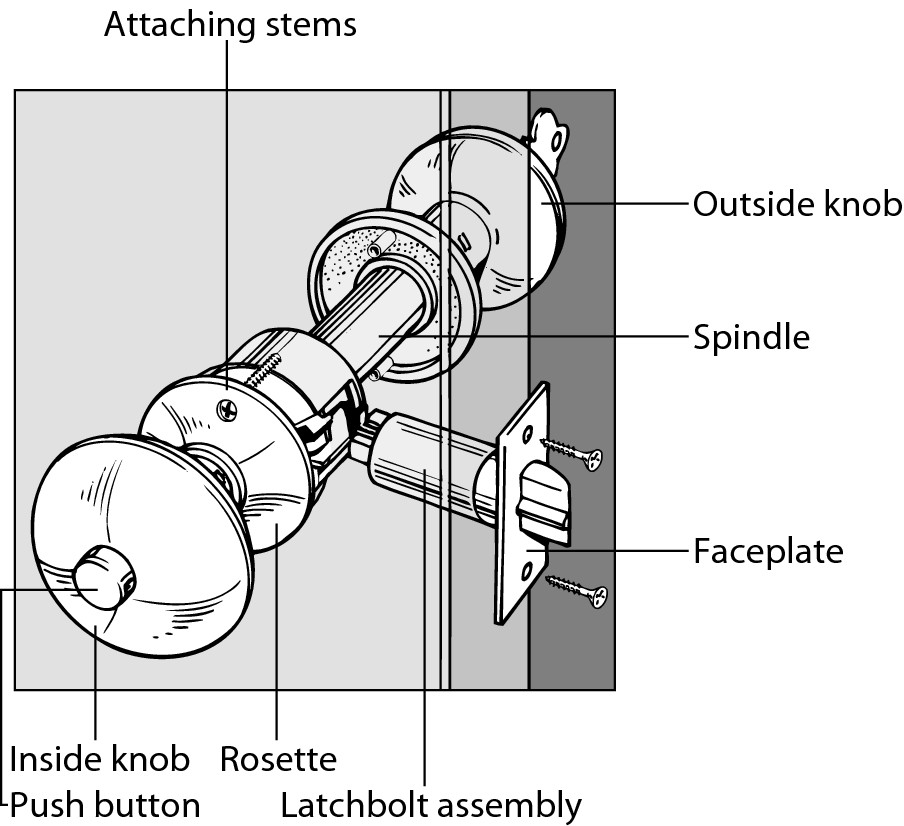

1. Insert the latchbolt assembly into its hole in the edge of the door.

2. Insert the exterior doorknob and spindle into its hole, aligning it so that the spindles and connecting screws pass through the holes in the latchbolt assembly, as shown in Figure 3-3.

|

Figure 3-3: Carefully align the spindles when reinstalling a latchbolt lock assembly. |

|

3. Drive in the latchbolt screws, but don’t tighten them until the lock is completely assembled.

4. Slide the interior doorknob onto the shaft, aligning the screw holes, and then drive in the screws.

Turn the doorknob back and forth to check that the cylinder and latchbolt are engaged and in proper alignment.

5. Tighten the screws on the latchbolt and recheck the alignment by turning the knob.

If you have any parts left over, guess what? You goofed. Disassemble the lock and replace all the pieces.

6. Test the lock by turning the knob and locking the lock.

If the lock doesn’t work smoothly, loosen the screws, realign the cylinder and latchbolt, and try again.

You can lubricate deadbolts the same way. Remove the connecting screws, the faceplate screws, and then the knobs. Next, pull out the latchbolt assembly and clean and lubricate the lock as just described. To reassemble the lock, reverse the procedure.

Tightening loose hinges

Loose hinges can cause a door to stick, bind, or scrape the floor. Lucky for you, this is another common, easy-to-solve problem. First, check that the hinge screws are tight. Open the door, grasp it by the lock edge, and move it up and down. If you encounter movement at the hinge screws, they need to be retightened.

If the hinge screws have been loose for only a short time, you may only need to tighten them with a screwdriver. But when hinge screws are left loose for a long time, the constant movement of the hinge plate and screws enlarges the screw holes. Eventually, the holes become so large that the screws can’t stay tight. The result: stripped screws that are completely useless!

If the door still moves even a tiny bit after you tighten its hinge screws, you have to repair the enlarged screw holes. Repair one screw hole at a time so that you don’t have to remove the door. Here’s how:

1. Remove the loose screw.

2. Dip the bare end of a wooden match in some carpenter’s glue and tap it with a hammer as far into the screw hole as it will go, as shown in Figure 3-4.

If the screw is large, you may have to put several glue-coated matches in the hole.

3. Break or cut off the match(es) flush with the hinge plate and discard the heads.

4. After you’ve filled the void in the screw hole with the wooden match(es), drive the screw into the hole with a screwdriver.

5. Remove the next screw and repair its hole, continuing until you have fixed all the enlarged screw holes.

|

Figure 3-4: Tighten a loose hinge screw by driving a glue-coated wooden match or small dowel into the screw hole and then reinstalling the screw. |

|

Fixing Bifold Doors

Bifold doors suffer from another chronic condition; they tend to jump off their tracks or become misaligned and, consequently, don’t open or open only partially.

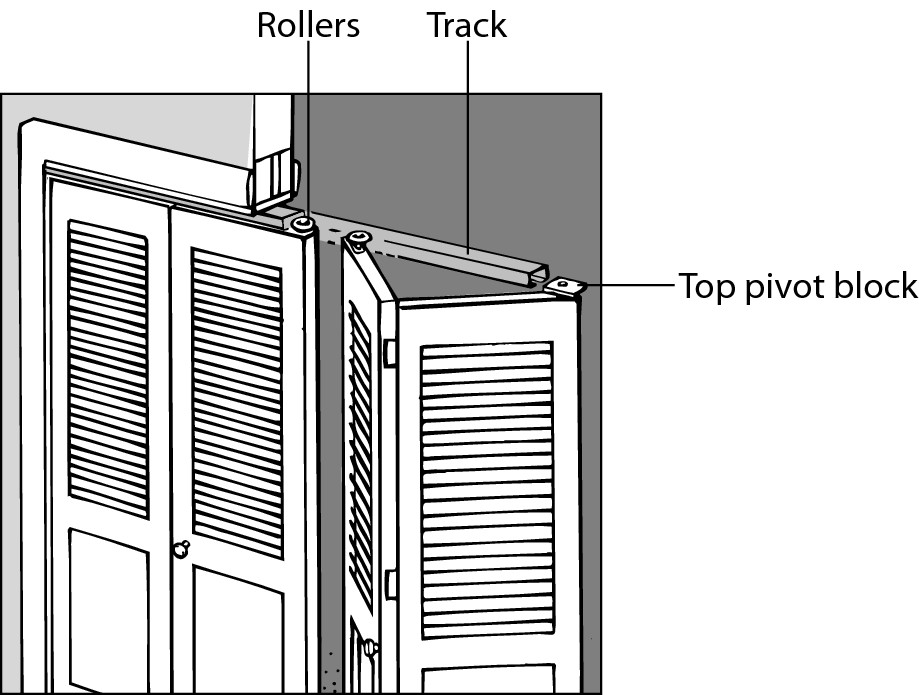

Bifold doors are arranged in hinged pairs that fold like an accordion toward both sides of the doorjamb or frame when opened. Because bifold doors permit you to open the doors fully and provide access to all storage, they’re often used on closets. They move via nylon rollers or pins mounted on the tops of the doors and travel on a track mounted at the top of the door jamb, as shown in Figure 3-5. The doors nearest the side jambs swing on pivot blocks installed at the top and, on some models, at the floor to keep the bottoms of the doors from swinging outward. To keep bifold doors operating smoothly, clean and lubricate the track, rollers, and pivot blocks at least once a year.

To tune up bifold doors and lubricate the top track, open the doors. Wipe the track with a clean cloth to remove dust. Use an aerosol lubricant to spray the track and rollers or pins. Apply the lubricant sparingly and be careful not to spray any clothes hanging in the closet. Leave only a light film of lubricant on the parts; use paper towels to wipe away any excess lubricant.

|

Figure 3-5: Bifold doors have rollers that run along tracks and pivots that enable the panels nearest the doorjambs to swing open. |

|

If your bifold doors bind (don’t open or slide on their tracks easily), first check to see whether all the hardware is secure and working properly. If the parts are broken, replacement hardware is available at home centers. Check the hinges between each pair of doors. If the hinge screws are loose, use a screwdriver to tighten them. If the screw holes are stripped so that you can’t tighten the hinge screws, remove the hinges and plug the screw holes following the steps we suggested for door hinges earlier in this chapter.

If, when you rehang the doors, the gap between the door and jamb is uneven, use a screwdriver or wrench to adjust the top pivot blocks and even the gap. Some bifold doors have adjustable pivot blocks at the bottom corner.

Maintaining Combination Storm/Screen Doors

Combination storm/screen doors relieve you of the seasonal hassle of taking down screen doors and putting up storm doors, taking down storm doors and putting up screen doors. These units come with both a screen and a storm insert that you can install and remove, depending on the season. Combination doors can have any variety of screw-in or bolt-in systems that hold the screen or storm panes in place. Some newer versions have a groove in the frame that the screen or glass fits into and a gasket to hold it in place. The doors themselves may be made of wood or metal, usually aluminum.

To keep these doors in good condition, provide maintenance service at least once a year. Spray an aerosol lubricant on the door lock, hinges, and closer mechanism. Also lubricate the push buttons that hold the glass or screen units in place. These buttons are located on the bottom edge, at both sides of the unit.

If the lock isn’t working properly, the easiest solution is usually to replace it. You can purchase replacement locks at home centers and hardware stores.

Replacing the screen

If you have a door with a loose or damaged screen (a given if you have kids or pets), don’t fret. Replacing screens is relatively easy, and it’s a useful skill to have, considering that you’re likely to be doing it for many years to come.

Both aluminum and fiberglass screening is available at home centers and hardware stores. The screening fabric comes in prepackaged sizes of 25 inches wide x 32, 36, and 48 inches long; and 84 inches long x 32, 36, and 48 inches wide. It’s also sold by the foot from bolts in the following widths: 24, 36, 48, 60, and 72 inches.

Measure your window before shopping for a replacement screen. Gauge the length and the width of the window opening and add a few extra inches to both dimensions to be safe.

The screen is held in a frame by a rubber or neoprene spline, which looks like a thin cord pressed into grooves. To replace an aluminum screen, you use a screen-installation splining tool. The tool looks like a pastry cutter with a convex roller on one end and a concave roller on the opposite end.

Installation steps are basically the same for an aluminum or fiberglass screen, with slight variations.

Aluminum screens

To replace an aluminum screen, follow these steps:

1. Remove the screen in its frame from the door and lay it flat on a workbench or a set of sawhorses.

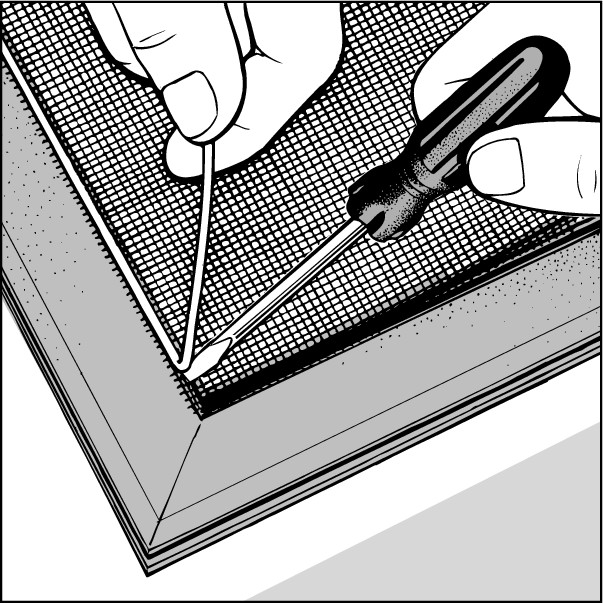

2. Use small pliers or a carpenter’s awl to pry the spline out of the groove and then lift out the screen.

To navigate around tight corners, use a screwdriver to ease the spline out of the frame, as shown in Figure 3-6. If the spline appears to be in good shape, set it aside for use with the new screen. If the spline is brittle or cracked, replace it with a new spline (available at hardware stores).

|

Figure 3-6: Pry out the old spline from the groove in the frame of the aluminum screen. Work carefully, and you can reuse the spline. |

|

3. Wipe the spline groove clean, making sure to remove the tiniest grit.

4. Lay a new aluminum screen over the frame so that it overlaps the groove by at least 1/8 inch on all four sides.

5. Cut off the corners of the screen at a 45-degree angle, just inside the outer edge of the spline groove.

6. Use the convex end of the splining tool to press the screen into the groove of the frame.

Hold the roller at a 45-degree angle toward the inside edge of the groove and then roll downward to press the screen into the groove. Hold the screen taut across the frame as you roll it into place. Sags and wrinkles are about as attractive on screen doors as they are on people.

7. Use the concave end of the roller to press the spline into the groove.

Don’t cut the spline at the corners: Instead, bend the spline around the corners and install it in one continuous piece. When you position it tightly in the groove, the spline holds the screen in place.

8. Use a sharp knife to trim away any excess screen.

Place the tip of the knife between the spline and the outside edge of the spline groove and pull the knife slowly along the entire groove perimeter.

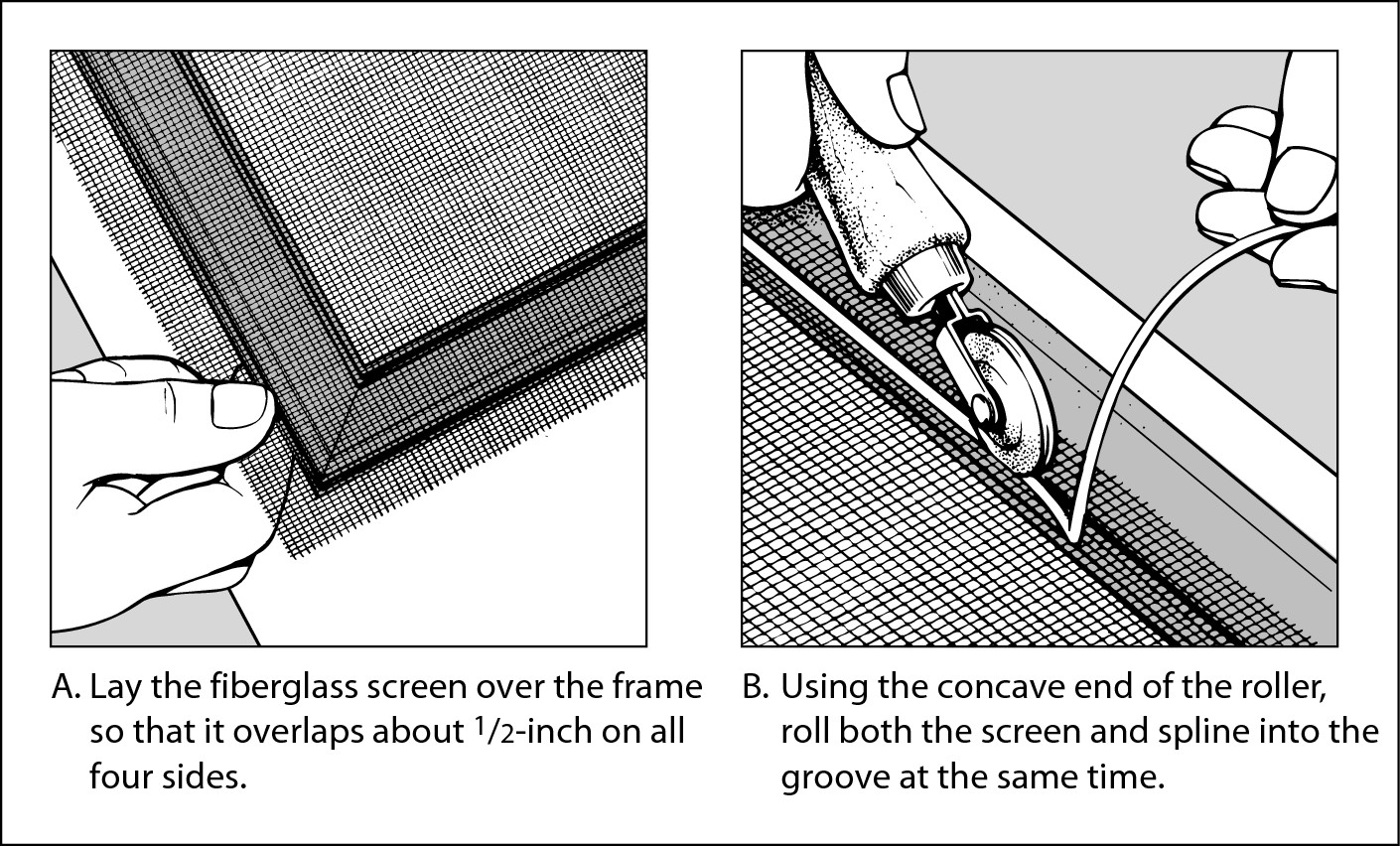

Fiberglass screens

To replace a fiberglass screen, first remove the old spline and clean the spline groove. Lay the fiberglass screen over the frame so that it overlaps about 1/2 inch on all four sides. Now use the concave end of the roller to roll both the screen and the spline into the groove at the same time, as shown in Figure 3-7. Be careful to hold the screen straight while you work on the first two sides and then roll in the last two sides. To cut away excess screen, position the knife tip between the spline and the exterior side of the spline groove.

|

Figure 3-7: Installing a new fiberglass screen. |

|

Tightening loose storm door panels

You want your storm door panels to sit firmly in their channels, secured against air infiltration by weather stripping that’s tucked into the grooves on all sides of the panel. When panels become loose from wear or weathering and begin to rattle in your door, it’s time for new weather stripping.

The weather stripping in your storm door may be felt strips (common on older models) or rubber or vinyl gaskets. Replacement weather stripping, especially the felt kind, may be difficult to find. Look in large home centers for storm window or storm door repair kits or check out the weather stripping department. Chances are, you’ll find something that comes close to the original.

Follow these steps to replace worn-out weather stripping:

1. Remove the panels.

Most panels slide into channels in the frame and are held in place by thumb screws. Loosen these screws, turn the brackets that hold the panel in place, and lift out the panel.

2. Remove the old weather stripping.

Pull up the weather stripping at one end and work it out of its groove. You may need to use a standard screwdriver to begin the job if the material is stuck in place.

3. Press the new weather stripping into the groove at one corner and slide it down the groove.

Depending on the type of weather stripping, you may have to use a screwdriver to push it into place.

4. Replace the panel by reversing the actions in Step 1.

Sliding By with Sliding Doors

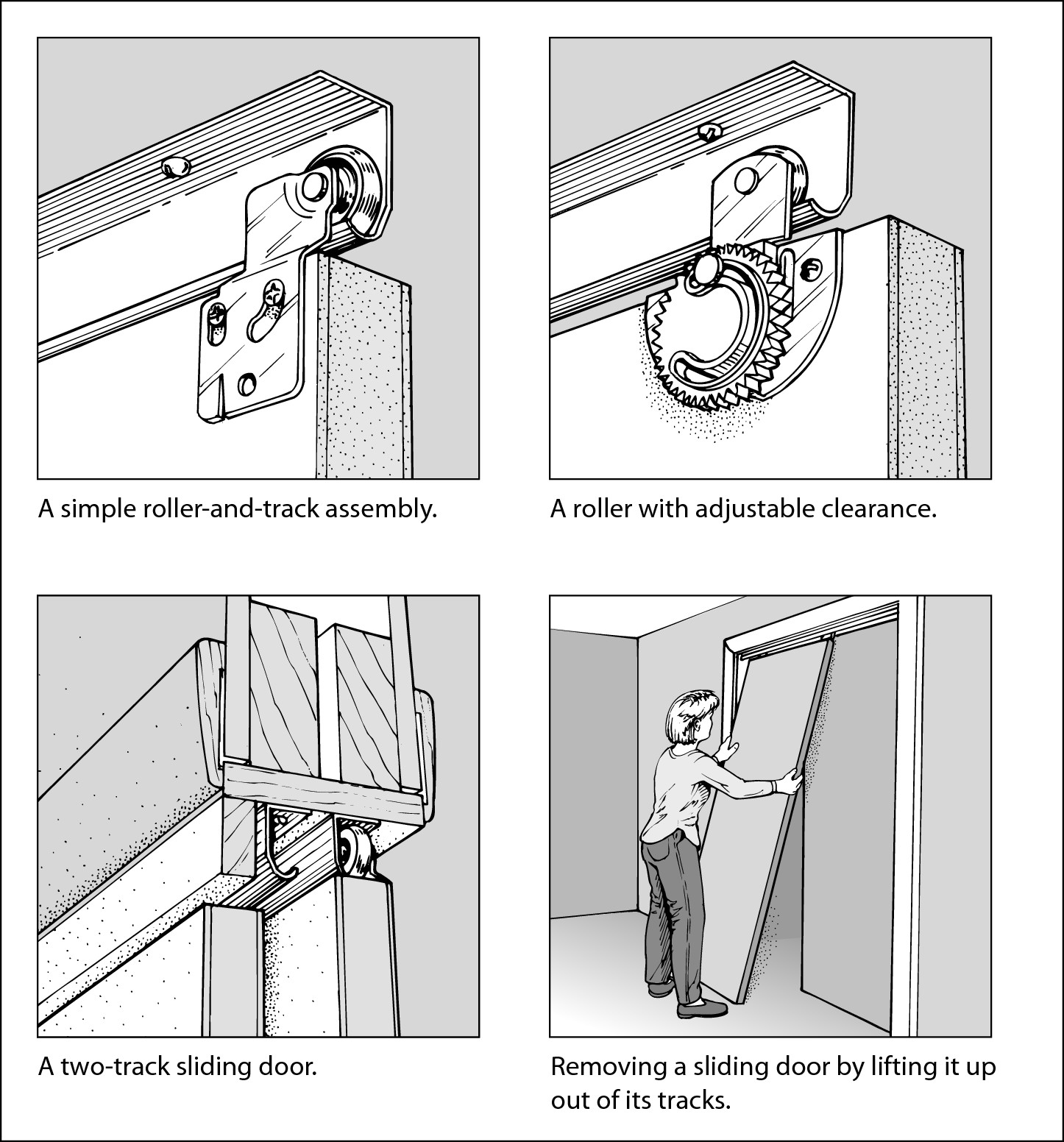

The two types of doors that are easiest to open don’t have hinges at all; instead, they slide on tracks. Sliding-glass doors are a popular feature in rooms with decks or patios because their full-length glass panels open the room visually to the great outdoors while providing easy access to the outside. Interior sliding doors are frequently used for closets and pantries, and sometimes to conceal water heaters and furnaces. You can remove sliding-door panels easily to gain complete access to what’s behind them. Follow simple repairs and maintenance procedures to keep your sliding doors on track.

Getting your patio door to slide better

Patio doors slide horizontally — or at least they’re supposed to. All too often, these big, pesky contraptions stubbornly resist opening, and getting outside becomes about as easy as dragging a refrigerator through a sandbox.

The most common cause of a sticking patio door is debris in the lower track. This channel easily becomes clogged with dirt, leaves, and such because people and pets walk over it whenever they go in or out. Each time you vacuum your floors, use a small brush attachment or cordless vacuum to clean the sliding-door tracks. Apply a lubricant to both upper and lower tracks to keep the door hardware clean and operating freely.

Sometimes, patio doors become hard to open even when the track is clean. In these cases, the problem is usually that the rollers at the bottom of the door have started to rub against the track. The rollers at the top can also wear down, lowering the bottom of the door so that it rubs on the track.

Most sliding doors have a mechanism called an adjusting screw located at the bottom of the door ends. Turning this screw raises or lowers the roller, as shown in Figure 3-8. Give the screw a clockwise turn and test to see whether the door slides easier. If the door becomes even harder to open, turn the screw in the opposite direction. After a bit of adjustment, the door should roll easily without rubbing on the bottom track.

|

Figure 3-8: A screw at the base of the door controls the clearance between the bottom of a sliding door and the track. |

|

Maintaining sliding closet doors

Sliding closet doors operate on rollers that are positioned in tracks at the top jamb and floor, allowing the doors to bypass each other in the tracks (see Figure 3-9). Because sliding doors don’t fold out the way bifold doors do, they allow access to only half the width of the opening at a time.

To clean and lubricate the hardware of a sliding closet door, use a stiff brush, a toothbrush, or a hand vacuum to clean dust from the tracks. Use an aerosol lubricant to lubricate all the door rollers. If the rollers are damaged, install replacement rollers (available at home centers).

|

Figure 3-9: Periodically clean and lubricate the tracks and roller assembly of a sliding closet door. |

|

If the door doesn’t hang level, leaving an uneven gap between the door and door frame, look for an adjustable mounting screw at the inside top of each door. Use a screwdriver to adjust the mounting screw and even out the door.

Locking Up

If a door in your house looks good, but its lock wobbles or shows signs of wear, consider replacing the lock. Standard interior locks come in a variety of styles and finishes that can improve the look of the door as well as provide security.

Replacing standard door locks

If your locks are becoming worn or damaged, replace them with new units. Because door locks vary somewhat in design, remove the lock and measure the diameter of the opening and the distance from the center of the hole to the edge of the door, which is either 2 3/8- or 2 3/4-inches. If you find an exact match, you won’t have to redrill the lock holes.

To replace a standard door lock, see the directions earlier in this chapter in the section titled “Maintaining Locks and Hinges.”

Installing a deadbolt

Many exterior doors are fitted with an ordinary cylinder lock that has a keyhole in the doorknob. This type of lock offers little resistance to a determined burglar (and what other kind of burglar is there?). The latchbolt of most standard locks extends only into the doorframe and a stiff kick from a booted foot can splinter most doorframes. And thieves can wrench out the exterior knobs of passage locks by using a pipe wrench. For added security, install a deadbolt lock on every exterior door.

Deadbolt locks have latchbolts that extend through the doorframe and into the wall stud next to the frame. A deadbolt lock has no exterior knob, so it’s impos-sible to wrench the lock from its hole in the door. From the inside, you operate a deadbolt lock by turning either a thumb-turn lever (if you have a single-cylinder lock) or a key (for a double-cylinder lock). If you have small children in the home who may not be able to find the key in an emergency, choose a thumb-turn lock. Keep in mind, though, that if your exterior door contains glass panels, a burglar can break the glass, reach inside, and unlock a thumb-turn lock.

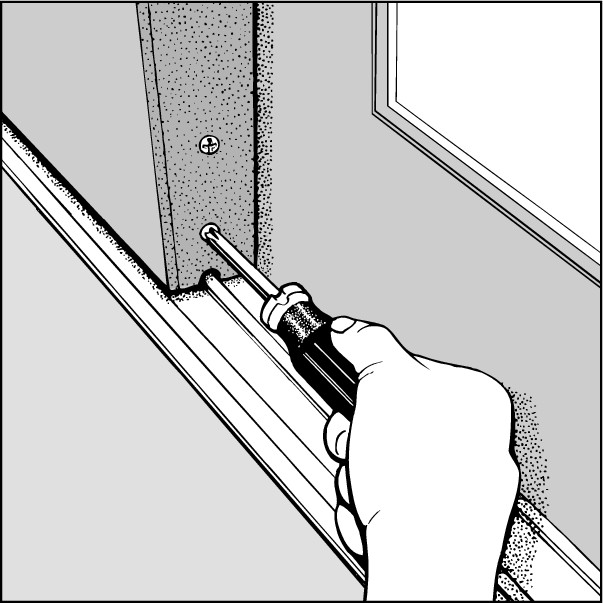

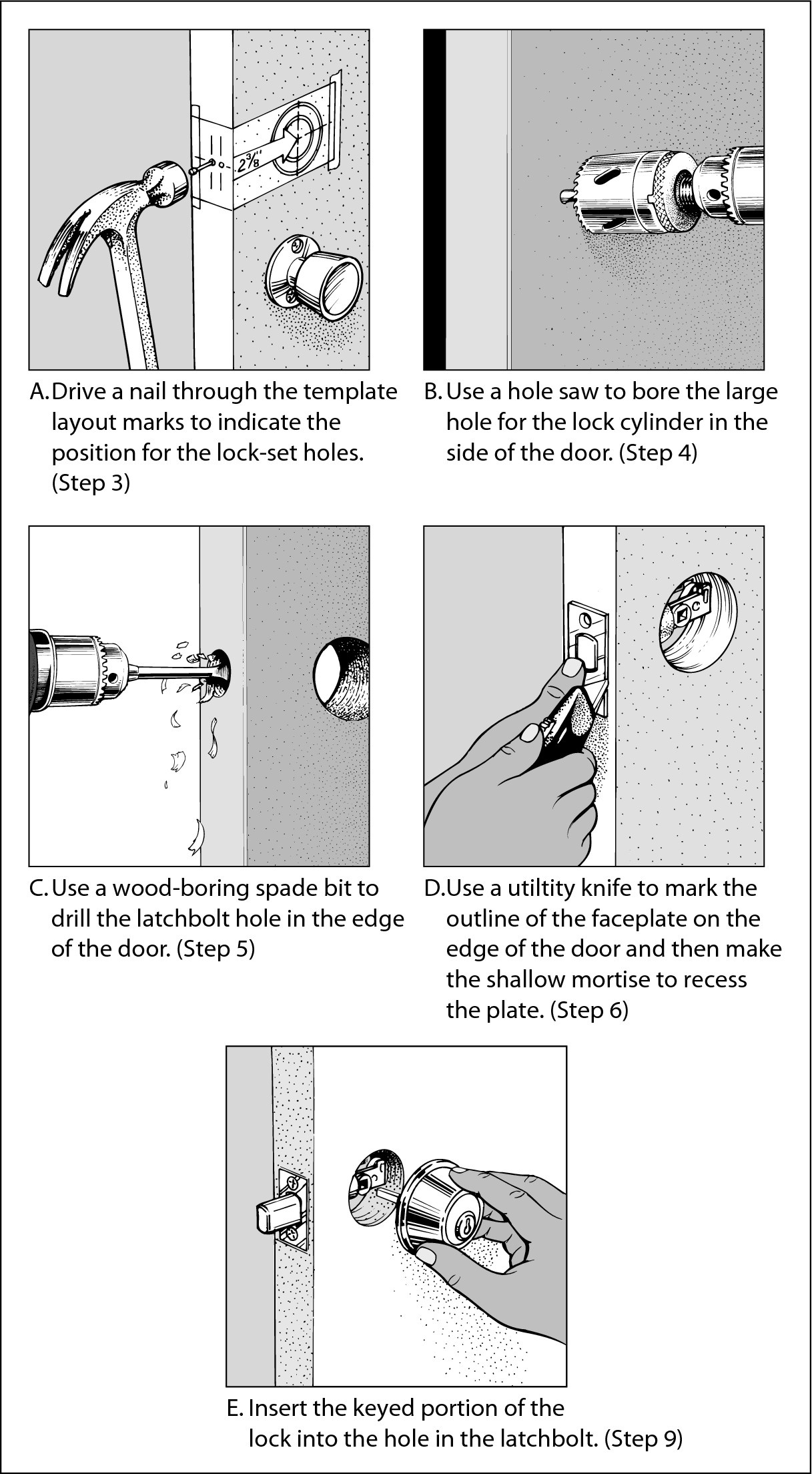

Deadbolt locks are relatively inexpensive, and most come complete with a cardboard template that shows where to drill the cylinder and latchbolt holes. Follow these general steps, illustrated in Figure 3-10, to install a deadbolt lock:

|

Figure 3-10: Installing a deadbolt lock for extra security. |

|

1. Choose a position on the door for the lock.

Most standard locks are set at or near 36 inches from the bottom of the door. Install the deadbolt lock above the standard lock or about 44 inches above the bottom of the door. If you have a combination storm door, position the deadbolt lock so that it doesn’t interfere with the operation of the storm doorknob or lock.

2. Use masking tape to affix the template to the door edge and face.

3. Use an awl, nail set, or large nail to mark the centers of the holes for the lock cylinder (through the face of the door) and the latchbolt (into the edge of the door).

4. Use the proper size of hole saw to bore the hole for the lock cylinder.

Some manufacturers offer a kit that includes a hole saw with the lock set. Drilling the hole from both sides helps prevent the door from splintering. The hole saw has a center pilot bit to guide the saw through the door. From one side of the door, drill until the tip of the pilot point pokes through the opposite side of the door, and then pull the hole saw out, position the bit in the hole, and finish boring the hole from the opposite side of the door.

5. Use a 1-inch spade bit to drill the latchbolt hole into the edge of the door.

The spade bit is an inexpensive wood-boring instrument that looks like a paddle with a triangular point on the end. Attach it to your drill to cut a perfectly round hole into the wood.

6. Cut a mortise, or recess, in the wood for the latchbolt faceplate.

The latchbolt faceplate must fit into a shallow mortise in the edge of the door. Cutting out this mortise isn’t nearly as difficult as it sounds. All you need is a sharp 1-inch chisel and a hammer.

To cut the latchbolt mortise, place the latchbolt in the hole and mark around the faceplate with a knife to indicate its outline on the end of the door. Use the chisel to deepen the marks about 1/8 inch. Then, starting at the top of the faceplate outline, make a series of closely spaced chisel cuts inside the marks. A 1-inch-wide chisel blade will fit inside the outline. Tap the chisel with a hammer so that it makes 1/8-inch-deep cuts.

Remove the resulting wood chips with the chisel blade. Then use the chisel to smooth the bottom of the mortise. Place the latchbolt in the door and check the fit of the mortise. If the faceplate is not flush with the door edge, chisel away a bit more wood.

7. When the faceplate fits flush with the door edge, hold it in place and use it as a template for installing the two mounting screws.

8. Before installing the lock, apply a thin film of aerosol lubricant to all the moving parts.

9. Place the latchbolt in its hole and then insert the keyed portion of the lock so that the tailpiece extends through the hole in the latchbolt.

10. From the inside of the door, fit the inside cylinder so that the holes for the retaining screws are aligned with the exterior portion of the lock.

11. Use the two retaining screws to secure the two sides of the lock together.

12. Shut the door and use a pencil to mark the spot on the doorjamb where the latchbolt meets the jamb.

13. Using the strikeplate as a template, trace and cut a mortise on the doorjamb; then dig out the mortise with a sharp chisel.

14. Use a spade bit to bore a latchbolt hole in the center of the mortise.

15. Use the screws provided to install the strike plate into the mortise.

16. Shut the door and test the fit by operating the deadbolt lock. If necessary, you can loosen the screws and adjust the lock set slightly so that the latchbolt passes easily into its hole.

Securing the patio door

Because they’re large and easy to force open, patio doors are common targets for intruders. Safeguard your residence by buying a locking device that blocks the track, preventing outsiders from forcing the door to slide open. Or create your own device by cutting a length of wood (such as a broomstick or a 2-x-2-inch board) to fit snugly between the doorframe and the stile of the operable door.

You can enhance this safety feature by drilling a hole through one door and into the other and then inserting a long nail or bolt through the holes: This setup prevents intruders from prying the door up and swinging out its bottom to gain entry. If the existing lock doesn’t work, check home centers for replacement locks.

To prevent a break-in through the door pane, install a tough window film (sold at local glass installers) that prevents the glass from shattering and resists forced entry.

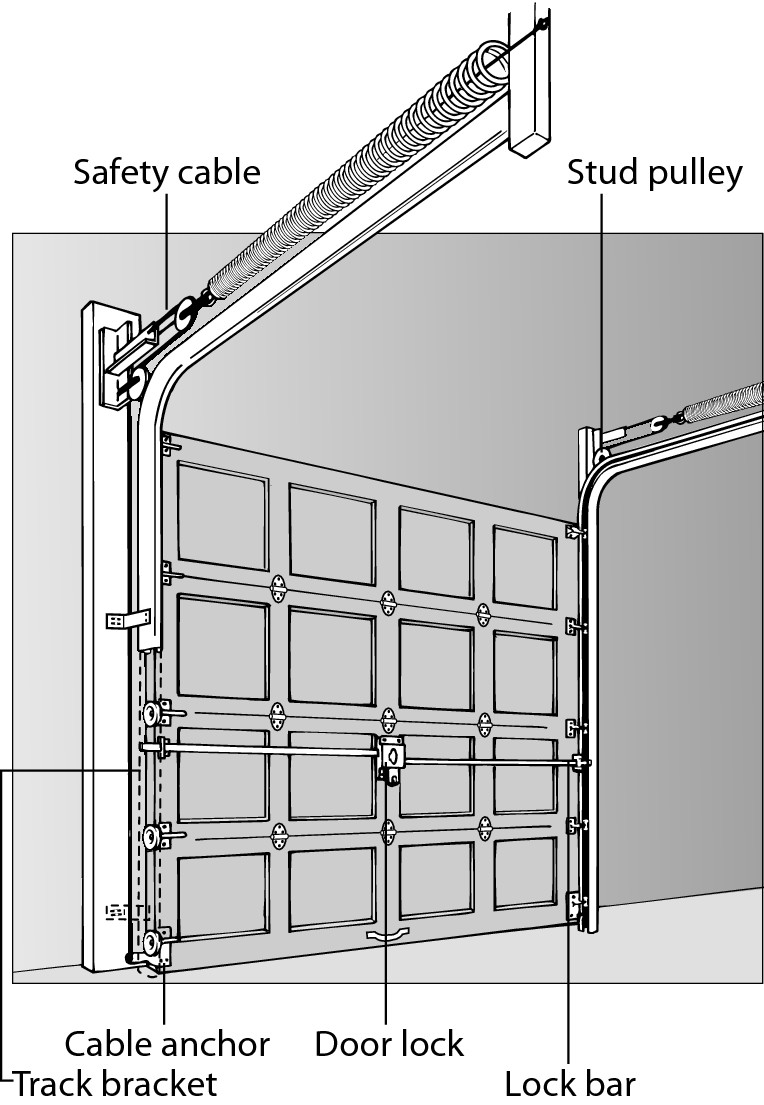

Maintaining Garage Doors

Because garage doors are especially exposed to weather extremes, you should inspect and service them at least once each year. Most modern garage doors consist of four or more panels that are hinged so that they can travel in a pair of tracks, as shown in Figure 3-11.

|

Figure 3-11: Lubricate the major parts of the garage door at least annually. |

|

Use an aerosol spray lubricant and wand to clean and lubricate all these moving pieces:

Combination hinge and rollers: These gizmos are located at either side of the door, between each pair of panels. Apply lubricant to the roller and the hinge to which the roller is attached. Use lubricant sparingly; too much doesn’t make the door work better, it just attracts dirt that will eventually gum up the works.

Combination hinge and rollers: These gizmos are located at either side of the door, between each pair of panels. Apply lubricant to the roller and the hinge to which the roller is attached. Use lubricant sparingly; too much doesn’t make the door work better, it just attracts dirt that will eventually gum up the works.

Hinges in the field or center of the door panels: The hinges that hold the center of the door panels together don’t have a roller. Apply lubricant to these hinges and then operate the door several times to distribute the lubricant to all moving surfaces of the hardware.

Hinges in the field or center of the door panels: The hinges that hold the center of the door panels together don’t have a roller. Apply lubricant to these hinges and then operate the door several times to distribute the lubricant to all moving surfaces of the hardware.

Lock mechanism on the door: Spray lubricant into the keyhole and work the key several times to distribute the lubricant to the lock’s moving parts. If your door is manually operated, lubricate the pair of locking latches at each side of the door.

Lock mechanism on the door: Spray lubricant into the keyhole and work the key several times to distribute the lubricant to the lock’s moving parts. If your door is manually operated, lubricate the pair of locking latches at each side of the door.

.jpg)