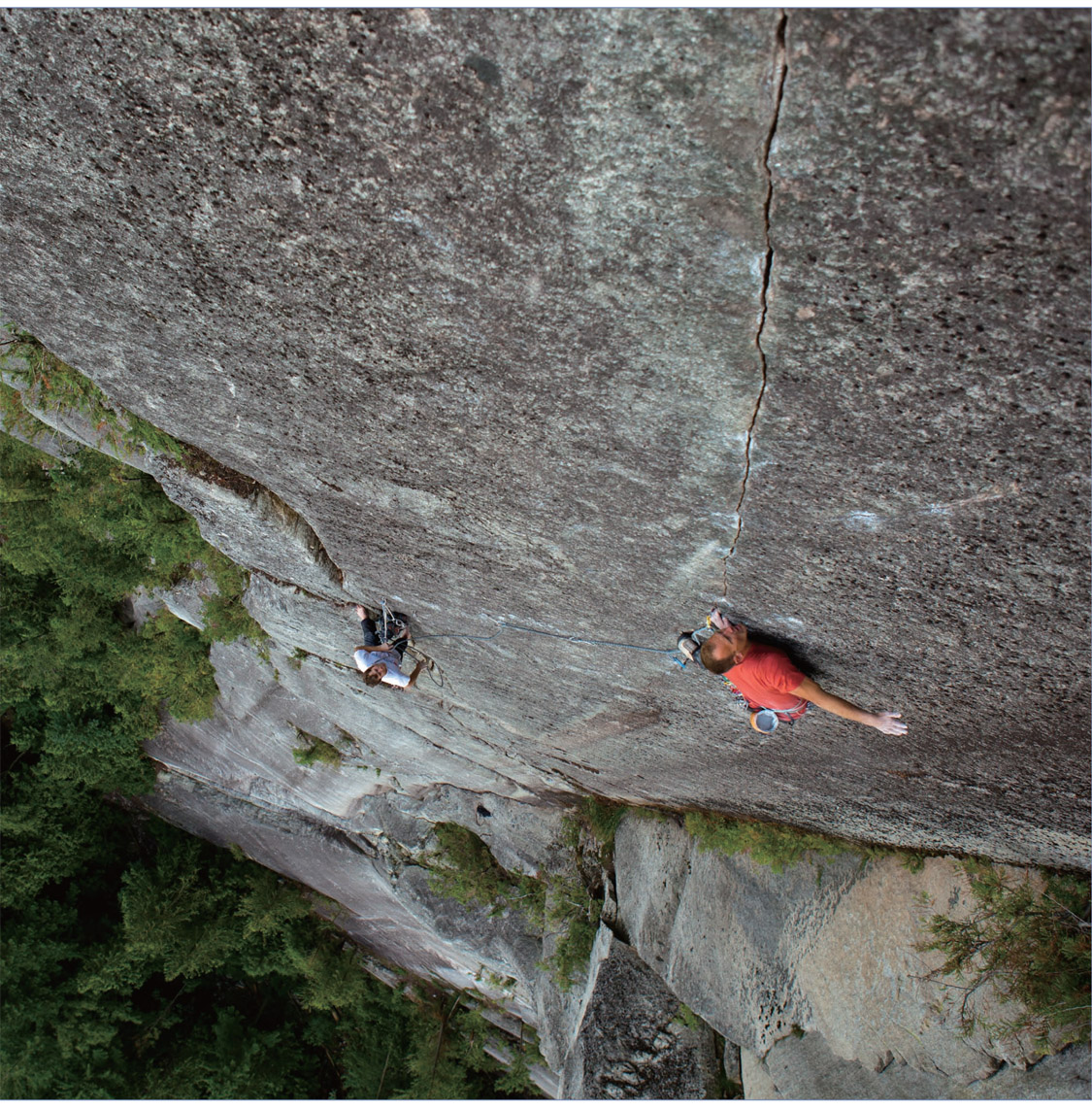

PHOTO BY ANDREW BURR

Now that we have reviewed the ways in which static and dynamic forces are generated and controlled in climbing, we need to see exactly how those forces are transmitted through the components of the roped safety system. This topic is generally referred to as “direction of pull,” meaning that a given force will pull on the system from a specific direction(s). No matter how well you understand the nature and the numbers about dynamic and static forces, unless you know where those forces are coming from, your rigging and anchor building will be founded on guesswork, not specific knowledge.

We have previously touched on direction of pull in various places. Now it’s time to thoroughly grasp one of the most crucial aspects of the climbing game. At a given belay on a given climb, the direction of pull will influence your choice of two rigging strategies: statically equalized or dynamically equalized—subjects we devote considerable time to exploring in the following chapters. In short, you can’t go about rigging an anchor to protect loading angles for which you are unaware. You need to know the direction of pull. Judging the direction of pull is as intuitive as knowing where the sun rises, providing you have a clear mental picture of what the pull is and how it is transmitted through the rope. Understanding the physics involved (forces) taught us the essential qualities of this pull. Now let’s look at the picture of those forces at play.

Imagine yourself on a flat, wide-open field while facing due north. You are anchored to a cherry tree directly behind and have the “soft” (belay) end of a 50-foot piece of rope wrapped around your waist. The business end of the rope runs to the waist of your partner who is standing in front of you. Your partner (the leader) walks 30 feet due north to an orange tree, then walks just past the tree and begins running due west (directly left). After 20 more feet, the leader runs out of rope. His forward momentum is stopped by the rope, transmitting a pull through the rope that runs back to you. Even though the leader has traversed 20 feet off due north, the direction of pull on the anchor is still due north, where the rope runs around the orange tree. That is, the direction of pull does not come from where the leader is once the rope comes tight—20 feet dead left of the orange tree—rather it comes from the orange tree because A) the “pull” is transmitted through the rope, and B) the rope runs around the orange tree.

The exact same dynamic occurs on a leader fall. The direction of pull is described by a direct line between you (the belay) and the first piece of protection through which the rope runs. When belaying someone following a pitch, the direction of pull is described by the last piece of pro through which the rope runs.

Obviously to properly judge the direction of pull, you need to know where the route goes. In our first example, when you were standing in the middle of a flat field, you could see the orange tree due north, so the direction of pull was obvious. But unless you’re heading for a bolt or other fixed protection, it’s hard to know exactly where the leader will place the first piece of pro—the Jesus Nut— and you won’t know till Jesus is in place. And until Jesus is placed and clipped off, you can’t know the exact direction of pull. But by observing the rock above the belay, and by referencing the topo (if you have one), you can normally predict the direction of the next lead—perhaps not exactly, but usually within 5 or so degrees.

Climbs following prominent cracks and chimneys clearly follow an obvious and certain direction, and the protection, and the direction of pull, can be extrapolated from the line of the obvious crack. But move out of conspicuous crack systems and the direction of pull can become less clear, particularly on face routes that wander around blind corners or connect various features on an open face. While no climb can go every direction at once, a leader might wander extravagantly trying to find the easiest route, placing protection first on the left and then on the right. This means the direction of pull can also change.

On vertical crack systems, the direction of pull is either straight down, in the case of a second climbing up to the belayer, or straight up, when the leader leaves the belay on the next pitch and clips the lead rope through protection placed in the vertical crack. In most every other case, the direction of pull will be in a direct line between the anchor and the pro nearest the anchor, in whatever direction that may be.

To clarify, if you’re belaying someone seconding (following) a pitch and the protection nearest the belay is a nut 10 feet down and 3 feet left of the fall line, if the second should fall before reaching the belay, the rope will snap taut between you (the anchor) and the nut down and left. If you’re belaying a leader who has traversed straight left off the belay and clipped a bolt 10 feet out left, if the leader falls, the direction of pull will be directly out and left, so long as the protection holds.

When you’re belaying someone following a pitch, the direction of pull is obvious because in the event of a fall, the rope will always come tight (consider the rope as an arrow pointing to the direction of pull) in a direct line between you and the last piece of gear. And you know where that last piece is because you placed it or you clipped it. But as mentioned, when leading, unless you’re heading for conspicuous fixed gear, who can say where the first protection will be placed; therefore, you can’t exactly predict where the direction of pull will come from. But normally the general direction is at least somewhat clear.

Determining the direction of pull is crucial because a belay anchor is often built to safeguard against specific directions of pull, and not against directions of pull that cannot occur on a given pitch. Anchors that protect against specific directions of pull are called “pre-equalized” (aka statically equalized) anchors. Anchors that protect against multiple directions of pull are called “self-equalizing” (aka dynamically equalized) anchors, subjects that by the end of this guide will be ground into your very bone marrow.

It should be pointed out that, barring routes with a lot of traversing, some climbers don’t much factor the direction of pull into their anchors, especially when the primary placements are bomber and the route follows a relatively plumb line trajectory. Here the anchor consists of bomber pro (especially the Jesus Nut), a good stance, and the rope—enough for some climbers to feel confident they can handle all loads in all likely directions of pull (mainly straight up and down). While optimum equalization might be absent in such anchors, between stout primary placements, rope stretch, flex and give in the rigging system—and using the body as counterweight against loading from whatever direction it might come—many climbers feel comfortable the anchor is good enough.

The climber following this pitch is unclipping the last piece. As long as that piece is still clipped, the direction of pull on the belayer and anchor in the event of a fall will be in a straight line toward that last piece. However, when the piece is unclipped, the direction of pull will be in an arc below the belayer, and the anchor better be built to withstand the swinging load. It’s no problem with this bolted belay, but hand-built anchors require careful thought.

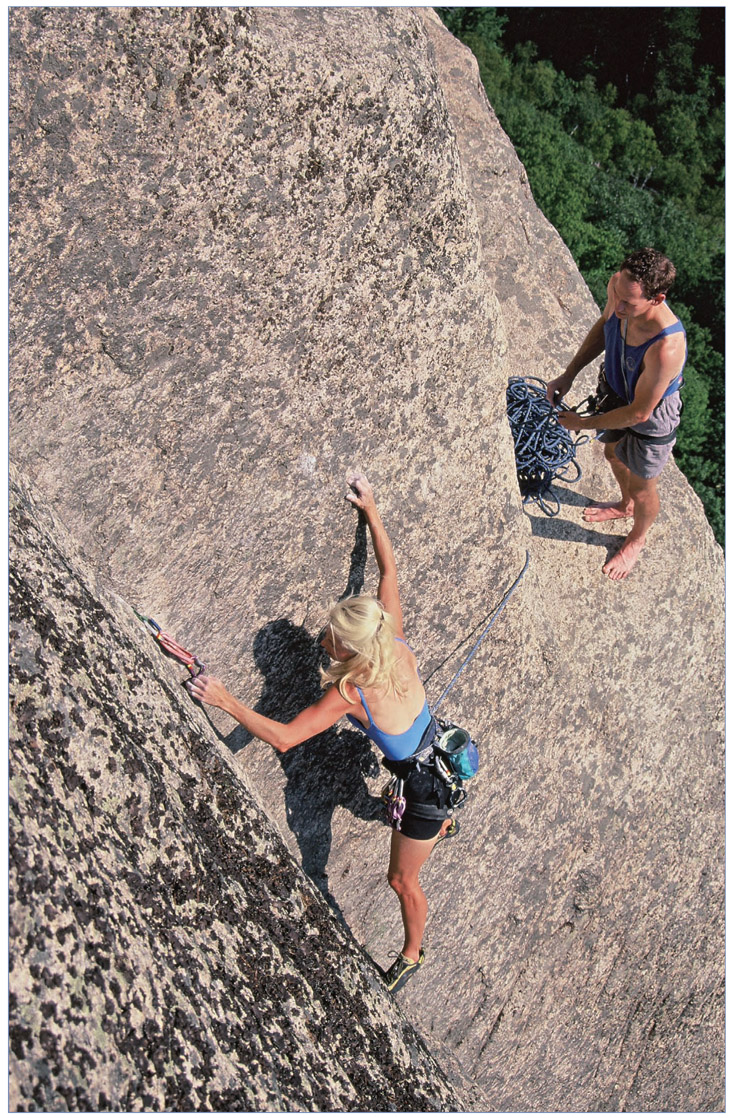

PHOTO BY STEWART M. GREEN

This practice leads to a question commonly asked: If we understand the directions of pull, why build an anchor to safeguard against direction(s) of pull that can never occur on a given climb? Isn’t that a little like facing a solar panel away from the sun, or building a guest house for friends who will never visit? Well, not exactly.

If we always climbed on bolted sport routes or in laser-cut vertical cracks, there would be little reason to ever build belays with a wide-loading axis, resulting in a multidirectional anchor. We could simply design the belay to target the anticipated directions of pull—with a few degrees to spare— and we’d be mint.

Direction of Pull

Every fall generates a dynamic force that will pull on the roped safety system from a specific direction or directions.

The direction of pull is described by a direct line between the belayer and the first piece (when belaying a leader) of pro, or the last piece of pro (when belaying a follower) through which the rope runs.

Lead protection and belay anchors must sustain loading from every direction of pull that is possible on a specific pitch.

To accurately judge the direction of pull, you must know where the route goes.

When the direction of pull is uncertain, a multidirectional belay anchor is required.

When a swinging fall directly onto protection, or onto the belay anchor, is possible, the pro and the belay anchor must be built to sustain loading across the full arc of the swing.

Knowing the direction of pull is to a climber what knowing the direction of a possible ambush is to a foot soldier: essential for survival.

In actual practice many climbers assess the direction of pull and build the anchor so it can withstand a worst-case scenario fall only in that direction or directions. Why safeguard against sideways forces, say, when the route goes straight up and down? Moreover, some argue, convincingly at times, the need for placements to sustain upward loading is also unnecessary, a discussion we’ll engage in shortly. There are pros and cons for each argument, but several recent anchor failures bring another, seldom-mentioned factor into the equation. Namely, swing.

Consider our previous example, when the leader traverses straight left off the belay, places a piece and falls. What happens when the piece rips out? The leader’s fall will describe a 90-degree arc, and then some, and the direction of pull will come from various rapidly changing vectors in a phenomenon called swing.

With swing, gravity is forcing, at a rapidly accelerating rate, a climber’s falling body directly into the fall line, which is always a direct line below the last piece through which the rope is clipped, or directly onto the anchor if a Jesus Nut has not been arranged or blows out in a fall. This swing is simply a pendulum coming to rest. When the leader swings onto the anchor as described, he will not load the system in the standard, quick-loading fashion. The loading during the first few feet of straight-down fall is not much, but the forces rapidly increase as the falling climber begins to weight the rope and arc toward the fall line. While there is little lab information detailing the fine points of swing-loading on an anchor, common sense tells us that the anchor best be sufficiently multidirectional to sustain loading across the entire 90-degree arc of the falling climber’s swing—and a little beyond as well—since the anchor will likely sustain lesser to greater loading throughout the entire arc.

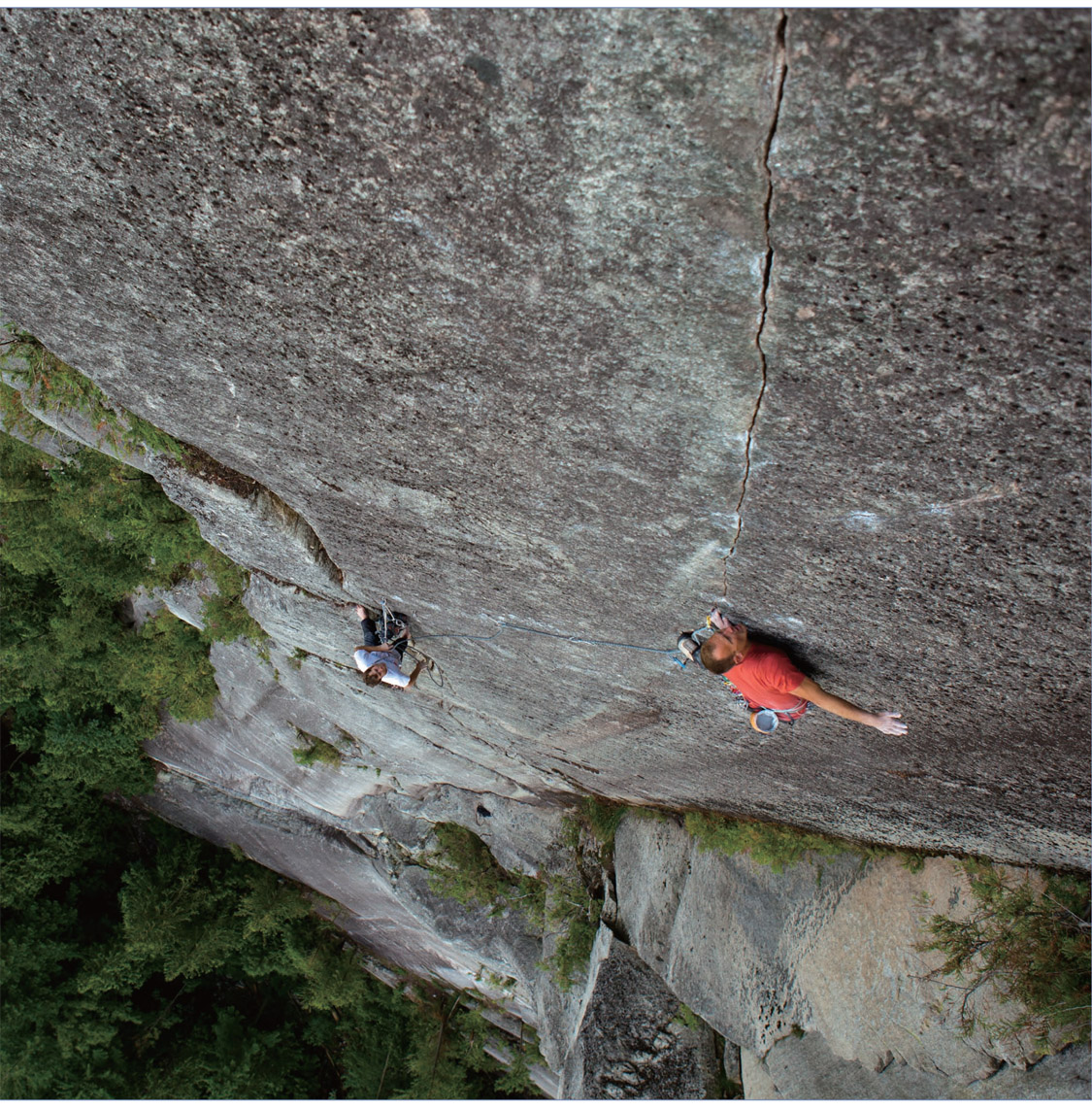

This leader has traversed left off the belay, and if she falls before clipping that first piece (the Jesus Nut), the load on the anchor will describe an approximately 90-degree arc below the belayer. If the anchor is built to withstand only a straight up or down pull, this could spell trouble. (Barefoot belaying, although sometimes comfy, is not recommended!)

PHOTO BY STEWART M. GREEN

The above must be kept in mind when the leader is just climbing off the belay and when there’s a possibility that the Jesus Nut might fail— always a very dangerous proposition. If a leader falls before arranging the Jesus Nut, or if the Jesus Nut blows, the leader will fall past the belay twice the distance he is out from the belay when he fell. The extent that the leader has climbed left or right of the anchor is the range of swing vectors that will be placed on the anchor. The greatest loading will likely occur when the falling leader’s vertical path comes tight and is converted to a roughly circular arc, thereby forcing the anchor to sustain an “off-axis” impact. After this point the leader’s full weight will be on the rope as he swings into the fall line and beyond. Several recent anchor failures suggest that swinging forces put significant and screwy forces on anchors. In short, if the anchors have not been built with those forces in mind, and these forces occur, people can and do perish.

Case in point was a recent fatal anchor failure at the top of Tahquitz Rock, in Southern California. While we cannot be certain of anything, the components of the failed anchor—which remained attached to the rope after the accident—gave strong evidence suggesting that the leader had placed an anchor in a horizontal crack near, or at the top, of the rock. When the second followed the pitch, he fell at a point when he was not in the fall line, meaning he was a ways left or right of the anchor overhead. The fall apparently put a swing load onto the anchor, which ripped out and sent the two climbers to their deaths. (The anchors were likely placed in poor quality rock, which possibly contributed to this anchor failure. How much—we can never know.)

This tragedy illustrates that even when belaying someone following a pitch, where the fall factors are far less than for lead falls, swinging loads can wreak havoc with anchors. Again, the changing and accelerating loading vectors of a swinging fall likely wrench the anchors in ways and in directions that potentially spell doom for any anchor not specifically designed to sustain them (i.e., multidirectional).

Bottom line: When a swinging fall is possible, any anchor that is not fashioned to withstand loading across the full arc of the swing and a few degrees beyond is not good enough.

While there are arguments against rigging multidirectional, dynamically equalized anchors in some cases—specifically when the direction of pull is known and remains a constant—such anchors are essential whenever a swinging fall is even remotely possible. Remember that so long as the first piece of protection above the belay holds (in the event of a leader fall), no matter where the leader climbs after that first piece, and no matter where she places protection past that first piece, the direction of pull will remain directly in line with that first piece. It can work no other way, since the force is transmitted through the rope, and the rope runs through the first pro.

Understanding the direction of pull is as important to a climber as understanding the direction of an ambush is to a foot soldier. Both are wise to keep an eye in all directions, but especially toward the direction of obvious threat—and for a climber building an anchor, the greatest threat comes precisely from the direction of pull. Whenever an old guide sees a belayer not in line with the direction of pull, the standard joke is to ask the student if he puts the seat belt on behind him when he drives a car because he obviously doesn’t understand the direction of pull.

As mentioned, with secure pitons, bolts, and trees (to list a few multidirectional anchors), you can yank from any direction and the anchor is good. Nuts and cams work on an entirely different principle and are secure only within a limited range of loading. Equalization techniques, though never perfect, allow us to greatly increase the direction(s) an anchor can be impacted while at the same time distributing the impact force over the components of the anchor matrix. In theory we’d like to enjoy 360 degrees of equal security, meaning we could pull on the anchor from any direction along the plane of the rock, and the load on the anchor would never change. This is a true, omnidirectional anchor. Unfortunately it’s unlikely we can ever perfectly achieve this, nor do we have to.

For example, consider the common scenario where you’re left to fashion an anchor in one or more closely aligned vertical cracks. Typically, in good rock with ready placements, you will slot several bomber nuts for a downward pull, then rig these against several lower nuts rigged for an upward pull. Even with textbook rigging, most every anchor can best sustain up and down forces. In other words, the anchor is stronger if you pulled up on it, or directly down on it, as opposed to pulling directly on it from the left or right side. A direct up or down force pulls directly in the attitude for which the nuts were designed to absorb loading, and in which they were placed. Your rigging might be so expertly arranged that the load is shared fairly equally by the primary placements, but the primary placements themselves are strongest when pulled in limited, not unlimited, directions.

Sage rigging can compensate for oblique forces on hand-placed gear, but never to the extent that sideways vectors will place exactly the same force when the nuts were impacted in their optimum orientation. Nor will the best rigging always and entirely eliminate the primary placements being loaded in directions in which the placements are not especially robust. The only way for this to be possible is if you perfectly equalized (impossible) primary placements that were themselves omnidirectional, such as bolts and pitons. Many cam placements can pivot somewhat within the crack and still remain sound. Passive nuts such as tapers are generally reliable only when loaded in one direction, though bottleneck placements increase that range. The process of rigging a combination of these components into an effective anchor matrix will be discussed shortly, after we go over a few necessary knots.