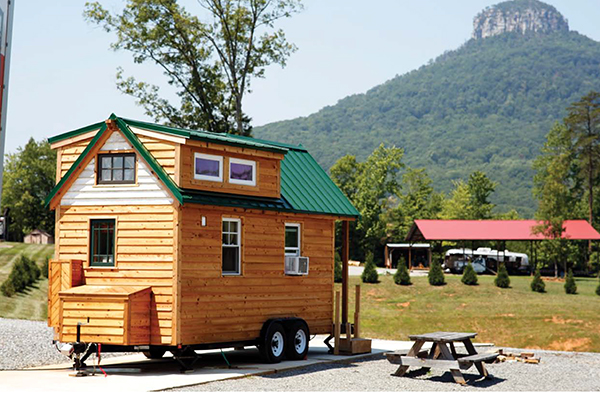

Photograph by Aaron Maret

Tiny houses have captured the imagination of people for more than a decade now. The promise of affordable housing is an enticing proposition in today’s world. We see people struggling to find themselves in this modern age, a time defined by “bigger is better,” “keeping up with the Joneses,” and a mentality that tells us we must always strive for more, go faster, and achieve perfection.

Tiny houses stand in stark contrast to this outlook. Small homes, which typically range from 100 to 400 square feet, have drawn much attention as a viable alternative to traditional housing because of cost, design sense, and environmental friendliness.

In this book we profile tiny houses of all shapes, sizes, and styles, which embody the spirit of the movement. These homes are built with a purpose: to pare down on space and possessions in order to focus on the important things in life.

While many want tiny houses to be confined in a neat box, the truth is a tiny house, at its core, is about breaking preconceived notions of what a house is.

The essence of a tiny home is not the square footage, it is not space-saving storage, it is not a particular style or design practice. Rather, a tiny house is a structure that provides everything you need to live your best life in the most efficient and cost-effective manner possible.

A tiny house is a home that conforms to the following three principles:

A tiny home for a family of four might be 1,000 square feet. For one single person a house of 150 square feet might be right, while another individual might want 300 square feet. All of these are tiny houses.

There is often a correlation between people who are interested in tiny homes and people who are both environmentally conscious and budget minded. Their ethos are closely aligned. It is no surprise then that we find a lot of people using reclaimed materials in tiny houses.

Many looking to make the move into a tiny house are looking for a more affordable way to live. Others want to live in a home that is gentle on the earth and lessens their impact. Reclaimed materials are great in meeting both of these goals.

Lots of people don’t have enough funds to build a home, so using reclaimed materials is the only way to make the construction of a house possible. They don’t want to spend years saving, so using reclaimed materials can cut down on the time to when they can walk in the front door. Time and money are both precious commodities, and using reclaimed materials as a way to achieve your dream of living in a tiny home more quickly can have a profound impact on the trajectory of your life.

There are others who are drawn to the aesthetics of reclaimed materials, the rich tones aged wood can bring, the unique look of their house that comes from materials with a history. Often using salvaged materials can lead to innovations, creating homes with a lot of character. Many people like the fact that they are able to design and build a house that is purpose-built to their lives, their tastes, and their needs.

This is a strong contrast with modern-day tract homes, which are built “on spec” and optimized for an “ideal buyer,” a data-driven profile created by market research. That research is used to create a home that appeals to the largest segment of home buyers. What this means is today’s modern homebuilding isn’t really built for anyone; it’s built to maximize sale and resale. The person who lives in that home doesn’t get a house built for her or his life but for someone else’s.

Finally tiny house people love reclaimed materials because they allow for a story. The story comes both from the life that the materials afford them in a tiny house and the stories from the materials themselves. Obtaining reclaimed materials is a complex process. You must interact with many different people to piece together the materials for your house. Such a process, finding everything you need, often requires a strong social network of individuals. Through all our interviews with people who used reclaimed materials in their homes, we found they had to construct a strong web of relationships for their homes to be completed. This brings a narrative of connected humans and objects to each of these houses.

All these things add up to stories about the people who helped you build your tiny home and the materials that ended up in it—stories that you then share with others when they come into the tiny house. In building your home, you are writing the next chapter in that material’s story.

A huge advantage of tiny houses and, in particular, the ones that use reclaimed materials, is their cost. The expense of a tiny house pales in comparison to that of a traditional house. The cost of housing has grown dramatically over the past sixty-five years. This is particularly noticeable today when income has stagnated. In 1950 the median household income was $4,237 and the average house cost was $7,354 for an income to home cost equivalent of 1.7. Compared to today, the median household income is $51,939 and the average house cost is $343,300 for an income to home cost equivalent of 6.6.

This sharp increase means that most people can no longer afford to purchase a home. Even if they are able to earn enough to qualify for a mortgage, more and more homeowners owe more on their mortgage than they can actually earn in a standard working life. Mortgages used to have fifteen-year terms; today the norm is thirty years, but we are beginning to see a rise in forty-year mortgages and reverse mortgages just to make owning a home possible.

Considering the average home in America sold for $341,500 in 2015, tiny houses are a breath of fresh air. The average tiny home built by its owner costs an average of $20,000, a price easily achievable for many people with a few years’ savings. The houses we profile in this book range in cost from $7,000 to $25,000, the average being around $13,000.

Photograph by Aaron Maret

Beyond the cost of the home, tiny houses are an attractive option because of their design. Often a great deal of care is devoted to their aesthetics and layout. They are homes that are built and designed from the ground up for the occupant, because to live in such a small space, you must have it perfectly customized to you.

Tiny home designers focus on both the structural and social aspects of a home. How does the design impact how its owner interacts with the space? How do the placement and design choices of storage, seating, windows, and materials impact the feeling of the space? Does the storage hide clutter to promote a clear mind? Do the windows extend the sight line to make the home feel bigger? Do the materials provide a warm sensory experience?

It is this attention to details and interactions that people find so appealing. Modern home designs largely ignore these things, so it is a breath of fresh air to many when they see quality design. Modern cookie-cutter neighborhoods are predicated on designs that maximize profits, not the owner’s happiness. Large-scale builders strive to minimize lot sizes to increase the number of units per acre. They focus on formulas for optimal marketability, and they cut corners in building quality to such an extent that code enforcers must step in to keep many builders honest.

Good design itself is difficult to put a number to, but the feeling it creates, a comfort within a space, is undeniable. Mass-market homebuilding can’t market design, so it concentrates on telling prospective buyers about the number of rooms, square footage, granite countertops, and walk-in closets. While big house Realtors sell to the largest number of people—which they define as their market—they have honed their house designs to a type; anyone outside of that ideal customer has a difficult time buying, building, or selling a home. Today most homebuilders design homes for large families, with extra rooms for entertaining and accommodating guests. As a result many single millennial home buyers are forced to buy homes with multiple bedrooms that will remain mostly empty.

The use of reclaimed materials in housing is nothing new, but it’s seen a recent rise in popularity as people look for unique ways to decorate and build their space. Reclaimed materials have a long history that is rooted in practicality. Reclaiming materials was and is an efficient way to build and maximize what you already have. At a time when hardware stores weren’t on every corner selling inexpensive lumber, you saved on the labor of milling boards.

Way back when, cutting trees into dimensional shapes was difficult and labor intensive. Back in the pioneer days, buildings were constructed by hand hewing logs with which to build and later hand sawing them. It was only later that modern lumber mills began processing lumber with methods that didn’t require removing material by hand with an axe or hand saw.

Today’s mills are advanced operations that precisely monitor moisture, use lasers to scan for perfect cuts, and employ computer-controlled milling to maximize the boards yield per log. Add to this a global transport system allowing for goods to be moved quickly around the world and we now have lumber that is easily accessible and cheap to buy. We’ve come a long way, but the appeal of reclaimed materials is still ever-present—however, for different reasons.

In today’s world we often focus on buying new, but there has been a rise in recycled and repurposed materials in all aspects of our lives. Lumber is no different. At its simplest definition reclaimed wood is lumber that was used for one construction project, but is then salvaged and used in another.

Typically when we speak of reclaimed wood, we are talking about wood that was harvested some time ago and possesses some unique attributes that new wood does not. Often people prefer to leave it in its original form, instead of milling it or chipping it. This doesn’t have to be the case, but it is often implicit.

Broadly speaking, we can also consider wood that has been recycled to be reclaimed as well. This is a growing trend in the building-material industry as it looks to maximize its use of materials.

There are two main types of recycling in wood products: industrial wood product waste and recaptured wood materials. With any manufacturing operation you will find some waste from the process; in the case of wood product manufacturing, this includes wood pulp, sawdust, and rejected materials. Recaptured wood products are discarded consumer wood products collected in mass, chipped, and then used to make new products; a good example is retired pallets that are chipped and turned into particle board.

Then there are items besides lumber, such as fixtures, handles, lights, scrap metal sheeting, used windows and doors, along with a whole host of other materials. These items are often kept in their original form and either used again in the same way or reconfigured into new creative uses.

Photograph by Aaron Maret

As is the case with tiny houses, the reasons for wanting to use reclaimed materials are varied. Reclaimed materials offer many opportunities and drawbacks, so it’s up to you to determine what makes sense for you to use in your tiny home. Following are some common reasons why people use them.

One of the biggest reasons people use reclaimed materials is because they can save a lot of money when it comes to building their home. There are opportunities to reclaim lumber from old buildings, items and fixtures from building salvage stores, and everything and anything from those who no longer need the materials.

You may not have a lot of funds, but you do have free time. In many cases it’s enough payment that you can show up and haul away the materials. In this way you’re able to gain building materials for free. In many cases you’ll have to act quickly so it’s important to be flexible and ready to take advantage of opportunities that present themselves.

Photograph by Christian Parsons, Tiny House Expedition

The lumber industry is a destructive one—by its very nature it cuts down trees to be fashioned into wood products. We have seen a lot of progress on this front with sustainable harvesting practices, more efficient use of trees, and greater environmental protections put into place, but in the end, lumbering is a damaging practice.

With reclaimed lumber, not only are you offsetting the use of new wood, but you are preventing that used wood from entering a landfill. Upcycling materials and displacing them from waste streams make this an ecofriendly activity.

By not purchasing new wood products we reduce the number of living trees that must be harvested. Currently 900 million trees are cut down each year; this represents a huge impact on our ecosystem. To put this in perspective, the average tree will sequester 1 ton of carbon in a forty-year period. In any given year a mature tree will produce enough oxygen for two human beings.

The damage is not just to the trees themselves but to the earth’s capacity to sustain life and maintain homeostasis. At the scale which trees are harvested each year, we begin to see how this can add up to create a long-term impact.

Going to places such as the Habitat for Humanity ReStore, a local salvage yard, or a similar place, capturing fixtures and other building materials before they enter into the waste stream . . . these things can have a big impact. Many of the items you can capture are still in good working order, some of them almost new, and many are available at a good price.

The quality of older-growth woods is undeniable. With reclaimed materials that are a few decades older or more, the wood quality is much higher in terms of wood grain, strength, cure, and fiber stability.

Older-growth woods tend to have a much denser fiber structure. This compares favorably to today’s lumber. The industry selects trees that grow quickly; this produces larger grains that are less tightly packed. The tighter the wood fibers, the stronger the wood, the more durable it is, and the better it is to work with.

Tighter fibers allow for a better-quality end product because this kind of wood tends to finish well. Woodworking is essentially the removal of material and then joining one piece to another. With a denser pack of fibers, we can better control the cuts and finish the wood in a more refined manner.

Another benefit of reclaimed wood is that it is often very stable. As with all natural materials a certain amount of warping will occur. With older wood, the grains have twisted to their full extent, and this means the wood will generally stay in its shape better than newer boards.

Even if the wood is warped you can either use it as is, highlighting its character, or you can remill it. There still is a chance that it will warp depending on air moisture, but it’s usually less than is the case with new wood.

It is worth noting that some people find older woods more difficult to cut because of the fiber density. In some cases it may require higher-powered tools to handle the denser material, particularly in the case of your table saw and router.

When it comes to fixtures and other hard goods, many people like the older styles of the items. Many also appreciate the quality that you can find; older things often were made to last longer and be more durable than those we turn out today.

The rise in popularity of reclaimed woods is often attributed to their character or the aesthetic qualities of the wood itself. Aging older wood often contains rich colors, which are hard to replicate through artificial techniques.

In aging, wood tends to take on two major tones, depending on how it was kept. Exposed to the elements, reclaimed wood will take on a shade of gray. These grays will vary depending on the type of wood, climate, and exposure. On the other hand, with prolonged exposure to the sun wood often suffers from UV degradation. This type of wood should only be used in accent pieces, not structural pieces. Wood that is protected from sun and most moisture often cures in brown tones, and because it isn’t exposed to UV rays, it often cures harder as the resins in the board dry and solidify.

You will often find unique patterns in reclaimed wood; these derive from how the pieces were processed. You’ll find old nail holes, saw blade patterns, or a chipped look that comes from the wood being hand hewn. These unique looks add character to your tiny house and tell the story of the wood.

Photograph by Aaron Maret

Today’s lumber is uniform: You have two-by-fours, four-by-fours, and so on. In older times, lumber often lacked uniformity in the dimensions of the wood because they were often determined by the size of the tree or resulted from the lack of precision of hand tools. Older-growth trees were generally larger. They yielded a wider board and longer beams.

Much of today’s lumber is often only available in smaller widths. Larger sizes cost a lot more—if you can even find them at all. The main reason for this is that most of today’s harvested trees are between twelve and twenty-four inches in diameter, compared to older lumber that was often milled from much larger trees. By comparison older-growth trees can be much bigger depending on the species; old-growth poplar trees can be six feet, an oak tree can be nine feet, and a redwood tree can grow to twenty-seven feet or more in diameter.

One thing that has struck me while talking to people who use reclaimed materials in their tiny houses is the stories that they tell about their reclaimed items. I think these stories are an interesting and often overlooked benefit of reclaimed materials.

Often the stories are about a key piece of the home, an accent feature, or focal point. When out and about collecting the materials, scrounging them from different places, you meet interesting people who tell you about themselves. The materials too have a history, a place that they came from, a life before they were part of your home.

The story could be an interesting or bizarre encounter with the previous owner, the struggle to get that material, or a past use that makes it interesting. Regardless, using reclaimed materials builds that history, adding a new chapter as the materials are gathered, worked, and reborn.

| Pros | Cons |

|---|---|

| Can be less expensive | Can be more time intensive |

| Visual character and uniqueness | Nonstandard sizes of wood |

| Denser grain, higher quality | Requires more labor to prepare for use |

| Materials with a story | More difficult to source materials |

| Inspires unique designs | Harder to plan; materials drive design |

| Environmentally friendly | Inefficiencies from sourcing uses more fossil fuels |

| Wood more stable, less likely to warp | Pests and mold may come with wood |

| Can be more durable from tighter grain | Unknown previous treatments (lead paint, chemicals, etc.) |

| Minimizes forest destruction | May require additional tools for processing |

As we move into the future, reclaimed and recycled materials are going to need to become a larger part of building structures for ourselves. We currently use recycled materials in some of our engineered wood products, but moving forward we need to increase our ability to capture more recyclable waste and find uses for it in our structures; doing so will bring our use of wood into a more sustainable future.

We are quickly approaching a point when we must grapple with the reality that harvesting wood the way we do today is not sustainable in the long term. Even with planned forestry, selective cutting, and efficiencies in our manufacturing processes we can’t displace the destructive nature of the practice.

For a variety of reasons it is difficult for us to make decisions as a global community. Our world operates on an economy that is predicated on perpetual growth on a planet with finite resources. Impacts are externalized to places we do not see and motivated by the drive for immediate profits.

It is difficult to steer a new course when there is so much wealth being accumulated by those who have a vested interest in seeing the status quo maintained. That said, the tides are turning.

We need to turn our focus to harvesting from existing wood sources; we must draw materials from buildings that need to be dismantled or demolished. This is, of course, already happening but on a very small scale, one that is not making a dent in the market. What we need is larger-scale operations that harvest wood from unused buildings en masse. It is at this scale, one where we could supply chipped wood in the hundreds of thousands of tons a year, that we can begin to move from live forest harvesting to reclaimed harvesting.

With sources such as these we can then design building materials to use chipped reclaimed wood. We can shape it into wood stud equivalents, into dimensional lumber replacements, and into other wood-based products that we use every day. The technology will be developed to match these, including more sustainable and environmentally friendly resins to bind these chipped materials together. However, without the source material (large-scale reclaimed chipped wood) there is no drive to expend R & D dollars on these innovations.