4

Brewing Bock Beer—Equipment and Procedures

Most of the techniques employed in brewing Bock beers are the same as those used in brewing other German lager beers. A four-vessel system is employed to perform a two- or three-decoction mash, which is lautered; the wort obtained is then boiled. The boiling may go on for a longer than normal period to increase wort concentration. Cooling is performed quickly and then a pure strain of lager yeast, as previously discussed, is pitched in relatively high quantities. The primary fermentation is conducted at 41 to 48 degrees F (5 to 9 degrees C) for one to two weeks (more likely the latter). Then a long period of lagering at 32 to 34 degrees F (0 to 1 degrees C) is employed to finish the beer. Lagering may continue for two to six months, depending on the brewer and the beer.

BREWING EQUIPMENT

Standard practice in making Bock beers, as with most of the German lager styles, is the two- or three-decoction mash. The former is employed for Helles Bocks and a few Dunkles and Doppelbocks, while the latter is used exclusively for the darker varieties. A decoction mash continues the melanoidin building process, aids in protein breakdown and coagulation, and maximizes the gelatinization of the starches in the malt.

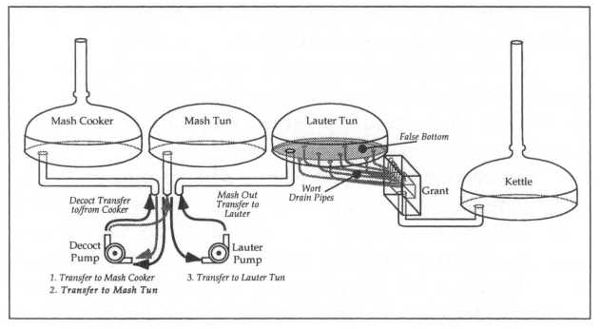

The standard four-vessel brewing system is composed of a mash tun, a mash cooker, a lauter tun, and a kettle. Mashing proceeds by doughing-in into the mash tun, and then pumping a portion of the mash off to the cooker, where it will go through a step program of rises and eventually be boiled. This will then be returned to the mash tun, causing the whole mash to raise to the next rest.

This process is repeated once or twice to effect the brewmaster’s mash step program. Once mashing is complete, the mash is pumped out of the mash tun into the lauter tun. From there, the wort is strained out and its volume increased by sparging. The clear liquid obtained is transferred to the kettle, where it is boiled and hopped.

Variations on this arrangement are common. The four-vessel system can be easily adapted to three- and even two-vessel arrangements. There is no technical reason to have a separate lauter tun from the mash tun. However, this means that the tun is in use while lautering proceeds, preventing a second mash from starting. The limitation on overlapping brew sessions lowers the overall throughput on the equipment.

A two-vessel system would include the changes needed for the three-vessel system, and further combine the function of the mash cooker with the kettle. Again, this reduces the amount of overlap that is possible between two successive batches, because the second mash cannot begin until the boil of the first batch is finished.

Four vessel system

For the home brewer, considerations of staggered brewing schedules are fairly low on the priority list. Curiously, decoction mashing requires less equipment than step infusion mashing, and the same as single infusion mashing. A brewing pot and a lauter tun are the requirements for decoction mashing.

MASHING

The goals of the mashing program for a Bock beer are to produce a high extract wort with a lot of malt character. Low molecular weight proteins and longer chain sugars are emphasized. Little in the way of unconverted starch or polyphenolic material (tannins) should make its way out of the mash.

Traditional mashing programs can be comprised of two decoctions or three; the decoctions can be quick or intensive; and they can include two, three, four, or even five different rest temperatures. Such a wide variety of parameters allows fine control of the finished product, but also makes for a confusing array of choices.

The choice of the number of decoctions and the duration of the boil provides control over the amount of darkening that occurs, protein coagulation, and malt sugar composition.

The decoction process begins when a portion of the mash, the decoct (or thick mash—the portion with the most solids), is brought into the mash cooker. It goes through a step mashing program, just as a step infusion mash would, with the exception that after the last saccharification step, the thick mash is then raised to boiling and held there for an extended period.

The decoct’s step program uses whatever enzymes are carried over into the cooker to convert the heavy proteins and starches that are brought along in the malt solids. The final boiling explodes any balled starch that may not have been affected by the chemical action. It also removes longer chained proteins in two ways; by degrading the protein structure through the mechanical action of the boil and the heat breakdown, and by complexing with polyphenols (the same action that is seen again in the kettle boil, when hop polyphenols can combine with malt proteins). This material will then have another opportunity for breakdown into FAN and sugars in the second and, if conducted, third decoction.

Once the decoction has boiled, it is pumped back into the mash tun, where it is mixed with the remaining thin rest mash. The addition of the heat energy brought by the boiling decoct raises the whole mash to the next temperature rest. The mash is allowed to rest for a few minutes before the next thick mash is removed again to the mash cooker. The thin mash remaining behind continues to rest until the next decoction is complete.

A typical grist bill for a dark Bock beer might be 86.3 percent Munich malt, 10 percent helles malt, 2.5 percent caramel malt, and 1.2 percent black malt.38 This combination would produce a wort color of 9 °Lovibond (20 °EBC). A pale Bock could have half helles malt, half Munich malt, and perhaps a small amount of pale caramel malt. The black malt would be omitted altogether.

The ratio of mash water to malt should be approximately 1.4 quarts per pound (3 L/kg).39 Although this may seem to be a looser mash than in conventional mashing, the extended mash period and lengthy decoction boils will remove a significant amount of mash liquor as steam. The extra liquid also helps to differentiate the thickest portion of the mash from the thinner, tending to retain more of the mash enzymes in the solution. The mash liquor can therefore act as a reservoir from which enzymes can be drawn as needed, preserving them from boiling.

Doughing-in is accomplished in a chamber that connects the incoming crushed malt line with a mashing vessel. This chamber has a water line also, and, depending on whether the dough-in water is cold or already heated, the vessel is either the mash cooker or the mash tun, respectively.

The arrangement of the chamber and the water injection creates a great deal of turbulence. This effectively mixes the grist and limits the amount of starch that balls up. Especially for decoction mashing, it is important to get all of the malt flour into solution. This liberates the various proteolytic and diastatic enzymes, ensuring that most of them will be maintained safely in the thin mash where they can do their jobs, rather than going into the mash cooker with the thick mash where they will be degraded.

Once dough-in is accomplished, if the dough-in water was cold, the entire mash is heated in the mash cooker to about 100 degrees F (37 degrees C). Otherwise, the temperature of the mash water is chosen to produce a mash at this temperature. The temperature necessary is dependent on the water to malt ratio, but generally a temperature of about 110 degrees F (43 degrees C) will work.

The first thick mash is separated from the rest mash. This thick mash should have a liquor to malt ratio of 1 quart per pound (2.2 L/kg). For the craft-brewer, this can only be estimated. Pulling the decoct from the bottom of the tun, after allowing the total mash to rest for five minutes, will select the right mix.

If the dough-in occurred in the mash cooker, the rest mash is pumped to the mash tun. Otherwise, the thick mash is pumped to the mash cooker.

The common wisdom, that a thick mash of a third of the total mash volume will be sufficient to raise the entire mash to the next rest, rarely proves to be true. There are many variables that come into play, including the insulating qualities of the mash tun, the surface area-to-volume ratio of the mash as it sits in the tun, and exactly how “thick” the thick mash is (e.g., where the thick mash is extracted from, how long the mash rests before the thick mash is extracted, and so forth).

Experience with the equipment is the best teacher. Unfortunately, it is not likely that a pilot brew will be helpful, as a pilot brewery will not have the same thermal properties as the full scale brewhouse. The best hedge is to estimate high on the thick mash volume and adjust downwards as experience is gained. A good starting point might be about 40 percent of the total mash volume. It should go without saying that scrupulous records need to be kept in the early stages of working out the decoction mash schedule with any particular equipment system.

During each of the decoctions, the mash must be stirred continuously as it is heated to prevent sticking, scorching, and burning. These flavors can easily be detected in the final product, and they are not a pleasant addition. Care must be taken that the mash cooker is appropriately sized and heated. If too little mash is placed in a very hot cooker, it will easily burn. On the other hand, the stirring must be done carefully so as not to splash, which could encourage significant hot side aeration.40 This can result in the oxidation of both melanoidins and, particularly at the high end of the saccharification range around 154 to 162 degrees F (68 to 72 degrees C), polyphenols.39

If working by hand, this can be accomplished by holding the mash paddle at a point slightly above the surface of the decoct with the weaker hand and using the stronger hand to turn the top of the mash paddle in an elliptical pattern. This breaks the surface the least, introducing the smallest amount of air. Heavy rubber gloves are advised since some splashing may still occur, especially when the worker grows tired.

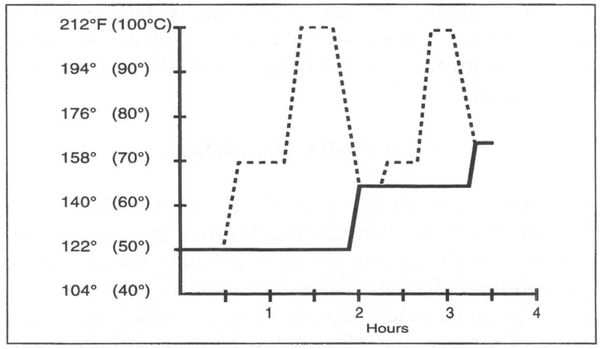

The diagram that follows shows a mash program used at the Bavarian State Brewery at Weihenstephan. It is typical of a full blown, three-decoction mash. That the mash process takes a full six and a half hours is not an error.

Each decoct goes through a full step mash program in order to ensure that the malt is as fully utilized as possible. In this case, the three-decoction mash program has mash cooker rests at 127 degrees, 149 degrees, and 162 degrees F (53 degrees, 65 degrees, and 72 degrees C) before going on to boiling.

Mash program at Bavarian State Brewery at Weihen—Stephan: Typical three-decoction mash program.

Recent work48 shows that the protein rest is only effective in extended (30 minutes or longer), concentrated mashes, such as those that occur in the rest mash and especially in the decoct. The protein rest is responsible for generally reducing the overall length of all protein molecules in the mash. In so doing, it tends to eliminate the longest proteins, which could otherwise cause foam instability (by reducing the surface tension in the beer) and haze (by complexing with polyphenols). It also liberates a large quantity of FAN by breaking it free from the longer chained protein molecules, which is critical to yeast growth.

The saccharification rests in the decoct are interesting; they occur at the extreme low and high ends of the range, 149 to 160 degrees F (65 to 72 degrees C). The goal in doing this, as opposed to employing a single rest in the middle of the range, is to emphasize the production of dextrins. A single rest in the middle of the saccharification range would cause both α-and β-amylaze enzymes to be active at close to their maximal levels, allowing the β-amylaze to further degrade linear branches of starch and dextrin chopped free by the α-amylaze. A separate low rest allows the β-amylaze enzymes to do only as much work as is possible with the available linear chains of sugars; the following high temperature rest then allows the α-amylaze enzymes to degrade the branched starch molecules into dextrins.

High dextrin content helps to create the rich character expected in the beer style. In particular, lower molecular weight dextrins (less than 12 glucose molecules long) increase head retention and help to provide a finer carbonation. Dark beers are generally distinguished from pale beers by the lower content of maltose and the higher content of dextrins.38 Dark beers are more likely to go through an extended triple decoction mash like this.

The decoct should show a negative reaction to iodine at the completion of the last step, 160 degrees F (72 degrees C), before proceeding on to boiling. This final step inactivates all of the enzymes present in the decoct. Full use should be made of them before they are lost.

The second decoction should likewise be a thick mash, and should proceed through the remaining temperature steps before going to a boil. The third decoction can be either another thick mash,38 or a thinner mash (sometimes called a lauter mash) of 40 percent of the total mash volume.39 In the latter case, the intention is to assure more fully the destruction of any remaining diastatic enzymes, in order to preserve the sugar and dextrin makeup of the wort.

Meanwhile the rest mash temperature plateaus should be reached at 100 degrees, 127 degrees, 149 degrees, and 167 degrees F (37 degrees, 53 degrees, 65 degrees, and 75 degrees C). The first rest is achieved at dough-in with warm water. The others are attained with the reintroduction of each successive decoct. The sum of the times spent by the decoct at each mash cooker rest determine the total time the rest mash spends at each of its temperature rests.

The second rest at 127 degrees F (53 degrees C) is used to degrade proteins and to enhance foam stability and β-glucans. High quality malt is a necessary ingredient, as it will have the lowest levels of β-glucans to start with. These compounds increase wort viscosity and can dramatically increase lautering times and sparging volumes. Longer and more intensive mashing breaks down more of the β-glucans and can reduce viscosity by as much as a third.40 High-quality pale malt will have retained some β-glucanase, an enzyme that degrades β-glucans, even after malting. This enzyme is active below 140 degrees F (60 degrees C), but will be destroyed at higher temperatures.

The emphasis on dextrin production continues in the rest mash process. Looking at the temperatures shows that once again there is no rest in the middle of the saccharification range. Instead, a rest at the low end of the range, 149 degrees F (65 degrees C) is followed by a final rest at the high end of the range, 167 degrees F (75 degrees C). This last rest is for mash off. A negative iodine reaction should have been achieved in the rest mash before the final decoct is returned to the mash tun.

A two-decoction mash is becoming more common for dark Bocks as a means of conserving energy and reducing the amount of time required in the brewhouse. However, it is still the exception and not the rule; more often the two-decoction mash is only employed in producing Helles Bocks.

Typical two-decoction mash program.

The reason for this is that the balance of flavors produced in a two-decoction mash is different from the longer and more intensive three-decoction mash. With less concentration of the mash, darkening due to melanoidin formation and caramelization is reduced. Other flavors in the beer arising from the remaining ingredients can, as a result, come to the fore.

A typical two-decoction mash program is diagrammed above. Here the acidification rest is dropped and with it, a very long decoction cycle is eliminated, cutting the mashing time to three and one-half hours.

The temperature rests are slightly different as well: the rest mash goes through a low saccharification rest at 149 degrees F (65 degrees C), and a mash off at 167 degrees F (75 degrees C). The decocts, instead, have a single rest at 158 degrees F (70 degrees C), which is at the high end of the saccharification rest. This combination is intended to produce a high dextrin content in the resulting wort, in spite of the compromise in the process. Even so, the difference between a pale and a dark Bock beer wort is that the dark wort will have a lower concentration of maltose and a higher level of dextrins and melanoidins.

INFUSION MASHING

Infusion mashing, especially for Bock beers, is nearly unheard of in Bavaria. The brewers interviewed for this book claimed that infusion mashing did not allow enough malt character to be extracted from the malt, did not provide as much extract, produced more starch and higher proteins, and yielded less color. It also does not allow for the sharp temperature changes that provide finer control over the balance of sugars produced during the mash.

These complaints are all true, but North American brewmasters, with an investment in an infusion system, can still make beers in the classic style. Other parameters will just have to be adjusted to make up for the problems.

The recipes in the next chapter are based on numbers that the author obtains on his equipment. Brewers must look at their own equipment, though, and adjust material quantities based on their circumstances. Extract levels should be calculated based on each brewer’s own experience.

Melanoidins are at the heart of most of the aromas and the color that is needed for beers of this style. (Lack of DMS character may only be a problem with two-row ale malts.)49 From the melanoidin discussion in the previous chapter, it can be realized that an infusion mash never gets hot enough for long enough to really drive the Maillard process. It cannot cause significant amounts of reducing sugars to combine with amino acids and proceed through the sequence of reactions that produce melanoidins. The two or three decoctions, which can call for boiling the thick, concentrated mash for as much as an hour, can cause significant darkening, indicating melanoidin formation is proceeding.

By working with increased quantities of caramel malts, and also including a long boil, more melanoidins can be included or formed. In the author’s experience, a wort created from a grain bill of 60 to 80 percent Munich malt and up to 10 percent of 20 to 40 °Lovibond (50 to 100 °EBC) caramel malt will produce a first wort that is pumpkin orange. (Do not attempt to make up for the lack of color by using substantial quantities of black malt. Remember that the Germans call these color malts because they are used for their coloring properties only. The heavy presence of roasted, coffee or ashy flavors that these malts can impart is not appropriate for the traditional style beer.) Combining a thorough (but not too thorough—see the section on lautering, just ahead) sparging to collect perhaps an extra third to half of the final volume, and then subjecting that to a very long boil of two and a half or three hours, will reduce the volume and increase the color into the 20 to 30 °Lovibond (50 to 65 °EBC) range of deep browns.

The remaining complaints regarding infusion mashing, that more starch and higher proteins are extracted than from a decoction mash, result directly from the less intensive processing. These problems can be cured by a long, very cold, lagering period. This will allow some polyphenols to gradually combine with higher weight proteins and drop out of solution. Starches will also tend to fall out of solution over time. A brewer might consider finings if a brilliantly clear beer could not be achieved. (The author has not needed them in the past to produce clear beers.)

So, some of the resistance to infusion mashing may be hide-bound tradition, some of it may be the cost of materials, and a part may be prejudice reflecting a “not-invented-here” point of view. Energy costs and process time are a place where infusion mashing certainly comes out ahead; the savings are obtained by eliminating the long heating times needed for each decoction step.

However, there is still room for the consideration that decoction does produce a more flavorful and aromatic product. It is a distinctly different technique, producing a different result in the end, not just a more involved way of achieving particular rest temperatures.

LAUTERING

At the end of the mashing process, the entire mash is brought into the lauter tun and allowed to settle for perhaps ten minutes. At this point, a substantial amount of the original volume will have been reduced. (An example shows an original mash liquor volume of 61 hL reduced to 40 hL when the mash reached the lauter tun following a six and one-half hour triple decoction.)38

The wort contained in the mash will be of a higher specific gravity than the intended original gravity for the beer. This is necessary because the wort will be diluted during sparging. In the example cited above, the gravity is almost 28 percent over the original gravity of the beer itself.

Recirculation is begun and continues until the wort runs clear. There are competing reasons for shorter and longer recirculation periods. A long recirculation, which minimizes the carry over of malt solids and precipitated proteins into the boiling kettle, also tends to strip out wort lipids freed during the mash. These lipids are important to yeast cell wall creation, and even though the continental two-row malts tend to be significantly higher in lipids than North American or British malts, the stripping action can still be overdone.

The sight tubes at the Kulmbacher Reichelbräu brewery. Wort from the lauter tun flows through these tubes, and allows the brewmaster to decide when acceptable clarity has been achieved. Photo by Darryl Richman.

Shorter recirculation periods will tend to carry over more solids. This is believed to be an advantage by some, who feel that the solids provide nucleation sites for the agglomeration of proteins during the boil, thus producing clearer worts at the end of the boil. On the other hand, the haze that may be brought into the boil along with the solids carries higher weight proteins. These can cause chill haze in the final product. In a richer beer such as a Bock, with its relatively low hopping rate, these may not completely agglomerate into floes in the boil or settle out during a cold lagering period. Then, a filtering would be needed. Unfortunately, a fine filtering can strip body, flavor, and color out of the beer.

In the end, traditional practice prevails in Germany, reportedly a ninety minute recirculation period followed by an eighty minute lautering process.38 A sample brewing log from the Bavarian State Brewery at Weihenstephan also indicates an hour and a half recirculation period followed by seventy minutes of sparging.20 Other breweries may go through shorter recirculations, though all witnessed by the author continue the recirculation of the wort back into the lauter tun until a visual inspection of it shows that it is running clear. Only at that point is the wort then allowed to run into the boil kettle.

A brewmaster might typically make the determination of “clear” wort by the presence of very slight or no haze visible in a two inch (5 cm), or even larger, diameter cylinder. For the purpose of inspection, a piece of glass or plastic tube will be placed in a strategic location in the piping that leads from the lauter tun, with a bright light set behind it. In some cases, the brewer may direct the wort onto the kettle with some fine solids still present. From long experience, though, he knows that this will run completely clear and free of solids within a few minutes of the beginning of the transfer.

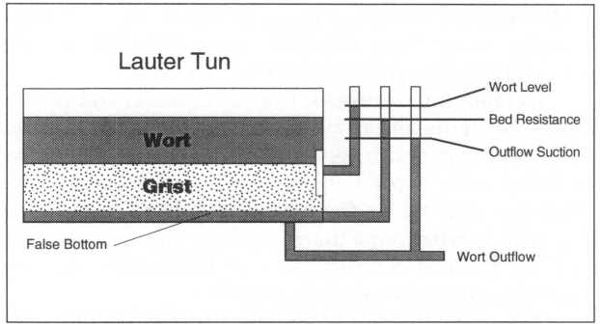

Since a decoction mash more completely liquefies and degrades the mash components, producing a wort with a higher sugar concentration after the extended process, it is much easier to slow its outflow, or have the mash “stick,” in the lauter tun. Especially for a Bock beer, with its high gravity, slow runoffs can be a problem. It is therefore important to consider the mechanics of the lauter tun in its design.

The grant is where the outflow from the lauter tun goes. Each faucet takes the outflow from under a different part of the grain bed. Photo by Klaus Koch.

The false bottom of the lauter tun stands off from the bottom of the tun by only 0.3 to 0.6 inches (8 to 15 mm). This minimizes the volume of underletting needed, as well as minimizing the hydrostatic head that, through the suction created, tends to compact the mash bed. The false bottom itself has an open area of no more than 25 percent, and often as little as 6 percent. This slows down the lautering speed, but holds back more of the mash solids, increasing the efficiency of the process. Holes or slits in the false bottom no bigger than 0.031 inches (0.8 mm) in width are recommended to hold back almost all of the smallest particles. These are in greater evidence here, as compared to an infusion mash, due to the vigorous decoction process.39

The outflow of the lauter tun is directed to a grant, or sink. The drain from the grant can be directed back into the lauter tun for recirculation of cloudy wort, or on to the boiling kettle. The usual design of a lauter tun has many separate outflow pipes from different areas under the false bottom. Each pipe will lead to a separate faucet at the grant. The end of each faucet is set very near to the level of the false bottom, minimizing the head and reducing the suction. The arrangement of the grant provides a great deal of flexibility in setting the mash bed. If a particular faucet is running cloudy wort, there is a tear in the bed that can be reset by slowing the lauter speed in that region. A faucet that is delivering a lower gravity wort than other faucets has a significant channel in the bed above its inflow pipe. These problems should be detected and corrected, so as not to produce an inferior product.

Particularly for Bock beers, efficient lautering is critical. If not conducted properly, either the total extract will be very low or else too much volume will be obtained, and an extremely long boil will be required to reduce it. The extract efficiency is inversely proportional to the rate of outflow of wort from the lauter tun. The slower the lautering, the more efficient the process, as long as the mash temperature can be maintained. Patience is a virtue when overseeing the lautering process.

Outflow is measured by the flow per unit of surface area of the mash tun.39 This makes sense, as this determines a maximum rate of travel for the heavy wort through the mash. This also implies that shallower lauter tuns will operate faster than deep ones, since the wort has to pass through less of the mash to reach the outflow. This concept only applies if the false bottom is equally open across the entire bottom, and there are no pressure buildups in the drainage.

Measuring Pressure and Compaction. After Narziß.18

The classical lauter program, for a decoction mash, begins recirculation at an outflow rate of 0.18 gallons per f2 minute (6.6 L per m2 minute), and rises in four steps over the course of a three hour lautering to 0.33 gallons per f2 minute (12 L per m2 minute). (The square feet (f2) and square meter (m2) measurements are to represent a cross sectional area of flow.) For the home brewer with a lauter tun of 16 inches in diameter, that implies a total surface area of 1.4 square feet; a one foot diameter bucket lauter tun has a total surface area of 0.79 square feet. Once the total surface area is determined, it can be multiplied by the square foot flow rate to obtain a total flow. For the 16-inch lauter tun, that would be a flow rate from 0.25 gallons per minute to 0.46 gallons per minute at the end of the sparge.

Since the outflow rate is determined strictly from the surface area, faster lautering can be obtained with a wide, shallow tun. A tall, narrow tun shape implies a smaller surface area, and a slower overall flow rate. In the traditional German brewhouse, the lauter tun is filled to a depth of no more than 23 inches (55 cm) of malt solids, and no fewer than 10 inches (25 cm).39

As lautering continues, the bed of husks and particulates will settle and compress under the pressure of the overlying wort and husks, and from the suction of the draining wort. A comparison of different columns, one taken from the side of the tun, another from underneath the false bottom, and the third from the outflow, can indicate the bed compression and hydrostatic pressure created in the bed from these sources.

This can indicate when the bed has become too compacted to allow efficient flow. Compaction of the bed is remedied by running the mash rakes through the bed. These can be lowered to different depths and cycled around the tun. Cutting the bed is done as often as four times during the course of a long lautering. After cutting the mash, outflow from the tun is recycled back into the tun until it runs clear again.

Sparging is performed as a series of three distinct water additions on top of the mash. These are coordinated with the action of the mash cutting. After the mash is cut, the wort is recycled until the bed is settled. Then the next sparging session begins.

The water for each session may be added on top of the bed all at once. This limits the amount of heat lost in the bed by providing an insulating layer above it. This is important because of the long duration of the lautering process.

The sparge water is added at 167 to 172 degrees F (75 to 78 degrees C). This temperature is chosen because it keeps the wort flowing, but tends to limit the extraction of tannins as the pH of the remaining mash rises. Tannin extraction increases greatly with higher temperatures and a pH over six. The pH rises as more extract is removed. This is because the extract has acidity, and the incoming water will be neutral or alkaline, especially if it has a significant amount of carbonates in it.

The total sparge water used is generally between 1.5 and 2.35 quarts per pound (3.1 to 4.9 L/kg) of malt. The different spargings use different quantities of water. The first is allocated 25 percent of the total. The second sparging is done with 45 percent, and the third with 30 percent.39 This program is followed in order to balance the need to limit the hydrostatic pressure in the lauter tun, maximizing the columnar flow of extract out of the tun. Both of these allow the lauter to be more efficient, and therefore produce the greatest amount of extract.

If an infusion mash program is followed, it is still wise to lauter slowly, maximizing efficiency. However, because the grist will have maintained more structural integrity throughout the less intensive mash, the bed will not compact as quickly or as completely, and the flow will be quicker. This is evidenced by the usual practice in Britain, where infusion mashing with highly modified malts is the rule. Here, the grain bed is often as deep as three feet. The runoff is much quicker, but the efficiency is generally a few percent lower.

BOILING

Boiling condenses the volume, sterilizes the wort, increases the wort color, drops haze-forming compounds out of solution, and extracts bitterness and aroma factors from the hops. In a Bock beer, the timing of the boil is very important.

Depending on the volume recovered from the lauter, the boiling time may have to be greatly expanded. The total of the mash and sparge water will be significantly larger than the intended batch size—from 50 percent to 100 percent larger. Therefore, the specific gravity of the sweet wort collected into the kettle will be correspondingly lower than intended.

In a normal situation, the boil will encompass one and a half to three hours. The wide variation is related to the equipment in use. The equipment will affect the efficiency of the lauter, and therefore, the volume brought into the kettle. The kettle itself affects the situation because its dimensions and heating potential control the evaporation rate. A wide, shallow kettle will have a large surface area to volume ratio, which will increase the evaporation rate. Similarly, a kettle that can deliver more energy to the wort will cause more of it to be boiled off in a given period. Steam heating systems vary, but all deliver more energy than directly fired kettles. It will be necessary for the brewer to discover the evaporation rate of the equipment in use. Without this information, too much volume may be boiled off, or not enough.

The timing is complicated by the need to put the hops in at the right point before the end of the boil. For homebrewers, it is best to allow the boil to go on a bit longer than needed before adding the hops. It is easier to add more water if needed than to adjust for boiling the hops for too long a period.

Wort sterilization is necessary, as with other beer styles, to ensure a successful product. Without this step, all sorts of invaders might have an effect on the final flavor and aroma.

Melanoidin formation is continued in the boil. The intensity of the process is proportional to the time and the gravity of the wort. The color change apparent in a long, high gravity boil is dramatic. A wort with first runnings that are an amber-orange color can take the entire wort to a deep red-brown.

Although a decoction mash produces a wort with significantly fewer high-weight proteins, it does not eliminate them. During the course of this step, these proteins are hurled into each other from the violence of the boil. They stick together, accreting into floes that fall out of solution. After the addition of the hops, polyphenolic material present in the hops and extracted into the boil can form complexes with any remaining proteins. These may fall out at cooling time, as the cold break. Hops, of course, also add their flavor, aroma, and bitterness characteristics as well.

As described in the beer profile, hop aroma is very limited, to nonexistent, in the dark Bocks. Even in the Maibock style, where the hop character begins to reach some parity with the malt flavors, their presence is usually still restrained.

Hopping rates are not low, however, when viewed in terms of quantity of α-acids added to the boil. The reason for this is that the high gravity of the wort inhibits the isomerization of the acids. This isomerization renders them soluble in the wort. Longer boiling makes up for this to some extent, but the effect is counteracted by the wort’s increasing density as water is evaporated.

Normally, a brewer might expect to convert 15 to 30 percent of whole flower hops and 30 to 40 percent of hop pellets available alpha acids to their isomerized form.40 However, at gravities above 1.048 (12 °Plato) the limit gets progressively lower. Rager’s formula46 suggests that a wort of 1.072 (18 °Plato) will have 11 percent less utilization, or 13.5 to 27 percent and 27 to 36 percent respectively.

Generally sixty to ninety minutes of boiling is recommended to get the most bitterness out of the hops. Beyond this time, flavor changes can occur that can reduce the perceived bitterness and lead to muddied flavors.

This is the timing problem mentioned above. The brewer needs to be able to judge accurately the evaporation rate in order to know when the brew is an hour or so from the end.

A long boiling time strips away much of the flavoring and all of the aromatic properties that the hops can bring to the beer. In order to get some of the hop character into a pale Bock, a second, and possibly a third addition of hops is needed at or near the end of the boil.

COOLING AND PITCHING

Cooling must be rapid and sanitary. Typically, hot break is removed by whirlpooling the hot wort, and cold break is allowed to settle out in a sedimentation tank. In between the two, the wort is cooled and then the yeast is pitched.

Whirlpooling occurs in a cylindrical vessel. The hot wort is pumped into the vessel from a horizontal pipe that connects tangentially to the side, part way up the vessel. This forms a laminar flow with a minimum of turbulence. The bright, bittered wort is then drawn off from a pipe, low on the side of the vessel. Nearly all of the hot break, being less dense than the wort, collects in the center of the vessel.

The wort is then brought to pitching temperature as quickly as possible, usually by a plate-and-frame heat exchanger. The wort flows through the exchanger in one direction and loses its heat to water that passes by in the other, separated from each other by a thin wall of stainless steel. (The warmed water that exits the other end of the exchanger is often used to mash in the next batch of beer.) Pitching temperature varies from about 41 to 50 degrees F (5 to 10 degrees C), with the lower end of this range preferred.

After cooling, the wort is aerated or oxygenated, often by an inline injector. Oxygen saturation in wort occurs at levels of 25 to 35 mg/L, while sterile air saturation results in only about 8 to 9 mg/L of oxygen. These levels are lowered by as much as 15 percent in higher gravity worts, since oxygen is less soluble in them.23

While different yeast strains can require differing levels of molecular oxygen, a lack of sufficient oxygen will cause long lag times and increased ester production, both of which are particularly deleterious to beers in the Bock family.

In spite of the greater food value available for the yeast in this concentrated wort, as compared to a standard lager, the brewer can expect only similar levels of growth. This is because the limiting factor is not the availability of wort sugars or FAN, but because the amount of oxygen that can be dissolved into the cold wort is quickly consumed. It might be possible to inject more oxygen into the wort during the lag phase, but as soon as ethanol begins to be produced, it can be oxidized to form undesirable aldehydes.

Once the cooled wort reaches the sedimentation tank, the yeast is pitched. The quantity of yeast used is high, even in terms of lager brewing, because greater quantities of yeast will be needed to ferment the very rich wort. Because the high gravity wort is far from an optimal growth environment for yeast, brewers generally do not reuse the yeast crop from a Bock beer.

Pitching rates for a standard beer (1.048 original gravity / 12 °Plato) are between 1 and 5 million cells per milliliter of wort. It is expected they will multiply to reach a six to eight times increase in cell count during the growth phase that occurs over the first day or two of the primary fermentation. The pitching rate for Bock beers should be higher to ensure a good start. Fifteen million cells/mL is a good point; levels over 20 million cells/mL are reported to cause excessive sulfury and yeasty flavors to remain in the finished beer.

Some controversy exists regarding whether it is better to filter out the trub completely before pitching, or to let some trub be carried over into the fermenting beer. Trub can form a nutrient source for invading bacteria. Studies have shown, however, that yeast can use sterols contained in the trub to enhance cell wall building during respiration. The Bavarian technique is to allow the yeast to respire on the trub and then separate it before the anaerobic fermentation begins.

The separation from the trub occurs during the twelve to twenty-four hour lag period (respiration phase). Since the yeast is already pitched into the cooled wort,50 it is critical to do whatever sedimentation can be done before the violent primary fermentation begins. All of the trub will be stirred up after that point.

As a result of the strong protein removal processes that have occurred in a double or triple decoction mash, as much as 16 percent less cold break will be present in the wort, than in a comparable wort produced from an infusion mash.

The beer and active yeast are removed from the sediment tank by the use of a floating outlet.39 This device allows beer to be drained from just below the surface inside the tank. Once the beer stops running bright, the end has been reached. The remaining beer is discarded along with the cold break.

PRIMARY FERMENTATION

The primary fermentation continues from the first pitching until the one-third gravity point is reached. This is the point at which the yeast have reduced the beer’s gravity to one-third of the wort’s original value. For example, if a Doppelbock beer had an original gravity of 1.072 (18 °Plato), the one-third point would be at about 1.024 (6 °Plato). At this point, the high kraeusen has been reached and the yeast is slowing down and building reserves as it enters the stationary phase. The fermentation always takes at least a week, (more likely ten to twelve days), to reach this point.

Typically, the wort cooling phase will bring the temperature to 41 to 45 degrees F (5 to 7 degrees C). As soon as the yeast begins to show signs of fermentation, the temperature of the ferment will rise. The brewer will try to control this rise, slowing it down and keeping it at a low maximum value.

The temperature of the primary fermentation will be held within the 41 to 50 degrees F (5 to 10 degrees C) range, going and staying as low as the brewer believes the yeast will tolerate. The temperature control is a matter of compromise between getting the beer fermented before the yeast flocculates and preventing or limiting unwanted high temperature fermentation by-products like diacetyl and esters.

One program in use is to cool to 41 degrees F (5 degrees C), hold it at that temperature for three days, allow the beer to rise to 48 degrees F (9 degrees C) over the course of the next eight days (a 0.5 degrees C rise every day), and then prevent any further rise in temperature. Signs of fermentation are visible on the second day, and the kraeusen head covers the beer on the third, building up from there. High kraeusen is reached by the fifth day. By the time the twelfth day is reached, the head is falling and the evolution of CO2 has slowed down.

At the end of the primary fermentation, the kraeusen head begins to fall and the beer begins to become bright. Most of the yeast will have fallen to the bottom of the fermenter. There will only be about twice the level present at the original pitching still in suspension.

This is exactly the point at which the yeast will begin to uptake the diacetyl and 2,3 pentanedione that it excreted early in the fermentation. Thus, it is very important that a significant amount of viable and active yeast be retained, or else the beer will end up with a distracting buttery aroma and flavor. Some yeast strains may require help at this point22 (Weihenstephan 308/Wyeast Munich 2308 is often indicated as such a yeast). This can be accomplished by raising the temperature to ale temperatures, for example, 62 degrees F (17 degrees C) for a day or more, heightening the yeast activity.

LAGERING

The beer is finished by a long, cold lagering period at or just slightly above freezing temperatures. This period allows the flavors to marry, provides another opportunity for protein-polyphenol complexes (chill haze) to form and sediment out, and for the beer to reach the peak of condition.

Most breweries use pressurized vessels and hold the pressure to assure the correct carbonation level. Generally, no other carbonation techniques are employed. This is for two reasons. A German brewery, when brewing other beer styles, usually obtains carbonation in beer through the addition of kraeusen, or fermenting young beer. For this reason, no facilities are available to collect CO2 from the primary fermentation, filter it, and inject it back into the finished beer. (Injection of commercially produced CO2 is not allowed if the brewery is to claim adherence to the Reinheitsgebot. The reasoning is that this is not an explicitly mentioned ingredient, even if the same compound gets into the beer naturally in other situations. CO2 captured from the primary can be added back because it was naturally formed during the process of brewing.)

On the other hand, kraeusening is not employed for Bock beers since the fermenting yeast may be stunned by the alcoholic strength and/or high osmotic pressures of the beer to which they are added, as discussed in the section on yeast in the previous chapter. These pressures can cause the yeast to mutate or shut down completely. This can result in new off-flavor problems such as high acetaldehyde or diacetyl levels, as well as provide an opportunity for spoilage bacteria or wild yeast to get a foothold.

The lagering period goes on for a minimum of two months, but can continue for half a year in the case of some specialty Bock beers. During this time, flavor maturation occurs. The lager yeast slows down as the twin forces of high ethanol content and dwindling simple sugars cause it to metabolize other compounds like diacetyl, 2,3 pentanedione, and acetaldehyde. Other redox reactions mediated by the yeast23 deliver a finished beer that is highly stable.

The yeast will eventually go dormant and fall to the bottom of the vessel, and will have a tendency to drag any remaining haze factors with it. These factors are composed of starches, high weight proteins, and husk and hop polyphenols.

The long lagering period allows the CO2 created by slowing fermentation to stay dissolved in the beer. The lagering tanks are held at a pressure and temperature that enforce the final carbonation levels of the beer. Overpressure is relieved, and any sulfides that might be generated in this last slow fermentative stage are therefore allowed to be purged. What results is a well conditioned, brilliantly clear beer, ready for packaging.

PACKAGING

At the end of the lagering step, the beer may go through a light polish filtering (at or above 3 p). This is more likely the case for beer destined to be bottled; kegged beer might not be further handled. The filtering assures that all remaining yeast is removed from the beer. However, filtering is not a replacement for the long lagering period; heavy filtering (under 1 p) to eliminate haze will remove a percentage of the melanoidins, dextrins and proteins that add mouth feel and create the perception of a rich, luxurious product.

Every precaution must be taken at this point to prevent any oxygen from getting into the beer. The filtering process requires extreme care to avoid reintroducing oxygen. As described in the section on melanoidins in the last chapter, these compounds will stabilize the beer and assure a long shelf life only if they make it into the final product in an unoxidized (reduced) state. If they do become oxidized, they can transfer this oxidation on to alcohols, forming aldehydes that will color and age the beer.

It is important for craft brewers who want to bottle to understand the limitations of this form of packaging. A long lagering reduces the quantity and viability of the yeast in suspension, which will cause very slow carbonation. Therefore, the beer should be primed and bottled after a shortened lagering period of no more than two months. The beer, once bottled, should be allowed to warm to primary fermentation temperatures for one or two weeks until carbonation is complete. It should then go through a subsequent lagering to clear and finish before serving.

Priming can be accomplished with unfermented wort or corn sugar (if the brewer is not concerned about the Reinheigsgebot). To obtain 2.1 to 2.3 volumes of CO2 (0.41 to 0.45 g CO2 / 100 g beer), wort should be added so that there are an additional 0.0038 to 0.0042 specific gravity points per gallon to five gallons of beer, 5 x 0.0038 → 0.019, or one gallon at 1.019 (4.75° Plato). This is a very diluted wort, and the extra volume it brings will unneccessarily dilute the beer. Adding one-half gallon of wort of specific gravity 1.038 (9.5° Plato)—twice the strength—will have the same effect.

Instead of saved wort, dry malt extract could be used. For five gallons (19 L) of beer, 0.43 to 0.47 pounds (195 to 214 g) dry malt added to enough water, boiled, cooled, and racked off of the trub will produce the needed extract. To use corn sugar (glucose), use 0.32 to 0.35 pounds (145 to 159 g) for each five gallons (19 L).