Flieger-Kopfhauben were produced in both summer and winter weights, either with or without integral Funk-Telegraphie/Telephonie or FT-Gerät (radio-telegraphy/telephony equipment). Throat microphones were fixed to a leather neck strap attached to the nape of the helmet, with press-stud fastening at the front. The internal communications loom emerged just above this in a 1.3 metre long cable with a black plastic quick-release jack plug. Oxygen mask fittings comprised flat metal hooks at the sides, and an adjustable wire stirrup mounted inside a tunnel at the crown. A pair of press stud-fastened leather straps to the rear sides secured the headband of the goggles. The helmets incorporated an awkwardly over-complex system of twin chinstraps, one having to be passed through a slit in the other.

This Flak Gefreiter, pictured in 1940, sports the rolled shoulder straps which were very occasionally seen during the French campaign. Simply formed by turning the strap back on itself and securing with a few stitches, this modification prevented rifle and equipment straps from slipping off the shoulder. Clearly inspired by the French practice, it was also occasionally seen on the overcoat. Note on his forearm the gunners’ specialist qualification insignia adopted on 23 July 1937, denoting a minimum of nine months’ service.

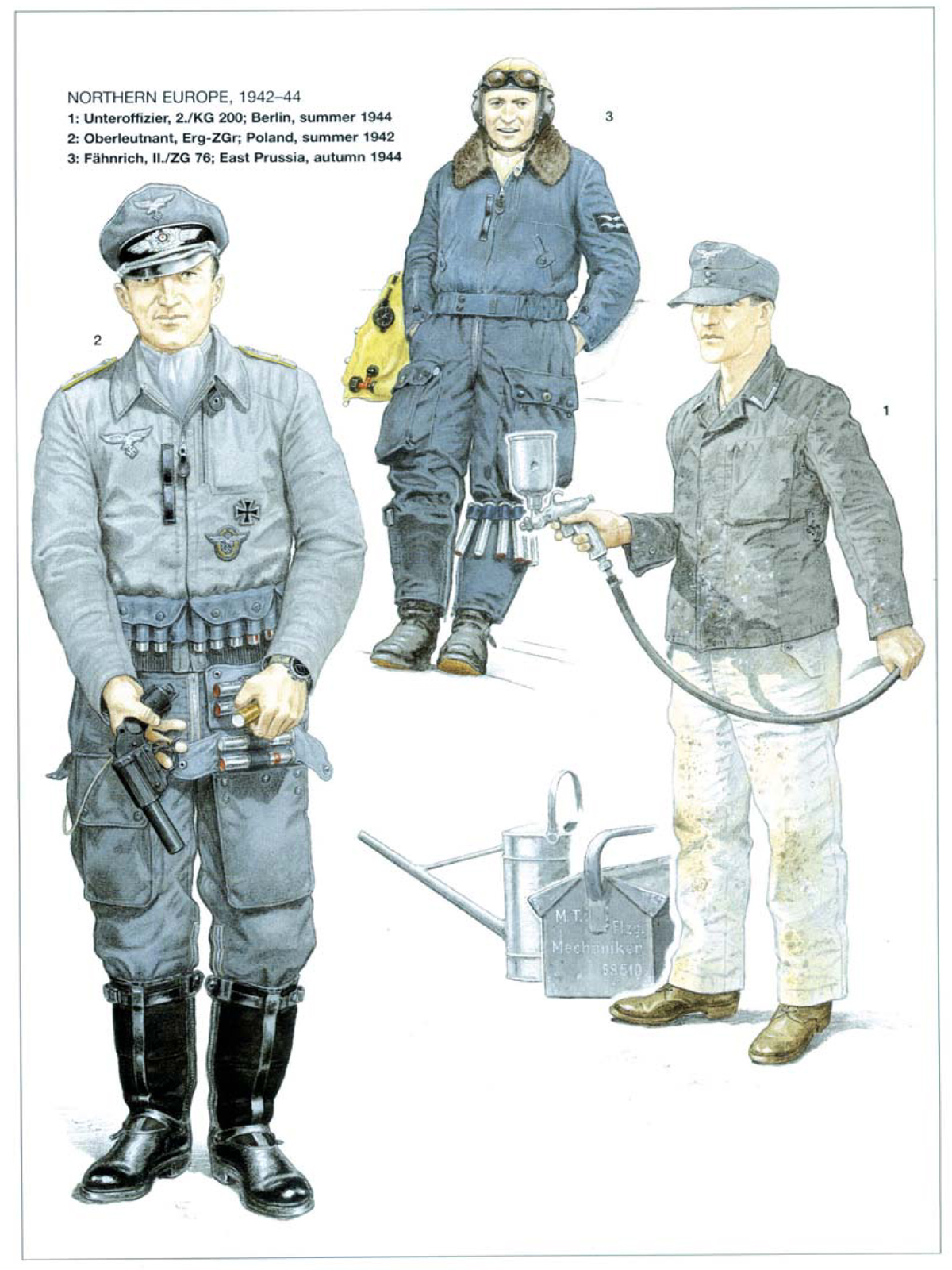

Principal summer-weight helmets were the Flieger-Kopfhaube für Sommer mit FT-Gerät – Baumuster S 100 (flight helmet for summer with RT equipment, Model S 100), and the LKp S 101; both made of Braunmeliert (mixed brown) thread Schilfleinen (reed linen), lined with tan or grey ‘Kettatlas’ sateen. Winter-weight versions, of dark brown leather with lambswool lining, were designated LKp W 100 and LKp W 101. The 100-series were identifiable by domed black-lacquered aluminium earphone covers (see Plates A3 & B2). The 101-series, adopted c.1938, featured improved communications equipment and leather-covered plastic earphone covers, incorporating a small ridge which held the goggle headband in place (see Plates B3 & C1).

A lightweight version, the Flieger-Netzkopfhaube or LKp N 101, with fine-mesh crown for improved ventilation in summer or the tropics, was approved on 16 June 1941 for use by fighter and destroyer pilots, but soon found favour among other aircrews. The earphones were set within large rigid leather side panels, connected by leather bands across forehead and nape. Oxygen mask fixing hooks were augmented or replaced by hexagonal-based aluminium posts fitted to the leading edges of these side panels, creating two distinct models. The first could take all two- or three-strap mask types, while the other (without adjustable crown stirrup) could only accept two-strap masks.

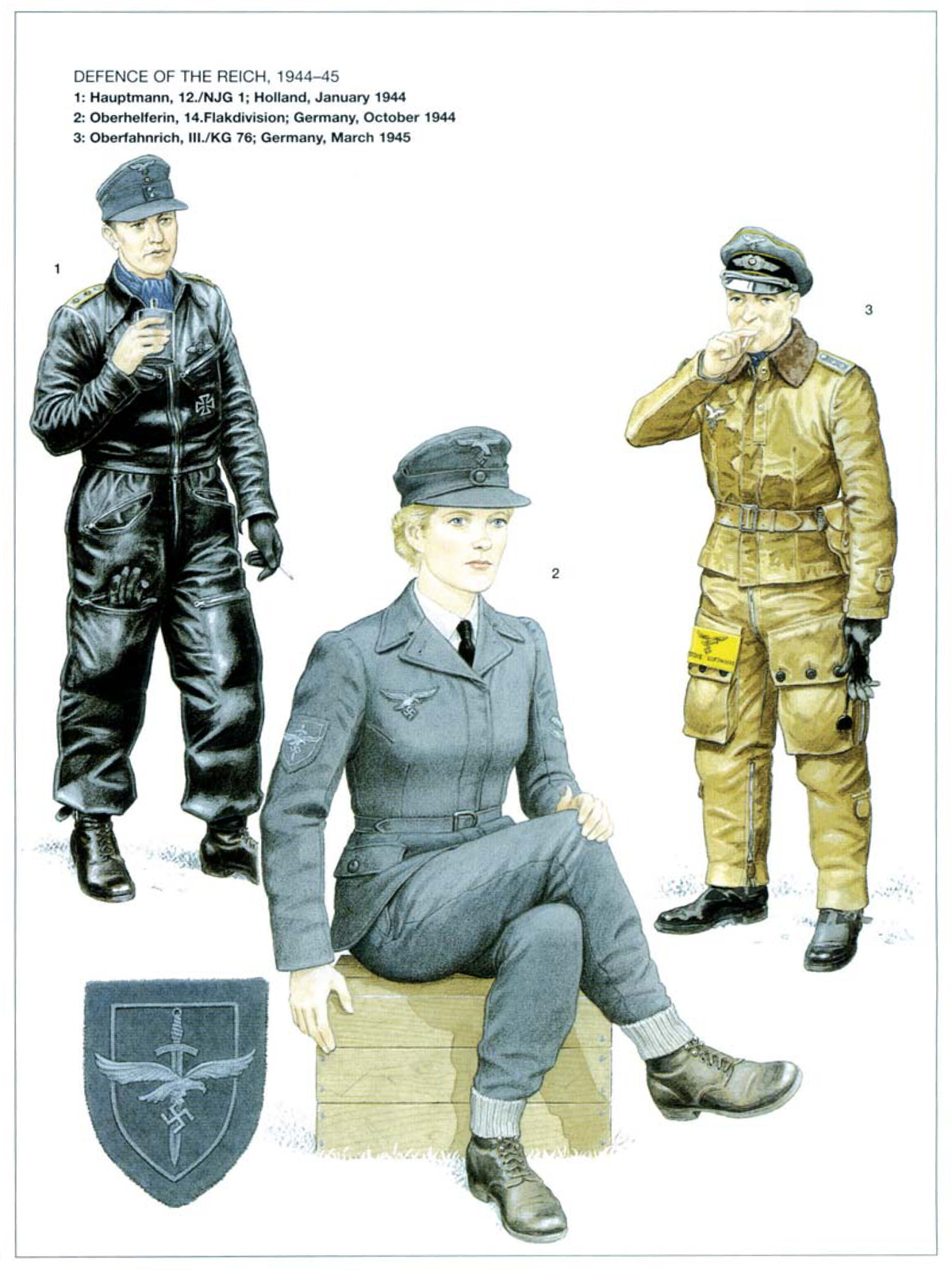

An Oberfähnrich (NCO serving as a probationary officer) displays a fine example of the Schirmmütze unique to this rank: officers’ aluminium wire chin cords are fitted to an enlisted ranks’ cap with Waffenfarbe piping to band and crown. His use of woven cap insignia was officially only permitted when off-duty. Silver Litze has been added to the collar patches and collar edge, and a pressstud between the lower two buttons prevents unsightly gape in the absence of a belt, further enhancing the appearance of his privately tailored Rock. The national badge is set extremely low on he pocket flap.

The communications cable had always been something of an encumbrance and was frequently shortened by base technicians, sometimes drastically so, with the balance transposed to the aircraft interior fittings (see Plates E3 & F3).

This Obergefreiter wears a grade-6 Schiessauszeichnung (marksmanship lanyard), SA-Wehrabzeichen, and belt buckle correctly aligned with the edge of the tunic. The more sartorially inclined airmen found many ways to enhance this already smart uniform for Ausgehanzug (walking-out dress). The Fliegerbluse could be retailored and even shortened, sometimes drastically so, rendering the pockets almost useless. Its somewhat fractured lining created many geometric patterns to the front panels and, when a replacement could be obtained, great care was taken to select the garment with the palest, most visible stitching. Tuchhose would be soaked in warm water, with wooden boards forced into each leg, and then left to dry. The desired silhouette was a close-fitting jacket and baggy trousers. (Martin J.Brayley)

Most of the world’s air force flying suits were simple developments of conventional overalls, with little consideration given to their potential as an aid to survival; their wearers continued to rely upon the chance of recovering survival packs stowed in the aircraft itself. Although the Fliegerschutzanzug (flight protective suit) was officially designated simply as a Kombination (overall), successive models incorporated innovative features that later became standard in flight clothing design the world over.

Fliegerschutzanzüge were available in summer and winter weights, further sub-designated for flight over land or sea, the latter constructed of materials affording greater insulation. Most aircrews followed this system of matching suit to environment, although availability or personal preferences often dictated what was worn.

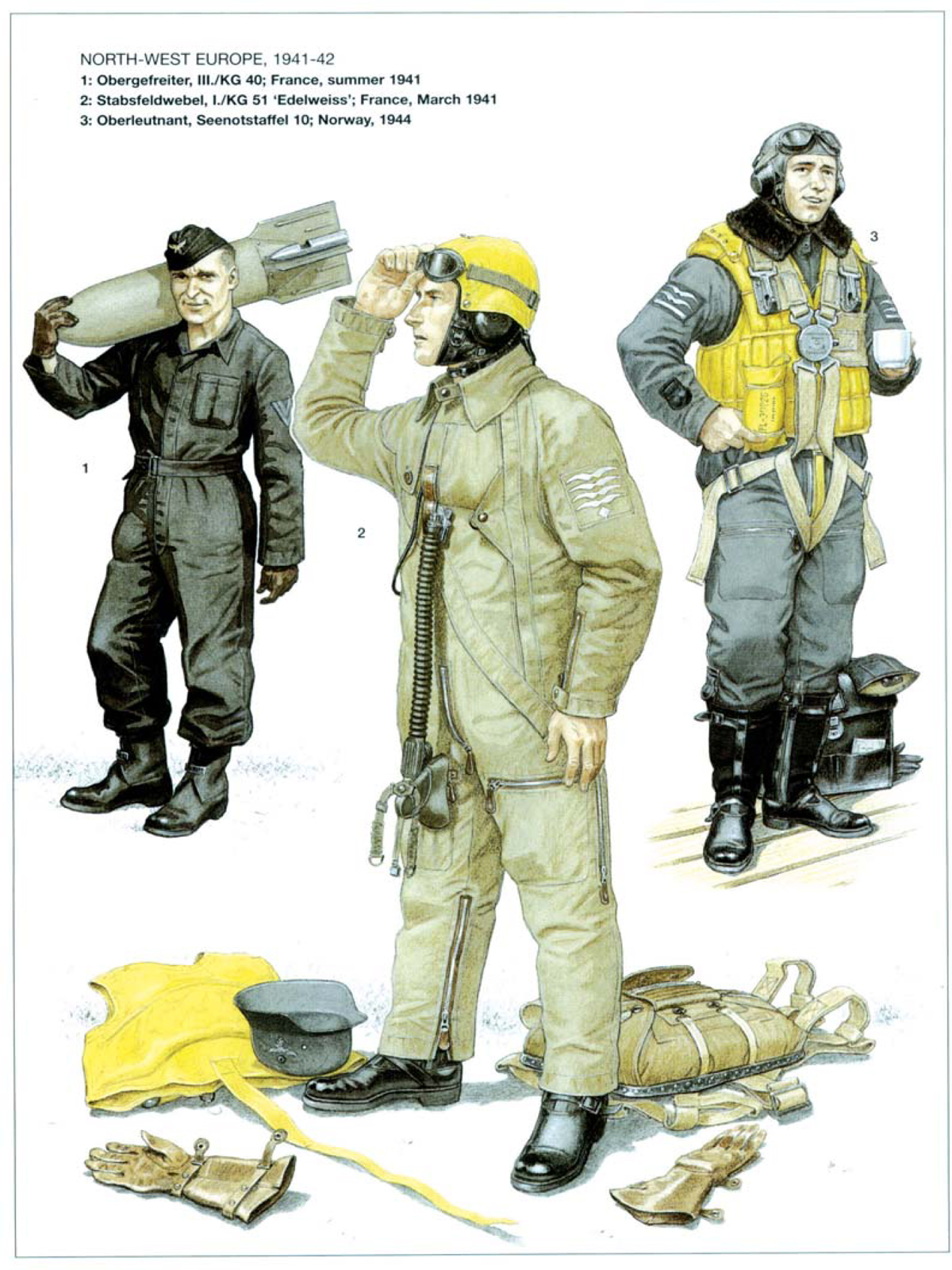

Summer: Developed from the K So/33 of the DLV, the Kombination, Sommer, 1934 (K So/34) was made of the same lightweight, durable Braunmeliert cloth as the LKp S helmets. The most notable feature was a long, concealed zip-fastener running diagonally from left hip to right shoulder, where it was covered by a buttoned wind-flap. A zipped patch pocket for maps, etc. was set high on the left breast. A vertically mounted 13.5cm × 3cm brown leather strap, stitched to lower mid chest and forming two separate loops, provided anchorage for the oxygen mask hose clamp. The sleeves were of three-piece ‘raglan’ style, incorporating elasticated inner cuff bands with zip closures to the cuff proper. Zip-fastened openings were provided at each hip for access to trouser pockets beneath, and horizontally zipped internal pockets to each knee accommodated survival equipment. Inner calf seams also closed with zips, and the crotch was fitted with a horizontal fly (for easier opening when seated). The K So/34 underwent a series of minor changes, creating seven principal variations.

On 17 December 1935 the addition of a short press-stud strap to each sleeve cuff was ordered, to prevent the zip fastener creeping open.

The adoption of an inflatable Schwimmweste (life jacket) in 1937 triggered the most significant development. It was intended that the suit be worn over the vest to protect it from snagging in the aircraft and chafing by parachute harness; it was therefore necessary to provide quick access to the vest’s inflation canister. The most immediate solution was the insertion of a short zip at the midriff, just below and parallel to the main zip (see Plate A2). When the vest required oral topping-up, however, the collar and main zip would have to be unfastened in order to reach its inflation tube.

The Berlin company of Karl Heisler developed a quick-opening ‘Reissverschluss’ (rip-fastener) device, comprising a series of 35 leather loops passed through 36 steel eyelets and secured by a cord.1 Tied to the centre of the cord, and concealed beneath a triangular safety flap with press-stud fastening, was a large steel Griffring (‘grasp ring’); a continuous pull on this drew the cord from its tunnel and opened the fastener.

Ground crew on a Heinkel He45C unit wear grey-blue Fliegermützen and the two-piece Drillichanzug in black. The Taillenhaken (belt support hooks) fitted to the blouse could be secured through a slit at each side of the trouser waistband, just visible on the two men at left. Note the full length collar Tresse of the senior NCO at second right.

This design gave complete and rapid access to both the vest’s inflation canister and the mouth tube. The large opening also provided for the expansion of the vest and alleviated chest restriction. Its presence dictated the omission of the chest pocket (see Plate A3). Heisler exclusively supplied the device to contracted flight suit manufacturers, hence the appearance of Karl Heisler labels (stitched directly to the fastener) inside suits made by Cunsel & Schroedter of Berlin, Bekleidungsfabrik Habett of Württemberg, and Striegel & Wagner (‘Striwa’) of Bavaria. To speed production, Friedrich Emmerich of Berlin and Tschache & Co of Dresden later made the device under licence. The rip-fasteners were delivered with cord ends knotted to prevent accidental deployment, and many appear to have remained that way throughout their service life.

From 20 May 1937 manufacturers were instructed to fit zipped pockets into the outer thigh seams for two wound dressing packets (at left), and the Flieger-Kappmesser 37 (aircrew knife) secured within a small inner pocket; a width increase from 47mm to 50mm to this inner pocket was ordered on 10 November (see Plate A3). Finally, on 7 June 1940, a slightly reduced left breast pocket was reinstated, now internally mounted with zipless external access. The fly zip was simultaneously lengthened and set vertically. As if in recognition of aircrews’ persistence in wearing the suit under rather than over the life vest, oxygen hose chest loop-straps were reduced to 2cm wide and positioned slightly higher – encroaching on the pocket – to avoid obstruction by the vest (see Plate B2).

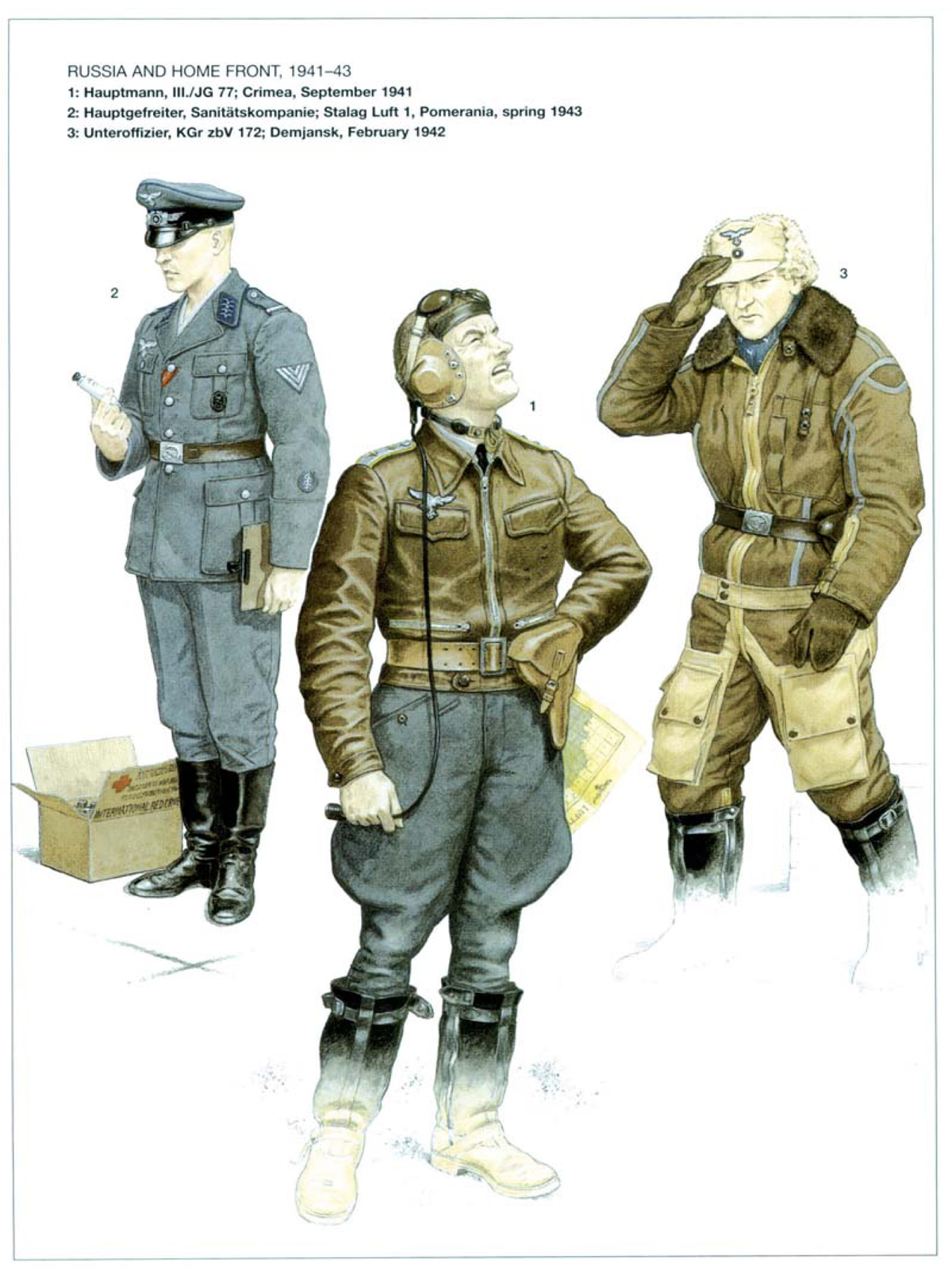

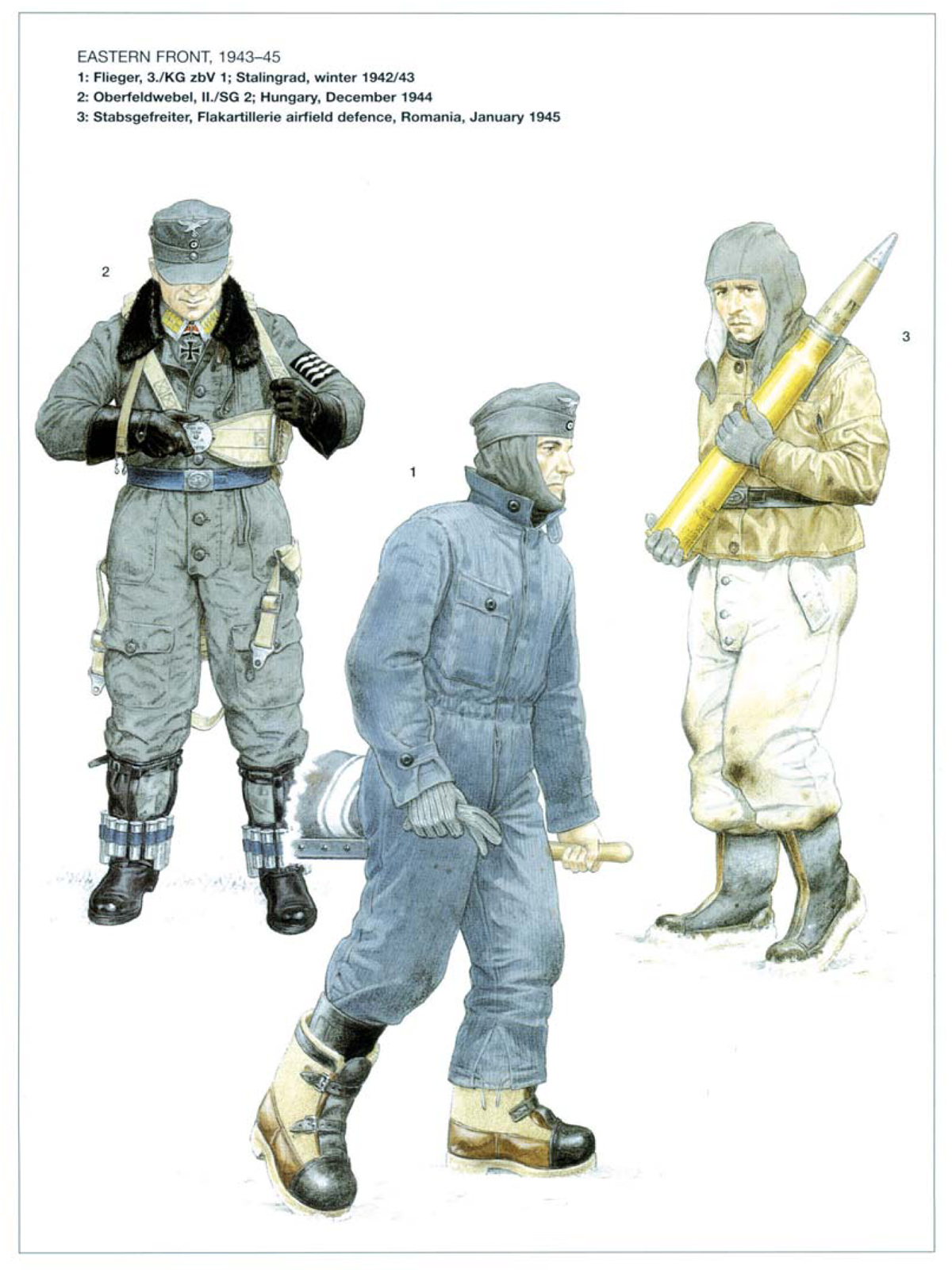

Winter, Land: The Kombination, Winter, Land, 1933 (KW 1/33) – nicknamed the ‘Bayerisch’ (Bavarian) – was of fine quality grey-blue or brown ‘Velveton’ moleskin cloth, lined throughout with sheepskin. A conventional vertical front closure was retained, in keeping with its contemporary K So/33 and KW s/33, but fastened with eight large ceramic buttons rather than a zip. Large patch pockets with deeply scalloped flaps and ceramic buttons were provided at the hips and just above the knees. These suits generally lacked the chest loop-straps of other models, the oxygen hose being clipped to the front placket instead. Despite its designation, possible use for flights over water prompted the addition of a vertical Schwimmweste access zip to the right of the button closure, or the Heisler-Reissverschluss. Outer thigh knife and dressing pockets also appeared concurrently with those of the summer model (see Plate G2).

Cockpit of a Heinkel He111, pictured c.1941. The ‘Spaten’ (‘spade’ – from the shape of the tail fin) had been able to outrun fighters over Spain, but was already nearing obsolescence by 1940; nevertheless, shortages of more modern types kept it in production until late 1944. The observer (left), here wearing a KW Fl bR/40 suit, LKp W 100 helmet (and, unusually, a small beard), served as navigator, bombardier, air-gunner and, occasionally, co-pilot. Many aircrew received informal instruction from their pilots, which might give them a chance of taking over the controls in an emergency. The pilot favours the K So/34 suit and LKp W 101 helmet, with twin throat microphones clearly visible. A narrow flip-up windshield in the cockpit roof, and a telescopic seat, afforded him a slightly better view – albeit an uncomfortable one – when taxying at night or in bad weather. (Martin J.Brayley)

Kanalkampf 1940 : Beobachter Feldwebel in the nose of a Heinkel of I./KG 4 ‘General Wever’, based at Soesterberg, Holland. He wears the K So/34 suit with special sleeve rank insignia, and LKp S 100 helmet. Just visible are the Schnellklinkhaken (quick-latch hooks) to the front of the Brustfallschirm harness, to which the parachute pack was rapidly attached when required. The large fully-glazed nose of the He111, with its off-centre MG15 mount, gave little protection from shell fragments; it also had a tendency to distort the pilot’s view and reflect sunlight back into the cockpit. (Hans Obert)

This layout remained unaltered until 7 June 1940, when all future production was ordered standardised with other types. The button front was replaced by a diagonal main zip, a vertical fly was added, and an internal pocket with external access was fitted to the left breast – existing stocks could be modified with an external patch pocket.

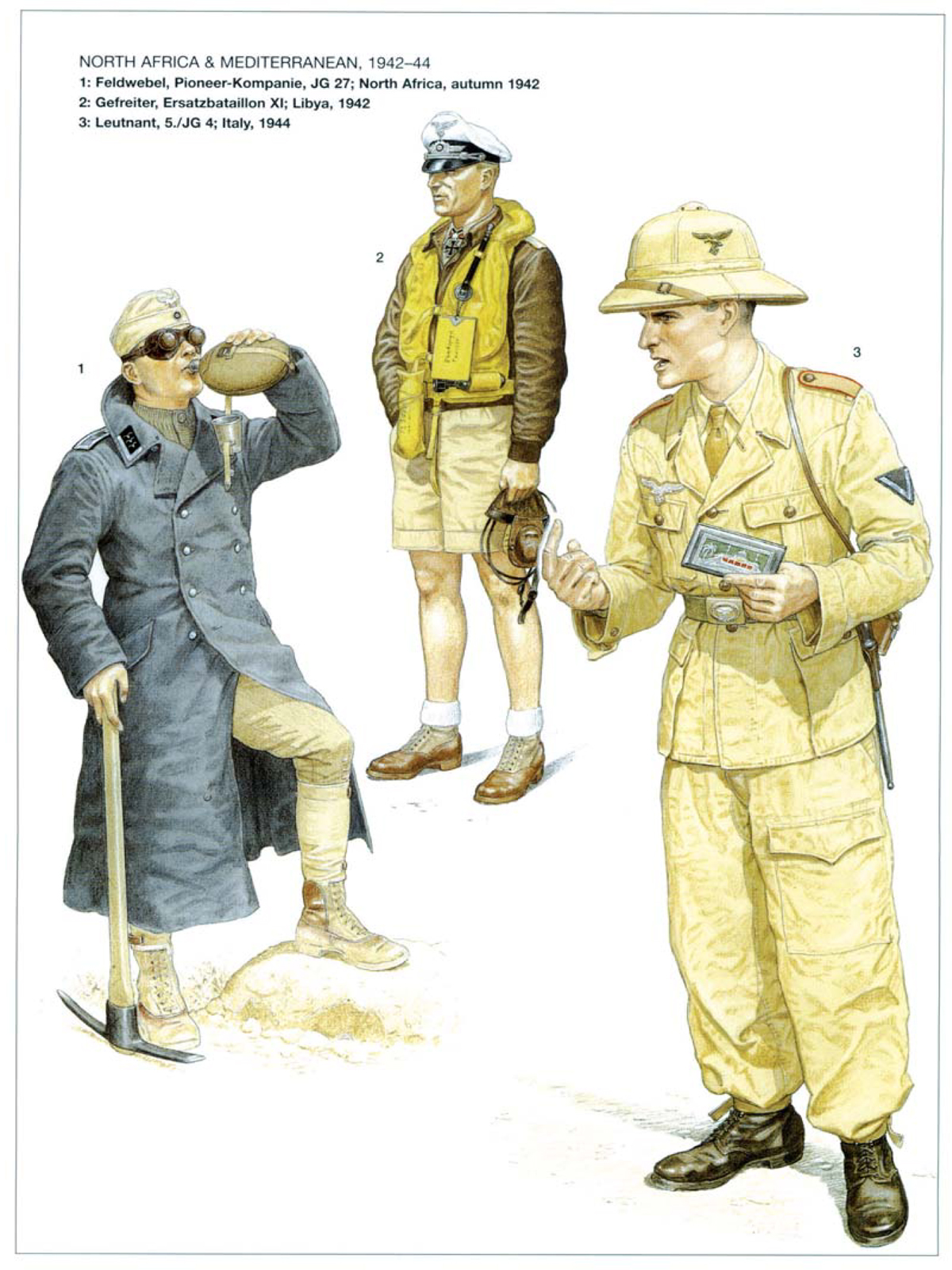

Winter, Sea: Evolved from the leather KW s/33, the KW s/34 was made of dark brown ‘Kalbin’ (calfskin), with diagonal main zip, heavy fleece lining, and large black or brown mouton collar. Principal details and modifications followed those of the K So/34 although, during 1940, the bulky hide was rejected in favour of supple ‘Nacktpelz’ (lit. ‘naked pelt’, or sheepskin); the suede outer surface was left undyed. The KW s/34 was fitted with midriff zip or Heisler-Reissverschluss from 1937, sometimes concurrently. Although the zip could be resealed, thereby preserving some warmth and comfort when immersed, it was difficult to operate with cold, wet or gloved hands.

The KW s/34 was costly and slow to produce, and a pre-war Austrian type, distinguished by two full-length zips running from collar to ankle cuff, was frequently issued instead.

Electrically heated: When necessary, winter suits could be worn over the dark grey cotton Kombination mit electrischer Beheizung (K 20/24) – an electrically heated undersuit adopted from 25 June 1936. This was worn in conjunction with Flieger-Füsslinge mit electrischer Beheizung (F 20/24) heated socks, and Flieger-Handschuhe mit electrischer Beheizung (Ha 14/24) heated gloves, worn over fine Unter ziehwoll-handschuhe (lit. ‘under heated wool gloves’). The power cable of the heated clothing left the suit at the small of the back, and could be passed through a hip pocket vent of the outer suit for connection to the aircraft’s circuit. This suit fell from use by 1939.

For single-seaters: The winter suits, awkward enough in the confines of a bomber, were quite unsuitable for the tiny cockpit of the Bf109, although many saw such use. On 16 February 1940 a new Kombination, Winter, für Flugzeuge mit beschränkten Raumverhältnissen, 1940 (KW Fl bR/40 ?) was approved for use in ‘aircraft with limited space’. These comparatively lightweight suits, of tightly woven grey-blue ‘Schappe’ synthetic silk twill, were lined throughout with 4mm Schappe velveteen of deep blue or purple, which also faced the large fall collar. Although not heated, the suit bore an electrical circuit with external connectors at wrist and calf, to convey power from the aircraft’s rheostat supply to heated gloves and boots (see Plate B3). Of standard diagonal-zipped style with Heisler-Reissverschluss, this suit was also subject to the modifications of 7 June 1940.

Major Heinz Cramer, Kommandeur II.(K)LG 1, and his crew celebrate his qualification for the Knight’s Cross, 18 September 1940; all wear either first or second type K So/34 suits. Today bomber and Stuka crews are seldom accorded the same esteem as the famous fighter pilots; but of some 1,320 Ritterkreuze awarded to aircrew, 538 went to fighter and destroyer pilots, while 640 were earned by bomber, dive-bomber and ground attack crews. In 1941 the criteria for the award included a minimum of 200 combat sorties – by which time a sizeable number of aircrew had already flown more than 300 missions.

The medium bomber crew comprised the Flugzeugführer (pilot), Beobachter (observer), Bordfunker (radio operator), Bordmechanik (flight engineer) and Bordschutz (gunner) – most of them in fact doubling as gunners when all guns were manned simultaneously. Most of the crew were stationed together in the nose sections of their comparatively small He111s, Do17s and Ju88s; consequently, well-placed enemy fire could rapidly inflict devastating casualties.

Production of one-piece suits was officially halted on 24 April 1941, although some existing contracts were not completed until 1942. Each type was henceforth to be produced as a Flieger-schutzanzug, Kombination (zweiteilig) 1941, and these two-piece suits began to see service by the middle of that year.

Summer 1940: two versions of the Fliegerschutzanzug K So/34 are worn here by officers of KG 54 ‘Totenkopf’, a Ju88 wing based at Coulommiers, France. At right is a suit made before May 1937, lacking zipped thigh pockets for knife and wound dressings. At left is the type with a horizontal fly zip and Heisler-Reissverschluss. Until supply of this rip-fastener finally met demand during 1939, most clothiers (such as Mohr & Speyer) continued to produce suits with a midriff zip for access to the life vest canister. The habit of wearing the vest over the suit makes it impossible to distinguish the two versions in most period photographs. (Manfred Griehl, via Lionel Leventhal, Greenhill Books)

The jacket was a relatively simple affair with single left breast pocket, and a double loop-strap of leather or matching cloth to one side of the vertical main zip. The real advance lay in the design of the trousers, with their voluminous pockets for rescue and survival equipment. The selection of items carried was to individual choice, but routinely included emergency rations and medical kit. Frequently worn with jackets other than that intended, the trousers offered not only versatility and greater ease of movement, but had obvious practical advantages during latrine visits. . . The use of insignia on the two-piece suits was limited; breast eagles and sleeve rank badges or epaulettes were often fitted to the cloth versions, while sheepskin types were usually left unadorned.

The KW I/33 ‘Bayerisch’ winter suit in its original form. The double-button cuffs and the knee pockets are clearly visible on this light brown example, as are the collar fastening straps. The buttoned front incorporated a double flap for effective insulation. His other equipment consists of the LKp S 100 helmet, and partially fastened Sitzfallschirm 30-1 seat parachute with snap-hook fittings rather than the later Schloss-Autoflug buckle. (Martin J.Brayley)

Summer: The jacket of the K So/41 had a small fall collar with press-stud tab, and plain split cuffs with two-button adjustment. The bulk of production was in grey-blue (sometimes grey-green) cloth with wool-knit waistband, but an alternative version was produced in the same tan Braunmeliert cloth as its parent K So/34. This type had a matching cloth waistband, adjustable at each side by internally mounted alloy friction buckles and cloth straps, and closed with two ‘Prym’ press-studs. Stocks of the tan cloth were exhausted during 1943. The trouser waistband was adjustable by friction buckles at each hip front, and fitted with buttons or web loop attachments for cloth braces. An internal flannel apron was often fitted to prevent heavy equipment from chafing the wearers’ thighs (see Plates D2 & F2).

Winter, Land: The KW l/41, equivalent of the ‘Bayerisch’ KW l/33, was primarily manufactured in soft blue cloth (occasionally olive-green), with sheepskin lining and large fleece collar. The canvas waistband had friction buckle adjusters. In addition to an internal chest pocket with external opening, two diagonal slash pockets were set at lower front and usually fastened with press-stud tabs (see Plate F3). Trouser cloth tended to be more tightly woven than that used for the jacket and of a deeper grey-blue colour.

Winter, Sea: Original production of the KW s/41 was of high quality natural sheepskin with dark brown or black inner fleece and collar. The single patch chest pocket and loop-strap were either of matching suede or contrasting leather, and the canvas waistband fastened with two press-studs. Diagonal slash pockets with press-stud fasteners were later added. The sheepskin trousers were considered too weak to support fully laden survival equipment pockets and so lacked this feature. Canvas reinforcement panels extending from the waistband were incorporated to distribute the load and resolve this weakness, these versions being produced in brown and grey-blue dyed sheepskin with similarly coloured pockets and reinforcements (see Plate C3).

Electrically heated: The KW Fl bR/41 was of the same heavy duty grey-blue canvas as the one-piece KW Fl bR/40, with Schappe lining and connectors for heated boots and gloves; similar contacts were necessarily added to the waistbands of jacket and trousers to complete the circuit (see Plate F3). An all-leather version of this suit was produced in late 1943, of substantial black, brown or grey hide, to provide limited protection from the highly corrosive synthetic fuels then in use (see Plate H3).

Jagdflieger were quick to adopt practical items suited to the close confines of the cockpit, a short leather jacket being the preference. Such garments were not issued but generally purchased at individual expense from various sources, and some sub-units or just small groups of friends would acquire matching jackets. Among the most coveted of the home-produced versions was an expensive black leather suit with distinctive zip-fastened slash pockets (see Plate H1). With the occupation of conquered nations countless alternatives were readily available from civilian outlets wherever the pilot was stationed. Differences in cut, fastenings and pockets soon proliferated, with a particular French style among the most popular. The occasionally encountered cloth versions tended to be blue, grey-blue or cream, with wool-knit waistband, collar and (sometimes) cuffs. When fitted with insignia the flight jackets were extremely handsome in appearance – which naturally appealed to the inherent panache of fighter pilots. Although collar patches were rarely added, a few NCOs applied Metallschwingen directly to the collar.

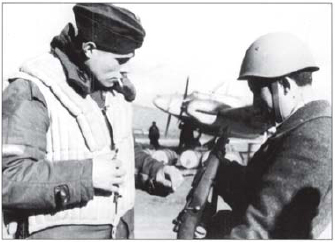

Sicily, early 1941: a Messerschmitt Bf110 crewman of ZG 26 ‘Horst Wessel’ examines the M1891/24 carbine of an Italian airfield guard. The Unteroffizier wears the electrically wired KW FI bR/40 suit with synthetic fur collar; a connector for the heated gloves can be clearly seen on the forearm, and the Doppelschwinge of his rank is on summer-weight braunmeliert cloth backing. The kapok Schwimmweste 10-76A is the original full-backed version with lifting collar.

The Bf110 ‘destroyer’ proved during the Battle of Britain to have no credible future as an unescorted heavy fighter, and was consistently outfought by single-engined types. On fronts where such opposition was rare – Africa and Russia in 1941 – it briefly remained useful as a light reconnaissance bomber; and it was later successfully converted for night interception, with a third crewman to operate the airborne radar. (Private collection)

Additional sources were the British Air Ministry, US Army Quartermaster Department and Soviet Voiyeno-Vozdushnui Syl – many items being ‘souvenired’ from downed Allied aircrews. The USAAF A2 flyers’ jacket was a particular favourite (see Plate E3), and was routinely worn by the legendary Heinz Bär; while Adolf Galland was famously pictured in RAF Irvin sheepskin jacket and trousers. Whatever their origin, all were for operational wear only and were not permitted to be worn off-base, where a more ‘military’ form of attire was demanded.

Four types of brown leather Flieger-Lederhandschuhe were adopted in 1933. Summer types were designated ‘mit’ or ‘ohne’ Stulpe, Ungefüttert (‘with’ or ‘without gauntlet, unlined’), HS 5 m/33 and o/33. Winter equivalents were designated ‘gefüttert’ (lined), FW 5 m/33 and FW 5 o/33. Press-stud or buckle-fastened straps were provided at wrist and cuff for a wind-resistant fit. Electrically heated FW m/40 gloves developed for the wired KW Fl bR/40 and /41 suits were of soft grey-blue or brown suede, with 8w/24v element, fine Schappe lining, and connectors at the gauntlet cuff. Black, brown and grey-blue coloured heated and unheated gloves were produced in conjunction with the all-leather KW/41 suit.

The Flieger-Pelzstiefel (flyer’s fur-lined boots) had a stout leather foot with rubber heel and sole. The black or charcoal-grey sheepskin shafts had full-length steel zips at inner and outer calf, to ease fitting over several layers of clothing; the outer calf zip was discontinued for economy during 1940. Leather tightening straps, buckled around the top of the shafts and across the front of the ankles, were intended to prevent boots being torn off by parachute opening shock. Material quality deteriorated from the mid-war period, with shafts assembled from joined off-cuts rather than single panels, and fugitive dyes resulted in some discoloration; but construction standards remained high. Heizbare Flieger-Pelzstiefel (heated flyers’ boots) for the KW Fl bR/40 and /41 suits differed only in the inclusion of an 11w/24v electric element inside the lining and leather connector tabs at the outer top.

High quality brown leather and suede boots with inner calf zips, commercially available from Paul Hoffmann & Co., Berlin, were particularly popular during the early years (see Plate A2). Black all-leather Flieger-Überziehlpelzstiefel (lit. ‘over heated fur boots’) with fine white lambswool lining, designed for wear over the electrically-heated F 20/24 socks, were officially discontinued in June 1939 but remained in (vigorously polished) service throughout the war.

1 A similar device, with 13 loops secured by a leather cord, was used on Heisler’s padded Flieger-Knieschutzer knee-protectors, also available to airmen.