Courtesy of Dale Mikolash

Female Factory Workers Rivet an Airplane, World War II/Lambert/via Getty Images

The United States was just finding its way out of the Great Depression when World War II hit. As Americans tuned their radios to listen to President Franklin Roosevelt’s address in December 1940, they heard the president appeal to all Americans to rise to the aid of Europe. “The people of Europe who are defending themselves do not ask us to do their fighting,” Roosevelt assured his listeners. “They ask us for the implements of war, the planes, the tanks, the guns, the freighters which will enable them to fight for their liberty and for our security . . . We must be the great arsenal of democracy.”

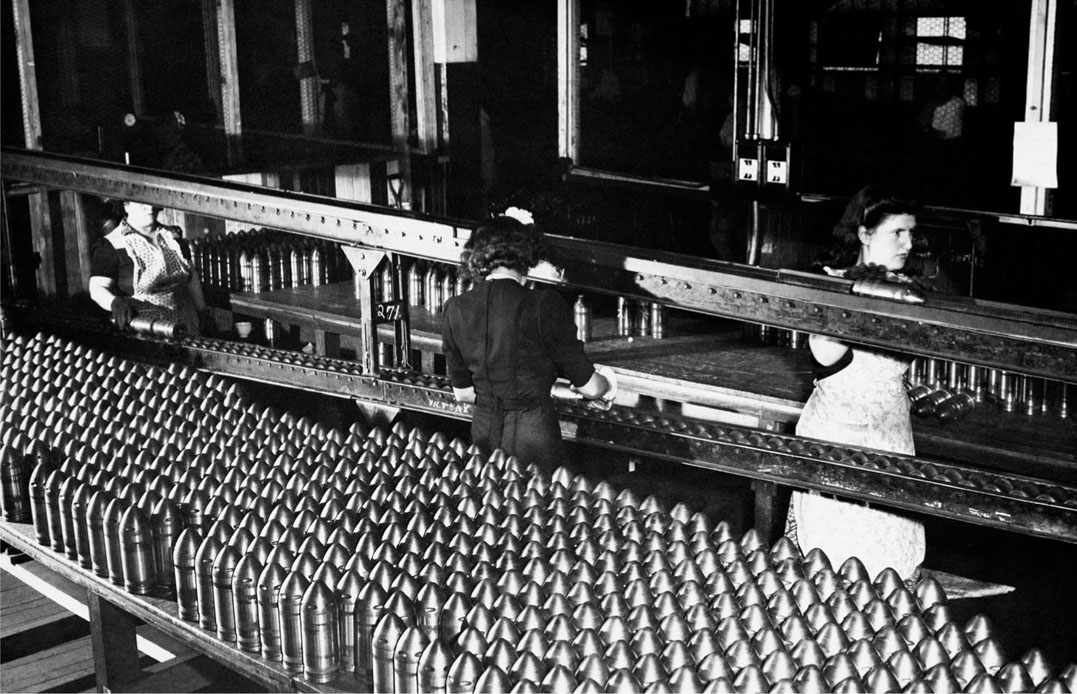

When the United States joined World War II, the majority of fighting-age men joined the Allies in Europe, leaving women to take over their industrial jobs at home in support of the war effort. This phenomenon led to Rosie the Riveter becoming a cultural icon for women during and after the war.

Women examining shells at a factory/SuperStock/via Getty Images

A year later, after the attack on Pearl Harbor, the United States found itself at war, and its production of wartime aircraft doubled. The following year, it doubled again, and by 1945 the country had produced 304,000 aircraft—more than Germany and Japan combined.

It seemed that the weight of the nation’s—indeed all of Allied Europe’s—chances for victory largely rested on the question of whether or not America could produce enough planes, tanks, and armaments to win the war. Across the country, all materials essential for the war—including rubber, steel, and oil—had started to be rationed so that they were available for this purpose. The automobile industry, which had manufactured three million cars in 1941 alone, suddenly ceased all regular operations and retooled its factories to manufacture airplanes, tanks, trucks, torpedoes, bombs, and ammunition under large government-issued contracts. Chrysler made fuselages. General Motors made airplane engines, guns, and trucks. Packard made Rolls-Royce engines for the British air force. The Ford Motor Company converted its factories to perform nothing short of a miracle, producing one B-24 Liberator long-range bomber airplane (which had 1,550,000 individual parts) on average every sixty-three minutes at the height of its production.

The rationing of rubber and steel also affected the toy industry. Before the war, cast-iron and steel toys, such as Radio Flyer wagons, ranked as favorites among most children. But by Christmas 1942, department-store shelves went bare of all roller skates, metal cap pistols, tricycles—and steel wagons.

Like many other American manufacturers outside of the traditional defense and automobile industries, Radio Steel, as well as other toy companies, such as Hubley, Fisher-Price, Manoil, and Marx, retrofitted its factory to make a wide range of smaller-scale wartime products. Auburn Rubber, which had produced rubber figures and vehicles before the war, manufactured boot soles and rubber gaskets. The A. C. Gilbert Company, best known for its all-steel construction Erector Sets (a kind of precursor to the Lego), designed and produced a new kind of nylon parachute for the paratroopers, a series of range indicators for anti-aircraft guns, trigger mechanisms for land mines, and booby traps to be slipped under doors, into desk drawers, or between books. By the end of the war, the toy industry had supplied the troops with gaskets, fuses for explosives, ship fenders, bomb crates, shell casings, pistol grips, parts for hand grenades, first-aid kits, and any number of other small pieces to support the auto companies’ and other wartime manufacturers’ production of tanks, trucks, and airplanes.

Antonio Pasin took the call to action seriously. From 1942 to 1945 all wagon production ceased at Radio Steel, and the factory was used to assist in the war effort. However, Antonio requested he not manufacture any weapons or armaments capable of killing. Instead, the War Production Board, which was established by President Roosevelt for regulating all industrial production of war materials, granted Radio Steel a large contract for producing a piece of military equipment called the blitz can. These were five-gallon steel containers that were mounted on the backs of jeeps, trucks, and tanks, and used to transport either fuel or water to troops stationed overseas. Radio Steel’s blitz cans saw service in Europe, the Pacific, and Africa.

Two stamped-steel blitz cans manufactured for Allied soldiers in World War II.

Photography by Chris Cassidy

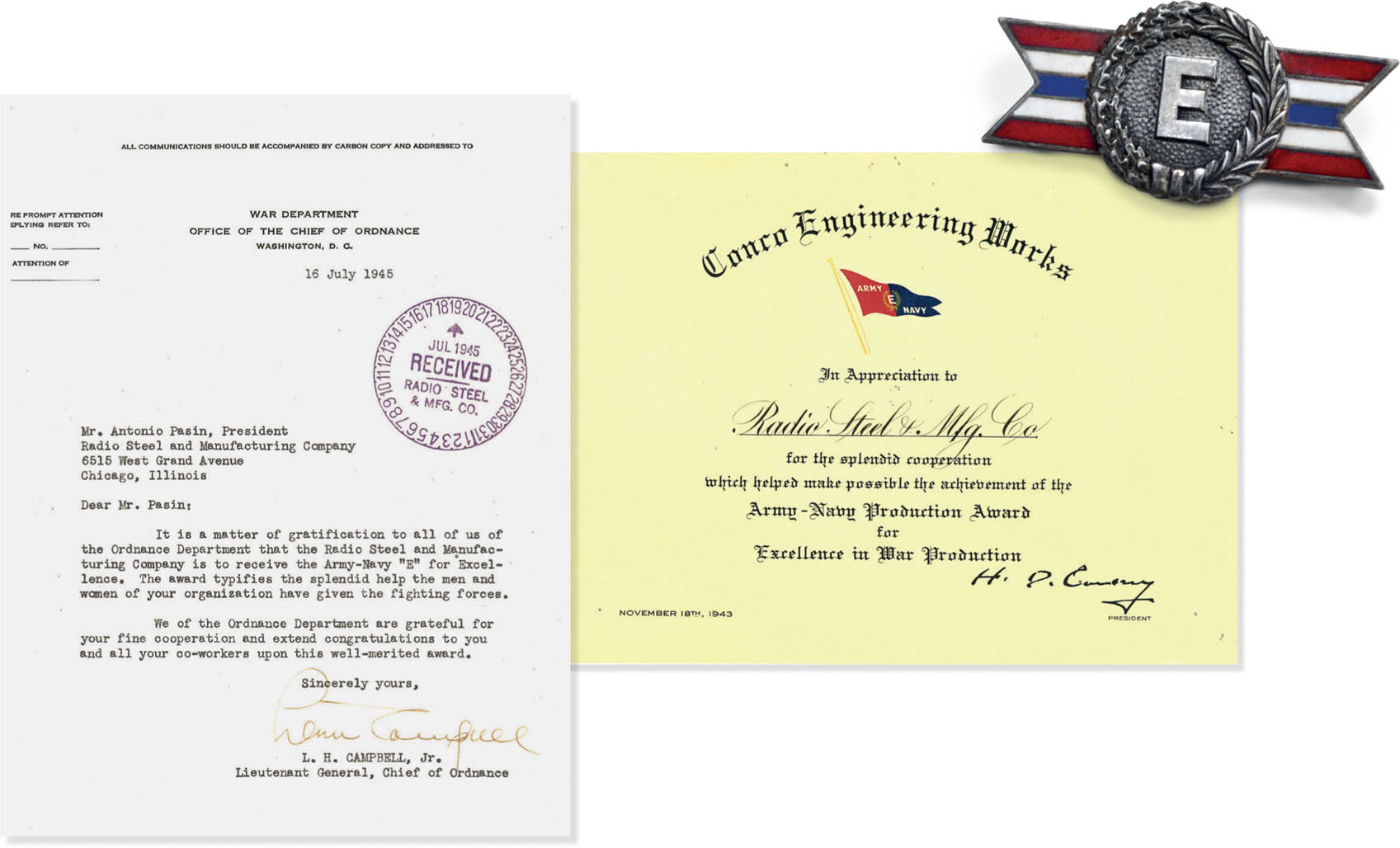

The war in Europe ended with an Allied victory in May 1945. All told, American industry manufactured almost two-thirds of all of the Allied military equipment produced in the war. In four years, America’s industrial production had doubled in size. On July 14, 1945, Radio Steel received an Army-Navy “E” award for excellence in producing essential wartime materials. The war was a pivotal moment for America and an important chapter in Radio Steel’s history. The factory and team had performed extremely well (and without compromising Antonio’s values), so much so that the military further tapped Antonio and his engineers for hands-on help with safely and properly converting other factories over for wartime production.

An Allied soldier carries two blitz cans, likely containing fuel.

Crewmen of C-47 transport planes unload jerricans of gasoline for 3rd US Army tanks at an airfield near Frankfurt/Photo12/UIG/via Getty Images

“Powerful enemies must be outfought and outproduced. It is not enough to turn out just a few more planes, a few more tanks, a few more guns, a few more ships than can be turned out by our enemies—we must outproduce them overwhelmingly.”

—PRESIDENT FRANKLIN D. ROOSEVELT

in his address to Congress a month after Pearl Harbor

A Conco Engineering Works award presented to Radio Steel & Manufacturing Company for “the splendid cooperation which helped make possible the achievement of the Army-Navy Production Award for Excellence in War Production.”

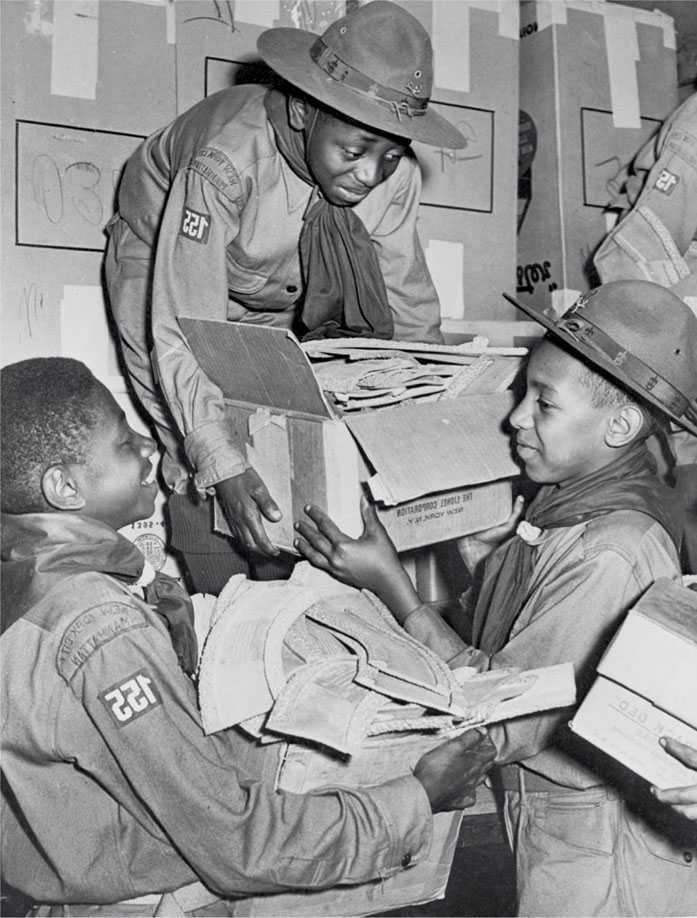

The TOY INDUSTRY PREPARES for BATTLE

Children living during World War II might not have understood all the ramifications of war, but they certainly noticed the change in their toys. Some toys became scarce, while others were made of new materials or had a different appearance.

This meant hard times for many toy manufacturers. Several companies closed their plants, while others did their best to make their former steel and cast-iron figures, trains, and trucks out of other materials. The April 1942 issue of Playthings magazine focused on how to successfully adapt product lines, suggesting that manufacturers consider alternatives such as making games and toys using wood.

Boy Scouts Collecting Toy Train Roadbed/Bettmann/via Getty Images