Lamé

Above Average

Lamé is a woven or knit fabric with metallic yarns in the length and/or width. Today’s lamés include metal, metal-coated plastic, plastic-coated metal or a metal-wrapped core yarn.

Lightweight and drapeable, lamé frays and snags, dulls shears and machine needles, and is easily damaged by needles, pins, and improper pressing.

Workroom Secrets

Layout/Cutting/Marking: Before cutting, check to be sure the foldline is not permanent. Use weights, temporary pattern adhesive, or position pins within the seam allowances. To control fraying, do not cut until you are ready to sew. Handle the sections as little as possible after cutting.

Cut seams 1" (2.5cm) wide, and use a seam sealant on the cut edges applied carefully to avoid spotting the fabric. Do not mark with clips.

Stitching: Start all new projects with a new needle in the smallest recommended size. Change needles frequently; metallic lamé dulls needles faster than natural fibers. To test the needle, stitch through an old nylon stocking. Baste seams as needed to avoid ripping.

Seam/Hem Finishes: To reduce fraying, turn under and stitch raw edges. For seams, use a safety stitch seam; or stitch the seam allowances together with a narrow zigzag; then trim to 3.8" (1cm).

Seams: Self-finished seams such as French and faux French are often too bulky. To reduce seam slippage, stitch seams again 1.8" (3mm) away.

Interfacings: Many designs do not require interfacing. If you want to add crispness, experiment with fusibles to determine if the lamé will be damaged by heat and/or steam.

Linings: To avoid skin irritations, line the garment, bind seams with tricot or chiffon, or wear a slip.

Embroidery: Use water soluble stabilizer on top and bottom of fabric.

Pressing: Test press. Some lamé fabrics are easily damaged by hot irons and steam; others are not.

GarmentCare: To protect skirts and pants from clip hanger marks, sew in ribbon hanger loops at the waist.

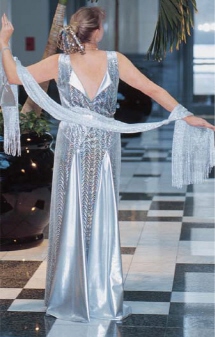

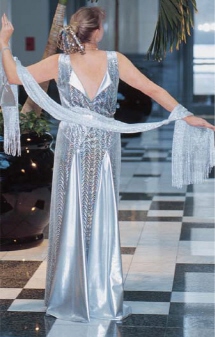

This stunning gown, designed by Tammy O’Connell, is panné velvet with hologram and accent piping with metallic drapes and revers. (Photo courtesy of Tammy O’Connell of Jitney Patterns and Patrick Manning.)

Similar Fabrics: Cloth of silver, cloth of gold, hologram, Lurex®, Metlon®, sheer metallics, stretch lamé, tissue lamé, tricot-backed lamé.

Uses: Dresses, blouses, bustiers, skirts, pants, eveningwear. Design Elements: Minimal seaming, bindings, pockets (inseam), casings. Avoid close fitting designs if you are not underlining.

Sewing Checklist

Essential Supplies

Needles: Sharp (HM, HJ), stretch (HS) universal (H); sizes 60/8-70/10.

Thread: Lightweight (machine embroidery cotton, cotton covered polyester), all-purpose (cotton, polyester, cotton covered polyester).

Cutting: Stainless steel shears, weights, rotary cutter/mat.

Marking: Chalk, erasable pens, super fine pins, safety pins, tailor’s tacks.

Miscellaneous: Super fine pins, seam sealant, weights, nylon stocking scrap, temporary pattern adhesive, water soluble stabilizer.

Interfacings: Optional, sew in or low temp fusibles.

Linings/Underlinings: Generally for formal designs, and scratchy fabrics.

Machine Setup

Stitch Length: 2-2.5mm (10-12spi).

Tension: Lightly balanced; light pressure.

Machine Feet: Wide straight stitch, roller, zigzag.

Sewing Basics

Test Garment: Recommended.

Fabric Prep: Hand wash or Dryclean, depending on manufacturer’s recommendation.

Layout: Nap – double layer.

Seams: Plain (pressed open or closed), tissue stitched.

Seam/Hem Finishes: Serged, turn under and stitch, zigzag.

Hems: Hand (blindstitch), topstitched, shirttail, pin, twin needle.

Edge Finishes: Facings (self fabric, lining, bias), bands, bindings, edge to edge linings.

Closures: Buttons/loops, buttonholes (machine, bound, inseam), ties, covered snaps, zippers (hand, machine, invisible).

Pressing: Medium heat, dry iron.

Garment Care: Dryclean or hand wash, depending on manufacturer’s recommendation.