Squirty Swirls

There are lots of fun tools available for creating unique and interesting designs in your soap. This recipe uses condiment squirt bottles to create a splashy, swirly two-color pattern.

Squirting the soap into the mold instead of pouring it can take up to 10 minutes, so it’s important to use a tried-and-true recipe (like this one) and a fragrance oil that’s guaranteed not to accelerate.

Approximately 12 bars

Ingredients & Equipment

Lye-Water Amounts

- 5.9 ounces sodium hydroxide (lye)

- 13.9 ounces distilled water

Base Ingredient Amounts

- 11.3 ounces palm oil

- 11.3 coconut oil (76°F)

- 1.7 castor oil

- 17.6 ounces olive oil

Colorants

- 11⁄2 teaspoons Ultramarine Blue Oxide

- 11⁄2 teaspoons Titanium Dioxide

- 3 tablespoons sunflower oil (or other liquid oil)

Fragrance

- 2.6 ounces Sage and Lemongrass fragrance oil

Equipment

- Standard equipment (see list on page 21)

- Mini-mixer

- Four 14-ounce condiment bottles (snip the tips of the spouts to widen them approximately 25 percent)

- Silicone loaf mold

Soap Safely!

- Work in a well-ventilated area. Do not breathe any fumes!

- Wear long sleeves, long pants, and closed-toe shoes.

- Don safety goggles (regular glasses are not sufficient protection) and rubber gloves during the entire soapmaking process.

- Keep children and pets away from your workspace.

Instructions

Prepare the colorant

Prior to starting the soapmaking process, mix the Ultramarine Blue Oxide in 11⁄2 tablespoons of the sunflower oil and the Titanium Dioxide in 11⁄2 tablespoons of the sunflower oil, using the mini-mixer. Push the powder under the surface of the oil with the tip of the blade to saturate the powder before you begin or you’ll stir up a messy cloud of pigment. Mix the colorants thoroughly for the most even color results.

Make the Soap Mixture

- 1. Add the lye to the water (never the other way around), stir gently, and set aside until clear.

- 2. Melt the palm oil in its original container, mix it thoroughly, and measure into a bowl large enough to hold all the oils and the lye-water with room for mixing. Melt and measure the coconut oil and add it to the bowl. Add the castor and olive oils.

- 3. When both the lye-water and oils are below 120°F, add the lye-water to the oils, pouring it over a spatula or down the shaft of the stick blender to minimize air bubbles. Tap the stick blender a couple of times against the bottom of the bowl to release any air trapped in the blades. Do not turn on the stick blender until it is fully immersed. Stick-blend until light trace (the consistency of a melted milkshake) is achieved, 1 to 2 minutes.

- 4. Divide the batch equally between two containers. Add the Ultramarine Blue Oxide mixture and 1.3 ounces of the Sage and Lemongrass fragrance oil to one batch, and the Titanium Dioxide mixture and the remaining fragrance oil into the other. Mix well, using a whisk so as not to accelerate trace.

Squirt and Swirl

- 5. Pour the soap into the condiment bottles; each color will fit into two bottles. As you use each bottle, periodically put your gloved finger over the tip and give it a good shake to keep the color blended.

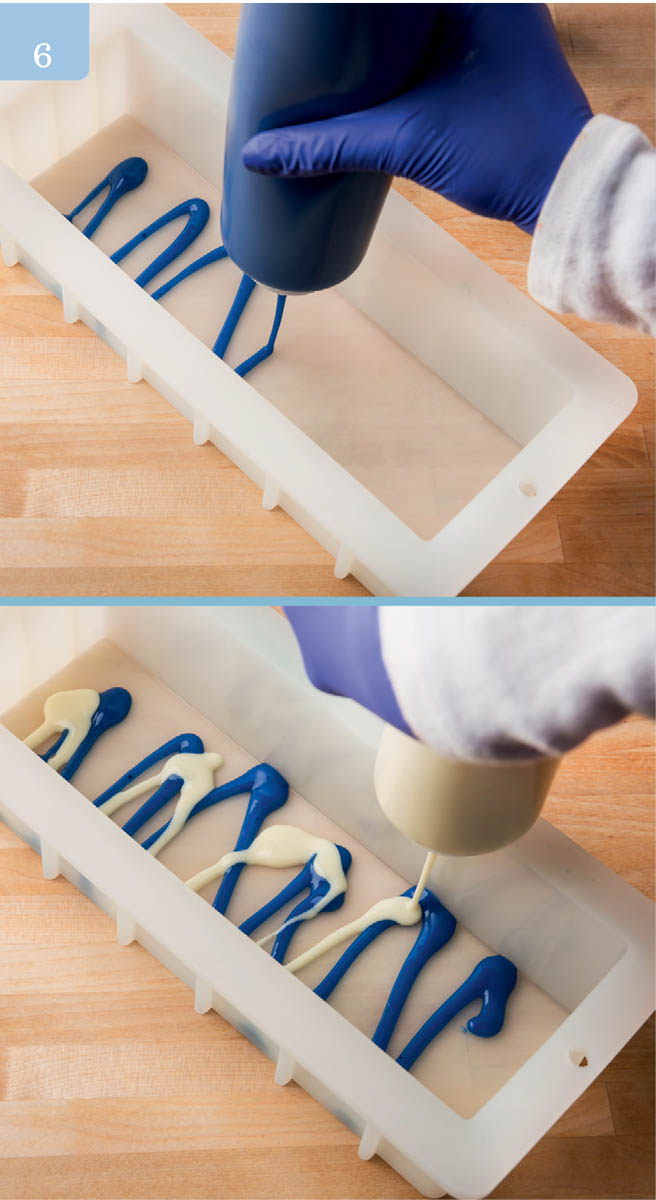

- 6. Choose a starting color and squirt the soap into the silicone loaf mold, making a tight zigzag pattern across the width of the mold. Make one pass, then switch to the next color, repeating the pattern in between the lines of the first color.

- 7. Continue alternating colors until the mold is full, turning the mold every so often so that one side isn’t heavier than the other.

- 8. Tamp the mold on the work surface periodically to remove any air bubbles.

- 9. If there’s any soap left in the bottles, shake it down to the nozzle and squeeze hard to splatter those last bits over the surface and create an artistic extra touch.

Final Steps

- 10. To help decrease soda ash formation, spray the entire surface with 91% isopropyl rubbing alcohol two or three times over a 90-minute period, then cover the mold with either plastic wrap or a lid fashioned out of cardboard.

- 11. Insulate the entire mold by wrapping it in a large towel and set it aside for at least 24 hours at room temperature before unmolding.

- 12. Cut the soap into bars and allow to cure in a well-ventilated area for 4 to 6 weeks, turning the bars over every few days to ensure that they cure evenly.