Within a month after establishing the Apollo Applications Office, Mueller took its preliminary plans to congressional committees. He found no enthusiasm for the program, even though committee members agreed that manned spaceflight should continue after the lunar landing. The straightforward extension of Apollo’s capability smacked too much of busywork—of “boring holes in the sky” with frequent long-duration flights, marking time rather than advancing American preeminence in space. Mueller had no better luck convincing NASA’s top officials of the intrinsic merit of AAP. James Webb was particularly cautious about starting a costly new program before he was absolutely certain that Apollo was going to achieve its goal. Mueller’s concern was twofold: he wanted some options, and he needed a worthwhile program to keep the manned spaceflight organization together. Well aware that Saturn and Apollo could encounter unexpected delays, he wanted a parallel program to maintain the momentum of manned spaceflight. Conversely, if all went well, he wanted to exploit the tremendous capability Apollo was so expensively building up. This was an immediate problem in the case of Marshall Space Flight Center, since after Saturn no major new launch vehicles were planned.1

Von Braun saw as clearly as anyone that Marshall must have a broader base than just launch vehicles, and in the period 1962–1965 Huntsville’s Future Projects Office studied a number of ideas. When Mueller conceived Apollo Applications as a way to use developed hardware for new purposes, one of these ideas was already under consideration. Called the “spent-stage laboratory,” this idea was based on converting, in orbit, an empty rocket stage into living and working space. A conceptual design study started at Marshall scarcely two weeks before Mueller formally established the AAP office at Headquarters. Although Headquarters’ studies provided the material for Mueller’s presentations to Congress in 1965 and 1966, the Marshall concept quickly got the inside track. Within the next year it became the core on which AAP was built—the vehicle for carrying out the AAP plans of 1964–1965.

Every orbiting spacecraft is accompanied by the last stage of the rocket that launched it. The empty upper stage is usually in a short-lived orbit, but a small adjustment to its fuel-burning program can stabilize that orbit. As far back as the Peenemünde days, von Braun and his colleagues had speculated on converting an empty stage into a shelter for a small crew. In 1959 the idea was put forth in the report of a study called Project Horizon, carried out by the Army Ballistic Missile Agency. Horizon was the Army’s last bid for a role in manned spaceflight: a proposal to establish and maintain an armed outpost on the moon. Heinz Koelle and Frank Williams were Horizon’s principal architects, and the report reflected their agency’s strong attachment to earth-orbit rendezvous as the principal mode for space operations.2

The Horizon study assumed that by 1965 the U.S. would have a permanent station in earth orbit and that it could serve as the base for launching the lunar missions. If no permanent station existed, however, minimum facilities would have to be provided in earth orbit for the crew that refueled the moon-bound rockets. The basic structure for this minimum orbital shelter was to be the empty third stage of the rocket that launched the crew’s spacecraft. In orbit, the crew would dock with the empty stage, empty the residual hydrogen from the fuel tank, and fit it out for occupancy with equipment brought along in their spacecraft. As more payloads were orbited in preparation for the lunar mission, more empty stages would be bundled around the first, providing storage space and protecting the crew’s quarters from meteoroids and cosmic radiation. Later, spent stages might be assembled into a larger station of the familiar wheel shape. The Horizon report included sketches of a station built from 22 empty stages.3

The report was as far as the Army’s lunar outpost ever got. Von Braun’s group was transferred to NASA; Koelle became director of the Future Projects Office at Marshall Space Flight Center, with Williams as his deputy. For the time being the spent-stage orbital shelter was forgotten in the press of more urgent business.

The next proposal to use a spent stage came from the Douglas Aircraft Company, builder of the Saturn S-IV stage. Douglas had been in the rocket business since the end of the Second World War; its biggest job before Saturn, and its biggest success, was the crash program undertaken in 1957 to build the Thor missile system.* When the Saturn stages were put up for bids in 1960, Douglas won the contract for the S-IV stage. S-IV was the first big stage to use cryogenic propellants (liquid hydrogen and liquid oxygen), and Douglas broke a good deal of technological ground in building it.*

The S-IV contract was managed by Marshall, and development of the stage brought Douglas and Marshall into a close working relationship. When design or production problems were being worked out, engineers from both organizations pitched in side by side; if Saturn was in trouble, Douglas’s problems were Marshall’s problems too. Engineers and managers built close professional and personal relationships over the years. It was no different at Houston; MSG’s Mercury and Gemini people built similar relationships with their opposite numbers at McDonnell Aircraft Corporation, prime contractor for both the Mercury and Gemini spacecraft.

For all its success with launch vehicles, Douglas had not been able to break into the manned spacecraft business. It was not for lack of trying: the company had bid on Mercury, on the Apollo command module (in a consortium of four companies), and on the lunar module, but without success. In the early 1960s Douglas management determined to change this. They set up a future-studies program to seek “targets of opportunity” in manned spaceflight programs and soon identified small space stations and orbiting laboratories as promising areas for the company to enter. By the end of 1963 Douglas had won several study contracts from NASA and was competing for the Air Force’s Manned Orbiting Laboratory.4

Douglas got into Apollo Applications, however, by a different route. When the S-IV was superseded by the S-IVB, Douglas won the contract for the new stage, but the S-IV became obsolete. In 1962, the chief engineer for Douglas’s Saturn program was put in charge of a study group to see what might be done with the S-IV. The group suggested making it into a small orbiting laboratory.

Exactly how the spent-stage idea jumped the gap between Marshall and Douglas—if it did—is not clear. There were plenty of opportunities. Von Braun traced the origin of Skylab to this first S-IV study, believing it resulted from prodding by Marshall engineers who “were thinking along similar lines at the time.” Heinz Koelle remembered discussing a spent-stage idea with von Braun in 1960 and thought von Braun discussed the idea with Douglas engineers, probably in 1961.5

The Douglas group compared existing NASA programs with the most likely long-term goals of space exploration and perceived a gap.

Gemini and Apollo were narrowly focused programs; neither seemed likely to produce much fundamental information about orbital operations, especially about man’s ability to function for long periods in zero gravity. Further, there were no specific plans to qualify hardware components in a true space environment. Sooner or later, both men and systems would have to be qualified, and the study group argued that an orbiting laboratory was the best way to carry out this essential research. Excluding experiment hardware, data handling, and administrative overhead, an S-IV could be outfitted as a laboratory for two men and put in orbit by 1965 at a cost of $220 million.6

The S-IV would need very little modification to make it habitable. A meteoroid shield would be fitted around the hydrogen tank before launch. A storage module on top of the stage would carry equipment that could not survive immersion in liquid hydrogen. Arriving in orbit, two crewmen would dock their Gemini spacecraft to the storage module, empty the fuel tank, pressurize it with a nitrogen-oxygen atmosphere, and move equipment from the storage module into the empty stage. In the next hundred days they would conduct more than 70 experiments in physiology, space technology, and orbital operations. The S-IV laboratory carried medical monitoring equipment, including a one-man centrifuge to provide artificial gravity and assess the effect of weightlessness on the human circulatory system. If serious deterioration was observed during the mission, the centrifuge could also be used to recondition the men before their return.7

Douglas submitted the studies to the Future Projects Office at Marshall as unsolicited proposals, after which the main ideas were published in professional journals. For several years Douglas continued to propose novel applications for the company’s favorite piece of rocket hardware.8

The S-IV study group was not aware of it, but the basic idea of a space laboratory had been anticipated within their own company three years earlier. While the first squadron of Thors was being deployed in England, the London Daily Mail decided to capitalize on public interest in space for its annual Ideal Home Exhibition. The “Home Show” is one of London’s major springtime exhibitions, and the Mail chose “A Home in Space” as its theme for 1960. The paper asked American aerospace contractors to submit concepts, and Douglas’s proposal was chosen. The company’s Advanced Design Section at Santa Monica produced blueprints for a full-scale model and numerous posters. The project intrigued many engineers in the section, and they probably bootlegged at least twice as much engineering time into it as the budget allowed.9

The Douglas entry was a space laboratory built into the empty upper stage of a hypothetical launch vehicle. The laboratory was equipped for a crew of four to stay 30 days in earth orbit, making astronomical observations above the atmosphere. The mockup was built inside London’s Olympia Exhibition Hall in March 1960, where promoters estimated that over a million people saw it and probably 150 000 walked through it. Back at home it attracted little attention, and the report was filed away and forgotten until Skylab was launched.10

Douglas’s proposals drew no immediate response from Huntsville. Marshall was less involved in space-station studies than either MSC or Langley, and besides, the kind of station NASA might eventually build was not at all clear in 1963. Both Koelle and von Braun sensed that a large station was becoming less likely as the next step in space. Money was going to be a problem, and only a small station was likely to be within NASA’s means. MSC’s study contract with North American on extending Apollo’s time in orbit reflected the trend in thinking, as did Langley’s Manned Orbital Research Laboratory studies, kicked off in June 1963 with the award of study contracts to Douglas and Boeing.11

An important new factor was George Mueller’s desire to have a program running parallel to Apollo—something that could maintain the momentum of the manned spaceflight program in case Apollo got snagged on unforeseen problems or succeeded ahead of schedule.12 Too, public opinion about Apollo was changing. When Mueller came into NASA, criticism of space spending was reaching a peak. Scientists, among others, were increasingly unhappy; the moon project was absorbing vast sums that would be more productive, in their view, in the unmanned satellite program. Using Apollo hardware to conduct scientific investigations in space would be politically attractive.

Mueller’s thinking dovetailed neatly with the situation developing at Marshall in 1964, where the Saturn program was moving smoothly and no new vehicles were in sight. Marshall management was particularly concerned about the Saturn IB—an excellent vehicle for earth-orbital operations, but one with a limited future. Concern was intensified when the Air Force chose the Titan III to launch its Manned Orbiting Laboratory. Koelle spent considerable time in 1964 trying to identify uses for the Saturn IB that would justify keeping it in production. Mueller’s interest in developing alternative uses for existing hardware prompted Koelle to resurrect the spent-stage plan and give it a closer look. Seeking a second opinion, Marshall awarded a nine-month, $100 000 contract to North American Aviation to study the utility of spent stages in NASA’s contemplated space programs, especially orbital operations and orbiting laboratories.13

North American’s study considered several schemes, including refueling S-IVB stages in orbit and launching them to the moon or one of the planets, fitting out an S-II stage (the second stage of Saturn V) as an orbital hangar for Apollo spacecraft, and assembling empty S-IVBs into a large station. After the midterm review of the study in January 1964, Marshall added a concept called “Apollo Support Module,” which called for using an empty S-IVB fuel tank as working space. The final report in April 1965 recommended this concept for further study. “The large volume of work space,” the report said, “can be practically utilized in near-term missions for accomplishing a large quantity of experimentation required for orbital operations support.”14

Koelle’s office had already considered one or two schemes for adapting Saturn hardware, such as using the oxygen tank of the S-IC (Saturn V’s first stage) as the structural shell for a laboratory, and something that Koelle referred to as “a minimum space laboratory [growing out of] the Apollo program.”15 Now, with the North American report in hand, the Future Projects Office took it and some of Marshall’s own ideas and began to assemble a spent-stage proposal to take to Headquarters.

Initially the idea was a simple undertaking in which an Apollo spacecraft would dock with a spent S-IVB. The crew would go inside to experiment with extravehicular mobility techniques in a protected environment. This could be done without major change to the S-IVB and without pressurizing it; two suited astronauts with cameras and portable lights could gather the necessary data. There was interest in doing more, however: pressurizing the tank and using its 281-cubic-meter volume for living quarters. Ideally a continuing program could be started, with later flights building on and adding to the results of earlier ones. Marshall saw considerable potential in spent stages and regarded them as logical candidates for Extended Apollo—candidates for which Marshall should logically have the responsibility.

It fell to Frank Williams to see this proposal through. At the end of June 1965 Koelle ended his 10-year association with the American space program and took a professorship in the Technical University of Berlin. Williams, who since late 1963 had been von Braun’s special assistant for advanced programs, returned to his old shop as its director. At the same time the Future Projects Office was rechristened the Advanced Systems Office.16 Williams’s first job was to finish pulling together the material on the spent-stage proposal for presentation to Headquarters.

Von Braun and Williams took the plans to the Manned Space Flight Management Council on 20 July, proposing to begin a conceptual design study to work out details. Mueller supported the idea and found $150 000 for a four-month study. Williams presented the plans to Marshall’s Future Planning Policy Board on 10 August, and on the 20th called the first meeting of the conceptual design study group.17

The first order of business at the organizational meeting on 25 August was to familiarize the group with the project and to review the plan that had been presented to Management Council. Three configurations of an orbital workshop were to be studied. Orbital workshop was the official designation for the spent stage. As the program progressed it came to include a ground-equipped, Saturn-V-launched, S-IVB workshop; the original concept was then informally referred to as the wet workshop to distinguish it from the ground-equipped version, which would never contain fuel—the dry workshop. Only the latter would be built.) The “minimum configuration” was simply the empty tank, fitted with a docking port but having no power or life-support systems. An “intermediate configuration” would have an airlock, power, and oxygen (but no carbon dioxide removal), and the crew could work without pressure suits. Finally, the “baseline* configuration” would have a complete environmental control system, as many experiments as weight and space limitations allowed, a power system sized to support the experiments, and positive attitude control. The first two versions could be used in missions 3 to 14 days long and would have only a few experiments; the third could support flights of 14–28 days with a substantial experiment program.18

The study picked up momentum slowly. Many questions required answers, which called for a great deal of information. How would power be supplied? What experiments could be ready for the first flight? What would they weigh, and how much power and attitude-control fuel would they require? How was excess propellant to be removed from the tank, and how could the tank openings be sealed? What was the risk from micrometeoroids and how could it be minimized?

Some solutions would be dictated by the limitations of the launch vehicle—orbital altitude and inclination, for example. Some would be settled by fiat (“ground rules”). Others would have to be worked out by a complex series of tradeoffs involving Marshall’s Saturn Program Office, Houston’s Apollo Program Office, and Douglas. All of this, of course, was simply the kind of systems management that Marshall had been doing for years, and it was just a matter of getting on with it.

Douglas had not been idle in the small space-station field. During 1963 the company had won a contract from Langley for the Manned Orbital Research Laboratory study and one from MSC for a study of a 24-man “Saturn V Class” laboratory. The company had designed, built, and tested a flight-weight airlock under contract to Langley, delivering it in May of 1965. In August of that year Douglas became the prime contractor for the Air Force Manned Orbiting Laboratory. Besides this contract work, the company’s Saturn Payload Applications Group had kept an eye on Extended Apollo, maintaining a file of published information on it. That group had assembled a document detailing the use of an empty S-IVB for mobility and maneuvering experiments, with proposals that closely resembled the three workshop configurations being studied at Marshall. The most advanced Douglas version was a pressurized stage remarkably similar to Marshall’s most sophisticated workshop. Von Braun, visiting Douglas in September 1965, gave company management an unofficial briefing on the orbital workshop concept (the same presentation Frank Williams had made to Management Council in July) and for the first time Douglas and Marshall learned how closely their ideas paralleled each other.19

The Manned Spacecraft Center was brought into the picture on 20 October, when Williams and a delegation from Huntsville flew to Houston to brief MSC on the study and what it had accomplished so far. Williams returned to Marshall feeling that his center had stolen a march on MSC with its studies on extravehicular activity; the Houston people, he told von Braun, “seemed surprised at the data and the vigor with which we were working on that area.” Much less gratifying was MSC’s insistence that extended operations in zero gravity were undesirable. MSC wanted a minimum of 0.1 g to be provided by rotating the workshop on a radius of 20 to 30 meters.20 This issue would long nag the workshop study, disappearing into limbo some time in 1966 under the pressure of schedule, funding, and design problems.

As the labs came to grips with the various aspects of the workshop mission, Williams and von Braun grew more confident that they had the makings of a substantial program. At the November Management Council meeting, Mueller encouraged von Braun to press on with the study, and at the end of the month Marshall got a chance to sell the program when Mueller and Deputy Administrator Robert Seamans visited Huntsville. Among other briefings they heard a summary of the workshop concept and the results of the conceptual design study, which at that time was concentrating on a minimum-configuration workshop for flight on Saturn-Apollo mission 211, scheduled for August 1968. More than mildly interested, Mueller asked for a presentation at the Management Council meeting three weeks away, showing what Marshall could do on SA-209 and how soon a pressurized workshop could be made ready. He wanted a pressurized version to fly on 209, six months ahead of 211, if possible. Von Braun, sensing a real opportunity for his center, promised the presentation would be ready. He suggested moving the spent-stage study into the project definition phase, and Mueller concurred.21

This unexpected surge of interest and the short time available produced immediate action. Williams announced the following day that the workshop must be ready for SA-209. Unfortunately there would be almost no money available from Headquarters; this would mean, among other things, that an airlock would have to be built in-house and financed out of current budgets. Williams wanted a half-day presentation, an honest appraisal of what Marshall could do, ready for von Braun in two weeks.22

The next day Williams’s office promulgated a new set of guidelines for the study. The primary goal was to “design, fabricate, and test to flight qualifications a pressurized version of the S-IVB workshop for Saturn IB flights 209 or 211.” A secondary effort to develop an unpressurized version was to be undertaken simultaneously. An airlock, an environmental control system, and a set of experiments were to be designed and developed, together with ground-support equipment, mockups, training hardware—everything needed to support the mission. Marshall would be wholly responsible for the pressurized version, Douglas for the unpressurized. Flight 209 was the target unless costs, production schedules, or a technological hitch dictated otherwise. Emphasis was on maximum use of flight-qualified hardware, minimum modification of the S-IVB, and minimum cost. The environmental control system should function for 14 days, but a lifetime of 2–6 days was acceptable if necessary to meet the schedule. A pure oxygen atmosphere would be used rather than a mixture of oxygen and nitrogen, because the hardware was simpler. Connections between the Apollo spacecraft and the spent stage would be kept to an absolute minimum. The S-IVB would maintain its attitude until the spacecraft docked, after which the Apollo systems would take over. The priority of experiment categories was laid down: first, basic maneuvering experiments and biomedical observations; second, maintenance, repair, and inspection of spacecraft systems, rescue, and cargo transfer; third, prepackaged experiments where the astronaut functioned primarily as a monitor.23

In a follow-up memo, Williams stressed the importance of preparing a proposal that Marshall could execute with confidence. The center was staking its reputation on the workshop. Not only was it important to propose a worthwhile program; it must also be one that the center could accomplish.24

The labs responded with gratifying speed, and after the review by von Braun, Williams took the proposal to Management Council on 21 December. As it had developed, the plan required an additional piece of hardware, a “Spent Stage Experiment Support Module,” an airlock that would also carry certain equipment and expendables. For this module, Marshall intended to make use of Douglas’s experience in building the Langley airlock, but apparently this was not stressed. After the presentation Mueller suggested that Marshall confer with McDonnell Aircraft Corporation to see if any Gemini components could be used in the airlock. Gemini production was about to end; Mueller thought that time and money might be saved if any useful hardware could be adapted.25

Williams wrote immediately to Charles W. Mathews, Gemini program manager at MSC, asking his help in coordinating talks with McDonnell. Williams wanted a technical briefing at Huntsville as soon as possible, so that Marshall and McDonnell could get acquainted and compare notes. The meeting was held at Houston instead, on 4–5 January 1966, and produced a set of ground rules for the proposals Marshall and McDonnell were to make to Headquarters. The most important rules were to use Gemini-qualified environmental control and electrical power systems and to keep the airlock functionally independent of the S-IVB instrument unit and the Apollo command module. Williams’s understanding was that McDonnell would furnish qualified systems to Marshall, which would do the actual fabrication; this would make the best use of Huntsville’s civil service personnel and would be in line with Mueller’s zero-cost dictum.26

The introduction of McDonnell complicated the picture unexpectedly. Marshall was comfortable with Douglas, which had experience designing an airlock. But that airlock, though it was flight weight and had been extensively tested on the ground, was not fully flight qualified. MSC engineers concluded that upgrading it to flight standards would increase its cost considerably.27 McDonnell had the advantage of being able to use components already qualified in the Gemini program, at a significant cost saving. But McDonnell and Marshall were strangers, while MSC had worked with the St. Louis firm since the beginning of Mercury. With McDonnell involved in the airlock project, there was a strong argument for MSC to manage it. And since the module would carry two important crew systems (environmental control and life support), Houston could make a case for taking complete responsibility for managing the airlock. MSC’s depth of experience in crew systems was unrivaled.

An advanced airlock concept by P. M. Chapman, Douglas Aircraft Co., 20 August 1966.

Logically enough, MSC did make this case, and Headquarters listened. MSC, in fact, seemed to be assuming that it would get the project as a matter of right. More than once Frank Williams had the feeling that MSC was not anxious to help him work with McDonnell. By early February the matter required resolution, and on the 11th, during a daylong series of meetings at Houston, von Braun sought it. In Gilruth’s office, von Braun argued at length that NASA’s interests would be best served if the project went to Huntsville. Unfortunately for his case he went further than that, sketching out plans he had for Marshall’s future—plans that included training men to assemble large structures in orbit. Sharing the responsibility for training was something that MSC could never accept, and in the end von Braun, sensing that he had pressed matters too far, conceded the airlock project to MSC rather than provoke a disruptive confrontation.28

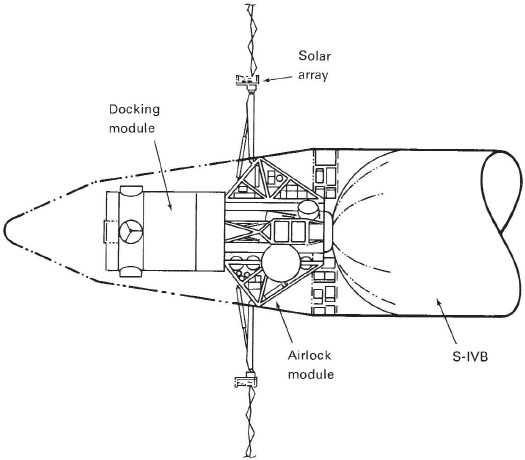

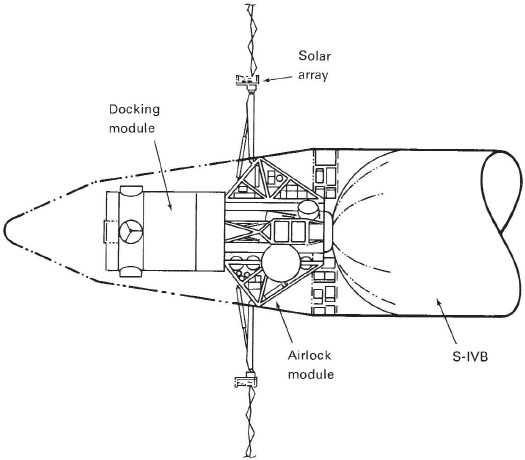

Early sketch of an orbital workshop prepared at Manned Spacecraft Center.

This disagreement over management of the airlock indicated that the spent-stage project posed a new problem for manned spaceflight: that of roles and missions for the two field centers. The conversion of an empty rocket stage into a manned workshop blurred the distinction between launch vehicles and spacecraft. No longer did each center have a clearly demarcated territory to work in. A new relationship of the centers to each other and to Headquarters was in the making, and it was not going to be easy to work it out.

After Marshall took itself out of contention for management of the airlock, Douglas still wanted a chance to build it. On 9 March a Douglas delegation went to Washington to brief Mueller on their proposal for an airlock. Mueller was interested in what they had to say, even though, as he told them, the spent-stage project was not yet an approved program and he still “had some selling to do” at higher levels in NASA. He said he had not known about the airlock Douglas had built for Langley, and he was impressed by what they showed him—especially by their proposal to build two units for $4 million. He suggested that Douglas submit proposals.29

On 11 March Houston’s planners submitted a procurement plan for the airlock, proposing sole-source procurement from McDonnell. Headquarters, however, could not justify sole-source procurement after Douglas’s presentation to Mueller; so at the 22 March meeting of Management Council both centers were directed to conduct studies to define the airlock and establish cost and schedule projections for its construction.30

Marshall, with so much at stake, began to fear that the airlock’s cost might send the whole project down the drain. As a fall-back position to save the workshop project, should that become necessary, the center defined a bare-bones airlock that was just adequate to support their intermediate-configuration workshop. MSC granted three 60-day, $50 000 study contracts to Douglas, McDonnell, and Grumman (prime contractor for the lunar module). Each company was to define an airlock based on its own hardware or concepts: Douglas on the Langley airlock, McDonnell on Gemini systems, and Grumman on modifying the lunar module to serve as an airlock. A source evaluation board chaired by Kenneth S. Kleinknecht, deputy program manager for Gemini at MSC, began considering proposals from the three contractors in late June.31 On 19 August, Headquarters announced that McDonnell had been selected for negotiation of an airlock contract. With some features added during negotiation, the final agreed price was $10 509 000. Marshall’s precautionary study proved unnecessary and was immediately terminated.32

While the airlock issue was being thrashed out, the Technical Working Group was busy with modifications to the S-IVB. Before astronauts could enter the hydrogen tank it had to be “passivated”—hydrogen and oxygen tanks vented, high-pressure helium bottles emptied, and the stage’s pyrotechnics* deactivated. Hazards inside the tank had to be eliminated. The internal insulation had to be painted a uniform color for a good photographic background. Provision had to be made for equipment to be mounted on the walls; restraints and mobility aids had to be added. By 15 December 1965 a list of stage modifications was drawn up and Marshall asked Douglas for a quick-response estimate of their cost. The reply was $1.5 million to modify stage 209. This was more than Marshall could afford, and negotiations ensued. A second estimate for a slightly different set of changes was $4.5 million for changes to five S-IVBs. Satisfied that this was the best price they were going to get—at least in time for SA-209—Marshall sent the figure to George Mueller on 20 January 1966. He found the quotation disappointingly high and put off all decisions for a month because he still had no budget for Apollo Applications. He told Marshall to determine if the changes could be made in-house and asked for a list of no-cost experiments to be assembled by mid-February.33

Just after the new year, Frank Williams had said the spent-stage project was “in high gear,” but at the end of January it was stalled by the unsettled funding situation. The S-IVB modifications identified before Christmas were being made at a snail’s pace. On 21 February, Williams was told that no more money could be spent for changes until the workshop was officially approved. To fly the workshop on SA-209, approval was required immediately.34

Fortunately one major change to the S-IVB had already been made. Early on, von Braun had noted that the “manhole,” a 71-centimeter circular opening in the forward dome, was too small to permit a suited astronaut to pass through. He was unable to find funds to make a change, however. Then in July 1965 Douglas engineers discovered cracks in welds around the manhole on stage 203; subsequent tests disclosed a structural weakness in the dome design. When it turned out that one solution was to enlarge the opening, Marshall and Douglas opted for that solution—with the workshop project in mind. The change, effective on stages 211, 507, and all subsequent S-IVBs, cost $600 000 and was financed out of Saturn funds. Von Braun also urged that the manhole cover—held on by 72 bolts—be replaced by a quick-opening hatch, but the estimate for that was $400 000, and those funds could not be found.35 A year later, however, when Houston raised the same objection on operational grounds, the change would be quickly adopted.

Another troublesome question was what to do about micrometeoroids—those tiny particles, no more than one or two millimeters in size, that speed through space at enormous velocities. Three Pegasus satellites, payloads on the last three Saturn I flights, were in earth orbit measuring the number and penetrating power of these particles. The information they were sending back indicated a small but not negligible chance that the S-IVB would be struck by a micrometeoroid. To assess possible damage, Marshall arranged for tests at the Air Force’s Arnold Engineering Development Center at Tullahoma, Tennessee, which had facilities for producing high-speed projectiles. Results of preliminary tests on S-IVB skin and insulation, reported in February 1966, were worrisome: micrometeoroids penetrating the metal skin could ignite the polyurethane insulation. Two solutions came to mind: an external shield to reduce the velocity of impact, or a coating on the insulation to retard the spread of combustion. A quick look at probable costs sent the engineers in search of a coating. Tests began immediately and continued for the rest of the year.36

Late in November Douglas was testing one coating, MSC was recommending another, and Marshall was reviewing the whole problem. Both Marshall and the contractor were reevaluating the risk of micrometeoroid damage and getting different answers. Depending on the data used, the chance the workshop would be penetrated in a 30-day mission was calculated by Douglas to be as high as 1 in 3 or as low as 1 in 40. Marshall’s own estimate was 1 in 50. Douglas engineers were beginning to think about an external shield; according to their study, this would reduce the chance to 1 in 200.37

The fire hazard was also a function of the pressure of oxygen in the workshop’s atmosphere, which was primarily a medical question. A medical staff paper prepared for Mueller in December 1966 recommended an atmosphere of 69% oxygen and 31 % nitrogen, at a total pressure one-third that at sea level, for long-duration missions, but indicated that other compositions were acceptable. Marshall engineers then analyzed the micrometeoroid problem taking into account the composition of the atmosphere, and concluded that there was a net advantage in using a mixture less rich in oxygen at a pressure half that at sea level—plus the addition of an external shield. The question remained unresolved for two more months.38

In September 1966, MSC, having begun to examine the workshop mission in some detail, objected to the plan for activating the workshop. As it then stood, that plan required two suited astronauts to remove the 72 bolts from the forward tank dome cover. Experience on three Gemini missions had shown Houston that extravehicular activity was not to be taken lightly. In zero-g simulations, two men took six hours to remove the bolts, an intolerable work load. Von Braun’s foresight was confirmed, but this time money was found to have Douglas design and manufacture a full-scale operating model of a quick-opening hatch for evaluation and to provide cost and schedule estimates so the decision could be made as quickly as possible.39

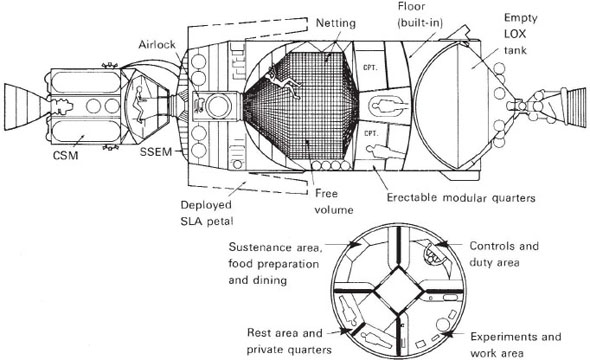

An early cluster concept sketched by Willard M. Taub, Manned Spacecraft Center. The spent S-IVB workshop is at the right. The Apollo telescope mount is attached below the multiple docking adapter, and an experiment module above. Solar cell arrays provide the power.

All these changes, however, were impeded by lack of money. NASA’s fiscal 1967 budget request had been slashed by the budget bureau, and Apollo Applications finally received only $42 million, just enough to maintain the program at survival level.* Until well into 1967 the actual development of the orbital workshop remained pretty much where it was in mid-1966.

Parallel to the efforts to define the workshop, the Office of Space Science and Applications (OSSA) was developing a major scientific project that would cause a major change in Apollo Applications. Called the Apollo telescope mount, this would be the first astronomical facility to use man as an in-orbit observer.* One of its major purposes, in fact, was to determine how useful a man could be at the controls of a sophisticated set of instruments in orbit.40 As things turned out, the telescope mount would assume considerable scientific importance as well: it would be the only set of instruments with a chance to collect data on the sun during the next period of maximum solar activity, expected in 1969–1970.

OSSA’s head, Homer Newell, began talks with George Mueller early in 1966 about working the Apollo telescope mount into the Apollo Applications Program. They agreed on the merits of the project, but differed about where it should be carried. OSSA planned to install it in the experiments bay of the Apollo service module, while OMSF intended to use a modified lunar module to carry bulky experiments like the telescope mount. At the end of August, Deputy Administrator Robert Seamans authorized the project and opted for Mueller’s proposal.41

There were both technical and management difficulties in working the telescope mount into a manned spacecraft. An elaborate and costly stabilization system seemed necessary to counteract the unavoidable motion of crewmen, which would disturb the instruments’ alignment. Effluents from the spacecraft could create a cloud of contamination in the vicinity of the telescopes, interfering with observations and possibly depositing material on delicate optical surfaces, degrading the results. MSC disliked using the lunar module as an experiments carrier, particularly since Mueller wanted Marshall to integrate the telescope mount with the spacecraft.42 Houston told Mueller it could not support this idea, but he persisted; on paper, at least, the lunar module-Apollo telescope mount combination was the official configuration for three years.

Mission plans coming out of Headquarters as early as March 1966 included solar astronomy flights both as single-purpose missions and as part of long-duration workshop flights. As the months passed and some of the problems associated with the lunar module became apparent, Mueller began to see advantages in operating the telescopes from the workshop. The lunar module’s systems were not designed to sustain it as a free-flying spacecraft for 28 days. Besides, Houston was dead set against flying it independently in earth orbit; if it became disabled, rescue would be extremely difficult, and reentry in a lunar module was impossible. It had no heat shield. The problems were given a thorough going-over at a briefing for Mueller at Huntsville on 19 August. At the end of the day he suggested that the observatory module might be operated while tethered to the workshop, drawing power, coolant, and oxygen through an umbilical. Marshall ran a quick feasibility study and reported the results to Management Council on 7 October, but the idea seemed to create as many problems as it solved and it gained no real support. Still, for several months Mueller kept it as a backup concept.43

A sketch by Associate Administrator for Manned Space Flight George E. Mueller indicates his thinking on the configuration of the S-IVB workshop in August 1966.

After the October meeting it seemed that the only solution was to provide a way for the telescope module to dock with the workshop. Back in May, while the airlock studies were in progress, Mueller and the Headquarters staff had agreed that the airlock must be kept simple and inexpensive, and they had specifically ruled out double docking;44 now that appeared to be necessary. But with the airlock contract negotiations completed, it was too late to change the design without losing several months and possibly having to go through another competition.

The only answer was to manufacture a new piece of hardware. It could be very simple: all that was needed was a shell—a cylindrical extension of the airlock—capable of withstanding launch and docking loads, but serving no purpose other than to provide two or more docking ports. It was literally a multiple docking adapter, a name that was soon made official. The details of its design changed several times during its first few weeks, but the basic idea was a cylinder, to be mounted above the airlock, carrying four radial tunnels at its upper end. The main structure and each radial tunnel would carry Apollo docking gear. The new module would have no active systems; power required at the docking ports would come from the airlock.

With the addition of the multiple docking adapter to the workshop and airlock, the nature of Apollo Applications missions was fundamentally changed. Planners began to speak of the “orbital cluster” as a core that could sustain a variety of missions. Multiple docking allowed the attachment of one or more specialized mission modules and permitted resupply for very long missions. Crews could be rotated without closing down the workshop. If a spacecraft became disabled, rescue was possible. With the birth of the cluster concept, what had been a simple experiment to use empty rocket stages looked a great deal like a small space station.

Two airlock mission configurations sketched by Wade W. Wilkerson of McDonnell Aircraft Corp., 22 December 1966.

By November, George Mueller had decided to present the orbital cluster as OMSF’s main post-Apollo plan when he discussed future programs with Webb and the Director of the Budget. He felt that he had a coherent program that could be clearly defined for planning purposes and that he could now campaign vigorously for funds.45

One thing that still had to be done was to design the multiple docking adapter. Originally it had been intended to let Marshall fabricate the docking adapter, but the module’s interface with the airlock justified asking McDonnell and MSC to see if they could do it equally well and equally cheaply. McDonnell drew up a $9-million design that Marshall considered “rather sophisticated [and] ‘unsellable’”; Marshall, in turn, modified its own design so that the adapter had room to carry experiment equipment into orbit. Experiments were being considered that could not be put into the workshop before launch. In the end, Houston’s design was similar to Huntsville’s, but it involved a number of substantial changes to the airlock, which would cost $21.8 million and delay delivery by six months. Before the month was out, Headquarters had assigned responsibility for the multiple docking adapter to Marshall.46

All of the mission plans made earlier in the year were now obsolete. At the end of 1966, the Apollo Applications Program Office issued program directive 3A, based on the cluster concept, defining the first four missions. The first two launches would set up the cluster, determine the feasibility of the workshop concept, and extend man’s time in space to 28 days. The third and fourth would revisit the workshop and bring up the Apollo telescope mount to gather data on the sun. A first launch in 1968 was still contemplated, but the schedule had slipped three months. After a year and a half, however, George Mueller had a program and perhaps a little breathing room.47

* Thor was the first intermediate-range missile deployed by a Western power; the first squadron reached England in 1959. Superseded by the intercontinental Atlas and Titan, Thor went on to a long career launching satellites and space probes. Delta, a Thor with an added upper stage, launched satellites through the 1970s.

* Centaur was the first, but it was much smaller. Developed by Convair as an upper stage for the Atlas, Centaur helped to launch a number of payloads. See Roger E. Bilstein, Stages to Saturn: A Technological History of the Apollo/Saturn Launch Vehicles, NASA SP-4206 (Washington, 1980), and John L. Sloop, Liquid Hydrogen as a Propulsion Fuel, 1945–1959, NASA SP-4404 (Washington, 1978).

* Baseline means a point of departure—for hardware, mission, or program—to which subsequent changes are related.

* A “command destruct system”—explosive charges detonated by radio signal—was built into the S-IVB in case the range safety officer had to destroy it in the early stages of flight.

* See chap. 3 for Apollo Applications’ fiscal problems in 1966.

* Development of the Apollo telescope mount is treated in chap. 4.