In the year following July 1969, Skylab program managers and engineers adjusted their plans to the new capabilities of the Saturn V dry workshop. Initially changes were limited, by Headquarters order, to those made necessary by the wet-to-dry conversion; but many improvements and additions were soon authorized. By July 1970 most of these new features had been assimilated; a program review reaffirmed Skylab’s schedule and budget, marking the end of major design refinements (pp. 125–27, 144–48). Later that summer, critical design reviews on the three major cluster modules put further changes under the jurisdiction of configuration control boards. Thenceforth only deficiencies discovered during testing could justify major modifications.

Comparing resources to the dry workshop’s new requirements in August 1969, Marshall’s program office determined that some of the required changes could not be accomplished at the center. The new support and deployment structure for the Apollo telescope mount, for example, would overtax Marshall’s shops, which were already building the mount and the multiple docking adapter. Instead, Marshall proposed to add the new structure, along with the shroud that protected Skylab until it reached orbit, to McDonnell Douglas’s contract for the airlock. Similarly it was apparent that equipping and checking out the multiple docking adapter, about to become the control center for both the solar observatory and the new earth-resource experiments, exceeded Marshall’s capacity. Accordingly, Huntsville’s managers decided to add to an existing contract with the Martin Marietta Corporation the responsibility for outfitting the docking adapter.1

Martin Marietta had held a contract for payload integration since AAP’s early days, when the program consisted of many small payloads each carrying a set of related experiments. Under this concept, the company was responsible for seeing that mission payloads were compatible, qualified for spaceflight, and suitable for accomplishing mission objectives. It was a broad responsibility, encompassing mission planning, operations, and training, as well as hardware procurement. As AAP shrank, however, during 1967 and 1968, Martin’s responsibilities dwindled; NASA program offices had trouble finding appropriate work for the company’s engineers to do. Martin was not happy with this situation, and company officials were particularly disappointed when AAP mission 1A was canceled (pp. 87–88). Early in 1969, Marshall redefined Martin Marietta’s duties in Apollo Applications and definitized the firm’s letter contract. Under the new arrangement Martin would conduct specific engineering studies in support of integration decisions made by the NASA centers: electrical power and thermal analyses, experiment compatibility studies, coordination of test plans, and mission planning. In addition, the contractor would assist NASA by keeping track of configuration changes, updating the interface specifications and interface control documents, and maintaining the document repository at Huntsville.2

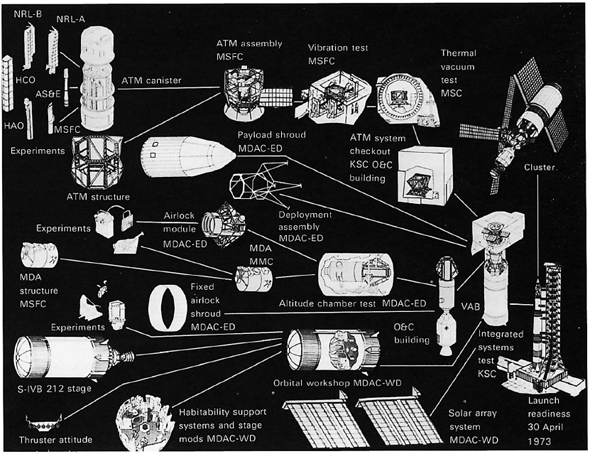

Movement and assembly of hardware for Skylab. Abbreviations: AS&E, American Science & Engineering; ATM, Apollo telescope mount; HAO, High Altitude Observatory; HCO, Harvard College Observatory; KSC, Kennedy Space Center; MDA, multiple docking adapter; MDAC-ED, McDonnell Douglas Astronautics-Eastern Div.; MDAC-WD, Western Div.; MMC, Martin Marietta Corp.; MSC, Manned Spacecraft Center; MSFC, Marshall Space Flight Center; NRL, Naval Research Laboratory; O&C, Operations & Checkout Bldg.; VAB, Vehicle Assembly Bldg. PM-7200-135.

Assignment of the multiple docking adapter to Martin Marietta’s Denver Division was both logical and helpful to the company. Completing the adapter was fundamentally a job of integration, which was Martin’s acknowledged task; but as long as the company had no hardware responsibilities, its relation to the other prime contractors had been somewhat ill-defined. While the integration contractor had provided much necessary information, it was NASA and the prime contractors who had made the integration decisions. The docking adapter, which connected to all the other cluster modules, put Martin on an equal footing with the other major contractors.3

Since Skylab was one of a kind, there would be no preliminary flights to discover and correct design deficiencies; preflight testing assumed critical importance early in the program. While some components of the cluster—the S-IVB stage, for example—were either well proven items or sufficiently similar to Apollo hardware that exhaustive testing was not required, many others were untried. Each new component had to be qualified during development. A carefully documented test program was formulated and followed, to ensure that every part would survive the stresses of launch and function as required under mission conditions for its specified lifetime.

Two primary documents defined the test program. The mission requirements document specified exactly what each mission was to accomplish; and the cluster requirements specification defined permissible materials, design and construction practices, and human engineering standards. From these documents, NASA test engineers developed the procedures for contractors to follow in order to satisfy the agency that hardware would be acceptable.4

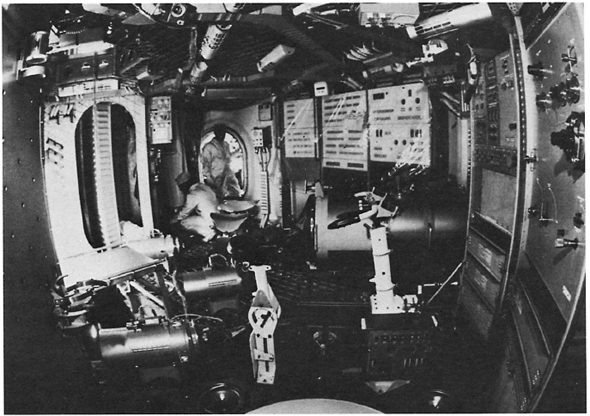

There were two main phases in the overall test program: development tests, used by contractors to work out the best choice of materials and designs, and qualification tests to demonstrate that a component was adequate for its intended function. For the first phase, design-verification test units were built that did not have to conform fully to flight specifications. When Marshall built the medical experiments, for example, design-verification test units enabled engineers to work out such things as the optimum size for the bicycle ergometer and the lower-body negative-pressure device, the range of adjustment necessary to accommodate the crewmen, and the electronic circuitry necessary to transmit medical data to the experiment support system. After the design was acceptably verified, a qualification unit, identical in all respects to the flight hardware, was fabricated and subjected to all necessary tests. Following the qualification tests, several of the test articles were refurbished and converted to training units or backup hardware.5

Since almost everything on Skylab functioned as a part of a larger system, compatibility was as important as reliability. As assembly proceeded, systems tests were conducted at progressively higher levels of complexity to discover and correct any mechanical, electrical, or electromagnetic incompatibilities. In principle, systems testing should have continued all the way through verification of the entire cluster with all its systems operating; in practice, this could not be done. It was impractical, for example, to test the jettisoning of the payload shroud, the deployment of the Apollo telescope mount, or the unfolding of the solar arrays on the workshop and telescope mount. Each of these operations, however, was verified by analysis, testing with nonflight hardware, and simulations.6

Because of the complexity of the modules and the number of tests they went through, program officials decided at the outset to set up a test team, composed of contractor and agency engineers, for each of the major modules. From contractors’ plants to Houston, Huntsville, and Cape Canaveral, these teams went with their modules to each test site, assisting resident personnel in post-acceptance testing. The experience thus accumulated was of great value in trouble-shooting and correcting test anomalies as they were encountered.7

Although the airlock and the multiple docking adapter were separate entities built by different contractors, they were in many respects simply two components of a single module. (When the adapter had first been proposed, in fact, Houston—then in charge of the airlock—had refused to consider it as anything but an extension of the airlock.) Production plans called for the two units to be joined and tested as a single unit before being shipped to KSC. Martin Marietta and McDonnell Douglas’s Eastern Division at St. Louis thus became close collaborators.

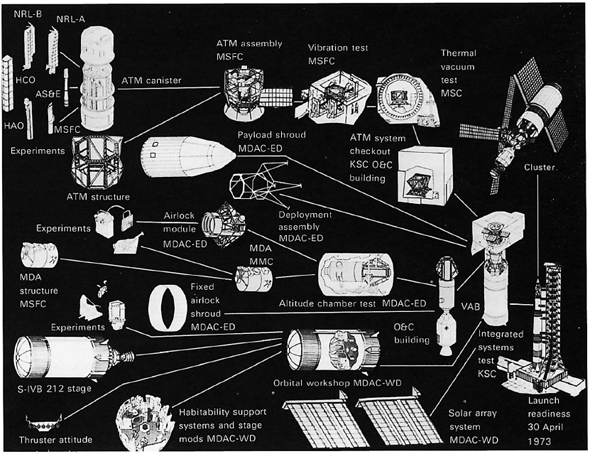

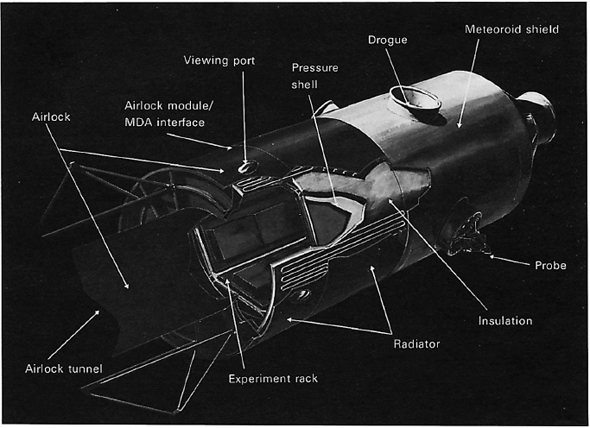

By July 1969, airlock and adapter had gone through considerable evolution. The airlock, which in 1965 had been a rather simple tunnel giving access to the S-IVB tank and to the outside, had grown much more complex as program concepts matured. Besides its airlock function, in the dry workshop it carried the cluster’s communications, electrical power distribution, and environmental control systems. A new structural transition section, 3.05 meters in diameter and 1.2 meters long, provided space for the control panels and equipment as well as the base for attachment of the multiple docking adapter. The airlock’s structural trusses carried cylinders of compressed gases for the workshop atmosphere. With the change to the dry workshop a fixed airlock shroud, of the same diameter as the S-IVB, was added to serve as the base on which the Apollo telescope mount deployment structure stood. During four years of change, the airlock’s launch weight had grown from about 3600 kg to nearly 35 000 kg.8

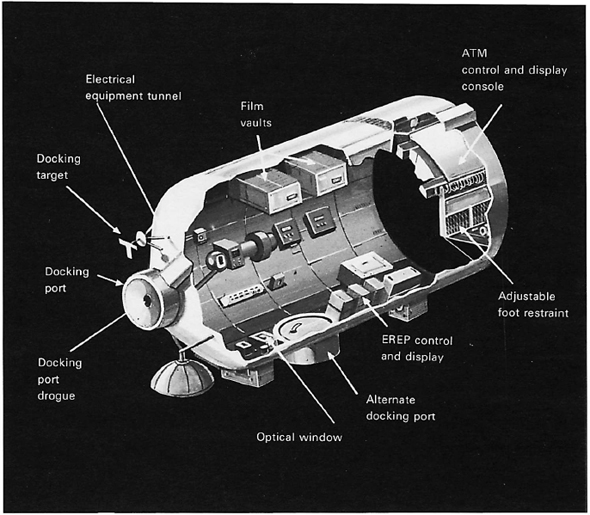

Similarly, the multiple docking adapter was no longer a simple passive module enabling the cluster to carry several experiment packages. During 1967 and 1968 it had been enlarged to provide space for carrying the workshop’s furnishings into orbit, meanwhile losing one after another of the original five docking ports. The dry-workshop decision, however, nullified this function, and at mid-1969 the adapter was once again a virtually empty shell: a cylinder 3.05 meters in diameter by 5.25 meters long, with the main docking port in its forward end and a contingency port on one side, enclosing about 35 cubic meters of space. Some of this space was immediately preempted for the Apollo telescope mount’s control and display panel; within a short time more of it would be taken up by the earth-resource experiments and their supporting equipment. Not surprisingly, the adapter became, in the latter stages of the program, a kind of catch-all for equipment storage and work space. This led to a somewhat random arrangement of crew stations within the adapter, making it quite a different environment from the workshop with its predominant one-g orientation. The difference was the subject of considerable comment by the crews, but no one found it distracting.9

During 1970 and 1971 much of the development testing for the airlock and adapter was conducted. Static tests at Huntsville subjected the test articles to the structural loads expected to be imposed at launch. Internal pressurization and leakage tests verified the integrity of hatches and seals under prelaunch and orbital conditions. Meanwhile, at NASA’s Plum Brook Station in Ohio contractor and NASA engineers were verifying the systems for jettisoning the payload shroud. Three separate tests of the explosive system for separating the shroud into four segments were successful, with only minor discrepancies requiring attention. Completion of these two sets of tests cleared the way for the next stage of cluster testing.10

The last major development tests on the cluster modules came in 1971 and 1972, when high-fidelity mockups were put through vibroacoustic tests at Houston. Subjecting the modules to the vibration and sound pressure expected during powered flight had two objectives: to determine that the structures could withstand the environment and to find out whether the criteria set for qualification tests were adequate. The tests had to be scheduled late enough in development so that the test articles would be faithful replicas of flight equipment, yet early enough for their results to be incorporated into the qualification test program. From February through May of 1971 the workshop was put through the 4500-cubic-meter test chambers at MSC; tests of the payload assembly (airlock, adapter, telescope mount, and payload shroud) began in September and ran through July 1972.11

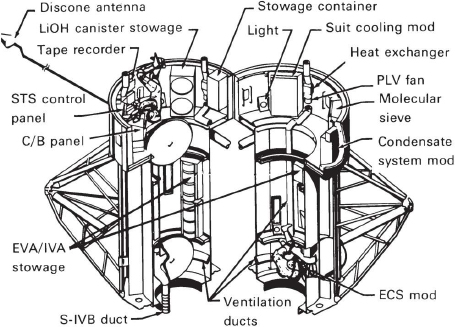

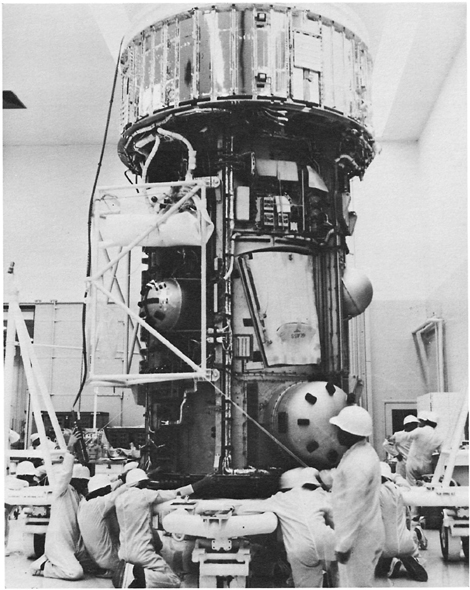

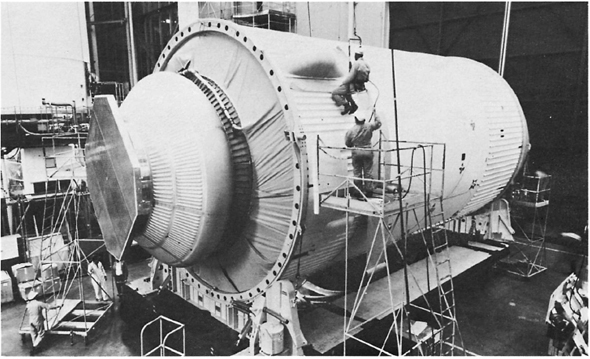

The airlock module in January 1968, left, S-68-604, and under construction at McDonnell Douglas Astronautics Co. in St. Louis in 1971, below, ML71-7322, and in 1972, right, 72-H-86.

No structural failures, and only a few anomalies, resulted from these tests. Test specifications, however, were changed in several areas of the workshop. Actual testing showed that specified vibration levels were too high in 33 of 53 environmental zones of the workshop, and too low in 6. Had those specifications gone unchanged, components tested at too low a level could easily have failed during launch after passing their qualification tests. On the other hand, many components would have unnecessarily failed their qualification tests, necessitating expensive redesign and retesting. The control moment gyros presented a problem of this sort; they could not pass the qualification tests at the vibration levels called for. When a test gyro was run through MSC’s vibration tests, however, engineers discovered that the specifications were much too conservative. The specifications were relaxed and the gyros passed without redesign.12

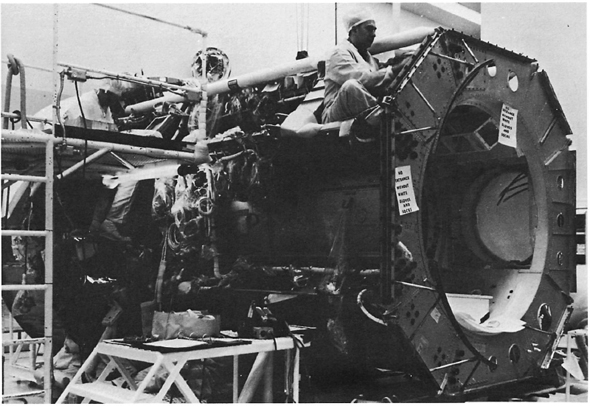

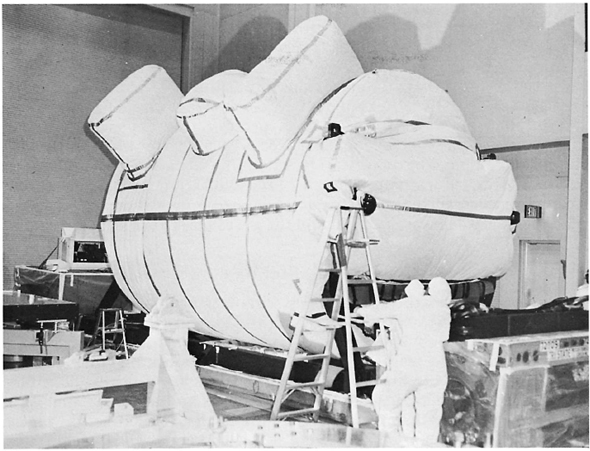

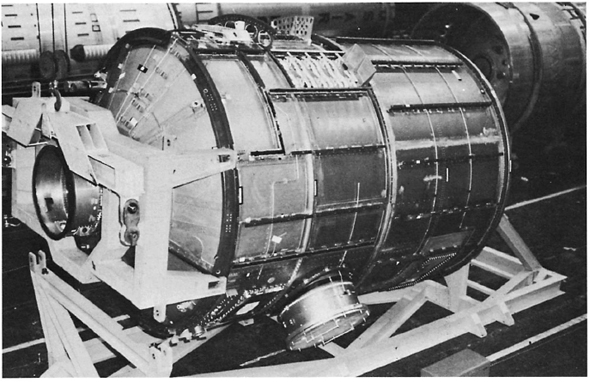

The multiple docking adapter during the Apollo Applications era (1967), top left, MSFC-67-IND 7200-021, and as built for Skylab, bottom left, ML71-5280. Above, the flight article being prepared for shipment in December 1971 from Martin Marietta’s Denver facility to the McDonnell Douglas plant at St. Louis, where it would be mated to the airlock. MSFC 026857. Below, the backup article being prepared for pressure tests. ML71-7637.

In addition to the test articles, engineering mockups, and flight equipment, both Martin Marietta and McDonnell Douglas built zero-g trainers, neutral buoyancy trainers, and high-fidelity mockups for one-g trainers. The zero-g trainers were usually partial mockups (small enough to fit into the KC-135 aircraft) that allowed weightless testing of critical features of each module, such as crew restraints and extravehicular aids. These trainers and mockups were useful in the developmental phase, while engineers and astronauts were still working out optimum designs, and provided much data applicable to manufacture of the flight articles. Neutral buoyancy trainers consisted of wire-mesh mockups of entire modules; immersed in the big water tank at Huntsville, they served principally to verify the astronauts’ ability to move objects within the modules, as well as developing procedures for extravehicular activity. The one-g trainers, accurate replicas of the flight modules containing equipment of the best fidelity available, came into use later in the program as crews began learning flight procedures.13

Progress in both the airlock and multiple docking adapter programs was satisfactory during 1971. In December, Leland Belew reported at a midterm program review that neither module had any technical problems that could delay the program. The earth-resource experiments, however, had faltered. Both the infrared spectrometer and the multispectral scanner were snagged on troubles with the coolers that maintained the proper operating temperature for their detectors; the scanner had faults in its data-recording system as well. The multiple docking adapter had already been accepted and delivered to St. Louis for attachment to the airlock, however, and the experiments would be installed there. A cautious estimate predicted that the combined modules could be delivered to Kennedy Space Center by 5 September 1972, as current plans required; but that assumed practically 100% success in the rest of the program.14

At St. Louis, engineers worked around the missing earth sensors for another six months while completing other tests and checkouts. By mid-1972 the two modules were ready for the last tests: a crew-compartment fit-and-function review, with astronauts methodically verifying every on-orbit procedure; and an altitude chamber test, simulating the performance of the modules in space. No serious discrepancies appeared during these final tests, but some minor testing remained for technicians at the Cape. On 5 October 1972 the airlock and multiple docking adapter, the last of the flight modules to be shipped, were loaded on a Super Guppy aircraft* in St. Louis. The next morning they arrived at KSC, where they were unloaded and trundled off to the Vehicle Assembly Building to be stacked atop the workshop.15

The airlock module and docking adapter arriving at Kennedy Space Center, October 1972. 108-KSC-72P-472.

The workshop project at McDonnell Douglas’s Huntington Beach, California, plant bore the brunt of change during 1969 and 1970. Work had started in April 1969, when McDonnell Douglas took S-IVB stage 212 out of storage and began modifying it for its new role. In the course of improving the habitability of the dry workshop, Houston’s designers completely changed the layout of the crew quarters, added a viewing window to the wardroom, and considerably upgraded the food storage and preparation requirements (chap. 7). Difficulties with the waste management system left its design up in the air until the end of 1970 (chap. 8). New requirements imposed by the earth-resource experiments required a change in the attitude control system (chap. 10). All these changes added to the engineering work load at McDonnell Douglas; the workshop had always been the most complex of the habitable modules, and such top-to-bottom redesign could only delay assembly.

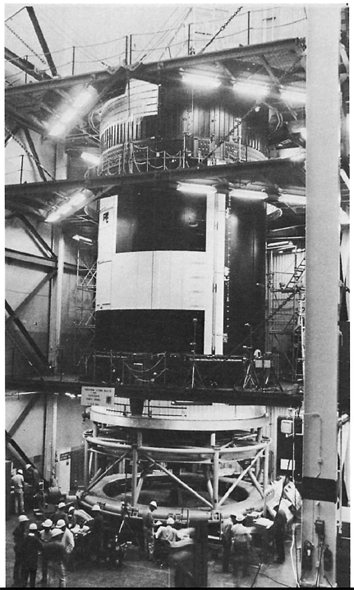

The workshop under construction at the McDonnell Douglas facility in Huntington Beach, Calif. Above, a test version being prepared for shipment to Manned Spacecraft Center, December 1970. 70-H-1628. Left, the flight unit. MSFC-71-PM 7234. Right, wide-angle-lens view of the aft compartment (lower deck) during the crew-compartment fit-and-function test. The ergometer (M171) is in the foreground, the lower-body negative-pressure device (M092) behind the handlebars. S-72-44799.

By mid-1971 Headquarters had become somewhat uneasy about the contractor’s progress, and the project integration office investigated. The resulting evaluation was about equally critical of McDonnell Douglas and the Marshall project office. It cited inefficient management, some questionable engineering practices, the company’s inability to forecast costs and schedules accurately, plus an unwieldy management arrangement among Huntsville’s Skylab office, its workshop project office, and the resident manager in California. Recommendations included strengthening Marshall’s management, advising the company of its shortcomings, and generally instilling a feeling of urgency into the contractor.16

After conferences among Headquarters, Marshall, and McDonnell Douglas officials, Marshall’s program manager, Leland Belew, appointed a 24-man Orbital Workshop Task Team headed by William K. Simmons, Jr., manager of the Marshall workshop project. The team’s job, as stated in its charter, was to provide “timely on-site programmatic and technical interface” with the contractor in all matters relating to completion of the workshop; the nickname applied to such groups—tiger team—was more indicative of its role. That role, plainly, was to get the project on track. In August 1971, Simmons and most of his group, which included James C. Shows of the Houston Skylab office and Richard H. Truly of the astronaut corps, moved to California for a year. McDonnell Douglas assigned two key officials at Huntington Beach to its side of the project: Walter Burke, president of McDonnell Douglas Astronautics Company, 26 years with the organization and a veteran of both the Mercury and Gemini spacecraft programs; and Fred J. Sanders, who had been manager of the airlock project before coming to California in 1969.17

Simmons and Sanders immediately set up a weekly meeting schedule to review progress and block out future work, and paired off tiger-team members with their company counterparts in several areas of responsibility. Houston’s two members were concerned mainly with problems pertaining to crew interfaces. Since those covered nearly every system in the spacecraft, Truly probably had the most hectic job of the lot. He proved to be a hard bargainer when it came to matters of crew convenience and workloads.18

At the heart of McDonnell Douglas’s difficulty with the workshop was the complexity of Skylab’s systems. Thousands of individual parts, some coming from the company’s own shops, some from suppliers (including NASA), had to flow into the project in an orderly sequence. Parts that failed, or that had to be redesigned after testing, could cause delays of days or weeks. One of the first discoveries Simmons made was that the contractor had no integrated schedule depicting the sequencing requirements for this flow of components. Another was that information was inordinately slow in percolating down through the management structure to the shops; change orders could take weeks to reach production workers. Simmons moved quickly to establish a master schedule from which priorities could be assigned, and the company moved its deputy operations manager into an office just off the shop floor to expedite changes. While Simmons and Sanders attended to details, Walter Burke’s role was to keep abreast of problems and see that necessary jobs were given proper attention. The company president’s presence had a salutary effect at all levels.19

Simmons’s notes to Belew that fall were filled with reports of major and minor snags. Paint flaked off stowage lockers and got scuffed in handling; the workshop window’s electrically conducting coating had somehow got scratched; brazed joints in hydraulic tubing were not always reliable. A major worry surfaced when it was found that the iodine used to disinfect drinking water extracted nickel ions from the brazing material. Engineers incorporated an ion-exchange resin in the system, which effectively removed the toxic nickel but pulled out the iodine as well. Their proposal to get around that problem involved a good deal of work by the crew, and Truly objected. At the same time, tests on the deployment of the workshop solar panels turned up half-a-dozen anomalies.20

By mid-October the situation seemed little improved. Looking toward a delivery date of 15 May 1972 for the completed workshop, Marshall Director Eberhard Rees was pessimistic. He urged Burke to do something about his company’s poor record, noting that while the airlock and docking adapter had passed 70% and 85% of their qualification tests, the workshop’s record was only 25% completion. Two months later, at the Skylab midterm review, Simmons acknowledged that development and qualification testing was still behind schedule. Systems still giving trouble included the thruster attitude-control system, the solar arrays, and the potable water system.21

Progress seemed no better in the early months of 1972; as old problems were solved, new ones arose. Starting in March, however, Simmons’s weekly reports noted that the checkout program was getting under way; by mid-May, he was looking ahead to the crew compartment fit-and-function review, when crewmen would go through the workshop from top to bottom. That four-day task was completed on 27 May, and the task team started evaluating McDonnell Douglas’s proposal to ship the workshop on 15 August.22

After 10 months of intensive work, and almost suddenly, the team’s work was nearly completed. During June and July preparations went forward for the final all-systems test of the workshop. Started on 17 July, this sequence was completed three weeks later. Only a few anomalies were discovered in the 510 hours of tests, which took every workshop system through its paces. Several items were left to be completed at the Cape, but little remained to be done in California. On 7 September 1972 Headquarters officials, including Administrator James C. Fletcher and Associate Administrator for Manned Spaceflight Dale D. Myers, participated in a ceremony marking acceptance of the completed workshop by NASA. The next day the module, aboard the U.S.N.S. Point Barrow, departed Seal Beach for the 13-day trip via the Panama Canal to Florida.23

Such a brief discussion of the assembly of the workshop necessarily fails to convey the magnitude of the effort involved. Not only were the workshop systems complex; everything in the spacecraft had to work properly before launch. No partial success, to be corrected on subsequent models, was tolerable. A valid analogy might be a new commercial aircraft—say the Concorde, which was perhaps comparable in complexity to the workshop. If engineers had been required to build the first model fault-free and ready for immediate and unlimited commercial service, supersonic passenger service might still be a hope for the future.

In any event, all the flight hardware was at the Cape by the end of September 1972, ready for stacking and preflight testing.

While the workshop, with no provision for controlled reentry, awaited assembly and checkout at the Cape, the time came to call for proposals to build Shuttle’s launch system. Implementing recommendations made the previous year (p. 354), Deputy Administrator George Low ordered that the request for proposals include the requirement for a study of the reentry hazard created by the large fuel tanks. Similar studies would be required for all future projects.24

At the same time Low directed the Office of Manned Space Flight to devise suitable means for deorbiting the S-IVB stages that would take the crews to Skylab. On Apollo missions the S-IVB stages had been disposed of in space (solar orbit) or on the lunar surface, but this technique was not applicable to the Skylab missions. When studies showed that the simplest way to deorbit the empty upper stages was by venting excess propellants through the engine, Low ordered this method adopted.25

The discussion of the hazards of orbital debris raised questions in the mind of Administrator James C. Fletcher, who had taken over in 1971 after the decision to forego controlled reentry for Skylab had already been made. Fletcher, unwilling to accept the risk involved if he had any practical alternative, ordered the matter reopened. With just over four months remaining before launch, program director William Schneider directed Marshall and MSC to study the possibility of using the main engine of the Apollo spacecraft to deorbit Skylab as the last crew left it.26

Initial reaction from both centers was negative. Besides many engineering problems, Houston found the potential crew hazards unacceptable; if the Apollo should have any trouble undocking after placing the workshop on a reentry trajectory, the astronauts would be in serious trouble. Marshall noted that modifications to the launch vehicle would be required, as well as changes in launch procedures; both would delay launch and increase costs. Just to conduct the necessary studies would take six months, leaving little time to incorporate changes before the last crew was launched.27

Nevertheless, Schneider persisted; and in April 1973 a group at Houston began reviewing the techniques and operational procedures for deorbiting the cluster with the service propulsion system of the Apollo spacecraft. By the time the workshop was launched the group was well into its task and had defined many of the problems that would have to be worked. But their efforts were wasted. The loss of the micrometeoroid shield and the damage to the workshop’s solar arrays during launch (chap. 14) created too many engineering uncertainties that could not be dealt with. On 13 July 1973 Schneider stopped all studies on controlled deorbit.28 Whatever problems might be created by the reentry of the workshop would have to be solved later.

* Super Guppy was built for NASA by Aero Spacelines, Inc., in the mid-1960s to carry outsized cargo, principally for the Apollo program. Made from sections of four Boeing 377 Stratocruisers, the plane was for a time the world’s largest aircraft in terms of cubic capacity. Its Skylab cargo included the telescope mount and the instrument unit, as well as the CSM.